Page 1

PHP-800 Series

Variable Speed

Positive Displacement

Diaphragm Metering Pump

Operating Manual

Page 2

Page 3

Page 2

TABLE OF CONTENTS

1.....Introduction ................................................................. .............. .......3

2.....Specifications ..................................................................... ..............3

3.....Features ....... .............. .............. .............. ..........................................3

4.....Unpacking .................. .............. .............. .............. .............. ..............4

5.....Installation .... .............. .............. .............. ..........................................4

5.1..Mounting location .............. .............. .............. .............. ..............4

5.2..How to install the tubing and fittings ..........................................6

5.3..Diaphragm Failure Detection.......................................................7

5.4..Flow Verification System............................................................. 8

6..... External Input/Output Signal Connection ............. .............. ..............9

6.1..How to operate the PHP-800 ............................................. .......10

7.... External Input/Output Signal connection....... ....................... .............11

7.1..How to operate the ...................................................................12

7.2..Operating Mode 1 - Output adjusted manually............................14

7.3..Operating Mode 2 - 4 - 20 mA input mode.................... ..............15

7.4..Operating Mode 3 - 0 - 10 VDC Mode.................. ......................18

7.5..Operating Mode 4 - Frequency Mode (Hz).................................20

7.6..Operating Mode 5 - Batch Mode ...... .............. .............. ..............23

8.0..Measuring the Pump’s Output - volumetric Test.................................25

9.0..How to maintain the pump..................................................................26

9.1..Routine Inspection and Maintenance.......................................... 26

9.2..How to clean the pump................................................................26

Pump head and Valve exploded view drawing..................................27

Replacement parts drawing ...... .............. .............. .............. ..............28

Replacement parts list ............................ .............. .............. ..............29

Warranty information .. .............. .............. .............. ............................31

Authorized service centers ...............................................................32

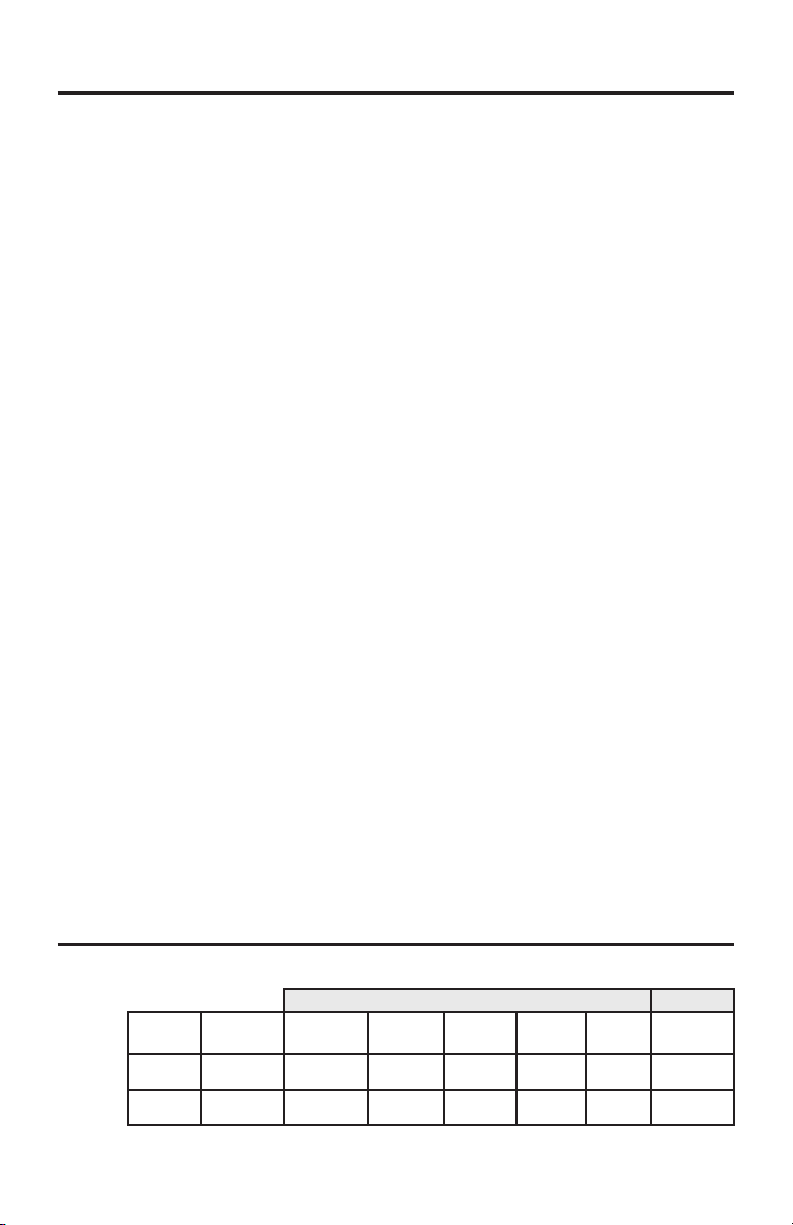

Series Comparison:

PHP-800

PHP-800ESC

Junction

Box

Optional

P

DFD

(Leak Detection)

P

P

External Communications (input)

FVS**

(Flow Verification)

4-20 mA

P

P

0-10 VDC

P

Pulsed*

P

Output

Alarm Relay

Batch

3 Amp

P

P

P

* Also known as Frequency Mode

** Requires Sensor sold separately

P

Page 4

1.0 Introduction

Congratulations on purchasing thePHP-800 Series Diaphragm Metering

Pump. The pump is designed to inject chemicals into piping systems

and is capable of injecting against a high system pressure up to 175 PSI

/ 12.1 bar*.

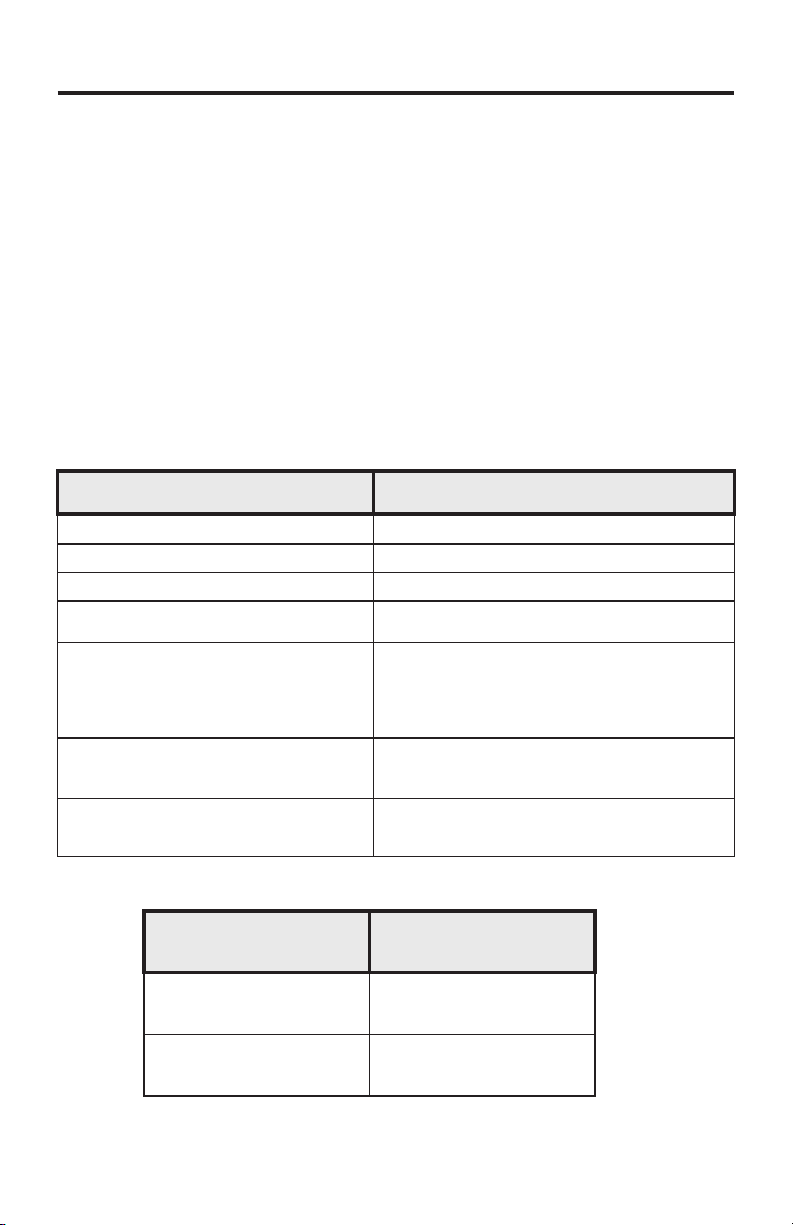

2.0 Specifications

Maximum Working Pressure* ..............175 psig / 12.1 bar

Maximum Fluid Temperature ...............130 F / 54 C

Ambient Temperature Range . ..............14 to 115 F / -10 to 46.1 C

Output adjustment Range....................1-100% in 0.1% increments

Turn Down Ratio.................................... 100:1

Duty Cycle ............................................Continuous

Maximum Viscosity .. .............. ..............1,000 Centipoise

Maximum Suction Lift ..........................15 ft. water / 4.5 m water

Enclosure Rating.................... ..............NEMA 4X / IP66

Power Requirements .............. ..............115v, 50/60Hz 1.5 Amp

Shipping Weight ....... .............. ..............29 lb. (approx.)

