Omega Products PX141-005V5V Installation Manual

PX140 Series

Pressure Transducers

INSTRUCTION

SHEET

M0258/1105

The OMEGA@PX140 Series

pressure transducers are solid state

piezoresistive devices ideally suited

to applications requiring exact

measurement of pressure where the

benefits of repeatability, low

hysteresis, and long term stability

are important. The PX140 series

offers state-of-the-art benefits of a

hybrid IC device, including

compactness, ruggedness and

reliability. Computer controlled

laser trimming provides close

control of important transducer

parameters at a lower total cost and

higher performance than can be

achieved with discrete circuitry.

Circuitry to provide temperature

compensation is an integral part of

the device and is optimized on each

unit as part of the calibration

procedure. Null and full scale

output are similarly controlled. No

adjustment or recalibration by the

user is required.

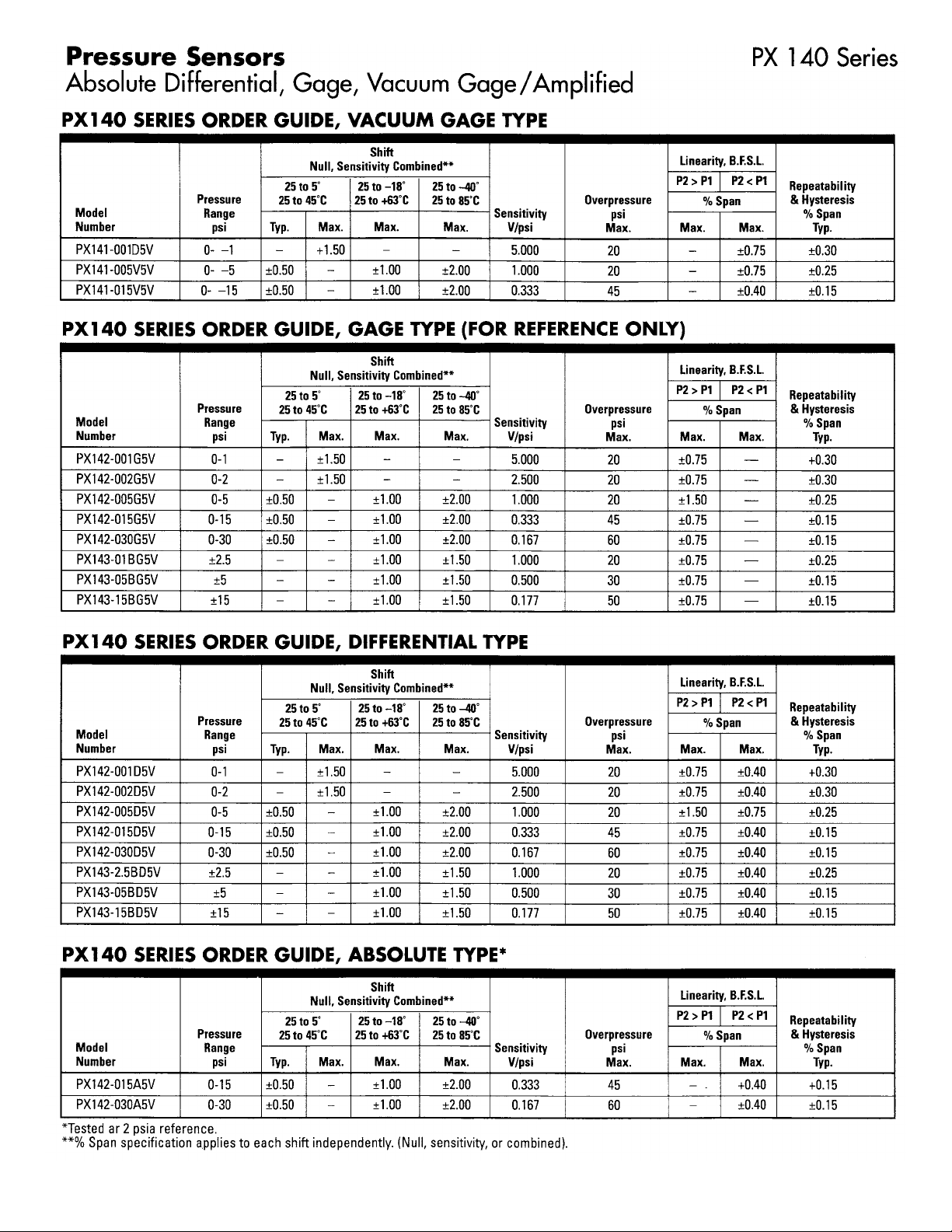

Three types of PX140 pressure

transducers are available to

measure positive pressures.

Differential and gage pressure types

measure pressure over five ranges

(0-1, 0-2, 0-5, 0-15, and 0-30 psi). For

vacuum measurement three

negative gage pressure ranges are

available (-1 to 0, -5 to 0, and -15 to

0 psi) Absolute types are available

in two ranges (0-15, 0-30, psi).

Two types are available to measure

both positive and negative

pressures. Differential and gage

types measure in four ranges ±1.0,

±2.5, ±5.0, ±15 psi).

PX140 pressure transducers

perform in industrial, consumer,

military, medical and automotive

environments. The heart of each

device is a 0.100" square silicon

sensor chip.

The sensing diaphragm with

implanted resistors is an integral

part of the chip. Pressure applied

on the diaphragm causes it to flex

and the resistance to change,

resulting in an output voltage

proportional to pressure. Because of

the unique construction, this output

is very predictable, providing an

ideal sensor element for OMEGA

pressure transducers.

The circuitry is contained in a

thermoplastic housing. The .010" x

.020" printed circuit board terminals

exit on opposite side from the ports.

SOLDERING

Limit soldering to 315°C (600°F)

maximum, with 10 seconds

maximum duration.

CLEANING

Select proper cleaning fluids, based

on contaminants to be removed.

OMEGA recommends alcohols or

fluorinated solvents.

WARNING!

READ BEFORE INSTALLATION

Fluid hammer and surges can destroy any pressure transducer and

must always be avoided. A pressure snubber should be installed to

eliminate the damaging hammer effects.

Fluid hammer occurs when a liquid flow is suddenly stopped, as with

quick closing solenoid valves. Surges occur when flow is suddenly

begun, as when a pump is turned on at full power or a valve is quickly

opened.

Liquid surges are particularly damaging to pressure transducers if the

pipe is originally empty. To avoid damaging surges, fluid lines should

remain full (if possible), pumps should be brought up to power slowly,

and valves opened slowly. To avoid damage from both fluid hammer

and surges, a surge chamber should be installed, and a pressure

snubber should be installed on every transducer.

Symptoms of fluid hammer and surge’s damaging effects:

a) Pressure transducer exhibits an output at zero pressure (large zero

offset). If zero offset is less than 10% FS, user can usually re-zero

meter, install proper snubber and continue monitoring pressures.

b) Pressure transducer output remains constant regardless of pressure.

c) In severe cases, there will be no output.

2

Loading...

Loading...