Page 1

User’s Guide

Shop online at

omega.com

e-mail: info@omega.com

For latest product manuals:

omegamanual.info

PHUCN600 Multi-parameter

Controller & Analyzer

Page 2

OMEGAnet®Online Service Internet e-mail

omega.com info@omega.com

Servicing North America:

U.S.A.: One Omega Drive, P.O. Box 4047

ISO 9001 Certified Stamford, CT 06907-0047

TEL: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1, Canada

TEL: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

U.S.A. and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Customer Service: 1-800-622-2378 / 1-800-622-BEST

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico: En Espan˜ ol: (001) 203-359-7803 e-mail: espanol@omega.com

FAX: (001) 203-359-7807 info@omega.com.mx

®

®

®

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

TEL: +31 (0)20 3472121 FAX: +31 (0)20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: sales@omegaeng.nl

Czech Republic: Frystatska 184, 733 01 Karviná, Czech Republic

TEL: +420 (0)59 6311899 FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342 e-mail: info@omegashop.cz

France: 11, rue Jacques Cartier, 78280 Guyancourt, France

TEL: +33 (0)1 61 37 2900 FAX: +33 (0)1 30 57 5427

Toll Free in France: 0800 466 342

e-mail: sales@omega.fr

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

TEL: +49 (0)7056 9398-0 FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified Northbank, Irlam, Manchester

M44 5BD United Kingdom

TEL: +44 (0)161 777 6611 FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

It is the policy of OMEGA Engineering, Inc. to comply with all worldwide safety and EMC/EMI

regulations that apply. OMEGA is constantly pursuing certification of its products to the European New

Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA accepts no liability for any

errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, human applications.

Page 3

Table of Contents

Subject Page No.

Introduction 1

Section 1 - Specifications 2

Section 2 - Installation 3 - 5

Section 3 - Electrical Connections & Setup 6 - 14

Differential Probe connection & setup 7

Combination Probe connection & setup 8

Conductivity Cell (Contacting style) connection & setup 9

Relay connections 10

Relay A & B setup 11

Alarm relay setup 12

Manual test mode & Relay override 13

4-20mA Isolated Outputs Channel 1 & Channel 2 14

Service & Fuse Replacements 15

Section 4 - Using the PHUCN600 in pH Mode 16

LCD Menu 17 - 43

LED Menu 44 - 45

Section 5 - Using the PHUCN600 in ORP Mode 46

LCD Menu 47 - 72

LED Menu 73

Section 6 - Using the PHUCN600 in Conductivity Mode 74

LCD Menu 75 - 101

LED Menu 102

Page 4

Introduction

The PHUCN600 series multi-parameter controller is a microprocessor based controller

capable of measuring one of the following parameters, pH, ORP or conductivity.

When shipped from the factory, the PHUCN600 series is not set to measure any one

parameter. When the PHUCN600 series is powered up for the first time, it will display

the meter selection screen where the meter type must be selected. (refer to section 4.6

Meter Selection)

This meter selection screen will only be displayed when the unit is powered up for the

first time.

After the user selects a meter type the PHUCN600 series will remain set to that meter

type until it is changed with the meter selection menu function in the Utilities menu.

To return the PHUCN600 series to its factory settings, the user must re-select the current meter type from the meter selection menu function. This will override all set-points

and return all settings back to the factory settings.

The PHUCN600 User’s menu has been divided into five main categories

- Calibration, used to calibrate the PHUCN600 series with the selected sensor

- Utilities, Used to manually control or override the outputs.

- Setup, used to configure the PHUCN600 series’ many options

- Diagnostics, used to troubleshoot any problems with the PHUCN600 series

- Outputs, used to configure the PHUCN600 series’ outputs.

There are two displays on the PHUCN600 series. A bright LED numeric display with bar

graph on the outside front panel, and a 2-line, 16-character LCD display on the inside.

The LED readout on the outside panel can be seen several yards away. The distinctive,color-coded bar graph will immediately indicate if you are within the process parameters that you set (green), if the control relays are on (yellow) and if you are in alarm

condition (red). This makes diagnosing pump and alarm malfunctions easy. All configuration and control functions are performed on the LCD menu on the inside front panel.

A universal mounting kit is included for surface,panel and pipe-mount applications. The

1/4 DIN enclosure makes panel-mount cutouts and engineering simple.

PHUCN600 series is packaged in a rugged NEMA 4X polycarbonate enclosure making

it ideally suited for heavy-duty applications such as industrial wastewater neutralization,

municipal water and wastewater, pulp and paper, and process control.

Introduction Page 1

Page 5

Section I - Specifications

pH ORP Conductivity Flow

Display

Power Requirements 120Vac (±10%) 50/60Hz (less than 12VA) or 240Vac (±10%) 50/60Hz (less than 12VA)

Measuring Range pH: 0.01 to 14.00 ORP: -1999 to +1999mV

Temperature Automatic or Manual

Compensation 0 to 100°C (32° to +212°F)

Temperature Unit °C or °F Not required

Temperature Sensor User selectable: 300Ω NTC Thermistor, 3000Ω NTC Thermistor or Pt. 1000 RTD Not required

Calibration Modes Manual Calibration

Ambient Conditions Temperature:-20°C to +60°C or -4°F to +140°F Humidity: 0 to 90% RH (non-condensing)

Menu Access

Front Panel

Menu Access Inside Panel Full Access to all parameters of operations menu

Sensor to PHUCN600 Differential Sensor: 3000 ft (914 m)

Distance Combination Sensor: 10 ft (3 m)

Relay Outputs

Analog Outputs 4 to 20mA Channel 2

Memory Back-up All user settings are retained indefinitely in memory (EEPROM)

Mechanical

Sensor Input

Invalid Entries Invalid entries cannot be stored

Manual Test Mode Process value can be simulated with arrow keys to verify correct setup of outputs

Manual Relay Override Relays can be set to on / off / auto, to verify correct wiring of auxiliary devices, or to manually adjust process

Output Hold All outputs are placed on hold when PHUCN600 is in Menu mode

Calibration Data

Auto Return User selectable auto return if unit is left in menu mode or if relays are left in manual override mode for more than 10 min.

Display Damping User can select rate at which the PHUCN600 updates display. Enables display damping of unstable process

Net Weight 2.2lbs (1kg)

Front Panel:4 x 7 segment 1/2” LED display, 1 LED indicator 0n-line,7 LED Bar Graph

Inside Panel: 2 x 16 alpha-numeric LCD display

MΩ/cm30 to 19.99 0.01

0 to 2.000 0.01

0 to 20.00 0.1

3

(Dependent on sensor)

Temp: 0 to 100°C or Temp: 0 to 100°C or

32° to +212°F 32° to +212°F (

uS/cm

mS/cm

Temp:

0 to 200.0 0.1

0 to 2000 1.0

0 to 20.00 10

3

0 to 200.0 50

0 to 100°C or 32° to +212°F

Flow: 0 to 9999 with selectable

flow rate units

Volume: 0 to 9999 with Auto Range

Flow rate units: Gallons (GP), Cubic

Feet (CF), Liters (LP), Cubic Meters

CM), custom by entering factor

related to Gallons

Time units: Seconds (S),

Minutes (M), Hours (H)

Automatic or Manual

Not required

User selectable temperature

compensation slope 0.0 to 10.0%/°C.

Not required

0 to 100°C (32° to +212°F)

Auto-Calibration

Temperature Calibration Temperature Calibration

Auto-Calibration,Manual

Calibration,Temperature

Display

Manual Calibration

Temperature Calibration

Manual-Calibration, Manual Calibration

Temperature Display Temperature Display

Dry Calibration

Sample Calibration K factor Input

Not available

300 ft (91.4 m) 2000 ft

Two Control Relays, 10A / NO, 5A / NC @ 240VAC or 28VDC.

Mode: Process control, Adjustable parameters: process direction,(rising or falling) on-set-point, off set-point,

(0 to 100% of full scale), cycle timer (on / off, 0 to 600 seconds), failsafe (on / off).

One Alarm Relay, 10A / NO, 5A / NC @ 240VAC or 28VDC.

Mode: High / Low Alarm, Adjustable parameters: Low on / Low off set-point (0 to 100% of full scale, low on must be less than

low off), High On / High Off set-point (0 to 100% of full scale, High on must be greater than High off).

4 to 20mA Channel 1

Isolated Output, Range expand 0 - 100% of full scale (min segment 10% of full scale),max. load 800Ω

Isolated Output, Range expand 0 - 100% of full scale (min segment 10% of full scale),max. load 800Ω

Can be set to track temperature if sensor is equipped with a temperature sensor

Enclosure: NEMA 4X, 1/4 DIN, polycarbonate enclosure with four 1/2”conduit holes

Mounting: Universal Mounting kit for surface, pipe and panel mount, is included

Probe: -600 to +600mV Probe: -1999 to +1999mV Cell:0 to 9999Ω

Temp. Sensor: 0 to 9999Ω Temp. Sensor: 0 to 9999Ω Temp. Sensor: 0 to 9999Ω

Recall data from last calibration, calibration mode,

1st & 2nd accepted buffer value and probe mV output,

calibration temperature, calibration slope, and probe

efficiency

Recall data from last

calibration, calibration buffer

accepted value, and cell Recall store K factor.

resistance, calibration

temperature

Paddle: 0 to 2000Hz

Section I - Specifications Page 2

Page 6

Section 2 - Installation

2.1 Unpacking

Save the shipping carton and packing material in case the instrument needs to be stored or

returned. Inspect the instrument and packing material for shipping damage and report any

problems immediately.

2.2 Location

Locate the controller/analyzer close to the sensor. The list below gives typical maximum distances for various sensors. Refer to the sensor specifications for exact information.

