Page 1

PowerDAQ PD2-AO, PDXI-AO

PCI/PXI High-Density 16-bit Analog Output Board

User Manual

High-Performance Multifunction I/O boards for PCI Bus Computers

August 2001 Edition

© Copyright 1998-2001 Omega Engineering, Inc. All rights reserved

Page 2

All rights reserved. No part of this publication may be

reproduced, stored in a retrieval system, or transmitted, in

any form by any means, electronic, mechanical, by

photocopying, recording, or otherwise without prior written

permission.

Third Edition

August 2001 Printing

Information furnished in this manual is believed to be

accurate and reliable. However, no responsibility is assumed

for its use, or for any infringements of patents or other

rights of third parties that may result from its use.

Contacting Omega Engineering

✉

Address:

OMEGA Engineering, Inc.

One Omega Drive

Stamford, Connecticut 06907-0047

U.S.A.

! Support:

Telephone: 1-800-622-2378

Fax: 1-800-848-4271

"Internet Access:

Support support@omega.com

Web site http://www.omega.com

FTP site ftp://ftp.omega.com

Page 3

Table of Contents

i

Table of Contents

How to Use This Manual ......................................................iv

Introduction .......................................................................................... iv

Who Should Read This Book? .............................................................. iv

Organization of This Manual ............................................................... iv

Conventions Used in This Manual........................................................ vi

Feedback............................................................................................... vi

Introduction ..............................................................................2

About the PowerDAQ™ Analog Output series board.......................... 2

Overview ............................................................................................ 2

Features.............................................................................................. 3

AO Applications..................................................................................... 4

PowerDAQ AO Models.......................................................................... 5

Getting Started ...................................................................................... 5

Installation and Configuration............................................. 8

Unpacking..............................................................................................8

Hardware ...............................................................................................8

Installing Multiple Boards ..................................................................9

Software ................................................................................................ 9

Installation..........................................................................................9

Base address, DMA, Interrupt settings ............................................10

Diagnostics ........................................................................................10

Accessories ...........................................................................................13

Cables................................................................................................13

Screw Terminal Panels ......................................................................15

Complete kits ....................................................................................16

J1 Connector......................................................................................16

J2 Connector (PD2-AO only)............................................................16

J3-J8 Connector(PD2-AO-96 only) .................................................. 17

Architecture ........................................................................... 20

Functional Overview ............................................................................ 20

Analog Output Subsystem (AO) ......................................................21

Digital Output Subsystem ................................................................ 25

Digital Input Subsystem ................................................................... 25

Counter/Timer Subsystem ............................................................... 25

Calibration Subsystem...................................................................... 27

DSP Processor .................................................................................. 27

PCI Bus Interface ............................................................................. 27

Timing and Control ..........................................................................28

API and Third-Party Software Examples........................ 32

Page 4

Table of Contents

API Function calls ................................................................................ 32

API Examples .......................................................................................34

Third-party examples........................................................................... 34

Interconnections.................................................................... 36

PD2- AO-8[16][32] Connectors ...........................................................36

PD2- AO-96 Connectors ..................................................................... 37

PDXI- AO-8[16][32] Connectors ..........................................................38

PD2-AO-8[16][32] J1 Analog Connector .......................................... 39

PD2-AO J2 DIO/Counter/Timers/IRQx Connector..........................40

J1-J2 Connection Example ................................................................40

Appendix A: Specifications................................................. 43

PD2-AO specifications:........................................................................43

AO subsystem ..................................................................................43

Digital Input and Output .................................................................44

DSP – based subsystems.................................................................44

Appendix B: Accessories ..................................................... 47

Overview .............................................................................................. 47

Cables: (PD[XI]-CBL-xx)................................................................... 47

Screw Terminal Panels: (PD2-AO-STP-xx).......................................49

Screw Terminal Panels: (PD-STP-3716) ............................................50

OEM Header Distribution Connector............................................... 52

Accessory Board Connections.......................................................... 53

Appendix C: Common Questions and Support .............. 55

Calibration Questions....................................................................... 55

Service and Support............................................................................. 55

Technical Support Form ................................................................... 57

Appendix D: Warranty ........................................................ 58

Overview ..............................................................................................58

Index........................................................................................ 60

ii

Page 5

List of Figures

Table of Contents

Figure 1: PowerDAQ Control Panel Application ................................... 11

Figure 2: PowerDAQ control panel application showing PD2-AO-32

board installed ..................................................................................12

Figure 3:

Figure 4:

Figure 5:

Figure 6:

Figure 7: PowerDAQ™ PDXI-AO-8[16][32] Connectors ......................38

Figure 8:

Figure 9:

Figure 10: Configuring the PD2-AO-STP with PD2-AO-8[16][32] ..........41

Figure 11: Configuring the PD2-AO-STP with PDXI-AO-8[16][32].......... 42

Figure 12: PD2-AO-STP-32 Wiring Diagram ......................................49

Figure 13: PD-STP-3716 Wiring Diagram ............................................50

Figure 14: PD-CONN-PCB wiring diagram .............................................. 52

PD2-AO-STP-32 Wiring Diagram .......................................15

Block Diagram of the PowerDAQ PD2-AO boards........... 20

PowerDAQ PD2-AO-8[16][32] Connectors........................36

PowerDAQ™ PD2-AO-96 Connectors .............................. 37

Connector pin assignment for the J1 ................................39

Connector pin assignment for the J2 ...............................40

List of Tables

Table 1: PowerDAQ™ AO Models ......................................................5

Table 2: Сonversion between the PD2-MF(S) and PD2-AO board J1

connector pinout. ............................................................................53

Table 3: Dimensions of PowerDAQ™ AO accessory products ..............54

iii

Page 6

How to Use This Manual

How to Use This Manual

Introduction

This manual describes the PowerDAQ™ Analog Output

boards. The following boards are supported:

PD2-AO-8/16

PD2-AO-16/16

PD2-AO-32/16

PD2-AO-96/16

PDXI-AO-8/16

PDXI-AO-16/16

PDXI-AO-32/16

Two different form-factors are available – 32-bit 33 MHz

PCI and 32-bit 33 MHz PDXI. PDXI is a PowerDAQ extension

for instrumentation and is a superset of Compact PCI and

PXI bus industry-oriented standards.

Who Should Read This Book?

This manual has been designed to benefit the user of

PowerDAQ™ PD2-AO and PDXI-AO boards. To use

PowerDAQ™ Analog Output Board, it is assumed that you

have basic PC skills, and that you are familiar with Microsoft

Windows NT/2000/95/98/Me and/or Linux/QNX operating

environments.

Organization of This Manual

The PowerDAQ™ PD2-AO User Manual is organized as

follows:

Chapter 1 - Introduction

This chapter gives you an overview of PowerDAQ™ Analog

Output series board’s features the various models available

and what you need to get started.

Chapter 2 - Installation and Configuration

This chapter explains how to install and configure your

PowerDAQ™ Analog Output series board.

iv

Page 7

How to Use This Manual

Chapter 3 - Architecture

This chapter discusses the internal structure and subsystems

of your PowerDAQ™ Analog Output series board.

Chapter 4 – API and Third-Party Software

Examples

This chapter explains how to use PowerDAQ™ Analog

Output series boards using the PowerDAQ™ API on

Visual C++, VB, Delphi, C++ Builder

or Third-Party software such as LabVIEW®,

TestPoint®, DASYLab®, HP VEE®, etc.

Chapter 5 - Interconnections

This chapter describes the I/O connections to your

PowerDAQ™ Analog Output series board.

Appendix A - Specifications

This chapter lists the PowerDAQ™ Analog Output series

board hardware specifications.

Appendix B - Accessories

This appendix lists the PowerDAQ™ Analog Output series

board accessories products.

Appendix C - Common Questions and Support

This appendix contains a list of commonly asked questions

and their answers relating to usage and special features of

your PowerDAQ™ Analog Output series board board. Should

you require assistance while installing or using PowerDAQ™

Analog Output series board, support service details are also

listed.

Appendix D - Warranty

This appendix contains a detailed explanation of

PowerDAQ™ Analog Output series board’s warranty.

Index

The Index alphabetically lists topics covered in this manual.

v

Page 8

How to Use This Manual

Conventions Used in This Manual

These are the main conventions used to help you get the

most out of this manual:

Tips are designed to highlight quick ways to get the

TIP

job done, or good ideas you might not discover on

your own.

Note Notes alert you to important information.

CAUTION!

avoid injury, data loss, or system crash.

Text formatted in bold typeface may also represent type

that should be entered verbatim or a command, as in the

following example:

You can instruct users how to run setup using a command

such as setup.exe.

Feedback

We are interested in any feedback you might have

concerning our products and manuals. A Reader Evaluation

form is available on the last page of the manual.

Caution advises you of precautions to take to

vi

Page 9

1

Introduction

1

Page 10

Chapter 1: Introduction

Introduction

This chapter describes the basic features of the

PowerDAQ™ PD2-AO boards.

About the PowerDAQ™ Analog Output

series board

Thank you for purchasing a PowerDAQ™ Analog Output

series board. The board you received is either a PD2-AO PCIbus board or a PDXI-AO CompactPCI bus board. These

boards differ in certain hardware respects however the

software is the same.

The PDXI series Analog Output boards utilize all advantages

of the PXI/cPCI form-factor.

The associated PowerDAQ™ Software Suite (PD-SDK) has

been written specifically for these products.

