Page 1

M-5071/1111

Electronic Pressure Switch

PSW14 series

Page 2

Page 3

NOTES

TABLE OF CONTENTS

1 Intended Applications.................................................................................................... 1

2 Safety Instructions......................................................................................................... 1

3 Standards........................................................................................................................ 2

4 Warranty/Guaranty......................................................................................................... 2

5 Installation/Commissioning .......................................................................................... 2

6 Maintenance/Cleaning ................................................................................................... 3

7 Technical Data................................................................................................................ 4

8 Operation ........................................................................................................................ 5

9 Programming.................................................................................................................. 5

Electronic Pressure Switch PSW14 Series

i

Page 4

1 Intended Applications

The pressure switch serves for monitoring a pressure system and has one or two switching outputs.

DANGER

The switch may only be used in the specified fields of application.

The stated pressures and electrical load values must not be exceeded.

Observe also the applicable national safety instructions for assembly, commissioning and

operation of the switch.

The switch is not designed to be used as the only safety relevant element in pressurized systems

according to DGR 97/23/EC.

2 Safety Instructions

The safety instructions are intended to protect the user from dangerous situations and/or material

damage.

In the operating instructions the seriousness of the potential risk is designated by the following

signal words:

DANGER

Refers to imminent danger to men.

Nonobservance may result in fatal injuries.

WARNING

Refers to a recognizable danger.

Nonobservance may result in fatal injuries, and destroy the equipment or plant parts.

CAUTION

Refers to a danger.

Nonobservance may result in light injuries and material damage to the switch and/or to the plant.

IMPORTANT

Refers to important information essential to the user.

Disposal

The switch must be disposed of correctly in accordance with the local regulations for

electric/electronic equipment.

The switch must not be disposed of with the household garbage!

Function Membrane keys LED

Activate/actuate

Reset RS

Switch the pressure switch on while

pressing the membrane key T2.

Press the membrane keys T1 and T2

for 4 s.

Error

IMPORTANT

SP > RS: increasing pressure evaluation

SP < RS: decreasing pressure evaluation

9.2 Version with two switch points

*** Re-actuation hysteresis 15 %, increasing pressure evaluation

Function Membrane keys LED

Activate teaching

SP1 teaching

Press the membrane keys

(T2) for 4 s.

Press the membrane key T1 for 4 s. The

current value for SP1 is transferred to the

pressure switch.

NOTE

When the operation is aborted, SP1 is not

updated.

SP2 teaching

Press the membrane key T2 for 4 s. The

current value for SP2 is transferred to the

pressure switch.

NOTE

When the operation is aborted, SP2 is not

updated.

Activate/actuate

Reset SP1

Switch the pressure switch on while

pressing the membrane key T1.

Press the membrane keys T1 and T2 for

4 s.

Activate/actuate

Reset SP2

Switch the pressure switch on while

pressing the membrane key T2.

Press the membrane keys T1 and T2 for

4 s.

Error

(T1) and

The LED flashes for 12 s green and red at

the ratio of 1:3. Subsequently the LED

shines green.

The LED flashes alternatingly red and

green. The LED shines green, when the

fault has been eliminated.

The LED flashes alternatingly for 12 s red

and green. During these 12 s SP1 and/or

SP2 have to be teached. Subsequently the

LED shines green.

The LED shines red for 4 s.

The LED flashes red 3x, after the pressure

switch has updated SP1.

Subsequently the LED shines green.

The LED shines green for 4 s.

The LED flashes green 3x, after the

pressure switch has updated the SP2.

Subsequently the LED shines green.

The LED flashes for 12 s red and green at

the ratio of 1:3. Subsequently the LED

shines green.

The LED flashes for 12 s green and red at

the ratio of 1:3. Subsequently the LED

shines green.

The LED flashes alternatingly red and

green. The LED shines green, when the

fault has been eliminated.

1

6

Page 5

8 Operation

The switch may only be put into service and operated by authorized persons. Do not use any hard

objects for making entries. A self-test is performed on first commissioning.

The pressure switch is operated via two membrane keys. These must not be touched by means of

hard objects.

IMPORTANT

When power supply is switched on the operational status of the switch is indicated by a green

LED. The switching function is not optically indicated.

9 Programming

IMPORTANT

The pressure switch is programmed by means of the membrane keys (T1) and (T2).