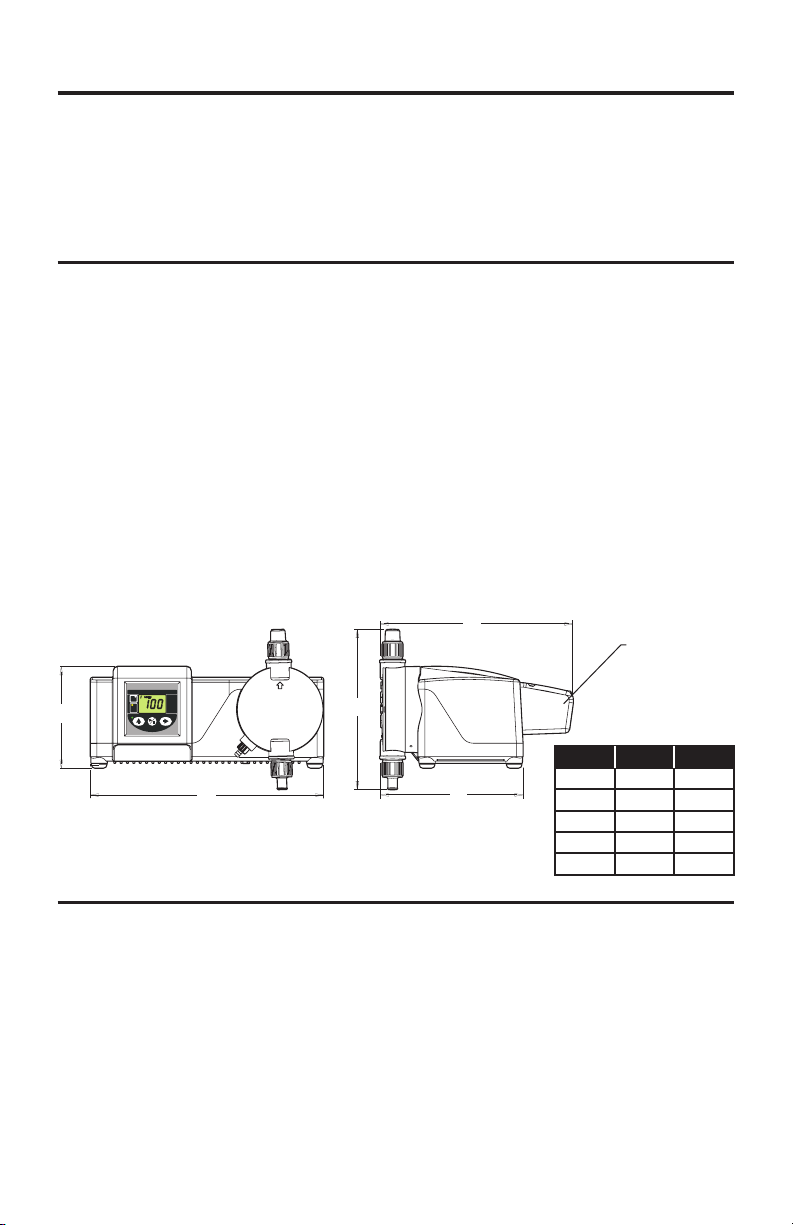

Dimensions:

Diaphragm Metering Pump

Program

MODE

Minimum

Maximum

A

PRIME

IP66

NEMA 4X

Made in the USA

B

C

o o

o o

230v, 50/60Hz 0.7Amp(optional)

E

Junction

Box

Inches

Dim

A

D

5-3/4”

13-1/8”

B

C

9”

8”

D

10-3/4”

E

Page 3

mm

144.8

332.7

228

203.2

274.3

3.0 Features

Oversized PVDF double ball valves.

Operator friendly digital touch pad.

– Easy to read Back Lit LCD display

– Display percentage of motor speed

DFD, Built-in Diaphragm Failure Detection system.

Priming / degassing valve built into the pumphead

NEMA 4X and IP66 rated enclosure

* Depending on model selection.

Page 5

Page 4

4.0 Unpacking

Your pump package should contain the following:

1 - Metering Pump

1 - 8 foot / 2.4 meter suction tube, clear PVC

1 - foot valve & strainer assembly

1 - Injection fitting with internal back -f low check val ve

1 - Mount in g hardware ki t (two mounting b rackets, 4 sc re ws)

1 - 5 Foot / 1.5 meter Priming Tubing

1 - Extra Brush Kit (located inside motor housing)

5.0 Installation

CAUTION: Always wear protective clothing, face shield, safety

glasses and gloves when working on or near your metering pump.

Additional precautions should be taken depending on the solution

being pumped. Refer to MSDS precautions from your solution

supplier.

5.1 Mounting Location

Choose an area located near the chemical supply tank, chemical injection point,

and electrical supply. Install the pump where it can be easily serviced.

!

Mount the pump to a secure surface using the enclosed hardware.

!

Mount the pump close to the injection point. Keep the inlet (suction) and outlet

(discharge) tubing as short as possible. Longer discharge tubing increases the

back pressure at the pump head.

!

Your solution tank should be sturdy. Keep the tank covered to reduce fumes. Do

not mount the pump directly over your tank. Chemical fumes may damage the

unit. Mount the pump off to the side or at a lower level than the chemical

container.

!

Be sure your installation does not constitute a cross connection with the drinking

water supply. Check your local plumbing codes.

