Page 1

http://www.omega.com

e-mail: info@omega.com

User ’s Guide

PHB-900 Series

pH Benchtop Meters

Page 2

Servicing North America:

USA: One Omega Drive, Box 4047

ISO 9001 Certified Stamford, CT 06907-0047

Tel: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1

Tel: (514) 856-6928 FAX: (514) 856-6886

e-mail: canada@omega.com

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

SM

Customer Service: 1-800-622-2378 / 1-800-622-BEST

SM

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

SM

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico and

Latin America:

Tel: (95) 800-TC-OMEGA

SM

FAX: (95) 203-359-7807

En Espan÷ol: (203) 359-7803 e-mail: espanol@omega.com

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

Tel: (31) 20 6418405 FAX: (31) 20 6434643

Toll Free in Benelux: 06 0993344

e-mail: nl@omega.com

Czech Republic: ul. Rude armady 1868, 733 01 Kavrine-Hranice,

Czech Republic

Tel: 420 (69) 6311627 FAX: 420 (69) 6311114

e-mail: czech@omega.com

France: 9, rue Denis Papin, 78190 Trappes

Tel: (33) 130-621-400 FAX: (33) 130-699-120

Toll Free in France: 0800-4-06342

e-mail: france@omega.com

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: 49 (07056) 3017 FAX: 49 (07056) 8540

Toll Free in Germany: 0130 11 21 66

e-mail: germany@omega.com

United Kingdom: 25 Swannington Road, P.O. Box 7, Omega Drive,

ISO 9002 Certified Broughton Astley, Leicestershire, Irlam, Manchester,

LE9 6TU, England M44 5EX, England

Tel: 44 (1455) 285520 Tel: 44 (161) 777-6611

FAX: 44 (1455) 283912 FAX: 44 (161) 777-6622

Toll Free in England: 0800-488-488

e-mail: uk@omega.com

omega.comomega.com

OMEGAnetSMOn-Line Service Internet e-mail

http://www.omega.com info@omega.com

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that

apply. OMEGA is constantly pursuing certification of its products to the European New Approach

Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct but OMEGA Engineering, Inc. accepts

no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient connected applications.

OMEGA

TM

®

Page 3

Table Of Contents

Quick Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ii

Getting Started

Front panel controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Digital display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Rear panel connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Connecting to a power source . . . . . . . . . . . . . . . . . . . . . . .2

Installing and Maintaining Electrodes . . . . . . . . . . . . . . . . . . . .3

Preparing glass electrodes . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Installing the combination glass pH electrode . . . . . . . . . . . .3

Installing the FET pH electrode . . . . . . . . . . . . . . . . . . . . . . . .4

Installing ORP or ISE electrodes . . . . . . . . . . . . . . . . . . . . . . . .4

Rinsing electrodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Storing electrodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Standardizing for pH Measurement . . . . . . . . . . . . . . . . . . . . . .6

Entering buffers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

The diagnostic electrode test . . . . . . . . . . . . . . . . . . . . . . . . .7

Selecting buffers based on 20oC or 25oC . . . . . . . . . . . . . . .8

Using Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Clearing Buffers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Reviewing electrode standardization . . . . . . . . . . . . . . . . . . .9

Selecting buffer sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Standardizing for Millivolt Measurement . . . . . . . . . . . . . . . . .11

(Relative Millivolts) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Entering a millivolt standard . . . . . . . . . . . . . . . . . . . . . . . . .11

Clearing a millivolt standard . . . . . . . . . . . . . . . . . . . . . . . . .12

Measuring pH or Millivolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Understanding pH Theory . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Defining pH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Measuring pH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

The “Error”Icon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

The “CAL Error”Icon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

The “Err oC”Icon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

The “Electrode Error”Icon . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Electrode testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Meter Operation testing . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Meter Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

