Page 1

PowerDAQ User Manual

PowerDAQ PD2/PDXI-MF/MFS and PDL-MF DAQ boards

High-Performance Multifunction I/O boards for PCI and Compact

PCI/PXI Computer

January 2002 Edition

© Copyright 1998-2002 Omega Engineering, Inc. All rights reserved

Page 2

All rights reserved. No part of this publication may be reproduced,

stored in a retrieval system, or transmitted, in any form by any means,

electronic, mechanical, by photocopying, recording, or otherwise

without prior written permission.

Fourth Edition

January 2002 Printing

Information furnished in this manual is believed to be accurate and

reliable. However, no responsibility is assumed for its use, or for any

infringements of patents or other rights of third parties that may result

from its use.

Contacting Omega Engineering

✉ Address:

OMEGA Engineering, Inc.

One Omega Drive

Stamford, Connecticut 06907-0047

U.S.A.

! Support:

Telephone: 1-800-622-2378

Fax: 1-800-848-4271

"Internet Access:

Support support@omega.com

Web site http://www.omega.com

FTP site ftp://ftp.omega.com

Page 3

Table of Contents

Table of Contents

How to Use This Manual...................................................................... vi

Introduction ...................................................................................... vi

Who Should Read This Book?..........................................................viii

Organization of This Manual...........................................................viii

Conventions Used in This Manual .................................................... ix

Feedback ........................................................................................... ix

Introduction .............................................................................. 1

About the PowerDAQ board................................................................. 2

Overview ............................................................................................ 2

Features.............................................................................................. 2

PowerDAQ Models ............................................................................ 3

Installation and Configuration............................................ 11

Before You Begin .................................................................................12

Installing PowerDAQ ............................................................................13

Installing the Software .........................................................................14

Confirming the Installation ..................................................................15

Configuring the PowerDAQ Board.......................................................16

Input Modes: ....................................................................................17

Test Program:....................................................................................21

Connectors for PD2/PDXI.................................................................21

Connectors for PDL-MF................................................................... 27

Architecture ............................................................................31

Functional Overview ............................................................................ 32

Analog Input Subsystem ..................................................................... 37

Input Modes ....................................................................................42

Input Ranges ....................................................................................44

Gain Settings....................................................................................44

Channel List .....................................................................................45

Clocking ...........................................................................................46

Triggering.........................................................................................48

ADC FIFO .........................................................................................49

Data format .....................................................................................50

Analog Output Subsystem ..................................................................53

Single Update................................................................................... 53

Event-based Waveform ...................................................................53

Continuous (polled-I/O) Waveform................................................ 53

Auto-regeneration Waveform (circular waveform) ........................54

Channel List .....................................................................................54

Clocking ...........................................................................................55

i

Page 4

Table of Contents

Triggering.........................................................................................55

Digital Input/Output Subsystem .........................................................56

User Counter-Timer Subsystem...........................................................58

PD2/PDXI .........................................................................................58

PDL-MF ............................................................................................59

PowerDAQ Software Development Kit (PD-SDK)........61

PowerDAQ Software ........................................................................... 62

PowerDAQ SDK Structure................................................................ 62

PowerDAQ Libraries......................................................................... 63

PowerDAQ Include Files...................................................................64

Analog Input Subsystem .....................................................................68

Analog Output Subsystem ..................................................................86

Digital Input/Output Subsystems........................................................94

User Counter-Timer Subsystem ...........................................................98

PD2/PDXI .........................................................................................98

PowerDAQ Example Programs ........................................................... 101

Third Party Software Support ............................................................103

Calibration.............................................................................105

Calibration ......................................................................................... 106

Overview ........................................................................................ 106

When to calibrate .......................................................................... 106

Appendix A: Specifications................................................107

Appendix B: Accessories .....................................................111

Accessories ..........................................................................................112

Screw Terminal Panels (PDL-MF only) ............................................112

Screw Terminal Panels (PD2/PDXI) .................................................112

BNC Connection Panels (PD2/PDXI) .............................................. 113

Thermocouple Input Racks (All)..................................................... 114

5B/7B/OEM Distribution Panels (PD2/PDXI)................................. 114

Mating cables, connectors, PCB connection board (PD2/PDXI) ... 114

Cables (PD2/PDXI) ........................................................................ 115

19” Racks (All) ................................................................................ 115

Solid State Relay Backplane (All).................................................... 115

Signal Conditioning Expansion Units (All)...................................... 116

Appendix C: Application Notes ........................................ 117

Application Note: 1............................................................................. 118

Application Note: 2 ............................................................................122

Appendix D: Warranty .......................................................123

Overview .............................................................................................124

ii

Page 5

Table of Contents

Appendix E: Glossary..........................................................127

Glossary ..............................................................................................128

Index...................................................................................................145

iii

Page 6

Table of Contents

List of Figures

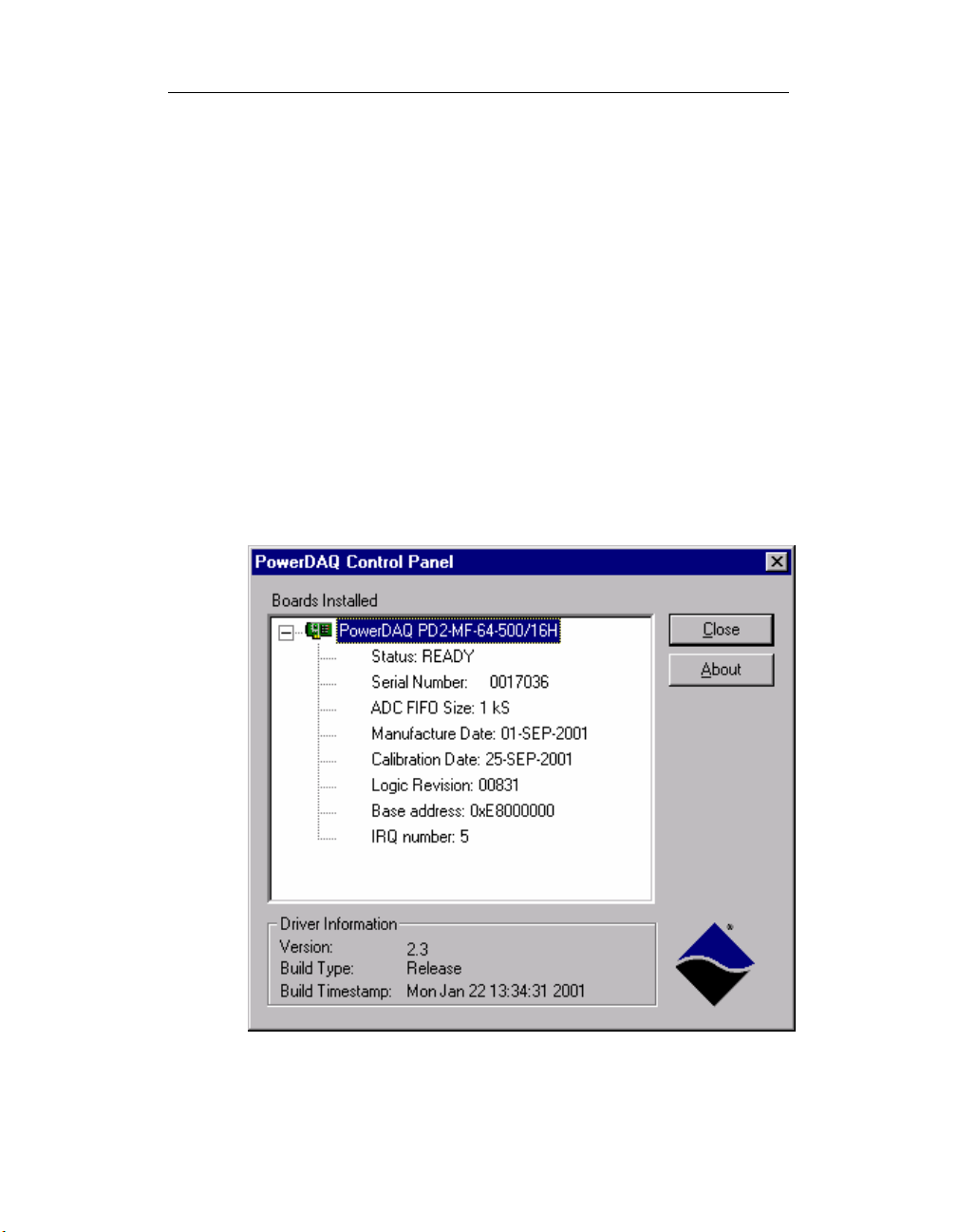

Figure 1: Control Panel Application ......................................................15

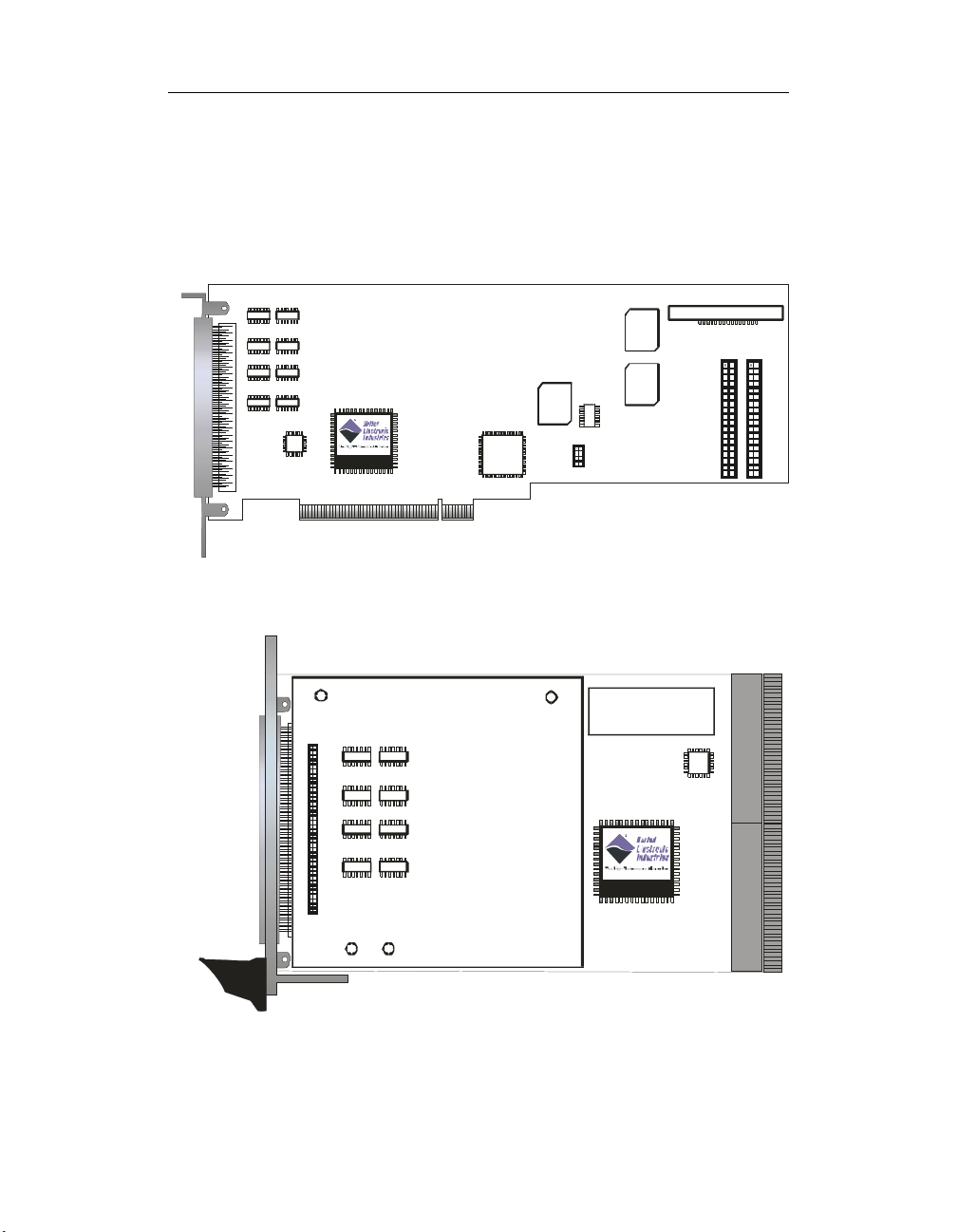

Figure 2: PD2- Board connector layout.............................................16

Figure 3: PDXI-MF Board connector layout ......................................16

Figure 4: PDL-MF- Board connector layout ......................................17

