Page 1

http://www.omega.com

e-mail: info@omega.com

User ’s Guide

PHB-215 pH Meter

PHB-220 pH/Conductivity Meter

PHB-225 pH/Ion Meter

PHB-250 pH/Ion/Conductivity Meter

PHB-215

pH m

eter

Page 2

Servicing North America:

USA: One Omega Drive, Box 4047

ISO 9001 Certified Stamford, CT 06907-0047

Tel: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1

Tel: (514) 856-6928 FAX: (514) 856-6886

e-mail: canada@omega.com

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

SM

Customer Service: 1-800-622-2378 / 1-800-622-BEST

SM

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

SM

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico and

Latin America:

Tel: (95) 800-TC-OMEGA

SM

FAX: (95) 203-359-7807

En Espan÷ol: (203) 359-7803 e-mail: espanol@omega.com

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

Tel: (31) 20 6418405 FAX: (31) 20 6434643

Toll Free in Benelux: 06 0993344

e-mail: nl@omega.com

Czech Republic: ul. Rude armady 1868, 733 01 Kavrine-Hranice,

Czech Republic

Tel: 420 (69) 6311627 FAX: 420 (69) 6311114

e-mail: czech@omega.com

France: 9, rue Denis Papin, 78190 Trappes

Tel: (33) 130-621-400 FAX: (33) 130-699-120

Toll Free in France: 0800-4-06342

e-mail: france@omega.com

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: 49 (07056) 3017 FAX: 49 (07056) 8540

Toll Free in Germany: 0130 11 21 66

e-mail: germany@omega.com

United Kingdom: 25 Swannington Road, P.O. Box 7, Omega Drive,

ISO 9002 Certified Broughton Astley, Leicestershire, Irlam, Manchester,

LE9 6TU, England M44 5EX, England

Tel: 44 (1455) 285520 Tel: 44 (161) 777-6611

FAX: 44 (1455) 283912 FAX: 44 (161) 777-6622

Toll Free in England: 0800-488-488

e-mail: uk@omega.com

omega.comomega.com

OMEGAnetSMOn-Line Service Internet e-mail

http://www.omega.com info@omega.com

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that

apply. OMEGA is constantly pursuing certification of its products to the European New Approach

Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct but OMEGA Engineering, Inc. accepts

no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient connected applications.

OMEGA

TM

®

Page 3

Quick Start Guide for pH Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . Page ii

Introduction

Menu Keys,Softkeys and Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Electrode Connectors and Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

LCD Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Function Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Electrodes

Preparing pH and Ion Selective Electrodes. . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Connecting Electrodes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Using and Storing Electrodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

pH Electrodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Solid-State FET Electrodes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Ion Selective Electrodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Meter Setup

Meter Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

pH Mode

pH Mode Standardization Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Cal Reminder Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Select Custom Buffer Set. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

pH Mode Options Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Standardizing and Measuring pH. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Clearing Buffers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

mV Mode

mV Mode Standardization Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

mV Mode Options Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Clearing Relative mV Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Quick Start Guide for Ion Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Ion Mode

Ion Mode Standardization Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Standardizing and Measuring Ion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Measuring Ion using a Known Addition type (incremental ion) method. . . 17

Quick Start Guide for Conductivity/Resistivity/Salinity/TDS Measurement. . . . 18

Conductivity/Resistivity/Salinity/TDS Modes

Conductivity/Resistivity/Salinity/TDS Standardize Menu . . . . . . . . . . . . . . . . 19

Conductivity/Resistivity/Salinity/TDS Options Menu . . . . . . . . . . . . . . . . . . . . 20

Data logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Meter Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

pH Theory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Ion Selective Electrode Theory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Determining Isopotential Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

RS-232 Serial Interface Meter Command Set. . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Table of Contents

i

Page 4

1.Connect power cable to meter connector on

the rear panel marked “power”and to AC power

source.

2.Connect the glass pH/ATC electrode to the

channel A BNC connector marked “ch.A”and to

the channel A temperature connector marked

“temp A”.

3.Verify the meter is in pH mode on channel A.Use

the Mode key and Channel key to set the meter

to the correct mode and channel if necessary.

(See Function keys).

4.Standardize the electrode by immersing the

electrode in a buffer,pressing Standardize, pressing 1) Auto-enter a buffer and following the

prompts.Repeat this step to enter each buffer.

The meter will check the electrode and buffers,

and give an error message if there is a problem.

Press Standardize to enter or clear buffers,select

buffers, set resolution, or set other parameters for

the current mode and channel.

5.The display shows the current measurement,and

indicates a stable reading with the indicator.

Press Cal Data to review and graph the electrode calibration data.

ii

Quick Start Guide for pH Measurement

A 7.000

pH

25.0°C

No buffers.

Mode

Channel A: pH mode

Standardize Menu

1) Auto-enter a buffer

2) Manual buffer entry

3) Clear buffers

4) Options menu

5) Cal reminder menu

6) Select buffer set

channel

indicator

units

indicator

Channel

Standardize

A 7.000

pH

25.0°C

4.008 pH

7.000

entered

buffers

“power”

“ch. A”

“temp A”

s

s

stability

indicator

s

c

h

. A

re

f. A

c

h

T

e

m

c

p

o

. A

n

d

. C

T

e

m

p

. B

R

S

2

3

2

C

p

o

w

e

r

c

h

. A

c

h

re

f. A

T

c

e

o

m

n

p

d

. A

. C

T

e

m

p

. B

R

S

2

3

2

C

p

o

w

e

r

Page 5

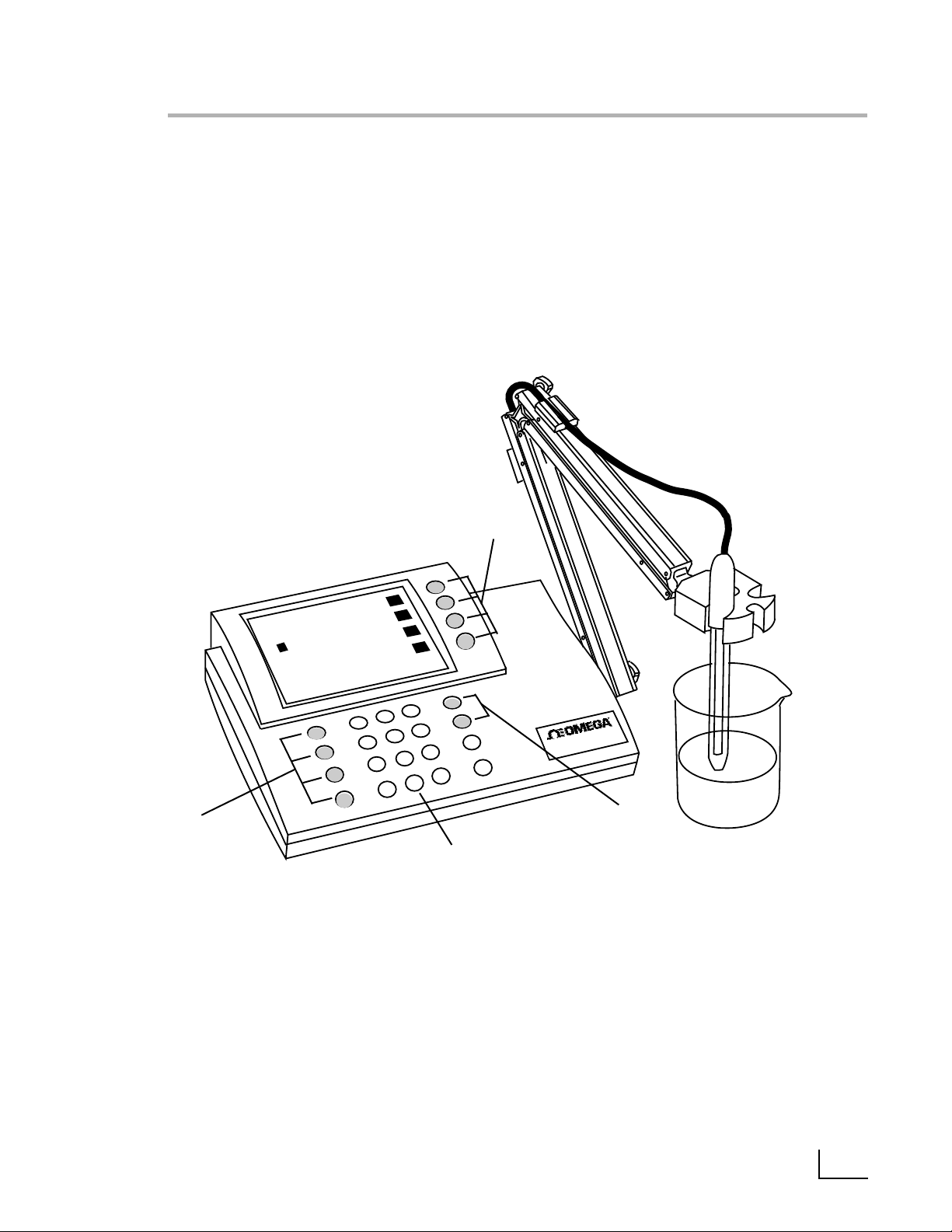

This Omega meter is a powerful,versatile and accurate instrument. It features

easy menu-based operation with easy to understand prompts and

electrode/standard error checking.

These meters feature many advanced options,such as programmable stability

criteria, programmable standardization reading delay times, multi-channel operation,fast reading update rates of twice per second for all channels,programmable alarms, programmable data logging of 500 data points and a superb RS232 serial interface for controlling the meter and obtaining data.

Omega meters use flash programmable ROM for the operating code.The meter

operating code can easily be upgraded as new features are made available.