i

Page 4

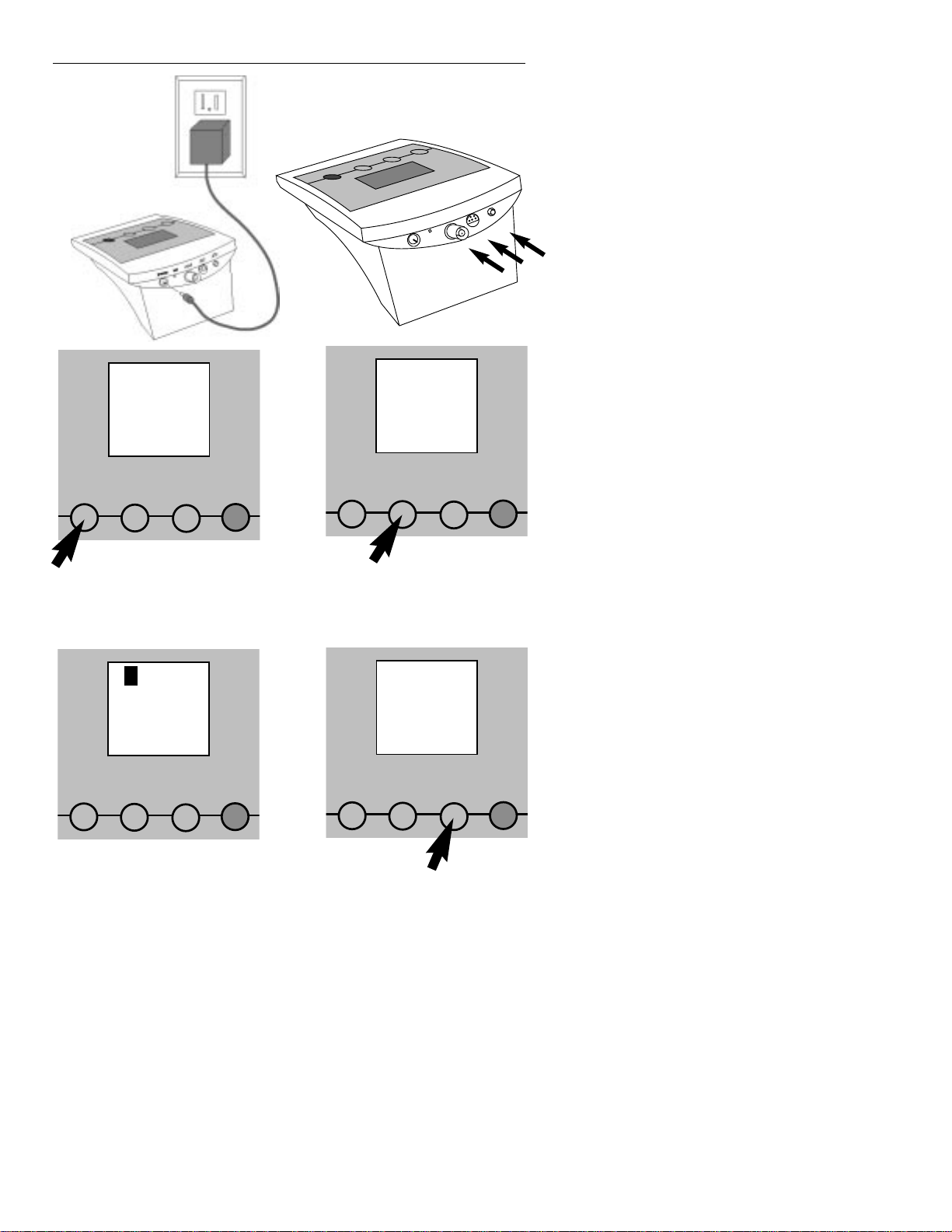

1. Connect power

cable to meter

power jack and

to AC power

source.

power

ref

input

FET

ATC

2. Connect the glass electrode to the

input and ATC connectors, or connect the FET electrode to the FET connector.

rel mV pH

3. Press pH/mV until the display indicates the appropriate measurement

mode.

4. Standardize the meter using

up to three buffers by immersing the electrode in a buffer,

then pressing Standardize to

enter each buffer.

Standardizing

PHB900 Series pH Meter Quick Reference

5. The display shows the current

reading in pH,mV,or relative

mV units.

6. Press Setup to review electrode calibration and to clear

or select buffer sets.

