Page 1

OMEGA®TEST GAUGES—TYPE T

HIGH ACCURACY AND MONEL®WETTED PARTS

41⁄2, 6, 81⁄2" DIALS

PGT Series

Monel Wetted

Parts on

All Ranges

PRESSURE

GAUGES

Starts at

$

390

†

Optional

⻬ High Accuracy: 0.25%

⻬ Stem and Panel Mount

⻬ Mirrored Scale

⻬ Monel

⻬ 4

The OMEGA®test gauge line

consists of highly accurate gauges

designed for use in instrument

shops, plants of all types, and

laboratories throughout industry.

Most models provide sustained

accuracy to 0.25% full scale.

Performance, reliability, and

precision measurement are

coupled with consistency in

meeting the demanding

service needs of numerous

test gauge applications.

OMEGA®test gauges are used

as master reference gauges,

in test stand measurements,

for production inspection,

and for verifying the accuracy

of general service gauges.

The gauge dial has a

stainless steel mirror ring for

pointer reflection, which

prevents parallax error. This

mirror surface reflects the pointer

in any position and allows the

gauge to be read with great

accuracy. The lightweight, frictionadjustable balanced pointer with

knife-edge tip ensures reading to

the smallest subdivision. The

accented dial graduations have a

true width equivalent to 0.25%

tolerance for quick and accurate

gauge checking.

®

1

⁄2, 6, or 81⁄2" Dials

Wetted Parts

PGT-85L-100, $745,

shown smaller than

actual size. See next

page for dimensions.

PGT-60B-100, back mount, $480,

shown smaller than actual size.

See next page for dimensions.

Warning:

all gauge components should be

chosen with an eye to the media

and ambient operating conditions

to which they will be exposed.

Improper application can be

detrimental to the gauge, causing

failure and possible personal injury

and property damage.

†

Refer to the accessories chart on page

G-62 for NIST calibration ordering information.

To prevent misapplication,

G-60

G

PGT-45L-100, stem or flush

mount, $390, shown smaller

than actual size. See next

page for dimensions.