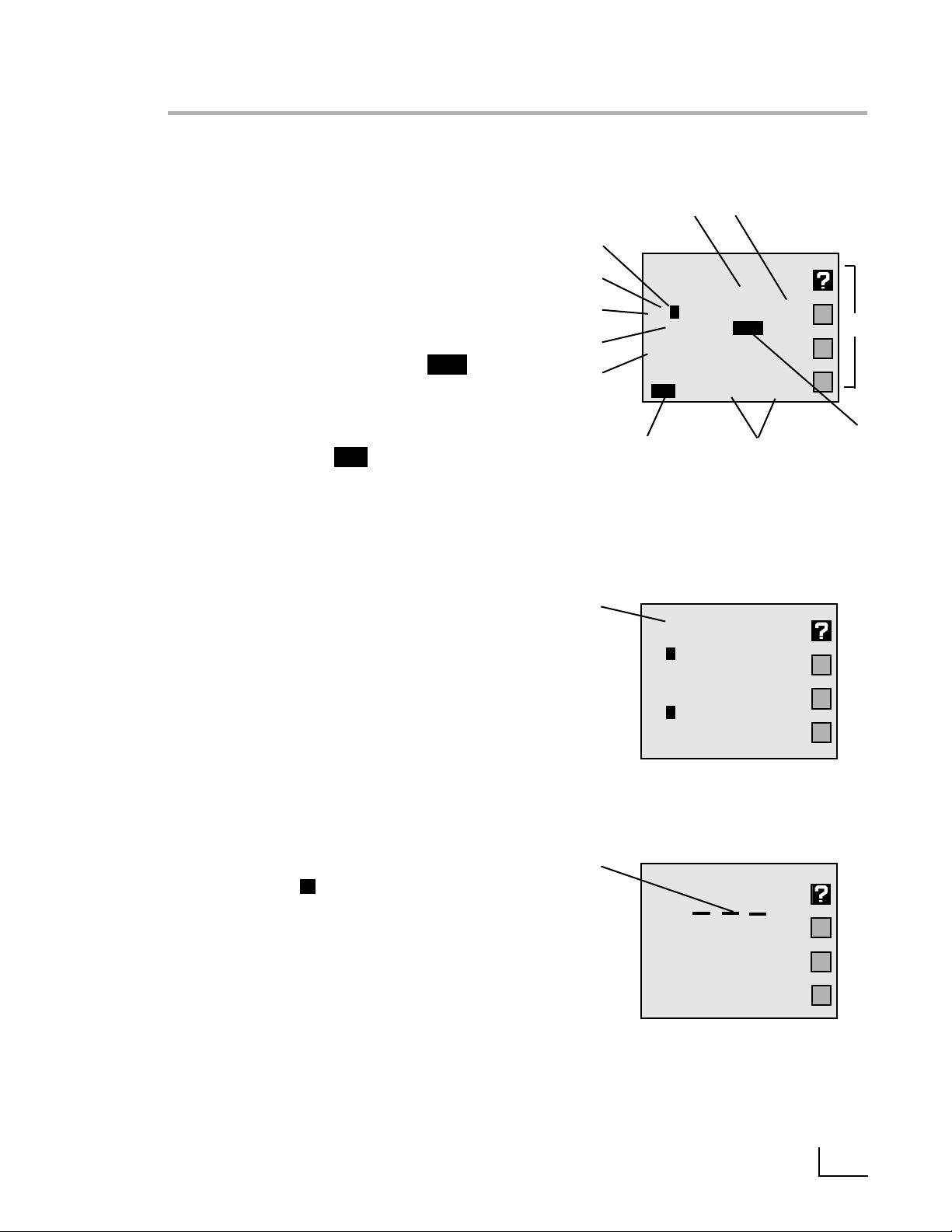

Direct Menu Keys, Softkeys and Display

The meter uses six Direct Menu keys to access the menus and operations (such

as selecting pH mode,standardizing,checking electrode calibration data,

selecting the electrode channel).

There are four Softkeys that provide additional operations; these Softkeys

change their function as needed and each Softkey has an icon to indicate its

current function.

The display is a backlit quarter-VGA screen capable of displaying all four electrode channels (of a PHB-250) simultaneously. The backlight will turn off after a 45

minute period of non-use; pressing any key will automatically turn the backlight

on again.

A S

7.001

pH

25.0¡C

4.008 pH

7.000

6/30/1998 02:28 PM

Denver Instrument

S

1

Introduction

Softkeys

Direct Menu

Keys

Direct Menu

Keys

Numeric

Keypad

PHB-215

pH m

eter

Page 6

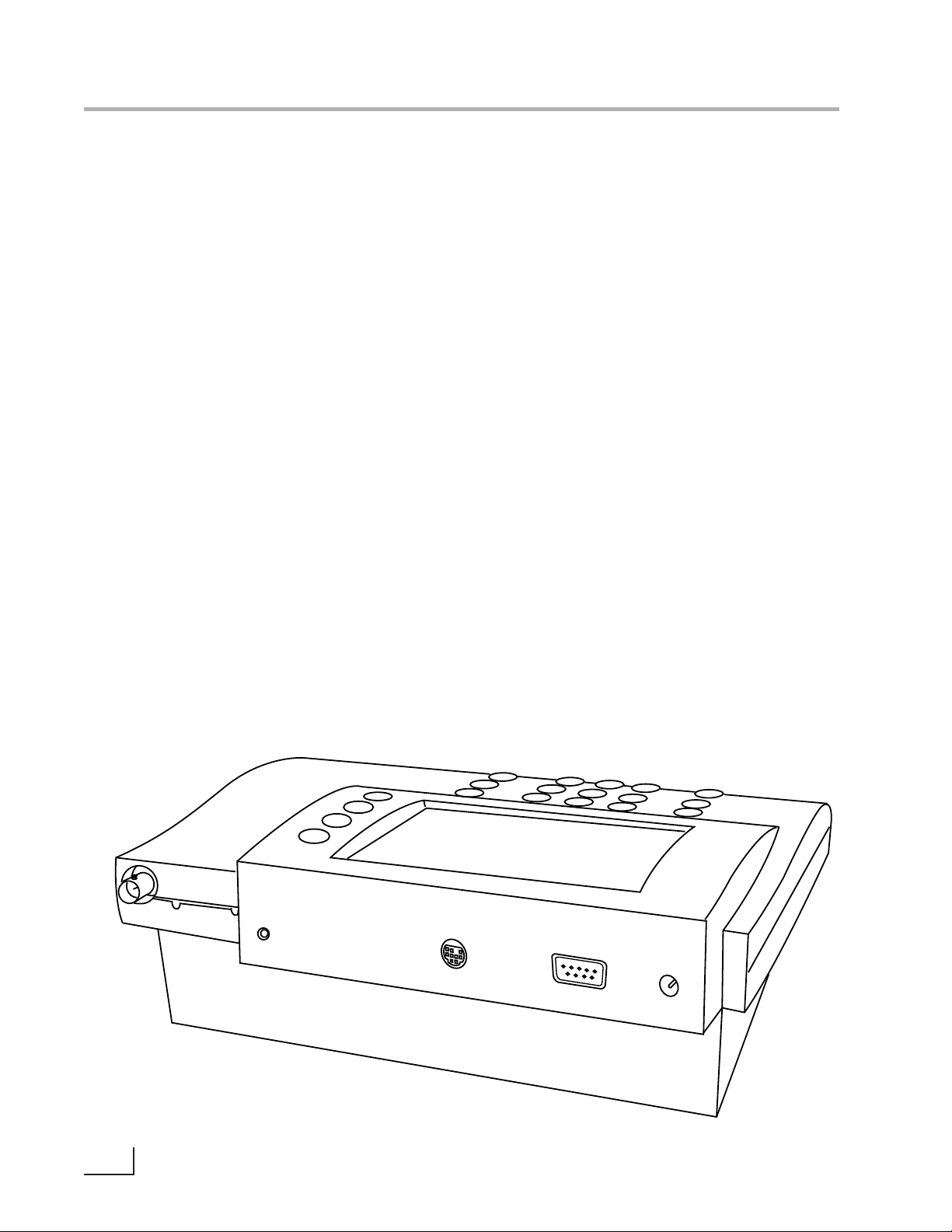

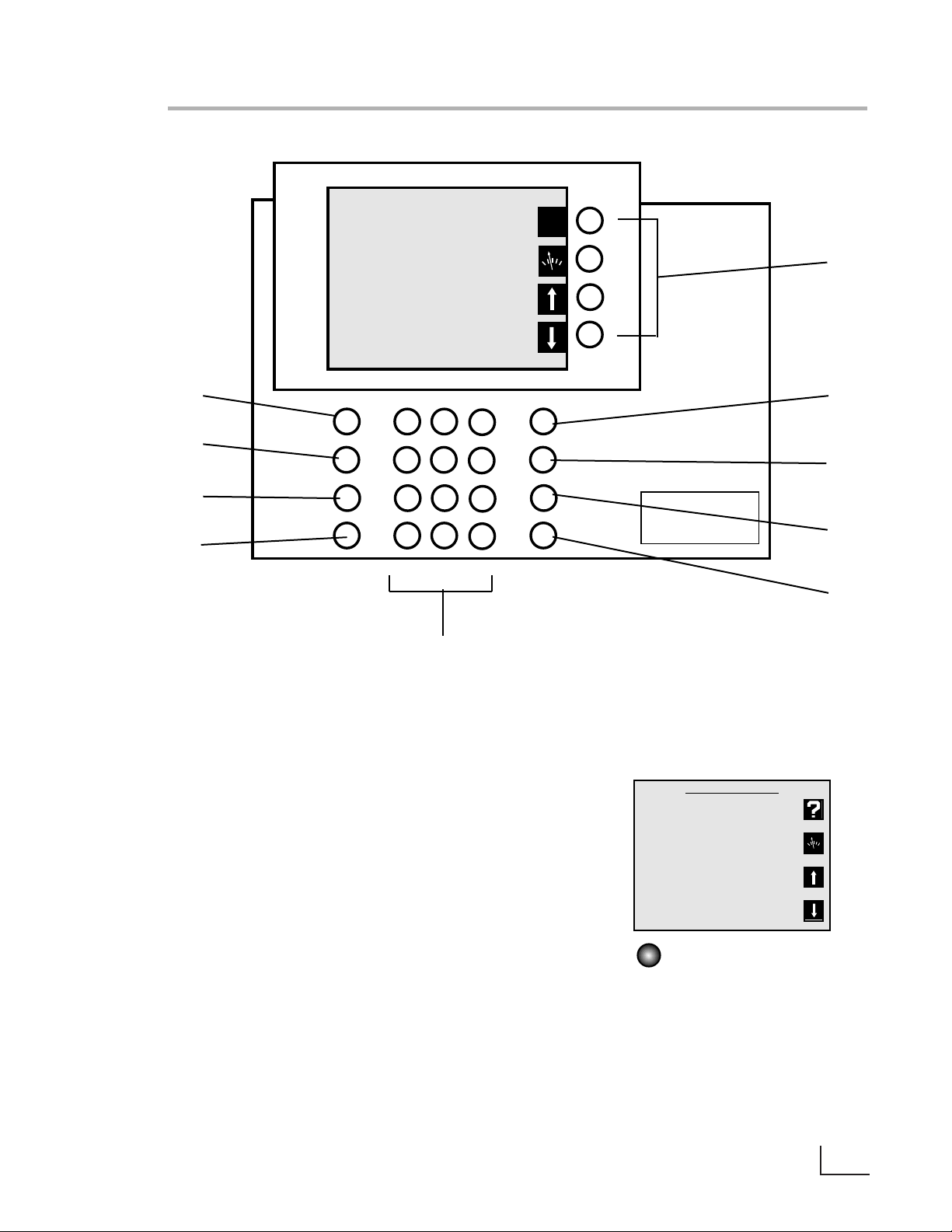

Electrode Connectors and Inputs

BNC ("ch.A" or "ch.B") connectors: pH,Ion

Selective Electrodes and ORP (redox) electrodes attach to the meter through a BNC

("round twist-on") connector to channel A or

channel B (PHB-225 and PHB-250 only).

Temperature ("temp A" or "temp B") connectors: use to connect the 2.5mm mini-phone

plug from the temperature sensor (built into

the pH electrode with the Omega standard

pH/ATC electrode) for Automatic Temperature

Compensation (ATC).

Reference ("ref.A" or "ref.B") connectors: use

for attaching a reference electrode tip-pin

plug when a separate reference electrode is

used.

Conductivity DIN (“ch.C conductivity”)

connector: use to connect a 4-band conduc-

tivity/ATC cell.These 4-band cells offer

improved linearity and stability over older 2band conductivity cells. (PHB-220 and PHB-250

only).

FET DIN ("ch.F FET") connector: use to connect

the Denver Solid-State Field Effect Transistor

(FET) pH/ATC electrode. These non-glass pH

electrodes offer certain advantages over conventional glass pH electrodes.

Serial port ("RS232") DB-9 connector: use to

connect a serial printer or Personal Computer.

This bi-directional interface outputs data and

receives meter commands.

Power (“power”) connector: use to connect a

5.5mm OD x 2.1 ID coaxial connector with

12VDC at 500mA (center pin negative).

2

Introduction

Connectors for PHB-250

ch. A

ref. A

ref

temp

A

ch. F

FET

RS232C

power

Page 7

D

Note: Not all of the following will display at the

same time.