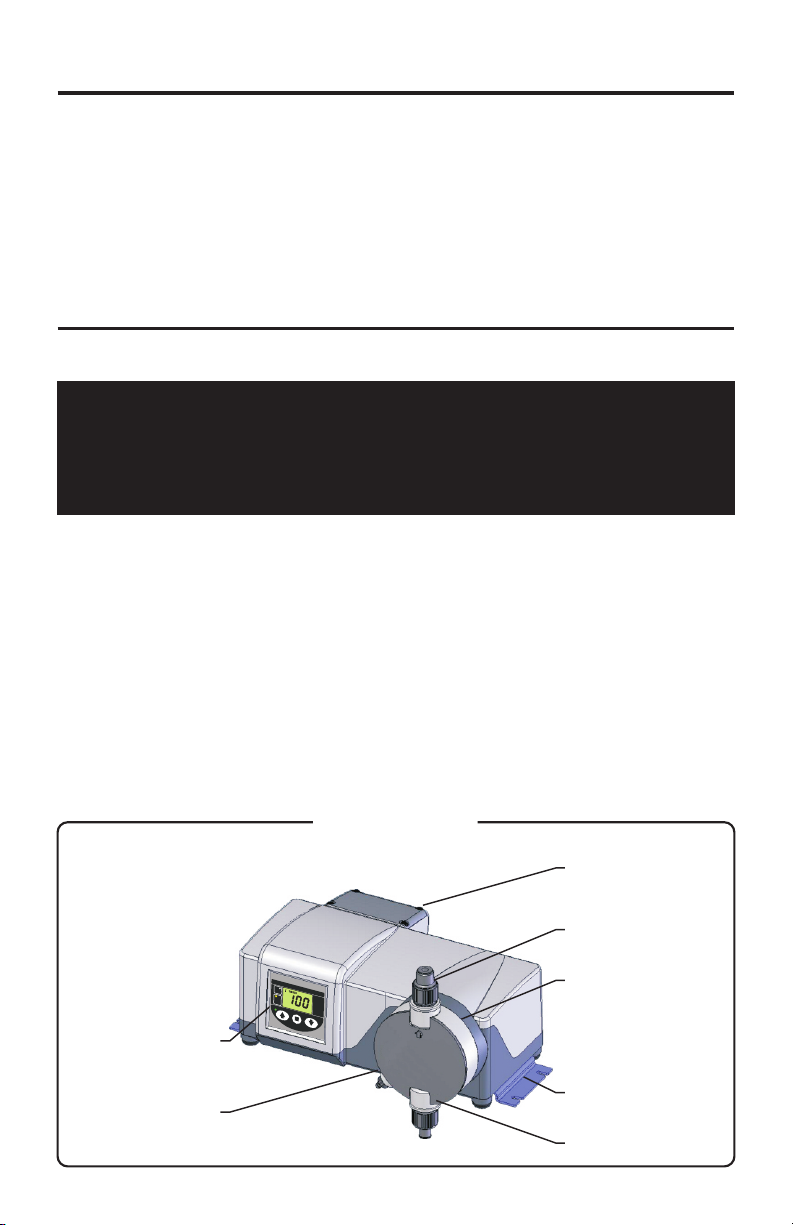

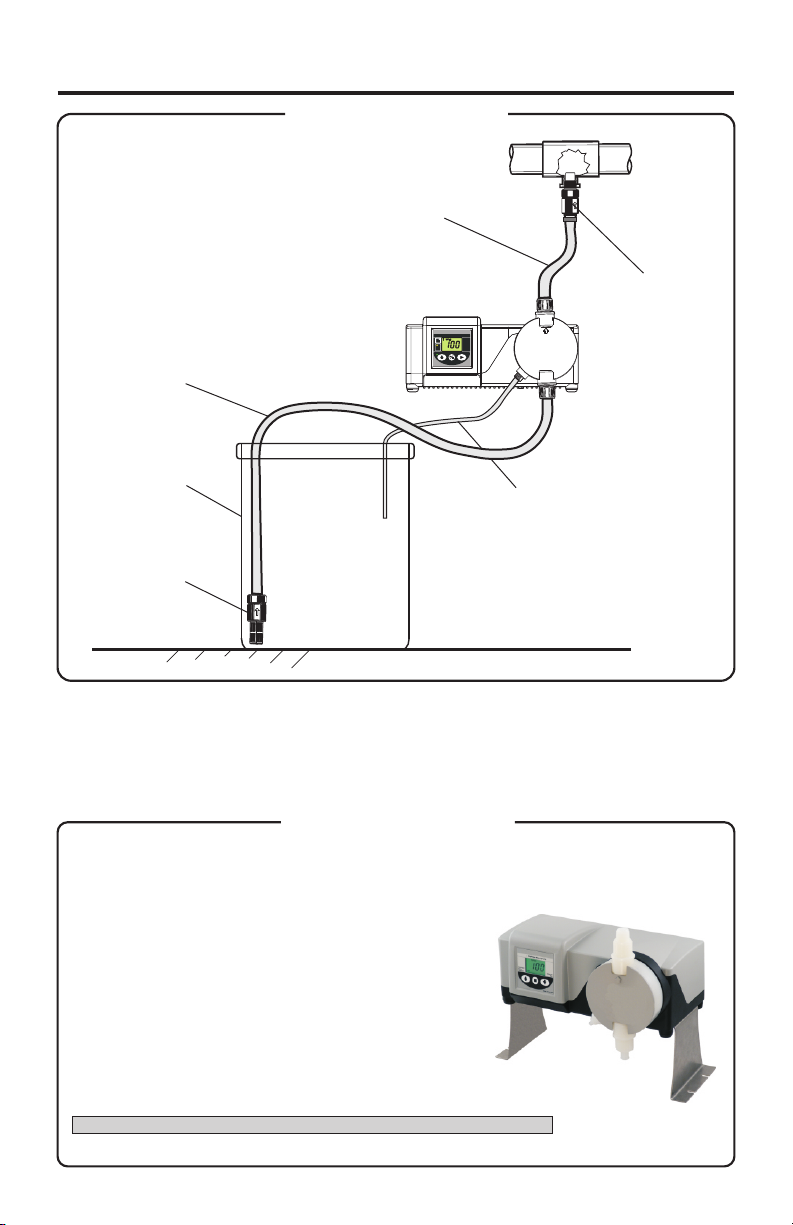

Parts Locator

Control Panel

Priming and

Degassing Valve

Junction Box

Outlet (discharge)

D

i

a

p

h

t

r

m

a

g

m

M

e

t

er

i

n

g

P

u

M

m

OD

p

E

P

r

o

g

r

P

a

m

R

I

ME

M

i

n

i

m

u

m

M

ax

i

m

u

m

M

a

d

e

i

n

t

h

e

U

S

A

I

P

6

6

N

E

M

A

4

X

Pumphead

Mounting Bracket

Inlet (suction)

Page 6

Suction Tubing

Typical Installation

Discharge Tubing

Diaphragm Metering Pump

Program

MODE

Minimum

Maximum

PRIME

IP66

NEMA 4X

Page 5

Injection /

Check Valve

Chemical Tank

Priming /

Degassing Tubing

Foot Valve

Note: All diagrams are strictly for guideline purposes only. Always

consult an expert before installing the pump into specialized systems.

The pump should be serviced by qualified persons only.

Extended Brackets

Model Number PHP-800-MB

Stainless Steel extended brackets allow the pump to be securely mounted to most any surface;

floor, shelf, or skid. The brackets lift the pump up 4-1/2 inches (11.43 cm), allowing you to easily

connect the suction side of the pump to your solution.

nRaise metering pump 4-1/2 inches (11.43 cm)

off the ground or a surface.

nMade out of tough Stainless Steel.

nProvides a stable mounting surface.

Model #

PHP-800-MB

Extended Mounting Bracket, 1 Pair, SS, 4 SS Screws

Description

Page 7

Page 6

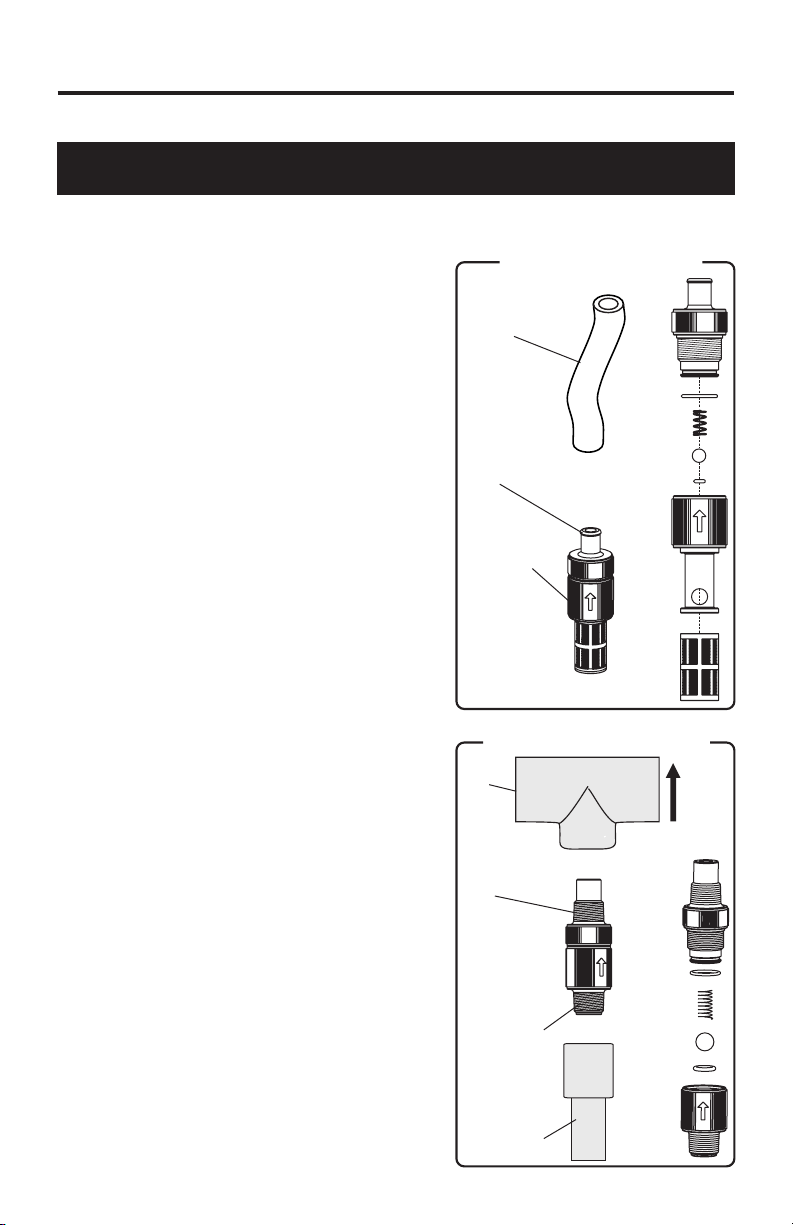

5.2 How To Install the Tubing and Fittings

CAUTION: Proper eye and skin protection must be worn when

installing and servicing the pump and fittings.