%slope

Clear

Set Buffers

Measuring

S

ii

pH/mV Standardize

pH/mV Standardize

Setup Enter

Setup Enter

pH/mV Standardize

pH/mV Standardize

Setup Enter

Setup Enter

Page 5

Getting Started

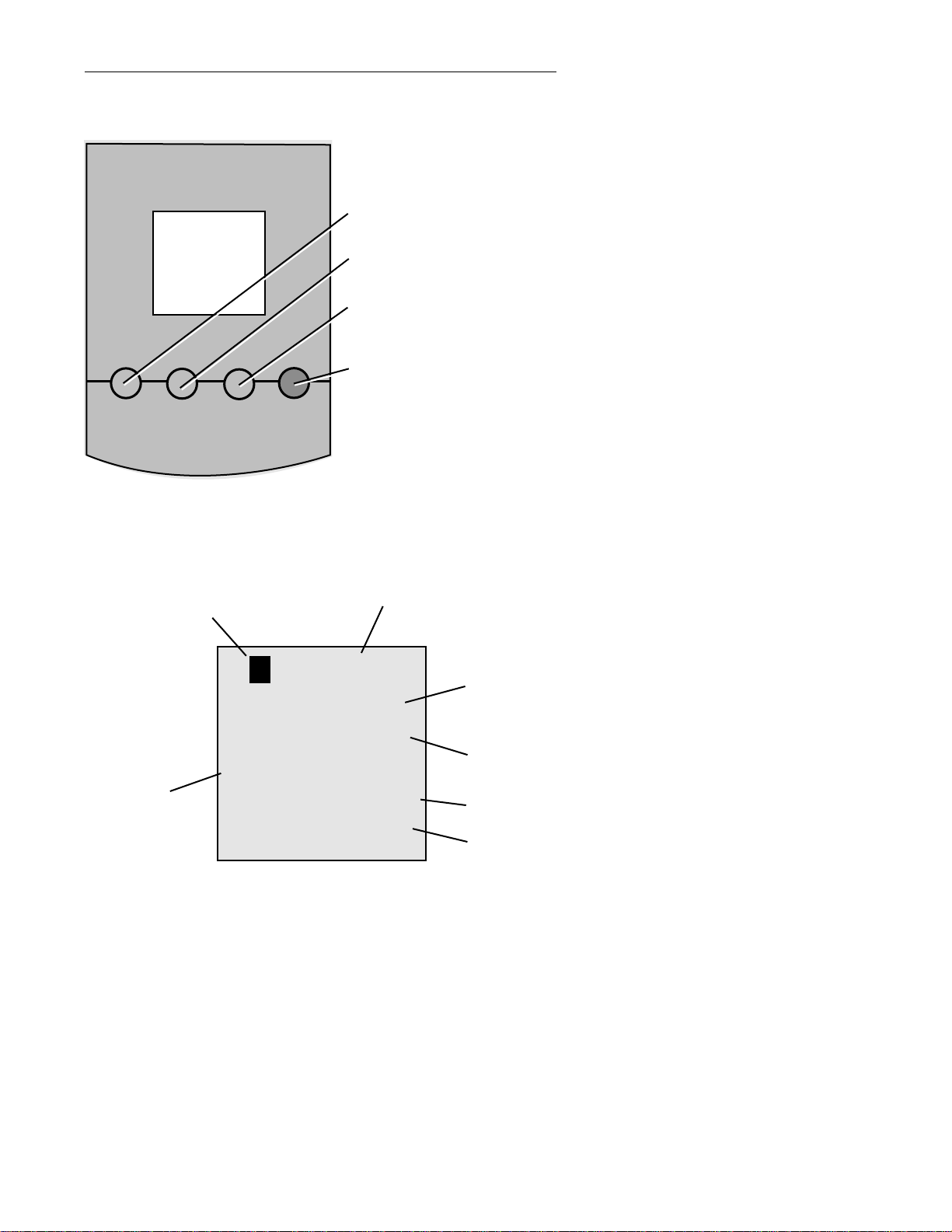

1

pH/mV Standardize

Setup Enter

pH/mV - button toggles

between pH and mV modes.

Standardize - the meter recognizes and displays buffers.

Setup - use to clear buffers

and to select new set of

buffers.

Enter - use to enter buffers.