A

. Result: current measurement.

B

.Units: displays the units for the current measure-

ment.Examples: pH, mV, mg/L F-,µS/cm or

W-cm.

C

.Softkey icons: show the current function

assigned to each softkey.

D

.Calibration due reminder: the icon means

a calibration is now due.

E

. Date and time: displayable in different formats.

F

.Da talogging: the icon indicates datalog-

ging is active.

G

.Buffers/Standards: in single channel mode,all

entered buffers or standards are displayed.A

“!”symbol beside a buffer indicates that buffer

is out of the entered calibration valid time (See

Calibration reminder,page 9).

H

.Temperature: displays the measured tempera-

ture when an electrode with ATC or separate

temperature probe is attached.Shows “M”

when a manually entered temperature is being

used.

I

.Alar m: “*”indicator means data is outside the

set alarm limits.

J

Channel: indicates which electrode channel

(input) is being displayed.Channel A and

Channel B (PHB-225 only) are BNC inputs.

Channel F is the FET electrode input.

K

.Stability: the indicates the electrode is sta-

ble to the selected criteria.

L

.Multiple Channel: display can show two

(PHB- 215),three (PHB-220 and PHB-225) or four

(PHB-250) electrode measurements with temperature simultaneously.

M

.Out-of-range or non-valid reading: dashes indi-

cate a measurement is not available.This usually means the reading is out of range,or can

mean in ion mode that no standards have

been entered,or strict calibration has been set

and the calibration expired.

3

Display

*

A 7.000

pH

25.0°C

4.008 pH

7.000

9.999

6/30/1998 02:28 PM

A B

J

I

H

G

E

C

Single channel display

K

F

A 6.998

pH

24.6°C

B 1.02

mg/L

23.4°C F-

30-6-1998 14:28:05

Dual channel display

L

A pH

23.8

°

C

1998.6.30 14:28:30

M

s

s

s

CAL!

Log

S

Page 8

A

.Mode: Selects the mode: pH,mV

(PHB-215),Ion (PHB-225 and PHB-250),

Conductivity - Resistivity-NaCl SalinityPractical Salinity-TDS (PHB-220 and

PHB-250) to use for the currently selected

channel (electrode input).

B

.Standardize: Enters buffers or standards

for the currently selected channel and

mode.Use to enter pH buffers,relative mV

offset,ion standards or conductivity /resistivity standards.

Also used to change other settings which

affect the measurement.

C

.Cal Data: Displays and graphs buffers or

standards with time and date stamp and

electrode calibration data for the selected channel and mode.

D

.Channel: Selects the channel(s) (elec-

trode inputs) to display.The PHB-215 can

display one or two channels simultaneously (Channels A and F).The PHB-225

can display one,two or three channels

simultaneously (Channels A,B and F). The

PHB-220 can display up to three channels

(Channels A,C and F).The PHB-250 can

display up to four channels (Channels A,

B,C and F).

E

.Setup: The Setup menu is used to set vari-

ous general meter settings,such as date

and time,display contrast,keypress beep

and serial port.

F

.Da ta Log: Displays the datalogging menu

used to set datalogging and view the

stored Data Log (see Datalogging).

G

.Clear: Exits from the current menu and

returns to the previous menu,cancels the

current operation or clears a number

entry.

H

.Enter/Pr int: Accepts numeric values,menu

selections or pending operations.In the

main measure screen,acts as a Print key,

sending all current measurements to a

printer/ computer through the serial port

and stores the measurements in the Data

Log.

I

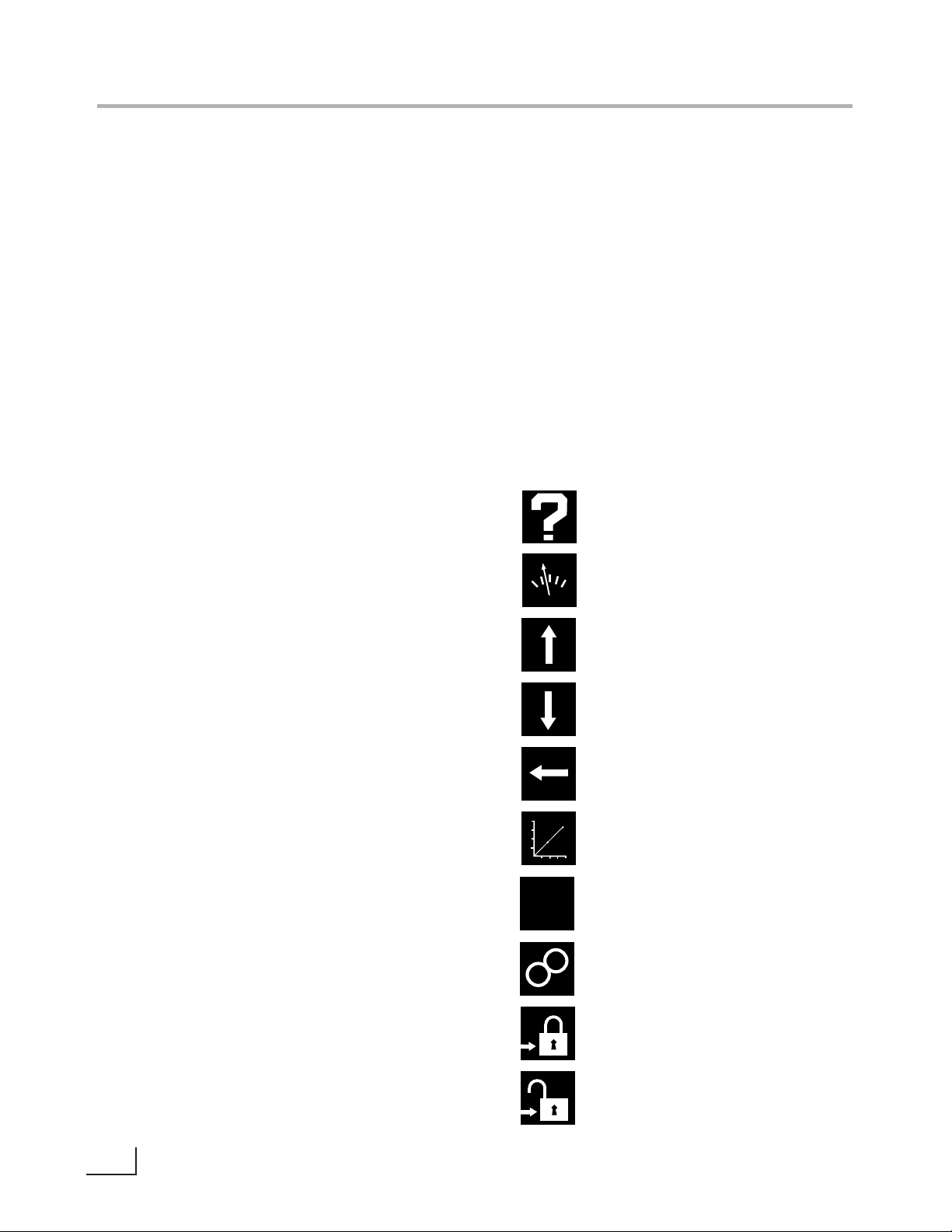

.Softkeys: These four keys access different

operations at different times.Most menus

offer a “Help” softkey and the “Measure”

softkey, w hich allows a direct return to the

main measuring screen,exiting all menus

immediately. The “Up Arrow”and “Down

Arrow”softkeys offer one way to select a

menu item.The “Left Arrow”key is a backspace,active during number entry.

J

.Numer ic Keys: Pressing a number key

selects a numbered item in a menu.The

number keys also allow entering values for

buffers, standards, and various meter settings.

4

Function Keys

Help

Measure

Scroll up

Scroll down

Backspace

Graph

Exponent number entry

Incremental ion method

Measure lock

Measure unlock

Softkeys

E

–

+

Page 9

5

Function Keys

A

B

C

D

E

F

G

H

I

J

Channels

The Channel key is used to turn on or off each

available channel.In single-channel operation,

additional information for the selected channel is

provided,including a display list of all entered

buffers or standards. In multi-channel operation,

the Mode,Standardize and Cal Data menus ask

for the channel before accessing the menu.

The PHB-215 offers single or dual channel operation using channel A ( pH and ORP electrodes)

and channel F (Solid-state FET pH electrode).The

PHB-225 offers up to three-channel simultaneous

operation of channel A and channel B (pH,ORP

and Ion Selective Electrodes) and channel F

(Solid-state FET pH electrode).

The PHB-220 has Channel A (pH and ORP electrodes),Channel C (Conductivity cells) and

Channel F (solid-state FET pH electrode).The

PHB-250 provides up to four channel measurement with Channel A and Channel B (pH and

ORP and Ion Selective electrodes),Channel C

(Conductivity cells) and Channel F (solid-state

FET pH electrode).

Configure Display

1) Turn channel A on/off: ON

2) Turn channel B on/off: ON

3) Turn channel F on/off: OFF

4) Turn channel C on/off: ON

5) Measurement screen

PHB-250 Select Channel

screen

Channel

?

Mode

Standardize

Data Log

Cal Data

Channel

Enter/Print

Setup

Clear

Page 10

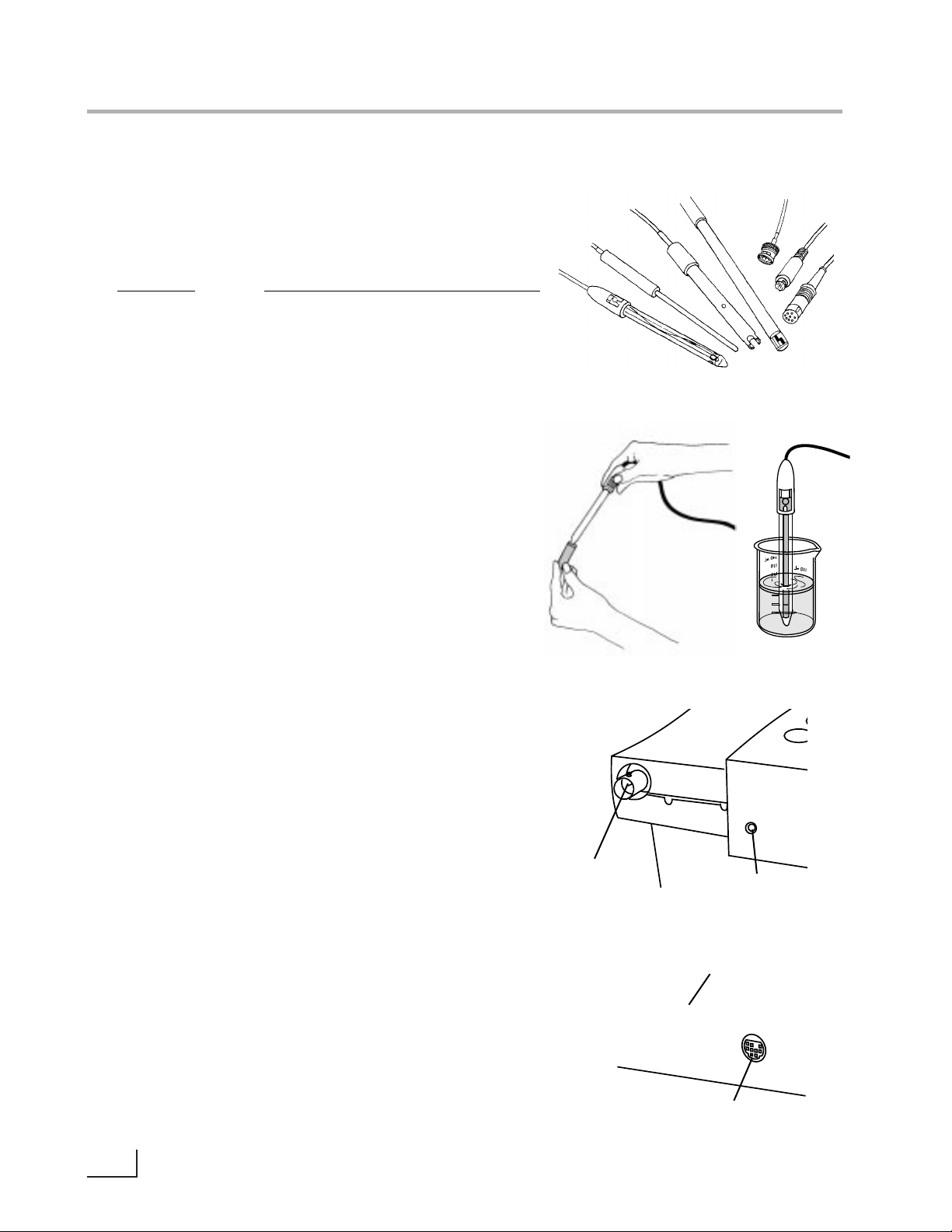

The meter allows you to use a variety of glass membrane (“glass”) pH/ATC electrodes,ion selective electrodes,Conductivity/ATC cells,the Omega Field Effect

Transistor (FET) Solid-State pH/ATC electrode,temperature (ATC) probes, combination electrodes using a BNC

connector,or separate electrode pairs with BNC connector and reference pin.