• PHE-600/610 Series Differential pH Probe 3000 ft (914 meters)

• ORE-600/610 Series Differential ORP Probe 3000 ft (914 meters)

• CDE-600 Series Conductivity Probe 300 ft (91 meters)

2.3 Mounting

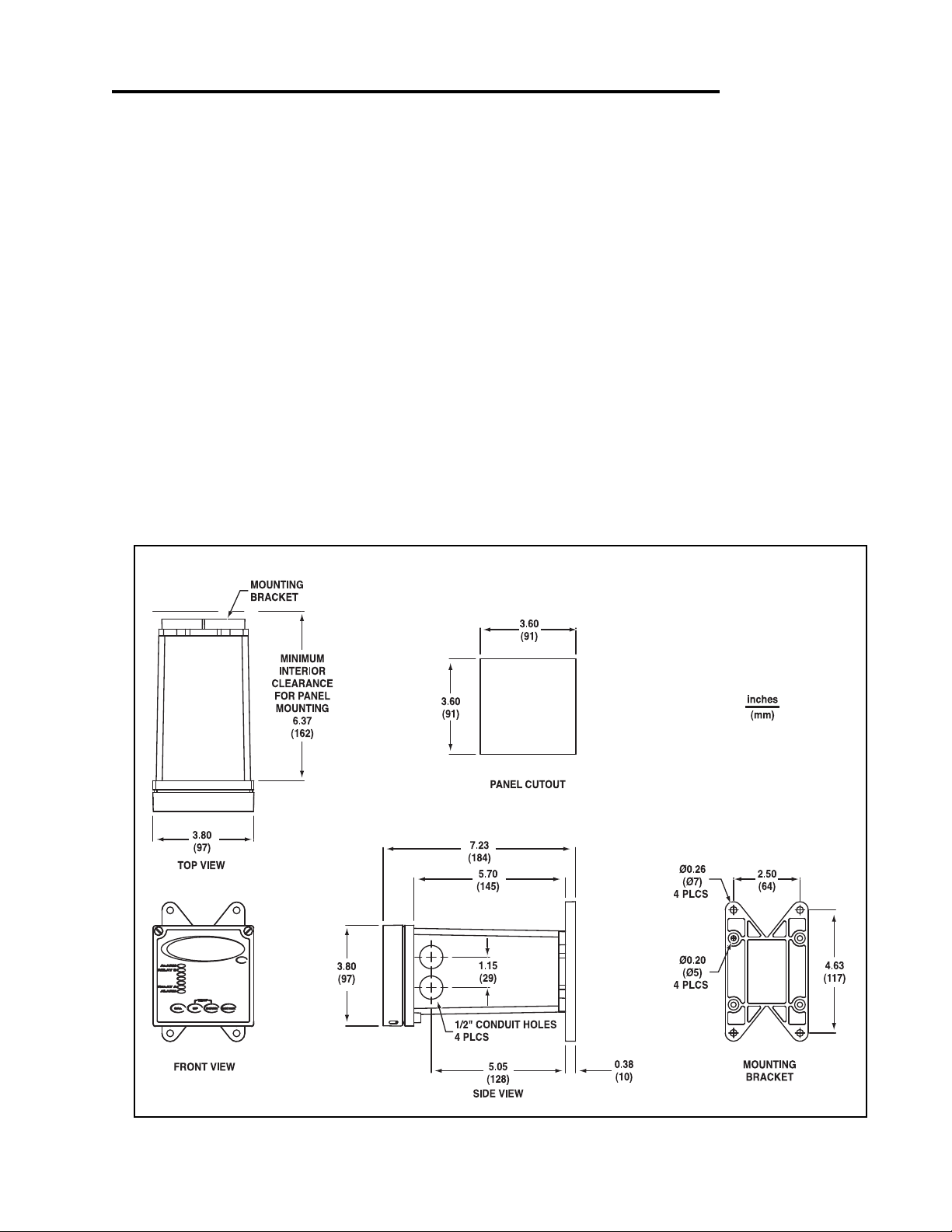

Fig 2.1 Controller dimensions

Section 2 - Installation Page 3

Page 7

Section 2 - Installation

MIN. PIPE DIA.

1" PIPE (NOMINAL)

MAX. PIPE DIA.

2" PIPE (NOMINAL)

NUT

10-24

QTY.4

SCREW

10-24 X 3-1/2"

QTY.4

UNIVERSAL MOUNTING

BRACKET

QTY.1

SCREW

1/4-20 X 6"

QTY.4

UNIVERSAL MOUNTING

BRACKET

QTY.1

PANEL

(CUSTOMER SUPPLIED)

EXTERNAL PANEL

GASKET QTY.1

UNIVERSAL

MOUNTING

CLAMP QTY.2

NUT

1/4-20

QTY.4

SCREW

10-24 X 1/2"

QTY.4

Panel Mount – The PHUCN600 series

can be panel mounted to a panel

using the hardware kit provided. The

panel cutout dimensions are shown in

fig. 2.1.

Figure 2.2 Panel Mount

Pipe Mount – The

PHUCN600 series can

also be mounted to a horizontal or vertical pipe

with:

• a minimum outside

diameter of 1.30” (33mm)

(for example 1” CPVC

pipe)

• and a maximum of

2.375” (60mm) (for

example 2” CPVC pipe)

Fig. 2.3 Vertical Pipe Mount

Section 2 - Installation Page 4

Page 8

Section 2 - Installation

UNIVERSAL MOUNTING

BRACKET

QTY.1

SCREW

10-24 X 1/2"

QTY.4

HOLES ¯1/4"

FOR MOUNTING SCREWS

QTY.4

(CUSTOMER SUPPLIED)

MIN. PIPE DIA.

1" PIPE (NOMINAL)

MAX. PIPE DIA.

2" PIPE (NOMINAL)

SCREW

10-24 X 3-1/2"

QTY.4

UNIVERSAL MOUNTING

BRACKET

QTY.1

NUT

10-24

QTY.4

Figure 2.4 Horizontal Pipe Mount

Surface Mount – The PHUCN600

series can be surface mounted using

the hardware kit provided with the

unit.

Figure 2.5 Surface Mount

Section 2 - Installation Page 5

Page 9

Section 3 - Electrical Connections and Setup

AC POWER CONNECTIONS FOR 120 VAC

AC POWER CONNECTIONS FOR 240 VAC

LINE

LINE

GROUND

PHUCN610

NEUTRAL

LINE

GROUND

PHUCN601

L

L

P3

G N

L

G

P3

3.1 Conduit Connections

The PHUCN600 series has four 1/2” conduit holes, 2 on each side of the enclosure as shown

on fig. 2.1. The unit is shipped with these holes plugged with liquid tight conduit seals. These

must be left in unused holes to maintain the NEMA 4X integrity. Use approved conduit hubs to

connect the conduit, connect these to the conduit before connecting to the enclosure.

Wire Specification

: Size and fuse wire according to local electrical code. Maximum current not

to exceed 10A when used to power auxillary decvices powered via internal connections.

3.2 A.C. Power Connections

Caution: This instrument uses 120 or 240 50/60 Hz AC power. Opening the enclosure

door exposes you to potentially hazardous line power voltage which might be present on the terminals of plug P3 and P4. Always remove line power before working in

this area. If the relay contacts on P4 are powered from a seperate source from the

line power on P3, be sure to disconnect that power before proceeding. The

PHUCN600 flip out door contains only low voltage and is safe to handle.

The PHUCN600 series is available in two power models.

The PHUCN610 is designed to operate at 240 VAC.

The PHUCN601 is designed to operate at 120 VAC.

To connect power to the PHUCN600, remove the terminal block plug P3 and connect the

wiring as shown below.

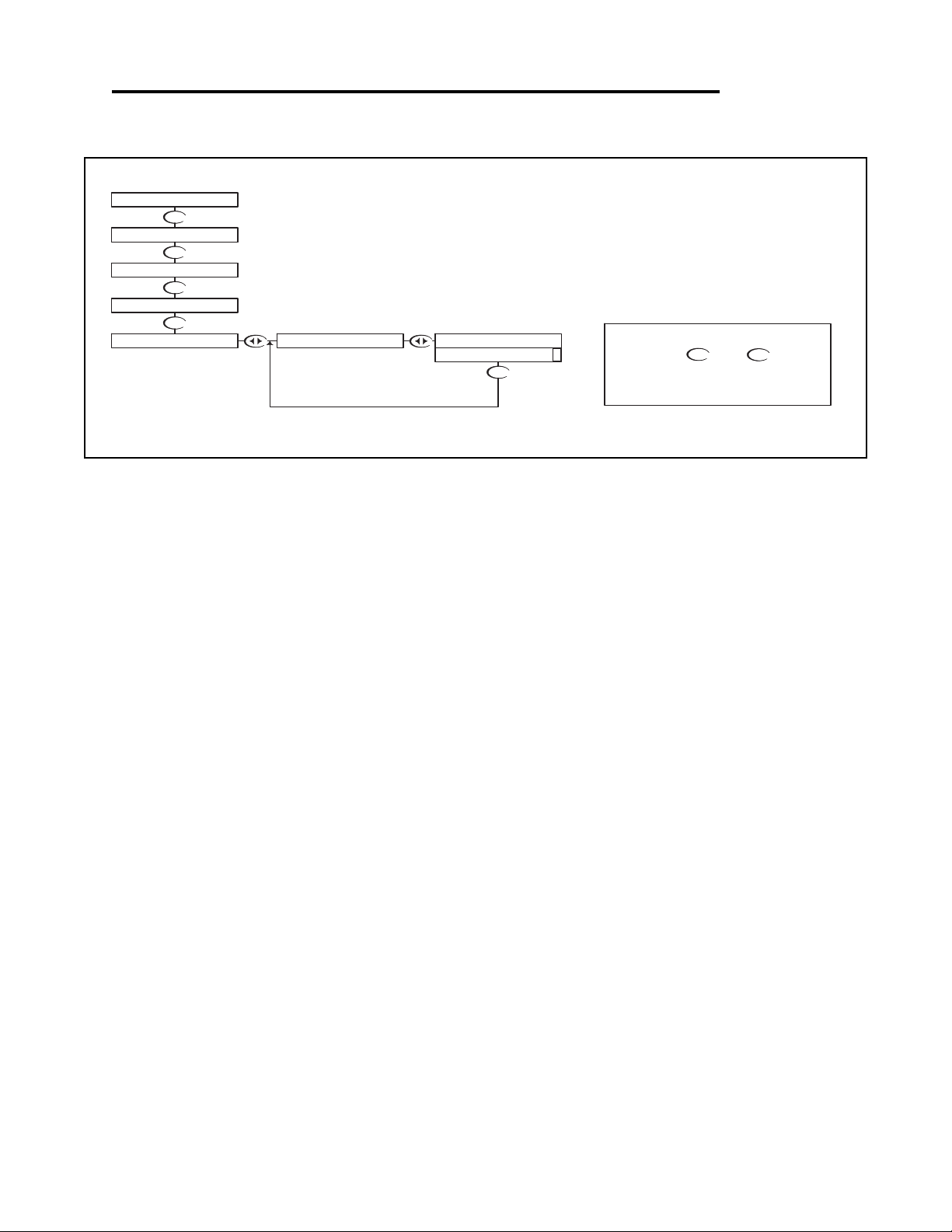

Figure 3.1 A.C. Power Connections

Section 3 - Electrical Connections and Setup Page 6

Page 10

Section 3 - Electrical Connections and Setup

BLACK (4)

