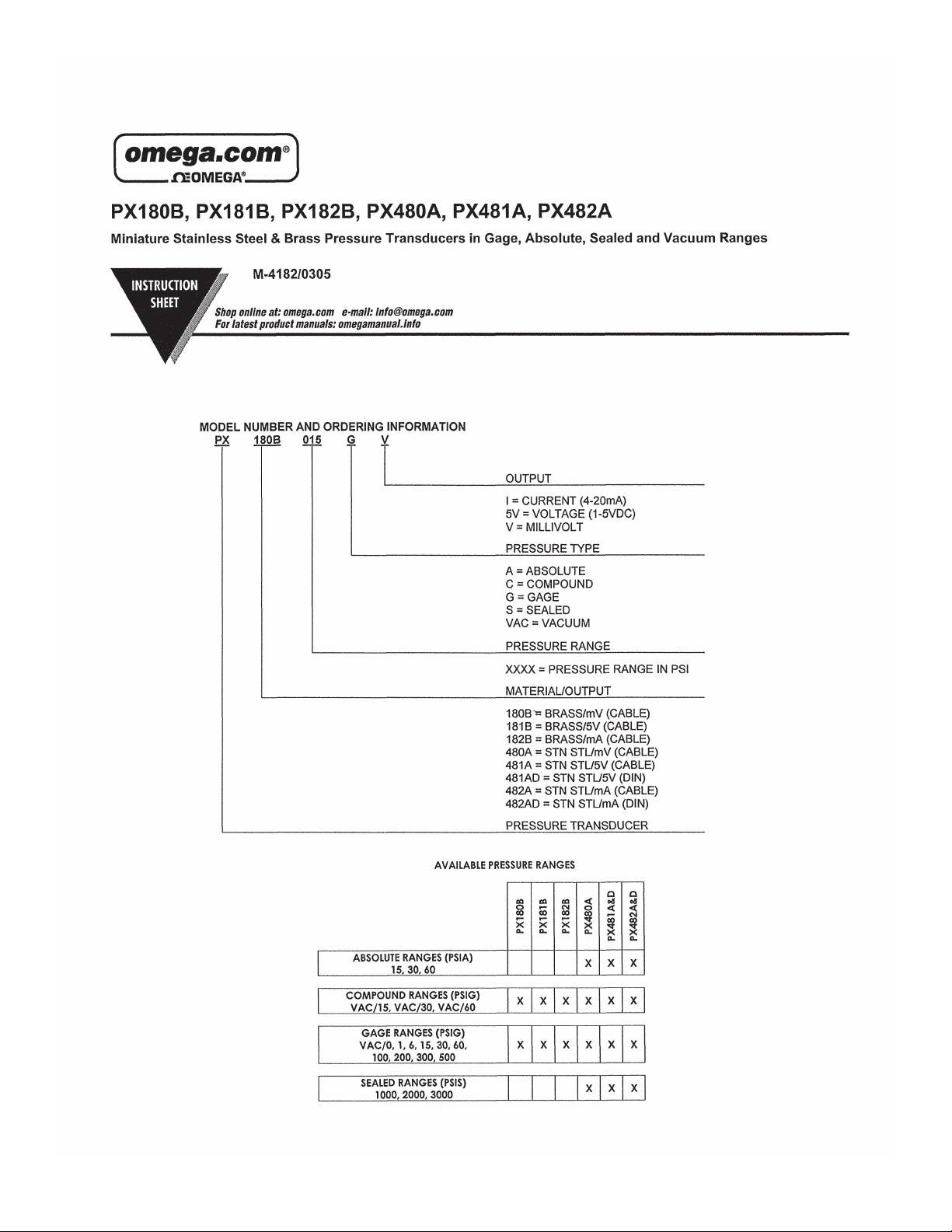

Page 1

Page 2

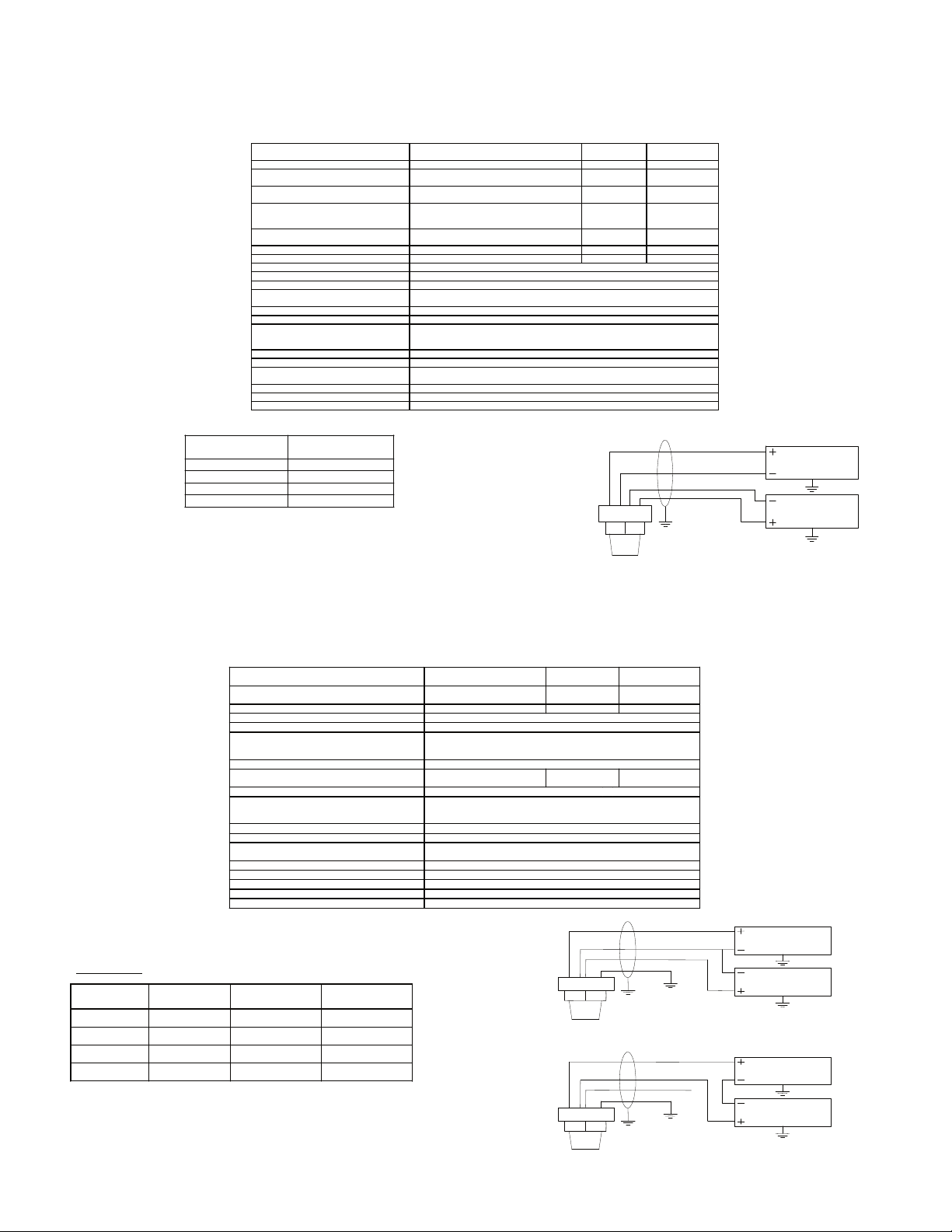

MILLIVOLT OUTPUT

PX181B/PX182B/PX481A/PX482A

PX180B/PX480A

4-20mA OR 1-5VDC

WIRE COLORS

NOTES:

1. FOR PX181B, PX182B,CONDUCTIVE MEDIA “

-Vin” SHOULD BE TIED TO CASE POTENTIAL.

2. THE CABLE SHIELD, POWER SUPPLY & RECEIVER GROUNDINGS ARE

OPTIONAL DEPENDING ON INSTALLATION (SHOWN BELOW).

CONDUCTOR

COLORS

DIN 43650-C

PIN No.