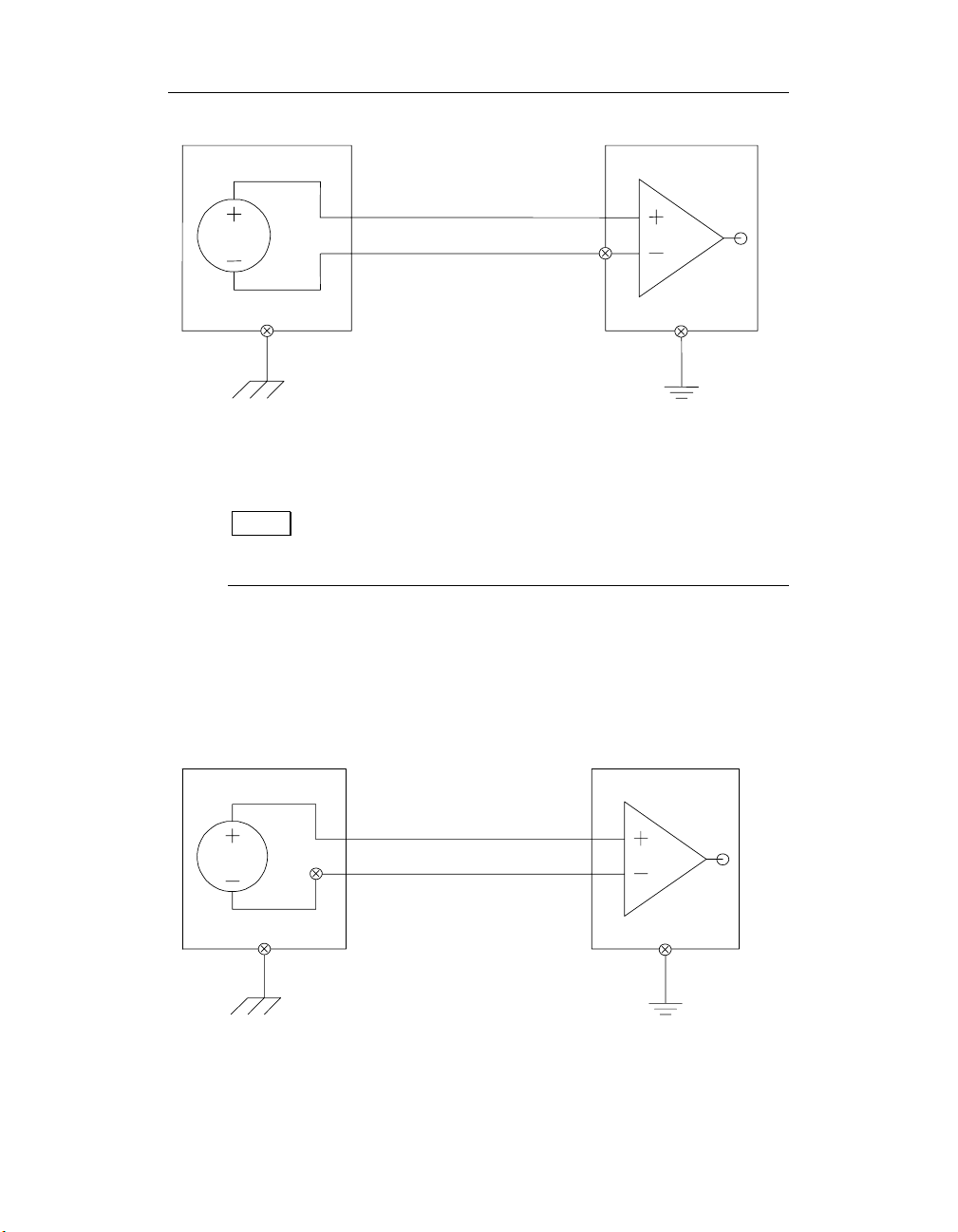

Figure 5: Single-ended Inputs and pseudo-differential inputs ........ 18

Figure 6: Differential Inputs ............................................................. 18

Figure 7: PDXI Configurator................................................................. 20

Figure 8: Simple Test Application ......................................................21

Figure 9: Fujitsu Connector Layout................................................... 22

Figure 10: PowerDAQ PD2 Block diagram ......................................... 32

Figure 11: PowerDAQ PDXI Block diagram ........................................ 33

Figure 12: PowerDAQ PDL-MF Block diagram ...................................34

Figure 13: PowerDAQ Multifunction Board front-end ......................38

Figure 14: PowerDAQ Sample and Hold Board front-end................. 39

Figure 15: PD2/PDXI Series Acquisition Process ................................40

Figure 16: PD2/PDXI Acquisition Process...........................................40

Figure 17: Single-Ended Inputs........................................................... 42

Figure 18: Differential Inputs ............................................................. 43

Figure 19: Digital Input Subsystem ....................................................56

Figure 20: PowerDAQ Software Structure .........................................62

Figure 21: Communication between user application and PowerDAQ

board 66

Figure 22: Advanced Circular Buffer ..................................................121

iv

Page 7

Table of Contents

List of Tables

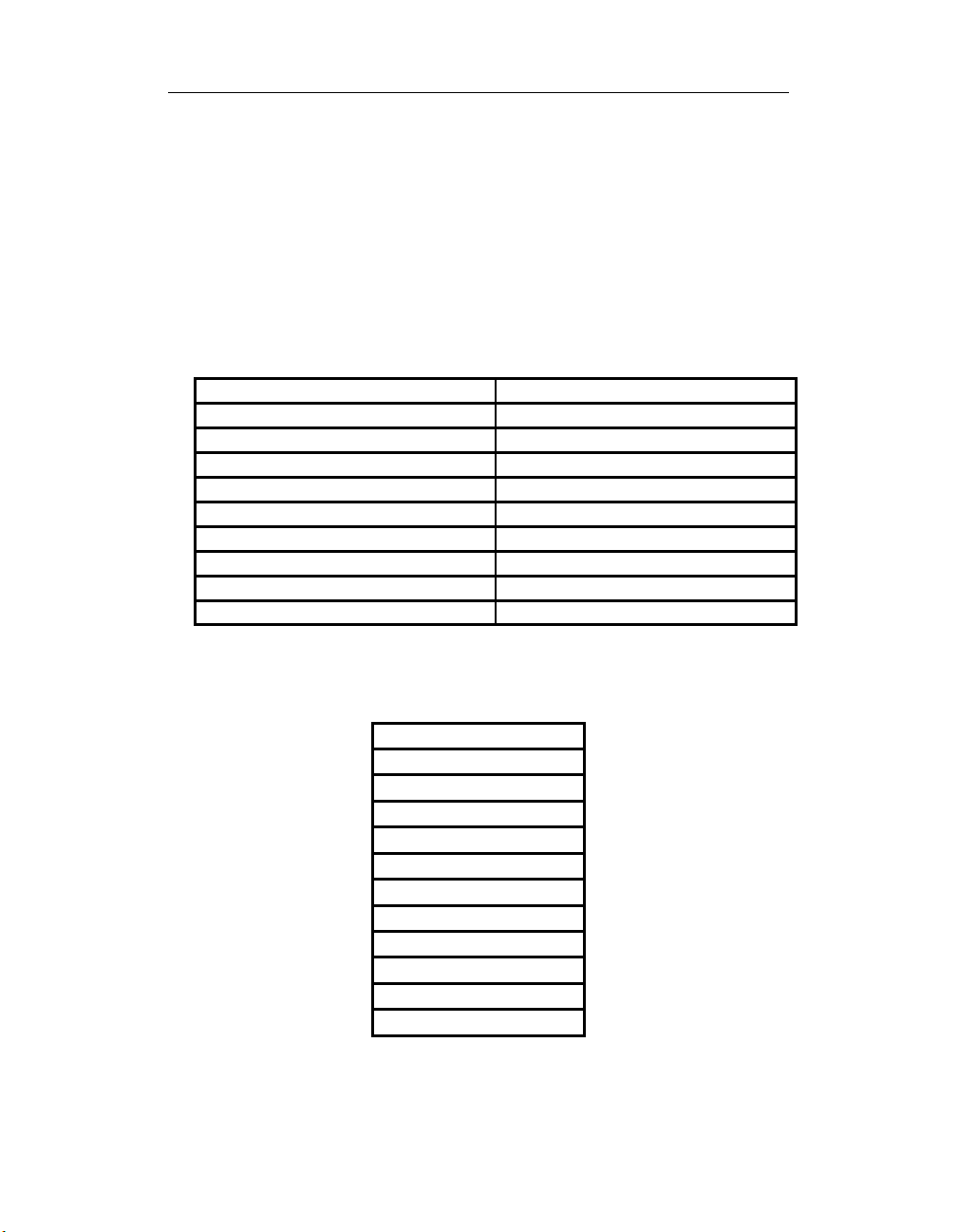

Table 1: PowerDAQ PD2-MF Models ...................................................4

Table 2: PowerDAQ PD2-MFS Models.................................................. 5

Table 3: PowerDAQ PD2-MF Models ................................................... 7

Table 4: PowerDAQ PDXI-MFS Models ................................................8

Table 5: MFS Differential Upgrade Options .........................................9

Table 6: PD2-/PDXI- FIFO upgrade options .........................................9

Table 7: PDL-MF board specifications .................................................10

Table 8: J1 Connector (Single-Ended Mode)................................... 23

Table 9: J1 Connector (Differential Input Mode) ............................... 24

Table 10: Connector Pin Assignments for J2.................................... 25

Table 11: Connector Pin Assignments for J4 ....................................... 26

Table 12: Connector Pin Assignment for J6 ..................................... 27

Table 13: Connector Pin Assignments for PDL-MF J1 ......................28

Table 14: Connector Pin Assignments for PDXI J2........................... 29

Table 15: Input Range Table .............................................................44

Table 16: Programmable Gains .........................................................44

Table 17: Channel List Format ..............................................................45

Table 16: Programmable Gain Codes................................................45

Table 19: Different Clocking Combinations...................................... 47

Table 20: External Trigger Modes .....................................................49

Table 21: Data Format Table for a 16-bit Board ..............................50

Table 22: PowerDAQ II 12-bit data format.......................................50

Table 23: PowerDAQ II 14-bit data format ......................................50

Table 24: PowerDAQ II 16-bit data format ......................................50

Table 25: Bit Weight vs. Input Range ................................................51

Table 26: Displacement vs. Input Range ..........................................51

Table 27: Analog Output Data Format .............................................54

Table 28: Digital Input Configuration Word (PD2/PDXI only)......... 57

Table 29: Setting up External Trigger ............................................... 76

Table 30: Third Party Software Support ..........................................103

v

Page 8

How to Use This Manual

How to Use This Manual

Introduction

This manual describes the hardware of each of the PowerDAQ series of

PCI and PXI DAQ boards. The following boards are supported:

PowerDAQ PD2-MF Multifunction Series:

PD2-MF-16-2M/14H PD2-MF-16-150/16L

PD2-MF-64-2M/14H PD2-MF-16-150/16H

PD2-MF-16-400/14L PD2-MF-16-333/16L

PD2-MF-16-400/14H PD2-MF-16-333/16H

PD2-MF-64-400/14L PD2-MF-64-333/16L

PD2-MF-64-400/14H PD2-MF-64-333/16H

PD2-MF-16-1M/12L PD2-MF-16-500/16H

PD2-MF-16-1M/12H PD2-MF-16-500/16L

PD2-MF-64-1M/12L PD2-MF-64-500/16H

PD2-MF-64-1M/12H PD2-MF-64-500/16L

PowerDAQ PD2-MFS Multifunction Sample and

Hold Series:

PD2-MFS-4-2M/14

PD2-MFS-8-2M/14

PD2-MFS-4-800/14

PD2-MFS-8-800/14

PD2-MFS-4-500/14

PD2-MFS-8-500/14

PD2-MFS-4-1M/12

PD2-MFS-8-1M/12

PD2-MFS-4-300/16

PD2-MFS-8-300/16

PD2-MFS-4-500/16

PD2-MFS-8-500/16

vi

Page 9

How to Use This Manual

PowerDAQ PDXI-MF Multifunction Series:

PDXI-MF-16-2M/14H PDXI-MF-16-150/16L

PDXI-MF-64-2M/14H PDXI-MF-16-150/16H

PDXI-MF-16-400/14L PDXI-MF-16-333/16L

PDXI-MF-16-400/14H PDXI-MF-16-333/16H

PDXI-MF-64-400/14L PDXI-MF-64-333/16L

PDXI-MF-64-400/14H PDXI-MF-64-333/16H

PDXI-MF-16-1M/12L PDXI-MF-16-500/16H

PDXI-MF-16-1M/12H PDXI-MF-16-500/16L

PDXI-MF-64-1M/12L PDXI-MF-64-500/16H

PDXI-MF-64-1M/12H PDXI-MF-64-500/16L

PowerDAQ PDXI-MFS Multifunction Sample and

Hold Series:

PDXI-MFS-4-2M/14

PDXI-MFS-8-2M/14

PDXI-MFS-4-800/14

PDXI-MFS-8-800/14

PDXI-MFS-4-500/14

PDXI-MFS-8-500/14

PDXI-MFS-4-1M/12

PDXI-MFS-8-1M/12

PDXI-MFS-4-300/16

PDXI-MFS-8-300/16

PDXI-MFS-4-500/16

PDXI-MFS-8-500/16

PowerDAQ PDL-MF Lab Boards:

PDL-MF

The word PowerDAQ will be used in this manual to reference

all the models listed above.

vii

Page 10

How to Use This Manual

Who Should Read This Book?

This manual has been designed to benefit the user of PowerDAQ

boards. To use PowerDAQ, it is assumed that you have basic PC skills,

and that you are familiar with Microsoft Windows XP/2000/NT/ 9x,

QNX or Linux/RTLinux/RTAI Linux operating environments.

Organization of This Manual

The PowerDAQ User Manual is organized as follows:

Chapter 1 - Introduction

This chapter gives you an overview of PowerDAQ features, the various

models available and lists what you need to get started.

Chapter 2 - Installation and Configuration

This chapter explains how to install and configure your PowerDAQ

board.

Chapter 3 - Architecture

This chapter discusses the subsystems of your PowerDAQ board.

Chapter 4 – PowerDAQ Software Development Kit

This chapter describes the software for your PowerDAQ board.

Chapter 5 - Calibration

This chapter discusses the auto calibration system of your PowerDAQ

board.

