Page 1

General

The Model PX106 is the digital output member of the

PX106 transducer family. The transducer’s output signal

is a frequency modulated square wave with a nominal

5 KHz range, set from 1 KHz to 6 KHz.

The PX106 logic level frequency output signal offers

unique advantages over conventional analog voltage

output transducers. The primary advantage is the ease

with which the transducer can be interfaced to most

microprocessors. Another advantage is superior noise

immunity which allows the PX106 to perform in a variety

of harsh environments without shielded cable or special

care to protect transmission lines. Also, since it is a logic

level signal at relatively low frequency, long

communication lines can be used, and simple wave shape

reconstruction can be performed if required.

The PX106 is designed to meet the needs of today’s high

technology requirements. It is the ideal choice for those

applications that need a rugged, reliable, cost efficient

transducer with the benefits of 0.5% accuracy, long-term

stability and a wide operating temperature range.

A unique stainless steel pressure chamber design insures

circuit protection from corrosive measurand while the

outer case of Valox protects against harsh environments.

This combination assures the Model PX106 performance to

continue within original specification limits. The internal

voltage regulator allows use of economical unregulated

power sources of 10-20 Vdc.

Typical media used with the PX106 include oil, gases,

saline solutions, ammonia, Freon, hydraulic fluids, alcohol,

acids, and gasoline.

Pressure ranges extend from 0-6 psi to 0-5000 psi. Typical

accuracy, including the effects of nonlinearity, hysteresis,

and repeatability, is within 0.5% of span from best fit line.

Installation

The Model PX106 may be easily mounted on a printed

circuit board using the two mounting holes or by

supporting it from the stainless steel pressure port. Many

applications require a threaded pressure port. For these we

recommend the use of threaded adapters and bushings. A

10-20 volt DC power supply is required to energize the

Model PX106. See power connections in diagram.

Maintenance

No maintenance is required with these transducers The

absence of moving parts and the solid-state electronics

make them trouble-free and reliable.

Pressure Overloads

PX106 transducers will withstand high overloads. If the

overload rating is exceeded, electrical failure may occur. As

a safety feature, the transducers have been designed to

withstand much higher burst pressures than the pressure

which will cause permanent damage.

Important: Both static and dynamic overloads must be

considered when selecting a pressure transducer. Pressure

fluctuations exist in most systems. These fluctuations can

have very large and very fast peak pressures, as in water

hammer effects. If the transducer is connected to a slow

responding instrument, such pressure peaks may not be

observed. An oscilloscope is a convenient tool for

determining if high pressure transients exist in a system.

Where pressure pulses are expected, the transducer rating

should be high enough to prevent overload by the peak,

pressure. Where high pressure transients are unavoidable,

use either a higher range transducer or a snubber, which

will reduce the peak pressure applied to the transducer.

The life of the transducer will be reduced if it is repeatedly

overloaded, particularly under dynamic conditions.

WARNING! READ BEFORE INSTALLATION

Fluid hammer and surges can any pressure transducer and must

always be avoided. A pressure snubber should be installed to

eliminate the damaging hammering effects.

Fluid hammer occurs when a liquid flow is suddenly stopped, as

with quick closing solenoid valves. Surges occur when flow is

quickly begun, as when a pump is turned on at full power or a

value is quickly opened.

Liquid surges are particularly damaging to pressure transducers if

the pipe is originally empty. To avoid damaging surges, fluid lines

should remain full (if possible), pumps should be brought up to

power slowly, and valves opened slowly. To avoid damage from both

fluid hammer and surges, a surge chamber should be installed, and

a pressure snubber should be installed on every transducer.

Symptoms of fluid hammer and surge’s damaging effects:

a) Pressure transducers exhibit an output at zero pressure (large

zero offset). If zero offset is less than 10% FS, user can usually

re-zero meter, install proper snubber and continue monitoring

pressures.

b) Pressure transducer output remains constant regardless of

pressure.

c) In severe cases, there will be no output.