Overview

The PowerDAQ analog output boards are configured as 8,

16, 32 or 96 channels. The PDXI versions are available in 8,

16 and 32 channel versions. The PowerDAQ Analog Output

board uses 16-bit DACs and allows you to configure the

start up states for each channel (200ms maximum delay

between system reset and power-on value loading). The onboard DSP/PCI interface allows you to use up to three 24bit counter timers, high-speed IRQ/External Clock lines,

eight digital inputs and eight high-drive (-32/64ma) digital

outputs. Additionally each board has a special calibration

subsystem, which is used to calibrate each analog output

channel.

2

Page 11

Features

The major features of the PowerDAQ AO boards are:

24-bit 66/100 MHz Motorola 56301 DSP (Digital Signal

Processor)

“Bus Master Ready” PCI Bus Host PC Interface (PCI 2.1

Compliant)

• 8/16/32/96 channel 16-bit +/- 10V DACs

• DC-100KHz per D/A throughput

• 2MHz/board maximum update rate

• 1/2/4/8/16/32/64 Fixed/Unlimited channel list length

• Asynchronous/Simultaneous update modes for the all

DACs

• Eight Digital Inputs

• Eight Digital Outputs

• Counters/Interrupt/Synchronization inputs

• Per-channel calibration

• Sense lines for the each DAC (optional), jumper-

selectable on PDXI models

• User-defined Power-Up states for the each DAC (200

ms maximum setup time after the system reset) Default

is 0V.

• Three 24-bit counter timers (16.5/25MHz maximum)

• On-board 2K FIFO (located in the DSP memory)

• 32Ksamples FIFO upgrade option

• Software:

Chapter 1: Introduction

PowerDAQ for

Windows95/98/Me/NT/2000/XP/Linux/QNX

Visual C++, VB, Delphi, C++ Builder, Kylix

Drivers for: LabVIEW®

HP VEE®

LabWindows/CVI®

TestPoint®

DASYLab®

DiaDem®

MATLAB DAQ Toolbox

Note For the full list of specifications,

Specifications.

see Appendix A:

3

Page 12

AO Applications

PowerDAQ Analog Output series boards provide a wide

range of powerful features that cover a wide range of

applications. The most common applications are:

• Process Control

• ATE

• Closed-loop Servo-Control

• Motor Control

• Individual DAC voltage output

• Telecommunications equipment control (micro mirrors)

The Digital Input and Digital Output Subsystems applications:

• Electro-mechanical relay control applications

• Solid-state relay applications

• Alarm System sensors

• Digital motion control

The Counter-Timer Subsystem applications:

• PWM modulator

• Frequency counter

• Pulse generator

Chapter 1: Introduction

4

Note The easiest way to expand the possibilities of the PD2AO/PDXI-AO board is to use the PD2-MF/S or PDXIU-MF/S

multifunction boards series in the same PC.

Page 13

PowerDAQ AO Models

PowerDAQ PD2-AO/PDXI-AO model numbers are derived as

follows:

PD2-[Type Of Board]-[Channels]-[Speed]/[Resolution][Gain]

PDXI-[Type Of Board]-[Channels]-[Speed]/[Resolution][Gain]

The types of boards are:

MF Multifunction

AO Analog Output

DIO Digital Input /Output

CTM Counter Timer

Models AO Features

PD2-AO-8/16 PCI bus Eight 16-bit Analog Output Channels

PD2-AO-16/16 PCI bus Sixteen 16-bit Analog Output Channels

PD2-AO-32/16 PCI bus Thirty-two 16-bit Analog Output Channels

PD2-AO-96/16 PCI bus Ninety-six 16-bit Analog Output Channels

PDXI-AO-8/16 PXI/CPCI bus Eight 16-bit Analog Output Channels

PDXI-AO-16/16 PXI/CPCI bus Sixteen 16-bit Analog Output Channels

PDXI-AO-32/16 PXI/CPCI bus Thirty-two 16-bit Analog Output Channels

Chapter 1: Introduction

Table 1: PowerDAQ™ AO Models

All PowerDAQ™ AO boards have the following additional

features:

Digital Input Eight static digital inputs

Digital Output Eight static digital outputs

Clock/Interrupt Lines

Counter Timers Three 24-bit (33/50MHz

Internal/16.5/25 MHz External)

Getting Started

To get your PowerDAQ AO board up and running, ensure

that you have the following:

A computer with PCI slots (for PD2-AO models) or PXI/CPCI

slots (for PDXI-AO models) and the BIOS compliant to

PCI Specifications 2.1 or greater. S

Common Questions and Support.

PowerDAQ™ PD2-AO PCI/PDXI-AO board with user manual.

ee Appendix C:

5

Page 14

Chapter 1: Introduction

Latest PowerDAQ™ Software Suite CD (PD-SDK) Software.

This can be downloaded from

www.PowerDAQ.com/download

Minimum 16MB RAM for Windows9x and 32MB for

Windows NT/98/Me and 64MB for Windows 2000

6

Page 15

2

Installation and

Configuration

7

Page 16

Chapter 2: Installation and Configuration

Installation and Configuration

This chapter describes the hardware and software

installation and configuration of the PowerDAQ AO board.

Unpacking

Your PowerDAQ™ AO board is wrapped in an anti-static

bag to protect against electrostatic charges that might

damage the board. To avoid damage, proceed as follows:

Ground yourself with a grounded wrist strap or grounded

source.

Discharge the static electricity by taking the board in the

antistatic bag and touching the metal part of your PC.

Remove the board from the antistatic bag. We suggest you

save the bag.

Inspect the board for any damage. If any damage is found,

notify your distributor to return the board to the

manufacturer.

Support.

See Appendix C: Common Questions and

Note The PowerDAQ AO boards contain sensitive electronic

components. Please make sure the proper grounding and

electrostatic conditions are used.

Hardware

You can install your PowerDAQ PD2-AO board in any PCI

slot. PDXI-AO boards should be installed into the Compact

PCI/PXI/PDXI chassis only. We recommend you use the first

available slot and complete the following instructions:

PCI board installation:

1. Turn off your PC.

Remove the cover and make sure you have clear access to

Connect all desired cables to the PD2-AO board.

Insert the PowerDAQ PD2-AO board into a PCI slot. (If the

8

the PCI slots.

PCI slots have not been used for a long time, insert the

PowerDAQ PD2-AO board, then remove it and clean

Page 17

Chapter 2: Installation and Configuration

the edge connector with alcohol. After this has been

done, replace the bard back into the slot.)

Screw the bracket and replace the cover.

Turn the PC on.

PDXI board installation:

1. Turn off your PC.

2. Remove the slot cover.

3. Insert the PowerDAQ PDXI-AO board into a slot.

4. Screw the bracket.

5. Turn the PC on.

The PowerDAQ AO board is now installed. All board

configurations are controlled via software using the PDSUITE.

Note For the Windows 95/98/Me/2000/XP platforms, you

should install PowerDAQ Software Suite prior the board

installation.

Installing Multiple Boards

You can install multiple PowerDAQ AO boards in one PC.

You are limited to the number of PCI/PDXI slots in your PC.

Software

PowerDAQ Software Suite CD contains drivers and software

(example code with source code) for Windows, Linux and

QNX (optional). You can always download the latest

software suite from www.PowerDAQ.com/download.

Installation

From the CD, run the SETUP.exe program. The setup

program will take you through the installation process. If

you downloaded the PowerDAQ software from the web you

just need to run the file downloaded and follow the setup

instructions.

9

Page 18

Chapter 2: Installation and Configuration

As the installation process modifies your Windows registry,

you must only install or uninstall the software using the

appropriate programs.

Note Never delete the PowerDAQ software from you PC

directly. Always use Uninstall program from PowerDAQ folder

or Control Panel/Add-Remove Programs applet.

Note Once the installation is complete, the PC must be

rebooted for proper operation.

Note Windows NT/2000/XP users must be logged in as an

administrator or have equivalent access.

Base address, DMA, Interrupt settings

The PowerDAQ AO boards are configured automatically by

the computer BIOS on power up. Usually you do not have to

set any base address, DMA channels or interrupt levels. The

PowerDAQ driver is designed to share interrupts over PCI

devices but very rarely will the BIOS assign same interrupt to

mass-storage devices such as a SCSI controller or video card

and a PowerDAQ board. In this case it could be significant

latency between the time when board fires an interrupt and

the time the PowerDAQ driver actually receives it. In this

case we recommend changing your BIOS settings and

assigning a dedicated interrupt for the PowerDAQ board.

Please refer to your motherboard/computer manual for the

BIOS settings change procedure.

Diagnostics

In order to confirm board operation, install the PowerDAQ

Suite. This automatically installs the PowerDAQ application

control panel diagnostic program that will display all

available PowerDAQ boards in your system.