YELLOW (5)

SHIELD (8)

WHITE (10)

RED (3)

GREEN (2)

P6

843

2

1

7

65

11109

1514

1312

17

16

DIFFERENTIAL

pH or ORP PROBE

SELECT pH SEC. 4.6

MANUAL CALIBRATE

SELECT DIFFERENTIAL PROBE

pH PROBE SEC. 4.1

or ORP PROBE SEC. 5.1

pH SEC. 4.7 or ORP SEC. 5.6

(IF NECESSARY)

or ORP SEC. 5.5

(IF NECESSARY)

MANUAL CAL PH

7.15pH 25.0C

PROBE SELECT

METER SELECTION

RUN MODE

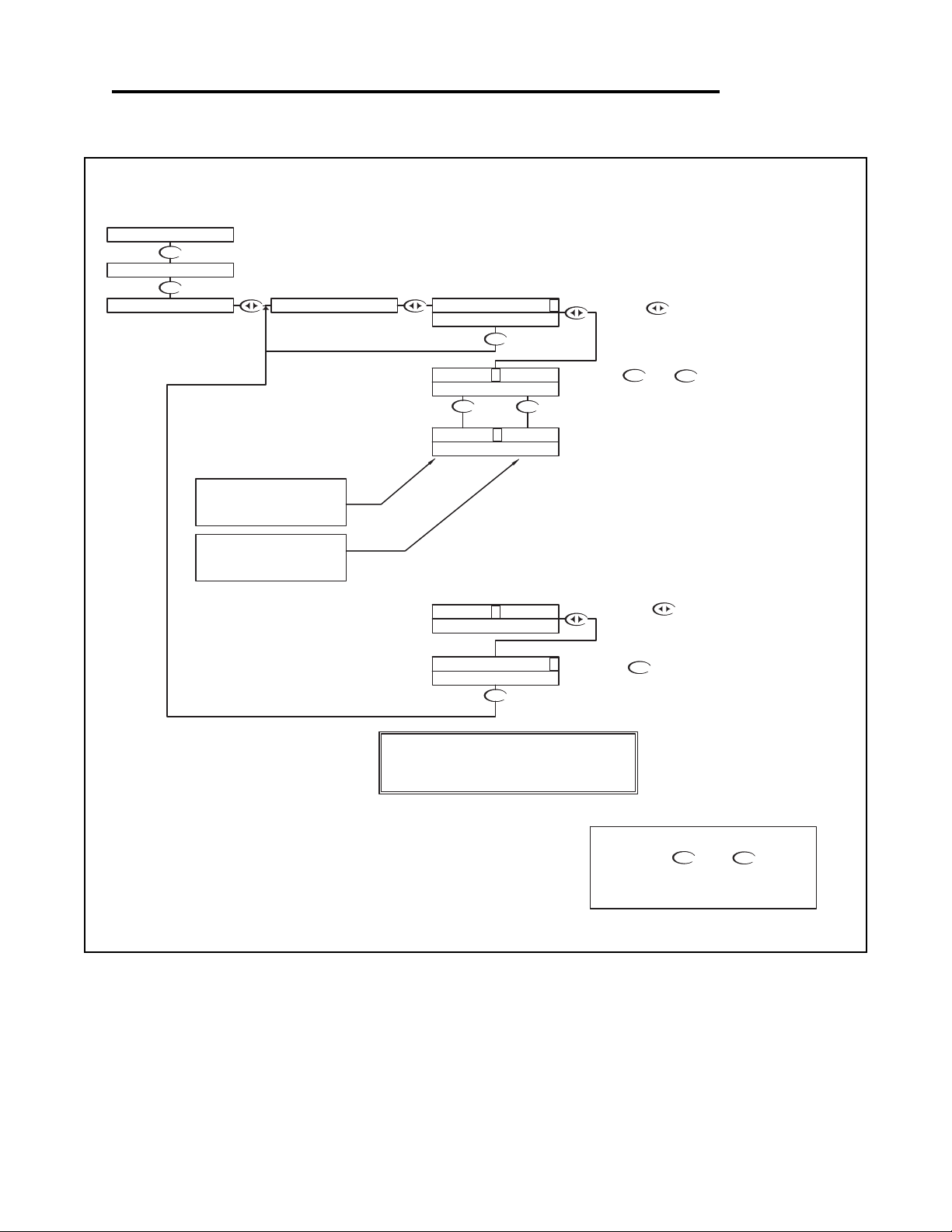

3.3 pH and ORP Differential Probe connections and setup

The drawing shows the connections for the 5-wire Differential probes. The cable should be run

in a conduit separate from AC power wires, and via a separate conduit hole.

Note: Leave 4” to 6”

slack for all wires

connected to the

terminals of P6.

Slack required so

that wires do not

interfere with opening or closing of the

front door.

If the cable of the

differential probe is

cut, the blue

wire is not used.

CAUTION:

Always remove line

power before

unplugging or

plugging in the P6

connector

Once connected, step through the LCD menus to

select the probe in the order shown. The first two

steps may be skipped if the meter is already configured for pH or ORP and a Differential Probe.

When using a pH probe, it is important to ensure

that the PHUCN600 is reading the probe temperature correctly for accurate temperature compensation. The ORP probe does not require temperature compensation, although the PHUCN600 can

display process temperature measured by the

probe. The factory temperature calibration is usually accurate enough that no adjustments are necessary.

Section 3 - Electrical Connections and Setup Page 7

Figure 3.2 Connections for Differential (5 wire) pH or ORP probe

Page 11

Section 3 - Electrical Connections and Setup

These wires are only

present with 4-wire

combination probe.

JUMPER 2-4 MUST BE

INSTALLED FOR

COMBINATION PROBE

(CUSTOMER SUPPLIED)

COAX SHIELD (4)

COAX CENTER (3)

WHITE (5)

GREEN (4)

P6

8

1

2

34 65

7

1091112 13

14 15

17

16

COMBINATION

pH or ORP PROBE

SEC. 5.8

SEC. 5.5

SEC. 5.1

ORP PROBE

SELECT COMBINATION PROBE

SELECT ORP METER

MANUAL CALIBRATE

PH PROBE

MANUAL CALIBRATE

SELECT PH METER

SELECT COMBINATION PROBE

SEC. 4.1

SEC. 4.6

SEC. 4.7

SEC 4.10

MANUAL PROBE

TEMPERATURE SETUP

DISABLE TEMPERATURE

SEC 5.10

DISPLAY

MANUAL CAL PH

METER SELECTION

PROBE SELECT

7.15pH 25.0C

T.COMP OVERRIDE

7.15pH 25.0C

PROBE SELECT

METER SELECTION

MANUAL CAL PH

T.DISP OVERRIDE

RUN MODE

TWO WIRE PROBE WITH NO TEMP SENSORTWO WIRE PROBE WITH NO TEMP SENSOR

RUN MODE

ORPpH

3.4 pH or ORP Combination Probe connections and setup

The drawing shows the connections for the Combination style probes. The cable should be run in a

conduit separate from AC power wires, and via a separate conduit hole. The cable length should not

exceed 10 feet (3 meters).

Fig. 3.3 Connections for the 2 and 4 wire Combination Probe

The 2 wire version has no

temperature sensor and is

connected via a coaxial wire.

In a pH meter, the user

should set the T COMP

OVERRIDE

(Section 4.11) and adjust the

temperature setting to the

actual probe temperature.

In an ORP meter, the user

should set the

to ON (Section 5.10) to

RIDE

blank the temperature reading

on the display.

menu to ON

T.DISP OVER-

4 wire version has two

The

additional wires for the probe

internal temperature sensor.

Ensure that the

T COMP

OVERRIDE or T.DISP

OVERRIDE

Note

: Leave 4” to 6” slack for

all wires connected to the terminals of P6. Slack required

is OFF.

so wires do not interfere with

opening/closing of front door.

CAUTION:

Always remove line

power before unplugging

or plugging in the P6

connector

Once connected, step throught the LCD menus to select the probe in the order

shown. The first two steps may be skipped if the meter is already configured for

a Combination Probe. If a two wire pH probe is used, which has no temperature

sensor, ensure that the Temp. Comp. Override is set to same temperature as

the buffer before calibrating. If a two wire ORP probe is used, you can blank the

Temp display with the T DISP OVERRIDE menu.

Section 3 - Electrical Connections and Setup Page 8

Page 12

Section 3 - Electrical Connections and Setup

WHITE (CELL) (1)

BLACK (CELL) (4)

RED (TEMP. SENSOR) (4)

GREEN (TEMP. SENSOR) (5)

P6

8

1

2

34 65

7

1091112 13

14 15

17

16

CONTACTING

CONDUCTIVITY

CELL

SET TEMPERATURE COMPENSATION

3Kohm NTC (thermistor)

1Kohm RTD

ENSURE SENSOR IS CORRECT TYPE

SEC. 6.7

SELECT CONDUCTIVITY RANGE

SELECT COND METER

SEC. 6.13

OR

FOR PROCESS

SEC 6.9

SEC. 6.6

1000uS 25.0C

MANUAL CAL COND

TEMP COMP CURVE

TEMP SENSOR

COND RANGE

METER SELECTION

CALIBRATE WITH

RUN MODE

REFERENCE SOLUTIONS

SEC 6.1

DRY CAL COND

CALIBRATE WITH FACTORY

SPECIFIED CELL CONSTANT

SEC 6.2

3.5 Conductivity Cell (Contacting style) connections and setup

The drawing shows the connections for the Conductivity Cells (Contacting style). The cable should be

run in a conduit seperate from the AC power wires, and via a seperate conduit hole.The cell cable length

should not exceed 300ft. (91 meters).

