Page 1

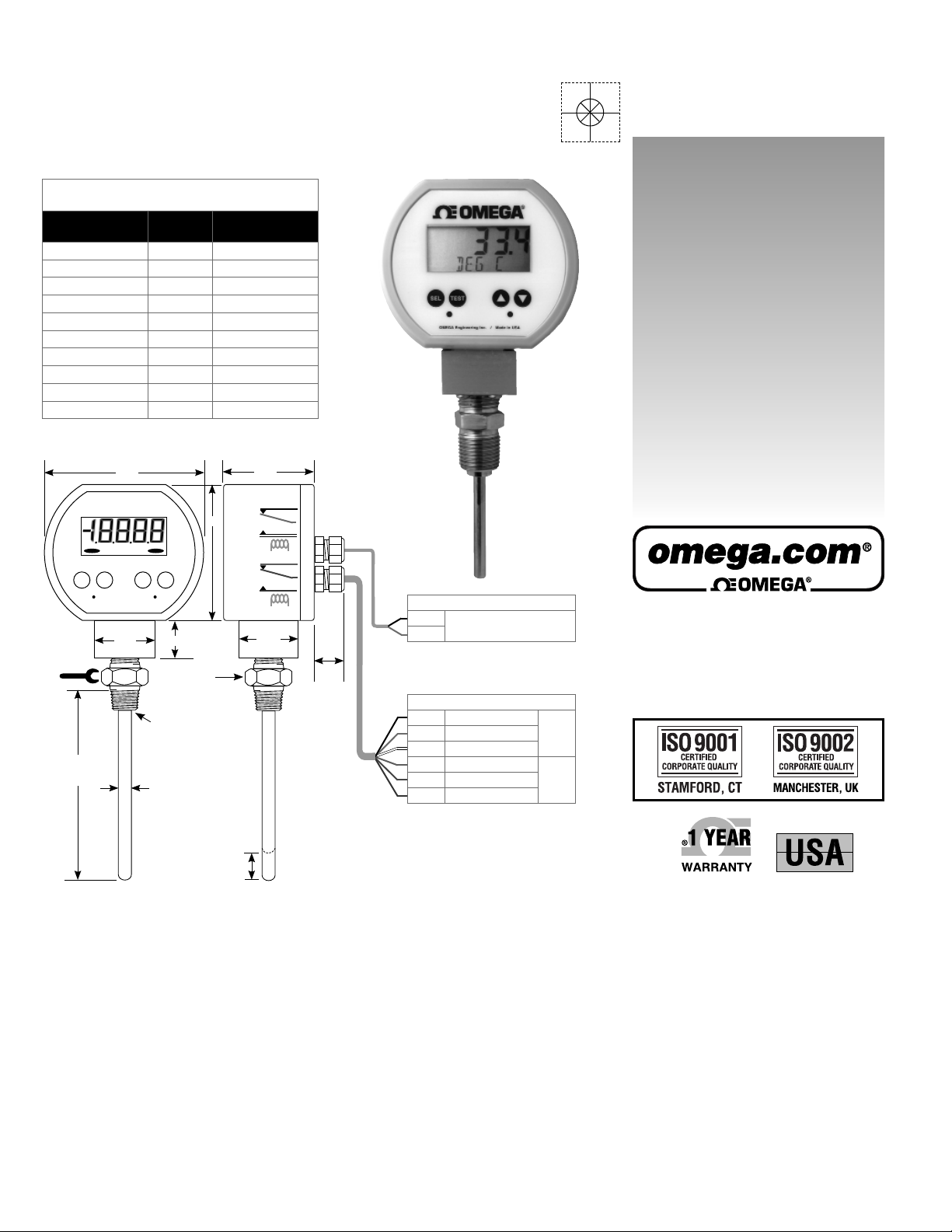

PRTXAL Series RTD Process

WHITE

Temperature Alarms

M-4997/1110

PRTXAL Series RTD Temperature Alarms

2 SPDT Configurable Relays

3.5"

8

1.37"

8

PROBE

LENGTH

8

1/2" NPT x 1/2" NPT

Continuous

weld on

non-spring

loaded

models

.25" dia.