Appendix A - Specifications

This chapter lists the PowerDAQ hardware specifications.

Appendix B - Accessories

This appendix lists the PowerDAQ accessories products.

Appendix C – Application Notes

Includes useful application notes on understanding PowerDAQ products.

Appendix D - Warranty

This appendix contains a detailed explanation of PowerDAQ warranty.

Glossary

viii

Page 11

How to Use This Manual

The Glossary contains an alphabetical list and description of terms used

in this manual.

Index

The Index alphabetically lists topics covered in this manual.

Conventions Used in This Manual

These are the main conventions used to help you get the most out of

this manual:

Tips are designed to highlight quick ways to get the job

TIP

done, or good ideas you might not discover on your

own.

Note Notes alert you to important information.

CAUTION! Caution advises you of precautions to

take to avoid injury, data loss, or system crash.

Text formatted in bold typeface may also represent type that should be

entered verbatim or a command, as in the following example:

You can instruct users how to run setup using a command such as

setup.exe.

Feedback

We are interested in any feedback you might have concerning our

products and manuals. A Reader Evaluation form is available on the last

page of the manual.

ix

Page 12

How to Use This Manual

x

Page 13

1

Introduction

1

Page 14

Chapter 1: Introduction

About the PowerDAQ board

This chapter describes the basic features of the PowerDAQ boards.

Overview

Thank you for purchasing a PowerDAQ board. The PowerDAQ board

was designed from the ground-up to overcome the problems associated

with previous ISA-based data acquisition boards.

The associated PowerDAQ software has been written specifically for

these products, using advanced software design.

Features

The major features of the PowerDAQ board are:

• 24-bit 80/100 MHz Motorola 56301 DSP (Digital Signal

Processor)

• PCI Bus Host PC Interface (PCI 2.1 Compliant)

• Custom designed programmable gain amplifier

• Analog Input - 16/64 channels- 12, 14 or 16 bit AD

resolutions

• Analog Output - 2 channels - 2K DSP based FIFO

• Digital In – 16 inputs (24 on PDL-MF)

• Digital Out – 16 outputs (24 on PDL-MF)

• Three Counter/Timers (8254) – 3 Clock In/Gate control

• Auto calibration (3 24-bit DSP shared counters on PDL-

MF)

• Extensive triggering and clocking of Analog Input

• Extensive triggering and clocking of Analog Output

• Simultaneous Analog In, Analog Out, Digital In, Digital

Out and Counter/Timer operations

2

Note For the full list of specifications,

Specifications.

see Appendix A:

Page 15

Chapter 1: Introduction

;

;

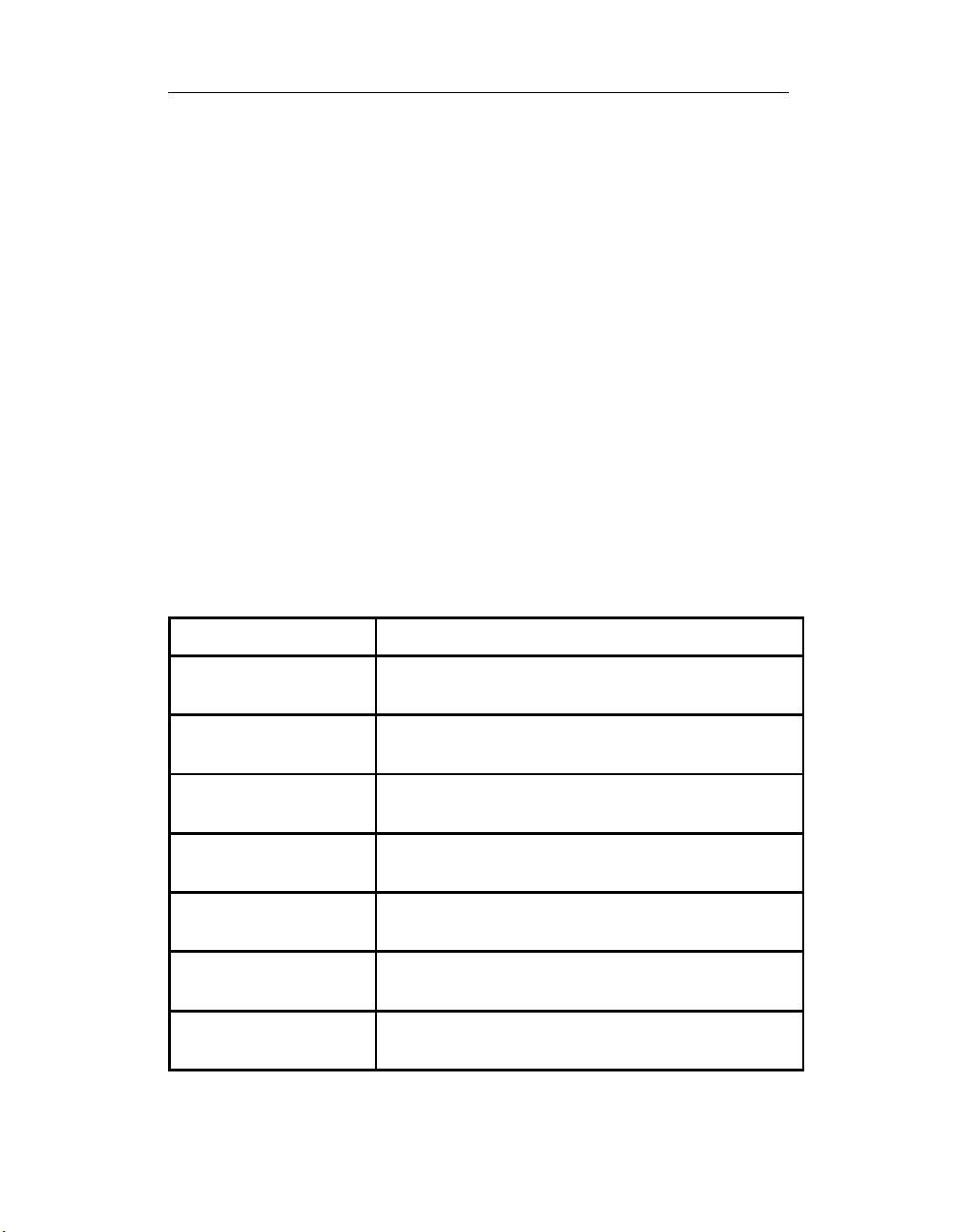

PowerDAQ Models

PowerDAQ model numbers are derived from the following:

[Family]-[Type Of Board]-[Channels]-[Speed]/[Resolution][Gain]

Family: PD2- PowerDAQ PCI Board

PDXI - PowerDAQ CompactPCI/PXI Boards

The types of boards are:

• MF Multifunction

• MFS Multifunction with sample and hold

• AO Analog Output (requires PD2-AO user manual)

• DIO Digital Input/Output (requires PD2-DIO user

manual)

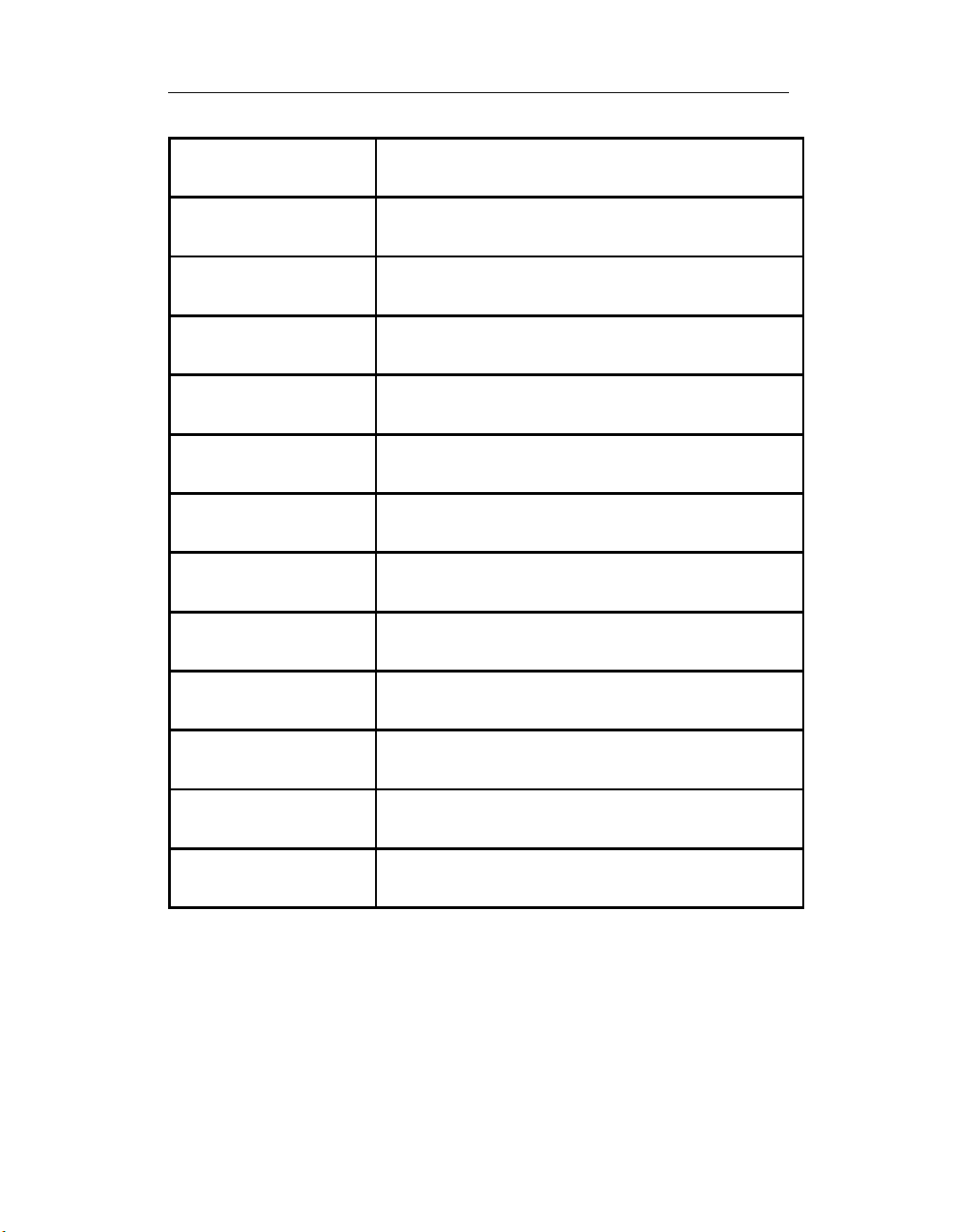

PowerDAQ PD2-MF Series:

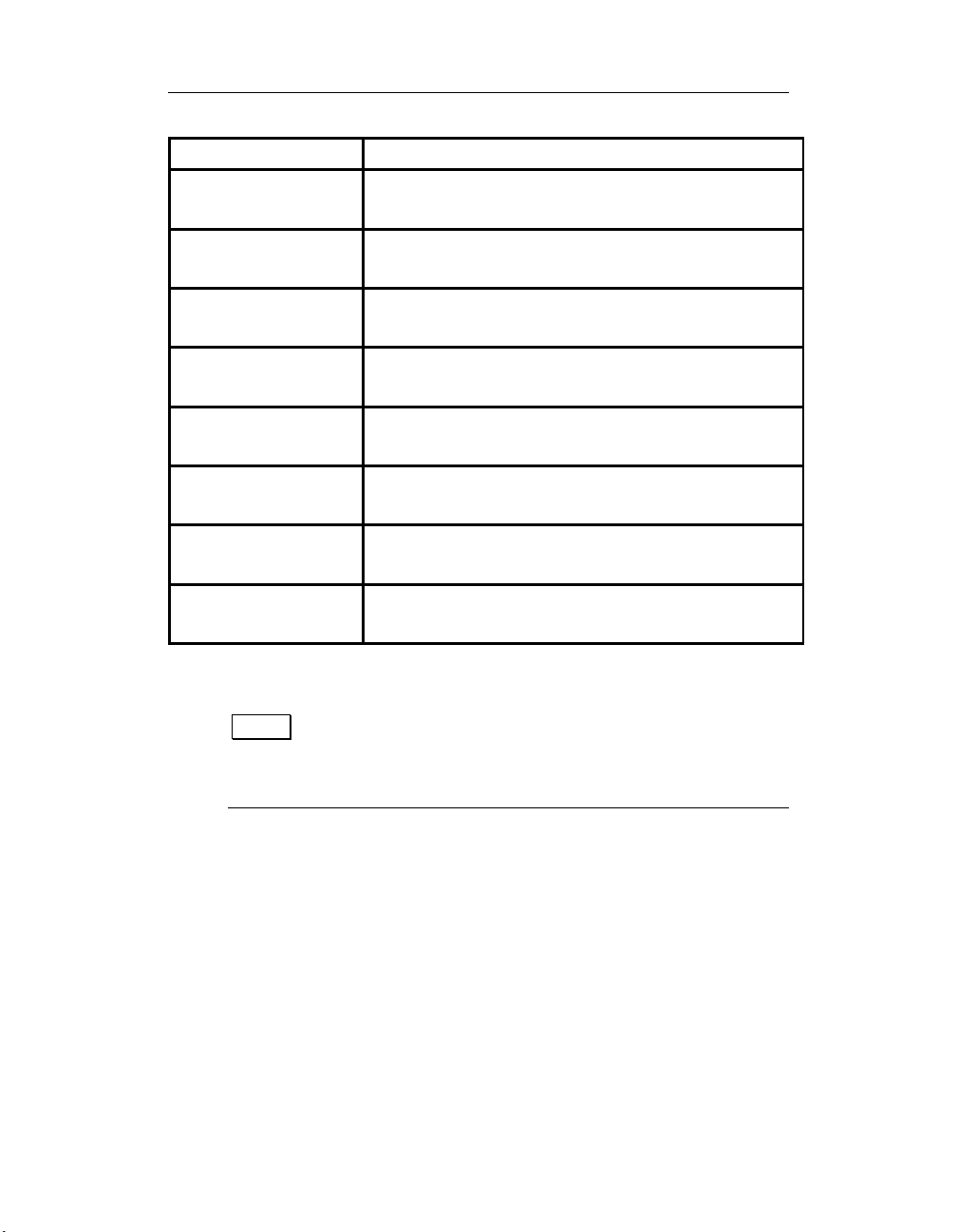

Model: Analog features:

PD2-MF-16-2M/14H 2.2 MS/s, 14-bit, 16SE/8DI A/D, Gains: 1,2,4,8;

Two 12-bit D/A

PD2-MF-64-2M/14H 2.2 MS/s, 14-bit, 64SE/32DI A/D, Gains: 1,2,4,8

Two 12-bit D/A

PD2-MF-16-400/14L 400 kS/s, 14-bit, 16SE/8DI A/D, Gains:

1,10,100,1000; Two 12-bit D/A

PD2-MF-16-400/14H 400 kS/s, 14-bit, 16SE/8DI A/D, Gains: 1,2,4,8;

Two 12-bit D/A

PD2-MF-64-400/14L 400 kS/s, 14-bit, 64SE/32DI A/D, Gains:

1,10,100,1000; Two 12-bit D/A

PD2-MF-64-400/14H 400 kS/s, 14-bit, 64SE/32DI A/D, Gains: 1,2,4,8

Two 12-bit D/A

PD2-MF-16-1M/12L 1.25 MS/s, 12-bit, 16SE/8DI A/D, Gains:

1,10,100,1000; Two 12-bit D/A

3

Page 16

Chapter 1: Introduction

8

PD2-MF-16-1M/12H 1.25 MS/s, 12-bit, 16SE/8DI A/D, Gains: 1,2,4,8;

Two 12-bit D/A

PD2-MF-64-1M/12L 1.25 MS/s, 12-bit, 64SE/32DI A/D, Gains:

1,10,100,1000; Two 12-bit D/A

PD2-MF-64-1M/12H 1.25 MS/s, 12-bit, 64SE/32DI A/D, Gains: 1,2,4,

Two 12-bit D/A

PD2-MF-16-150/16L 150 kS/s, 16-bit, 16SE/8DI A/D, Gains:

1,10,100,1000; Two 12-bit D/A

PD2-MF-16-150/16H 150 kS/s, 16-bit, 16SE/8DI A/D, Gains: 1,2,4,8;

Two 12-bit D/A

PD2-MF-16-333/16L 333 kS/s, 16-bit, 16SE/8DI A/D, Gains:

1,10,100,1000; Two 12-bit D/A

PD2-MF-16-333/16H 333 kS/s, 16-bit, 16SE/8DI A/D, Gains: 1,2,4,8;

Two 12-bit D/A

PD2-MF-64-333/16L 333 kS/s, 16-bit, 64SE/32DI A/D, Gains:

1,10,100,1000; Two 12-bit D/A

PD2-MF-64-333/16H 333 kS/s, 16-bit, 64SE/32DI A/D, Gains: 1,2,4,8;

Two 12-bit D/A

PD2-MF-16-500/16L 500 kS/s, 16-bit, 16SE/8DI A/D, Gains:

1,10,100,1000; Two 12-bit D/A

PD2-MF-16-500/16H 500 kS/s, 16-bit, 16SE/8DI A/D, Gains: 1,2,4,8;

Two 12-bit D/A

PD2-MF-64-500/16L 500 kS/s, 16-bit, 64SE/32DI A/D, Gains:

1,10,100,1000; Two 12-bit D/A

PD2-MF-64-500/16H 500 kS/s, 16-bit, 64SE/32DI A/D, Gains: 1,2,4,8;

Two 12-bit D/A

Table 1: PowerDAQ PD2-MF Models

All PowerDAQ PD2 models include 3 counter/timers and 32 Digital I/O

lines

4

Page 17

Chapter 1: Introduction

d

d

d

d

d

d

d

d

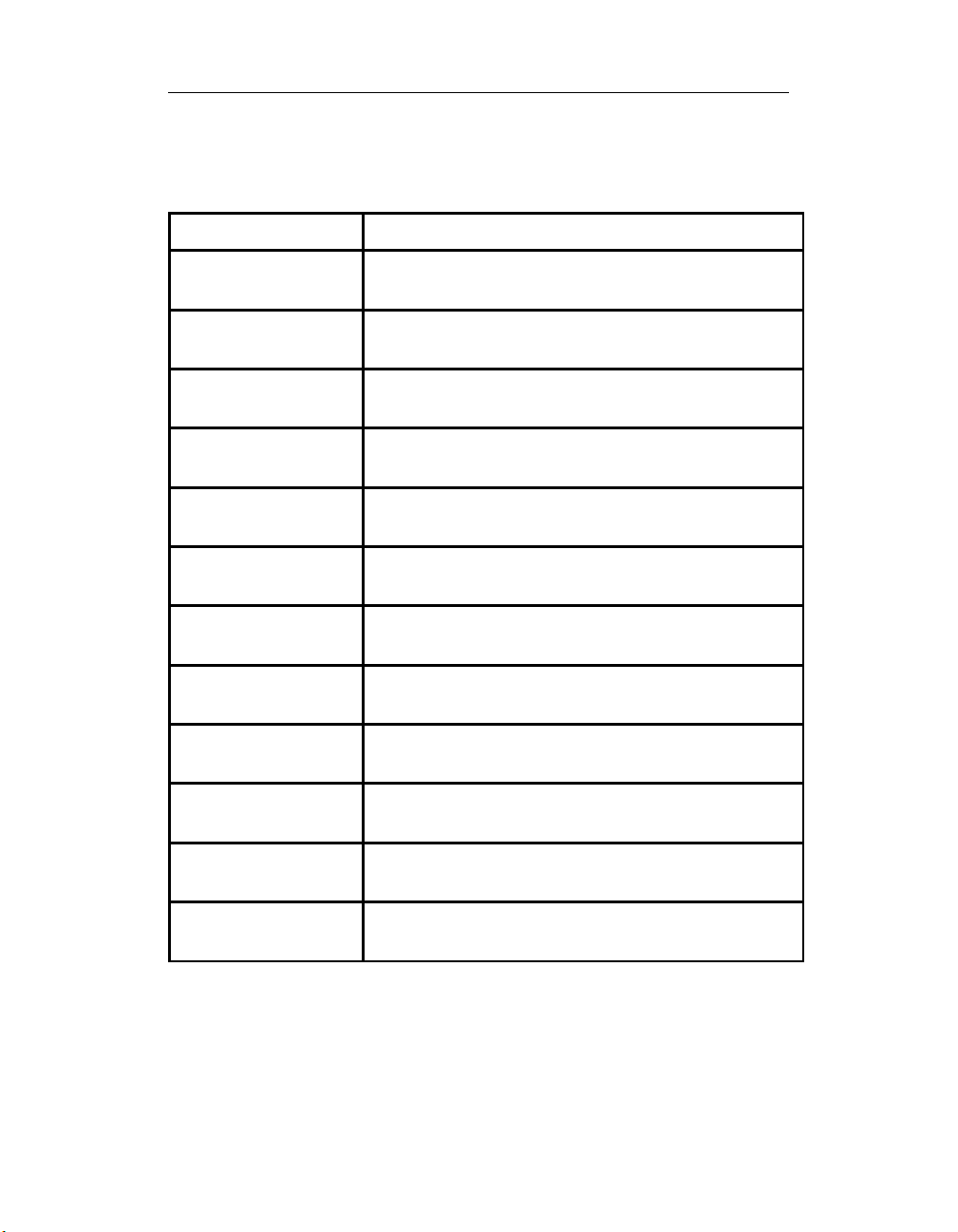

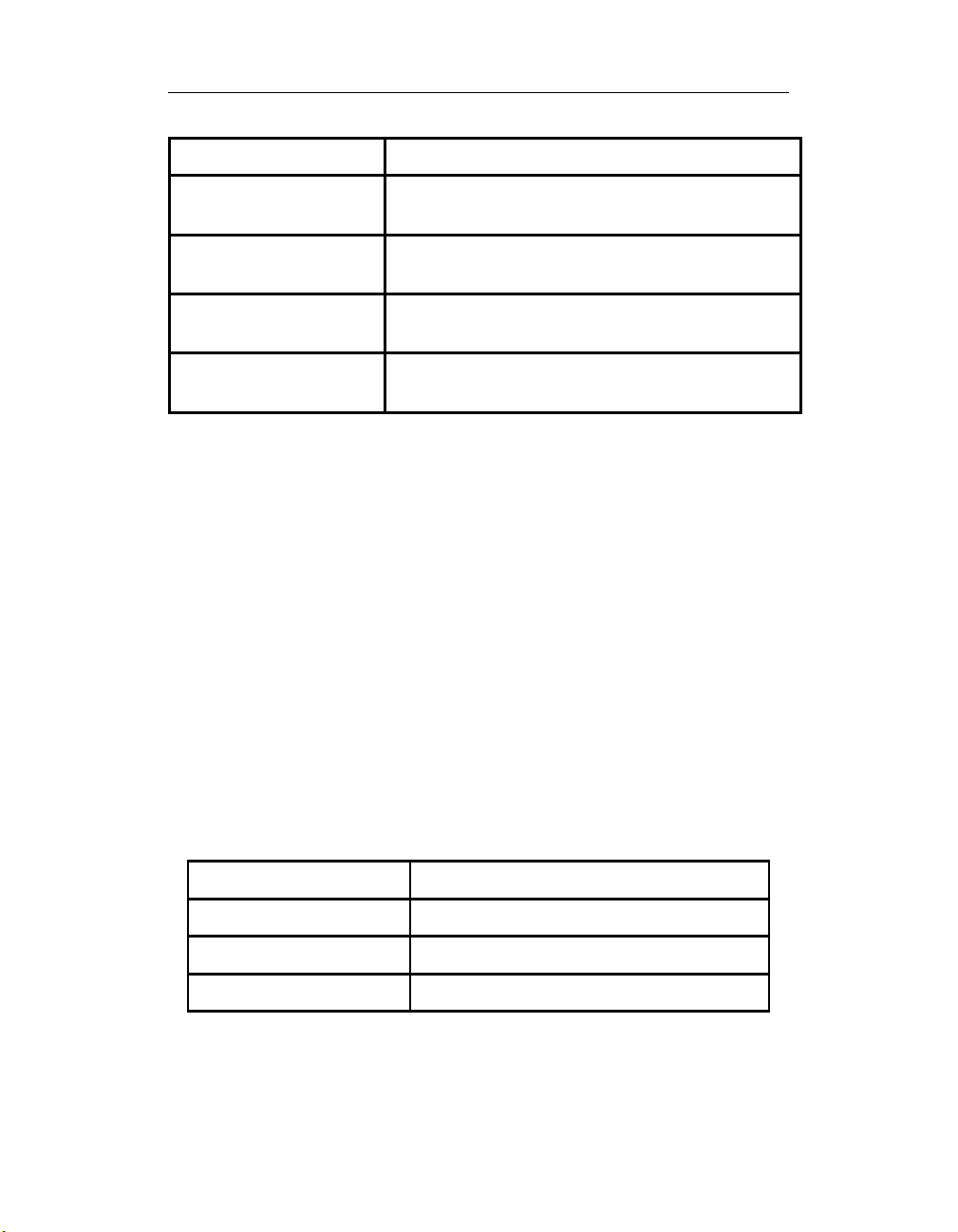

PowerDAQ PD2-MFS Series:

Model: Analog features:

PD2-MFS-4-2M/14 1.65 MS/s, 14-bit, 4SE Simultaneous Sample &

Hold; Two 12-bit D/As

PD2-MFS-8-2M/14 1.65 MS/s, 14-bit, 8SE Simultaneous Sample &

Hold; Two 12-bit D/As

PD2-MFS-4-800/14 800 kS/s, 14-bit, 4SE Simultaneous Sample & Hol

Two 12-bit D/As

PD2-MFS-8-800/14 800 kS/s, 14-bit, 8SE Simultaneous Sample & Hol

Two 12-bit D/As

PD2-MFS-4-500/14 500 kS/s, 14-bit, 4SE Simultaneous Sample & Hol

Two 12-bit D/As

PD2-MFS-8-500/14 500 kS/s, 14-bit, 8SE Simultaneous Sample & Hol

Two 12-bit D/As

PD2-MFS-4-1M/12 1 MS/s, 12-bit, 4SE Simultaneous Sample & Hold;

Two 12-bit D/As

PD2-MFS-8-1M/12 1 MS/s, 12-bit, 8SE Simultaneous Sample & Hold;

Two 12-bit D/As

PD2-MFS-4-300/16 300 kS/s, 16-bit, 4SE Simultaneous Sample & Hol

Two 12-bit D/As

PD2-MFS-8-300/16 300 kS/s, 16-bit, 8SE Simultaneous Sample & Hol

Two 12-bit D/As

PD2-MFS-4-500/16 500 kS/s, 16-bit, 4SE Simultaneous Sample & Hol

Two 12-bit D/As

PD2-MFS-8-500/16 500 kS/s, 16-bit, 8SE Simultaneous Sample & Hol

Two 12-bit D/As

Table 2: PowerDAQ PD2-MFS Models

5

Page 18

Chapter 1: Introduction

;

;

8

Note The PD2-MFS series have onboard sample and hold

amplifiers for each channel. These are part of the boards

hardware design and do not require any software programming

to be enabled.

