Page 1

PRG 350 Series

Stainless Steel Regulators

Page 2

OMEGAnet®Online Service Internet e-mail

omega.com info@omega.com

Servicing North America:

U.S.A.: Omega Engineering, Inc., One Omega Drive, P.O. Box 4047

ISO 9001 Certified Stamford, CT 06907-0047 USA

Toll Free: 1-800-826-6342 TEL: (203) 359-1660

FAX: (203) 359-7700 e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec), Canada H7L 5A1

Toll-Free: 1-800-826-6342 TEL: (514) 856-6928

FAX: (514) 856-6886 e-mail: info@omega.ca

For immediate technical or application assistance:

U.S.A. and Canada: Sales Service: 1-800-826-6342/1-800-TC-OMEGA

Customer Service: 1-800-622-2378/1-800-622-BEST

Engineering Service: 1-800-872-9436/1-800-USA-WHEN

Mexico: En Español: 001 (203) 359-7803 FAX: (001) 203-359-7807

info@omega.com.mx e-mail: espanol@omega.com

®

®

®

Servicing Europe:

Benelux: Managed by the United Kingdom Office

Toll-Free: 0800 099 3344 TEL: +31 20 347 21 21

FAX: +31 20 643 46 43 e-mail: sales@omega.nl

Czech Republic: Frystatska 184

733 01 Karviná, Czech Republic

Toll-Free: 0800-1-66342 TEL: +420-59-6311899

FAX: +420-59-6311114 e-mail: info@omegashop.cz

France: Managed by the United Kingdom Office

Toll-Free: 0800 466 342 TEL: +33 (0) 161 37 29 00

FAX: +33 (0) 130 57 54 27 e-mail: sales@omega.fr

Germany/Austria: Daimlerstrasse 26

D-75392 Deckenpfronn, Germany

Toll-Free: 0 800 6397678 TEL: +49 (0) 7059 9398-0

FAX: +49 (0) 7056 9398-29 e-mail: info@omega.de

United Kingdom: OMEGA Engineering Ltd.

ISO 9001 Certified One Omega Drive, River Bend Technology Centre, Northbank

Irlam, Manchester M44 5BD England

Toll-Free: 0800-488-488 TEL: +44 (0)161 777-6611

FAX: +44 (0)161 777-6622 e-mail: sales@omega.co.uk

It is the policy of OMEGA Engineering, Inc. to comply with all worldwide safety and EMC/EMI

regulations that apply. OMEGA is constantly pursuing certification of its products to the European Ne

Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification

The information contained in this document is believed to be correct, but OMEGA accepts no liability for any

errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, human applications.

.