PX106

PRESSURE TRANSDUCER

INSTRUCTION

SHEET

M0214-1008

Shop online at: omega.com e-mail: info@omega.com

For latest product manuals: omegamanual.info

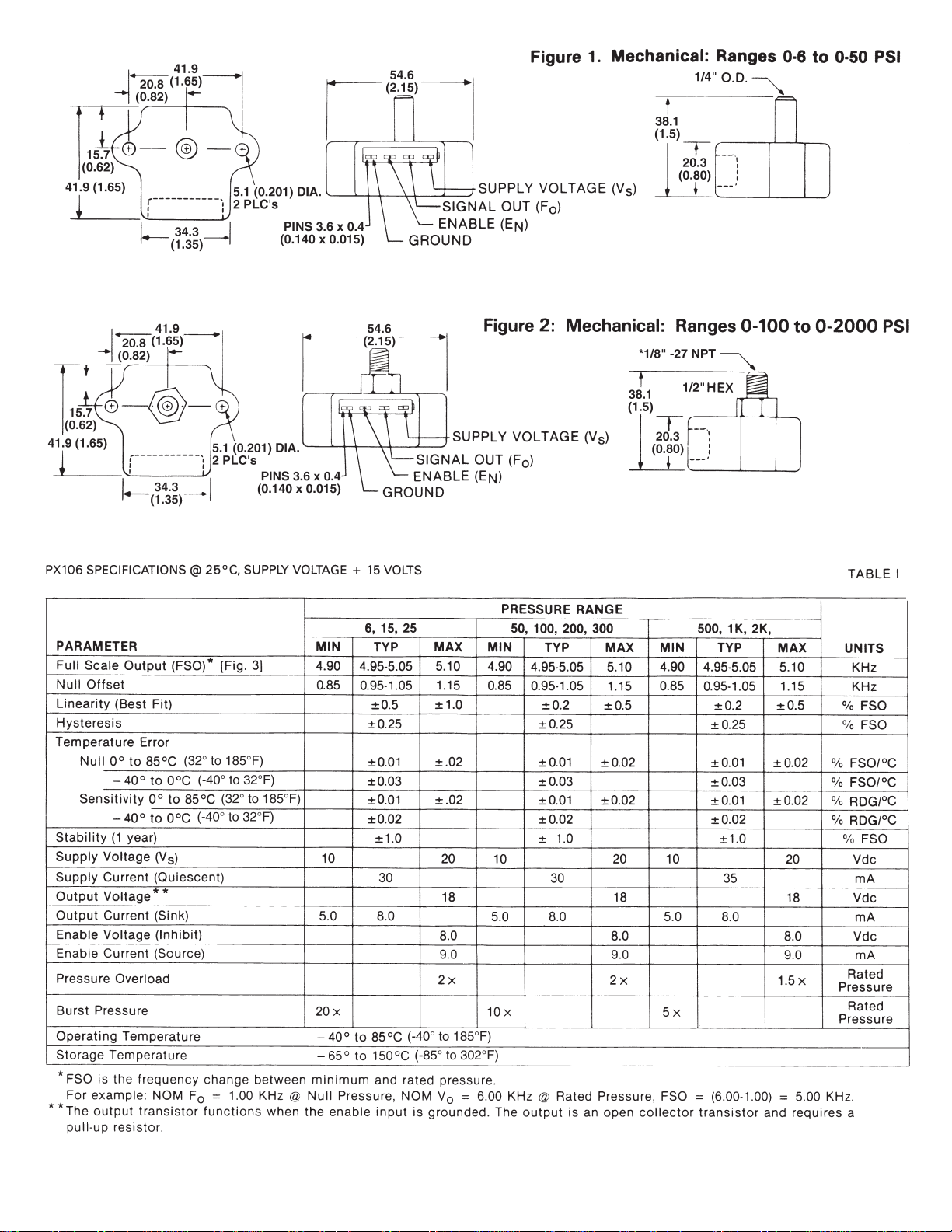

Page 2

DIMENSIONS mm (in.)

Page 3

Page 4

It is the policy of OMEGA Engineering, Inc. to comply with all worldwide safety and EMC/EMI regulations that apply. OMEGA is constantly pursuing certification of its products to the European New Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA accepts no liability for any errors it contains, and reserves the right to alter specifications without notice. WARN -

ING: These products are not designed for use in, and should not be used for, human applications.