Digital Display

100.0°C

%slope rel mV pH

-18.0.0.0

Good Electrode Error FET

Standardizing Clear

Measuring Set Buffers

2 4 7 10 12 1 3 5 8 10 13

1.68 4.01 6.86 9.18 12.46

1.08 3.06 4.86 6.79 9.23 12.76

S

Stability

Icon

Temperature

Mode

Front Panel Controls

Result

Electrode

Check

Icons

Prompts

Buffer

Icons

Page 6

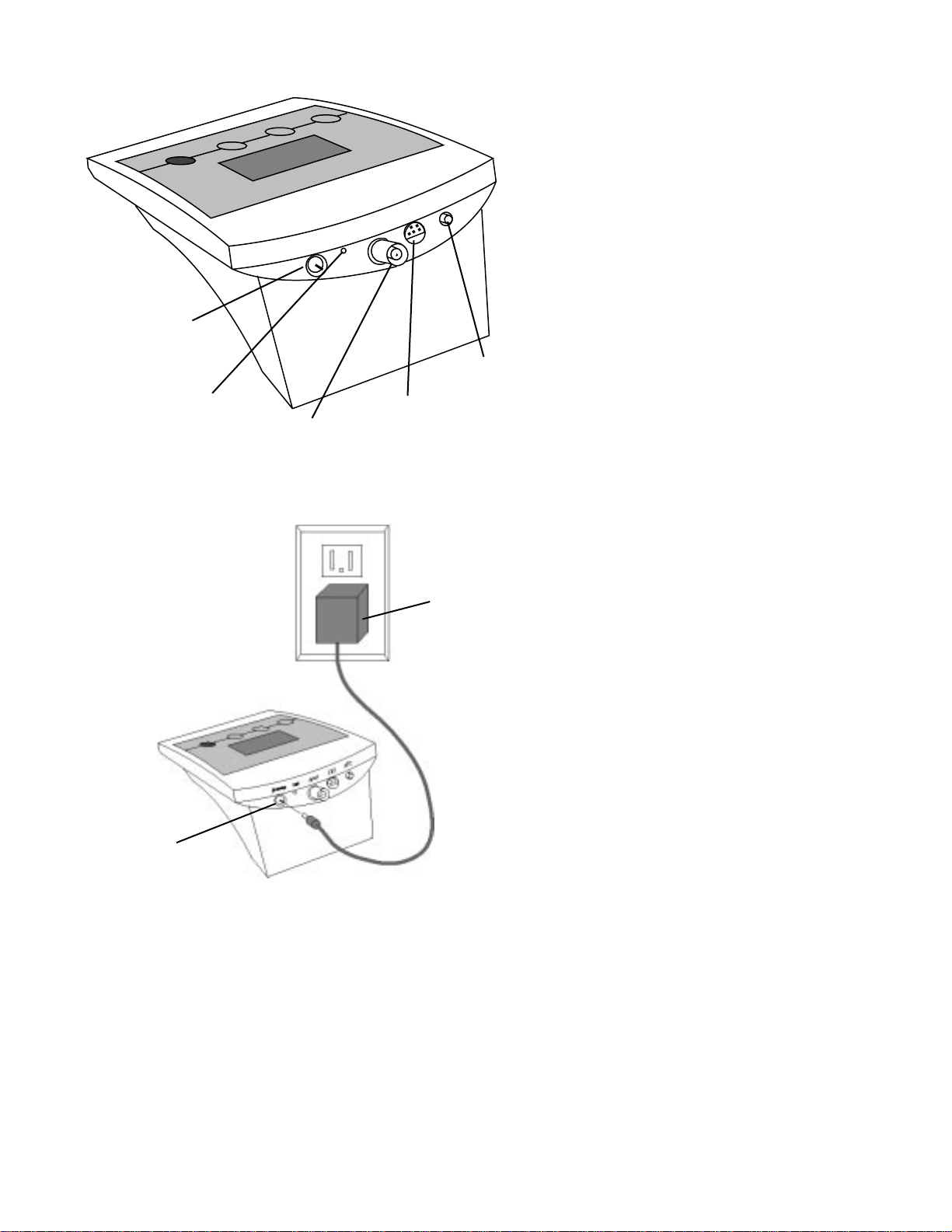

power

ref

input

FET

ATC

Rear Panel Connectors

Power

Cable

Connector

Reference

Electrode

Connector

Glass pH or

ISE

Electrode

Connector

FET

Electrode

Connector

Temperature

Probe

2

AC

Adapter

Power

Connector

Page 7

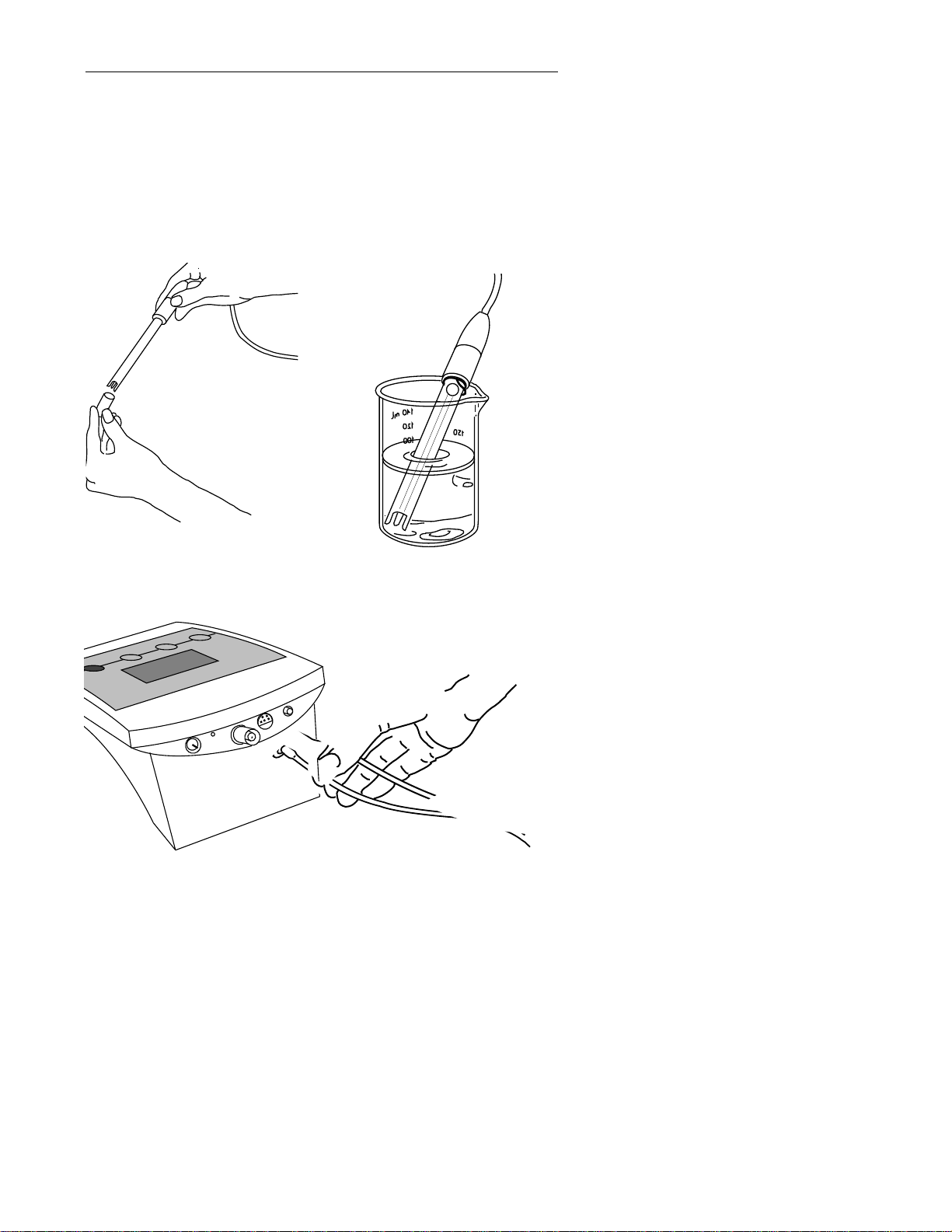

Installing and Maintaining Electrodes

This meter allows you to use two types of pH electrodes: the

pH glass electrode and the field effect transistor (FET) pH electrode.If both types of electrodes are installed,the meter will

read the FET electrode.

NOTE: If both electrodes are connected to the meter, do not put them in a solution together

because you will get inaccurate measurements.

3

1.Remove the protective end

cover from electrode.

3.Remove the shorting cap on the BNC connector.Install the combination glass pH electrode by plugging it into the input connection (twist-lock) and the ATC connector into the ATC jack.

2.Before first use of your glass pH

electrode,or whenever the

electrode is dry,soak over-night

in a filling or KCI solution.

ATC

FET

input

ref

er

w

o

p

Page 8

4

ATC

4.

Option:

Install the optional FET electrode by plugging it into the FET

jack on the back of the meter panel.Allow the FET electrode to

warm up for one minute prior to use.

5.

Option:

Install ORP or Ion Selective Electrode pairs by removing the

BNC shorting cap and plugging the BNC connector (twist-lock)

into the BNC jack.If a combination electrode is not used, plug the

reference electrode into the ref pin.

FET

input

ref

er

w

o

p

ATC

FET

input

ref

er

w

o

p

Page 9

5

6. Rinse and blot-dry electrodes between each

measurement (do not

wipe).Rinse electrodes

with distilled water or

deionized water,or part

of the next solution to be

measured.

7. Store glass and FET pH electrodes in electrode filling solution or KCI solution.Always

leave the filling hole open

and refill with filling solution

when the internal solution

level gets low.

Page 10

6

E

Standardizing for pH Measurement

Because electrodes vary in their response,you must standardize your pH meter and electrode to compensate for electrode

variation.The more frequently you standardize,the more

accurate your measurements.Standardize daily,or more

often,for accurate results.

1.Immer se electrode in a buffer