2.5"

2.5"

4"

4"

6"

6"

9"

9"

12"

12"

.75"

Hex nipple

316 stainless

Spring-loaded models

approx. .25" longer to

compress element in

thermowell.

compression

MODEL

PRTXAL-2

PRTXAL-2-SL

PRTXAL-4

PRTXAL-4-SL

PRTXAL-6

PRTXAL-6-SL

PRTXAL-9

PRTXAL-9-SL

PRTXAL-12

PRTXAL-12-SL

*

Thermowell required for spring-loaded versions

ALARM 1 ALARM 2

XXXXX

8

8

SEL

TEST

Turn at

hex

fitting

only!

Stem

Length

L

PROBE

Spring-Loaded

Spring-Loaded

Spring-Loaded

Spring-Loaded

Spring-Loaded

NC 1

3.0"

C 1

NO 1

NC 2

C 2

NO 2

.50" max.

TYPE

Fixed

Fixed

Fixed

Fixed

Fixed

"

2.0

1.25"

Probe length is measured

from top of full threads to

tip of probe.

Length = thermowell

“A” or “element length”

dimension.

User’s Guide

*

*

*

*

*

Shop online at

.75"

2-conductor 22 AWG power cable

BLACK

RED

BLACK Normally Closed (NC)

RED Common (C)

GREEN Normally Closed (NC)

BROWN Common (C)

BLUE Normally Open (NO)

Alarm Contact Ratings

0.5A/115VAC, 1A/24VDC, non-inductive

8 to 24 VAC 50/60 Hz or

9 to 32 VDC

6-conductor 22 AWG relay cable

SPDT 1

Normally Open (NO)

SPDT 2

e-mail: info@omega.com

For latest product manuals:

omegamanual.info

omega.com

MADE IN

Range and Resolution

–58.0°F to 392.0°F or –50.0°C to 200.0°C

User selectable °F or °C

0.1 degree resolution over entire range

Accuracy

±0.1% of span plus maximum sensor error of

±0.3°C at 0°C, ±1.1°C at 150°C

11 point linearization

Sensor

100 Ω RTD element

0.00385 alpha coefficient

IEC-751 Class B: ±0.3°C at 0°C, ±1.1°C at 150°C

10 second time constant

Display

4 readings per second nominal display update rate

4 digit LCD,

Alarm Outputs

Dual form C (SPDT) relay contacts

Relay contacts rated 1A/24VDC, 0.5A/115VAC, non-inductive

Bi-color (red/green) LEDs on front panel

Alarm trip update rate approximately 4 times per second

1

/2" digit height, alphanumeric lower display for units

Setpoint Functionality

Two independent alarm set points

Setpoint 1 high or low alarm

Setpoint 2 high or low alarm

Setpoint 1 deadband adjustment

Setpoint 2 deadband adjustment

Normal or reverse acting relays

Test Function

Front panel TEST button toggles both SP1 and SP2 alarm status,

independent of temperature input to allow testing of system

operation. Access can be pass code protected.

Out of Range Indication

User configurable upscale or downscale burnout

ALARM1 on display above 392°F or 200°C

ALARM2 on display below –58°F or –50°C

Below approx. –103°F (–75°C) or above approx. 482°F (250°C), the

display will indicate 1.-.-.-.

Controls and Functions

TEST Test alarm function

SEL Select

Up: increment up for setup, pass code, or calibration

Down: increment down for setup, pass code, or calibration

Calibration

User settable pass code to enter calibration mode

Zero and span temperature calibration

Electrical Connections

3 foot long, 2-conductor 22AWG cable for power

3 foot long, 6-conductor 22AWG cable for relays

Power

8 to 24 VAC 50/60 Hz or 9 to 32 VDC

1.0 watt maximum power consumption

Weight

Thermometer: approx. 14 ounces

Shipping weight: approx. 1 pound

Housing

NEMA 4X ABS/polycarbonate, gasketed rear cover

Connection and Probe Material

1

/2" NPT male hex nipple, 316 stainless steel

316 stainless steel probe sheath

Environmental

Storage: –40 to 203°F (–40 to 95°C) at housing

Operating: –4 to 185°F (–20 to 85°C) at housing

Page 2

2

PRTXAL Series RTD Process Temperature Alarms

Precautions

Read these instructions before installation. Configuration may be

easier before installation.