Note: Leave 4” to 6”

slack for all wires

connected to the

terminals of P6.

Slack required so

that wires do not

interfere with opening or closing of the

front door.

CAUTION:

Always remove line

power before

unplugging or

plugging in the P6

connector

Figure 3.4 Connections for Conductivity Cells

Once connnected, step

through the LCD menus to

select the cell in the order

shown. The TEMP COMP

CURVE setup default is

1.8%/deg C. This is acceptable for most process applications. If your process is

significantly different from

this, change the setting in

the TEMP COMP CURVE

menu.

Section 3 - Electrical Connections and Setup Page 9

Page 13

Section 3 - Electrical Connections and Setup

N.C.

N.O.

N.C.

N.O.

N.C.

N.0

GND

RELAY B

ALARMRELAY A

NEUTRAL

GROUND

LINE

LINE OUT (21)

connections

Internal

NEUTRAL OUT (22)

RELAY CONNECTIONS FOR 120VAC

PHUCN601

P3

G

L

N

21

P4

22

23

24 25

26

27

28

29

30

31

WARNING

PIN 21 must be

connected to relays

for power.

PIN 22 cannot be

connected to the

relays.

N.C.

N.O.

N.C.

N.O.

N.C.

N.0

GND

RELAY B

ALARMRELAY A

RELAY CONNECTIONS FOR 240vac

PHUCN610

LINE

GROUND

LINE

LINE OUT (21)

connections

Internal

LINE OUT (22)

G

L

L

P3

21

P4

22

23

24 25

26

27

28

29

30

31

WARNING

PIN 21 must be

connected to relays

for power.

PIN 22 cannot be

connected to the

relays.

3.7 Relay connections

The PHUCN600 series controller has three internal relays. Relays A and B are for control, the

Alarm Relay can be configured for alarm functions or as an additional control relay.

The connections to the relays are shown in the drawing.

Note that the AC power is internally connected to the

relay terminal plug P4. This is used to provide 120V or

240V AC power for the relay contacts.

Wire Specification

: Size and fuse wire accroding to local

electrical code. Wire size not to exceed 14 AWG.

Figure 3.6 Connections for Relay A, B and Alarm

DISCONNECT POWER FROM

CONTROLLER AND LOADS WHILE

CONNECTING TO THE RELAY

OUTPUT TERMINAL PLUG.

WARNING

The contacts are rated at 10 amp N.O. and 5 amp N.C. Do

not exceed this rating.When switching larger currents, use an

auxillary relay switched by the controller relay to extend the

controller relay life. If the relays are controlling an inductive

load, use appropriate transient suppression at the load.

Section 3 - Electrical Connections and Setup Page 10

Caution:

Page 14

Section 3 - Electrical Connections and Setup

3.8 RELAY A and B Setup

(LCD MENU SECTIONS - pH: 4.18 & 4.19, ORP: 5.17 & 5.18,

Conductivity: 6.18 & 6.19)

Relay A & Relay B on the PHUCN600 series are

SPDT dry contact relays. They are configurable to

operate in response to rising or falling process values. Each relay has independently adjustable on

and off set-points, cycle times, and fail-safe

options.

The operator would use the control relays if the

device to be controlled is a simple on/off device.

For example a pump, solenoid valve, fan, or an

indicating light.

The control relays have 6 user configurable settings:

CYCLE OFF time

amount of time in seconds that the relay will be deenergized, it can be set between 0 and 600 seconds. To disable the cycling feature set the cycle

off time to 0.

VERFEED TIMER: The overfeed timer is

O

designed to help safeguard against a process or

instrumentation error causing one of the control

relays to remain energized for extended periods of

time.

When enabled, the overfeed timer will time out if

the control RELAY OFF set point is not reached

inside the overfeed time out. The control relays will

de-energize, the alarm relay will energize and an

LED will flash at the front.

: The CYCLE OFF time is the

DIRECTION

: The relay can be set to control either

a rising or falling process. If for example the relay

is set to control a falling process, the ON set-point

must be set lower than the OFF set-point. If the

relay is set to control a falling process, the

PHUCN600 will not allow the RELAY OFF set

point to be set lower than the RELAY ON set-point.

This rule will also apply to a rising process.

Y ON set-point: This is the process value at

RELA

which the relay will energize.This value can be set

anywhere between 0-100% of the range.

Y OFF set-point: This is the process value at

RELA

which the relay will de-energize.Depending on the

direction for which the relay is configured, the

RELAY OFF set-point will only be setable in a limited range.

CYCLE ON time

: To obtain a tighter process control, and limit over-shoot, the control relay can be

set with the cycling feature. This feature, if

enabled, will cause the control relay to cycle when

the process is between the RELAY ON set-point

and RELAY OFF set-point. The cycle on time is the

amount of time in seconds that the relay will be

energized. It can be set between 0 and 600 seconds.

AILSAFE: The FAILSAFE feature is designed to

F

reverse the normal action of the control relay.

When the relay is set to FAILSAFE OFF the relay

will operate as a normal relay. When the relay is

de-energized the NO contacts are open and the

NC contacts are closed. Thus the device connected via the NO contacts will be off. When the relay

becomes energized the device will be on.

When the relay is set to FAILSAFE ON, the normal

action of the relay is reversed. Thus the NO contacts act as the NC contact and the NC act as the

NO. The device connected to the NC contacts will

be energized when the RELAY ON set-point is

reached. The relay will be de-energized but

because it is acting in reverse the device will be

energized. When the RELAY OFF set-point is

reached the relay will energize and the device

connected to the NC contact will de-energize.

The purpose of the Fail Safe option is to have the

device turned on in the event of a power interruption.

The factory default for FAILSAFE is OFF.

Section 3 - Electrical Connections and Setup Page 11

Page 15

Section 3 - Electrical Connections and Setup

3.9 ALARM RELAY Setup

(LCD MENU SECTIONS - pH: 4.20, ORP: 5.19, Conductivity: 6.20)

The third relay (Relay C) is used as an alarm relay.

The alarm relay on the PHUCN600 is a SPDT dry

contact relay.

This relay will respond to both a rising and falling

process. The alarm relay will act as a low alarm

(falling process) and a high alarm (rising process).

Both relays will have independently adjustable on

and off set-points. The ALARM ON set-points will

always be set before the ALARM OFF set-points.

The controller will not let the user input a value

below the ALARM ON set-point. The same rule

holds true for the high alarm.

The control relays have 5 user configurable settings:

ALARM LO

value that will cause the relay to energize. This

value can be set anywhere between 0-100% of the

range.

ALARM LOW OFF set-point: This is the value that

the process must reach in order to de-energize the

alarm relay after it has dropped below the ALARM

LOW ON set-point.This value must be higher than

the ALARM LOW ON set-point.

ALARM HIGH ON set-point

value that will cause the relay to energize. This

value can be set anywhere between 0-100% of the

range.

ALARM HIGH OFF set-point

the process must reach in order to de-energize the

alarm relay after it has increased over the ALARM

HIGH ON set-point. This value must be lower than

the ALARM HIGH ON set-point.

W ON set-point:This is the low process

: This is the process

: This is the value that

ALARM SET

ON set-point is set higher than the factory default

ALARM LOW OFF set-point, when the user

advances from the ALARM LOW ON set-point to

the ALARM LOW OFF set-point the shark will

adjust the ALARM LOW OFF set-point to be equal

to the ALARM LOW ON set-point. If the user then

tries to decrease the ALARM LOW OFF set-point

the controller will display the ALARM LOW

ALARM setup error screen.

This screen will be displayed for 10 seconds, then

return back to the setup screen that was previously displayed. If the user presses the down key

again the error message will be displayed again

for 10 seconds. The user must accept the LOW

OFF set-point, equal to, or greater than the LOW

ON set-point.

The same conditions apply to the ALARM HIGH

set-points. Except the ALARM HIGH OFF setpoint must be lower than the ALARM HIGH ON

set-point. If the user tries to increase the ALARM

HIGH OFF set-point higher than the ALARM HIGH

ON set-point the High Alarm setup error screen

will be displayed.

ALARM RELA

ALARM LOW ON set-point and the ALARM LOW

OFF set-point equal to 0% of the range. It will disable the low alarm relay.

If the user sets the ALARM HIGH ON set-point

and the ALARM HIGH OFF set-point equal to

100% of the range. It will disable the high alarm

relay.

-POINT ERROR: If the ALARM LOW

Y DISABLE: If the user sets the

AILSAFE: This option can be turned on or off. It

F

reverses the normal action of the relay. (see

description under control relay)

Section 3 - Electrical Connections and Setup Page 12

Page 16

Section 3 - Electrical Connections and Setup

3.10 MANUAL TEST MODE

(LCD MENU SECTIONS - pH: 4.4, ORP: 5.3, Conductivity: 6.4)

Once the relays are configured, the setup can be

tested using Manual Test Mode to simulate process

changes.

MANUAL TEST MODE is used to simulate a process

reading in order to verify the correct response of the

outputs. When in the MANUAL TEST MODE, the

relays and outputs are no longer placed on hold as

they are when in the rest of the menu. The relays and

outputs will react to the simulated change in process

as if the controller was in RUN MODE.

Note that when the user exits the MANUAL TEST

MODE, the relays and outputs will remain in the

MANUAL TEST MODE state until the user enters

RUN MODE.

3.11 RELAY OVERRIDE

(LCD MENU SECTION - pH: 4.5, ORP: 5.4, Conductivity: 6.5)

Relay Override is used to manually override the state

of the relays. The user is able to set the operating

mode of the relay as AUTO/ON/OFF (the default and

RUN MODE states are AUTO).