solution.Stir gently.

pH

4.12

2.Press and release the pH/mV

button until your digital display indicates pH mode.This

button toggles between pH

and mV modes.

pH

Clear

Buffers

3.Clear existing buffers when

doing a new 2 or 3 point standardization.Use the Setup

button to clear existing buffers

and to select a new set of

buffers.

4.Press Standardize.The meter

recognizes the buffer and

flashes a buffer icon.When

the signal is stable,or when

you press Enter,the buffer is

entered.

pH

4.00

Standardizing

4

nter

pH/mV Standardize

Setup Enter

pH/mV Standardize

Setup Enter

pH/mV Standardize

Setup Enter

Page 11

7

pH/mV Standardize

5.The meter displays the %slope

of the electrode as 100.0% On

entering a second or third

buffer,the meter performs a

diagnostic check on the electrode.

%slope

100.0

4

6.To enter a second buffer,

place the electrode in the

second buffer solution and

press Standardize again.The

meter recognizes the buffer

and displays the first and second buffer icons.

pH

7.00

Standardizing

4 7

7.Next, the meter performs a

diagnostic test of the electrode.The display indicates

either Good Electrode or

Electrode Error.The meter displays the % slope of the electrode.

8.Electrode Error indicates that

your electrode is not working

properly. The electrode

response must be between 90

and 105% slope.Measurements causing Electrode Error

are not accepted,used or

stored by the meter.

%slope

99.4

Good Electrode

4

%slope

82.3

Electrode Error

4

Setup Enter

pH/mV Standardize

Setup Enter

pH/mV Standardize

Setup Enter

pH/mV Standardize

Setup Enter

Page 12

8

pH/mV Standardize

9.To set a third standard,place

the electrode in the third

buffer solution and press

Standardize.The results will be

the same as in steps 6 and 7,

except the display will show

three buffer icons.

10.After enter ing each buffer,

the

Standardizing

icon goes

off and the

Measuring

icon

appears on the display to

indicate that the meter

returns to

Measuring

.

22.5°C

pH

10.03

Standardizing

4 7 10

11.The first set of buffers in the

meter is used at 25°C in

North America and, typically,

at 20°C in Europe.In pH

mode,press Standardize and

Setup together to show the

current buffer temperature

setting.Press both

Standardize and Setup again

to toggle between the temperature settings.Press Enter

to select the displayed temperature setting and to

return to

Measuring.

12.Standardize your meter and

electrode using at least two

buffers with pH values bracketing the expected pH of

your samples.Stirr ing with a

magnetic stir bar and stirrer

provides faster electrode

response.