VOLTAGE

OUTPUT

CURRENT

OUTPUT

RED 1 +Vin +Vin

BLACK 2 -Vin -Vin

WHITE 3 Vout N/A

GREEN GND CASE GROUND CASE GROUND

C AB LE S HI EL D

4 - 2 0m A O U T P UT

T Y P I CA L W IR IN G

1 2 3 4

-V i n ( BL AC K)

G ND ( GR EE N )

+ Vi n ( R ED )

C ON TR O LL E R/

R EC O RD ER /

C UR RE NT S EN S E

D C

P OW ER S U PP LY

N /C ( WH IT E)

V D C O U T PU T

T Y P I CA L W IR IN G

V

OU T

( WH IT E)

+ Vi n ( R ED )

G ND ( GR EE N )

-V i n ( BL AC K)

C AB LE S HI EL D

1 2 3 4

D C

P OW ER S U PP LY

C ON TR O LL E R/

R EC O RD ER /

V OL TA G E S E NS E

SPECIF ICATIO NS

PRESS URE R ANGE – PX18 1B/182 B

PX4 81A/48 2A

VACUU M - UP TO 500 PSI

VACUU M

– UP T O 3000 PSI

0 – 1 PSI 0 – 6 PSI

ACCUR ACY @25°C I NCLUDING LI NEARIT Y

(BFSL) , HYSTE RESIS & REP EATABI LITY

±0.2% FS TYP, ±0.3 % FS

MAX

±1.0% FS MAX ±0.5% FS MAX

1 YR. S TABILITY < 0.25 % FS < 1.0% FS < 0.5% FS

LOAD L IMITAT ION 50K OH M MIN (ALL V OLTAGE OUTP UTS) 600 O HMS MAX (4-2 0MA)

OPERA TING T EMPERATUR E -40 TO 80 °C ( -40 TO 176°F)

PROCE SS TE MPERA TURE - PX181B/182B

P X481A/482A

-40 TO 125°C (-40 TO 257°F)

-40 TO 100°C (-40 TO 212°F, 125°C/257° F FOR LO W PRESSURE

GA GE RANGES)

COMPE NSATED TEM PERATURE -25 TO 7 5 °C (-1 3 TO 167°F)

TOTAL ERROR BAN D

(INCLU DES

TEMPE RATURE EFFE CTS, Z ERO & SPAN SET)

±1% F S ±2.5% FS MAX ±1.5% FS MAX

OVERP RESSURE 2X FS ( 750 PSI FOR 500 PS I RANG E)

BURST PRESSURE - PX181B /182B

PX48 1A/482 A

3X FS (O R 750 PS I, W HICHEVER I S LESS)

3X FS ( 750 PSI, FOR 300 & 5 00 PSI) PROC ESS MEDIA

CONTA INMEN T OF 2 000 PS I ON L OW GAG E RANGES

VIBRATI ON 10G, 5 5 – 200 0 Hz

SHOCK 30G

PROCE SS WETTED MATERIAL - P X181B/182B

PX48 1A/482 A

BRASS, BOROSILICA TE, SILICON, RTV, EP OXY

STAINL ESS TEEL

ELECT RONICS HOUSING M ATERIA L ALUMI NUM, B LACK A NODIZED

PROCE SS CO NNECTION 1/8-27 NPT

ELECT RICAL CONNE CTION 36” CA BLE 24 AWG, DIN 436 50 FORM C C ONNECT OR

INPUT/ OUTPUT – PX 181B, PX481A 9-30VDC / 1-5VDC

INPUT/ OUTPUT – PX 182B, PX482A 11-30VD C / 4-20 MA

SPECIFICATIONS

PRESSURE RANGES – PX180B

PX480A

VACUUM - UP TO 500 PSI

VACUUM

– UP TO 3000 PSI

0 – 1 PSI 0 - 6 PSI

REFERENCE ACCURACY (BFSL) ± 0.2% FS TYP, ± 0.3% FS MAX ± 1.0% FS MAX ± 0.5% FS MAX

NULL OFFSET @25°C (77°F) – PX180B

PX480A

± 1% FS

± 1% FS

± 2.0% FS MAX

± 2.0% FS MAX

± 1.0% FS MAX

± 1.5% FS MAX

SPAN SET @25°C (77°F) – PX180B

PX480A

± 1% FS

± 1% FS

± 2.0% FS MAX

± 2.0% FS MAX

± 1.0% FS MAX

± 1.5% FS MAX

THERMAL EFFECT ON NULL (ZERO)

WITHIN COMPENSATED RANGE

– PX180B

PX480A

± 0.5% FS TYP OVER COMP. RANGE, ± 2% MAX

± 4% FS MAX

± 5% FS MAX

± 2% FS MAX

± 3% FS MAX

THERMAL EFFECT ON SPAN

WITHIN COMPENSATED RANGE

± 0.5% FS TYP OVER COMP. RANGE, ± 2% MAX ± 4% FS MAX ± 2% FS MAX

1 YR. STABILITY < 0.25% FS < 1.0% FS < 0.5% FS

OUTPUT VOLTAGE 10mV/V 5mV/V 10mV/V

INPUT SUPPLY VOLTAGE 10VDC MAX.