9.1 Version with one switch point

* The switch point SP is set to the measuring range end value.

** The re-actuation point RS is set to the measuring range end value.

Function Membrane keys LED

Activate teaching

SP teaching

RS teaching

Activate/actuate

Reset SP

Press the membrane keys

(T2) for 4 s.

Press the membrane key T1 for 4 s.

The current value for the SP is

transferred to the pressure switch.

NOTE

When the operation is aborted, the SP

is not updated.

Press the membrane key T2 for 4 s.

The current value for the RS is

transferred to the pressure switch.

NOTE

When the operation is aborted, the RS

is not updated.

Switch the pressure switch on while

pressing the membrane key T1.

Press the membrane keys T1 and T2

for 4 s.

(T1) and

The LED flashes alternatingly for 12 s red

and green. Subsequently the LED shines

green.

The LED shines red for 4 s.

The LED flashes red 3x, after the pressure

switch has updated the SP.

Subsequently the LED shines green.

The LED shines green for 4 s.

The LED flashes green 3x, after the

pressure switch has updated the RS.

Subsequently the LED shines green.

The LED flashes for 12 s red and green at

the ratio of 1:3. Subsequently the LED

shines green.

3 Standards

The standards applied during development, manufacture and configuration are listed in the CE

conformity and manufacturer's declaration.

4 Warranty/Guaranty

Warranty

Our scope of delivery and services is governed by the legal warranties and warranty periods.

Terms of guaranty

We guaranty for function and material of the pressure switch under normal operating and

maintenance conditions in accordance with the statutory provisions.

Loss of guaranty

The agreed guaranty period will expire in case of:

• incorrect use

• incorrect installation or

• incorrect handling or operation contrary to the provisions of these operating instructions

No liability is assumed for any damage resulting there from, or any consequential damage.

5 Installation/Commissioning

DANGER

Only install or uninstall the switch when deenergized (electrically and

hydraulically/pneumatically).

Pressure connection and electrical connection must be carried out by trained or instructed

personnel according to state-of-the-art standards.

The switch must only be installed in systems where the maximum pressure P

(see type label).

WARNING

Be aware of the fact that in case of operation with higher temperatures the casing surface may

become very hot!

CAUTION

Mount the pressure switch from the bottom to the •tting with a wrench SW 24 and tighten to a

torque of 45 Nm torque.

Do not put the switch into operation when the switch itself or the connection cable is damaged.

Avoid impact and severe vibration during transport. Even if the switch housing remains

undamaged inside parts may be damaged and cause malfunctions.

is not exceeded

max

5

2

Page 6

()

5

)