25°C

Set Buffer

2 4 7 10 12

pH

10.00

Standardizing

4 7 10

NOTE: The meter continually

adjusts for temperature. Therefore,

buffers may vary slightly from the

nominal values because of temperature variations.

Setup Enter

pH/mV Standardize

Setup Enter

pH/mV Standardize

Setup Enter

Denver Instrument

22.2¡C

pH

S

6

0

.

4

g

n

i

r

u

s

a

e

M

4

Enter

Setup

Standardize

pH/mV

BASIC

Page 13

9

Using Setup

The Setup button lets you clear all the buffers that you have

entered,review calibration information,or select the buffer set

that you want.

NOTE: You can escape setup mode at any

time by pressing pH/mV.

1.Press Setup and the meter displays a flashing

Clear Buffers

icon.

Use this step only when

you wish to clear all buffers

you have entered

.To clear all

existing buffers, press Enter.The

meter clears all buffers and

returns to

Measuring.

2.Press Setup again to show

electrode performance.If the

meter has accepted an electrode and buffers, it will display

Good Electrode

,display

the slope between the first

and second buffers and display the two buffer icons.

3.Pressing Setup again shows

the electrode slope between

the second and third buffers

(if three buffers have been

entered) and shows the second and third buffer icons.

4.Press Setup again to display a

flashing

Set Buffers

icon and

to display the first buffer set

icons.

%slope

99.4

Good Electrode

4

pH

Set Buffers

2 4 7 10 12

pH

Clear

Buffers

%slope

98.7

Good Electrode

7 10

pH/mV Standardize

Setup Enter

pH/mV Standardize

Setup Enter

pH/mV Standardize

Setup Enter

pH/mV Standardize

Setup Enter

Page 14

10

5.Press Enter to select the set of

buffers shown on the display

or

Press Setup again to view the

next set of buffers. Continue

pressing Setup to view the

third and fourth buffer sets.

6.Press Enter to select the displayed buffer set that contains the buffer you want to

use.Press Setup again,or

press pH/mV at any time,to

return to

Measuring

.

NOTE: You may mix buffers

from different sets.

pH

Set Buffers

1.68 4.01 6.86 9.18 12.46

pH

Set Buffers

1 3 5 8 10 13

pH/mV Standardize

Setup Enter

pH/mV Standardize

Setup Enter

Page 15

11

E

Standardizing for Millivolt

Measurement (Relative Millivolts)

You will use millivolt measurement for measuring ion concentration

and for measuring redox potential (also called ORP, oxidation reduction potential).You will normally use an ion selective electrode (ISE),

combined with a reference electrode,to measure ion concentration.

The ISE senses the ion concentration and responds with a millivolt

potential.The millivolt readings are then used to calculate ion concentrations.You will normally use a platinum indicator electrode,

combined with a reference electrode,to measure redox potential

(ORP).ORP measurements indicate the oxidizing or reducing capability of a solution.You can use ORP values to monitor or control solutions requiring a set amount of oxidants or reductants.

1.Immer se electrode in a standard solution.

mV

100.0

2.Press the pH/mV button until

your digital display indicates

mV mode.

3.Press Standardize to enter a

mV standard and read relative mV.

NOTE: Relative mV mode is not

allowed with the FET electrode.

4.When the signal becomes stable,or when you press Enter,

the current absolute mV

value becomes zero relative

millivolts.

rel mV

0.0

Measuring

mV

100.0

Standardizing

nter

pH/mV Standardize

Setup Enter

pH/mV Standardize

Setup Enter

pH/mV Standardize

Setup Enter

Page 16

pH/mV Standardize

5.To clear a mV offset and

return to absolute millivolt

mode,press Setup.The meter

displays a flashing

Clear

icon,

and the current relative millivolt offset.

6.To clear your previous mV

standard,press Enter.You then

return to absolute mV mode.

rel mV

0.0

Measuring

mV

100.0

Clear

12

Measuring pH or Millivolts

1.Standardize your meter. See page 10.

2.Rinse electrode and immerse in sample solution.Stir gently.

3.Press pH/mV until your display indicates the correct mode.

4.The display shows the current reading in pH, mV,or relative

mV units.When the signal is stable, the meter displays the S

icon.The S icon means the signal is changing less than 0.007

pH or 0.08 mV from the prior reading.

5.You may receive an out of range error, Err,if your electrode is

not immersed in a solution.To correct the error,immerse the

electrode in a solution.

6.Separate calibrations for the glass and FET electrodes are

stored in memory.Plugging the FET in recalls it’s calibration,

unplugging the FET recalls the glass electrode calibration.

Measuring

S

rel mV pH

Err

Electrode Error

Measuring

Setup Enter

pH/mV Standardize

Setup Enter

pH/mV Standardize

Setup Enter

pH/mV Standardize

Setup Enter

Page 17

13

Understanding pH Theory

Defining pH

The measurement of pH plays an important role in identifying

and controlling acidity and alkalinity levels for industry and

research. pH is a measure of the acidity or alkalinity of a solution and can be represented by this equation:

pH = -log [H+]

with [H+] representing the concentration of hydrogen ions in

the solution. pH is sometimes referred to as the power of the

hydrogen ion in a solution.