! Suction (Inlet) Tubing

Locate the inlet fitting of the pump head. Push the clear suction tubing onto the

fitting barb.

! Footvalve / Strainer

Trim the inlet end of the suction tubing so

that the strainer will rest approximately two

inches from the bottom of the solution tank.

This will prevent sediment from clogging the

strainer. Press the strainer’s barbed fitting

into the end of the tube. Drop the footvalve /

strainer into the solution tank.

Footvalve / Strainer

Suction

(inlet)

Tubing

Hose

Barb

FootValve

Strainer

Assembly

! Injection / Check Valve Fitting Installation

The Injection / Check valve fitting is designed

to install directly into 1/2” female pipe

threads. This fitting will require periodic

cleaning, especially when injecting fluids that

calcify such as sodium hypochlorite.

Install the Injection / Check valve directly into

the piping system. To prevent trapped

gasses, install the fitting in an upward

direction. Use Teflon thread sealing tape on

the pipe threads.

At high pressures, Omega recommends

using a threaded connection.

Injection / Check Valve is available with 1/2”

Male NPT or 1/2” Hose Barb. This is based

on the outlet connection selected for the

pump.

Keep discharge (outlet) tube as short as

possible.

Injection / Check Valve

Pipe

Tee

1/2” Male

NPT

1/2” Male NPT

(optional 1/2”

Hose Barb)

Discharge

Pipe or

1/2” Tubing

(not included)

Install

upward

for best

results

Page 8

Page 7

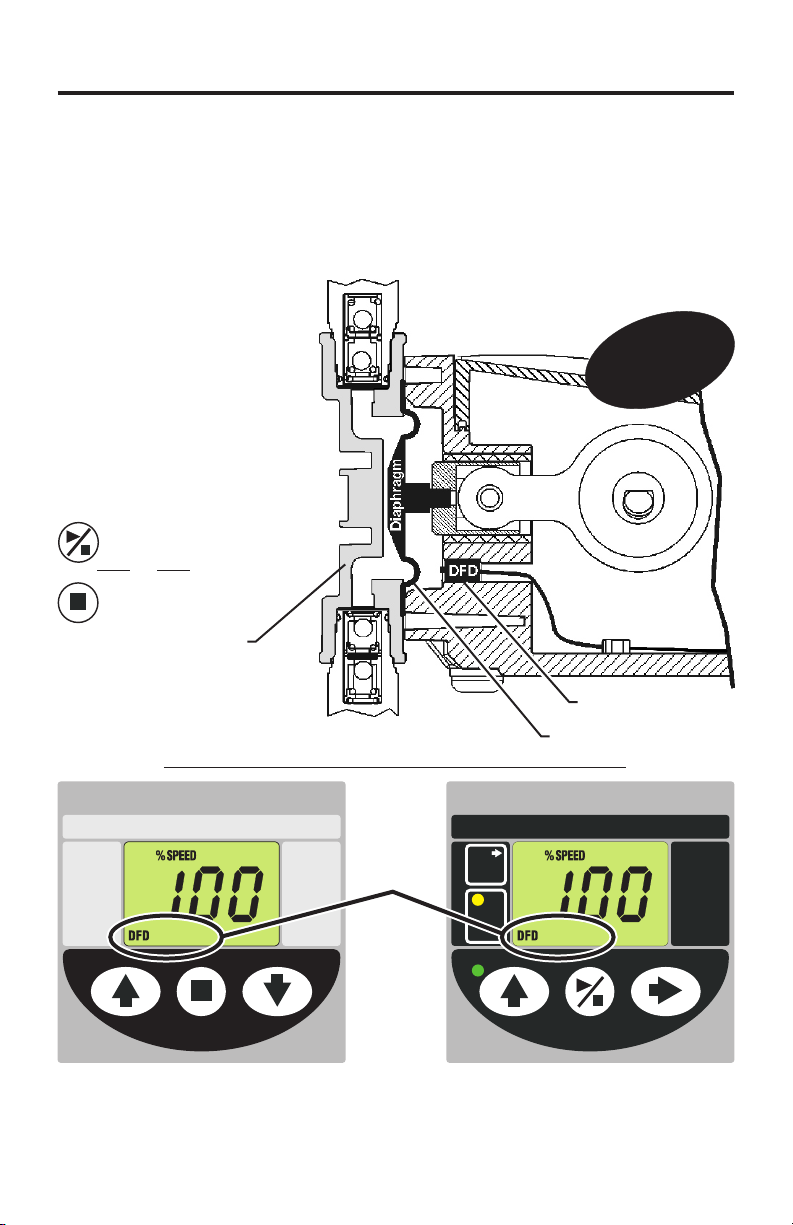

5.3 DFD (Diaphragm Failure Detection)

The Pump includes DFD sensors built directly into the pump. Although it doesn’t

happen often, diaphragm failure can occur. The DFD sensors will detect the

chemical behind the diaphragm caused by diaphragm failure. The pump will then

shut down and energize an internal 3 amp relay. You can wire the 3 amp relay to an

alarm, SCADA system, backup pump, or nothing at all.

Outlet

(discharge)

If the DFD Alarm has been

triggered, the diaphragm

must be replaced and the

pumphead must be

thoroughly cleaned.

You can reset the DFD

alarm by pressing the

Start/Stop button.

PHP-800-ESC

or

PHP-800

Pumphead

(suction)

PHP-800 Display

Diaphragm Metering Pump

Diaphragm

Failure

Detection

ALARM ALARM

Inlet

NEMA 4X

IP66

DFD ALARM

icons

lt

ui

B

h

p

ia

D

DFD Sensors

Diaphragm

PHP-800-ESC Display

Diaphragm Metering Pump

MODE

PRIME

-I

r

D

a

ete

gm F

DFD

n

on

ti

c

Program

Minimum

Maximum

ure

l

ai

Made in the USA

Made in the USA

NEMA 4X

If the DFD Alarm is triggered, the DFD and ALARM icons will begin

flashing.

Note: The DFD system will not reset until you have removed all traces of chemical

from behind the diaphragm.

IP66

Page 9

Page 8

- (sensor and adaptor Fittings

5.4 Flow Verification System

sold separately)

The Pump is equipped with a Flow Verification System which is designed to stop

the pump and provide a contact closure output in the event the sensor does not

detect flow during pump operation. This could indicate a clogged injection fitting,

empty chemical solution tank, loose tubing connection, etc.

To allow the pump to clear any gasses that may have accumulated during

stopper operation (such as with chlorine), an alarm delay time value from 1-255

seconds must be programmed (An alarm delay value of 000 seconds disables

the system).

Install the FTB 300 Series Flow Sensor (sold separately) - The Flow

Verification Sensor should be installed on the outlet (discharge) side of the

pump head valve.

Connect the red/white, black, and white wires from the sensor to the red, black,

Contact Closure Alarm Output - A contact closure output (relay) is provided

with the system. The relay can be configured for normally open (factory default)

or normally closed operation by properly positioning the connector plug on the

circuit board .

FTB300

Series

Diaphragm Metering Pump

Program

MODE

Minimum

Maximum

PRIME

IP66

NEMA 4X

Made in the USA

Page 10

6.0 External Input / Output Signal Connection

SIGNAL INPUT/OUTPUT WIRE COLOR CODES

Page 9

INPUT TYPE

ALARM RELAY

connect 2-conductor plug to either

normally open (NO) (factory default)

or normally closed (NC) side of receptacle.