10

Page 19

Chapter 2: Installation and Configuration

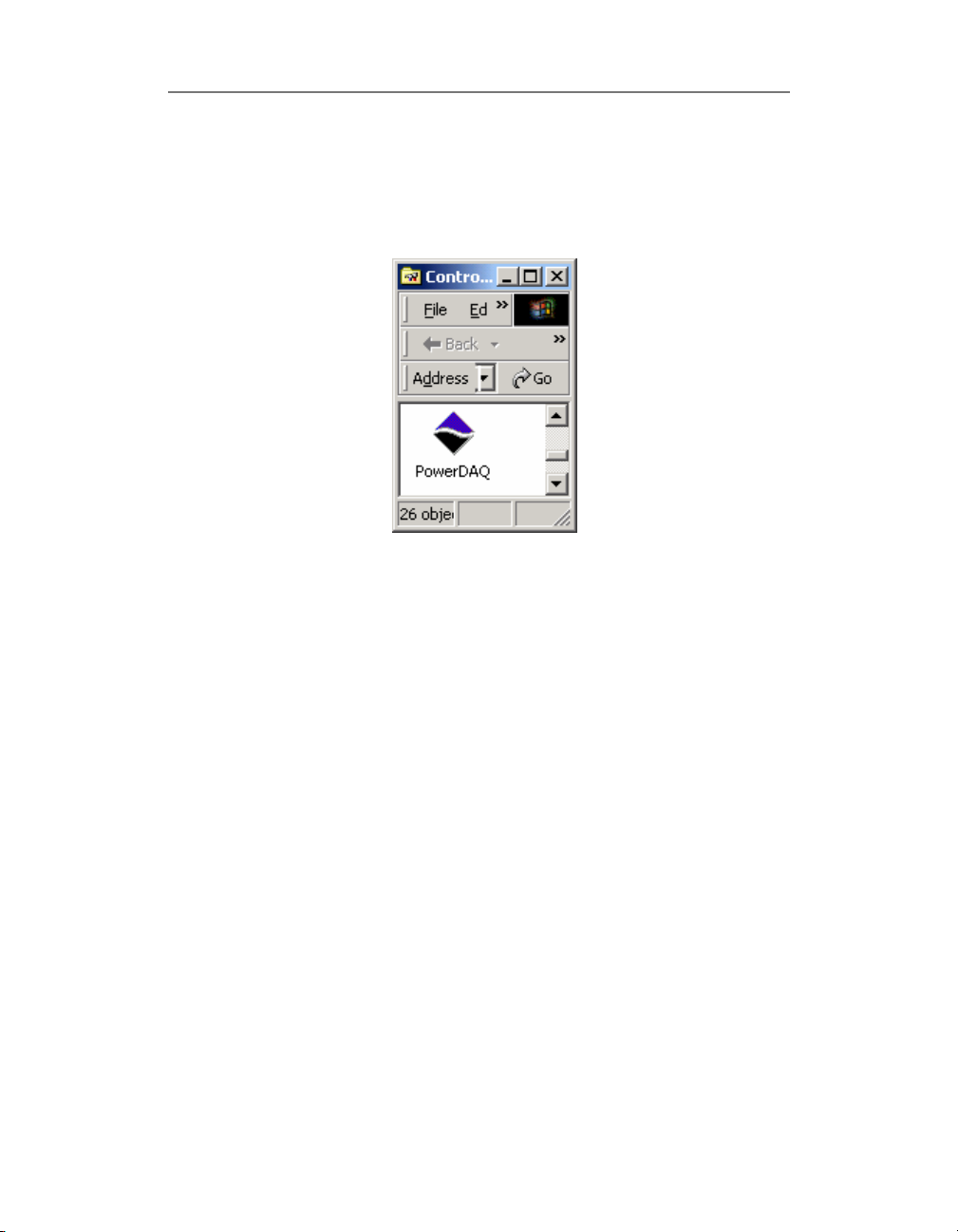

To access the PowerDAQ control panel, select START >

Settings > Control Panel and the PowerDAQ icon will be

displayed.

Figure 1: PowerDAQ Control Panel Application

An alternative test is to use the SimpleTest program installed

by the Software Suite. Attached a oscilloscope of multimeter

to the outputs of the AO board. Run the SimpleTest.exe

program by selecting START > Programs > PowerDAQ >

Delphi Acquisition Demo. This program shows all

information about the board(s) installed and allows you to

test all subsystems available on the board selected for the

test.

11

Page 20

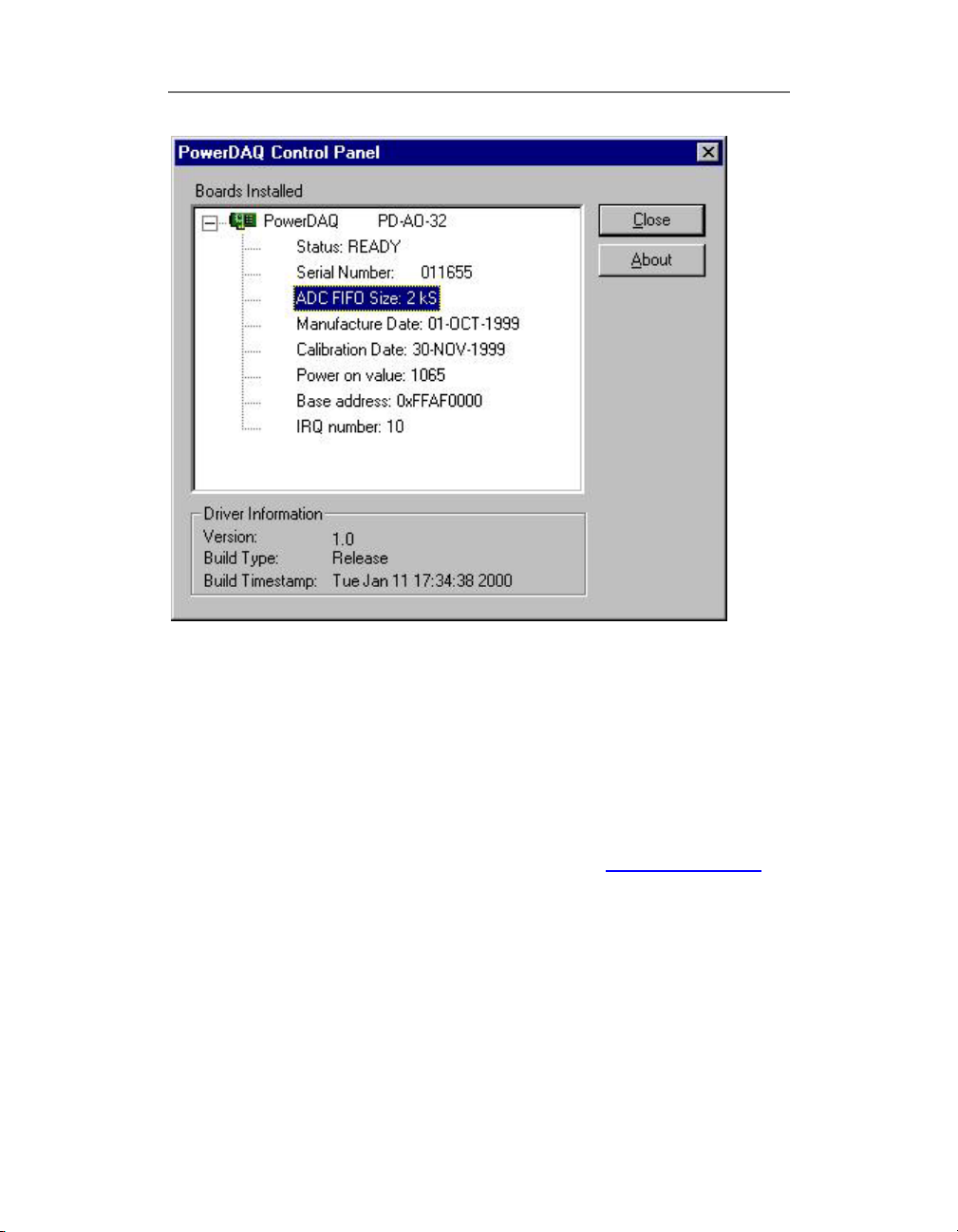

Chapter 2: Installation and Configuration

Figure 2: PowerDAQ control panel application showing PD2-AO-

32 board installed

Please refer to the PowerDAQ Software manual for a

complete set of ready to run example programs and the

detailed API for programming of the PowerDAQ AO boards.

All PowerDAQ AO manuals are supplied in electronic Adobe

Acrobat PDF format. If you require the PDF reader, this can

be downloaded from the Internet from www.adobe.com

12

Page 21

Accessories

PowerDAQ AO boards have an extensive range of optional

accessories:

Cables (3ft, 6ft or 9ft)

Screw terminal panels

Complete kits

J1 high-density analog cable (PD2-AO-8[16][32] only)

J2 PD-CBL-37 DIO connection kit (PD2-AO only)

J3-J8 IDC40 to DB37 flat/twisted pair ribbon cable (PD2-

AO-96 only)

J1 to J1/J2 splitter analog/digital cable

Cables

Digital cable (PD2-AO boards only)

PD-CBL-37: The J2 connector uses a 37-way ribbon

Chapter 2: Installation and Configuration

connector set. It comprises of a 13” internal

ribbon cable, which connects from the

PowerDAQ AO board J2 internal digital

connector (DIO /Counters/IRQs) to a 37-way

D-SUB bracket. A 1-meter ribbon cable then

connects from the bracket to the PD2-AOSTP accessory panels.

Analog cable (PD2-AO-8[16][32] boards only)

PD-CBL-96: The J1 connector uses a 96-way shielded

round 1-meter cable with a metal connector

on either end. It connects to: PD2-AO-STP16or 32, PD-BNC-16 or 64 accessory panels.

13

Page 22

Chapter 2: Installation and Configuration

Analog cable (PD2-AO-96 boards only)

PD-CBL-4037TP: The J3-J8 connector uses a 36-way flat

or twisted pair ribbon cable (DB37 to IDC40)

to bring out the analog output signals. It

connects to: PD-STP-3716, so one PD2-AO96/16 board requires a set of six cables and

terminals for all ninety-six channels.