By using a pH meter,you can determine exact pH levels of

solutions. For example, rather than say that lemon juice is quite

acidic,you can say that lemon juice has a pH of 2.4. An

exact pH value can be used to control or measure acidity levels for manufacturing processes or for basic research.

pH values generally range from 0 to 14,with a pH value of 7

being the neutral point,or the value of pure water. The pH

values above the neutral point represent increasing alkalinity,

whereas pH values below the neutral point represent increasing acidity (Figure 1).

Strong Acid

Lemon Juice

Tomato Juice

Coffee

Pure water

Baking Soda

Ammonia

Strong Base

Neutral

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14

more acidic

more basic

pH

Figure 1.

pH Scale showing the relative acidity or basicity

of some common substances.

Page 18

Measuring pH

To measure pH with a conventional glass pH electrode,the

meter uses a pH-sensing glass bulb electrode that is sensitive

to hydrogen ions.The potential developed at the glass bulb is

directly related to the pH of the solution.

The glass bulb electrode is paired with a reference electrode

which completes the electrical measuring circuit and provides

a stable reference point.These two electrodes are joined to

create a combination electrode.The combination glass electrode is connected to the pH meter which reads the voltage,

converts it to pH units,and displays the result.

Combination Glass pH Electrode

This meter can also use a field effect transistor (FET) electrode

for measuring pH.The FET uses an ion-sensitive solid state

membrane attached to the transistor to measure the hydrogen ion concentration of a solution.The FET is paired with a

reference electrode and counter electrode that maintain a

constant potential while the FET responds to the sample.

14

Reference

Electrode

(Outer Body)

Glass

Membrane

Glass

Electrode

(Inner Body)

Porous

Junction

Glass

Membrane

Temperature

Sensor

Reference

Electrode

pH-Sensitive

Membrane

Counter

Electrode

FET

Temperature

Sensor

Annular Porous

Junction

Page 19

Troubleshooting

15

Err

Electrode Error

1. If the signal from the electrode is

out of range

,the display will show Err.This may

happen when the electrode

is not in a solution.

Electrode Error

2. The meter will display

Electrode Error

when it

detects an error in electrode

response.During standardization,the message indicates

that the electrode is less than

90% or more than 105% of the

correct response.The

Electrode Error

message can

indicate either a bad electrode or bad buffer(s).

Err°C

Error

3. If the meter detects an error

in the temperature probe,the

display shows

Err°C

.If you do

not use a temperature probe,

the meter uses the default

temperature that you set to

either 20°C or 25°C.

4. To test the pH electrode,

place it in a good pH 7

buffer. Press pH/mV to use the

mV mode,and note the millivolt reading.Repeat for either

a pH 4 or pH 10 buffer. The

electrode signal must be

within the limits shown below

(when temperature is near

25°C).

Electrode Test

pH 7 0 + 30 mV

pH 4 159 to 186 mV

more than pH 7

pH10 159 to 186 mV

less than pH 7

pH/mV Standardize

Setup Enter

pH/mV Standardize

Setup Enter

pH/mV Standardize

Setup Enter

Page 20

16

Cal

Error

5. To test the meter for correct operation,install the BNC (input) shorting cap.

Press pH/mV to use the mV mode,and note the mV reading.If the meter

reads ) + 0.5 mV,it is measur ing correctly.

6. If the meter detects a loss of

calibration or a hardware

error during its power-up selftest,the display shows

CAL

Error

.This means the mV

accuracy may be reduced,

but pH accuracy after standardization will be the same.

Press Enter to continue using

the meter.If recalibration is

desired,contact Technical

Support.

ATC

FET

input

ref

er

w

o

p

pH/mV Standardize

Setup Enter

Page 21

Meter Specifications

pH -1.99 to 19.99 pH

displayed to 0.01 pH

accurate to 0.01 pH

mV -1800.0 to 0.01 mV

displayed to 0.1 mV

accurate to 0.5 mV

Temperature -5.0 to 105.0°C

displayed to 0.1°C

accurate to 0.1·°C

Standardization 0,1, 2 or 3 buffers

Auto buffer recognition 22 buffers

2,4, 7, 10,12

1,3, 6,, 8,10, 13

1.68,4.0, 6.86, 9.18,12.46

1.09,3.06, 4.65, 6.79,9.23, 12.75

Auto Temperature Compensation

Automatic electrode slope correvtion for 90-105%

Direct reading with both a glass and FET pH electrode

17

Page 22

Page 23

WARRANTY/DISCLAIMER

MEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and

orkmanship for a period of 37 months from date of purchase. OMEGA Warranty adds an

dditional one (1) month grace period to the normal three (3) years product warranty to

over handling and shipping time. This ensures that OMEGA’s customers receive maximum

overage on each product.

the unit should malfunction, it must be returned to the factory for evaluation. OMEGA’s

ustomer Service Department will issue an Authorized Return (AR) number immediately upon

hone or written request. Upon examination by OMEGA, if the unit is found to be defective it will

e repaired or replaced at no charge. OMEGA’s WARRANTY does not apply to defects resulting

om any action of the purchaser, including but not limited to mishandling, improper interfacing,

peration outside of design limits, improper repair, or unauthorized modification. This

WARRANTY is VOID if the unit shows evidence of having been tampered with or shows evidence

f being damaged as a result of excessive corrosion; or current, heat, moisture or vibration;

mproper specification; misapplication; misuse or other operating conditions outside of OMEGA’s

ontrol. Components which wear are not warranted, including but not limited to

ontact points, fuses, and triacs.