3 AMP MAX @ 125VAC (24VDC)

FLOW VERIFICATION SENSOR (FVS)

WIRE COLOR CODE

PURPLE & PURPLE

RED/WHITE (+ 20VDC)

BLACK (-)

YELLOW (signal)

Page 11

Page 10

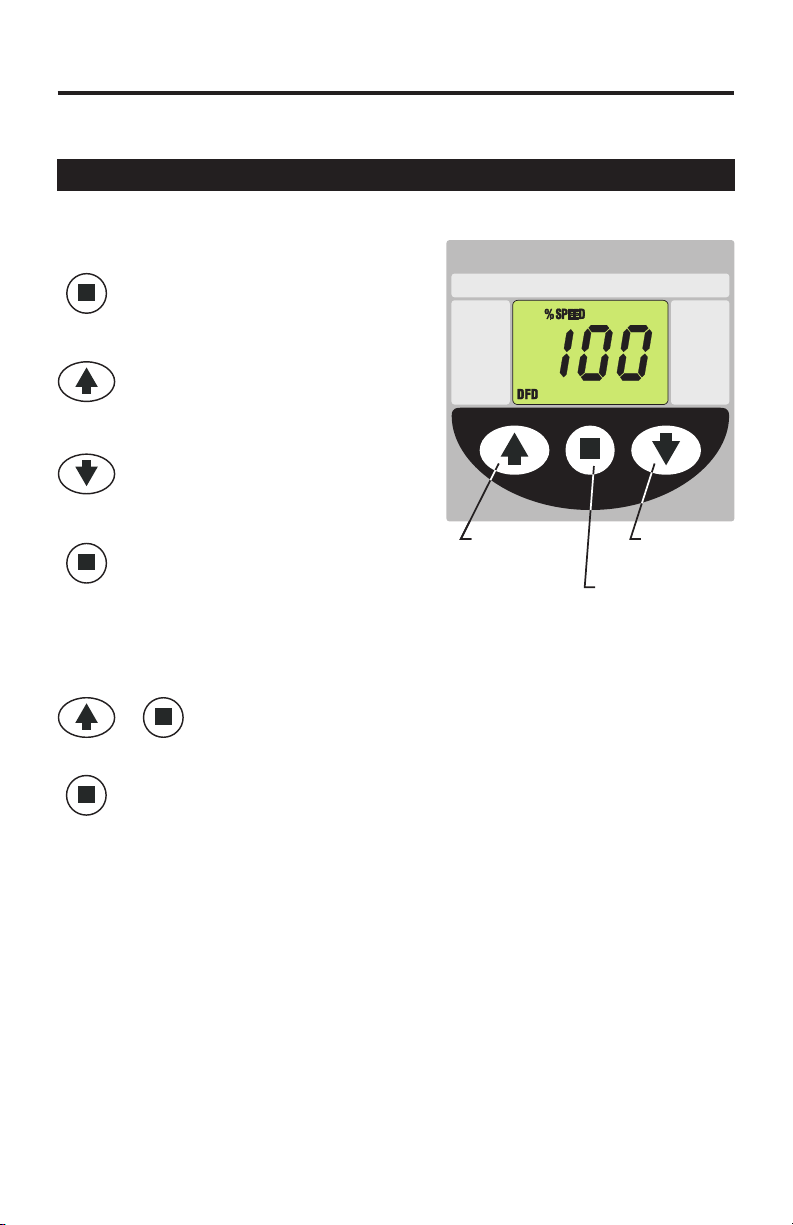

6.1 How To Operate The Pump

Operation

The Pump is a powerful yet simple to

operate metering pump.

To start the pump, press the

Start / Stop button

To increase the output, press

the Up button

To decrease the output, press

the Down button

To stop the pump, press the

Start / Stop button

Priming the Pump

To prime the pump, press the Up button and the Start / Stop

+

To stop priming before the 60 seconds, press the Start / Stop

button.

button at the same time. The pump will run in prime mode for

60 seconds at 100% output.

| Diaphragm Metering Pump

Diaphragm

Failure

Detection

Increase

output speed

NEMA 4X

Made in the USA

Decrease

output speed

Stop and

Start the pump

IP66

Page 12

7.0 External Input/Output Signal Connection

The pump will accept a variety of external control input signals: 4-20mA, 010VDC, TTL, CMOS, AC Sine waves, contact closures, Hall Effect, NPN. The 420mA and 0-10 VDC loops must be powered. Two types of frequency inputs, AC

sine waves (magnetic coils type outputs) and Digital Square waves (Hall Effect

signals, contact closures), are acceptable.

All wiring connections are to be made inside of the junction box located on the

side of the Pump. liquid-tite connectors are supplied and should be used for the

external signal cables. The signal input wires are color coded to the type of

signal being used.

SIGNAL INPUT/OUTPUT WIRE COLOR CODES

Page 11

INPUT TYPE

4-20 mA

0-10 VDC

AC sine wave, TTL, CMOS

CONTACT (10v @ 2 mA max)

HALL EFFECT, NPN

connect 2-conductor plug to either

normally open (NO) (factory default)

or normally closed (NC) side of receptacle.

3 AMP MAX @ 125VAC (24VDC)

FLOW VERIFICATION SENSOR (FTB300)

ALARM RELAY

MOTOR ON SIGNAL

5-20V DC open collector output

closed while motor is energized

PADDLEWHEEL SENSOR SIGNAL INPUT WIRING

PADDLEWHEEL

SENSOR TYPE

HALL EFFECT SENSOR

AC SINE WAVE SENSOR

WIRE COLOR CODE

BLUE (+) (non-powered) & BLACK (-)

ORANGE (+) & BLACK (-)(non-powered)

WHITE (+) & BLACK (-)

RED (+) & WHITE (-)

PURPLE & PURPLE

RED/WHITE (+ 20VDC)

BLACK (-)

YELLOW (signal)

BROWN (+) & BLACK (-)

PUMP INPUT

WIRE COLOR CODE

RED (+ 20VDC)

BLACK (-)

WHITE (signal)

WHITE (+)

BLACK (-)

Page 13

Page 12

7.1 How To Operate The Pump

Operation

MODE button is used to

MODE

select the mode you would

like to run the pump in. See

below for more MODE

information.

PRIME button is used to

prime the pump. The pump

PRIME

will run at full speed for 60

seconds.

To stop the priming

function before the 60

seconds, press the

Start/Stop button.

UP button is used to

change the selected digit.

Start/Stop button is used to

Start and Stop the pump.

RIGHT button is used to

select the digit to program.

PRIME

Button

Green LED

Indicates

pump is

pumping

MODE Selection Button

Diaphragm Metering Pump

MODE

PRIME

Made in the USA

UP button,

To Change

Selected Digit

Start/Stop,

To start and stop

the pump

Program

Minimum

Maximum

IP66

NEMA 4X

Right button,

To Select Digit

To Program

Page 14

Modes

MODE 0 = DFD (Diaphragm Failure Detection) On/Off

FTB300 flow verification system 0 = OFF, 1-255 Seconds = ON

Please Note: You will not see the FVS icon or be able to configure

the FVS unless an FVS sensor is wired to the PHP-800

MODE 1 = Manual Adjustment, 1 - 100% (external input disabled)

MODE 2 = 4-20 mA input

MODE 3 = 0-10 VDC input

MODE 4 = Frequency input (Hz), also known as pulse input

Frequency (Hz) mode is commonly used in proportional feed

systems. Pump can be wired to a paddlewheel flowmeter,

ultrasonic flowmeter, or any type of high frequency flowmeter.

Pump will smoothly speed up and slow down based on frequency

signals. Range = 1 - 1000 Hz

MODE 5 = Batch

Batch mode can be used with water meters, contact closure switch,

and other single pulse or low pulse equipment.

In Batch mode, the pumps’ ‘motor speed’ and ‘on time’ is

configured to be initiated by a single pulse or multiple pulses (up to

1,000 pulses). In MODE 5 the pump ‘motor speed’ is fixed

(1 - 100%) for a specified amount of ‘on time’ (0.1 - 199.9 seconds

or 0.1 - 199.9 minutes).

Page 13

Tip! To View current Input value

From an external source

Press and hold the UP button to toggle from current pump speed

output to current Input value.

Page 15

Page 14

7.2 OPERATING MODE 1 - Output adjusted manually

In this mode, the pump’s motor speed is adjusted manually using the

front panel touch pad. The motor speed can be adjusted from 0-100%.

4

Set the pump for mode 1.

Press the MODE button until MODE 1

is shown on the LCD display.

MODE

The %SPEED icon will light.

The large LCD will indicate the

currently programmed percentage of

speed.

4

Enter the programming mode.

Press and MODE button for more than

MODE

two seconds.

Mode 1

Diaphragm Metering Pump

MODE

PRIME

Program

Minimum

Maximum

A blinking ARROW will point to the

word PROGRAM indicating the

Made in the USA

program mode has been activated.

Press the Right button to select the digit to program. The digit will blink

when selected.

Press the UP button to change the selected digit.

Repeat until all digits are programmed.

To exit the programming mode, press the MODE button for more than two

MODE

seconds.

The arrow next to the word PROGRAM will disappear.

[

NOTE: If while in the program mode no buttons are pressed within 20

seconds, the circuitry will automatically return to the run mode, without

saving changes.

IP66

NEMA 4X

Page 16

7.3 OPERATING MODE 2 - 4-20 mA input Mode

In this mode, the pump’s motor speed is adjusted automatically based on the

value of the 4-20 mA input signal. Any motor speed can be assigned to either

the minimum or maximum milliamp input values.

4

Set the pump for mode 2.

Press the MODE button until MODE 2

MODE

is shown on the LCD display.

The %SPEED or mA icon will light

depending on the current display

setting.