Note The PowerDAQ PD2-AO-8/16/32 boards require a PDCBL-96 and the PD2-AO-96 requires up to 6 PD-CBL-4037TP.

If digital IO/CTM is going to be used, an optional PD-CBL-37

cable is required.

Custom cables are available. Please contact the factory for

more details.

Splitter analog/digital cable (PDXI-AO boards

only)

PDXI-CBL-AO: The J1 connector uses a split round

shielded cable, which brings out the analog signals to a 96way “pin-less” Fujitsu connector and the digital I/O signals

to 37-way DB-37 connectors.

14

It connects to: PD2-AO-STP-xx, PD-BNC-xx accessory panels.

Page 23

Screw Terminal Panels

The PD2-AO-STP-16/32 is a 16/32-channel screw terminal

panel, which also includes connections for the counter

timers, high speed interrupt/synchronization lines and DIO

ports. Using the jumpers, each sense line can be connected

to the appropriate output directly on the screw terminal.

Note For the all PDXI-AO boards, the sense to force line

jumpers are located directly on the board. All jumpers should

be removed from the PD2-AO-STP panel in this case.

Because of compatible pin-outs, the PD-BNC-xx terminals

can be used with PD2-AO-8[16][32] boards. Custom terminal

panels are available. Please contact the factory for more

details.

Chapter 2: Installation and Configuration

Cable PD-CBL-96

PD-AO-STP-32

PDXI-CBL-AO

PD2-AO Board

Cable PD-CBL-37

PDXI-AO

board

PD-AO-STP-32

Figure 3: PD2-AO-STP-32 Wiring Diagram

15

Page 24

The PD-STP-3716 is a low cost 16-channel screw terminal

panel, which can be used with the PD2-AO-96/16 or PD2AO-8/16. This terminal contains analog signals only. For the

digital signals, you will need the PD-STP-DIO.

Complete kits

We have included the PD-CBL-96 and the PD2-AO-STP-32

into a complete kit for the PD2-AO-8[16][32] boards. The

product is available by ordering PN PD2-AO-STP-16KIT or -

32.

Also complete kits are available for the PDXI-AO boards.

These products are available by ordering PN PDXI-AO-STP16KIT or –32KIT.

J1 Connector

If you wish to develop you own custom cable, you can

purchase the connector and metal cover from your

distributor or the factory. The part number is PD-CONN.

Chapter 2: Installation and Configuration

The manufacturer is:

Fujitsu Takamisawa America, Inc.

Telephone: 408-745-4990 Fax: 408-745-4995

The manufacturers’ part number for the connector is

FCN-230C096-C/E and the metal cover FCN-247J096G/E.

Custom terminal panels are available. Please contact your

distributor or the factory.

J2 Connector (PD2-AO only)

J2 connector is a 36-way boxed IDC header.

The manufacturer is Tomas & Betts (www.tnb.com

The manufacturers’ part number for the connector is 609-

3627.

16

) .

Page 25

Chapter 2: Installation and Configuration

J3-J8 Connector(PD2-AO-96 only)

J3-J8 connectors are 40-way boxed IDC headers.

The manufacturer is 3M (http://www.mmm.com/esm/

The manufacturers’ part number for the connector is 25406002UB.

).

17

Page 26

Chapter 2: Installation and Configuration

18

Page 27

3

Architecture

19

Page 28

Chapter 3: Architecture

Architecture

This chapter describes the functional operation of the PowerDAQ

AO boards.

AOUT31 SENSE

AOUT30 SENSE

)

1

J

(

r

o

t

c

e

n

n

o

C

t

u

p

t

AOUT1 SENSE

u

O

g

o

l

a

n

A

l

a

n

r

AOUT0 SENSE

e

t

x

E

AOUT31

AOUT30

AOUT1

AOUT0

s

r

e

i

f

i

l

p

m

A

t

u

p

t

u

O

g

o

l

a

n

A

AOut Calibration

DACs

DAC31

DAC30

DAC29

DAC28

DAC3

DAC2

DAC1

DAC0

Voltage

Reference

AOut Control

s

s

e

r

d

d

Local Data Bus

A

M

m

l

k

O

c

F

o

I

I

l

F

S

C

t

S

t

u

E

u

O

O

A

A

Motorola 66MHz DSP 56301

Bus Master P CI Interface

l

o

r

t

n

o

C

a

e

r

n

g

A

n

M

o

a

r

A

M

h

P

R

D

C

k

6

2

1

s

s

e

r

d

d

A

32 Bit PCI Bu s

A

p

a

R

r

k

r

t

a

M

c

e

t

s

o

s

O

t

a

l

o

U

R

C

D

o

k

B

2

1

a

t

a

D

DIn Control

k

r

c

e

o

s

l

U

C

DOut Control

Counter

3x24-bit

Interrupt

(Driver)

IRQA

IRQB

IRQC

Configuration

& Calibration

EEPROM

Timer

Digital

Buffer

Latch

Digital

Output

Figure 4: Block Diagram of the PowerDAQ PD2-AO boards

Functional Overview

Although there are some functional differences between the

PD2-AO and PDXI-AO boards they all utilize the same

PowerDAQ software, which significantly simplifies the

software development process.

User

Input

Clock

Out

(8)

3

2

J

r

3

o

t

c

e

n

n

o

C

(8)

O

/

I

l

a

t

i

g

i

D

l

a

n

r

e

t

n

I

20

Page 29

Analog Output Subsystem (AO)

The PowerDAQ II analog output boards are configured as 8,

16, 32 or 96 sixteen-bit output channels. On the PD2-AO8[16][32] each channel has an optional sense line to provide

16-bit accuracy at rated output current. The PDXI-AO board

allows the use of sense lines on the first sixteen channels by

installing on-board jumpers. The PD2-AO-96 does not

provide the sense line option.

Note The default sense line option is not available on PD2AO boards because of noise considerations – high currents

going through the cable induce more noise) and sense lines

carry the same signal as corresponding output lines inside the

cable. Please take this into consideration when configuring the

sense lines (if required).

The AO subsystem also includes input modes, channel

queue, trigger and clocking control.

Interrupt (event) generation: You can use events to provide

gap-free updates of the analog outputs.

Chapter 3: Architecture

There are three update modes for the analog subsystem

• Single update

• Event (interrupt) – based waveform mode

• Continuous pulled-IO waveform mode and auto-

regeneration waveform mode.

The user can define the power-on value of each channel

(the default start-up value is set to zero). The included

utility application “Start-Up Configuration Wizard”

(StartUpState.exe) is installed by the SDK can be used to

modify the start-up states.

Note The Power-On state will be loaded into the DACs with

200 ms maximum delay after the system reset. The calibration

values will be loaded only when PowerDAQ driver is loaded

and up to +/-30 mV offset is possible on the outputs during

the system boot process.

21

Page 30

Chapter 3: Architecture

Note The quad output DACs has current limitations. Only

one output of each quad can be continuously shorted to

ground. Two, three and even four channels shorted to ground

MUST NOT exceed five seconds.

Analog Output Mode

Single Update

The PowerDAQ AO boards operate with either a singleupdate or streaming (waveform) output configuration.

Single-update mode allows direct write access to any of the

16-bit DACs of the PowerDAQ AO board. The update

frequency is at least 1kHz for the single update mode and

can be as high as 15KHz in real-time operating

environments. The single update speed is dependent on your

PC system speed.

Note There is a special sub-mode of the single update mode

when all or selected DAC’s outputs are updated

simultaneously.

22

Event-based Waveform

Event-based waveform mode allows continuous waveform

generation and is not limited by the amount of data. Each

time the DSP based FIFO is ½ full an interrupt is fired to

request additional data to be sent to the board. The

PowerDAQ advanced buffering mechanism hides those

interrupts from the user and allows you to work with big

output arrays logically divided by frames. The end of each

frame can generate an event, which will request more data

from the application. Complete information on the

PowerDAQ advanced circular buffer (ACB) can be found at

www.POwerDAQ.com

Note If the on-board FIFO is empty or the last value is

outputted, the board will continue outputting the last DC

value.

Page 31

Chapter 3: Architecture

Auto-regeneration Waveform (circular waveform)

Auto-regeneration waveform mode can be used to create

fixed length waveforms without any host intervention of

user software after the subsystem has initialized. An

application writes data to the buffer of the PowerDAQ AO

board and each time the end of buffer is reached, it starts

to resend the same buffer again. Note, that 2048 samples

can fit into the on-board DSP memory and auto

regeneration of up to 2048 samples will not require any

intervention of the host PC.

Channel List

There are two ways do define a Channel List for the

PowerDAQ AO board. First, when the output data and

channel number are combined together to provide the

output channel selection. In this situation, the lower 16 bits

are data, the following upper 8, the channel number and

special flags (see the picture below).

This mode supports update rates up to 455KS/sec

31 23 15 0

Not used 16-bit output data

Bits 16-20 are used to define the output channel number on

a PD2/PDXI-AO-8[16][32] board.

Bit 21, when set is used as a Write and Hold Flag – this is

used to write data to the DAC WITHOUT updating it on a

PD2/PDXI-AO-8[16][32] board.

Bit 22, when set is used as an Update All Flag – all DAC’s

will be updated by the previously written data on a

PD2/PDXI-AO-8[16][32] board.