This feature can be used to energize or de-energize

the relays to manually correct the process, or to shut

down an ancillary device to perform maintenance.

When in the RELAY OVERRIDE mode, the relays are

no longer placed on hold as they are when in the

other menus.

Note that if the RELAY AUTO RETURN is set to

"ON", the controller will place all the relay settings

back to AUTO 10 minutes after the controller returns

to the run mode..

Section 3 - Electrical Connections and Setup Page 13

Page 17

Section 3 - Electrical Connections and Setup

P6

54

P1

P4

P3

423

1

7

895 6

15

1311 12

141017

16

24

23

21 22

29

28

26

25

27

6364 6267

66

65 57 56 55

61

60 59 58

CH1 4-20mA -

CH1 4-20mA +

Primary Output

CH2 4-20mA -

CH2 4-20mA +

Secondary Output

31

30

52

53 51

3.12 4-20 mA Isolated Outputs

Channel 1 and Channel 2

(LCD MENU SECTIONS - pH: 4.21 & 4.22, ORP: 5.20 & 5.21,

Conductivity: 6.21 & 6.22)

The PHUCN600 Series Controller

has two 4 to 20mA outputs, electrically isolated from each other and

ground. Either output can source

current into a maximum of 800

ohms.

Channel 1 (the primary output) is

located on the flip out door, terminal

plug P6. Channel 1 is dedicated to

track the process and has fully independent and fully adjustable 4 & 20

mA output setpoints.This will enable

the operator to span the output over

the desired range.

Figure 3.7 Connections for the 4-20mA outputs

Channel 2 (the secondary output) is

located in the enclosure terminal

plug P1. Channel 2 can be selected

to track the process value or temperature and has fully independent

and adjustable 4 & 20 mA output

setpoints.

Both Channel 1 and 2 can be precisely trimmed through the LCD

menu for precision applications.

The drawing shows the connections

for both outputs.

Wire Specification

: 22 AWG 7/30,

insulation 0.010”

Note: Leave 4” to 6” slack for all

wires connected to the terminals of

P6. Slack required so that wires do

not interfere with opening or closing

of the front door.

Section 3 - Electrical Connections and Setup Page 14

Page 18

Section 3 - Electrical Connections and Setup

FUSE

P6

54

P1

P4

P3

423

1

7

895 6

15

1311 121410

17

16

24

23

21 22

29

28

26

25

27

6364 6267

66

65 57 56 55

61

60 59 58

31

30

52

53 51

3.13 Service

PHUCN600 SERVICE TO BE PERFORMED BY QUALIFIED PERSONNEL ONLY.

3.14 Fuse Replacement

WARNING:

DISCONNECT LINE POWER TO THE UNIT

TO AVOID THE POSSIBILITY

OF ELECTRICAL SHOCK.

Figure 3.8 Fuse Location

1. Proceed after disconnecting line

power from the instrument.

2. Open the front panel by rotating the

quarter-turn fasteners, using a flat blade

screwdriver, to expose the relay board.

3. The fuse, F1, is located in the middle

of the relay board, directly above the

three terminal connectors.

4. Remove the open fuse and replace it

only with a fuse of the same type and

rating. REFER TO THE FUSE RATING

TABLES BELOW.

5. Close the front panel and secure

using the quarter-turn fasteners.

6. Restore power to the unit.

Fuse Rating Table for

Fuse Type: Slo-Blo

fuse 5 x 20mm

120 volt operation

Fuse Ratings: 250

VAC, 100mA

Fuse Rating Table for

Fuse Type: Slo-Blo

fuse 5 x 20mm

Fuse Ratings: 250

VAC, 50mA

240 volt operation

Section 3 - Electrical Connections and Setup Page 15

Page 19

Section 4 - Using the PHUCN600 in pH Mode

RUN LED (GREEN)

LED WILL BE ILLUMINATED WHEN THE

CONTROLLER IS IN THE RUN MODE.

IT WILL BE OFF WHEN THE CONTROLLER

IS IN THE MENU MODE.

4 DIGIT, 7 SEGMENT LED DISPLAY

DISPLAYS PROCESS VALUE IN RUN MODE.

DISPLAYS CALIBRATION DATA IN

CALIBRATION MODE.

RELAY C (ALARM RELAY)

STATUS LED's (RED)

BOTTOM LED WILL ILLUMINATE

WHEN ALARM RELAY IS

ENERGIZED BECAUSE OF LOW

ALARM CONDITION.

TOP LED WILL ILLUMINATE WHEN

ALARM RELAY IS ENERGIZED

BECAUSE OF HIGH ALARM

CONDITION.

BAR GRAPH LED's (GREEN)

LINEAR INDICATOR OF PROCESS

VALUE.

(REFER TO SECTION 4.13)

1/4" TURN SCREWS

RELAY A STATUS LED (YELLOW)

LED WILL BE ILLUMINATED WHEN

RELAY A IS ENERGIZED.

REMOVABLE TERMINAL BLOCK

CONNECTORS

"SNAP-ON" CONNECTORS FOR EASY

WIRING OF YOUR pH SENSOR AND

PRIMARY 4-20mA OUTPUT.

(REFER TO SECTIONS 3.3, 3.4 & 3.12)

SIMPLE THREE-BUTTON INTERFACE

FOR FAST & EASY SETUP

(REFER TO SECTIONS 4.0 TO 4.21)

RELAY B STATUS LED (YELLOW)

LED WILL BE ILLUMINATED WHEN

RELAY B IS ENERGIZED.

UNIT LABEL

LABEL TO INDICATE UNIT OF

MEASURE THE CONTROLLER IS

CONFIGURED FOR.

AUXILLARY LED's

NOT USED IN pH MODE.

CALIBRATION FROM THE

FRONT PANEL

4 PUSH BUTTONS USED TO

CALIBRATE THE CONTROLLER

FROM THE FRONT PANEL.

(REFER TO SECTIONS 4.22 & 4.23)

2 LINE, 16 CHARACTER

LCD DISPLAY

MAIN MENU INTERFACE

SCREEN

TEMPERATURE DISPLAY

WHEN THE 'UP' AND 'DOWN' ARROW

KEYS ARE PRESSED

SIMULTANEOUSLY, THE LED WILL

DISPLAY THE CURRENT PROCESS

TEMPERATURE FOR 5 SECONDS.

THIS FEATURE WILL BE DISABLED IF

THE 'TEMPERATURE COMPENSATION

OVERRIDE' IS TURNED ON IN THE

SETUP MENU.

IN THIS CASE THE LED WILL DISPLAY

---- IN PLACE OF THE

TEMPERATURE.

P6

843

2

1

7

65

11109

1514

1312

17

16

FRONT PANEL

INSIDE PANEL

NOTE

WHEN THE CONTROLLER IS TAKEN

INTO MENU MODE VIA THE INSIDE LCD

SCREEN, THE FRONT 7-SEGMENT LED

WILL DISPLAY

----. THE STATUS &

BAR GRAPH LED's WILL BE TURNED

OFF. THE 4 PUSH BUTTONS ON THE

FRONT WILL NOT RESPOND.

Section 4 - Using the PHUCN600 in pH Mode Page 16

Page 20

pH - Menu Overview 4.0

DOWN

DOWNDOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWNDOWN

DOWNDOWN

DOWN

DOWN

DOWNDOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWNDOWN

DOWN

DOWN

DOWN

DOWNDOWN

SELECT DEG C OR DEG F

ENABLE TIME OUT

PROBE W/O TEMP. SENSOR

TEMPERATURE SETUP FOR

SETUP DISPLAY AND

OUTPUT RESPONSE TIME

SELECT TYPE OF

4-20 mA CH 1 OUTPUT

4-20 mA CH. 2 OUTPUT

SETUP

ALARM RELAY

SEC 4.20

SETUP

SEC 4.21

SETUP

SEC 4.22

SETUP

RELAY A

SEC 4.18

SETUP

RELAY B

SEC 4.19

FROM MENU

DISPLAY

FIRMWAVE REVISION

SEC. 4.15

DISPLAY PREVIOUS

CALIBRATION DATA

SEC 4.16

DISPLAY UNCALIBRATED

PROBE DATA

SEC 4.17

SEC. 4.11

SEC 4.12

SEC 4.13

SETUP RESOLUTION

OF FRONT PANEL BAR GRAPH

SEC 4.14

SEC. 4.8

SEC 4.9

SELECT TYPE OF

TEMP SENSOR

SEC 4.10

pH PROBE

RUN MODE

SEC. 4.3

UP

NOTE

PRESS THE AND KEYS

TOGETHER TO GO IMMEDIATELY BACK TO

RUN MODE

DOWN

RELAYS

SELECT TYPE

OF METER

SEC. 4.5

SEC. 4.6

RESETS RELAY

OVERFEED TIMER

SEC. 4.7

VERIFY OUTPUTS

SIMULATE PROCESS

MANUALLY OVERRIDE

SEC. 4.4

AUTO CALIBRATE

MANUAL CALIBRATE

SENSOR IN pH PROBE

CALIBRATE TEMP.

pH PROBE

SEC. 4.1

pH PROBE

SEC. 4.2

DIAGNOSTICS

EXIT

EXIT

ALARM RELAY

4-20mA CH1

4-20mA CH2

RELAY A

RELAY B

SENSOR INPUT

CALIBRATION DATA

FIRMWARE REV

EXIT

OUTPUTS

DISPLAY DAMPING

BAR GRAPH O/R

T.COMP OVERRIDE

EXIT

AUTO RETURN

TEMP UNIT

TEMP SENSOR

PROBE SELECT

7.15pH 25.0C

UTILITIES

SETUP

CALIBRATION

MANUAL TEST MODE

METER SELECTION

RESET OVERFD TMR

RELAY OVERRIDE

EXIT

EXIT

TEMP CALIBRATION

MANUAL CAL PH

AUTO CAL PH

pH - Menu Overview 4.0 Page 17

Page 21

pH - Calibration Menu - Manual Calibrate 4.1

DOWN

DOWN

DOWN

UP DOWN

DOWN

DOWN

UP DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

UP

DOWN

DOWN

UP

DOWN

DOWN

Please wait for the controller to complete

the measurement

After 5 seconds, the controller will

compute the slope of the calibration, the

estimated probe efficiency and the probe

temperature.

