Omega Products PX139-0.3D4V Installation Manual

General Description

The OMEGA®PX139 Series Pressure Transducer uses state-of the-art

micromachined silicon pressure sensors in conjunction with stress-free

packaging techniques to provide highly accurate, temperature-compensated

pressure transducers for the most demanding applications. Designed to

operate from a regulated 5 volt DC power source, the PX139 provides a

calibrated 4 volt output span of 0.25 to 4.25 volts.

PX139 pressure transducers are available in absolute and differential models.

Differential models can also be used to measure gage pressure or vacuum by

simply varying the pressure connections. To measure gage pressure, make the

pressure connection to port B and leave port A open to the atmosphere. For

vacuum measurement, connect to port A and leave port B open. When using

absolute models connect to port A.

Available Models

Gage/Differential

Pressure Ranges Model

±0.3 PSI PX139-0.3D4V

±1 PSI PX139-001D4V

±5 PSI PX139-005D4V

±15 PSI PX139-015D4V

±30 PSI PX139-030D4V

Absolute

Pressure Ranges Model

0 to 15 PSIA PX139-015A4V

0 to 30 PSIA PX139-030A4V

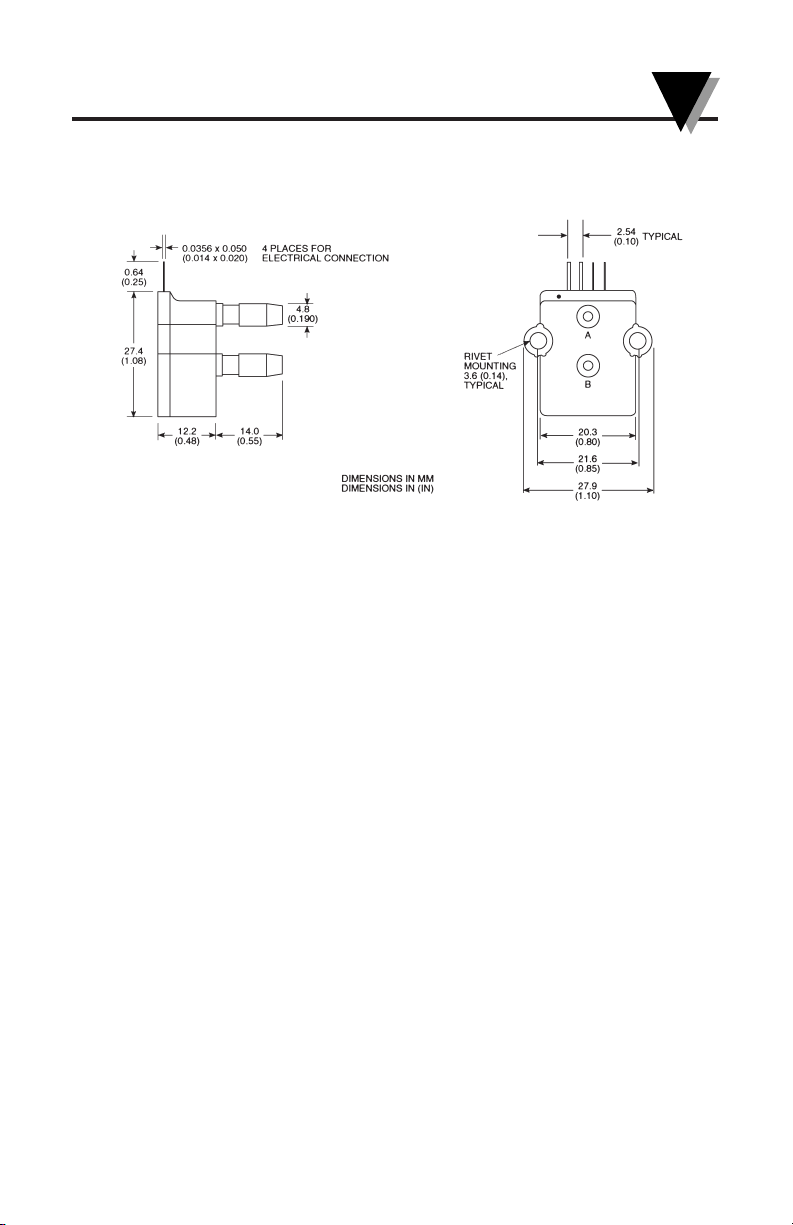

PX139 Pinouts

1 = + Excitation

2 = Common

3 = + Signal

4 = No Connection

PX139 Series

Pressure Sensors

INSTRUCTION

SHEET

M2003/0208

Shop online at: omega.com e-mail: info@omega.com

For latest product manuals: omegamanual.info

Read Before Installation

Fluid hammer and surges can destroy any pressure transducer and must always be

avoided. A pressure snubber should be installed to eliminate the damaging hammer

effects. Fluid hammer occurs when a liquid flow is suddenly stopped, as with quick

closing solenoid valves. Surges occur when flow is suddenly begun, as when a pump

is turned on at full power or a valve is quickly opened.

Liquid surges are particularly damaging to pressure transducers if the pipe is

originally empty. To avoid damaging surges, fluid lines should remain full (if

possible), pumps should be brought up to power slowly, and valves opened slowly.

To avoid damage from both fluid hammer and surges, a surge chamber should be

installed, and a pressure snubber should be installed on every transducer.

Symptoms of fluid hammer and surge’s damaging effects:

1. Pressure transducer exhibits an output at zero pressure (large zero offset). If zero

offset is less than 10% FS, user can usually re-zero meter, install proper snubber

and continue monitoring pressures.

2. Pressure transducer output remains constant regardless of pressure.

3. In severe cases, there will be no output.

PX139 Series Pressure Sensors

Unpacking

Remove the Packing List and verify that you have received all equipment,

including the following:

PX139 Series Pressure Sensor

Operator’s Manual

If you have any questions about the shipment, please call the OMEGA

Customer Service Department.

When you receive the shipment, inspect the container and equipment for

any signs of damage. Note any evidence of rough handling in transit.

Immediately report any damage to the shipping agent.

The carrier will not honor any damage claims unless all shipping material is

saved for inspection. After examining and removing contents, save packing

material and carton in the event reshipment is necessary.

NOTE

WARNING

Dimensions

Specifications

Excitation Voltage: 5 Vdc

Output: 0.25 to 4.25 volts

Linearity and Hysteresis: ±0.1% FS typical, 0.5% max.

(0.5% typ., 1% max. for 0.3 PSI range)

Repeatability: ±0.3% FS

Zero Balance: 0.25 Vdc ±0.05 Vdc

Storage Temperature: -40 to 125°C (-40 to 257°F)

Compensated Temp.

Range: 0 to 50°C (32 to 122°F)

Zero Temp. Effects: ±0.5% FS (±1% FS for 0.3 PSI)

Span Temp. Effects: ±0.5% FS (±1% FS for 0.3 PSI)

Proof Pressure: > 3 X FS Pressure

Burst Pressure: > 5 X FS Pressure

Common Mode

Pressure: 50 PSI

Media Compatibility: For use with gases compatible with silicon,

glass-filled nylon, and alumina ceramic

PX139 Series Pressure Sensors

PINOUT:

1. + Excitation

2. Common

3. + Signal

4. No Connection

Loading...

Loading...