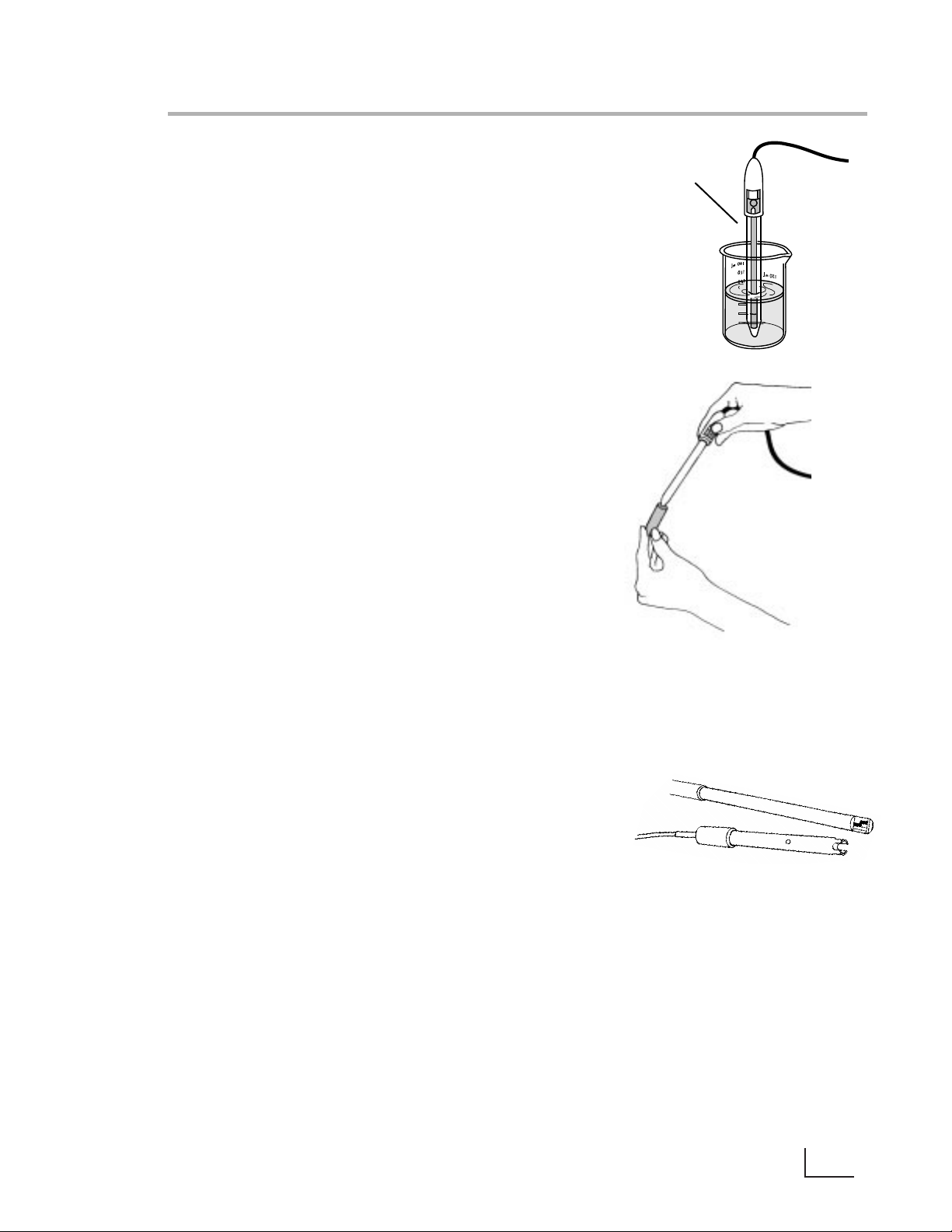

Preparing Electrodes and Conductivity Cells

Remove the wetting cap or storage cap from the electrode.Before first using your pH electrode or whenever

the electrode is dry,soak it several hours in an electrode filling or storage solution (3 Molar KCl solution) or

in a buffer for pH electrodes. Condition ISE’s in the recommended solutions. Rinse Conductivity cells with

deionized water before use.

Connecting Electrodes

pH, ORP or ISE electrodes (with BNC connector):

Connect the electrode to the BNC input,either channel A or channel B (PHB-225 and PHB-250 only),located

at the rear of the meter.Push in and rotate the electrode’s BNC connector until it locks in place.Connect

the ATC connector to the temp.A or temp.B connector. To disconnect, twist the BNC connector in the

opposite direction and pull.

Electrode Pair Using a Reference Electrode (with

Reference Pin Plug):

Connect the indicating electrode to the BNC input.

Connect the reference electrode to the Reference

input.Push the electrode’s tip pin plug into the input to

connect and pull out to disconnect.

Conductivity Cells (with DIN connector):

Align and push in the DIN connector fully to the channel C input (PHB-220 and PHB-250 only).Pull carefully to

disconnect.

6

Electrodes

To measure Use channel (connector)

pH A (BNC)*

or

B (BNC)*

mV (ORP) A (BNC)*

or

B (BNC)*

ion (ISE) A (BNC)*

or

B (BNC)*

Conductivity C (DIN)

Resistivity C (DIN)

Salinity C (DIN)

TDS C (DIN)

pH (FET) F (mini-DIN)

*Separate reference electrodes can be used with “Ref A”or

“Ref B”connectors

BNC

Connector

Channel C

Conductivity Input

ATC

Connector

Channel F

FET pH Input

ch. A

ref. A

ref

temp

A

ch. F

FET

Page 11

Using and Storing Electrodes

pH Electrodes

• Provide moderate stirring for faster electrode

response.

• Leave the fill hole open during all use.

• Rinse the electrode between each measurement

with a portion of the next sample or buffer to be

measured,or with deionized or distilled water.

• Keep glass electrodes wet when not being used

by placing some electrode filling solution in the

wetting cap and storing with the wetting cap on.

• Keeping glass electrodes “wet”will improve their

performance.Store electrodes in electrode filling

solution or storage solution (3M KCl).

Solid-State FET Electrode

• All models allow use of both standard glass

pH/ATC and Solid-State FET (Field Effect Transistor)

pH/ATC electrodes.The meter can store a calibration for both types of electrodes.Plug the FET

electrode into the channel F mini-DIN input.

• Allow the FET about 1 minute to stabilize when

first connected.The FET electrode can be stored

dry or in electrode storage solution.Provide moderate stirring.

Ion Selective Electrodes

• Add proper amount of Ionic Strength Adjuster

(ISA) to all standards and samples,usually 1 mL

ISA to 50 mL standard or sample.

• Provide moderate stirring for faster electrode

response.

• Rinse the electrode(s) between each measurement with a portion of the next sample or standard to be measured,or with deionized or distilled water.

• Follow the instruction sheets for the individual

electrode.Store as recommended.

Conductivity Cells

• When changing samples or standards,immerse

the cell into the new solution,then lift and allow

solution to drain out.Repeat two more times.

• Gently tap cell to dislodge air bubbles.

7

Electrodes

Store with wetting

cap and Fill

Solution (3M KCl)

Provide

moderate

stirring

Store FET and

Conductivity

Cells dry

Page 12

Meter Setup Menu

Press Setup to access the Meter Setup menu:

1.Time and date menu: use to set the time format

(HH:MM AM/PM or HH:MM:SS),set the time,set the

date format (MM/DD/YY,DD-MM-YY or YYYY.MM.DD),

and set the date.

2.Select temperature units: use to select temperature

measurement and display in degrees Celsius,degrees

Fahrenheit or Kelvin.

3.Select contrast: use to select the display contrast, making the displayed characters lighter or darker.Select

setting “5”for typical conditions.

4.Select baud rate: use to set the ser ial RS232 port baud

rate. This must match the baud rate setting of the

printer or computer being used with the meter.

5.Setup serial port: use to configure the serial port start

bits and parity setting. This must match the settings of

the printer or computer being used with the meter.

6.Keypress beep on/off: use to turn on or off a "beep"

upon each keypress as an audible signal that a key

has been pressed.

7.Select video color scheme: use to set the display to

black characters on a white background or white

characters on a black background.

8.Show meter information: use to show the meter

model,software version and serial number.

9.Enable measure lock: use to enable the measure lock

where a stable measurement is locked (frozen) for

later review. Sta bility criter ia should be set to SLOW for

all channels and modes in use.

0.Enable strict calibration: use to set strict calibration

where no measurements are displayed if the calibration reminder has expired.

“±”Set screen saver timeout: use to set a time for the

backlight to turn off and the screensaver to activate.

"•" Restore factory defaults: use to reset all settings to

factory defaults.On occasion it may be useful to

completely reset the meter,for example,if other users

have changed a setting.

Warning!

A reset also clears all electrode standardizations.

8

Meter Setup

!

Meter Setup Menu

1) Time and date menu

2) Select temperature units

3) Select contrast

4) Select baud rate

5) Setup serial port

6) Keypress beep on/off

7) Select video color scheme

8) Show meter information

9) Enable measure lock

0) Enable strict calibration

±) Set screen saver timeout

•) Restore factory defaults

Setup

Select Time Format

1) hr : min : sec

2) hr : min AM/PM

Select Date Format

1) mm / dd / yyyy

2) dd – mm – yyyy

3) yyyy.mm.dd

Enable Measure Lock

Display lock/unlock softkey?

1) Yes

2) No

If “measure lock” is enabled, a

“lock” soft key will appear on

the measurement screen

Enable Strict Calibration

Require calibration?

1) Yes

2) No

If strict calibration is enabled,

no measurements will be

displayed for a channel with an

expired cal reminder.

Page 13

9

pH Mode

pH Mode Standardize Menu

Press Mode and select 1) pH.

Press Standardize and the pH Mode Standardize

Menu appears:

1.Auto-enter a buffer: use to add a new buffer which

is auto recognized by the meter,or update an existing buffer.Follow the prompts.