Press and hold the UP button to toggle

from current pump speed output to

current Input mA signal.

The large LCD will indicate the current

motor speed or the current mA input

value.

4

Enter the programming mode.

While MODE 2 is displayed, press the MODE button

for more than two seconds.

MODE

Blinking ARROW’s will point to the words PROGRAM

and MINIMUM indicating the program mode is

activated and the minimum value is ready to be

programmed. The % SPEED icon will blink indicating

the percentage of speed is ready to be programmed.

Mode 2

Diaphragm Metering Pump

MODE

PRIME

Made in the USA

C3V | Diaphragm Metering Pump

MODE

PRIME

Page 15

Program

Minimum

Maximum

IP66

NEMA 4X

Program

Minimum

Maximum

4

Enter the motor speed at the minimum mA input

signal value.

Blue-White Ind.

Press the RIGHT button to select the digit to program.

Made in the USA

The digit will blink when selected.

Press the UP button to change the selected digit.

Repeat until all digits are programmed.

Press the MODE button. The % SPEED icon will stop blinking and the mA

icon will blink indicating the minimum mA value is ready to be programmed.

MODE

The currently programmed minimum value is shown on the LCD.

4

Enter the minimum mA input signal value.

Note: this value must be less than the maximum mA input signal value.

Press the RIGHT button to select the digit to program. The digit will blink

when selected.

Press the UP button to change the selected digit.

IP66

NEMA 4X

Page 17

Page 16

MODE

4

Repeat until all digits are programmed.

Press the MODE button. The mA icon will stop blinking

and the % SPEED icon will blink. The ARROW next to

C3V | Diaphragm Metering Pump

the word MAXIMUM will blink indicating the maximum

value is ready to be programmed. The currently pro-

MODE

grammed maximum motor speed value is shown on the

LCD.

PRIME

Enter the motor speed at the maximum mA input

signal value.

Program

Minimum

Maximum

Press the RIGHT button to select the digit to program.

The digit will blink when selected.

Blue-White Ind.

Made in the USA

Press the UP button to change the selected digit.

Repeat until all digits are programmed.

Press the MODE button. The % SPEED icon will stop

blinking and the mA icon will blink indicating the

MODE

maximum mA value is ready to be programmed. The

currently programmed maximum value is shown on the

LCD.

4

Enter the maximum mA input signal value.

Note: this value must be greater than the minimum mA input signal value.

Press the RIGHT button to select the digit to program. The digit will blink

when selected.

Press the UP button to change the selected digit.

Repeat until all digits are programmed.

Press the mode button. Programming is complete.

MODE

To exit the programming mode, press the MODE button for more than two

MODE

seconds. The PROGRAM arrow will disappear.

IP66

NEMA 4X

Page 18

Mode 2 Programming Examples

Page 17

Pump Output

20%

Output

Pump Output

0%

Output

Motor Speed

100%

75%

50%

25%

0%

100%

75%

6

8

4

from external source

12

10

Milliamp input (mA)

16

20

18

14

Example 1

4 mA will result in a pump output of

70%

20.0%

Output

16 mA will result in a pump output of

70.0%

Example 2

100%

Output

4 mA will result in a pump output of 0.0%

50%

Motor Speed

25%

0%

6

8

4

Milliamp input (mA)

from external source

10

16

20

18

14

12

20 mA will result in a pump output of

100.0%

Tip! To View current Input value

Press and hold the UP button to toggle from current pump speed

output to current Input value.

Page 19

Page 18

7.4 OPERATING MODE 3 - 0-10 VDC Mode

In this mode, the pump’s motor speed is adjusted automatically based on the

value of the 0-10VDC input signal. Any motor speed can be assigned to either

the minimum or maximum DC input signal values.

4

Set the pump for mode 3.

Mode 3

Press the MODE button until MODE 3

MODE

is shown on the LCD display.

Diaphragm Metering Pump

The % SPEED or VDC icon will light

depending on the current display

setting.

Press and hold the UP button to toggle

MODE

PRIME

from current pump speed output to

current VDC Input value.

The large LCD will indicate the current

motor speed or the VDC input value.

4

Enter the programming mode.

Made in the USA

While MODE 3 is displayed, Press and hold the MODE button for more than

two seconds.

MODE

Blinking ARROW’s will point to the words PROGRAM and MINIMUM

indicating the program mode is activated and the minimum value is ready to

be programmed. The % SPEED icon will blink indicating the percentage of

speed is ready to be programmed.

4

Enter the motor speed at the minimum VDC input signal value.

Press the RIGHT button to select the digit to program. The digit will blink

when selected.

Program

Minimum

Maximum

IP66

NEMA 4X

MODE

Press the UP button to change the selected digit.

Repeat until all digits are programmed.

Repeat until all digits are programmed.

4

Press the MODE button. The % SPEED icon will

stop blinking and the VDC icon will blink indicating

the minimum VDC value is ready to be programmed.

The currently programmed minimum value is shown

on the LCD.

Enter the minimum VDC input signal value.

Note: this value must be less than the maximum VDC input signal value.

Program

Minimum

Maximum

Page 20

Press the RIGHT button to select the digit to program. The digit will blink

when selected.

Press the UP button to change the selected digit.

Repeat until all digits are programmed.

4

Press the MODE button. The VDC icon will stop

blinking and the % SPEED icon will blink. The

ARROW next to the word MAXIMUM will blink

MODE

indicating the maximum value is ready to be

programmed. The currently programmed maximum

motor speed value is shown on the LCD.

4

Enter the motor speed at the maximum VDC igit.

4

input signal value.

Press the RIGHT button to select the digit to program. The digit will blink

when selected.

Press the UP button to change the selected digit.

Repeat until all digits are programmed.

Press the MODE button. The % SPEED icon will stop blinking and the VDC

icon will blink indicating the maximum VDC value is ready to be pro-

MODE

grammed. The currently programmed maximum value is shown on the LCD.

4

Enter the maximum VDC input signal value.

Note: this value must be greater than the minimum VDC input signal value.

Page 19

Program

Minimum

Maximum

MODE

MODE

Pump Output

0%

Output

Press the RIGHT button to select the digit to program. The digit will blink

when selected.

Press the UP button to change the selected digit.

Repeat until all digits are programmed.

Press the MODE button. Programming is complete.

To exit the programming mode, press and hold the MODE button for more

than two seconds. The PROGRAM arrow will disappear..

Mode 3 Programming Examples

Motor Speed

100%

75%

50%

25%

0%

2

0

4

VDC input

from external source

8

6

10

Example 1

0 VDC will result in a pump output of

70%

0.0%

Output

8 VDC will result in a pump output of

70.0%

Page 21

Page 20

100%

90%

Output

75%

50%

25%

0%

Pump Output

Motor Speed

Continued - Mode 3 Programming Examples

Example 2

0 VDC will result in a pump output of

90%

0%

10 VDC will result in a pump output of

Output

0.0%

8

2

0

4

VDC input

from external source

6

10

100%

75%

100%

Output

Example 3

0 VDC will result in a pump output of

Pump Output

0%

Output

50%

Motor Speed

25%

0%

2

0

from external source

4

VDC input

8

6

10

0.0%

10 VDC will result in a pump output of

100.0%

Tip! To View current Input value

Press and hold the UP button to toggle from current pump speed

output to current Input value.

7.5 OPERATING MODE 4 - Frequency (Hz) Mode

Also known as Pulse Input. In this mode, the pump’s motor speed is adjusted

automatically based on the frequency (Hz) of the input signal. Any motor speed

can be assigned to either the minimum or maximum Hz input signals.

4

Set the pump for mode 4.

Press the MODE button until MODE 4

MODE

is shown on the LCD display.

The % SPEED or Hz icon will light

depending on the current display

setting.

Press and hold the UP button to toggle

from current pump speed output to

current Hz Input value.

Mode 4

Diaphragm Metering Pump

MODE

PRIME

Program

Minimum

Maximum

The large LCD will indicate the current

motor speed or the Hz input value.

4

Enter the programming mode.

Made in the USA

IP66

NEMA 4X

Page 22

While MODE 4 is displayed, press and hold the MODE button for more than

MODE

two seconds.

Blinking ARROW’s will point to the word PROGRAM and MINIMUM

indicating the program mode is activated and the minimum value is ready to

be programmed. The % SPEED icon will blink indicating the percentage of

speed is ready to be programmed.

4

Enter the motor speed at the minimum Hz input signal value.

Press the RIGHT button to select the digit to program. The digit will blink

when selected.

Press the UP button to change the selected digit.

Repeat until all digits are programmed.