Page 2

TEST GAUGES—HIGH ACCURACY WITH MONEL®WETTED PARTS

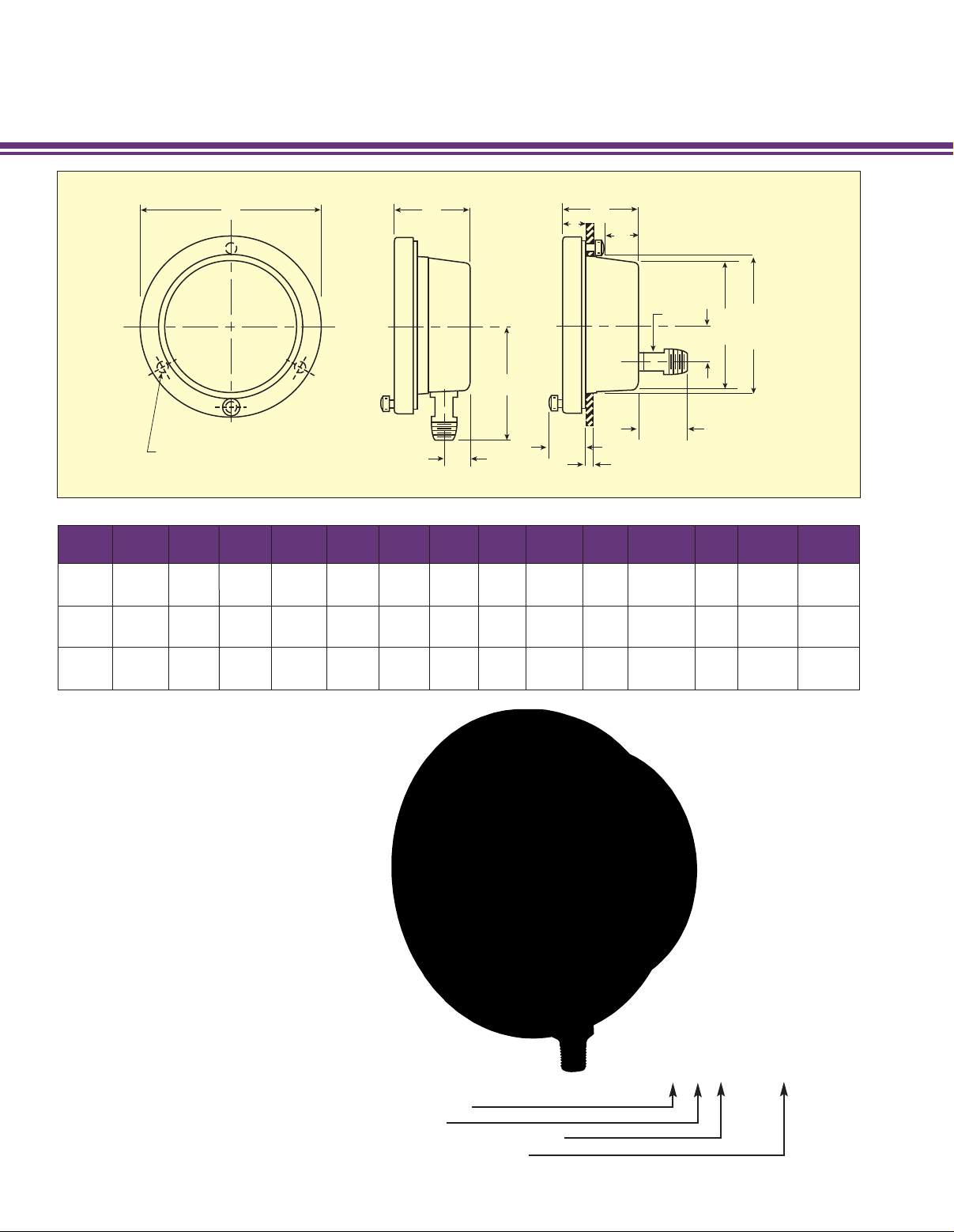

A

3 MOUNTING STUDS

G

D

B

M

Hole in

Panel

H

B

T

F

C

K

LL

CC threaded equally spaced

on E dia. B.C. (back connection only)

U

S

Dimensions: mm (in)

DIAL

SIZE

1

2

/

4

"

6"

1

2

/

8

"

ABCD EFGHKMS&T U CC LL

155 73 121 30 137 41 100 35 34 124 16 19

3

(

)(

6

⁄

32

192 73 121 30 178 41 114 35 34 165 16 19

9

(

) (

7

⁄

16

257 73 121 30 244 41 152 35 34 229 16 19

1

(

)(

10

⁄

16

Lower Mount

7

2

⁄

7

2

⁄

7

2

⁄

)(

4

8

) (

4

8

)(

4

8

3

)(

⁄

4

3

)(

⁄

4

3

)(

⁄

4

3

1

⁄

16

3

1

⁄

16

3

1

⁄

16

3

)(

)(

5

⁄

8

)(7)(

5

)(

)(

9

⁄

8

5

1

5

1

5

1

15

)(

⁄

8

) (

⁄

8

)(6)(

⁄

8

3

⁄

16

1

4

⁄

2

)(

)(

3

)(

1

⁄

8

3

)(

1

⁄

8

3

)(

1

⁄

8

Back Mount

11

1

/

11

1

/

11

1

/

7

) (4

32

) (6

32

)(9)(

32

)(

⁄

8

1

)(

⁄

2

5

⁄

8

5

⁄

8

5

⁄

8

3

)(

)(

)(

⁄

3

⁄

3

⁄

#10-24

)(

4

1

⁄4-20

)(

4

1

⁄4-20

)(

4

3 to 13

1

to

⁄

8

3 to 13

1

to

⁄

8

3 to 13

1

to

⁄

8

1

)

⁄

2

1

)

⁄

2

1

)

⁄

2

SPECIFICATIONS

Case: Solid aluminum with epoxy-

coated black finish

Window: Glass

Movement: Stainless steel

Bourdon Tube: Monel

Connection: Monel

Fitting:

Dial: Externally adjustable, aluminum,

white background, black graduations

and polished mirror band

Mounting:

Accuracy: 0.25% FS

Ring:

Safety Features: Solid front with pressure

relief back

Media Temperature: 66°C (150°F)

[models will withstand continuous

temperature up to 177°C (350°F), but there

will be discoloration of case and dial face]

Temperature Compensation:

0.005% FS/°F

1

⁄2 NPT

Stem: Lower connection

Panel or Stem: Back connection

Lower Connection Model:

Threaded aluminum

Back Connection Model: Mounting

flange, hinged cover ring secured by

knurled screw

Ordering Example:

1. Pressure Gauge:

Test Type

2. Dial Size: 41⁄2 "

3. Connection: Lower (L) or Back (B)

4. Range Code: See p. G-62

G-61

PGT-45L-100, stem or flush

mount, $390, shown

smaller than actual size.

See dimensions above.

PGT-45q– Range Code

Page 3

HOW TO ORDER TYPE T

TEST GAUGES

DIAL DIA. MODEL NO. CONNECTION PRICE

1

⁄

"

4

2

6"

1

⁄

"

8

2

[*] Insert range code from table below. To order cleaned for oxygen service, add suffix

“-X6B” to model number and $65. Note: Precision test gauges cannot be oil filled.

Ordering Example: PGT-45B-300, test gauge with 4

0 to 300 psi range, $390.