2.Manual buffer entry: use to enter a buffer value by

manually entering the pH of the buffer.

3.Clear buffers: use to clear all buffers entered for the

current channel (pH mode).If all entered buffers are

being re-entered,it is usually not necessary to clear

buffers before re-entering them.

4.Options Menu: A menu of additional specific pH

mode settings. (See page 10).

5.Cal reminder menu: use to set a timer reminding

you to recalibrate.A icon will appear on the

main screen and an exclamation mark will appear

beside the buffers for which time has expired.

The calibration reminder is a reminder of when

electrode calibration (with buffers) should be

redone.It is based on elapsed time from the oldest

entered buffer.

If strict calibration is set (see Meter Setup Menu),when

a calibration has expired the icon appears, and

"- - - " is displayed in place of the measurement. No

measurements can be obtained until a calibration is

performed.

Note: When strict calibration is set,the calibration

reminders for all channels are turned ON,and can't

be turned off from the Cal Reminder Menu.

6.Select buffer set: There are five auto-recognition

buffer sets and the option to configure and use a

custom buffer set of your own.

Select custom buffer set

Use Custom Buffer Set to make a set of buffers containing the specific buffers in use (up to five buffers).

Select Custom Buffer Set,configure the custom

buffer set,then buffers from this set will be automatically recognized and entered.

Custom buffers can have any numeric pH value,or

can be selected from the built-in temperature corrected buffers. Using the built-in buffers allow temperature correction of the pH values of the buffers ,

offering more accuracy.

Channel A: pH mode

Standardize Menu

1) Auto-enter a buffer

2) Manual buffer entry

3) Clear Buffers

4) Options Menu

5) Cal reminder menu

6) Select buffer set

Standardize

Channel A: pH mode

Manual Buffer Entry

Enter the actual pH of this

buffer, after correcting

for temperature:

pH

Press Enter to accept.

Channel A: pH mode

Cal Reminder Menu

1) Turn reminder On/Off: OFF

2) Set reminder interval:

01, 00 : 00 days, hr : min

3) Standardization menu

When the cal reminder expires, a “CAL!”

(or “!”) icon will be displayed with the

measurement and with each expired standard. If strict cal is ON, reminders are

always ON, and expired channels show no

measurements.

Channel A: pH mode

Select Buffer Set

1) 2, 4, 7, 10, 12 at 25C

2) 2, 4, 7, 10, 12 at 20C

3) 1, 3, 6, 8, 10, 13

4) 1.68, 4.01, 6.86, 9.18, 12.46

5) 1.09, 3.06, 4.65, 9.23, 12.75

6) Select custom buffer set

Custom Buffer

No buffers

CAL!

Channel A: pH mode

Configure Custom Buffer Set

1) Add a “built-in” buffer

2) Add a manual buffer

3) Delete a buffer

4) Standardize menu

Custom Buffer Set

No buffers

CAL!

Page 14

pH Mode Options Menu

1.Select resolution: use to set pH readings to 0.1,0.01,

or 0.001 pH units.

2.Select stability criteria: use to set stability criteria to

slow,medium or fast to match the electrode's speed

of response and the variability of the signal allowed

for a “stable” ( ) measurement.

3.Select signal averaging: use to set filtering of the

electrode signal to very slow (10 readings),slow (8),

medium (6),fast (4) or very fast (2). Slower settings

give more stable readings,although may require

longer times to reach stability.

4.Set standardization delay: use to set a reading delay

time for the meter to wait before accepting an electrode signal during standardization.Programming a

standardization reading delay helps slow responding

electrodes reach equilibrium before the electrode

signal is accepted.

5.Set pH slope: use to set a known electrode slope

used by the meter with a zero- or single-point standardization.The normal default slope is 59.16 mV/pH.

The meter allows between 80 and 120 % efficiency to

be entered.

6.Standardize menu: Retur ns to the pH mode

Standardization Menu.

7.Manual temperature menu: use to set a temperature

to be used in the absence of an ATC probe or when

manually overriding the ATC.

8.Data alarm menu: use to set pH limits.If the limits are

exceeded an alarm indication (“*”) is displayed and

recorded with any data points placed in the Data

Log.

9.Set isopotential point: use to set an isopotential point

for use in high accuracy electrode measurements

(See Isopotential,page 20).

10

pH Mode

Channel A: pH mode

Options Menu

1) Select resolution

2) Select stability criteria

3) Select signal averaging

4) Set standardization delay

5) Set pH slope

6) Standardize menu

7) Manual temperature menu

8) Data alarm menu

9) Set isopotential point

S

Page 15

Notes:

1.Auto-recognized buffers are found in the Auto-recognized built-in buffer sets.These buffers are autorecognized by the meter,and are also automatically

temperature corrected for the variation of buffer pH

with temperature.

2.When manually entering buffers, the exact pH of the

buffer at the current temperature must be entered.

All buffers change pH with temperature.For best

accuracy, either use the built-in buffers or make sure

manually entered buffers are at the expected temperature (so that their pH as entered is correct).

3.Auto-recognition Buffer Sets:

1) 2,4, 7, 10, 12 (nominal value adjusted at 25°C)

2) 2,4, 7, 10, 12 (nominal value adjusted at 20°C)

3) 1,3, 6, 8, 10,13

4) 1.68,4.01, 6.86, 9.18, 12.46 (NIST buffers)

5) 1.09,3.06, 4.65, 9.23, 12.75 (DIN buffers)

6) Select custom buffer set

4.Temperature Correction of Electrodes and Buffers

The meter automatically compensates for the temperature dependence of the electrode's response when

measuring pH.The meter also compensates for buffer

change in pH value with temperature.Temperature

compensation is based on temperature either from an

ATC probe or a manually entered temperature.

Using a Solid-state FET (Field Effect Transistor)

pH/ATC Electrode

By turning channel F (FET) on,an Omega FET pH/ATC

electrode can be directly used.pH and mV modes are

available with the FET electrode.FET devices can have

large offset potentials that vary with each transistor

chip,so Manual buffer entry must be used to enter the

first buffer.After one buffer has been entered using

“Manual buffer entry”, following buffers can usually be

entered with “Auto-enter a buffer”.

pH Mode

Actual Buffer pH vs. Temperature

pH 4.00(4.01)/7.00/10.00 buffer (nominal 25°C)

Temperature Buffer 4 Buffer 7 Buffer 10

(°C)

30 4.016 6.991 9.947

25 4.008 7.003 10.000

20 4.003 7.020 10.057

15 4.000 7.042 10.119

10 3.998 7.069 10.187

11

Page 16

12

Standardizing and Measuring pH

1.Immerse the electrode in a buffer and stir moderately. The meter displays the current pH measurement.

2.Allow the electrode sufficient time to reach

equilibrium.

3.Press Standardize,then press either 1) Auto-enter a

buffer or 2) Manual buffer entry.

4.Follow the prompts on the display.

5.The meter waits for a stable signal,automatically recognizes the buffer (if using “Auto-enter”),checks the

electrode and buffer and enters the buffer.The

entered buffer appears in the display.

6.Alternatively,if the signal is not sta ble, you can press

Enter when the reading stabilizes according to your

tolerance criteria.The meter then enters the buffer.

7.Repeat steps 1 through 4 to enter a second,third,

fourth or fifth buffer.With more than one buffer the

meter performs a diagnostic check on the electrode.

The electrode is considered good if the slope is

between 90 to 105%.If a sixth buffer is entered,the

buffer farthest away is replaced by the new buffer.

Hints to achieve better accuracy:

• During standardization,allow time for the electrode

to stabilize before entering the buffer into the meter.

• Standardize using at least two buffers , bracketing the

expected pH of your samples.

• Standardize at least daily for the most accurate read-

ings.

• Open the Fill Hole on the electrode.

• Stir all buffers and samples.

• Rinse the electrode with DI water between samples

and buffers.

• Always use fresh buffers.

Clearing Buffers

Press Standardize,then press 3) Clear buffers to clear

buffers. If all previously entered buffers will be reentered,it is not necessary to clear buffers since the

meter will replace the previous values.If re-enter ing

only some buffers, all the old buffers should be cleared.

Channel A: pH mode

pH Checklist

Prepare buffer or sample.

Rinse electrode.

Place electrode in solution.

Stir moderately.

Press Enter to continue.

Channel A: pH mode

Standardize Menu

1) Auto-enter a buffer

2) Manual buffer entry

3) Clear buffers

4) Options menu

5) Cal reminder menu

6) Select buffer set

Standardize

Channel A: pH mode

Manual Buffer Entry

Enter the actual pH of this

buffer, after correcting

for temperature:

pH

Press Enter to accept.

mV

4 7 10

pH buffers

samples

Page 17

Electrode Potential,mV

Titrant Volume, mL

Redox Titration

Standardize

Millivolt measurements are used to measure ORP (oxidation-reduction potential) or redox potential,to

check performance of pH or Ion Selective Electrodes,

and for redox titrations.

The meter will measure millivolts (mV) by pressing Mode

and selecting 2) mV.Relative mV can be measured

by entering a mV offset or using the current mV value

as the mV offset.

mV Standardization Menu

In mV mode,press Standardize and the mV mode

Standardization Menu appears:

1.Auto-enter mV offset: use to set the relative mV offset equal to the current mV reading. The current mV

becomes 0.0 relative mV.

2.Set mV offset: use to manually enter a mV offset.

3.Clear mV offset: use to clear any offset that has

been entered,returning the meter to absolute mV

mode.

4.Options menu: a menu of additional settings specific to the mV mode.See below.

mV Mode Options Menu

1.Select resolution: use to set mV readings to 1 or 0.1

millivolt resolution.

2.Select stability criteria: use to select stability criteria

for slow, medium or fast response which use a tight,

average or loose requirement to indicate a “stable”

( ) reading.

3.Select signal averaging: use to set the meter to

average readings that are very slow (10 readings),

slow (8),medium (6),fast (4) or very fast (2).

4.Set standardization delay: use to set a length of time

for the meter to wait before entering a relative mV

standardization.

5.Set mV offset: use to manually enter a mV offset

(same as in the mV Standardize menu).

6.Standardization menu: retur ns to the mV

Standardization Menu.

Clearing Relative mV Mode

Press Standardize,then press 3) Clear mV offset to clear

offset and return the meter to absolute mV mode.

mV Mode

Channel A: mV mode

Standardize Menu

1) Auto-enter mV offset

2) Set mV offset

3) Clear mV offset

4) Options menu

Channel A: mV mode

Options Menu

1) Select resolution

2) Select stability criteria

3) Select signal averaging

4) Set standardization delay

5) Set mV offset

6) Standardize

13

S

Page 18

14

Quick Start Guide for Ion Measurements

1.Connect the Ion Selective Electrode (ISE) and

Reference Electrode,if required, to the

meter.”Combination” ISE’s have a reference

electrode built-in,and do not require a separate reference electrode or connection.

2.Prepare two or more ion standards at concentrations bracketing typical sample solutions.

Add the appropriate Ionic Strength Adjuster

solution to each standard.

3.Set the meter to display the correct channel

(the channel with the ISE attached,either A or

B) using Channel.Set the meter to Ion mode:

press Mode,then 3) Ion.

Note: The meter will display “— — —”(no valid

data) until an ion standard has been entered.

4.Place the electrode(s) in the standard,provide

stirring (a magnetic stirrer is recommended),

and allow sufficient time (1 to 5 minutes

depending on the ISE) for the electrode to

reach a stable signal.