Avoid shock hazards! Turn power off before connecting or

disconnecting wiring. All wiring must be performed by a qualified

electrician or instrumentation technician. See diagrams on other

side for wiring examples. Consult factory for assistance.

Install or remove thermometer using a wrench on the hex fitting

only. Do not attempt to turn by forcing the housing.

Do not exceed maximum allowable housing temperature.

The spring-loaded design must be used with a thermowell. The non-

spring-loaded design can be used in non-pressurized applications

or applications with no flow. Due to the hardness of 316 stainless

steel, it is recommended that a thread sealant be used to ensure

leak-free operation.

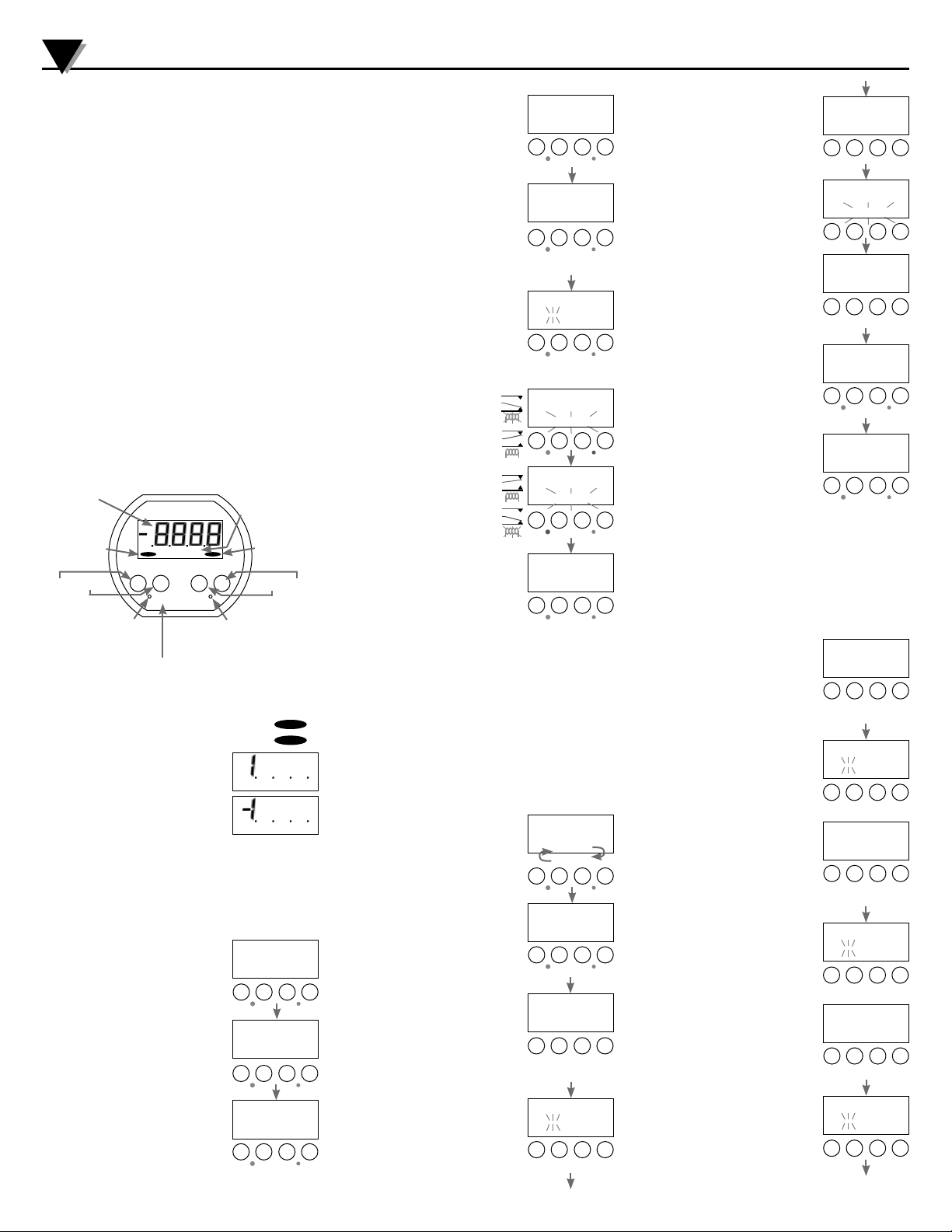

Normal Operation

The factory default configuration is °F, downscale burnout, Setpoint

1 High Alarm, Setpoint 2 Low Alarm, 1.0 degree alarm deadband,

normal acting relays, no pass code required for configure/test

alarms mode.