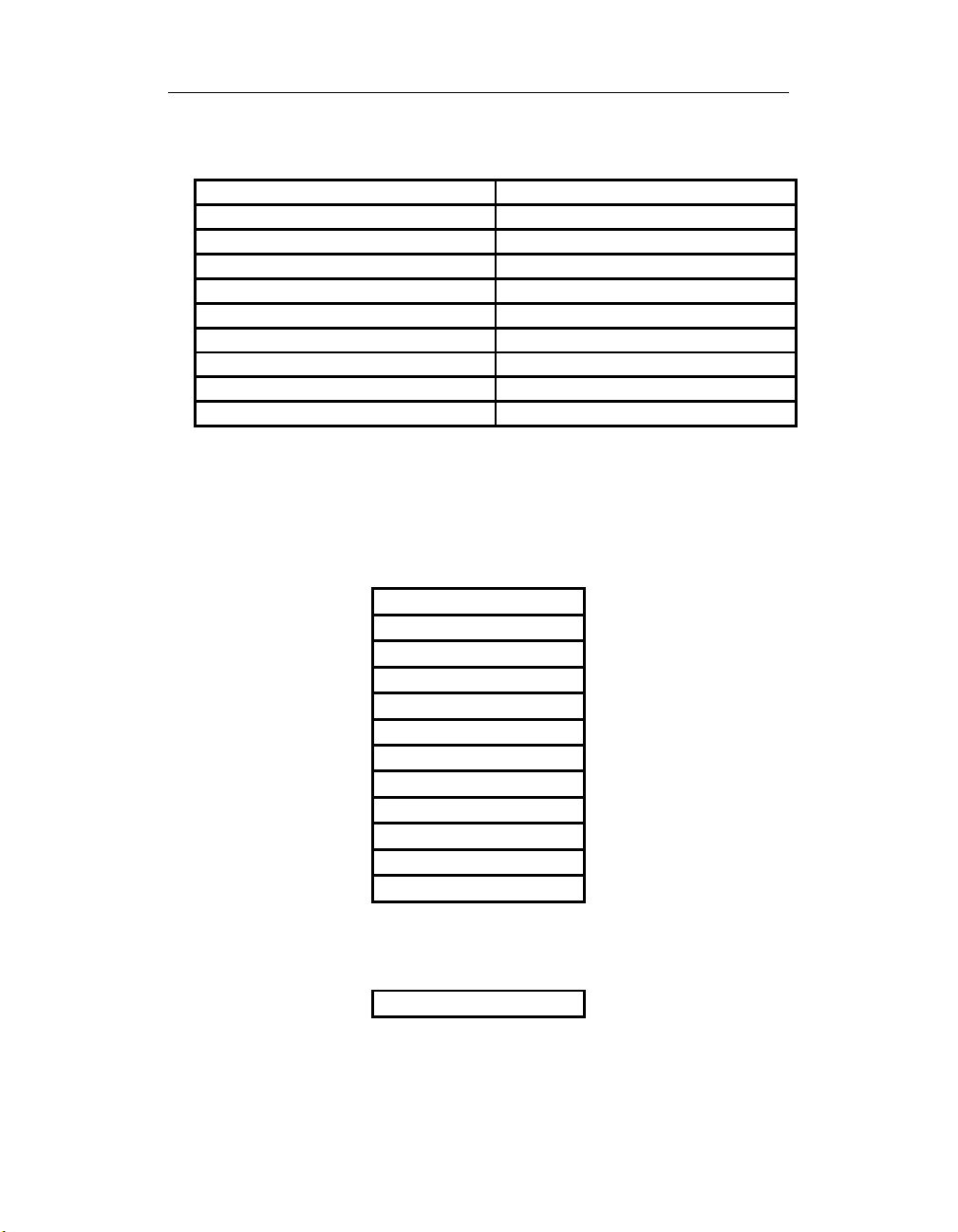

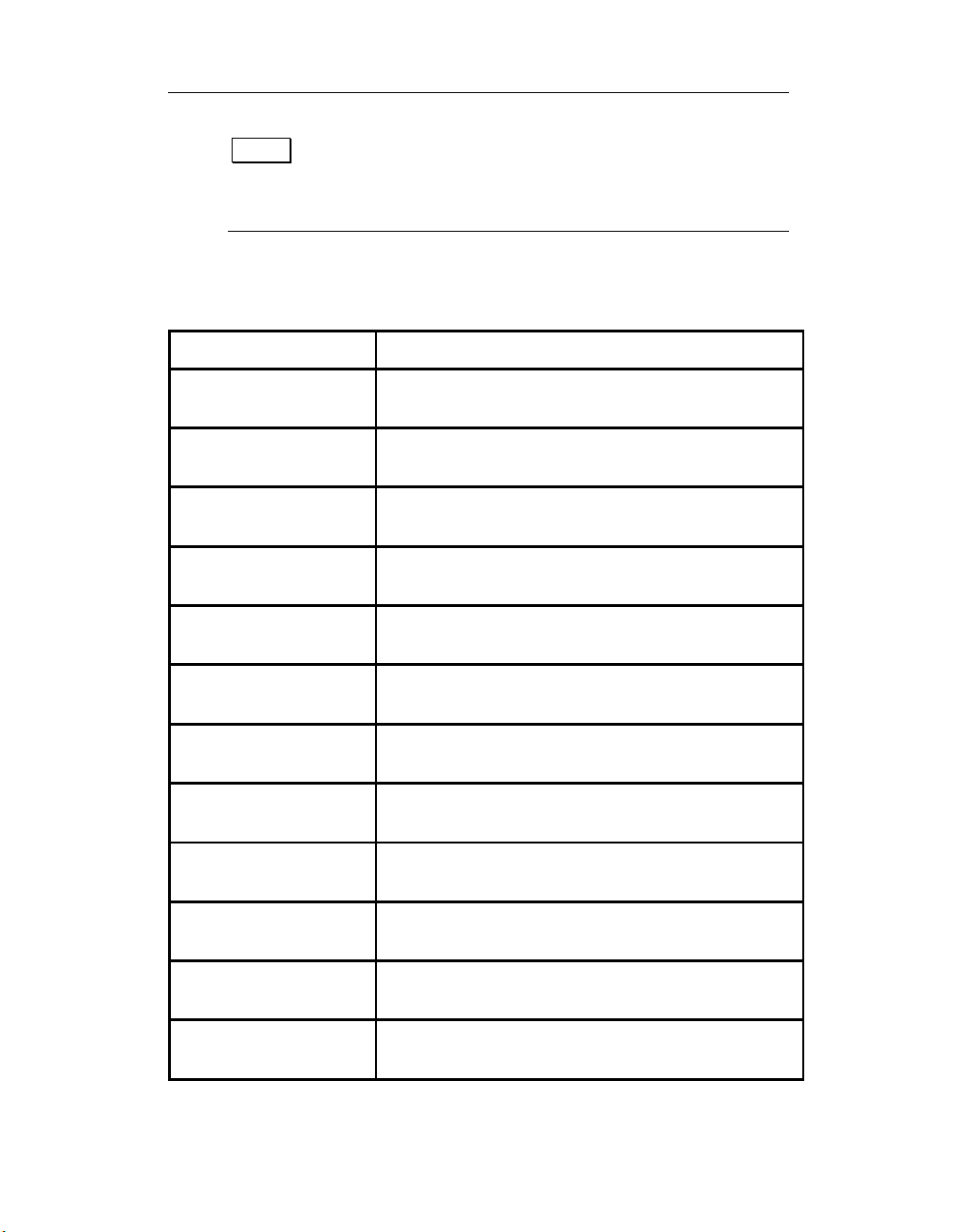

PowerDAQ PDXI-MF Series:

Model: Analog features:

PDXI-MF-16-2M/14H 2.2 MS/s, 14-bit, 16SE/8DI A/D, Gains: 1,2,4,8;

Two 12-bit D/A

PDXI-MF-64-2M/14H 2.2 MS/s, 14-bit, 64SE/32DI A/D, Gains: 1,2,4,8

Two 12-bit D/A

PDXI-MF-16-400/14L 400 kS/s, 14-bit, 16SE/8DI A/D, Gains:

1,10,100,1000; Two 12-bit D/A

PDXI-MF-16-400/14H 400 kS/s, 14-bit, 16SE/8DI A/D, Gains: 1,2,4,8;

Two 12-bit D/A

PDXI-MF-64-400/14L 400 kS/s, 14-bit, 64SE/32DI A/D, Gains:

1,10,100,1000; Two 12-bit D/A

PDXI-MF-64-400/14H 400 kS/s, 14-bit, 64SE/32DI A/D, Gains: 1,2,4,8

Two 12-bit D/A

PDXI-MF-16-1M/12L 1.25 MS/s, 12-bit, 16SE/8DI A/D, Gains:

1,10,100,1000; Two 12-bit D/A

PDXI-MF-16-1M/12H 1.25 MS/s, 12-bit, 16SE/8DI A/D, Gains: 1,2,4,8;

Two 12-bit D/A

PDXI-MF-64-1M/12L 1.25 MS/s, 12-bit, 64SE/32DI A/D, Gains:

1,10,100,1000; Two 12-bit D/A

PDXI-MF-64-1M/12H 1.25 MS/s, 12-bit, 64SE/32DI A/D, Gains: 1,2,4,

Two 12-bit D/A

PDXI-MF-16-150/16L 150 kS/s, 16-bit, 16SE/8DI A/D, Gains:

1,10,100,1000; Two 12-bit D/A

PDXI-MF-16-150/16H 150 kS/s, 16-bit, 16SE/8DI A/D, Gains: 1,2,4,8;

Two 12-bit D/A

6

Page 19

Chapter 1: Introduction

d

d

PDXI-MF-16-333/16L 333 kS/s, 16-bit, 16SE/8DI A/D, Gains:

1,10,100,1000; Two 12-bit D/A

PDXI-MF-16-333/16H 333 kS/s, 16-bit, 16SE/8DI A/D, Gains: 1,2,4,8;

Two 12-bit D/A

PDXI-MF-64-333/16L 333 kS/s, 16-bit, 64SE/32DI A/D, Gains:

1,10,100,1000; Two 12-bit D/A

PDXI-MF-64-333/16H 333 kS/s, 16-bit, 64SE/32DI A/D, Gains: 1,2,4,8;

Two 12-bit D/A

PDXI-MF-16-500/16L 500 kS/s, 16-bit, 16SE/8DI A/D, Gains:

1,10,100,1000; Two 12-bit D/A

PDXI-MF-16-500/16H 500 kS/s, 16-bit, 16SE/8DI A/D, Gains: 1,2,4,8;

Two 12-bit D/A

PDXI-MF-64-500/16L 500 kS/s, 16-bit, 64SE/32DI A/D, Gains:

1,10,100,1000; Two 12-bit D/A

PDXI-MF-64-500/16H 500 kS/s, 16-bit, 64SE/32DI A/D, Gains: 1,2,4,8;

Two 12-bit D/A

Table 3: PowerDAQ PD2-MF Models

All PowerDAQ PD2 models include 3 counter/timers and 32 Digital I/O

lines

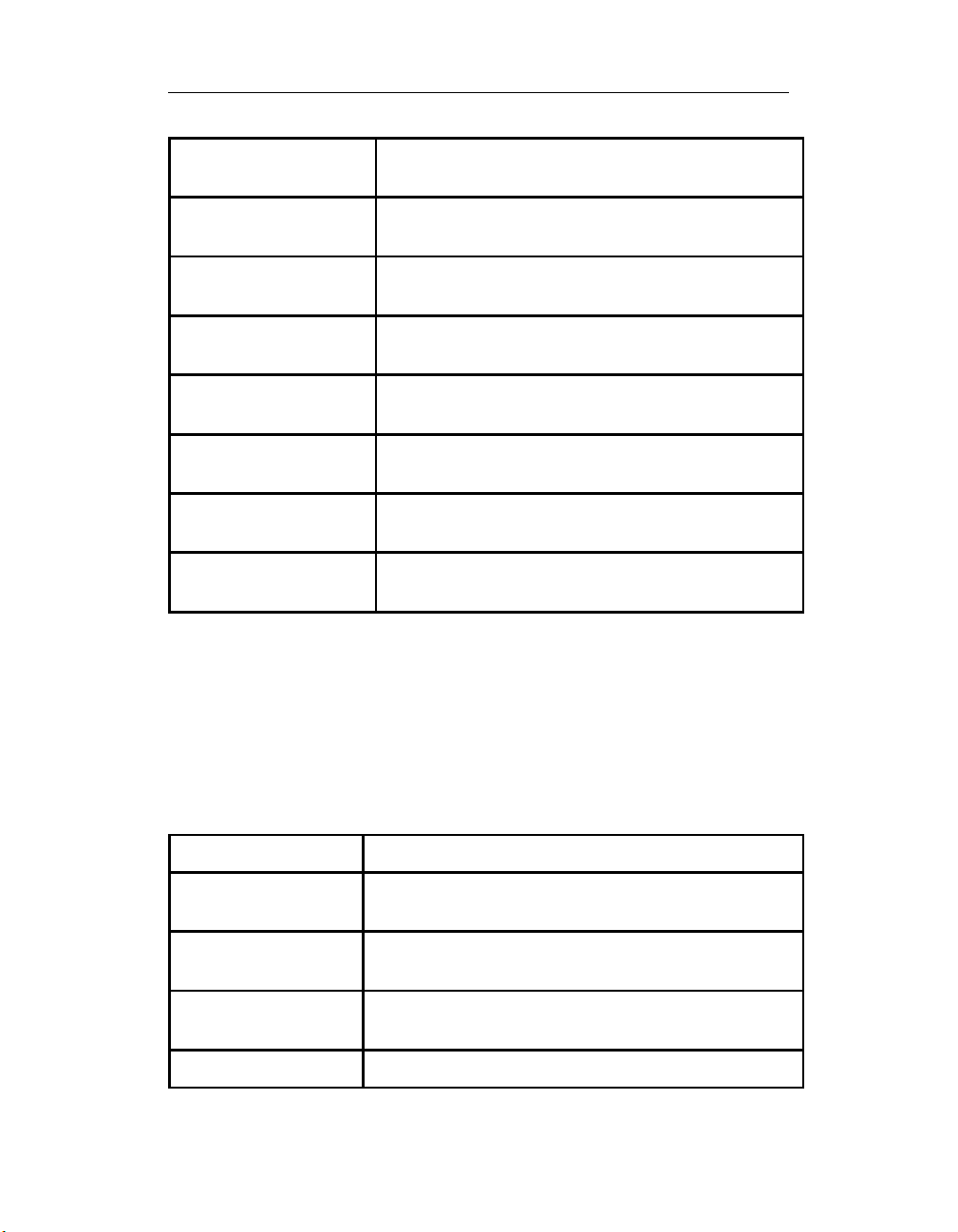

PowerDAQ PDXI-MFS Series:

Model: Analog features:

PDXI-MFS-4-2M/14 1.65 MS/s, 14-bit, 4SE Simultaneous Sample &

Hold; Two 12-bit D/As

PDXI-MFS-8-2M/14 1.65 MS/s, 14-bit, 8SE Simultaneous Sample &

Hold; Two 12-bit D/As

PDXI-MFS-4-800/14 800 kS/s, 14-bit, 4SE Simultaneous Sample & Hol

Two 12-bit D/As

PDXI-MFS-8-800/14

7

800 kS/s, 14-bit, 8SE Simultaneous Sample & Hol

Page 20

Chapter 1: Introduction

d

d

d

d

d

d

Two 12-bit D/As

PDXI-MFS-4-500/14 500 kS/s, 14-bit, 4SE Simultaneous Sample & Hol

Two 12-bit D/As

PDXI-MFS-8-500/14 500 kS/s, 14-bit, 8SE Simultaneous Sample & Hol

Two 12-bit D/As

PDXI-MFS-4-1M/12 1 MS/s, 12-bit, 4SE Simultaneous Sample & Hold;

Two 12-bit D/As

PDXI-MFS-8-1M/12 1 MS/s, 12-bit, 8SE Simultaneous Sample & Hold;

Two 12-bit D/As

PDXI-MFS-4-300/16 300 kS/s, 16-bit, 4SE Simultaneous Sample & Hol

Two 12-bit D/As

PDXI-MFS-8-300/16 300 kS/s, 16-bit, 8SE Simultaneous Sample & Hol

Two 12-bit D/As

PDXI-MFS-4-500/16 500 kS/s, 16-bit, 4SE Simultaneous Sample & Hol

Two 12-bit D/As

PDXI-MFS-8-500/16 500 kS/s, 16-bit, 8SE Simultaneous Sample & Hol

Two 12-bit D/As

Table 4: PowerDAQ PDXI-MFS Models

Note The PDXI-MFS series have onboard sample and hold

amplifiers for each channel. These are part of the boards

hardware design and do not require any software programming

to be enabled.

PowerDAQ Sample and Hold differential

upgrade with gains:

The PD2-MFS/PDXI-MFS series can be upgraded to differential inputs

with gains for each channel. One PGA per channel is installed on the

board.

8

Page 21

Chapter 1: Introduction

O

O

O

Upgrade Part Number: Additional features added:

PD2-MFS-4-DG4 Upgrade any PD2-MFS board from 4SE to 4DI

with Gains (1,2,5,10)

PD2-MFS-8-DG8 Upgrade any PD2-MFS board from 8SE to 8DI

with Gains (1,2,5,10)

PDXI-MFS-4-DG4 Upgrade any PDXI-MFS board from 4SE to 4DI

with Gains (1,2,5,10)

PDXI-MFS-8-DG8 Upgrade any PDXI-MFS board from 8SE to 8DI

with Gains (1,2,5,10)

Table 5: MFS Differential Upgrade Options

PowerDAQ D/A, DIO and Counter Timer

features:

All PowerDAQ PD2/PDXI boards have the following additional features:

• Analog Output Two 12-bit 200 kHz DAC’s

• Digital Input 16 TTL (of which 8 can generate

interrupts)

• Digital Output 16 TTL

• Counter Timers Three 16-bit (8254 type)

PowerDAQ MF/MFS FIFO Upgrade options:

PD2/PDXI PowerDAQ multifunction boards can have the analog input

FIFOs upgraded. Below is a list of current upgrade options:

Upgrade part number: Additional features added:

PD-16KFIFO Upgrade board from 1K FIFO to 16K FIF

PD-32KFIFO Upgrade board from 1K FIFO to 32K FIF

PD-64KFIFO Upgrade board from 1K FIFO to 64K FIF

Table 6: PD2-/PDXI- FIFO upgrade options

9

Page 22

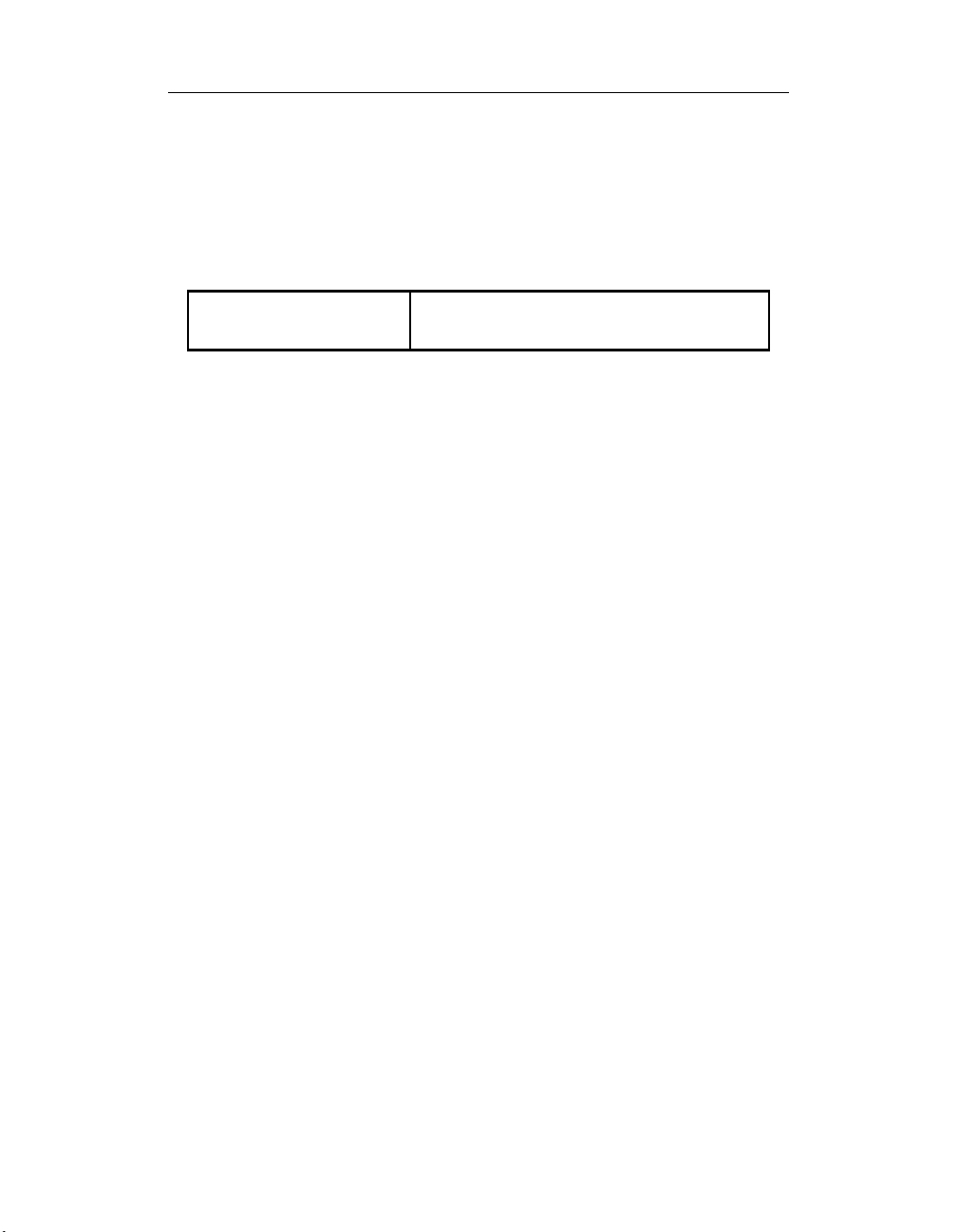

PowerDAQ PDL-MF Lab Board:

This low cost Lab series board features:

150 kS/s, 16-bit, 16SE/16PDI, 8DI ; Two

PDL-MF

Table 7: PDL-MF board specifications

The PDL-MF board have the following additional features:

• Analog Output Two 12-bit 200 kHz DAC’s

• Digital Input 24 lines

• Digital Output 24 lines

• Counter Timers Three 24-bit 16.5/33 MHz

12-bit D/As, 48 DIO and 3 CTM

Page 23

2

Installation and

Configuration

11

Page 24

Chapter 2: Installation and Configuration

Before You Begin

Before you install your PowerDAQ board, you should read and

understand the following information.

System Requirements:

To install and run your PowerDAQ board, you must have the following:

• A PC with PCI slots, a Pentium-class processor, and a

BIOS that is compliant with

Revision 2.1

• Windows 95, 98, NT 4.0, 2000/XP

• Linux, QNX, RTLinux

or greater

Packing List

In your PowerDAQ package you should have received:

• A PowerDAQ board

• A user manual

• A CD containing the PowerDAQ software development kit

(SDK) and documentation

PCI Local Bus Specification

Note The CD label shows the version number of the SDK.

• A calibration certificate

Precautions

PowerDAQ boards contain sensitive electronic components. When

handling your PowerDAQ board, you should:

• Ensure that you are properly grounded.

• While holding the board in its antistatic bag, discharge

any static electricity by touching the metal part of your

PC.

12

Page 25

Chapter 2: Installation and Configuration

Installing PowerDAQ

Installing the Board:

To install your PowerDAQ board:

1. Turn off your PC and remove the cover from your PC.

2. Locate an empty PCI slot and remove the slot cover on

the back panel of your PC. Save the screw.

3. Insert the board into the PCI slot.

4. Fasten the board’s mounting bracket to your PC’s back

panel with the screw that held the slot cover.

5. Inspect the board and ensure that it has been properly

inserted in the slot.

6. Replace the cover of your PC and turn on the power.

Note The PowerDAQ PCI interface must be set to 32-bit, 5V

power and signaling (the default setting for most PCs).

13

Page 26

Chapter 2: Installation and Configuration

4

Installing the Software

To install the PowerDAQ SDK:

1. Start your PC and, if you are running Windows NT, login as an

administrator.

2. Insert the PowerDAQ CD into your CD-ROM drive. Windows should

automatically start the PowerDAQ Setup program. If you see the

OMEGA logo and then the PowerDAQ welcome screen, go to step

6.

3. If the Setup program does not start automatically, select Run from

the Start menu.

4. Enter D:\Setup.exe in the Open: textbox. (Substitute the correct

letter if D is not the drive letter of your CD-ROM drive.)

5. Click OK.

6. As the Setup program runs, you will be asked to enter information

about your PowerDAQ configuration. Unless you are an expert user

and have specific requirements, you should select a Typical

installation and accept the default configuration.

1

Page 27

Chapter 2: Installation and Configuration

5

7. If the Setup program asks for information about third-party

software packages that you do not have installed on your PC, leave

the textbox blank and click the Next button.

8. When the installation is complete, you should restart your PC when

prompted.

Confirming the Installation

Once you have installed the PowerDAQ board and software on your PC,

you should confirm the installation:

• Select Programs ! PowerDAQ !

the Start menu. If the Control Panel applet is displayed

and correctly identifies your PowerDAQ board, the

installation is correct.

! Control Panel: from

!!