5.Press Standardize,1) Enter a standard and follow the prompts.Repeat these steps to enter

up to seven ion standards.See the

Standardizing and Measuring Ion section for

more information.

6.Check the ISE response by pressing Cal Data to

see the standards and the ISE slope between

calibration points (standards).The meter will

allow an ion electrode slope between 5.92

mV/decade (10% slope) and 70.99

mV/decade (120% slope).

Mode

Channel

+

ISA

Example: 1 mg/L 10 mg/L Ionic Strength

Adjuster

BNC

ref

measuring or

Combination ISE

reference

Cal Data

Channel A:

Select Mode

1) pH

2) mV

3) Ion

Channel A: ion mode

Ion Cal Data

1.00 mg/l 08/01/1998 08:32 AM

57.15 mV/decade

10.0 mg/l 08/01/1998 08:35 AM

Channel A: ion mode

Standardize Menu

1) Enter a standard

2) Set ion slope

3) Clear standards

4) Options menu

5) Cal reminder menu

c

h

. A

re

f. A

c

h

T

e

m

p

. A

T

e

m

p

. B

R

S

2

3

2

C

p

o

w

e

r

E

Page 19

Ion Mode Standardization Menu

Select channel A or B.Press Mode and then press 3) Ion for ion

mode.Press Standardize and the Ion Mode Standardize Menu

appears.

1.Enter a standard: use to add a new standard or update (reenter) an existing standard.Follow the prompts.With the first

standard you select the ion name and units.

2.Set ion slope: use to manually enter a slope for the selected

ion electrode.Used with a one-point ion calibration.Useful if

the ISE has a known,stable slope,so that measurements can

be made after entering a single ion standard.

Note: when two or more standards are entered,the meter

uses the actual determined slope(s).

3.Clear standards: use to clear standards for the electrode

standardization selected.

4.Cal reminder menu: use to set a timer reminding you to

recalibrate.A icon will a ppear on the main screen

and an exclamation mark will appear beside the standards

which need to be re-entered.

5.Options Menu: use to set various additional parameters to

the ion mode.See below.

Ion Mode Options Menu

1.Resolution: use to set the readings to 1,2, or 3 significant digits.

2. Select stability criteria: use to set the sta bility cr iteria to slow,

medium or fast to match the electrode's speed and stability

of response,providing tight,medium and loose requirements

for a stable ( ) indication.

3.Select signal averaging: use to set filtering of the electrode

signal to very slow (10 readings),slow (8),medium (6),fast (4)

or very fast (2). Slower settings give more stable readings,

although may require longer times to reach stability.

4.Set standardization delay: use to set a reading delay time for

the meter to wait before accepting an electrode signal during standardization.Programming a standardization reading

delay helps slow responding electrodes reach equilibrium

before the electrode signal is accepted.Delays of one

minute for fast ISE’s and five to ten minutes for slow ISE’s are

appropriate.

5.Set ion slope: use to enter a known ion electrode slope for a

one point standardization.

6.Standardize menu: returns to the ion standardize menu.

7.Manual temperature menu: use to set a manual temperature

for use in the absence of an ATC probe or when manually

overriding the ATC.

8.Data alarm menu: use to enter ion limits to be entered. If the

limits are exceeded an alarm indication (“

*

”) is displayed.

9.Set isopotential point: use to enter an isopotential point. See

page 20.

0.Enable incremental: use to turn on the known addition/subtraction type ion methods.See page 17.

Ion Mode

Channel A: ion mode

Standardize Menu

1) Enter a standard

2) Set ion slope

3) Clear standards

4) Options menu

5) Cal reminder menu

Channel A: ion mode

Options Menu

1) Select resolution

2) Select stability criteria

3) Select signal averaging

4) Set standardization delay

5) Set ion slope

6) Standardize menu

7) Manual temperature menu

8) Data alarm menu

9) Set isopotential point

0) Enable incremental modes

15

CAL!

S

Page 20

16

Standardizing and Measuring Ion

Standardizing and Measuring Ion

1.Set the meter to ion mode (use Mode) and turn

ON the channel (use Channel) with the Ion

Selective Electrode (either Channel A or B).

The meter displays “— — —”,indicating no valid

measurement,until at least one ion standard has

been entered.

2.Prepare a standard,and add the appropriate

Ionic Strength Adjuster (ISA) solution to the standard.

3.Immerse the electrode(s) in the solution and stir

continuously.

4.Press Standardize,select the correct channel if

prompted to do so,and select 1) Enter a stan-

dard to add a standard. If this is the first standard

to be entered,select the ion name and units.

Follow the prompts.Be sure to allow enough time

for the electrode to reach a stable signal.

Note: The default standardization delay for ion

mode is 30 seconds.This can be set by the user.

See Ion Mode Options Menu,page 15.

5.The meter waits for a stable signal and enters the

standard.The entered standard appears in the

display (in single channel mode).Alternatively, if

the signal is not stable,you can press Enter when

the reading stabilizes according to your tolerance criteria.The meter then enters the standard.

6.Repeat steps 2 through 5 to enter additional

standards.Up to seven standards can be

entered.With more than one standard,the meter

performs a diagnostic check on the electrode.

Helpful Hints:

• Provide stirring.

• Allow the electrode time to reach a stable read-

ing before entering the standard into the meter.

• To achieve better accuracy, standardize using at

least two standards,bracketing the expected

range of your samples.

• Standardize from low to high concentrations.

• Always use fresh standards.

• Use standards and samples near the same tem-

perature.

• Remember to add Ionic Strength Adjuster to

each standard and sample.

mV

ion standards

log [ion]

Channel B: ion mode

A 25.0°C

No standards.

08/01/1998 08:40 PM

Channel B: ion mode

Ion Checklist

Prepare standard or sample.

Add Ionic strength Adjuster.

Rinse electrode.

Place electrode in solution.

Stir moderately.

Press Enter to continue.

Standardize

Channel A: ion mode

Standardize Menu

1) Enter a standard

2) Set ion slope

3) Clear standards

4) Options menu

5) Cal reminder menu

Page 21

Measuring Ion using Known Addition type

(Incremental Ion) Methods

The meter provides known ("standard") addition/subtraction and analate ("sample") addition/subtraction

incremental methods for measuring ion concentrations. These advanced ion measurement techniques

are useful in overcoming certain problems in ion

analysis.

In known addition/subtraction a volume of sample is

obtained,Ionic Strength Adjuster is added,and the

ion electrode potential is obtained. Then a small volume of standard is added to the sample,and a second electrode potential is obtained. From the

change in electrode potential,the ion concentration

in the sample can be calculated.Interference from

complexation and other ions can often be overcome

by the known (standard) addition method.

In analate addition/subtraction the ion electrode is

placed in a volume of standard and the potential

obtained. Then a small volume of sample is added

and a second electrode potential is obtained. This

method helps overcome problems from widely differing sample ionic strengths or temperatures.

Enable Incremental Ion Modes

Press Standardize, select the channel (if necessary),

4) Options menu, 0) Enable incremental modes, then

1) Yes.

This will "turn on" a special softkey in the main measure screen which is a direct access softkey to start a

known addition type measurement.

Using a known addition type incremental ion measurement

Press the incremental method softkey, select 1)

Known (standard) addition or 2) Analate (sample)

addition. Follow the prompts to place the electrode

in the first solution and obtain a reading,add an

aliquot (a known volume) of standard or sample,

obtain a second electrode reading,and enter the

sample volume and standard volume and concentration. The meter then displays the calculated ion

concentration in the original sample. Press Enter to

leave the result screen and return to the measure

screen to use direct reading ion measurements or

start another known addition type measurement.

Channel A: ion mode

Enable Incremental Modes

Display ion soft key?

1) Yes

2) No

If incremental modes are enabled,

a ‘+/- ion’ softkey will appear

on the measurement screen.

Select Measurement Technique

1) Known (standard) addition

2) Analate (sample) addition

Select ‘known addition’ to add

a small volume of known

standard to the sample.

Select ‘analate addition’ to add

a volume of sample to a

volume of known standard.

The meter will automatically

detect subtraction techniques.

Channel A: Known addition mode

Incremental Ion Measurement

S 58.7 mV

Prepare sample and note volume.

Add Ionic Strength Adjuster.

Rinse electrode.

Place electrode in solution.

Stir moderately.

Press Enter to accept.

17

Channel A: Known addition mode

Incremental Ion Measurement

S 95.2 mV

Delta = 36.5 mV

Add aliquot of known standard.

Stir moderately.

For best accuracy, add volume

until Delta > 4.0 mV.

Note total volume added.

Press Enter to accept.

+

–

Page 22

18

Quick Start Guide for

Conductivity/Resistivity/Salinity/TDS

Measurements

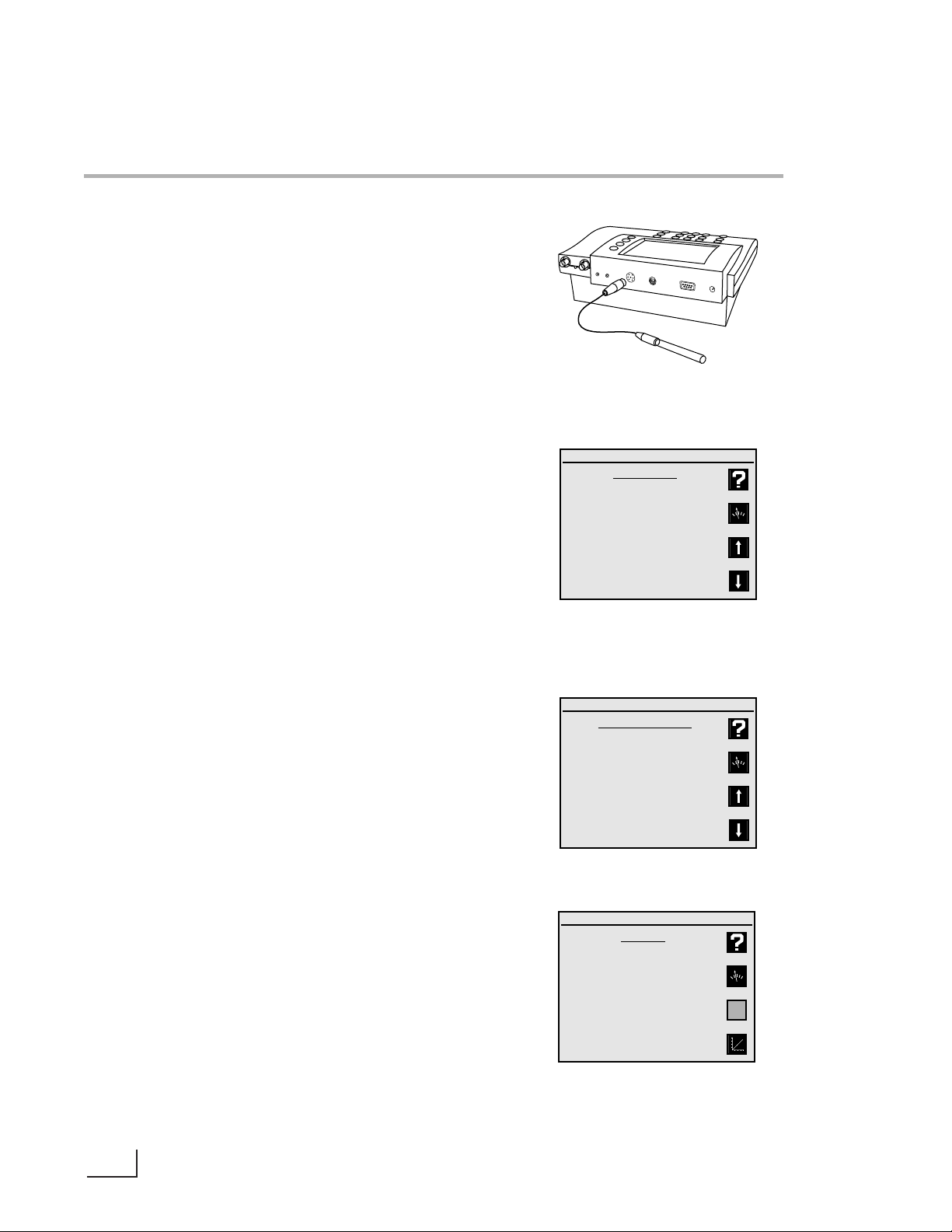

1.Connect the conductivity/ATC cell to the meter.