MEGA is pleased to offer suggestions on the use of its various products. However,

MEGA neither assumes responsibility for any omissions or errors nor assumes liability for

ny damages that result from the use of its products in accordance with information proided by OMEGA, either verbal or written. OMEGA warrants only that the parts

manufactured by it will be as specified and free of defects. OMEGA MAKES NO OTHER

WARRANTIES OR REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESSED OR

MPLIED, EXCEPT THAT OF TITLE, AND ALL IMPLIED W ARRANTIES INCLUDING ANY WAR-

ANTY OF MERCHANTABILITY AND FITNESS FOR A P AR TICULAR PURPOSE ARE HEREBY

ISCLAIMED. LIMITATION OF LIABILITY: The remedies of purchaser set forth herein are

xclusive and the total liability of OMEGA with respect to this order, whether based on con-

act, warranty, negligence, indemnification, strict liability or otherwise, shall not exceed

he purchase price of the component upon which liability is based. In no event shall OMEGA

e liable for consequential, incidental or special damages.

ONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as

“Basic Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity;

r (2) in medical applications or used on humans. Should any Product(s) be used in or with any

uclear installation or activity, medical application, used on humans, or misused in any way,

MEGA assumes no responsibility as set forth in our basic WARRANTY/DISCLAIMER language,

nd additionally, purchaser will indemnify OMEGA and hold OMEGA harmless from any liability

r damage whatsoever arising out of the use of the Product(s) in such a manner .

RETURN REQUESTS / INQUIRIES

irect all warranty and repair requests/inquiries to the OMEGA Customer Service Department.

EFORE RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN

UTHORIZED RETURN (AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT

N ORDER TO AVOID PROCESSING DELAYS). The assigned AR number should then be

marked on the outside of the return package and on any correspondence.

he purchaser is responsible for shipping charges, freight, insurance and proper packaging to

revent breakage in transit.

OR W

ARRANTY RETURNS, please have

he following information available BEFORE

ontacting OMEGA:

. P.O. number under which the product was

PURCHASED,

. Model and serial number of the product

under warranty, and

. Repair instructions and/or specific

problems relative to the product.

FOR NON-WARRANTY REPAIRS,

consult

OMEGA for current repair charges. Have the

following information available BEFORE

contacting OMEGA:

1. P.O. number to cover the COST

of the repair,

2. Model and serial number of product, and

3. Repair instructions and/or specific problems

relative to the product.

MEGA’s policy is to make running changes, not model changes, whenever an improvement is possible.

his affords our customers the latest in technology and engineering.

MEGA is a registered trademark of OMEGA ENGINEERING, INC.

Copyright 1996 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied,

produced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without

ior written consent of OMEGA ENGINEERING, INC.

UUSASA

MADE

ININ

Page 24

M2832/0298

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

TEMPERATURE

MU

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

MU

Wire: Thermocouple, RTD & Thermistor

MU

Calibrators & Ice Point References

MU

Recorders, Controllers & Process Monitors

MU

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

MU

Transducers & Strain Gauges

MU

Load Cells & Pressure Gauges

MU

Displacement Transducers

MU

Instrumentation & Accessories

FLOW/LEVEL

MU

Rotameters, Gas Mass Flowmeters & Flow Computers

MU

Air Velocity Indicators

MU

Turbine/Paddlewheel Systems

MU

Totalizers & Batch Controllers

pH/CONDUCTIVITY

MU

pH Electrodes, Testers & Accessories

MU

Benchtop/Laboratory Meters

MU

Controllers, Calibrators, Simulators & Pumps

MU

Industrial pH & Conductivity Equipment

DATA ACQUISITION

MU

Data Acquisition & Engineering Software

MU

Communications-Based Acquisition Systems

MU

Plug-in Cards for Apple, IBM & Compatibles

MU

Datalogging Systems

MU

Recorders, Printers & Plotters

HEATERS

MU

Heating Cable

MU

Cartridge & Strip Heaters

MU

Immersion & Band Heaters

MU

Flexible Heaters

MU

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

MU

Metering & Control Instrumentation

MU

Refractometers

MU

Pumps & Tubing

MU

Air, Soil & Water Monitors

MU

Industrial Water & Wastewater Treatment

MU

pH, Conductivity & Dissolved Oxygen Instruments

Loading...

Loading...