Figure 1: Control Panel Application

1

Page 28

Chapter 2: Installation and Configuration

6

Configuring the PowerDAQ Board

1

J1 Con nector

Pow erDAQ II MF b oard

Inp ut Multi p le xors

DSP

PowerDAQ

PCI Bu s

Control

Logic

Boot

ROM

1

J6 Connector

Logic

FIFO

Onboard

FIFO

Onboard

Low Noise DC-DC

1

1

J4 C onnector

J2 Connector

Figure 2: PD2- Board connector layout

PDXI-MF board

1

J1 C onn e ct o r

J2 Connector

Input M ultiple xors

Low N oise DC-DC

PXI

DSP

Po w er D AQ

CompactPCI Bus

Figure 3: PDXI-MF Board connector layout

1

Page 29

Chapter 2: Installation and Configuration

7

1

J1 Connector

PowerDAQ PDL-MF board

Boot

ROM

DSP

PowerDAQ

PCI Bus

Figure 4: PDL-MF- Board connector layout

Input Modes:

The analog input section multiplexes the active input channels (64/16

single-ended or 32/8)differential) to a single 12- or 16-bit successive

approximation analog-to-digital converter (ADC).

Single-Ended:

PowerDAQ boards can be configured to operate with either a singleended or differential input. Single-ended inputs allow up to 64 channels

and share a common return path connected to analog ground (AGND).

1

Page 30

Chapter 2: Installation and Configuration

Ain

V1

Aout

Agnd

Figure 5: Single-ended Inputs and pseudo-differential

inputs

Note Unused channels should be shorted to ground using 0-

to 1-KΩ resistor. In pseudo-differential mode ground reference

level is taken from remote system.

Differential Inputs:

Differential inputs allow up to 32 channels. Each differential channel

uses two analog channels — one analog channel connects to the positive

input of the programmable gain amplifier, and the other to the

negative.

Ain (+)

V1

Ain (RETURN)

AGND

Figure 6: Differential Inputs

18

Page 31

Chapter 2: Installation and Configuration

Note Positive and negative differential inputs should not be

driven by voltages more then AGND ±14V.

When wiring applications to your PowerDAQ board, consider the

following:

• When working in an environment with electrical noise or

when using gains, use differential input.

• When working in an environment with electrical noise,

use individually shielded twisted-pair wiring.

• Physically separate wiring paths or conduits carrying

power lines and signal lines.

• Signal cables should never be put in the same wiring

harness as high-current or high-voltage cables. Avoid

routing signal and power cables together in parallel paths

unless a reasonable distance separates the paths —

reasonable

power signals and the amount of shielding.

• Signal lines near devices that create high levels of

electrical noise should be run through a metal cable

trough above or below the work area.

• Power lines, poorly designed video monitors and

switching power supplies, solenoids, electric arcs from

breakers or welders, and unshielded signal cables can

affect the accuracy of your measurements.

being determined by the strength of the

Installing Multiple Boards (PD-CBL-SYNC):

You can install multiple PowerDAQ boards in one PC. The internal J6

synchronization header will allow a master/slave configuration to be

setup. A special PowerDAQ cable (PD-CBL-SYNC): will allow you to

connect up to four boards in one PC. Synchronization cables for more

than four boards are available from your distributor or the factory.

19

Page 32

Chapter 2: Installation and Configuration

Note PXI boards are synchronized via PXI interface using the

PXI Configurator program.

Figure 7: PDXI Configurator

PDL-MF board is synchronized via connections on a screwterminal panel.

Note When using more than 4 PCI slots (standard PC), you

will need a PCI bridge chip to support additional PCI slots. These

bridge chips reduce the PCI bus throughput and will reduce your

maximum sampling speed.

Base address, DMA, Interrupt settings

The PowerDAQ boards are configured automatically by the PCI bus on

power up. You do not have to set any base address, DMA channels or

interrupt levels. In case of the performance problems try for more

PowerDAQ boards and mass-storage/video/network/USB devices for

different IRQs.

20

Page 33

Chapter 2: Installation and Configuration

Test Program:

After you have wired an application to your PowerDAQ board, you

should run the Simple Test program:

1. Select Programs " PowerDAQ " Simple Test : from

the Start menu. The Simple Test dialog box is displayed.

Figure 8: Simple Test Application

2. Use the Analog In, Analog Out, Digital In, Digital Out,

and Counters tabs to observe your application running

on the board.

Connectors for PD2/PDXI

PowerDAQ multifunction boards have four connectors:

• 96-contact pin-less main connector (J1)

Manufactured by: Fujitsu: PN# FCN-245P096-G/U (Male)

http://www.fta.fujitsu.com/

21

Page 34

Chapter 2: Installation and Configuration

2

• 36-pin internal digital connector (J2)

Manufactured by: Thomas and Betts PN# 609-3627

(Male)

http://www.thomasandbetts.com/

• 36-pin internal digital connector (J4)

Manufactured by: Thomas and Betts PN# 609-3627

(Male)

http://www.thomasandbetts.com/

• 8-pin internal digital clock-signal connector (J6)

Manufactured by: Adam Tech PN# PH2-08-TA-SMT

http://www.adam-tech.com/

Connector Pin Assignments for J1

Figure 9: Fujitsu Connector Layout

2

Page 35

Chapter 2: Installation and Configuration

J1 Connector (Single-Ended Mode)

49

AGND

AGND

AGND

AGND

DGND

AGND

AIN55

AIN53

AIN51

AIN49

AGND

AIN38

AIN36

AIN34

AIN33

AIN23

AIN21

AGND

AIN18

AIN16

AIN6

AIN5

AIN3

AIN1

DSP Trigger Input/AO External Clock

*ADC Conversion Start Out/ Pacer clock out

ADC Channel List Start Input / Burst Clock

AGND

N/C

AGND

AIN62

AIN60

AIN59

AIN57

AIN47

AGND

AIN44

AIN42

AIN40

AGND

AIN29

AIN27

AIN25

AIN24

AIN14

AIN12

AGND

AIN9

Table 8: J1 Connector (Single-Ended Mode)

AGND

1

50

AOUT0

2

351

AGND

452

AOUT1

553

AGND

AGND

654

755

AIN54

AIN52

856

57

AIN50

AIN48

10 58

AIN39

11 59

AIN37

12 60

AIN35

13 61

AGND

62

AIN32

15 63

AIN22

16 64

AIN20

17 65

AIN19

18 66

AIN17

19 67

AIN7

20 68

AGND

21 69

AIN4

22 70

AIN2

23 71

AIN0

24 72

AGND

25 73

26 74

+5V (100 mA max)

ADC Conversion Start Input / Pacer clock

27 75

28 76

AGND

N/C

29 77

30 78

AIN63

AIN61

31 79

32 80

AGND

AIN58

33 81

34 82

AIN56

AIN46

35 83

36 84

AIN45

37 85

AIN43

38 86

AIN41

39 87

AIN31

40 88

AIN30

41 89

AIN28

42 90

AIN26

43 91

AGND

44 92

AIN15

45 93

AIN13

46 94

AIN11

47 95

AIN10

48

96

AIN8

* Disconnected by default, consult factory if you need this clock on J1

connector.

23

Page 36

Chapter 2: Installation and Configuration

4

J1 Connector (Differential Input Mode)

AGND

AGND

AGND

AGND

DGND

AGND

AIN55

AIN53

AIN51

AIN49

AGND

AIN38

AIN36

AIN34

AIN33

AIN23

AIN21

AGND

AIN18

AIN16

AIN6

AIN5

AIN3

AIN1

AGND

DSP Trigger Input/AO External Clock

ADC Conversion Start Out/ Pacer clock out

N/C

AGND

ADC Channel List Start Input / Burst Clock

AIN54 Return

AIN52 Return

AIN51 Return

AIN49 Return

AIN39 Return

AGND

AIN36 Return

AIN34 Return

AIN32 Return

AGND

AIN21 Return

AIN19 Return

AIN17 Return

AIN16 Return

AIN6 Return

AIN4 Return

AGND

AIN1 Return

49

AGND

1

50

AOUT0

2

351

AGND

452

AOUT1

553

AGND

AGND

654

755

AIN54

AIN52

856

57

AIN50

AIN48

10 58

AIN39

11 59

AIN37

12 60

AIN35

13 61

AGND

62

AIN32

15 63

AIN22

16 64

AIN20

17 65

AIN19

18 66

AIN17

19 67

AIN7

20 68

AGND

21 69

AIN4

22 70

AIN2

23 71

AIN0

24 72

AGND

25 73

26 74

+5V (100 mA max)

ADC Conversion Start Input / Pacer clock

27 75

28 76

AGND

N/C

29 77

30 78

AIN55 Return

AIN53 Return

31 79

32 80

AGND

AIN50 Return

33 81

34 82

AIN48 Return

AIN38 Return

35 83

36 84

AIN37 Return

37 85

AIN35 Return

38 86

AIN33 Return

39 87

AIN23 Return

40 88

AIN22 Return

41 89

AIN20 Return

42 90

AIN18 Return

43 91

AGND

44 92

AIN7 Return

45 93

AIN5 return

46 94

AIN3 Return

47 95

AIN2 Return

48

96

AIN0 Return

Table 9: J1 Connector (Differential Input Mode)

2

Page 37

Chapter 2: Installation and Configuration

5

Connector Pin Assignments for J2

The J2 digital internal connector contains eight digital input and eight

digital output lines.

CTR0-IN

CTR0-OUT

CTR0-GATE

CTR1-IN

CTR1-OUT

DIN0

DIN1

DIN2

DIN3

DIN4

DIN5

DIN6

DIN7

Burst Clock / ADC Channel List Start Input

Pacer Clock / ADC Conversion Start Input

DGND

Burst Clock /ADC Channel List Start Output

Table 10: Connector Pin Assignments for J2

CTR2-IN

12

CTR2-OUT

34

CTR2-GATE

56

CTR1-GATE

78

+5V (100 mA max)

910

DGND

11 12

DOUT0

13 14

16

DOUT1

17 18

DOUT2

19 20

DOUT3

21 22

DOUT4

23 24

DOUT5

26

DOUT6

27 28

DOUT7

DGND

29 30

ADC Conversion Start Output / Pacer Clock Output

31 32

DGND

33 34

35 36

NC

2

Page 38

Chapter 2: Installation and Configuration

6

Connector Pin Assignments for J4

The J4 Connector contains eight digital input and eight digital output

lines.

DIN8

DIN9

12

DGND

34

DGND

56

DGND

78

DGND

910

+5V (100 mA max)

11 12

DGND

13 14

DOUT8

16

DOUT9

17 18

DOUT10

19 20

DOUT11

21 22

DOUT12

23 24

DOUT13

26

DOUT14

27 28

DOUT15

29 30

DGND

DGND

31 32

33 34

DGND

35 36

DGND

DGND

DGND

DGND

DGND

DGND

DIN10

DIN11

DIN12

DIN13

DIN14

DIN15

DGND

DGND

DGND

DGND

DGND

Table 11: Connector Pin Assignments for J4

2

Page 39

Chapter 2: Installation and Configuration

7

Connector Pin Assignments for J6

The J6 Interboard Synchronization Connector contains two pairs of

clock signal lines:

• The ADC Clock (also known as the conversion clock.

• The Channel List Clock (also known as the scan clock or

burst clock).

CV_START_OUT

CL_START_OUT

CV_START_IN

CL_START_IN

12

34

56

78

DGND

DGND

DGND

DGND

Table 12: Connector Pin Assignment for J6

Connectors for PDL-MF

PowerDAQ multifunction boards have one connector:

• 100-way connector (J1)

Manufactured by: Fujitsu : PN# FCN-245P096-G/U

(Male)

http://www.fta.fujitsu.com/

2

Page 40

Chapter 2: Installation and Configuration

Connector Pin Assignments for PDL-MF J1

TMR0

DGND

TMR1

DGND

TMR2

DGND

DOUT22

DOUT20

DOUT18

DOUT16

DOUT14

DOUT12

DOUT10

DOUT8

+5VPJ2

DOUT6

DOUT4

DOUT2

DOUT0

DIN22

DIN20

DIN18

DIN16

DGND

DIN14

DIN12

DIN10

DIN 8

DIN 6

DIN 4

DI N 2

DIN 0

AGND

AOUT1

EXT_GND

AIN 7

AGND

AIN 6

AGND

AI N 5

AGND

AIN 4

AGND

AI N 3

AGND

AI N 2

AGND

AIN 1

AGND

AIN 0

EXT_C LK

1

51

2

DGND

52

IRQC

3

53

4

DGND

54

EXT_TRIG

55

5

DGND

56

6

DOUT 23

7

57

DOUT 21

8

58

DOUT 19

9

59

DOUT 17

10

60

DOUT 15

11

61

DOUT 13

12

62

DOUT 11

63

13

DOUT 9

14

64

DGND

65

15

66

DOUT 7

16

DOUT 5

17

67

DOUT 3

18

68

DOUT 1

19

69

DIN2 3

20

70

DIN2 1

21

71

DIN19

22

72

23

DIN17

73

DGND

74

24

DIN15

25

75

DIN13

26

76

DIN11

77

27

DIN9

28

78

DIN7

79

29

DIN5

30

80

DIN3

31

81

DIN1

32

82

AGND

33

83

AOUT 0

34

84

AGND

35

85

AIN15

36

86

37

AGND

87

AIN14

88

38

AGND

39

89

AIN13

40

90

AGND

91

41

AIN12

42

92

AGND

93

43

94

AIN11

44

AGND

45

95

AIN10

96

46

AGND

47

97

AIN9

48

98

AGND

99

49

AIN8

50

10 0

Table 13: Connector Pin Assignments for PDL-MF J1

28

Page 41

Chapter 2: Installation and Configuration

Connector Pin Assignments for PDXI J2

DOUT11

DIN13

DOUT12

DIN14

DOUT13

DIN15

DOUT14

DOUT15

DGND

DGND

DGND

DGND

DGND

DGND

DGND

DGND

DGND

DGND

DGND

DGND

DGND

DGND

DGND

DGND

DGND

DGND

DGND

DGND

DGND

DGND

DGND

DGND

DGND

UCT0_CLK_IN

UCT2_CLK_IN

UCT0_OUT

UCT2_OUT

UCT0_GATE

UCT2_GATE

UCT1_CLK_IN

DIN12

2

1

DOUT10

3

4

DIN11

5

6

DOUT9

7

8

DIN10

9

10

DOUT8

11

12

DIN9

13

14

DGND

15

16

DIN8

18

+5VPJ2

19

20

DGND

21

22

CL_DONE_OUT

23

24

CL_START_OUT_BACK

25

26

DGND

28

DGND

29

30

CL_START_OUT

31

32

CL_START_IN_BACK

33

34

DGND

35

36

TRIG_IN_BACK

37

38

DOUT7

39

40

CL_START_IN_BACK

41

42

DOUT6

43

44

DIN7

45

46

DOUT5

47

48

DIN6

49

50

DOUT4

51

52

DIN5

53

54

DOUT3

55

56

DIN4

57

58

DOUT2

59

60

DIN3

61

62

DOUT1

63

64

DIN2

65

66

DOUT0

67

68

DIN1

69

70

DGND

71

72

DIN0

73

74

+5VPJ2

75

76

UCT1_OUT

77

78

UCT1_GATE

79

80

Table 14: Connector Pin Assignments for PDXI J2

29

Page 42

Chapter 2: Installation and Configuration

0

PXI lines support

Following PXI lines may be used for the synchronization: PXI_TR16 0..7,

PXI_STAR

3

Page 43

3

Architecture

31

Page 44

Chapter 3: Architecture

2

Functional Overview

PowerDAQ PD2-MF/MFS series have very extensive input modes,

clocking and triggering capabilities as well as simultaneous subsystems

operations.