PD2-AO-96 board only:

Bits 16-22 are used to define the output channel number on

PD2/PDXI-AO-8[16][32] boards.

Flags,

23

Page 32

Chapter 3: Architecture

Bits 21,22,23 when all set together are used as a Write and

Hold Flag – written to DAC’s data with this bit set will not

update output.

Bits 23, when set is used as Update All Flag – all DAC’s will

be update by previously written data.

This is the default configuration, which provides an

unlimited channel list length.

Another way to define the channel list is a series of

continuous channel numbers(1/2/4/8/16/32/64), up to the

number of ports available on the AO board, starting at any

channel. For example, the PD2-AO-32, channels 0 through

15 can be specified as a channel list of channels to be

updated in Event-based Waveform Mode and the remaining

channels can be used in Single Update Mode.

This mode is called DMA-based update mode and supports

output rates up to 1.6 MS/sec.

Note There is a dedicated function in the PowerDAQ API

called _PdAO32SetUpdateChannel which can be used to

specify the update channel number. Any write to this channel

will force the update of all DAC’s.

24

Page 33

Digital Output Subsystem

There are eight static digital outputs on the PowerDAQ

analog output board. They are TTL/CMOS output level

compatible, 2000V ESD protected. Due to the static nature

of the outputs they can be updated at any time without any

limitations. Digital outputs provide high current compatibility

(-32/64 ma), which support drive relays or these lines can

be used for control applications.

Digital Input Subsystem

There are eight static digital inputs on the PowerDAQ analog

output board. They are TTL/CMOS input level compatible,

2000V ESD protected. Due to the static nature of the inputs

they can be read at any time without any limitations.

Chapter 3: Architecture

Counter/Timer Subsystem

Depending on your PowerDAQ AO operation mode, the

board can support up to the three DSP based 24-bit

counter/timers with a maximum count rate up to 33 MHz

for 66MHz DSP and 50MHz for 100MHz DSP (PDXI-AO

only) for an internal base clock and 16.5 MHz/25MHz for

the external clock. The minimum count rate is 0.001 Hz for

the internal clock and no low limits for the external clock.

Note For all waveform modes, only Timer0 and Timer1 are

available for use.

Programming of the counter/timer subsystem of the PD2AO board requires a minimal understanding of the Triple

Timer Module of the Motorola 56301 DSP. For this

information please refer to the

Manual

(Motorola P/N DSP56301UM/AD).

Motorola DSP 56301 User

25

Page 34

Chapter 3: Architecture

Each timer can be used for internal or external clocking and

can interrupt the on-board DSP after a specified number of

events (clocks) or signal an external device after counting

internal events. Each timer can also be used to trigger DMA

transfers after a specified number of events (clocks) have

occurred. Each timer connects to the external world through

one bi-directional pin TIO that is 7kV ESD protected. When

TIO is configured as input the timer functions as an external

event counter or can measure external pulse width/signal

period. When TIO is used as output, it functions as a timer,

watchdog or Pulse Width Modulator.

Some common timer/counter/output functions that

microprocessors require are:

Real time clock,

Event counter

Digital one-shot

Programmable rate generator

Square wave generator

Binary rate multiplier

Complex digital wave form generator

Complex motor control

26

Note Each counter is a 24-bit count-up counter

After power-up, the count value and output of all counters

are set to zero

Each counter must be programmed before it can be used

Unused counters need not to be programmed

Use the PowerDAQ API to program counters.

Each counter is fully independent of the others. Only

prescaler, when used, is a common part of the counter-timer

subsystem. Each counter may operate in a different mode

Page 35

Calibration Subsystem

The calibration subsystem is used to calibrate each analog

output zero offset (with 150-microvolt accuracy) and output

range (PD2-AO only). The calibration data is stored in the

on-board EEPROM. Additionally a PowerDAQ AO board

provides an application for the user to configure the startup output value of the any DAC. This value will be loaded

immediately after a system reset or power-on with 200 ms

maximum latency.

DSP Processor

All PowerDAQ AO boards are based on the Motorola 56301

DSP. This is a 24-bit 66/100 MHz processor with an

integrated PCI interface. The PCI interface implements the

PCI Local Bus Specifications so the board is fully autoconfigured (base address, interrupt).

When the PowerDAQ software is loaded, the PowerDAQ AO

firmware is downloaded to the DSP via the PCI bus. This

firmware contains all the code necessary to communicate

with the board subsystems and the host PC driver.

Chapter 3: Architecture

Note The drivers from the PowerDAQ web site always

contain the latest versions of the DSP firmware.

Note Custom programming of the DSP is not available with

the standard PowerDAQ AO product. However, should you

require DSP processing, please contact the factory.

PCI Bus Interface

The PowerDAQ AO boards communicate via the PCI bus. The

PCI bus interface is embedded in the Motorola 56301 DSP.

On power up, the host PC automatically configures the

boards base address and interrupt resources.

27

Page 36

Timing and Control

The PowerDAQ AO clocking and triggering features are

extensive and can be configured in various different ways.

Analog Output Clocking

Clocking comprises of two input signals:

1. Clock In – used to clock analog output channels in

channel list.

2. Trigger In – used to start/stop acquisition

.

You must load the channel list prior to starting this

operation.

Clocking can be controlled by:

Software Strobe

Internal Clock (DSP)

External Clock

Chapter 3: Architecture

28

Universal External Interrupt/Clock/Synchronization Inputs

Note You can only use these lines for Analog Output

Clocking OR Triggering

Triggering is configured as follows:

Use the IRQB pin to asynchronously update all DACs.

Use the IRQC pin to supply your external trigger source.

Trigger modes:

Start trigger (acquisition starts on rising edge of the trigger

signal)

Stop trigger (acquisition stops on rising edge of the trigger

signal)

Trigger lines should be pulled-down to ground via 4.7Kohm

resistors.

Page 37

Chapter 3: Architecture

Synchronizing two or more boards

Note Using the PowerDAQ AO control panel application,

please ensure the software driver recognizes the two or more

PowerDAQ AO boards. No custom synchronization cables are

required – all connections can be made directly on the screw

terminal. PDXI-AO boards provides a special configuration

program PDXICFG.EXE that allows synchronize boards via the

PXI bus extension. This feature is not available in standard

Compact PCI chassis.

If internal connection between multiple boards is required,

the following connections should be made (PD2-AO boards

only):

The PowerDAQ PD2-AO J2 internal connector has a TMR2

Clock I/O pin. You can connect this pin to the TMR2 pin of

the next board you wish to synchronize acquisition. It is

preferable to use a 100-200 Ohm series resistor for the clock

connection.

For a custom cable contact the factory.

29

Page 38

Chapter 3: Architecture

30

Page 39

4

API and Third-Party

Software Examples

31

Page 40

Chapter 4: API and Third-Party Software

API and Third-Party Software

Examples

The PowerDAQ Software Suite API and third party software

drivers support all PowerDAQ AO board features. This

chapter provides an overview on how to use the API calls

and examples using third-party software.

API Function calls

Please refer to PowerDAQ SDK and programmer manual for

the details about Analog Output board programming.

Generally Analog Output subsystem works in the same way

as all other paced subsystems. The following command

sequence should be used to program the PowerDAQ AO

board in a low-level language such as C/C++/VB/Delphi:

• Open Driver. This allows you to check that the driver

is installed properly and started and also gets a

number and parameters of the PowerDAQ boards

installed in the system.

32

• Open Adapter. After the adapter is opened the

PowerDAQ SDK return a special handle that should

be used for all calls referring to a specific

PowerDAQ board installed. This call locks the

specific PowerDAQ board by the specific application.

• Open Subsystem. This call grants access to one of

the available PowerDAQ board subsystems. The

following subsystems can be accessed on a

PowerDAQ Analog Output board: Analog Output,

Digital Input, Digital Output, DSP Counter and

Calibration.

• Work with subsystem. There are two different ways

to use a subsystem – in synchronous and

asynchronous mode.

Page 41

Chapter 4: API and Third-Party Software

• In Synchronous Mode (known as Single Update on

the AO subsystem) there is a set of calls available

which gives direct and immediate access to the

DACs (DIO ports and DSP Timers). Timed access can

be made using the operating system based timing

loops.

• In Asynchronous Mode (which has two sub-modes

on PowerDAQ AO boards – event-based and

regenerate mode) , a dedicated acquisition buffer is

allocated in host PC memory. This buffer is divided

by the number of logical blocks called frames,

usually between 4 and 16 frames should be

allocated. The following steps should be considered

when Asynchronous acquisition mode is used:

# User application uses API calls to allocate the

acquisition buffer and fill it with initial data for all

output subsystems.

# Subsystem configuration word should be assembled

using the API constants provided.

# The user application should define a set of events

from the board. A typical set of events include data

availability events and error events

# Start of asynchronous operation

# WaitForSingleObject operating system function call

or an equivalent should be used to check for events

from the board. It is preferable to put this call into

a separate thread. After an event, the application

should re-initialize it and process the data.

# Terminate asynchronous operation

# Auto-regenerate mode user application can allocate

one or more frames in the buffer, fill it with data

and start acquisition. The PowerDAQ driver will

control event handling and supply more data into

the on-board FIFO as requested. Note, that frame

size cannot exceed 64Mbytes. The size of the

buffer itself is limited by the amount of Physical

memory installed on your PC.

33

Page 42

Chapter 4: API and Third-Party Software

• Close subsystem. When the application closes the

subsystem it’s frees-up resources.

• Close adapter. After the adapter is closed it is

accessible from other applications.