To turn the unit on, apply power. If so equipped, the optional display

backlighting will be on. The display backlighting will not be apparent

under bright lighting conditions.

The display segments are tested for approximately 1 second. During

the startup sequence, the alarm relays are de-energized and the

alarm status LEDs are off.

After power-up the RTD temperature and units are displayed along

with the alarm relay states as indicated by the LEDs. The display

and alarm status are updated approximately 4 times per second,

Display and Keypad

Numeric

display

RTD over-

range

Select Test Up Down

ALARM 1

XXXXX

8

8

8

8

8

SEL

TEST

ALARM 2

Lower alpha-

numeric display

RTD under-

range

Alarm 1 status LED

Green = Normal

Red = Alarm

Red blinking LED = unacknowledged alarm

Press Test to acknowledge alarm

Out-of-Range Indications

RTD over-range condition >392.0°F or >200.0°C

RTD under-range condition <–58.0°F or <–50.0°C

If the RTD temperature is outside of the

extrapolated range, a burnout condition will

be assumed.

1. . . . if upscale burnout is selected

–1. . . . if downscale burnout is selected.

Alarm Indications

The relevant bi-color LED will be illuminated green for a normal

condition or red for an alarm condition.

The red LED will blink at a slow rate until the alarm is acknowledged

or the alarm condition clears.

To acknowledge an alarm condition, press and release the TEST

button.

Viewing Alarm Trip Points

The RTD temperature, the value of Trip

Point 1, and the value of Trip Point 2 may be

selected for display as follows.

When the RTD temperature is being

displayed, press and release the SEL

(select) button. The Trip Point 1 value will be

displayed with TRIP1 on the lower display.

When the Trip Point 1 value is being

displayed, press and release the SEL button.

The Trip Point 2 value will be displayed with

TRIP2 on the lower display.

When the Trip Point 2 value is being

displayed, press and release the SEL button.

The RTD temperature will be displayed.

Alarm 2 status LED

Green = Normal

Red = Alarm

ALARM 1

ALARM 2

DEG F

DEG F

200.0

TRIPI

SEL

TEST

I80.0

TRIP2

SEL

TEST

I88.0

DEG F

SEL

TEST

Alarm Test Mode

This mode allows testing of the alarms

regardless of the alarm trip points or the

temperature reading.

From the normal mode with temperature

being displayed, press and hold the TEST

button and then press the SEL button.

Release both buttons when the display

indicates - - - - .

- or If pass code protection is enabled, before

the unit enters the Alarm Test Mode, the

display initially indicates _ _ _ _ with the

left-most underscore blinking, and with

TSTPC on the lower display. Enter the userdefined pass code (3510 factory default) as

described in the Pass Code Entry section.

Note: During pass code entry the LEDs will

turn off and the unit will not respond to

changes in RTD temperature. The alarm

relays will maintain their prior states. The

unit will automatically revert to normal

operation if no buttons are operated for

approximately 15 seconds.

While in the Alarm Test Mode

with no buttons pressed,

the display will indicate the

temperature with DEG C or DEG

F slowly blinking on the lower

display.

While the TEST button is pressed

and held, both LED indicators

and alarm relays will toggle to

their opposite state. The display

will continue to indicate the

temperature.

To exit the Alarm Test Mode,

press and release the SEL

button. The display briefly

indicates - - - - and then returns

to normal operation.

Adjusting Set Points

Go to the User Configuration Mode to set up the alarm parameters

before setting up the alarm setpoints. Whenever the user

configuration mode is entered, even if no changes are made, all

alarm set points will be reset to the factory default maximum and

minimum values.

Alarm 1 factory default: HI alarm, 392.0°F trip point.

Alarm 2 factory default: LO alarm, –58.0°F trip point.

“Set Point” is defined as the temperature that will result in a change

of state only from a normal to an alarm condition.

“Trip Point” is defined as the temperature value that will result in

a change of state of alarm condition, and includes the effect of

deadband when returning from an alarm to

a normal condition.