Press the MODE button. The % SPEED icon will stop

MODE

blinking and the Hz icon will blink indicating the

minimum Hz value is ready to be programmed. The

currently programmed minimum value is shown on

the LCD.

4

Enter the minimum Hz input signal value (to the nearest 10 Hz).

Note: this value must be less than the maximum Hz input signal value.

Press the RIGHT button to select the digit to program. The digit will blink

when selected.

Page 21

Program

Minimum

Maximum

Press the UP button to change the selected digit.

Repeat until all digits are programmed.

Press the MODE button. The Hz icon will stop

blinking and the % SPEED icon will blink. The

MODE

ARROW next to the word MAXIMUM will blink

indicating the maximum value is ready to be programmed. The Currently programmed maximum

motor speed value is shown on the LCD.

4

Enter the motor speed at the maximum VDC input signal value.

Press the RIGHT button to select the digit to program. The digit will blink

when selected.

Press the UP button to change the selected digit.

Repeat until all digits are programmed.

Press the MODE button. The % SPEED icon will stop blinking and the Hz

icon will blink indicating the maximum Hz value is ready to be programmed.

MODE

The currently programmed maximum value is shown on the LCD.

Program

Minimum

Maximum

Page 23

MODE

MODE

Pump Output

0%

Output

90%

Output

Pump Output

Pump Output

0.0%

Output

Enter the maximum Hz input signal value (to the nearest 10 Hz).

Note: this value must be greater than the minimum Hz input signal value.

Press the RIGHT button to select the digit to program. The digit will blink

when selected.

Press the UP button to change the selected digit.

Repeat until all digits are programmed..

Press the MODE button. Programming is complete.

To exit the programming mode, press and hold the MODE button for more

than two seconds. The PROGRAM arrow will disappear.

Mode 4 Programming Examples

Motor Speed

Motor Speed

Motor Speed

100%

75%

50%

25%

0%

100%

75%

50%

25%

0%

100%

75%

50%

25%

0%

200

0

0

0

400

Hz input

from external source

200

400

Hz input

from external source

200

400

Hz input

from external source

600

600

600

800

800

800

1000

1000

1000

Example 1

100%

Output

0 Hz will result in a pump output of 0.0%

1000 Hz will result in a pump output of

0.0%

Example 3

0 Hz will result in a pump output of

90.0%

0%

1000 Hz will result in a pump output of

Output

0.0%

Example 3

0 VDC will result in a pump output of

0.0%

50.0%

Output

800 Hz will result in a pump output of

50.0%

Tip! To View current Input value

Page 22

Press and hold the UP button to toggle from current pump speed

output to current Input value.

Page 24

Page 23

7.6 - OPERATING MODE 5 - Batch Mode

In this mode, the pump’s ‘motor speed’ and ‘on time’ is configured to be initiated

by a single pulse or up to 1,999 pulses.

You will configure the pump in the following order:

a. Select the % SPEED.

(1% to 100%)

b. Select the pump ON time.

(0.1 to 199.9 and select units: seconds (SEC) or minutes (MIN)

c. Select the amount of pulses to receive to trigger the pump.

(1 pulse up to 1999 pulses)

4

Set the pump for mode 5.

Press the MODE button until MODE 5

MODE

is shown on the LCD display.

The % SPEED and Hz icon will light.

The large LCD will indicate the current

motor speed or the Hz input value.

4

Enter the programming mode.

While MODE 5 is displayed, press and

hold the MODE button for more than

MODE

two seconds.

Blinking ARROW’s will point to the

word PROGRAM and MINIMUM

A blinking ARROW will point to the word PROGRAM and the % SPEED icon

will blink indicating the program mode is activated and the % SPEED value

is ready to be programed.

4

Enter the motor speed. (1% to 100%)

Mode 5

Diaphragm Metering Pump

MODE

PRIME

Made in the USA

Program

Minimum

Maximum

IP66

NEMA 4X

Press the RIGHT button to select the digit to program. The digit will blink

when selected. (Moves to the next digit to the right.)

Press the UP button to change the selected digit.

Repeat until all digits are programmed.

Press the MODE button. The % SPEED icon will stop blinking and the SEC

or MIN icon will blink indicating the pump ON-time value is ready to be

MODE

programmed.

4

Enter the pump ON-time. (0.1 to 199.9 seconds or minutes)

Press the RIGHT button to select the digit to program. The digit will blink

when selected. (Moves to the next digit to the right.)

Press the UP button to change the selected digit.

Repeat until all digits are programmed.

Page 25

Once all the digits are programmed, press the RIGHT arrow to then select

between SEC (seconds) and MIN (minutes).

Use the UP arrow to scroll through SEC and MIN.

Press the MODE button. The SEC or MIN icon will stop blinking and the Hz

MODE

icon will blink indicating the number of pulses is ready to be programmed.

4

Enter the number of pulses to trigger the batch. (1 to 1999 pulses)

Press the RIGHT button to select the digit to program. The digit will blink

when selected. (Moves to the next digit to the right.)

Press the UP button to change the selected digit.

Repeat until all digits are programmed.

Press the MODE button. Programming is complete.

MODE

To exit the programming mode, press and hold the MODE button for more

MODE

than two seconds. The PROGRAM arrow will disappear.

Tip! To View current Input value

Press and hold the UP button to toggle from current pump speed

output to current Input value.

Page 24

CAUTION: Always wear protective clothing, face shield, safety glasses and gloves

when working on or near your metering pump. Additional precautions should be

taken depending on the solution being pumped. Refer to MSDS precautions from

your solution supplier.

Page 26

Page 25

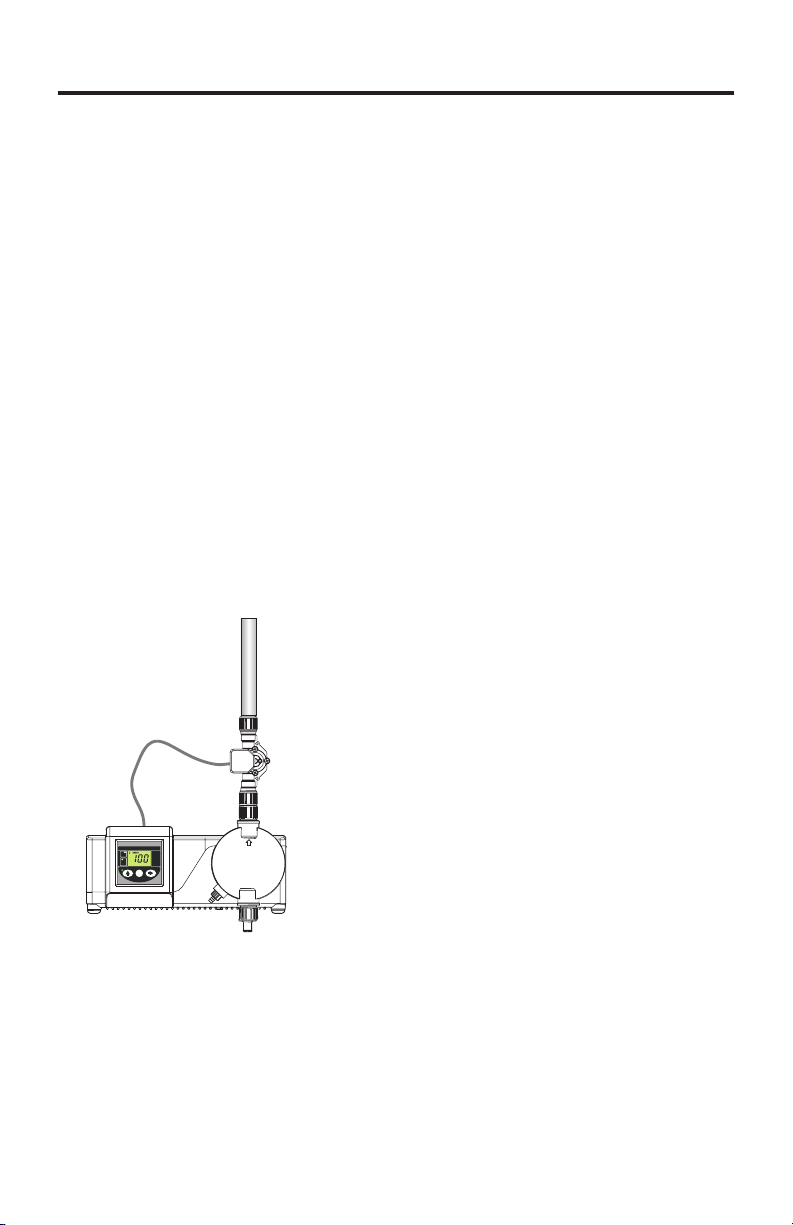

8.0 Measuring the Pump’s Output - Volumetric Test.

This volumetric test will take into account individual installation factors such as

line pressure, fluid viscosity, suction lift, etc. This test is the most accurate for

measuring the injector’s output in an individual installation.