OUTPUT IMPEDANCE

3.5K

ohms

- 6.0K

ohms

OPERATING TEMPERATURE -40 TO 80 °C (-40 TO 176°F)

PROCESS TEMPERATURE – PX180B

PX480A

-40 TO 125 °C (-40 TO 257°F)

-40 TO 100 °C (-40 TO 212°F) 125°C/257°F FOR LOW PRESSURE GAGE RANGES

COMPENSATED TEMPERATURE -25 TO 75 °C (-13 TO 167°F)

OVERPRESSURE 2X FS (750 PSI FOR 500 PSI RANGE)

BURST PRESSURE – PX180B

PX480A

3X FS (OR 750 PSI, WHICHEVER IS LESS)

3X FS (750 PSI FOR 300 & 500 PSI, PROCESS CONTAINMENT OF 2000 PSI ON LOW

PRESSURE GAGE RANGES

)

VIBRATION 10G, 55 – 2000 Hz

SHOCK 30G

PROCESS WETTED MATERIAL – PX180B

PX480A

BRASS, BOROSILICATE, SILICON, RTV, EPOXY

STAINLESS STEEL

ELECTRONICS HOUSING MATERIAL ALUMINUM, BLACK ANODIZED

PROCESS CONNECTION 1/8-27 NPT

ELECTRICAL CONNECTION 36” CABLE, 24 AWG

GREEN

mV OUTPUT

TYPICAL WIRING

1 2 3 4

CABLE SHIELD

BLACK

WHITE

RED

SIGNAL COND ITIONER

/mV SENSE

DC

POWER SUPPLY

CONDUCTOR

COLORS

OUTPUT

RED +Vin

BLA CK -Vin

WHI TE -S

GRE EN +S

NOT ES :

1. F OR PX180 B, CON DU CTI VE MEDIA “

-Vi n” SH OUL D B E T IED TO CASE PO TENTI AL

2. THE CABL E SHI EL D, POWER SU PP LY & R EC EIVER GROU ND ING S ARE

OPT IO NA L D EPEND IN G O N INS TA LLATI ON (S HO WN BE LOW)

3. FOR VA CU UM RA NG ES, REVERS E G RE EN AN D W HITE WIRES

Page 3

1 1/8 HEX

36" CABLE

24 AWG, 4 COND.

1.17 [29.7]

2.84

72.0

1/8-27 NPT

36" [914], 24 AWG

1.17 [29.7]

CABLE OUTPUT

7/8 HEX

36" CABLE

24 AWG, 4 COND.

2.28

57.9

PX480A/PX481A/PX482A GAGE PRESSURE

(STAINLESS STEEL)

(BRASS)

PX180B/PX181B/PX182B

PX480A/PX481A/PX482A ABSOLUTE & HIGH PRESSURE

(STAINLESS STEEL)

3

1 1/8 HEX

GND

2

1

1.17 [29.7]

2.10

53.2

36" [914], 24 AWG

1.17 [ 29.7 ]

CABLE OUTPUT

7/8 HEX

36" CABLE

24 AWG, 4 COND.

CABLE OUTPUT

36" [914], 24 AWG

1/8-27 NPT

2.6510

MAX

DIN 43650-C OUTPUT

(INCLUDES MATING CONNECTOR)

3

1.17[29.7]

7/8 HEX

1/8-27 NPT

DIN 43650-C OUTPUT

(INCLUDES MATING CONNECTOR)

2

GRND

WIDE PIN

1

1.76

44.6

Dimensions shown in inches [mm]

Page 4

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that apply. OMEGA is constantly pursuing certification of its products to the

European New Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts no liability for any errors it contains, and reserves the right to alter specifications without

notice. WARNING: These products are not designed for use in, and should not be used for, human applications.

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a period of 13 months from date of purchase.