w

Page 3

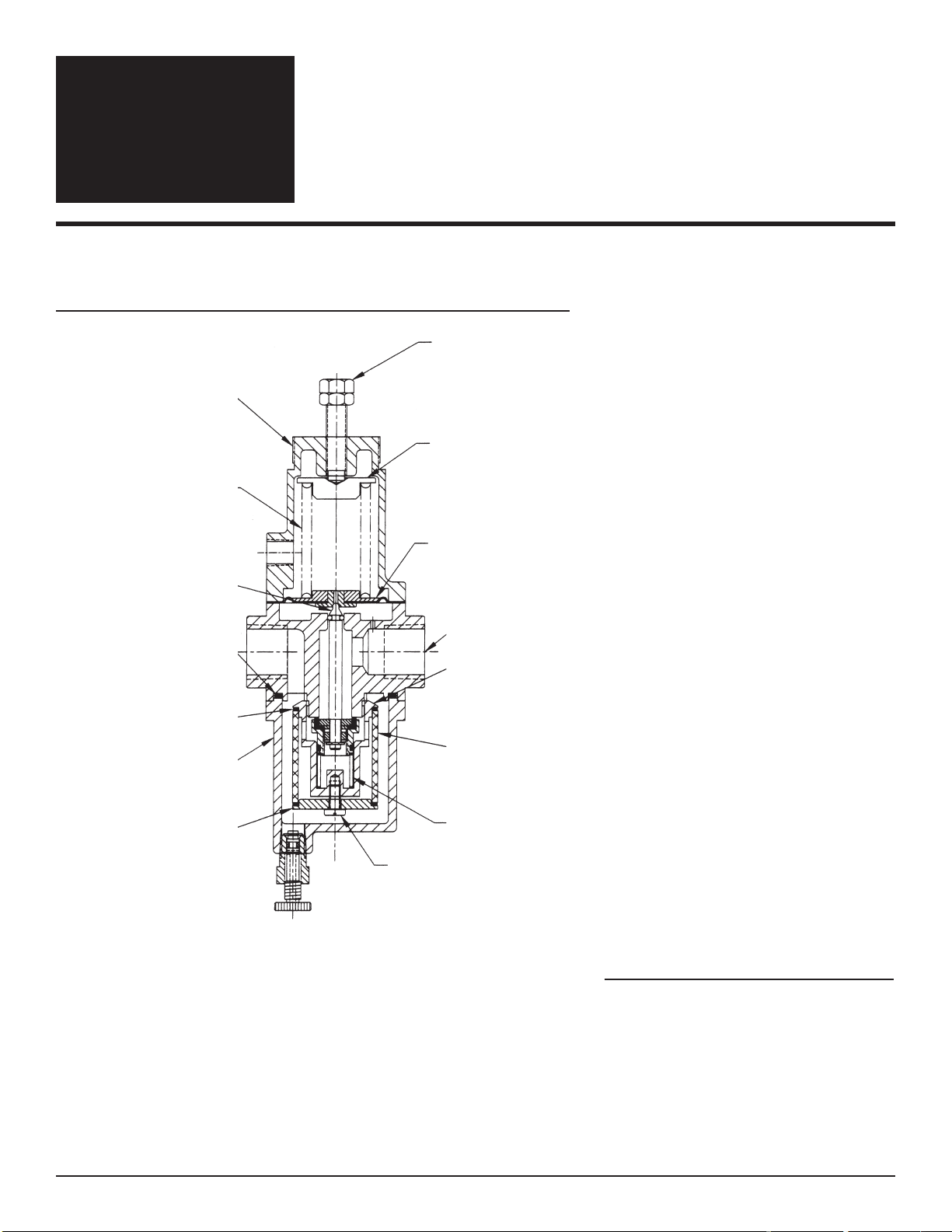

PRG 350

Series

Stainless Steel Regulators

Installation, Operation and

Maintenance Instructions

PRG 350SS 1/2" NPT

Bonnet

Range Spring

* Pintle Assembly

* Housing Seal O-Ring

* Filter O-Ring (2)

Drip Well Housing

Assembly

Adjustment Screw

Assembly

Spring Guide

*Diaphragm

Assembly

Body Assembly

Collar

Filter, 25 Micron, SS

Filter Retainer

Filter Retaining Screw

Pintle Spring

Contents

Section Description Page

1.0 Specifications 2

2.0 Installation 2

3.0 Operation 3

4.0 Maintenance & Repair 3

5.0 Warranty 5

*Included with repair kit

M-4808/0809 PRG 350 Series Page 1

Page 4

DANGER, WARNING, CAUTION and NOTE statements

DANGER

WARNING

CAUTION

NOTE

DANGER

Refers to conditions or hazards which could result in serious personal injury or death.

Refers to conditions or hazards which could result in personal injury.

Refers to conditions or hazards which could result in equipment or property damage.

Alerts you to facts or special instructions.

ALL DANGER, WARNING, AND CAUTION NOTICES MUST BE COMPLIED WITH IN FULL

Personal injury, property damage, equipment damage, or leakage due to escaping gas or bursting of

pressure containing parts may result if this regulator is over pressurized or installed where service

conditions could exceed the limits given in the specifications. To avoid such injury or damage, provide

pressure-relieving or limiting devices (as required by the appropriate code, regulation or standard) to

prevent service conditions from exceeding those limits.