Then press to store the value and

complete the Manual Calibration

Then press to store the value and move

to BUFFER2

Use the and keys to adjust

the reading until it agrees with the actual

buffer pH value

When complete, the controller will report

the measured value

The controller will read the pH value,

averaging a number of results to get a

stable calibration value.

Place the probe in the second buffer.

Be sure to clean and rinse the Probe first with

D.I. water and then insert it in the 4.00 buffer.

Press

Use the and keys to adjust

the reading until it agrees with the actual

buffer pH value

When complete, the controller will report

the measured value

Please wait for the controller to complete

the measurement

The controller will read the pH value,

averaging a number of results to get a

stable calibration value.

Place the probe in the first buffer solution, be

sure to clean and rinse the Probe first with D.I.

water and then insert it in the 7.00 buffer.

Press

If the calibration is OK, use the key

to move the cursor over the Y text and

press the down key.

If the calibration did not appear to be

correct, press the key

which will return back to the Manual

Cal menu.

RUN MODE

UP

NOTE

PRESS THE AND KEYS

TOGETHER TO GO IMMEDIATELY BACK TO

RUN MODE

DOWN

Press to store the calibration

data and return back to the Manual

Cal menu so the user can select

another function.

Then press to move the

cursor to the RH position

Then press to move the

cursor to the RH position

STORE? Y N STORE? Y N

IF BUFFER1 READYCALIBRATION MANUAL CAL PH

MANUAL CAL PH

MANUAL CAL PH

BUFFER2 4.00 >

SLOPE 61.22MV/PH

EFF 95% 24.8C

BUFFER1 7.00 >

MANUAL CAL PH

BUFFER2 4.4 0 >

MANUAL CAL PH

BUFFER2 4.0 0 >

BUFFER2 WAIT...

RUNNING MANU CAL

IF BUFFER2 READY

PRESS 'DOWN'

MANUAL CAL PH

MANUAL CAL PH

BUFFER1 7.0 0 >

RUNNING MANU CAL

BUFFER1 WAIT...

PRESS 'DOWN'

BUFFER1 7.3 5 >

MANUAL CAL PH

7.15pH 25.0C

MANUAL CAL PH

This example shows a MANUAL

calibration with buffers of 7pH & 4pH.

When performing a manual

calibration, any two known buffer

solutions can be used.

pH - Calibration Menu - Manual Calibrate 4.1 Page 18

Page 22

pH - Calibration Menu - Auto Calibrate 4.2

DOWN

DOWN DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

If an errors occurs, the controller will indicate a

"BUFFER ERROR" alarm. This could be caused by

- using a defective buffer

- incorrect probe wiring

- defective probe

Press to return to the Auto cal menu, try to

correct the problem and calibrate again, or go to the

diagnotics menus to test the probe

see Section 4.17

If an errors occurs, the controller will indicate a

"BUFFER ERROR" alarm. This could be caused by

- using the same buffer twice

- using a defective buffer

- incorrect probe wiring

- defective probe

Press to return to the Auto cal menu, try to

correct the problem and calibrate again, or go to the

diagnotics menus to test the probe

If the calibration did not appear to

be correct, press the key

which will return back to the Auto cal

menu.

UP

NOTE

PRESS THE AND KEYS

TOGETHER TO GO IMMEDIATELY BACK TO

RUN MODE

DOWN

This will store the calibration

data and return back to the

Auto cal setup so the user

can select another function.

If the calibration is OK, use the key to

move the cursor over the Y text and press the

down key.

After 5 seconds, the controller will

compute the slope of the calibration, the

estimated probe efficiency and the probe

temperature.

When complete, the controller will report the

measured value

When complete, the controller will report

the measured value

Press the key to move to Buffer 2

Please wait for the controller to complete

the measurement

The controller will read the pH value,

averaging a number of results to get a

stable calibration value.

Place the probe in the second buffer

solution.Be sure to clean and rinse the

Probe first with D.I. water and then insert

it in the 4.00 buffer.

Press the key

Please wait for the controller to complete

the measurement

The controller will read the pH value,

averaging a number of results to get a

stable calibration value.

Place the probe in the first buffer solution,

be sure to clean and rinse the Probe first

with D.I. water and then insert it in the 7.00

buffer.

Press

RUN MODE

AUTO CAL PH

STORE? Y N

STORE? Y N

AUTO CAL PH

AUTO CAL PH

EFF 95% 24.8C

SLOPE 61.22MV/PH

BUFFER2 4.00 >

AUTO CAL PH

AUTO CAL PH

BUFFER ERROR

CONTINUE >

RUNNING AUTO CAL

BUFFER2 WAIT...

BUFFER1 7.00 >

PRESS 'DOWN'

IF BUFFER2 READY

BUFFER ERROR

CONTINUE >

PRESS 'DOWN'

IF BUFFER1 READY

RUNNING AUTO CAL

BUFFER1 WAIT...

CALIBRATION

7.15pH 25.0C

MANUAL CAL PH

This example shows an AUTO

calibration with buffers of 7pH & 4pH.

When performing an auto calibration,

any two standard buffers of 4.00, 7.00

or 10.00 pH can be used. The buffers

will be automatically recognized if the

probe measures them within +/- 1 pH

of their nominal value.

pH - Calibration Menu - Auto Calibrate 4.2 Page 19

Page 23

pH - Calibration Menu - Temperature Calibration 4.3

DOWN

DOWN DOWN

DOWNUP

DOWN

DOWN

DOWN

UP

DOWN

DOWN

DOWN

If the Temperature Compensation Override is set to ON

(see section 4.11), the controller cannot calibrate the

temperature sensor. This display will appear to alert the

user to the condition.

If the calibration did not appear to

be correct, press the key

which will return back to the Temp

Calibration menu.

UP

NOTE

PRESS THE AND KEYS

TOGETHER TO GO IMMEDIATELY BACK TO

RUN MODE

DOWN

This will store the calibration data

and return back to the Temp

Calibration setup so the user can

select another function.

Use the and to adjust

the reading until it agrees with the

known temperature of the probe

Press the key to accept the

reading and move to the store function

"T FACTOR SHIFTED" will be

displayed for 5 seconds to indicate that

the temperature sensor has been

calibrated.

The controller will then move to the

store function.

The controller displays the current probe

temperature.

If this incorrect, the controller can be

adjusted to compensate.

Press the key once

which will move the cursor

back to the RH side of

temperature display.

Press the key once which will move

the cursor over the least sign. digit of the

temperature display.

RUN MODE

AUTO CAL PH

STORE? Y N

TEMP CALIBRATION

STORE? Y N

TEMP CALIBRATION

TEMP CALIBRATION

25.0C >

T FACTOR SHIFTED

25. 0 C >

TEMP CALIBRATION

TEMP CALIBRATION

TEMP CALIBRATION

TEMP CALIBRATION

22. 4 C >

22.4C >

TEMP CALIBRATION

TEMP O/R ON >

7.15pH 25.0C

CALIBRATION MANUAL CAL PH

pH - Calibration Menu - Temperature Calibration 4.3 Page 20

Page 24

DOWN

DOWN

DOWN

UP DOWN

DOWN

UP

DOWN

Manual Test Mode is used to simulate a process reading

in order to verify the correct response of the outputs.

When in the Manual Test Mode, the outputs are no

longer placed on hold as they are when in the rest of the

menu.

NOTE:

When the user exits the Manual Test Mode, the relays

and 4-20mA outputs will remain in the Test Mode state

until the operator enters the run mode. The relays and

outputs will then revert back to the previous On-line state.

The CH1 4-20 mA output will

track the change in process

When a relay is energized, the

characters a,b,c will change to

upper case A,B,C

RUN MODE

UP

NOTE

PRESS THE AND KEYS

TOGETHER TO GO IMMEDIATELY BACK TO

RUN MODE

DOWN

As the value is changed, the state of the relays

will change depending on their settings in the

OUTPUTS menu.

a/A - state of Relay A

b/B - state of Relay B

c/C - state of Alarm relay

Press the key once to

move the cursor to the RH side

of the display

As well, Channel 1 4-20 ma output will also

follow the process value change. The actual

change will depend on how the CH1 output

was scaled in the OUTPUTS menus.

(See Section 4.21)

Press the key to return to the

MANUAL TEST MODE menu

Use the and keys to change

the simulated process value.

Press the key once which will

move the cursor over the least digit of the

simulated process value.

TEST 7.0 0 >

TEST 7.00 >

7.15pH 25.0C

CALIBRATION

UTILITIES

a b c 19.0mA

a b c 19.0mA

TEST 13.1 5 >

TEST 13.15 >

MANUAL TEST MODE

a b c 12.0mA

a b c 12.0mA

a B c 19.0mA

TEST 13.1 5 >

DOWN

pH - Utilities Menu - Manual Test Mode 4.4

pH - Utilities Menu - Manual Test Mode 4.4 Page 21

Page 25

pH - Utilities Menu - Relay Override 4.5

UP

UP

UP

To Alarm Relay (Relay C) Override

UP

UP

DOWN

DOWN

UP

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

Relay Override is used to manually override the state of the relays, the user

is able to set the operating mode of the relay as AUTO/ON/OFF (the default

and run mode state are AUTO).

This feature can be used to turn the relays ON or OFF to manually correct

the process, or to shut down an ancillary device to perform maintenance.

When in the Relay Override mode, the outputs are no longer placed on hold

as they are when in the other menus.

If you wish to Override Relay

B, Press the key once

which will move the cursor over

to the AUTO/ON/OFF text

If you wish to Override Relay

A, Press the key once

which will move the cursor over

to the AUTO/ON/OFF text

If you do not wish to

Override Relay B, then

use the key to

the Alarm Relay

If you do not wish to

Override Relay A, then

use the key to

move to Relay B

RUN MODE

UP

NOTE

PRESS THE AND KEYS

TOGETHER TO GO IMMEDIATELY BACK TO

RUN MODE

DOWN

If you wish to accept the

Override setting,

Press the key once

to move the cursor to the

RH of the display

Use the key to change

the Override state from

AUTO - controlled by process

settings

ON - relay forced on

OFF- relay forced off

The relay will react

immediately.