The instructions illustrate how to change

Trip Point 1. The procedure is the same for

Trip Point 2.

From the normal mode press and release

the SEL button to display Trip Point 1. If

you want to change Trip Point 2, press SEL

again until TRIP2 is displayed.

While TRIP1 is displayed, press and hold the

TEST button and then press the SEL button.

NC 1

C 1

NO 1

NC 2

C 2

NO 2

NC 1

C 1

NO 1

NC 2

C 2

NO 2

200.0

deg f

SEL

TEST

12

press both

- - - -

SEL

TEST

release both

- or -

____

TSTPC

SEL

TEST

release both

i88.7

deg F

SEL

TEST

i88.7

deg f

SEL

TEST

- - - -

DEG F

SEL

TEST

exit

200.0

TRIPI

TRIP2

or

SEL

TEST

200.0

tripi

SEL

TEST

12

press both

- - - -

Release both buttons when the display

indicates - - - - .

If pass code protection is enabled, before

the unit enters the Alarm Test Mode, the

display indicates _ _ _ _ with the left-most

underscore blinking, and with TSTPC on the

lower display.

SEL

TEST

release both

- or -

____

TSTPC

SEL

TEST

release both

Enter the user-defined pass code (3510

factory default) as described in the Pass

Code Entry section.

Note: During pass code entry the LEDs

will turn off and the unit will not respond

to changes in RTD temperature. The alarm

relays will maintain their prior states. The

unit will automatically revert to normal

operation if no buttons are operated for

approximately 15 seconds.

While in the Set Point 1 Adjust Mode, the

display will indicate Trip Point 1 with TRIP1

blinking at a slow rate on the lower display.

To adjust Set Point 1, press and hold the

TEST button and the display will indicate

SP1 on the lower display. If the alarm is not

tripped the display will change by an amount

equal to the deadband value.

While holding the TEST button operate the

and buttons to adjust Set Point 1 to the

desired value. The Set Point 1 value is stored

when the TEST button is released.

Note that the unit will not respond to

changes in temperature, LEDs are turned off,

and the alarm relays will maintain their prior

states while the TEST button is held.

To change Trip Point 2 press SEL until TRIP

2 is shown. The procedure is the same as

Trip Point 1.

To exit, press the SEL button until the display

indicates - - - -. The unit then returns to

normal operation.

Pass Code Entry

Pass codes are used to prevent unauthorized changes to settings.

Up to three different pass codes can be used to allow access to the

configuration, alarm settings and output test, or calibration.

During pass code entry the LEDs will turn off and the unit will not

respond to temperature changes. The alarm relays will maintain

their prior states. The unit will automatically revert to normal

operation if no buttons are pressed for 15 seconds.

Configuration Pass Code

From the normal operating mode press and

hold the TEST and the buttons. Then

press the SEL button. Release all buttons

when the display indicates CFG.

The display initially indicates _ _ _ _ with

the first underscore blinking, and with

CFGPC on the lower display.

Enter the user-defined pass code as

described on the next page.

Calibration Pass Code

Press and hold the TEST and the buttons.

Then press the SEL button. Release all

buttons when the display indicates CAL.

The display initially indicates _ _ _ _ with

the first underscore blinking, and CALPC on

the lower display.

Enter the user-defined pass code as

described on the next page.

Test and Set Point Adjust Pass Code

The optional for pass code protected alarm

testing or set point changes is set in CFG

mode. It is not used in the factory default

configuration.

Press and hold the TEST button. Then press

the SEL button. Release all buttons when the

display indicates - - - - .

If TSTPC pass code is enabled, the display

indicates _ _ _ _ with the first underscore

blinking, and TSTPC on the lower display.

Enter the user-defined pass code as

described on the next page.

35 i0

TSTPC

SEL

TEST

200.0

TRIPI

SEL

TEST

205.0

SP I

SEL

TEST

hold

250.0

Trip2

SEL

TEST

- - - -

Trip2

SEL

TEST

exit

cf6

tpv27

SEL

TEST

2

1

then

together

____

cfgpc

SEL

TEST

- or -

CAL

tpv27

SEL

TEST

12

togetherthen

____

calpc

SEL

TEST

- or -

- - - -

SEL

TEST

12

then

____

tstpc

SEL

TEST

or

1

1

Page 3

PRTXAL Series RTD Temperature Alarms

3

User-Defined Pass Code Entry

Enter the user-defined pass code (3510

factory default).