∅

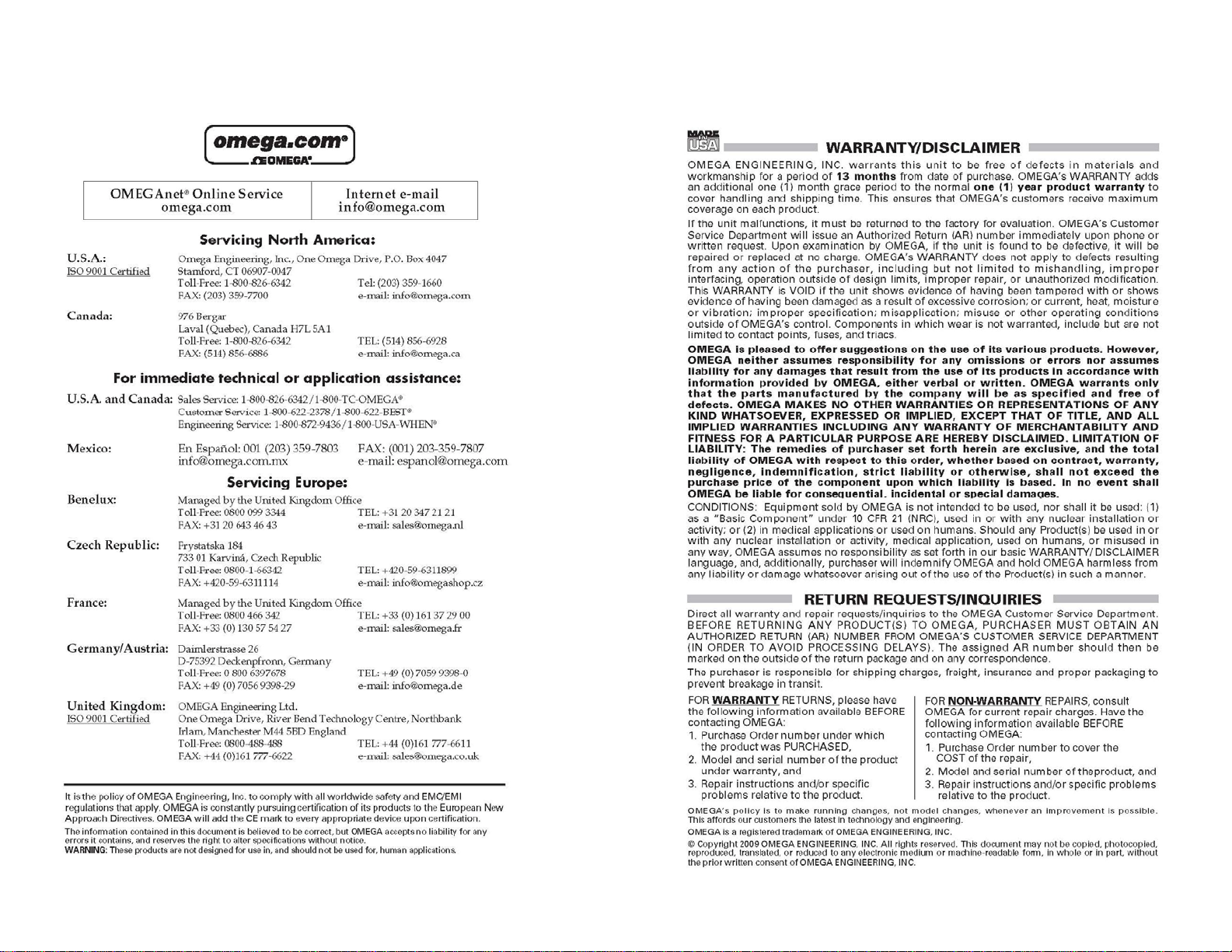

Electrical connection is to be carried out dependent on the type of switch (see type label) according

to the chart below. Wrong assignment of the connections may cause malfunctions or incorrect

switch outputs.

Plug

M 12x1

4-pin

Pin 1

Version with

1 switching output

(1 switch point SP1)

Version with 2 switching

outputs

(2 switch points SP1/SP2)

+Ub (15... 32 V DC) +Ub (15... 32 V DC)

brown

Pin 2

white

Pin 3

- SP2 (0.2 A max.)

NO

0 V 0 V

blue

Pin 4

black

SP1 (0.2 A max.)

NO

SP1 (0.2 A max.)

NO

1

4

2

3

+Ub

SP1

0 V

1

4

2

SP2

3

WARNING

Check the operation of the switch regularly. If the switch does not work properly, stop operation

immediately!

6 Maintenance/Cleaning

The switch requires no maintenance.

CAUTION

The membrane keys may be damaged by the use of unsuitable cleaning agents. Do not use any

cleaning agents containing solvents or abrasive additives.

SP1

+Ub

0 V

7 Technical Data

PSW14

Measuring element Piezoresistive silicon measuring cell with internal stainless steel

diaphragm or ceramic measuring cell

Measuring ranges 0 ... 10 bar to 0 ... 600 bar

0 ... 150 psi to 0 ... 9000 psi

relative pressure

Transistor switching outputs PNP 1 or 2 x NO contacts

Operating temperature range -10... +70 C / +14... +158 °F

Media temperature range -25 ... +100°C / -13 ... +212 °F

Process connection

G1/4

(fitting "A" without adapter)

Protection system/class IP65/III

Electrical connection Plug 4-pin, M 12x1

Auxiliary power 15...•32 V DC

For further technical data and options please refer to the data sheets

Operating and display elements/Dimensions

M12x1

11

(0.29)

Dimensions (example) mm (in)

Item 1: LED

2

1

2

green

red

Operational status

indicator

approx. 100

24 (0.94)

Item 2: Membrane keys

T1

42 (1.6

17

(0.67)

1/4" NPT

SW 24

Programming keys

"Up“ and "Down“

T2

3

4

Loading...

Loading...