Then use the key

to move to the Override

setting for Relay B

CAUTION:

Note that if the Relay Auto Return Menu is set to

"ON", the controller will place all these settings

back to AUTO 10 minutes after the controller

returns to the run mode.

Use the key to change

the Override state from

AUTO - controlled by process

settings

ON - relay forced on

OFF- relay forced off

The relay will react

immediately.

If you wish to accept the

Override setting,

Press the key once

to move the cursor to the

RH of the display

To use the Relay Override

function, press the key

Then use the key

to move to the Override

setting for Relay A

RELAY OVERRIDE

RELAY B A UTO >

RELAY OVERRIDE

RELAY B O N >

RELAY OVERRIDE

RELAY B O FF >

RELAY A O FF >

RELAY OVERRIDE

RELAY A O N >

RELAY OVERRIDE

RELAY OVERRIDE

RELAY A A UTO >

RELAY OVERRIDE

MANUAL TEST MODE

RELAY OVERRIDE

RELAY B AUTO >

RELAY A AUTO >

RELAY OVERRIDE

CALIBRATION

7.15pH 25.0C

UTILITIES

RELAY B ON >

RELAY B AUTO >

RELAY B OFF >

RELAY OVERRIDE

RELAY OVERRIDE

RELAY OVERRIDE

RELAY A ON >

RELAY A AUTO >

RELAY A OFF >

RELAY OVERRIDE

RELAY OVERRIDE

RELAY OVERRIDE

pH - Utilities Menu - Relay Override 4.5 Page 22

Page 26

pH - Utilities Menu - Relay Override 4.5

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

UP DOWN

DOWN

DOWNUP

UP

DOWN

DOWN

DOWN

DOWN

UP DOWN

Use the or key to

change the Override state from

AUTO - controlled by process

settings

ON - relay forced on

OFF- relay forced off

The relay will react

immediately.

If you do not wish to

Override Relay C, then

use the key to

the Store function

With "N" highlighted, pressing the

key will NOT store the Override states of

the relays, but they will revert to the

state they were in before the menu was

entered. Note that, if any of the relays

were in a specific Override state before

the menu was entered (i.e. not in

AUTO), they will revert to that state

again unless the changes are STORED.

TO RELAY

OVERRIDE MENU

NOT

STORED

FROM RELAY B

OVERRIDE MENU

Then press the key to store the

Override states of all the relays and

return back to the Override menu

STORED

UP

NOTE

PRESS THE AND KEYS

TOGETHER TO GO IMMEDIATELY BACK TO

RUN MODE

DOWN

If you wish to accept the

Override setting,

Press the key once

to move the cursor to the

RH of the display

If you wish to store the state

of the Relay Overrides,

press the key to

highlight the Y character

If you wish to Override Relay

C, Press the key

once which will move the

Then use the key

to move to the Override

setting for Relay C

NOTE

Relay C is the Alarm Relay

STORE? Y N

RELAY C AUTO >

RELAY OVERRIDE

RELAY OVERRIDE

STORE? Y N

RELAY OVERRIDE

RELAY OVERRIDE

RELAY OVERRIDE

RELAY C O N >

RELAY C O FF >

RELAY OVERRIDE

RELAY C A UTO >

RELAY OVERRIDE

RELAY OVERRIDE

RELAY C ON >

RELAY C OFF >

RELAY OVERRIDE

RELAY C AUTO >

pH - Utilities Menu - Relay Override 4.5 Page 23

Page 27

pH - Utilities Menu - Meter Selection 4.6

DOWNDOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN DOWN

DOWN

If you do not wish to initialize to this

type of meter after all, then press

key to return back to the Meter

Selection menu

To reset the controller back to all

the factory default values, reselect

the current meter type

Then press

The controller will initialize itself for a

specific meter

If you do wish to initialize to this

type of meter, press the

key to highlight the Y character

UP

NOTE

PRESS THE AND KEYS

TOGETHER TO GO IMMEDIATELY BACK TO

RUN MODE

DOWN

Press the key to Exit and

return to the Utilities menu

RUN MODE

Press the key to initialize the

controller as a Flow meter

Press the key to initialize the

controller as a Conductivity meter

The Meter Selection menu is used to select the meter type that the

controller is configured for, either pH, ORP or Conductivity.

Once selected, the controller will initialize itself for the selected meter's

functionality and move to run mode.

Press the key to initialize the

controller as an ORP meter

Press the key to initialize the

controller as a pH meter.

INITIALIZE? Y N

INITIALIZE? Y N

INITIALIZE? Y N

INITIALIZE? Y N

INITIALIZE? Y N

PH

PH

E XIT

MANUAL TEST MODE

7.15pH 25.0C

UTILITIES

CALIBRATION

RELAY OVERRIDE

METER SELECTION

C ONDUCTIVITY

FLOW

EXIT

F LOW

CONDUCTIVITY

O RP

CONDUCTIVITY

FLOW

ORP

P H

ORP

PH

pH - Utilities Menu - Meter Selection 4.6 Page 24

Page 28

pH - Utilities Menu - Overfeed Timer Reset 4.7

DOWN

DOWN

DOWN

DOWN

DOWN

DOWNDOWN

DOWN

If you wish to reset the overfeed timer,

then press the key to proceed

and return back to the Utilities menu.

If you do not wish to reset the

overfeed timer after all, press

the key to highlight the N

character and press the

key to return back to the Utilities

menu.

DOWN

UP

NOTE

PRESS THE AND KEYS

TOGETHER TO GO IMMEDIATELY BACK TO

RUN MODE

DOWN

RUN MODE

Press the key to

choose between Y or N.

If the control relay overfeed timer has been enabled, the relay

will “time out” after the specified overfeed time. When the

relay times out, it must be manually reset. The time out will be

signaled by the time out LED flashing on the front panel.

The reset overfeed timer will reset the timers for both relay A

& relay B at the same time.

Y N

MANUAL TEST MODE

7.15pH 25.0C

UTILITIES

CALIBRATION

RELAY OVERRIDE

METER SELECTION

RESET OVERFD TMR

RESET OVERFD TMR

Y N

RESET OVERFD TMR

pH - Utilities Menu - Overfeed Timer Reset 4.7 Page 25

Page 29

pH - Setup Menu - Probe Select 4.8

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

UP DOWN

DOWN

DOWN

DOWN

UP

DOWN

Then press the key to store the

selection and return to the PROBE

SELECT Menu.

With "N" selected, pressing the

key will NOT store the selection, but

simply return to the PROBE SELECT

Menu. This function is useful if you

wish to view the current selection

without making any changes.

Not stored

Stored

Or press the key to highlight

the Y character.

Note:

If using the 2 wire Combination Probe (which

doesn't have a temperature sensor), T COMP

OVERRIDE must be set to ON, and the actual

probe temperature set through the T COMP

OVERRIDE menu.

(see sec. 4.12)

PROBE SELECT will allow the user to select

whether the probe is a 2 or 4 wire

combination probe, or a 5 wire differential

probe.

RUN MODE

UP

NOTE

PRESS THE AND KEYS

TOGETHER TO GO IMMEDIATELY BACK TO

RUN MODE

DOWN

Use the or keys to scroll through

the probe types available.

In this case, the user can select

- the 2 or 4 wire combination probe

- the 5 wire differential probe

Press the key to accept the

setting and move to the store function

Press the key once

which will move the cursor

back to the RH side of the

display.

Once the correct probe type is selected,

move to the store function to save the

selection

Press the key once

which will move the cursor

over the first character of the

probe type.

STORE? Y N STORE? Y N

PROBE SELECT PROBE SELECT

7.15pH 25.0C

UTILITIES

SETUP

CALIBRATION

PROBE SELECT

COMBINATION >

C OMBINATION

PROBE SELECT

D IFFERENTIAL

PROBE SELECT

PROBE SELECT PROBE SELECT

DIFFERENTIAL >

Note: Refer to Appendix A - Probe

Configuration Table

pH - Setup Menu - Probe Select 4.8 Page 26

Page 30

pH - Setup Menu -Temp Unit 4.9

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

UP DOWN

DOWN

UP

DOWN

With "N" selected, pressing the

key will NOT store the selection, but

simply return to the TEMP UNIT

Selection Menu. This function is useful if

you wish to view the current selection

without making any changes.

RUN MODE

Or press the key to highlight

UP

NOTE

PRESS THE AND KEYS

TOGETHER TO GO IMMEDIATELY BACK TO

RUN MODE

DOWN

Then press the key to store the

selection and return to the TEMP UNIT

Selection Menu.

Not stored

Stored

the Y character.

Use the or to select C or F

Press the key to accept the

change and move to the store function

Press the key once

which will move the cursor

over the unit type, C or F.

Press the key once

which will move the cursor

back to the RH side of the

display.

TEMP UNIT allows the user to select either

Degrees Centigrade or Fahrenheit units for

display

7.15pH 25.0C

CALIBRATION

UTILITIES

SETUP

TEMP UNIT

PROBE SELECT

STORE? Y N

STORE? Y N

TEMP UNIT TEMP UNIT

DEGREE C >

DEGREE F >

TEMP UNIT

DEGREE F >

DEGREE C >

TEMP UNIT

TEMP UNIT

TEMP UNIT

pH - Setup Menu - Temp Unit 4.9 Page 27

Page 31

pH - Setup Menu - Temp. Sensor 4.10

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

UP

UP

DOWN

DOWN

DOWN

UP

DOWN

the Y character.

Or press the key to highlight

With "N" selected, pressing the

key will NOT store the selection, but

simply return to the TEMP SENSOR

Selection Menu. This function is useful if

you wish to view the current selection

without making any changes.

Not stored

UP

NOTE

PRESS THE AND KEYS

TOGETHER TO GO IMMEDIATELY BACK TO

RUN MODE

DOWN

Press the key to accept the

change and move to the store function

Then press the key to store the

selection and return to the TEMP

SENSOR Selection Menu.