Use the and buttons to increase or

decrease the numerical value.

Press and release the SEL button to index to

the next position.

Once the 4-digit the user-defined pass code

has been entered, press and release the

SEL button to proceed to the specific mode

of operation.

Note: If an incorrect pass code was entered,

the unit will to exit to the normal operating

mode.

Pass Code Modification

To modify any of the default factory pass

codes, enter pass code 1220 using the same

procedure as described above.

Once the 1220 pass code has been entered,

press and release the SEL button to proceed.

If an incorrect pass code was entered, the

unit will to exit to the normal operating

mode.

The display will then indicate the existing

pass code with CFGPC, CALPC, or TSTPC

on the lower display, depending on the key

combination used.

Operate the or button to select the first

character of the new pass code. Press and

release the SEL button to proceed to the next

character. Repeat until the entire pass code

is complete. Write down the new pass code

in a secure place.

To exit the Pass Code Modification mode,

press and hold the SEL button. Release the

button when the display indicates - - - - to restart the unit in the

normal mode.

User Configuration Mode

Whenever the user configuration mode is entered, even if no

changes are made, all alarm set points will be reset to the factory

default maximum and minimum values.

From the Normal Mode with RTD

temperature being displayed, press and hold

the TEST and the buttons. Then press the

SEL button. Release all buttons when the

display indicates CFG.

Enter the user-defined pass code (3510

factory default) as described in the Pass

Code Entry section.

____

cfgpc

calpc

TSTpc

SEL

TEST

next #

35 i0

SEL

TEST

i220

SEL

TEST

hold

35 i0

cfgpc

calpc

cfgpc

SEL

TEST

next #

- - - -

SEL

TEST

save and exit

cf6

tpv27

SEL

TEST

2

1

then

together

____

cfgpc

SEL

TEST

move

to next

1

or

or

or

or

or

or

or

or

35 i0

cfgpc

SEL

TEST

Temperature Scale Selection

The upper display will be blank, and the

lower section will display either DEG C or

DEG F.

To change from degrees Celsius to

Fahrenheit, press and release the button.

The lower display will change to DEG F.

To change from degrees Fahrenheit to

Celsius, press and release the button.

The lower display will change to DEG C.

Press and release the SEL button to move on

to the next parameter.

def f

deg c

SEL

TEST

deg f

SEL

TEST

press to save

or

Upscale/Downscale Burnout Action

The upper display will be blank, and the

lower section will display either DN BO or

UP BO.

To change from Downscale Burnout to

Upscale Burnout, press and release the

button. The lower display will change to UP

BO.

To change from upscale burnout to

downscale burnout, press and release the

button. The lower display will change to

DN BO.

Press and release the SEL button to move on

to the next parameter.

Set Point 1 LO or HI

The upper display will be blank, and the

lower section will display either SP1LO or

SP1HI.

To configure Setpoint 1 as a High Alarm,

press and release the button. The lower

section of the display will indicate SP1HI.

To configure Setpoint 1 as a Low Alarm,

press and release the button. The lower

section of the display will indicate SP1LO.

Press and release the SEL button to move on

to the next parameter.

Set Point 2 LO or HI

The upper display section will be blank, and

the lower section will display either SP2LO

or SP2HI.

To configure Setpoint 2 as a High Alarm,

press and release the button. The lower

section of the display will indicate SP2HI.

To configure Setpoint 2 as a Low Alarm,

press and release the button. The lower

section of the display will indicate SP2LO.

Press and release the SEL button to move on

to the next parameter.

Normal/Reverse Alarm Action

The upper display section will be blank, and

the lower section will display either NOR

or REV.

To configure the relays for reverse action,

press and release the button. The lower

section of the display will indicate REV.

To configure the relays for normal action,

press and release the button. The lower

section of the display will indicate NOR.

Press and release the SEL button to move on

to the next parameter.

Set Point 1 Deadband

The upper display will indicate the Setpoint 1

deadband in °C or °F, and the lower section

will display SP1DB.

Use the and buttons to set the desired

Setpoint 1 deadband value.