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a period of 13 months from date of purchase.

OMEGA’s WARRANTY adds an additional one (1) month grace period to the normal one (1) year product warranty to cover handling and

shipping time. This ensures that OMEGA’s customers receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Service Department will issue an Authorized Return (AR)

number immediately upon phone or written request. Upon examination by OMEGA, if the unit is found to be defective, it will be repaired or replaced

at no charge. OMEGA’s WARRANTY does not apply to defects resulting from any action of the purchaser, including but not limited to mishandling,

improper interfacing, operation outside of design limits, improper repair, or unauthorized modification. This WARRANTY is VOID if the unit shows evidence of having been tampered with or shows evidence of having been damaged as a result of excessive corrosion; or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating conditions outside of OMEGA’s control. Components in which wear is not warranted, include but are not limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However, OMEGA neither assumes responsibility for any omissions or errors nor assumes liability for any damages that result from the use of its products in accordance with information provided by

OMEGA, either verbal or written. OMEGA warrants only that the parts manufactured by the company will be as specified and free of

defects. OMEGA MAKES NO OTHER WARRANTIES OR REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT

THAT OF TITLE, AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total liability of OMEGA with respect to this order, whether based on contract, warranty, negligence, indemnification, strict liability or otherwise,

shall not exceed the purchase price of the component upon which liability is based. In no event shall OMEGA be liable for consequential,

incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic Component” under 10 CFR 21 (NRC), used in

or with any nuclear installation or activity; or (2) in medical applications or used on humans. Should any Product(s) be used in or with any nuclear

installation or activity, medical application, used on humans, or misused in any way, OMEGA assumes no responsibility as set forth in our basic

WARRANTY/ DISCLAIMER language, and, additionally, purchaser will indemnify OMEGA and hold OMEGA harmless from any liability or damage

whatsoever arising out of the use of the Product(s) in such a manner.

Servicing North America:

U.S.A.: One Omega Drive, Box 4047

ISO 9001 Certified Stamford, CT 06907-0047

Tel: (203) 359-1660

FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1, Canada

Tel: (514) 856-6928

FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

U.S.A. and Canada: Sales Service: 1-800-826-6342/1-800-TC-OMEGA

®

Customer Service: 1-800-622-2378/1-800-622-BEST

®

Engineering Service: 1-800-872-9436/1-800-USA-WHEN

®

Mexico: En Espan˜ol: (001) 203-359-7803

FAX: (001) 203-359-7807

e-mail:espanol@omega.com

info@omega.com.mx

OMEGAnet®Online Service Internet e-mail

omega.com info@omega.com

Servicing Europe:

Czech Republic: Frystatska 184, 733 01 Karviná, Czech Republic

Tel: +420 (0)59 6311899

FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342

e-mail: info@omegashop.cz

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: +49 (0)7056 9398-0

FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9001 Certified Northbank, Irlam, Manchester

M44 5BD United Kingdom

Tel: +44 (0)161 777 6611

FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

RETURN REQUESTS / INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE RETURNING ANY PRODUCT(S) TO

OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN (AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER

TO AVOID PROCESSING DELAYS). The assigned AR number should then be marked on the outside of the return package and on any

correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent breakage in transit.

FOR WARRANTY

RETURNS, please have the following information

available BEFORE contacting OMEGA:

1. Purchase Order number under which the product was PURCHASED,

2. Model and serial number of the product under warranty, and

3. Repair instructions and/or specific problems relative to the product.

FOR NON-WARRANTY REPAIRS,

consult OMEGA for current repair charges.

Have the following information available BEFORE contacting OMEGA:

1. Purchase Order number to cover the COST of the repair,

2. Model and serial number of the product, and

3. Repair instructions and/or specific problems relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords our customers the latest in technology and engineering. OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2008 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied, reproduced, translated, or reduced to any electronic

medium or machine-readable form, in whole or in part, without the prior written consent of OMEGA ENGINEERING, INC.

Loading...

Loading...