Stored

TEMP SENSOR allows the user to select the

type of temperature sensor used the in the

probe.

The factory default for pH is a 300 NTC

Thermistor. The user can also select a 3000

NTC Thermistor or a 1000 RTD.

RUN MODE

Use the or to select the

sensor type

Once the correct Sensor has

been selected press the

key once which will move the

cursor back to the RH side of

the display.

Press the key once

which will move the cursor

over to the sensor type.

7.15pH 25.0C

SETUP

UTILITIES

CALIBRATION

STORE? Y N

STORE? Y N

TEMP SENSOR

300 NTC >

3 000 NTC >

TEMP SENSOR

Ω

TEMP SENSOR

TEMP UNIT

TEMP SENSOR

1 000 RTD >

TEMP SENSOR

TEMP SENSOR

3 00 NTC >

TEMP SENSOR

Ω

Ω

300 NTC >

TEMP SENSOR

PROBE SELECT

Ω

Ω

Ω

Ω

pH - Setup Menu - Temp. Sensor 4.10 Page 28

Page 32

pH - Setup Menu - Auto Return 4.11

DOWN

DOWN

DOWN

DOWN

DOWN

Not stored

DOWN

DOWN

Stored

DOWN

DOWN

DOWN

DOWN

UP DOWN

DOWN

UP

DOWN

DOWN

DOWN

DOWN

DOWN

UP DOWN

DOWN

UP

CAUTION:

If AUTO RETURN RELAYS is ON, regardless of

the user settings of the states of the relays, Relays

will default to AUTO 10 minutes after the controller

returns to Run Mode.

UP

NOTE

PRESS THE AND KEYS

TOGETHER TO GO IMMEDIATELY BACK TO

RUN MODE

DOWN

With "N" selected, pressing the

key will NOT store the selection, but

simply return to the AUTO RETURN

Selection Menu. This function is useful if

you wish to view the current selection

without making any changes.

Then press the key to

store the selection and return

to the Auto Return Selection

Menu.

Press the key to

accept the change and move

to the STORE function

Or press the key to highlight

the Y character.

Press the key to accept the change

and move to the RELAYS auto return

function. RELAYS ON will cause the relays to

return to the AUTO mode if the controller

returns to Online after 10 minutes of inactivity.

This ensures the controller will be put back in

control of the process if accidentally left

offline.

Use the or keys

to select either ON or OFF.

Press the key once

which will move the cursor to

the ON or OFF text

Press the key once

which will move the cursor

back to the RH side of the

display.

RUN MODE

To change the MENU

RETURN setting,

Press the key once

which will move the cursor to

the ON or OFF text

Use the or

keys to select either ON or

OFF.

Press the key

once which will move

the cursor back to the

RH side of the display.

MENU ON will cause the controller to exit the menu and

revert back to the online run mode after 10 minutes with no

buttons pressed. This feature ensures that if a user forgets

to return back to run mode, the controller will not be left in

an offline state. If for some reason, the user would like to

remain in the menu mode for extended periods of time, the

AUTO RETURN function can be set to "OFF".

AUTO RETURN is used to select what conditions will

cause the controller to time-out of the operations

menu, or reset the relay override function.

7.15pH 25.0C

SETUP

UTILITIES

CALIBRATION

STORE? Y N

STORE? Y N

AUTO RETURN

RELAYS OFF >

AUTO RETURN

AUTO RETURN

RELAYS ON >

RELAYS O N >

RELAYS O FF >

AUTO RETURN

AUTO RETURN

AUTO RETURN

AUTO RETURNAUTO RETURN

MENU ON >

TEMP SENSOR

TEMP UNIT

PROBE SELECTION

AUTO RETURN

MENU OFF >

AUTO RETURN

AUTO RETURN

MENU O FF >

MENU O N >

pH - Setup Menu - Auto Return 4.11 Page 29

Page 33

pH - Setup Menu - T.Comp Override 4.12

UP

DOWN

UP

DOWN

DOWN

DOWN

DOWN DOWN

DOWN

DOWNUP

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWNUP

DOWN

DOWN

DOWN

Use the or keys to

select either ON or OFF.

Press the key to accept the

change and move to the Temperature

Entry function

Press the key once

which will move the cursor

back to the RH side of the

display.

Press the key once

which will move the cursor

over the least significant digit

of the temperature display.

Use the and to

adjust the reading until it agrees

with the known temperature of the

probe or process

Press the key to accept the

reading and move to the store function

Press the key once

which will move the cursor

back to the RH side of

temperature display.

The user can now enter the actual

probe or process temperature

Then press the key to store the

selection and return to the T. COMP

OVERRIDE Menu.

UP

NOTE

PRESS THE AND KEYS

TOGETHER TO GO IMMEDIATELY BACK TO

RUN MODE

DOWN

With "N" selected, pressing the

key will NOT store the selection, but

simply return to the T. Comp Override

Menu. This function is useful if you wish

to view the current selection without

making any changes.

If you wish to save the setting, press the

key to highlight the Y character

Not stored

Stored

RUN MODE

Press the key once

which will move the cursor to

the ON or OFF text

Temperature Compensation Override is used to manually set

the actual probe or process temperature. This is useful if the

probe does not have a temperature sensor or if the process

temperature is constant. When the override is enabled, the

controller will use the selected temperature when performing

temperature compensation calculations.

T.COMP OVERRIDE

STORE? Y N

STORE? Y N

TEMP 35. 7 C >

TEMP 35.7C >

T.COMP OVERRIDE

T.COMP OVERRIDE T.COMP OVERRIDE

TEMP 25. 4 C >

T.COMP OVERRIDE

T.COMP OVERRIDE

TEMP 25.4C >

AUTO RETURN

T.COMP OVERRIDE

CALIBRATION

UTILITIES

SETUP

7.15pH 25.0C

TEMP UNIT

TEMP SENSOR

PROBE SELECTION

COMPENSATE O FF >

COMPENSATE O N >

T.COMP OVERRIDE

T.COMP OVERRIDE

COMPENSATE O N >

T.COMP OVERRIDE

COMPENSATE OFF >

T.COMP OVERRIDE

pH - Setup Menu - T.Comp Override 4.12 Page 30

Page 34

pH - Setup Menu - Display Damping 4.13

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

UP

DOWNUP

DOWN

UP

NOTE

PRESS THE AND KEYS

TOGETHER TO GO IMMEDIATELY BACK TO

RUN MODE

DOWN

The Display Damping menu allows the user to adjust

the rate at which the display and all outputs are

updated. This allows the user to dampen out

unstable process readings.

The damping can be set from 0 seconds to 10

seconds. (default value is 0 sec.)

With "N" selected, pressing the

key will NOT store the selection, but

simply return to the Display Damping

Menu. This function is useful if you wish

to view the current selection without

making any changes.

Not stored

RUN MODE

Use the and to adjust

the damping time, the default

setting is 0 seconds.

The setting can be adjusted from 0

to 10 seconds.

Then press the key to store the

selection and return to the Display

Damping Menu.

Stored

If you wish to save the setting, press the

key to highlight the Y character

Press the key once

which will move the cursor back

to the RH side of the display.

Press the key to accept the

setting and move to the store function

Press the key once

which will move the cursor

over the seconds digit

STORE? Y N

UPDATE 10 SEC >

UPDATE 0 SEC >

DISPLAY DAMPING

UPDATE 1 0 SEC >

DISPLAY DAMPING

DISPLAY DAMPING

DISPLAY DAMPING

STORE? Y N

DISPLAY DAMPING

7.15pH 25.0C

CALIBRATION

SETUP

UTILITIES

DISPLAY DAMPING

AUTO RETURN

T.COMP OVERRIDE

DISPLAY DAMPING

UPDATE 0SEC >

TEMP UNIT

PROBE SELECTION

DOWN

TEMP SENSOR

pH - Setup Menu - Display Damping 4.13 Page 31

Page 35

pH - Setup Menu - Bar Graph O/R 4.14

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

UP

DOWN

DOWN

UP

DOWN

DOWN

DOWN

DOWN

UP

DOWN

DOWN

DOWNUP

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

UP

DOWN

DOWN

DOWNUP

DOWN

DOWN

Then press the key to store the

selection and return to the Bar Graph

O/R Menu.

Stored

Not stored

UP

NOTE

PRESS THE AND KEYS

TOGETHER TO GO IMMEDIATELY BACK TO

RUN MODE

DOWN

Press the key skip the

setting for the Low Green Led

and move to the setting for the

High Green Led.

With "N" selected, pressing the

key will NOT store the selection, but

simply return to theBar Graph O/R

Menu. This function is useful if you wish

to view the current selection without

making any changes.

Press the key skip the

setting for the HIgh Green Led

and move to store function.

Use the and to

adjust the setting for the High

Green Led.

Press the key to accept

the reading and move to the store

function.

Press the key once

which will move the cursor

back to the RH side.

If you wish to save the setting, press the

key to highlight the Y character

The controller displays the current

setting for the highest green Led of

the bar graph.

Press the key to accept

the reading and move to the High

Green Led setting.

Press the key once

which will move the cursor

over the least sign. digit.

Press the key once

which will move the cursor

back to the RH side.

Use the and to

adjust the setting for the Low

Green Led.

The BAR GRAPH O/R menu allows the user control

over the resolution of the bar graph on the front

panel of the controller. The factory default for this

function is "OFF" which means the 3 green LEDS

are set to operate between the ON set points of

Relay A and B. This may not always be acceptable,

and this function allows the user to override these

settings.

The controller

displays the

current setting

for the lowest

green led of

the bar graph.

RUN MODE

Press the key

once which will move the

cursor back to the RH

side of the display.

Press the key to adjust the

resolution setting. If OFF was

selected, the menu will move to

the store function directly.

Press the key once

which will move the cursor

over the least sign. digit.

Use the and to select

the override either ON or OFF.

Press the key once

which will move the cursor

over the first character

7.15pH 25.0C

SETUP

UTILITIES

CALIBRATION

LOW GRN 0.0 0 >

STORE? Y N

BAR GRAPH O/R

BAR GRAPH O/R

STORE? Y N

HIGH GRN 10.80 >