Press and release the SEL button to move on

to the next parameter.

Set Point 2 Deadband

The upper display will indicate the Setpoint 2

deadband in °C or °F, and the lower section

will display SP2DB.

Use the and buttons to set the desired

Setpoint 2 deadband value.

Press and release the SEL button to move on

to the next parameter.

up bo

dn bo

SEL

TEST

up bo

SEL

TEST

press to save

spihi

spilo

SEL

TEST

spihi

SEL

TEST

press to save

sp2hi

sp2lo

SEL

TEST

sp2lo

SEL

TEST

press to save

nor

rev

SEL

TEST

rev

SEL

TEST

press to save

spidb

SEL

TEST

spidb

SEL

TEST

press to save

sp2db

SEL

TEST

sp2db

SEL

TEST

press to save

or

or

or

or

0.5

or

i.o

0.5

or

i,0

Test Mode and Set Point Security

The upper display will be blank, and the

lower section will display either TSTPC or

NOTPC.

To enable Test and Set Point Adjust Mode

pass code protection, press and release the

button. The lower section of the display

will indicate TSTPC.

To disable Test and Set Point Adjust Mode

pass code protection, press and release the

button. The lower section of the display

will indicate NOTPC.

Save Settings and Exit

Press and release the SEL button to save

the configuration parameters and restart the

unit. Note: The configuration parameters will

not be saved if the procedure is interrupted before completion.

The unit proceeds through a restart sequence during which all active

display segments are turned on for approximately 1 second. During

the restart sequence, the alarm relays are de-energized, the alarm

status LEDs are off.

Calibration

Temperature calibration is performed at two points: ice point and

at a temperature above ice point. For general service, the full scale

temperature is normally used for the second point. However, if a

particular temperature is of critical interest, it may be used instead

for greatest accuracy at that point. When the applied temperature

is below approximately 12 °C (or 54 °F), the unit will automatically

select the ice-point calibration mode.

Entering Calibration Mode

From the normal mode with RTD

temperature being displayed, press and hold

the TEST and the buttons. Then press the

SEL button. Release all buttons when the

display indicates CAL.

Enter the user-defined pass code (3510

factory default) as described in the Pass

Code Entry section.

Upon successful pass code entry, the upper

segments of the display will indicate the RTD

probe temperature. The lower segments of

the display will alternate as indicated below.

Note: To store the calibration parameters

and exit calibration mode at any time, press

and hold the SEL button until the display

indicates - - - - .

Ice-Point Calibration

Apply 0.0°C or 32.0°F to the RTD. The lower

display segments will alternate between ICE

and DEG C or DEG F.

Use the and buttons to adjust the

upper display segments to indicate 0.0°C

or 32.0°F.

SEL

SEL

SEL

2

then

____

SEL

SEL

sensor at ice point

SEL

Span Calibration

Apply full-scale temperature to the RTD.

The lower display segments will alternate

between CAL and DEG C or DEG F.

Use the and buttons to adjust the

upper display segments to indicate the

applied temperature value.

Exit and Save

To store the calibration parameters and exit

calibration mode, press and continue to hold

the SEL button until the display indicates

- - - - .

sensor at span point

250.0

SEL

SEL

tstpc

notpc

TEST

or

notpc

TEST

press to save & exit

unit restarts

cal

tpv27

TEST

1

together

calpc

TEST

or

move

to next

35 i0

calpc

TEST

32.0

ice

deg f

TEST

or

cal

deg f

TEST

or

- - - -

TEST

hold to save and exit

1

Page 4

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

OMEGAnet

www.omega.com info@omega.com

USA: One Omega Drive, Box 4047

ISO 9001 Certified Stamford CT 06907-0047

Canada: 976 Bergar

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Mexico: En Espan˜ ol: (001) 203-359-7803 e-mail:espanol@omega.com

FAX: (001) 203-359-7807 info@omega.com.mx

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that apply. OMEGA is constantly pursuing certification of its products to the

European New Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts no liability for any errors it contains, and reserves the right to alter specifications without

notice. WARNING: These products are not designed for use in, and should not be used for, human applications.