2.Prepare one or more conductivity/resistivity standard solutions at values near typical sample solutions.

3.Set the meter to display channel C using

Channel. Set the meter to the correct mode

(Conductivity,Resistivity,NaCl salinity,Practical

salinity or Total dissolved solids) using Mode.

4.Place the conductivity cell in the standard,

immerse the cell past the fill vent hole,then lift

and allow the solution to drain out. Immerse and

drain at least three times to fully flush the inner

chamber of the cell. Gently tap the cell to dislodge any air bubbles.

5.Press Standardize,then 1) Enter a standard and

follow the prompts to enter the value of the standard. Repeat these steps to enter up to five conductivity/resistivity standards. Each standard is

displayed in the main measuring screen when in

single channel display.

6.Check the cell performance by pressing Cal Data

to display the standards and the cell constants

between standards.

Channel C: Conductivity mode

Select Mode

1) Conductivity

2) Practical salinity

3) NaCl salinity

4) Resistivity

5) Total dissolved solids

Channel C: Conductivity mode

Standardize Menu

1) Enter a standard

2) Set cell constant

3) Clear standards

4) Options menu

5) Cal reminder menu

Channel C: Conductivity mode

Cal Data

1.0051 /cm

100.1 µS/cm 08/01/98 08:45 AM

1.0092 /cm

1000 µS/cm 08/01/98 08:47 AM

Conductivity/ATC cell

c

h

. A

c

h

re

f. A

c

h

. C

C

o

T

n

e

m

d

u

p

c

. A

tiv

ity

T

e

m

p

c

. B

h

. F

F

E

T

R

S

2

3

2

C

p

o

w

e

r

Page 23

Conductivity/Resistivity/Salinity/TDS Menus

Conductivity/Resistivity/Salinity/TDS

Standardize Menu

Turn ON Channel C using the Channel key. Press

Standardize and the Standardize Menu is displayed.

1.Enter a standard: use to enter or re-enter a conductivity standard. Follow the prompts.

2.Set cell constant: use to manually enter a known

conductivity cell constant for use with no standards.

If the cell constant is known and stable,then this

allows standardizing the cell without using standard

solutions. If a standard is entered,the actual cell

constant is calculated and used.

3.Clear standards: use to clear all existing standards.

This is useful if new standards are to be entered.

4.Options menu: accesses additional settings used

with each conductivity-type mode.See below.

5.Cal reminder menu: use to set a timer reminding you

when to recalibrate. A icon appears on the

main screen and an exclamation mark appears

beside those standards which need to be reentered.

6.[TDS mode only] Calculate solids factor: use this to

allow the meter to calculate a solids factor. *

7.[TDS mode only] Set solids factor: use to manually

enter a known solids factor * for a particular sample

type.

* The "solids factor" is used to correlate the conductivi-

ty measurement with the weight based TDS measurement for a sample type.

Conductivity Mode Options Menu

1.Select resolution: use to set readings to 1 through 4

significant digits resolution.

2.Select stability criteria: sets stability criteria used to

determine when the meter indicates Stable .

3.Select signal averaging: use to set filtering of the

cell signal to very slow (average 10 readings),slow

(8),medium (6), fast (4) or very fast (2 readings).

Slower settings give more stable readings, and are

recommended with conductivity measurements.

4.Set standardization delay: use to set a reading delay

time used by the meter when entering conductivity

standards.Programming a reading delay helps by

ensuring sufficient time for the cell signal to become

stable before being entered into the meter.

5.Set cell constant: use to manually enter a known

conductivity cell constant. (Same as in Standardize

Menu).

6.Standardize Menu: use to return to the Standardize

Menu.

Channel C: Conductivity Mode

Standardize Menu

1) Enter a standard

2) Set cell constant

3) Clear standards

4) Options menu

5) Cal reminder menu

Options Menu

1) Select resolution

2) Select stability criteria

3) Select signal averaging

4) Set standardization delay

5) Set cell constant

6) Standardize menu

7) Manual temperature menu

8) Data alarm menu

9) Select display units

0) Set temperature coeff.

19

CAL!

S

Page 24

20

Conductivity/Resistivity/Salinity/TDS Modes

7.Manual temperature menu: Use to set a manual

temperature for use in the absence of an ATC

probe or when manually overriding the ATC.

8.Data alarm menu: use to set ion limits to be

entered.If the limits are exceeded an alarm indication (“*”) is displayed.

9.Select display units: the meter automatically switches between uS/cm and mS/cm in conductivity, or

between ohm-cm,Kiloohm-cm and Megohm-cm in

resistivity. If it is better to display a fixed unit,the

"Fixed" settings allow that.

0.Set temperature coefficient: use to set the reference

temperature to correct all conductivity and TDS

measurements to,and set the temperature coefficient for the temperature correction. Salinity measurements by definition are corrected to 20°C.

Resistivity measurements are not temperature corrected.

Standardizing and Measuring

Conductivity/Resistivity/Salinity/TDS

1.Set the meter to display channel C (use Channel).

Set the meter to the correct mode (Conductivity,

Resistivity,NaCl salinity,Practical salinity or Total dissolved solids) using Mode.

2.Place the conductivity cell in the standard,immerse

the cell past the fill vent hole,then lift and allow the

solution to drain out. Immerse and drain at least

three times to fully flush the inner chamber of the

cell. Gently ta p the cell to dislodge any air bubbles.

3.Press Standardize, select the channel if necessar y,

then 1) Enter a standard and follow the prompts to

enter the value of the standard. Repeat these steps

to enter up to five conductivity/resistivity standards.

Each standard is displayed in the main measuring

screen when in single channel display. Use multiple

standards that cover the range of values expected

in samples. Generally, standards should be a factor

of ten apart in conductivity.

Channel C: Conductivity mode

Standardize Menu

1) Enter a standard

2) Set cell constant

3) Clear standards

4) Options menu

5) Cal reminder menu

Channel C: Conductivity mode

Set T

emperature Coefficient

Enter the value for this cell:

%/°C

Press Enter to accept.

Channel C: Conductivity mode

Select Reference T

emperature

1) 15°C

2) 20°C

3) 25°C

Channel C: Conductivity mode

Select display units

1) Automatic

2) Fixed µS/cm

3) Fixed mS/cm

1.90

Page 25

The meter will store up to 500 data points in an

internal data log. Press Print when in the main measure screen to store the current result with units,

temperature,time,date,channel, sample number

and stability in the data log. Pr int also outputs this

data through the RS232 serial port. All channels displayed are printed and data logged.

Data Log Menu

Press Data Log and the Data logging menu will

appear.

1.View data log: Shows the stored data,one

screen at a time.Press the arrow soft keys to

page up and down through the stored data.

Press Clear or Enter to return to the menu.

2.Data logging on/off: Turns the data logging on or

off for all displayed channels.

3.Set logging frequency: Allows you to enter the

time interval for automatic data logging.

4.Clear data log: Clear s all stored data points from

memory.

5.Set sample number: Allows a number to be

assigned to the first sample.This number will

increment for each consecutive sample logged.

6.Print data log: Use to send all data points in the

Data Log to the RS232 serial port.

Warning

The Data log is kept in instrument RAM (Random

Access Memory), which is powered by the external

power supply. Removing power from the meter will

lose the stored data in the Data log.

Note:

Meter settings and electrode standardization data

are kept in separate non-volatile memory.

Unplugging the meter has no effect on these

stored items.

Data logging

!

Data Log Menu

1) View data log

2) Turn logging On/Off: ON

3) Set logging interval

4) Clear data log

5) Set sample number

6) Print data log

Number of points in log:

350

Data Log

A S 25.3C 4.176 pH

00102 06/26/98 9:32AM

B S 25.4C 1.03 mg/L F-

00101 06/26/98 9:31AM

A S 25.3C 6.713 pH

00100 06/26/98 9:31AM

21

Set Logging Interval

Enter the time between

data samples.

hr:min:sec

Please Enter to accept

01 : 00 : 00

Printing Log

Points remaining:

321

Press any to abort printing.

Page 26

22

Testing the Electrode and Meter

To test the meter for correct operation with a pH,

ORP or Ion Selective electrode,shor t the BNC input

connector (either Channel A or B) using the BNC

Shorting Cap that was supplied with the meter on

the BNC connector(s).Select the correct channel

using Channel. Select mV mode by pressing Mode

and selecting 2) mV. Verify meter is in absolute mV

mode (display shows “mV”, not “rel mV”). If the

meter reads 0 ± 0.1 mV*, and is sta ble, the meter is

measuring correctly.

To test the pH electrode,place it in a fresh pH 7

buffer.Select the correct channel for the electrode

using Channel.Press Mode and select 2) mV.Verify

that the meter is in absolute mV mode (display

shows "mV",not "rel mV") and note the mV reading.

Repeat for either a pH 4 or pH 10 buffer. If the electrode potential is within the limits shown,it is measuring correctly.

pH 7 0 ± 30 mV

pH 4 159 to 186 mV higher than pH 7 reading

pH 10 159 to 186 mV lower than pH 7 reading

* Note: Meter accuracy is ±0.1 mV at calibration

temperature,not including long term drift and a

temperature error. The zero and slope temperature

coefficients of the meter over the range of 15 to

40°C specify 85ppm/°C,or ±4 mV at full scale

(worst case).The long ter m dr ift will not exceed 0.1

mV per month.

Troubleshooting

Page 27

PHB-215, PHB-220, PHB-225 and PHB-250

Modes pH mV Temperature

Range -2.000 to 20.000 ±1800.0 -5.0 to 105.0˚C

Resolution 0.001/ 0.01 / 0.1 0.1 / 1 0.1

Accuracy ±0.002 ±0.1 ± 0.3

Temperature

Automatic & manual: -5 to 105˚C

Compensation

Slope Control Automatic,90 to 105%

Manual,80 to 120%

Environmental

15 to 40°C,humidity from 0 to 90% (noncondensing)

Conditions

Power Requirements 115V 50/60Hz (Additional voltages available)

Ordering Information

Meter with kit includes: Meter,power supply,high performance glass-body pH/ATC “3-in-1”

electrode,electrode ar m and operation manual.

Meter only kit includes: Meter,power supply, electrode arm and operation manual.