Standard psi Ranges

Type T

RANGE & TAB MINOR MINOR MINOR

CODE RANGE INTERVAL GRAD GRAD GRAD

15 0/15 1 0.05 0.05 0.02

30 0/30 2.5 0.1 0.1 0.05

60 0/60 5 0.2 0.1 0.1

100 0/100 5 0.5 0.2 0.2

150 0/150 10 0.5 0.5 0.2

200 0/200 10 0.5 0.5 0.5

300 0/300 25 110.5

400 0/400 25 111

600 0/600 50 221

800 0/800 50 222

1000 0/1000 50 522

1500 0/1500 100 552

2000 0/2000 100 10 55

3000 0/3000 250 10 10 5

5000 0/5000 500 20 10 10

10,000 0/10,000 500 50 20 20

VACUUM

30V 30/0" Hg 2.5 0.1 0.1 0.05

COMPOUND

RANGE INCHES

CODE MERCURY psi inHg psi inHg psi inHg psi inHg psi

30V/15 30 inHg Vac/0/15 psi 530.2 0.1 0.2 0.1 0.1 0.05

30V/30 30 inHg Vac/0/30 psi 550.5 0.2 0.2 0.1 0.2 0.1

30V/60 30 inHg Vac/0/60 psi 550.5 0.2 0.5 0.2 0.5 0.2

30V/100 30 inHg Vac/0/100 psi 10 510.5 0.5 0.5 0.5 0.2

30V/150 30 inHg Vac/0/150 psi 10 10 1 0.5 1 0.5 0.5 0.5

30V/200 30 inHg Vac/0/200 psi 30 20 2110.5 1 0.5

30V/300 30 inHg Vac/0/300 psi 30 20 212 110.5

30V/400 30 inHg Vac/0/400 psi 30 20 522 12 1

See the following page for custom and metric ranges.

ACCESSORIES

MODEL NO. PRICE DESCRIPTION

EI-CAL-3-PRESSURE†$150 NIST-traceable calibration

PGT-CC 140 Universal carrying case for all size test gauges

PGT-45L-[*] Lower $390

PGT-45B-[*] Back 390

PGT-60L-[*] Lower 480

PGT-60B-[*] Back 480

PGT-85L-[*] Lower 745

PGT-85B-[*] Back 745

1

⁄2" dial, back connection,

MOST POPULAR MODELS HIGHLIGHTED!

1

⁄2" DIAL 6" DIAL 81⁄2" DIAL

FIGURE

RANGE 41⁄2" DIAL 6" DIAL 81⁄2" DIAL

4

FIGURE MINOR GRAD MINOR GRAD MINOR GRAD

PRESSURE

GAUGES

G

PGT-45L-100,

stem or flush

mount, $390,

shown smaller

than actual size.

See dimensions

on page G-61.

PGT-45B-100, back mount, $390,

shown smaller than actual size.

See dimensions on page G-61.

Recommended Reference Book:

Pump Handbook,

ME-0341, $150.

Visit omega.com/bobi

for Additional Books

G-62

Page 4

SPECIAL METRIC RANGES FOR TYPE S (PAGES G-55 TO G-57)

AND TYPE T GAUGES (PAGES G-60 TO G-62)