• Close driver.

API Examples

The PowerDAQ Software Suite contains a complete set of selfdocumented examples dedicated to PowerDAQ AO boards

programming. The best way to write your own program is to use a

ready-to-run example and modifiy it as required by your application.

The examples are available in the following languages:

C/C++/Delphi/VisualBASIC:

• Single Update Example (Separate example available for the

PD2-AO-96/16 board)

• Buffered output Example (Event-based)

Please refer to the example sources for extensive programming details.

All examples are located in

<Program Files

Dir>\PowerDAQ\SDK\Examples\<Language>\<Example>

Third-party examples

All third-party drivers, supplied by OMEGA include a set of examples,

which support all of the PowerDAQ Analog Output board features.

They are usually installed during the SDK installation process into the

folders defined by third-party software vendors. Please refer to the

readme file of the SDK version to find an exact location of the

examples you need.

34

Page 43

5

5

Interconnections

3

Page 44

Chapter 5: Interconnections

Interconnections

PD2- AO-8[16][32] Connectors

The PowerDAQ PD2-AO-8[16][32] boards have two

connectors and one header:

96-contact high-density Fujitsu header – analog output

connector (J1)

36-way boxed IDC header (DIO/Timer and IRQ lines)

J2

J1 Connector

PowerDAQ(tm)

PD-AO-8[16][32] board

Figure 5: PowerDAQ PD2-AO-8[16][32] Connectors

Note For manufacturers part numbers,

Specifications

.

Connector

see Appendix A:

36

Page 45

PD2- AO-96 Connectors

The PowerDAQ PD2-AO-96 boards have seven headers on it:

40-way boxed IDC header – analog output connectors (J3-

J8)

36-way boxed IDC header (DIO/Timer and IRQ lines)

Chapter 5: Interconnections

J2 Connector

Connectors from all cables are going through the

PCI bracket. Following connector layout is defined :

J3 - AOut 0..15, J4 - AOut 16..31, J5 - AOut 32..47,

J6 - AOut 48..63, J7 - AOut 64..79, J3 - AOut 80-..95

PowerDAQ(tm) PD-AO-96 board

J2- DIO/Timers

Figure 6: PowerDAQ™ PD2-AO-96 Connectors

Note For manufacturers part numbers,

Specifications

.

J4 Connector

J3 Connector

J6 Connector

J5 Connector

J8 Connector

J7 Connector

see Appendix A:

37

Page 46

Chapter 5: Interconnections

PDXI- AO-8[16][32] Connectors

The PowerDAQ PD2-AO-8[16][32] boards have only one

connector:

96-contact high-density Fujitsu header – analog output and

DIO/Timers connector (J1)

J1

PowerDAQ™ PDXI-AO-8[16][32]

Channels 0..15 sense line jumpers. Install 1-2 and 3-4

jumpers to short sense line with corresponding output on

the board. SNSx terminals are grounds in this case. Install

2-3 jumpers to keep sense line in the cable. In this case

screw terminal jumpers should be installed. Rows :

A-AOut3, B-AOut2, C-AOut1, D-AOut0,

E-AOut7, F-AOut6, G-AOut5, H-AOut4,

I-AOut11, J-AOut10, K-AOut9, L-AOut8,

M-AOut15, N-AOut14, O-AOut13, P-AOut12

Factory-installed jumpers (PDXI-AO-8[16] boards only).

Connects outputs 16..31 to the analog ground to provide more

grounds in the cable

38

Figure 7: PowerDAQ™ PDXI-AO-8[16][32] Connectors

Note For manufacturers part numbers,

Specifications

.

see Appendix A:

Page 47

Chapter 5: Interconnections

PD2-AO-8[16][32] J1 Analog Connector

AGND

AGND

AGND

AGND

AGND

AOUT31

AOUT29

AOUT27

AOUT25

AGND

AOUT22

AOUT20

AOUT18

AOUT17

AOUT15

AOUT13

AGND

AOUT10

AOUT8

AOUT6

AOUT5

AOUT3

AOUT1

AGND

AGND

AGND

AGND

AGND

AGND

AOUT30 SE NSE

AOUT28 SE NSE

AOUT27 SE NSE

AOUT25 SE NSE

AOUT23 SE NSE

AGND

AOUT20 SE NSE

AOUT18 S ENSE

AOUT16 S ENSE

AGND

AOUT13 S ENSE

AOUT11 SENSE

AOUT9 SENSE

AOUT8 SENSE

AOUT6 SENSE

AOUT4 SENSE

AGND

AOUT1 SENSE

AGND

49

1

50

AGND

2

351

AGND

452

AGND

AGND

553

NC

AGND

654

755

AOUT30

856

AOUT28

AOUT26

57

AOUT24

10 5 8

AOUT23

11 59

AOUT21

12 60

AOUT19

13 61

AGND

62

AOUT16

15 6 3

AOUT14

16 64

AOUT12

17 6 5

AOUT11

18 6 6

AOUT9

19 6 7

AOUT7

20 68

AGND

21 69

AOUT4

22 70

AOUT2

23 71

AOUT0

24 72

AGND

25 7 3

26 74

AGND

27 7 5

AGND

AGND

28 76

AGND

29 7 7

AOUT31 SENSE

30 78

31 79

AOUT29 SENSE

32 80

AGND

33 81

AOUT26 SENSE

34 82

AOUT24 SENSE

35 8 3

AOUT22 SENSE

36 84

AOUT21 SENSE

37 8 5

AOUT19 SENSE

38 86

AOUT17 SENSE

39 8 7

AOUT15 SENSE

40 88

AOUT14 SENSE

41 89

AOUT12 SENSE

42 90

AOUT10 SENSE

43 91

AGND

44 92

AOUT7 SENSE

45 9 3

AOUT5 SENSE

46 94

AOUT3 SENSE

47 9 5

AOUT2 SENSE

48 96

AOUT0 SENSE

Figure 8: Connector pin assignment for the J1

39

Page 48

Chapter 5: Interconnections

The compatible pin out was used for the PD2-AO-8[16][32] and PD2MF(S) J1 connector to provide the ability to use common accessories.

For the details see conversion table in Appendix B. Note, that on PD2AO-8[16] AOUT16..31 and AOUT16..31 SENSE are connected to the

ground.

PD2-AO J2 DIO/Counter/Timers/IRQx

Connector

DGND

TMR0

DGND

DGND

TMR1

DGND

DGND

Figure 9: Connector pin assignment for the J2

J1-J2 Connection Example

The example below shows how to connect PD2-AO board to

the PD2-AO-STP screw terminal.

Note For the PD2-AO-8[16] board lines OUT16-OUT31 and

OUT16S-OUT32S are tied to the analog ground.

DIN0

DIN1

DIN2

DIN3

DIN4

DIN5

DIN6

DIN7

IRQA

IRQB

IRQC

11

13

15

17

19

21

23

25

27

29

31

33

35

2

DGND

1

4

TMR2

3

6

5

DGND

8

7

DGND

10

9

+5VPJ2

12

DGND

14

DOUT0

16

DOUT1

18

DOUT2

20

DOUT3

22

DOUT4

24

DOUT5

26

DOUT6

28

DOUT7

30

DGND

32

DGND

34

DGND

36

DGND

40

Page 49

j

j

PowerDAQ II Analog Output Board

(8/16/32 Channels)

Local

/Remote

Sense

umpers

PD-AO-STP-32

PD-CBL-96

Screw Ter minal

Channels 16-31

Channels 0-15 and digital lines

Jumpers JP1-JP32 defines the sense configuration for the

channels 0..31 respectively. When shunts installed at

locations B-C the channel is configured to remote sense

and SNSx terminal used to connect this line to the remote

equipment. If shunts are installed at A-B and C-D locations

the channel is configured to local sense (at screw terminal)

and SNSx terminal for the selected channel connected to

the AGND

Chapter 5: Interconnections

PD-CBL-37

IRQx and

TMRx

termination

umpers

AOUTx

SNSx

AOUTx – channel x output

SNSx – channel x sense line

or AGND (see jumpers JP1-

To the servomotors, etc.

To/from

Digital

sensors

Figure 10: Configuring the PD2-AO-STP with PD2-AO-8[16][32]

41

Page 50

Chapter 5: Interconnections

j

j

PDXI Analog Output Board

(8/16/32 Channels)

J6

J8

PDXI-CBL- AO

PD-AO-STP-32

Sense-to-Out jumpers. JP0.15 jumpers should be

installed only if jumpers on J6 jumper pattern on

PDXI-AO board in 2-3 positions. JP16..31 should

NEVER be i nst all e d.

See PD2-AO-8[16][32] connect ion for the details.

Screw Terminal

Local

/Remote

Sense

umpers

Chan nels 16-31

Channels 0- 15 and digital lines

AOUTx

SNSx

AOUTx – channel x output

SNSx – channel x sense line

or AGND (s ee j umpe rs J P1-

JP32 settings)

IRQx and

TMRx

terminatio n

umpers

To/from

Dig it al

sensors

To the ser vomot or s, et c.