1. SPECIFICATIONS

Output Ranges: 0-30 psig (0-2.0 BAR), 0-60 psig (0-4.0 BAR), 0-100 psig (0-7.0 BAR),

0-150 psig (0-10.0 BAR)

Exhaust Capacity: 1.0 SCFM (1.7 m3/hr) at downstream pressure of

10 psig (0.7 BAR) above set point

Maximum

Supply Pressure: 290 psig (20.0 BAR)

Air Consumption: 4 SCFH (0.1 m3/hr)

Operating

Temperatures: -20° to +185° F (-29° to +85° C)

Filter: 25 micron

Porting: Inlet/Outlet: 1/4" NPT or 1/2" NPT

Gauge (2): 1/4" NPT

Exhaust: 1/8" NPT

Materials: 316 stainless steel: body, bonnet, filter

Fluorocarbon: diaphragm, seals

Inconel: range spring, pintle spring

Weight: 1/4" NPT: 2.2 lbs. (1.0 kg)

1/2" NPT: 2.8 lbs. (1.3 kg)

2. INSTALLATION

2.1 Install the regulator/filter as close as possible to the instrument or tool it is to service.

2.2 Clean all pipelines to remove dirt and scale prior to installation.

NOTE

WARNING

Failures attributable to air supply contamination are not covered by the warranty.

This instrument vents to atmosphere. The use of gas other than air may create a

hazardous environment.

2.3 Install the regulator/filter so that the direction of flow is from the "IN" to "OUT" connec-

tion as marked on the body of the regulator/filter.

M-4808/0809 PRG 350 Series Page 2

Page 5

2.4 For best drainage, orient the drain valve so that it is at the lowest point on the drip well

housing. Positioning of the drain valve may be improved by rotating the drip well with

respect to the body.

2.5 The exhaust port should be kept free and unplugged. Position the regulator so that the

vent is at the lowest point possible, or provide additional protection to prevent contaminants from entering the regulator. Rotating the bonnet relative to the body may change

the vent hole orientation.

WARNING

The PRG 350 Series has a low capacity internal relief that provides limited down stream protection

against over pressurization.

2.6 Exhaust may be remotely vented by installing tubing to the 1/8" NPT port.

2.7 Apply pipe compound or sealing tape to the male pipe threads prior to installing

regulator/filter. Use caution to prevent the sealant from getting inside the regulator/filter.

3. OPERATION

3.1 Prior to turning on supply air, back off adjusting screw until there is no compression of

the range spring.

3.2 After applying the air supply, output pressure will be increased by rotating the adjust-

ment screw clockwise. Pressure can be decreased by turning counter clockwise.

3.3 Tighten locknut to maintain desired pressure setting.

4. MAINTENANCE & REPAIR

4.1 To remove condensate from the PRG 350 Series, slowly open drain valve by turning

clockwise and bleed accumulated liquid.

DANGER

To avoid personal injury, property damage, or equipment damage caused by sudden release of pressure or explosion of accumulated gas, do not attempt any maintenance or disassembly without first

isolating the regulator from system pressure and relieving all internal pressure from the regulator.

4.2 To clean filter element

4.2.1 Shut off supply pressure and relieve all internal pressure.

4.2.2 Drain condensate from drip well.

4.2.3 Remove four corner bolts from bottom of unit and remove drip well housing.

4.2.4 Remove filter retaining screw.

4.2.5 Remove filter retainer, filter o-ring seals and filter.

4.2.6 Clean parts and reassemble in reverse order.

4.3 To clean/replace pintle assembly

4.3.1 Follow steps 4.2.1 through 4.2.4.

4.3.2 Unscrew collar and remove.

4.3.3 Remove pintle spring and pintle. 1/4" NPT version may require needle nose pliers or push pintle stem from above by

removing bonnet and diaphragm assembly.

4.3.4 Clean/replace parts and reassemble in reverse order.

M-4808/0809 PRG 350 Series Page 3

Page 6

4.4 To clean/replace diaphragm assembly

4.4.1 Back out the adjusting screw until the spring is no longer compressed.

.4.2 Remove the four bonnet screws and separate the bonnet from the body of the regulator. Remove the spring guide

4

and spring.