Models 225 and 250

Mode Ion

Range 1.00E-9 to 9.99E9

Resolution 1,2,or 3 significant figures

Accuracy ± 0.17%n (n = ion charge)

Slope Control Automatic or manual,5.9 mV/decade (10% slope)

to 71 mV/decade (120%)

PHB-220 and PHB-250

Practical NaCl

Mode Conductivity Resistivity Salinity Salinity TDS

Range 0.01 – 300,000 µS/cm• 30 - 20M½•cm* 0.01 - 42 ppt* 0.01 - 70ppt* 0.005 - 150,000*

Resolution 1,2, 3, or 4 significant figures

Accuracy ± 0.5% ±0.01µS/cm

Cell Constant Automatic or manual,0.01 - 100 /cm

Temperature Coeff Off or On (0 - 4% /°C)

Number of Standards 5

*depending on cell constant (from 0.1 to 10 /cm)

Meter Specifications

23

Page 28

24

pH Theory

The measurement of pH plays an important role in

water quality, industry and research.pH is a measure of

acidity or alkalinity of a solution,and is usually written:

pH = -log [H+]

Where [H+] is the concentration of hydrogen ions.

pH levels generally range from 0 to 14,with a pH value

of 7 being the neutral point.pH values greater than 7

are alkaline,and pH values less than 7 indicate acidic

solutions.

Conventional pH meters use a combination glass pH

electrode,which includes a reference electrode.The

reference electrode provides a stable reference point

and completes the electrical circuit.The pH meter

reads the voltage of the two electrodes,converts it to

pH units, and displays the result.

These meters can also use a Field Effect Transistor (FET)

pH/ATC electrode for measuring pH.The FET uses an

ion-sensing solid state membrane attached to a transistor to measure the hydrogen ion concentration of a

solution.These non-glass pH electrodes offer durability,

dry storage and no glass construction.

The electrode signal varies with the pH,according to

the Nernst Equation:

E = E° + S • log [H+]

Where:

E = measured electrode potential

E° = standard potential of the system (constant)

S = slope

pH

0 Strong Acid

1

2 Lemon Juice

3

4 Tomato Juice

5 Coffee

6

Neutral 7 Pure water

8 Baking Soda

9

10

11

12 Ammonia

13

14 Strong Base

More Acidic

More Basic

pH scale showing the

relative acidity or basicity of

some common substances

Ion Selective Electrode Theory

The measurement of ions plays an important role in

water quality, industry,research and environmental

monitoring. Ion-selective Electrodes (ISE’s) respond,

more or less exclusively, to a specific type of ion in

solution.The particular ion to which an ISE responds

depends on the chemical makeup of its sensing

membrane.ISE’s operate according to a form of the

Nernst equation:

E = Eo+ S • log [ion]

Page 29

The Isopotential point is the potential of an electrode system which does not change with

temperature.Typical pH electrodes have isopotential points near zero mV (which is the

default setting for the meter).For high accuracy pH measurements,or for ion measurements where the sample temperature may widely vary,the isopotential of the pH or ion

electrode may be experimentally determined and entered into the meter.

• Prepare a set of buffers or ion standards spanning the linear range of the electrode.

Place the buffers or standards in a temperature bath at known temperature.

• Place the meter into mV mode.

• Measure and record mV readings of each pH or concentration,and repeat at several temperatures.

• Plot the log of concentration or pH value versus mV reading.

• Connect the points for each temperature.

Where the lines intersect is the Isopotential point.

Determining the Isopotential Point

200

100

0

10

-3

10

-4

Log of Ion Concentration, moles/L

Electrode

Output

(mV)

10°C

60°C

Isopotential Point:

3.07 x 10-4moles/L, 162 mV

Ion Electrode Isopotential Point

50

150

-180

0

180

4 7 10

pH

Electrode

Output

(mV)

25°C

10°C

Isopotential Point:

7.04pH 9 mV

pH Electrode Isopotential Point

25

Page 30

26

Omega meters have a bi-directional RS-232 serial port,which can be used to

send commands to the meter and output data from the meter. Special characters (W, µ, é) are coded using ASCII (not ANSI); use an ASCII font like

“Terminal”.Also use a ter minal emulation like TTY or ANSI,not VT100.

Serial commands follow either "keystroke" mode or high level command

mode consisting of "SET","GET" and "DO" instructions.

(Note: “GET”and “DO”are optional).

Keystroke instructions

KEYS M Mode

Z Standardize

C Cal Data

H Channel

S Setup

L Data Log

R Clear

N Enter/Print

[0 to 9] Equivalent to pressing a numeric key

- +/- key

. Decimal key

E Used within a number to enter values in exponential form

! Press softkey #1 (at top,usually Help)

@ Press softkey #2 (usually return to measuring screen)

# Press softkey #3 (usually up arrow)

$ Press softkey #4 (at bottom,usually down arrow)

Notes: Key commands are acknowledged by the meter with a reply

Keys = COMMAND_RECEIVED.Multiple keys can be concatenated

together into a single command,for example,Keys Z413@

(Standardize,options, resolution, set to 3,main),or Keys Z4721.2-N@

(Set manual temperature to -1.2).

High level instructions

Use commands SET,GET,DO.

Follow command by a keyword like MODE,STDZPH,STDZCONDO,

CALDATA,STDZCLEAR, CHANNEL,DATETIME,TIMESTAMP,DISPLAY, READ, INFO

Typical Syntax: [command] [keyword] [channel] [variable(s)]

Error conditions are replied to with an Error response; for example:

"Error: Need channel","Error: Need mode","Error: Unspecified"

Accepted commands have a response; indicated below for each command.

Mode operations

set mode "channel character" "mode id"

Examples: SET MODE A PH

SET MODE B MV

SET MODE B ION

SET MODE C CONDUCTIVITY

Returns confirmation; for example "SET MODE A PH" returns "A mode = PH".

Valid modes are (depending on the meter model) PH,MV,CONDUCTIVITY,

RESISTIVITY, PRAC_SALINITY, NACL_SALINITY, DISSOLVED_SOLIDS.

RS-232 Serial Interface Meter Command Set

Page 31

27

RS-232 Serial Interface Meter Command Set

[get] mode "channel character" "mode id"

Examples: [GET] MODE A

Returns mode information on selected channel;

"A Mode = MV".

Channel operations

set channel "channel character" "on|off"

Examples: SET CHANNEL A ON

SET CHANNEL C OFF

Returns confirmation; for example "A Channel = ON".

[get] channel "channel character"

Example: [GET] CHANNEL B

Returns channel information; "A Channel = OFF".

(DO) READ “channel character” (Take reading w/temperature with-

out sending to data log).

Standardization operations

[DO] STDZPH "channel character"

[DO] STDZCLEAR "channel character"

[DO] STDZCONDO "conductivity standard value"

[DO] CALDATA "channel character"

[DO] STDZPH A [Auto-enter a buffer]

Returns "Stdz pH = COMMAND_RECEIVED",followed by the Calibration

Data printout.

[DO] STDZCLEAR A [Clear all buffers/standards.]

Returns "Stdz Clear = COMMAND_RECEIVED".

[DO] STDZCONDO 1000 [Enter a standard of 1000 uS/cm.]

Returns "C Stdz Condo = COMMAND_RECEIVED",followed by the

Calibration Data printout.

[DO] CALDATA A

Returns "A Cal Data = COMMAND RECEIVED" followed by the Calibration

Data printout.

General meter setup operations

SET DATETIME MM/DD/YYYY HH:MM:SS [Leading 0's required, 24

hour time]

[GET] DATETIME Returns: "MM/DD/YYYY

HH:MM:SS"

[GET] INFO Returns Model,Ver sion,

Serial#.

(DO) DISPLAY display_text_string (at 0,0) [x = pixel from left,0 - 319]

(DO) DISPXY x y display_text_string [y = pixel from top,0 - 239]

Example: DO DISPXY 15 0 Device ready, press any key.

SET TIMESTAMP # (Set date/time using ‘unix’

(GET) TIMESTAMP seconds).

Page 32

28

Maintenance

This product contains no user serviceable parts . All replacement

parts should be obtained from the manufacturer or an authorized

distributor.

Cleaning

The exterior surfaces of this product may be cleaned with a damp

cloth or with mild detergent.

CAUTION

Changes or modifications not expressly approved by the manufacturer will void the user’s warranty for this equipment.

!

Page 33

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and

workmanship for a period of 37 months from date of purchase. OMEGA Warranty adds an

additional one (1) month grace period to the normal three (3) years product warranty to

cover handling and shipping time. This ensures that OMEGA’s customers receive maximum

coverage on each product.

If the unit should malfunction, it must be returned to the factory for evaluation. OMEGA’s

Customer Service Department will issue an Authorized Return (AR) number immediately upon

phone or written request. Upon examination by OMEGA, if the unit is found to be defective it will

be repaired or replaced at no charge. OMEGA’s WARRANTY does not apply to defects resulting

from any action of the purchaser, including but not limited to mishandling, improper interfacing,

operation outside of design limits, improper repair, or unauthorized modification. This

WARRANTY is VOID if the unit shows evidence of having been tampered with or shows evidence

of being damaged as a result of excessive corrosion; or current, heat, moisture or vibration;

improper specification; misapplication; misuse or other operating conditions outside of OMEGA’s

control. Components which wear are not warranted, including but not limited to

contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or errors nor assumes liability for

any damages that result from the use of its products in accordance with information provided by OMEGA, either verbal or written. OMEGA warrants only that the parts

manufactured by it will be as specified and free of defects. OMEGA MAKES NO OTHER

WARRANTIES OR REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESSED OR

IMPLIED, EXCEPT THAT OF TITLE, AND ALL IMPLIED W ARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY AND FITNESS FOR A P AR TICULAR PURPOSE ARE HEREBY

DISCLAIMED. LIMITATION OF LIABILITY: The remedies of purchaser set forth herein are

exclusive and the total liability of OMEGA with respect to this order, whether based on contract, warranty, negligence, indemnification, strict liability or otherwise, shall not exceed

the purchase price of the component upon which liability is based. In no event shall OMEGA

be liable for consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as

a “Basic Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity;

or (2) in medical applications or used on humans. Should any Product(s) be used in or with any

nuclear installation or activity, medical application, used on humans, or misused in any way,

OMEGA assumes no responsibility as set forth in our basic WARRANTY/DISCLAIMER language,

and additionally, purchaser will indemnify OMEGA and hold OMEGA harmless from any liability

or damage whatsoever arising out of the use of the Product(s) in such a manner .

RETURN REQUESTS / INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department.

BEFORE RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN

AUTHORIZED RETURN (AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT

(IN ORDER TO AVOID PROCESSING DELAYS). The assigned AR number should then be

marked on the outside of the return package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to

prevent breakage in transit.

FOR W

ARRANTY RETURNS, please have

the following information available BEFORE

contacting OMEGA:

1. P.O. number under which the product was

PURCHASED,

2. Model and serial number of the product

under warranty, and

3. Repair instructions and/or specific

problems relative to the product.

FOR NON-WARRANTY REPAIRS,

consult

OMEGA for current repair charges. Have the

following information available BEFORE

contacting OMEGA:

1. P.O. number to cover the COST

of the repair,

2. Model and serial number of product, and

3. Repair instructions and/or specific problems

relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible.

This affords our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 1996 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied,

reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without

prior written consent of OMEGA ENGINEERING, INC.

UUSASA

MADE

ININ

Page 34

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

TEMPERATURE

MU

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

MU

Wire: Thermocouple, RTD & Thermistor

MU

Calibrators & Ice Point References

MU

Recorders, Controllers & Process Monitors

MU

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

MU

Transducers & Strain Gauges

MU

Load Cells & Pressure Gauges

MU

Displacement Transducers

MU

Instrumentation & Accessories

FLOW/LEVEL

MU

Rotameters, Gas Mass Flowmeters & Flow Computers

MU

Air Velocity Indicators

MU

Turbine/Paddlewheel Systems

MU