OMEGA’s WARRANTY adds an additional one (1) month grace period to the normal one (1) year product warranty to cover handling and

shipping time. This ensures that OMEGA’s customers receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Service Department will issue an Authorized Return (AR)

number immediately upon phone or written request. Upon examination by OMEGA, if the unit is found to be defective, it will be repaired or replaced

at no charge. OMEGA’s WARRANTY does not apply to defects resulting from any action of the purchaser, including but not limited to mishandling,

improper interfacing, operation outside of design limits, improper repair, or unauthorized modification. This WARRANTY is VOID if the unit shows

evidence of having been tampered with or shows evidence of having been damaged as a result of excessive corrosion; or current, heat, moisture or

vibration; improper specification; misapplication; misuse or other operating conditions outside of OMEGA’s control. Components which wear are not

warranted, including but not limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However, OMEGA neither assumes responsibility for any

omissions or errors nor assumes liability for any damages that result from the use of its products in accordance with information provided

by OMEGA, either verbal or written. OMEGA warrants only that the parts manufactured by it will be as specified and free of defects.

OMEGA MAKES NO OTHER WARRANTIES OR REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESS OR IMPLIED, EXCEPT THAT OF

TITLE, AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE

ARE HEREBY DISCLAIMED. LIMITATION OF LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total liability of

OMEGA with respect to this order, whether based on contract, warranty, negligence, indemnification, strict liability or otherwise, shall not

exceed the purchase price of the component upon which liability is based. In no event shall OMEGA be liable for consequential, incidental or

special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic Component” under 10 CFR 21 (NRC), used in

or with any nuclear installation or activity; or (2) in medical applications or used on humans. Should any Product(s) be used in or with any nuclear

installation or activity, medical application, used on humans, or misused in any way, OMEGA assumes no responsibility as set forth in our basic

WARRANTY/ DISCLAIMER language, and, additionally, purchaser will indemnify OMEGA and hold OMEGA harmless from any liability or damage

whatsoever arising out of the use of the Product(s) in such a manner.

Servicing North America:

USA: One Omega Drive, Box 4047

ISO 9001 Certified Stamford CT 06907-0047

Tel: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1, Canada

Tel: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

®

Customer Service: 1-800-622-2378 / 1-800-622-BEST

®

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

®

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico: En Espan˜ol: (001) 203-359-7803 e-mail:espanol@omega.com

FAX: (001) 203-359-7807 info@omega.com.mx

OMEGAnet®Online Service Internet e-mail

www.omega.com info@omega.com

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

Tel: +31 (0)20 3472121 FAX: +31 (0)20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: sales@omegaeng.nl

Czech Republic: Frystatska 184, 733 01 Karviná, Czech Republic

Tel: +420 (0)59 6311899 FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342 e-mail: info@omegashop.cz

France: 11, rue Jacques Cartier, 78280 Guyancourt, France

Tel: +33 (0)1 61 37 2900 FAX: +33 (0)1 30 57 5427

Toll Free in France: 0800 466 342

e-mail: sales@omega.fr

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: +49 (0)7056 9398-0 FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified Northbank, Irlam, Manchester

M44 5BD United Kingdom

Tel: +44 (0)161 777 6611 FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

M-4182/0305

RETURN REQUESTS / INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE RETURNING ANY PRODUCT(S) TO

OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN (AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER

TO AVOID PROCESS IN G DELAYS ). Th e assigne d AR nu mber sh ould then be marked on t he ou tside of the r eturn pack age and on any

correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent breakage in transit.

PATENT NOTICE: U. S. Pat. No. 6,074,089; 5,465,838 / Canada 2,228,333; 2,116,055 / UK GB 2,321,712 / Holland 1008153 / Israel 123052 / France

2 762 908 / EPO 0614194. Other patents pending.

FOR

W

ARRANTY

RETURNS, please have the following information

available BEFORE contacting OMEGA:

1. Purchase Order number under which the product was PURCHASED,

2. Model and serial number of the product under warranty, and

3. Repair instructions and/or specific problems relative to the product.

FOR NON-W

ARRANTY

REPAIRS,

consult OMEGA for current repair charges.

Have the following information available BEFORE contacting OMEGA:

1. Purchase Order number to cover the COST of the repair,

2. Model and serial number of the product, and

3. Repair instructions and/or specific problems relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords our customers the latest in technology and

engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2004 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied, reproduced, translated, or reduced to any electronic

medium or machine-readable form, in whole or in part, without the prior written consent of OMEGA ENGINEERING, INC.

Loading...

Loading...