4.4.3 Remove the diaphragm assembly, clean or replace it as necessary and reassemble in reverse order. After placing the

diaphragm assembly on the body, push down the assembly to make sure that the pintle is seated properly and

strokes smoothly.

4.5 Repair kits/replacement parts

.5.1 Repair kits include all parts marked with an asterisk (*). See diagrams on page 1.

4

4.5.2 When ordering repair kits or replacement filters, order as:

REPAIR KITS

PRG 350 Includes: Pintle Assembly, Housing Seal O-Ring, Diaphragm Assembly, Filter Seal O-Ring (2)

Model Porting Description Part Number

PRG 354 1/4” NPT Relieving 449-871-068

PRG 352 1/2” NPT Relieving 449-871-070

4.5.3 Other replacement parts are available. Please consult Omega Engineering, Inc. for part numbers and availability.

M-4808/0809 REV 09/03/09 PRG 350 Series Page 4

Page 7

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a

period of 13 months from date of purchase. OMEGA’s WARRANTY adds an additional one (1) month

grace period to the normal one (1) year product warranty to cover handling and shipping time. This

ensures that OMEGA’s customers receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Servic

Department will issue an Authorized Return (AR) number immediately upon phone or written request

Upon examination by OMEGA, if the unit is

charge. OMEGA’s WARRANTY does not

found to be defective, it will be repaired or replaced at no

apply to defects resulting from any action of the purchaser,

including but not limited to mishandling, improper interfacing, operation outside of design limits,

improper repair,

having been

or current,

or unauthorized modification. This WARRANTY is VOID if the unit shows evidence of

tampered with or shows evidence of having been damaged as a result of excessive corrosion;

heat, moisture or vibration; improper specification; misapplication; misuse or other operating

conditions outside of OMEGA’s control. Components in which wear is not warranted, include but are not

limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or errors nor assumes liability for any

damages that result from the use of its products in accordance with information provided by

OMEGA, either verbal or written. OMEGA warrants only that the parts manufactured by the

company will be as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR

REPRESENTATIONS OF ANY

TITLE, AND

ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY

KIND WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF

AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF

LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total liability of

OMEGA with respect to this order, whether based on contract, warranty, negligence,

indemnification, strict liability or otherwise, shall not exceed the purchase price of the

co mpone nt upon w hich liability is based. In no event shall OM EGA be liable for

consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic

Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical

applications or used on humans. Should any Product(s) be used in or with any nuclear installation or

activity, medical

as set forth in our basic WARRANTY/DISCLAIMER language,

OMEGA

and hold OMEGA harmless from any liability or damage whatsoever arising out of the use of the

application, used on humans, or misused in any way, OMEGA assumes no responsibility

and, additionally, purchaser will indemnify

Product(s) in such a manner.

e

.

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE

RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETUR

(AR) NU MBE R FROM OMEGA’S CU S T OM E R SERVICE DE PARTMEN T (IN OR DE R TO AVO ID

PROCESSING DELAYS). The assigned AR number should then be marked on the outside of the retur

package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to preven

breakage in transit.

FOR WARRANT

following information available BEFORE

contacting OMEGA

1. Purchase Order number under which the produc

was PURCHASED,

2. Model and serial number of the product unde

warranty, an

3. Repair instructions and/or specific problems

relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords

our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC

© Copyright 2009 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied,

reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without th

prior written consent of OMEGA ENGINEERING, INC

Y RETURNS, please have the

:

d

FOR NON-WARRANTY REPAIRS,

consult OMEGA

for current repair charges. Have the following

information available BEFORE contacting OMEGA

t

1. Purchase Order number to cover the COST

of the repair,

r

2. Model and serial number of the product, an

3. Repair instructions and/or specific problems

.

relative to the product.

.

d

N

n

t

:

e

Page 8

M-4808/0809

Loading...

Loading...