®

Online Service Internet e-mail

Servicing North America:

Tel: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Laval (Quebec) H7L 5A1, Canada

Tel: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

®

Customer Service: 1-800-622-2378 / 1-800-622-BEST

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

®

Toll Free in Benelux: 0800 0993344

Czech Republic: Frystatska 184, 733 01 Karviná, Czech Republic

Tel: +420 (0)59 6311899 FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342 e-mail: info@omegashop.cz

France: 11, rue Jacques Cartier, 78280 Guyancourt, France

e-mail: sales@omega.fr

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified Northbank, Irlam, Manchester

®

M44 5BD United Kingdom

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

Tel: +31 (0)20 3472121 FAX: +31 (0)20 6434643

e-mail: sales@omegaeng.nl

Tel: +33 (0)1 61 37 2900 FAX: +33 (0)1 30 57 5427

Toll Free in France: 0800 466 342

Tel: +49 (0)7056 9398-0 FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

Tel: +44 (0)161 777 6611

FAX: +44 (0)161 777 6622

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a period of 13 months from date of purchase.

OMEGA’s WARRANTY adds an additional one (1) month grace period to the normal one (1) year product warranty to cover handling and shipping

time. This ensures that OMEGA’s customers receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Service Department will issue an Authorized Return (AR)

number immediately upon phone or written request. Upon examination by OMEGA, if the unit is found to be defective, it will be repaired or replaced

at no charge. OMEGA’s WARRANTY does not apply to defects resulting from any action of the purchaser, including but not limited to mishandling,

improper interfacing, operation outside of design limits, improper repair, or unauthorized modification. This WARRANTY is VOID if the unit shows

evidence of having been tampered with or shows evidence of having been damaged as a result of excessive corrosion; or current, heat, moisture or

vibration; improper specification; misapplication; misuse or other operating conditions outside of OMEGA’s control. Components which wear are not

warranted, including but not limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However, OMEGA neither assumes responsibility for any omissions or errors

nor assumes liability for any damages that result from the use of its products in accordance with information provided by OMEGA, either verbal or

written. OMEGA warrants only that the parts manufactured by it will be as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR

REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESS OR IMPLIED, EXCEPT THAT OF TITLE, AND ALL IMPLIED WARRANTIES INCLUDING ANY

WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF LIABILITY: The remedies

of purchaser set forth herein are exclusive, and the total liability of OMEGA with respect to this order, whether based on contract, warranty, negligence,

indemnification, strict liability or otherwise, shall not exceed the purchase price of the component upon which liability is based. In no event shall OMEGA be

liable for consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic Component” under 10 CFR 21 (NRC), used

in or with any nuclear installation or activity; or (2) in medical applications or used on humans. Should any Product(s) be used in or with any nuclear

installation or activity, medical application, used on humans, or misused in any way, OMEGA assumes no responsibility as set forth in our basic

WARRANTY / DISCLAIMER language, and, additionally, purchaser will indemnify OMEGA and hold OMEGA harmless from any liability or damage

whatsoever arising out of the use of the Product(s) in such a manner.

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE RETURNING ANY PRODUCT(S) TO

OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN (AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN

ORDER TO AVOID PROCESSING DELAYS). The assigned AR number should then be marked on the outside of the return package and on any

correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent breakage in transit.

PATENT NOTICE: U. S. Pat. No. 6,074,089; 5,465,838 / Canada 2,228,333; 2,116,055 / UK GB 2,321,712 / Holland 1008153 / Israel 123052 / France

2 762 908 / EPO 0614194. Other patents pending.

FOR WARRANTY RETURNS, please have the following information

available BEFORE contacting OMEGA:

1. Purchase Order number under which the product was PURCHASED,

2. Model and serial number of the product under warranty, and

3. Repair instructions and/or specific problems relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords our customers the latest in technology and

engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2004 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied, reproduced, translated, or reduced to any electronic

medium or machine-readable form, in whole or in part, without the prior written consent of OMEGA ENGINEERING, INC.

FOR NON-WARRANTY REPAIRS,

consult OMEGA for current repair charges.

Have the following information available BEFORE contacting OMEGA:

1. Purchase Order number to cover the COST of the repair,

2. Model and serial number of the product, and

3. Repair instructions and/or specific problems relative to the product.

M-4997/1110

RETURN REQUESTS / INQUIRIES

Loading...

Loading...