Figure 11: Configuring the PD2-AO-STP with PDXI-AO-8[16][32]

42

Page 51

Appendix A: Specifications

Appendix A: Specifications

PD2-AO specifications:

The following conditions apply:

A

= 0°C to +85°C

T

AO subsystem

Parameter Value

Number of channels 8,16,32 or 96 (PD2-AO only)

Resolution 16 bits

Update rate

Buffer Size

Type of D/A Double-buffered

Accuracy +/- 3 LSB max

DNL +/- 3 LSB max

Monotonicity Over

Temperature

Gain Error 0.02% (PDXI-AO), 0.05% (PD2-AO)

Range

Output Coupling DC

Output Impedance 0.15 Ohm max

Current Drive +/-5mA (PDXI-AO,PD2-AO-96)

Capacitive Loads 180 pF min

Settling time 10uS to 0.003%

Slew Rate 10V/uS

Gain Bandwidth 1 MHz

Noise 2LSB RMS, 0-10000Hz

Output protection Short to ground, +/- 15 Volts

Power-on state, default, user

programmable

Gain drift 25ppm/deg C

100 KS/s channel, up to 1600 KS/s aggregate

throughput in DMA mode, 455 KS/s in unlimited

channel list mode.

2k samples (upgradeable to 32 KSamples on PDXIAO models)

15 bits

+/- 10V fixed, 0..10V factory-installed option

available for PD2-AO-96/16 board

+/-20mA(PD2-AO-8[16][32])

0.0000V +/-25mV (PD2-AO-8[16][32]

0.0000V +/-5mV (PD2-AO-96, PDXI-AO)

43

Page 52

Appendix A: Specifications

Note Due to the quad DACs, the current is limited. Only one

output of each may be continuously shorted to ground. The

current is limited to 40 ma for PD2-AO-8[16][32] boards and

20 ma for all other models.

Digital Input and Output

Parameter Value

Number of channels 8 inputs and 8 outputs

Compatibility CMOS/TTL, 2KV ESD protected

Power-on state Logic Zero

Input termination 4.7Kohm pull-up to 5V

Output High Level 3.0V min @ -32 mA, 3.4V min @ -16 mA,

4.2V min @ -2 mA

Output Low Level 0.55V max @ 64 mA

Input Low Voltage 0.0 - 0.8 V

Input High Voltage 2.0 - 5.0 V

Input current 1uA

DSP – based subsystems

There are two DSP-based subsystems available on the PowerDAQ DIO

boards:

• Counter/timers

• High-speed interrupts

DC ELECTRICAL CHARACTERISTICS FOR DSPBASED SUBSYSTEMS

Counter/timers

Parameter Value

Number of channels 3

Resolution 24 bits

Maximum frequency 16.5/25MHz for the external,

33/50 MHz for the internal clock (see notes)

Minimum frequency DC for input, 0.001Hz for output

Minimum Pulse Width 20 nS

44

Page 53

5

Output High Level 2.0V min @ -4 mA

Output Low Level 0.5V max @ 4 mA

Input Low Voltage 0.0 - 0.8 V

Input High Voltage 2.0 - 5.0 V

Input current 1uA

• External Event Counter

• Input Width Measurement

• Input Period Measurement

• Event Capture

• Pulse Width Modulation (PWM)

• Watchdog Pulse

• Watchdog Toggle

Note The external clock frequency should be less than the

internal operating frequency divided by 4 (I.e. 16.33/25.00

MHz for 66/100 MHz DSP). The standard PowerDAQ boards

ships with a 66 MHz DSP.

Appendix A: Specifications

COUNTER/TIMER SPECIFICATIONS:

NoteThe maximum timer frequency is 16.33 MHz for external

clock and 33 MHz for internal clock (66 MHz DSP core). TIO

assumes timer I/O pin, CLKOUT – DSP clock. The minimum

pulse width is 20 ns for an external clock/event.

The following conditions apply:

A

= 0°C to +100°C; C load = 50pF + 2 TTL loads

T

4

Page 54

Appendix A: Specifications

CONNECTORS SPECIFICATIONS

Connector Description/Manufacturer/P/N

J1 (PD2-AO-8[16][32],

PDXI-AO)

J2 (PD2-AO) J2 connector is a 36-way boxed IDC header.

J3-J8 (PD2-AO-96) J3-J8 connectors are 40-way boxed IDC headers.

Fujitsu Takamisawa America, Inc.

408-745-4990 Fax: 408-745-4995.

Connector p/n FCN-230C096-C/E and the metal

cover p/n FCN-247J096-G/E.

The manufacturer is Tomas & Betts

(www.tnb.com

3627.

The manufacturer is 3M

(http://www.mmm.com/esm/

connector is 2540-6002UB.

), p/n for the connector is 609-

), p/n for the

ENVIRONMENT

Operating environment 0°C to 70°C

46

Page 55

Appendix B: Accessories

Appendix B: Accessories

Overview

The PowerDAQ AO boards can connect to a variety of

stand-alone or 19” rack-mount accessory panels. A complete

range of cables and options are available.

If you require a custom accessory, please contact the

factory.

These are following options available for use with

PowerDAQ AO boards:

• The universal screw terminal PD2-AO-STP-32 includes

both analog and digital terminals and allows you to

connect Analog Output and Sense lines directly at the

screw terminal. May be used with all PowerDAQ AO

boards except PD2-AO-96 (note, that digital part of this

screw terminal still can be utilized)

• PD-BNC-16/64. This BNC terminal connects each Analog

Output line using the BNC-terminated cable that allows

eliminating or reducing external noise. PD-BNC-16 may

be used with PD2/PDXI-AO-8 boards only. PD-BNC-64

may be used with all PowerDAQ AO boards except PD2AO-96.

• PD-CONN-PCB – This small terminal panel is useful in

OEM applications but does not provide the ability to

connect the digital signals to/from the board

• PD-STP-3716. This terminal connects sixteen analog

output channels to PD2/PDXI-AO-8 or PD2-AO-96

board. May be considered as a low cost termination

option

Cables: (PD[XI]-CBL-xx)

PD-CBL-96: The J1 connectors use a 96-way shielded

round 1-meter cable with a metal connector

on either end. It connects to: PD2-AO-STPxx, PD-BNC-xx accessory panels. Used with

all PD2-AO boards except PD2-AO-96.

47

Page 56

Appendix B: Accessories

PDXI-CBL-AO:The PDXI-AO J1 connectors use a split 96-

way shielded round 1-meter cable. It

connects to: PD2-AO-STP-xx, PD-BNC-xx

accessory panels. Note, that both analog and

digital signals are connected to the screw

terminal using this cable.

PD-CBL-37: This is a 37-way ribbon connector set. It

comprises of a 13” internal ribbon cable

which connector from the PowerDAQ™ II AO

board J2 internal digital connector

(DIO/Counters/IRQx) to a 37-way D-SUB

bracket. A 1-meter ribbon cable then

connects from the bracket to the PD-AO-STP

accessory panels. The PD-CBL-37 is available

as an option.

PD-CBL-4037TP: This is a 36-way ribbon cable which

connectos from the PowerDAQ™ II AO 96

channel board J3-J8 internal analog

connector to a 37-way D-SUB bracket. A 1meter ribbon cable then connects from the

bracket to the PD-STP-3716 accessory panels.

Used with PD2-AO-96 boards only.

48

Page 57

Appendix B: Accessories

Screw Terminal Panels: (PD2-AO-STP-xx)

The PD2-AO-STP-32 is a 32-channel screw terminal panel,

which includes connections to the counter timers, highspeed interrupt/synchronization lines and DIO ports.

Custom terminal panels are available. Please contact your

distributor or the factory.

Cable PD-CBL-96

PD-AO-STP-32

PD-AO-STP-32

Figure 12: PD2-AO-STP-32 Wiring Diagram

PDXI-CBL-AO

Cable PD-CBL-37

PD2-AO Board

PDXI-AO

board

49

Page 58

Appendix B: Accessories

Screw Terminal Panels: (PD-STP-3716)

The PD-STP-3716 is a simple 16-channel screw terminal

panel, which includes connections to the analog signals only.

This terminal panel can be used with PD2-AO-96 and

PD2[PDXI]-AO-8 boards only. Note, that different cables are

required for the different boards:

• PD-CBL-9637 – used with PD2-AO-8

• PDXI-CBL-AO – used with PDXI-AO-8

• PD-CBL-4037TP – used with PD2-AO-96

Cable PD-CBL-9637

PD2-AO-8

PD-STP-3716

Cable PDXI-CBL-AO

Cable PD-CBL-4037TP

6

PD2-AO-96

PDXI-AO-8

Figure 13: PD-STP-3716 Wiring Diagram

Note That if Sense lines are available on PD2-AO-8 or J6

jumpers in 2-3 position on PDXI-AO-8 AOutx line should be

connected to ASensex line on the screw terminal.

50

Page 59

Appendix B: Accessories

Terminal

Pin

1 OUT0 Clk. In. 20 SNS0 Clk.Out

2 AGND Ext. Trig 21 OUT1 DGND

3 SNS1 DGND 22 AGND AGND

4 AGND OUT0 23 OUT2 AGND

5 SNS2 OUT1 24 AGND AGND

6 AGND OUT2 25 OUT3 AGND

7 SNS3 OUT3 26 AGND AGND

8 AGND OUT4 27 OUT4 AGND

9 SNS4 OUT5 28 AGND AGND

10 AGND OUT6 29 OUT5 AGND

11 SNS5 OUT7 30 AGND AGND

12 AGND OUT8 31 OUT6 AGND

13 SNS6 OUT9 32 AGND AGND

14 AGND OUT10 33 OUT7 AGND

15 DNC OUT11 34 SNS7 AGND

16 DNC OUT12 35 DNC AGND

17 DNC OUT13 36 DNC AGND

18 DNC OUT14 37 DNC N/C

19 DNC OUT15 DNC= Do

PD2

[PDXI]-AO-8

PD2-AO-96 Termi

nal

Pin

PD2

[PDXI]-AO-8

not connect

PD2-AO-96

51

Page 60

Appendix B: Accessories

OEM Header Distribution Connector

For the OEM the PD2-AO and PDXI-AO board provides the PDCONN-PCB – a small terminal panel. The PD-CONN-PCB allows

you to connect both PD2-MF/MFS and PD2-AO/PDXI-AO boards.