1. Be sure the Injection Fitting and Footvalve /

Strainer are clean and working properly.

2. Fill a large graduated cylinder with the

solution to be injected.

3. With the pump installed under normal

operating conditions, place the suction

tubing with the Footvalve / Strainer installed

in the graduated cylinder.

4. Push 3/8” tubing onto the priming valve.

Place the other side of the 3/8” tubing in the

solution tank. Make sure the priming valve

is closed by turning the valve to the right.

5. Run the pump until all air is removed from

the suction line and the solution enters the

discharge tubing.

If the pump does not easily prime, loosen

the priming valve 1 - 2 turns counter clock

wise. Once the air is removed close the

priming valve.

6. Remove the suction tubing from the

graduated cylinder and refill the graduated

cylinder if necessary. Note the amount of

solution in the graduated cylinder.

lace suction tubing with the Footvalve / Strainer installed back into the

7. P

graduated cylinder.

8. Run the injector for a measured amount of time. A longer testing time will

produce more accurate results.

9. Remove the suction tubing from the graduated cylinder. Measure the amount

of chemical injected.

Example:

During your 1 minute calibration period, say the Chem-Pro pumped 1000

Milliliters in 1 minute.

Injection Fitting /

Check Valve

Discharge / Outlet

(not provided)

Diaphragm Metering Pump

Program

MODE

Minimum

Maximum

PRIME

IP66

NEMA 4X

Made in the USA

3/8” Priming

Tubing

(not provided)

Graduated

Container

(not provided)

Footvalve /

Strainer

Suction

Tubing

1 US Gallon = 3.785 Liters = 3785 Milliliters

1000 ML/Min

3785

Note: All diagrams are strictly for guideline purposes only. Always consult an expert

before installing the pump into specialized systems. The pump should be serviced

by qualified persons only.

60 = 15.85 GPH (US gallons per hour)

Minutes per hour

Milliliters in a US gallon

Page 27

9.0How to Maintain the Pump

CAUTION: Proper eye and skin protection must be worn when

installing and servicing the pump.

9.1Routine Inspection and Maintenance

The pump requires very little maintenance. However, the pump and all accessories should be checked regularly. This is especially important when pumping

chemicals. Inspect all components for signs of leaking, swelling, cracking,

discoloration or corrosion. Replace worn or damaged components immediately.

Cracking, crazing, discoloration and the like during the first week of operation

are signs of severe chemical attack. If this occurs, immediately remove the

chemical from the pump. Determine which parts are being attacked and replace

them with parts that have been manufactured using more suitable materials.

The manufacturer does not assume responsibility for damage to the pump that

has been caused by chemical attack.

Brush Kit Life Cycle over 3,000 hours of continuous use.(Part number

72000-378)

9.2How to Clean the Pump

The pump will require occasional cleaning, especially the Injection fitting, the

Footvalve / Strainer, and the pump head valves. The frequency will depend on

the type and severity of service.

]

Inspect and replace the pumphead valves as required.

]

When changing the diaphragm, the pump head chamber and pump head

cover should be wiped free of any dirt and debris.

]

Periodically clean the injection / check valve assembly, especially when

injecting fluids that calcify such as sodium hypochlorite. These lime deposits and

other build ups can clog the fitting, increase the back pressure and interfere with

the check valve operation.

]

Periodically clean the suction strainer.

]

Periodically inspect the air vents located under the motor housing and in the

back on the rear housing cover. Clean if necessary.

Page 26

Page 28

Page 27

PUMP HEAD AND VALVE EXPLODED VIEW

Page 29

Page 28

Replacement Parts Drawing

22

30

16

13

17

29

18

19

20

15

12

28

6

14

3

1

5

8

21

25

7

23

11

27

26

0

1

24

21

9

2

4

Page 30

PARTS LIST

Item Part No. Description Qty.

1. 71000-583 J-Box w/ Cover 1

2. 90001-158 P-Head Cover 1

3. 90008-035 Liquid Tight Connector (large) 1

90008-199 Liquid Tight Connector (small) 1

4. 90011-081 Screw P-Head Cover SS 2

5. 71000-584 Cover housing model (std.) 1

71000-585 Cover housing model (ESC) 1

6. 71000-175 Power Cord,115v 1

71000-176 Power Cord,220v 1

71000-177 Power Cord,230v 1

7 72000-382 Controller Kit model (Std.) 115V 1

72000-383 Controller Kit model (Std.) 230V 1

72000-384 Controller Kit model (esc) 115V 1

72000-385 Controller Kit model (esc) 230V 1

8. 90012-287 Label Overlay model (std) 1

90012-289 Label Overlay model (deluxe) 1

9. 90011-181 Screw P-Head SS # 10-32 x 1.25L 8

10. 90011-094 Washer SS #10 screw 4

11. 90011-180 Screw Nylon #8-32 4

12. 90003-560 Diaphragm TFE/Hypalon 1

13. 90003-561 Bumper Feet 4

14. 71000-588 Frame Housing Assy. 1

- Includes TFD Sensor

15. 76001-347 Backup Washer Diaphragm 1

16. 90011-115 Screw for housing 10-32x.50L SS 10

17. 76000-361 Tubing Suction .75” OD x .50” ID x 8ft 1

18. 70002-276 Motor 130RPM 1

70002-277 Motor 62RPM 1

19. 90008-367 Clamp Heat Sink 1

20. 90011-182 Screw #10-32 x .31 SS 2

21. 20000-194 Kit 4 cartridge insert Viton 4

20000-195 Kit 4 cartridge insert EP 4

22. 71000-573 Cam .06’ S/A complete 1

71000-574 Cam .10’ S/A complete 1

23. 90002-258 Pump Head molded PVDF 1

24. 70001-347 Cart. Valve Assy. .50T Viton 1

70001-348 Cart. Valve Assy. .50T EP 1

25. 70001-349 Cart. Valve Assy. .50 Male NPT/Viton 1

70001-350 Cart. Valve Assy. .50 Male NPT/EP 1

70001-351 Cart. Valve Assy. .50 Female NPT Viton 1

70001-352 Cart. Valve Assy. .50 Female NPT EP 1

26. 70001-353 Primer Valve Assy. Viton 1

70001-354 Primer Valve Assy. EP 1

27. 70001-356 Kit Head Complete .50T & .50M/NPT Viton 1

70001-357 Kit Head Complete .50T & .50M/NPT EP 1

70001-358 Kit Head Complete .50T & .50F/NPT Viton 1

70001-359 Kit Head Complete .50T & .50F/NPT EP 1

28. 71000-575 Foot Valve Assy. Viton 1

71000-576 Foot Valve Assy. EP 1

29. 90008-043 Clamp #5 SS 1

30. 71000-579 Injection Valve Assy. Viton 1

71000-580 Injection Valve Assy. EP 1

Bearings

Bumper Feet

Page 31

NOTES

Page 30Page 29

Page 32

Page 33

Page 34

Where Do I Find Everything I Need For

Process Measurement and Control?

OMEGA... Of Course!

Shop on line at www.Omega.com

TEMPERATURE

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

Wire: Thermocouple, RTD & Thermistor

Calibrations & Ice Point References

Recorders, Controllers & Process Monitors

Infrared Pyrometers

PRESSURE / STRAIN FORCE

Transducers & Strain Gauges

Load Cells & Pressure Gauge

Displacement Transducers

Instrumentation & Accessories

FLOW / LEVEL

Rotameters, Gas Mass Flowmeters & Flow Computers

Air Velocity Indicators

Turbine / Paddlewheel Systems

Totalizers & Batch Controllers

pH / CONDUCTIVITY

pH Electrodes, Testers & Accessories

Benchtop / Laboratory Meters

Controllers, Calibrators, Simulators & Pumps

Industrial pH & Conductivity Equipment

DATA ACQUISITION

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

Wire: Thermocouple, RTD & Thermistor

Calibrations & Ice Point References

Recorders, Controllers & Process Monitors

Infrared Pyrometers

HEATERS

Heating Cable

Cartridge & Strip Heaters

Immersion & Band Heaters

Flexible Heaters

Laboratory Heaters

ENVIRONMENTAL MONITORING AND CONTROL

Metering & Control Instrumentation

Refractometers

Pumps & Tubing

Air, Soil & Water Monitors

Industrial Water & Wastewater Treatment

pH, Conductivity & Dissolved Oxygen Instruments

M-4630/0408

Loading...

Loading...