TYPE S RANGE DIAL GRADUATIONS RANGE DIAL GRADUATIONS

OUTER SCALE

WHEN DUAL

2

kg/cm

PRESSURE

0/1 0/1 0.1 0.01 0/100 10 1 0/14

0/1.6 0/1.6 0.2 0.02 0/160 20 2 0/22

0/2.5 0/2.5 0.5 0.05 0/250 50 5 0/35

0/4 0/4 0.5 0.05 0/400 50 5 0/55

0/6 0/6 0.5 0.1 0/600 50 10 0/85

0/10 0/10 1 0.1 0/1000 100 10 0/140

0/16 0/16 2 0.2 0/1600 200 20 0/220

0/25 0/25 5 0.5 0/2500 500 50 0/350

0/40 0/40 5 0.5 0/4000 500 50 0/550

0/60 0/60 510/6000 500 100 0/850

0/100 0/100 10 1 0/10,000 1000 100 0/1400

0/160 0/160 20 2 0/16,000 2000 200 0/2200

0/250 0/250 50 5 0/25,000 5000 200 0/3500

0/400 0/400 50 5 0/40,000 5000 500 0/5500

0/600 0/600 50 10 0/60,000 5000 500 0/8500

0/1000 0/1000 100 10 0/100,000 10,000 1000 0/14,000

VACUUM

-1/0 -1/0 0.1 0.01 - 100/0 kPa 10 1 30/0 inHg

COMPOUND

-1/0/1.5 -1/0/1.5 0.5 0.05 - 100/0/150 kPa 50 5 30 inHg/0/20

-1/0/3 -1/0/3 0.5 0.05 - 100/0/300 kPa 50 5 30 inHg/0/40

-1/0/5 -1/0/5 0.5 0.1 - 100/0/500 kPa 50 10 30 inHg/0/70

-1/0/9 -1/0/9 1 0.1 - 100/0/900 kPa 100 10 30 inHg/0/125

bar

TYPE T RANGE

2

kg/cm

PRESSURE

0/1 0/1 0/100

0/1.6 0/1.6 0/160

0/2.5 0/2.5 0/250

0/4 0/4 0/400

0/6 0/6 0/600

0/10 0/10 0/1000

0/16 0/16 0/1600

0/25 0/25 0/2500

0/40 0/40 0/4000

0/60 0/60 0/6000

0/100 0/100 0/10,000

0/160 0/160 0/16,000

0/250 0/250 0/25,000

0/400 0/400 0/40,000

0/600 0/600 0/60,000

VACUUM

-1/0 -1/0 -100/0

COMPOUND

-1/0/1.5 -1/0/1.5 -100/0/150

-1/0/3 -1/0/3 -100/0/300

-1/0/5 -1/0/5 -100/0/500

-1/0/9 -1/0/9 -100/0/900

FIGURE MINOR FIGURE MINOR RANGE

INTERVAL

bar kPa

GRADUATION

kPa

- 100/01500 kPa 200 0 30 inHg/0/215

INTERVAL GRADUATION

PGS-25L-150, $80, shown

smaller than actual size.

SPECIFIED

PGT-45L-100, $390,

shown smaller than

actual size.

PGS-35L-30, $90, shown

smaller than actual size.

Ordering Special Ranges:

Type S and Type T custom dials are

available to fulfill the varying needs of

our customers. There is a $135 setup

fee and a 5-piece minimum order

per customized dial.

G-63

(psi)

Page 5

One Omega Drive | Stamford, CT 06907 | 1-888-TC-OMEGA (1-888-826-6342) | info@omega.com

EPG05

www.omega.com

UNITED KINGDOM

www. omega.co.uk

Manchester, England

0800-488-488

UNITED STATES

www.omega.com

1-800-TC-OMEGA

Stamford, CT.

CANADA

www.omega.ca

Laval(Quebec)

1-800-TC-OMEGA

GERMANY

www.omega.de

Deckenpfronn, Germany

0800-8266342

Karviná, Czech Republic

FRANCE

www.omega.fr

Guyancourt, France

088-466-342

CZECH REPUBLIC

www.omegaeng.cz

596-311-899

BENELUX

www.omega.nl

Amstelveen, NL

0800-099-33-44

More than 100,000 Products Available!

Temperature

Calibrators, Connectors, General Test and Measurement

Instruments, Glass Bulb Thermometers, Handheld Instruments

for Temperature Measurement, Ice Point References,

Indicating Labels, Crayons, Cements and Lacquers, Infrared

Temperature Measurement Instruments, Recorders Relative

Humidity Measurement Instruments, RTD Probes, Elements

and Assemblies, Temperature & Process Meters, Timers and

Counters, Temperature and Process Controllers and Power

Switching Devices, Thermistor Elements, Probes and

Assemblies,Thermocouples Thermowells and Head and Well

Assemblies, Transmitters, Wire

Flow and Level

Air Velocity Indicators, Doppler Flowmeters, Level

Measurement, Magnetic Flowmeters, Mass Flowmeters,

Pitot Tubes, Pumps, Rotameters, Turbine and Paddle Wheel

Flowmeters, Ultrasonic Flowmeters, Valves, Variable Area

Flowmeters, Vortex Shedding Flowmeters

pH and Conductivity

Conductivity Instrumentation, Dissolved Oxygen

Instrumentation, Environmental Instrumentation, pH

Electrodes and Instruments, Water and Soil Analysis

Instrumentation

Data Acquisition

Auto-Dialers and Alarm Monitoring Systems,

Communication Products and Converters, Data

Acquisition and Analysis Software, Data Loggers

Plug-in Cards, Signal Conditioners, USB, RS232, RS485

and Parallel Port Data Acquisition Systems, Wireless

Transmitters and Receivers

Pressure, Strain and Force

Displacement Transducers, Dynamic Measurement

Force Sensors, Instrumentation for Pressure and Strain

Measurements, Load Cells, Pressure Gauges, Pressure

Reference Section, Pressure Switches, Pressure Transducers,

Proximity Transducers, Regulators,

Strain Gages, Torque Transducers, Valves

Heaters

Band Heaters, Cartridge Heaters, Circulation Heaters,

Comfort Heaters, Controllers, Meters and Switching

Devices, Flexible Heaters, General Test and Measurement

Instruments, Heater Hook-up Wire, Heating Cable

Systems, Immersion Heaters, Process Air and Duct,

Heaters, Radiant Heaters, Strip Heaters, Tubular Heaters

click here to go to the omega.com home page

Loading...

Loading...