See table on the next page for the pinout conversion.

PowerDAQ II/PDXI AO Board

(8/16/32 Cha nne ls)

PD-CONNPCB

To the servomotors, etc.

Figure 14: PD-CONN-PCB wiring diagram

Custom terminal panels are available. Please contact the

factory or your distributor.

52

Page 61

Appendix B: Accessories

Accessory Board Connections

PD2-MFx PD2-AO-32 J1 J1 PD2-AO-32 PD2-MFx

Ext. Trig In AGND 26 74 AGND +5V

CL Clock In AGND 30 78 AOUT 31 SENSE AIN63

Pin Pin

AGND AGND 1 49 AGND AGND

AGND AGND 2 50 AGND AOUT0

AGND AGND 3 51 AGND AGND

AGND AGND 4 52 AGND AOUT1

DGND DGND 5 53 AGND AGND

AGND AGND 6 54 AGND AGND

AIN55 AOUT31 7 55 AOUT30 AIN54

AIN53 AOUT29 8 56 AOUT28 AIN52

AIN51 AOUT27 9 57 AOUT26 AIN50

AIN49 AOUT25 10 58 AOUT24 AIN48

AGND AGND 11 59 AOUT23 AIN39

AIN38 AOUT22 12 60 AOUT21 AIN37

AIN36 AOUT20 13 61 AOUT19 AIN35

AIN34 AOUT18 14 62 AGND AGND

AIN33 AOUT17 15 63 AOUT16 AIN32

AIN23 AOUT15 16 64 AOUT14 AIN22

AIN21 AOUT13 17 65 AOUT12 AIN20

AGND AGND 18 66 AOUT11 AIN19

AIN18 AOUT10 19 67 AOUT9 AIN17

AIN16 AOUT8 20 68 AOUT7 AIN7

AIN6 AOUT6 21 69 AGND AGND

AIN5 AOUT5 22 70 AOUT4 AIN4

AIN3 AOUT3 23 71 AOUT2 AIN2

AIN1 AOUT1 24 72 AOUT0 AIN0

AGND AGND 25 73 AGND AGND

CV Clock

Out

N/C AGND 28 76 AGND AGND

AGND AGND 29 77 AGND N/C

AIN62 AOUT 30 SENSE 31 79 AOUT 29 SENSE AIN61

AIN60 AOUT 28 SENSE 32 80 AGND AGND

AIN59 AOUT 27 SENSE 33 81 AOUT 26 SENSE AIN58

AIN57 AOUT 25 SENSE 34 82 AOUT 24 SENSE AIN56

AIN47 AOUT 23 SENSE 35 83 AOUT 22 SENSE AIN46

AGND AGND 36 84 AOUT 21 SENSE AIN45

AIN44 AOUT 20 SENSE 37 85 AOUT 19 SENSE AIN43

AIN42 AOUT 18 SENSE 38 86 AOUT 17 SENSE AIN41

AIN40 AOUT 16 SENSE 39 87 AOUT 15 SENSE AIN31

AGND AGND 40 88 AOUT 14 SENSE AIN30

AIN29 AOUT 13 SENSE 41 89 AOUT 12 SENSE AIN28

AIN27 AOUT 11 SENSE 42 90 AOUT 10 SENSE AIN26

AIN25 AOUT 9 SENSE 43 91 AGND AGND

AIN24 AOUT 8 SENSE 44 92 AOUT 7 SENSE AIN15

AIN14 AOUT 6 SENSE 45 93 AOUT 5 SENSE AIN13

AIN12 AOUT 4 SENSE 46 94 AOUT 3 SENSE AIN11

AGND AGND 47 95 AOUT 2 SENSE AIN10

AIN9 AOUT 1SENSE 48 96 AOUT 0 SENSE AIN8

AGND 27 75 AGND CV Clock In

Table 2: Сonversion between the PD2-MF(S) and PD2-AO board J1

connector pinout.

53

Page 62

Appendix B: Accessories

Dimensions:

The following table contains the dimensions of the

PowerDAQ™ AO and accessory products.

Accessory Dimensions (W x L x H)

PDXI-AO-x 3.9”x6.3”x0.5”

PD2-AO-96 4.2”x13.275”x0.5”

PD2-AO-32 4.2”x11”x0.5”

PD2-AO-16 4.2”x8.2”x0.5”

PD2-AO-8 4.2”x8.2”x0.5”

PD2-AO-STP-32 4.2”x7.0”x2.1”

PD-STP-3716 2.8”x4.4”x0.5”

PD-CONN-PCB 3.3”x3.33”x0.4”

Table 3: Dimensions of PowerDAQ™ AO accessory products

54

Page 63

Appendix C: Common Questions and Support

Appendix C: Common

Questions and Support

Q

What is PCI Specification 2.1?

A

The PCI LocalBus is a high-performance bus that provides a

processor-independent data path between the CPU and high-speed

peripherals. PCI is a robust interconnect mechanism designed

specifically to accommodate multiple high performance peripherals for

graphics, full motion video, SCSI, LAN, etc.

The PCI Local Bus Specifications, Rev 2.1 includes the protocol,

electrical, mechanical and configuration specification for the PCI Local

Bus components and expansion boards.

The Rev 2.1 was published June 1, 1995 by the PCI Special Interest

Group.PO Box 14070,Portland,OR 97214. Web site:

www.pcisig.com

Calibration Questions

Q

How often should I calibrate my board?

A

The PD2-AO series board should be calibrated once a year.

-----------------------------------------------------------------------------

Service and Support

If you have technical problems using PowerDAQ™ PD2-AO, our

Technical Support department can be reached by:

Telephone: (617) 924 1155

Fax: (617) 924 1441

Email: support@powerdaq.com

55

Page 64

Appendix C: Common Questions and Support

Web Site: www.powerdaq.com

For the most efficient service, please be available at your computer

and be prepared to answer several questions listed on the following

page when you call for technical support. This information helps us

identify specific system and configuration-related problems.

56

Page 65

Appendix C: Common Questions and Support

Technical Support Form

Photocopy this form and update it each time you make changes to

your software or hardware. Completing this form accurately before

contacting us for technical support helps our application engineers

answer your questions more efficiently.

What is the name and version number of the product?

____________________________________________

What version of Windows are you using?

____________________________________________

What programming language and version?

____________________________________________

Is the board set at factory configuration?

____________________________________________

Have you run the board diagnostics? What were the results?

____________________________________________

Did the system ever work ? If so, what changed (moved location,

installed other boards, software etc..)

____________________________________________

Have you run the sample programs? What were the results?

____________________________________________

Have you verified that all your connections are made properly and

are secure?

____________________________________________

Have you been able to isolate the source of your problem: input or

output device, board, software?

____________________________________________

What other boards or applications are installed in your system?

____________________________________________

How much RAM do you have?

____________________________________________

What size hard disk are you using?

____________________________________________

How fast is your CPU?

____________________________________________

How fast is your host data bus?

____________________________________________

If you are on a network, what type of network are you using and

approximately how many users are on the network?

____________________________________________

Please specify whether or not the problem occurred more than once

____________________________________________

57

Page 66

Appendix D: Warranty

Appendix D: Warranty

Overview

IBM, IBM PC/XT/AT and IBM PS/2 are trademarks of

International Business Machine Corporation.

BASIC is a trademark of Dartmouth College.

Microsoft is a trademark of Microsoft Corporation.

LabVIEW, LabWindows/CVI, DASYLab, DIADEM is a trademark of

National Instruments Corporation

All PowerDAQ™ PD2-AO boards have received CE Mark

certification according to the following:

EN55011

EN50082-1

Life Support Policy

OMEGA ENGINEERING' PRODUCTS ARE NOT AUTHORIZED FOR

USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR

SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE

LEGAL AFFAIRS DEPARTMENT OF OMEGA ENGINEERING

CORPORATION. As used herein:

1. Life support devices or systems are devices or systems which,

(a) are intended for surgical implant into the body, or (b) support

or sustain life, and whose failure to perform, when properly used

in accordance with instructions for use provided in the labeling,

can reasonably be expected to result in a significant injury to the

user or (c) should the device or system fail to perform, may

reasonably be expected to result in a significant hazard to human

life, or a significant potential for injury to the user.

2. A critical component is any component of a life support device

or system whose failure to perform can be reasonably expected to

cause the failure of the life support device or system, or to effect

its safety or effectiveness.

58

Page 67

Appendix D: Warranty

Omega Engineering, inc. warrants that the products furnished

under this agreement will be free from material defects for a

period of one year from the date of shipment. The customer shall

provide notice to Omega Engineering of such defect within one

week after the Customer’s discovery of such defect. The sole

obligation and liability of Untied Electronic Industries under this

warranty shall be to repair or replace, at its option, without cost

to the Customer, the product or part which is so defective and as

to which such notice is given.

Upon request by Omega Engineering, the product or part claimed

to be defective shall immediately be returned at the customer’s