Voltage

Referenc e

Aln Calibrat ion

DACs

Aln Power

Conditioner

(64)

r

o

t

c

e

n

n

o

C

Ext. Aln Con v Clock

O

/

I

Ext. Al n Scan Clock

g

o

l

Ext. Tr igger

a

n

A

Aln C lock Ou t

l

a

n

r

e

t

x

E

Amplifiers

AOut Calibration

16 or 64

Channe l

Analog

Multiplexer

Channe l/

Contr ol

Logic

Analog

Output

DACs

Gain

+

Cust om

PGIA Gain

Amp.

-

Channe l

List

FIFO

DAC0

DAC1

Voltage

Referenc e

12,14,

16-bit

Sampling

A/D

Conver ter

Aln Control

s

s

e

Local Data Bus

r

d

d

A

l

m

e

a

r

n

g

A

n

M

o

a

r

M

A

h

P

R

D

C

k

6

2

1

s

s

e

r

d

d

A

32 Bit PCI Bus

M

p

A

a

R

r

t

M

a

s

t

t

O

a

o

R

D

o

B

k

2

1

k

O

c

F

o

I

l

I

F

C

S

t

S

t

u

E

u

O

O

A

A

Motorola 66MHz DSP 56301

Bus Master PCI Interface

l

o

r

t

n

o

C

Upgradable

1k Sample

ADC

FIFO

UCT Con trol

DIn Control

DOut Control

AIn Clocking & Triggering

v

n

n

a

k

k

o

c

c

c

S

C

o

o

l

l

n

n

C

C

l

l

A

A

a

t

a

D

Figure 10: PowerDAQ PD2 Block diagram

(82C54)

Ext. Aln Con v Clock

Ext. Al n Scan Clock

Ext. Tr igger

Aln C lock Ou t

Interrupt

Config uration

& Calibration

EEPROM

User

Counte r

Timer

Digital

Input

Buffer

Latch

Digital

Output

(Driver)

Clock

Gate

Out

(16)

3

3

4

J

,

2

J

3

s

r

o

t

c

e

n

n

o

C

O

/

I

l

a

t

i

g

i

(16)

D

l

a

n

r

e

t

n

I

n

o

i

t

a

z

i

(4)

n

o

r

h

c

n

y

S

d

r

a

o

b

r

e

t

n

I

3

Page 45

Chapter 3: Architecture

Ext erna l A n al og I/O C onnec t o r

(64)

Mul ti plexer

Ext. Aln Conv Clock

Ext. Aln Scan Clock

Ext. Trig ger

Aln Clock Out

Analog

Outp ut

Amp l if ie r s

AOut Calibration

DA Cs

16 or 64

Ch annel

Analog

Cha nnel/

Gain

Co ntrol

Lo gic

Voltage

Refere nce

+

Custom

PGIA Gain

Amp.

Chann el

Li st

FIF O

DAC0

DAC 1

Voltage

Reference

Aln Calibra tion

DACs

-

Dat a Acqu is ition

ES SI

AOut FIFO

Moto rola 66MHz DSP 56301

Bus Master PCI Interface

Cont rol

Aln Power

Conditioner

12,14,

16-bit

Sam pli ng

A/D

Conver ter

Aln Control

Upgradable

1k Sampl e

ADC

FIF O

UCT Control

PowerDAQ II

Clock ing & Trig gering Lin es

ROM

Clock

Clo ck

Aln Scan

Aln Conv

Bootstrap

Data

DIn Control

DOut Control

Con figuration

& Ca libration

EE PR OM

Control and

Timing Logic

Local Da ta B us

Address

DMA

RAM

6 Channel

12k Program

AOut Clock

32 Bit CompactPCI Bus PXI

12 k D at a RA M

Address

User

Counte r

Timer

(82C5 4)

Ext. Aln Conv Clock

Ext. Aln Scan Clock

Ext. Trigger

Aln Clock Out

Digital

Input

Buffer

Latch

Interrupt

Digit al

Outp ut

(D rive r)

PXI

Contr ol

Logi c

Out

(16)

Clock

Gate

3

3

3

(16)

Internal Digital I/ O Conne ctor J2

Figure 11: PowerDAQ PDXI Block diagram

33

Page 46

Chapter 3: Architecture

4

Remoute Ground

(16)

16 Channel

Analog

Mu ltip lexe r

Channel/

Gain

Co ntrol

Logic

Analog

Out put

Amplifiers

AOut Calibration

DA Cs

Ext. Aln Conv Clock

Ext. Trigger

Aln Clock Out

Voltage

Reference

+

PGIA

Gain

Amp.

-

DSP

Channel List

FIFO

DAC0

DAC1

Volt ag e

Reference

External Analog/Digi tal I/O Conne ctor

Aln Calibration

DA Cs

16-bit

Sam pli ng

A/D

Conve rter

Aln Control

Aln P ow e r

Conditioner

Po w er DAQ I I

Data Acquisition

Control and

Timin g Log ic

Local Da ta Bus

Addr es s

ES SI

DMA

AOut FI FO

6 Chan nel

AOu t Cl o ck

Moto rola 66MH z DSP 56301

Bus Mast er PCI Inte rface

Co ntrol

32 Bit PCI Bus

ROM

RAM

Bootstrap

12k P ro g r am

12k Dat a RA M

Ad d re ss

Dat a

U pgradable

1k S ampl e

ADC

FIFO

Clo ck

Aln Scan

Aln Conv

Cou nter

UCT Control

DIn C on t rol

DOut Control

Clo ck

(3)

DSP

Timer

Figure 12: PowerDAQ PDL-MF Block diagram

(24)

Co n f i g u r a ti o n

& Ca li b r at io n

EE PR OM

Di git al

Input

Buffer

Latch

Digital

Out put

(Driver)

(24)

The heart of the board is the Motorola DSP 56301 running at 66 MHz.

The DSP ensures a highly efficient interface with the PCI bus and

sophisticated control over all board subsystems.

Analog Input subsystem includes:

• The Input multiplexor (MUX) selects which channels to

acquire. The channel list (CL) FIFO controls the input

muxes. PD2-MFS boards have sample-and-hold amplifiers

(SHA) preceding the muxes. SHA amplifiers sample all

3

Page 47

Chapter 3: Architecture

5

input channels simultaneously and then hold the acquired

voltages while the ADC converts channel by channel.

• The Programmable Gain Amplifier (PGA) amplifies an

input signal in order to provide adequate voltage to the

analog-to-digital converter (ADC). The PGA amplification

depends on the board model and can be software

selected {1,2,4,8} or {1,10,100,1000} for MF series boards

and {1,2,5,10} for MFS/PDL-MF boards when the

differential gain (DG) option is installed. Gains are

software selectable on a per-channel basis.

• The A/D FIFOs hold digitized samples until the DSP

transfers them into the host memory, via the PCI bus. The

default A/D FIFO size is 1kS. You can upgrade the A/D

FIFO size to 16kS or 32kS depending on your application.

Larger FIFOs give you smother operations especially at

high acquisition rates and degrade response time in a

case of control loop application.

• The Calibration DACs provide voltages to adjust the

offset and gain settings. All boards are factory calibrated

for each input range and mode specified.

• The Timing, triggering and clocking controls allow you to

select the timebase, clock and triggering sources, “slow

bit” and other options.

• The Interrupt mechanism notifies the DSP about interrupt

conditions

Analog Output subsystem includes:

• DSP based D/A FIFO keeps up to 2kS of digitized

waveform values.

• Digital-to-analog converter (DAC) converts digitized

waveform values into analog output voltages.

• Calibration DACs provide voltages to adjust offset and

gain of analog output.

• Timing, triggering and clocking controls allow you to

select analog output rate and clock source.

• Interrupt mechanism notifies the DSP about interrupt

conditions.

3

Page 48

Chapter 3: Architecture

6

Digital Input/Output subsystem includes

• 16-bit input register to read logical levels on digital input

lines (24-bit on PDL-MF)

• 8-bit Schmidt trigger to catch logic level changes on

digital input lines (not present on PDL-MF)

• 16-bit output register to hold logical levels on digital

output lines, once data has been written (24-bit on PDLMF)

• Interrupt mechanism to notify DSP about interrupt

conditions

User Counter-Timer subsystem includes

• Three 16-bit Intel 82C54 counter timers (fully accessible)

(24-bit DSP 56301 sharable counter/timers on PDL-MF)

• Clock source selection and control logic

• Gate source selection and control logic

• Interrupt mechanism to notify DSP about interrupt

conditions

3

Page 49

Chapter 3: Architecture

7

Analog Input Subsystem

The analog input front-end multiplexes multiplex the first stage of the

input channels (64/16 single-ended or 32/8 differential) into a single,

12, 14 or 16-bit successive approximation ADC. The A/D subsystem also

includes input modes, polarity, gain settings, channel gains, channel

queue, trigger and clocking control.

MF boards have multiplexors located at the signal inputs and can be

switched to select single ended (SE) or differential (DF) mode of

operation (Fig 8). SE/DF mode is selected for all input channels. The

output of the mux signal is fed into a instrumentation amplifier (INA)

and then into a custom programmable gain amplifier (PGA). Channel

numbers along with their gains are stored in the channel list. This allows

you to select different gains on a per-channel basis.

Note Input muxes have high input impedance. It is highly

recommended to ground all unused channels. Use signal sources

with low output impedance (<100 Ohms) to avoid crosstalk;

place a capacitor between signals and ground (SE) or between

signal and return lines on screw terminal (suggested capacitor

values can be 1000pF to 0.047uF depending on your input

frequency).

Note PDL-MF boards also have a jumper-configurable

pseudo-differential mode when ground reference level is taken

from the remote source.

3

Page 50

~

Analog

input 0

…

~

Analog

input N

…

…

MUX A

MUX B

Chapter 3: Architecture

channel and

gain control

INA

SE/DI/PD (PDL-MF only)

switch control signal

PGA

… to range

control,

calibration

circuitry and

ADC

Figure 13: PowerDAQ Multifunction Board front-end

MFS boards have sample and hold amplifiers (SHA) located at the

signal inputs. PD2-MFS-DGx options include a INA and PGA in the one

device located on the back side of the board (Fig. 9). SE or DF mode is

selected by grounding negative input of the INA to the boards analog

ground (AGND). Channel numbers along with their gains are stored in

the channel list. This allows you to select different gains on a perchannel basis.

38

Page 51

Chapter 3: Architecture

Analog

input 0

~

INA SHA

PGA

MUX

……

Analog

input N

~

INA SHA

PGA

SE/DF

switch

control

signal

Gain

contro

l

S/H

signal

channel

select

signal

Figure 14: PowerDAQ Sample and Hold Board front-end

The major difference between MF and MFS boards are the SHAs.

‘Sample and Hold’ signal switches SHAs between ‘sampled’ and ‘hold’

states. When the SHA is in a sample state its output repeats its input.

In the hold state, SHAs keep the output voltage at the same level at

time of switching.

… to range

control,

calibration

circuitry

and ADC

39

Page 52

Chapter 3: Architecture

0

Channels

Ch 0

Ch 1

Ch 2

t0 t1t2

Moment of digitizing

Signal level at the moment of

Figure 15: PD2/PDXI Series Acquisition Process

Channels

Ch 0

Ch 1

Ch 2

Hold

t0 t1t2

Moment of digitizing

Signal level

Time

Sampl

Time

Figure 16: PD2/PDXI Acquisition Process

4

Page 53

Chapter 3: Architecture

Figures 10 and 11 show the differences in data acquired using MF and

MFS boards. When a sine wave is applied to the channels 0, 1 and 2.

, t1 and t2 is the time when the channel reading has happened.

t

0

Minimum delay between them is limited by the rated speed of the

board and can be calculated as 1/rate in kS (seconds).

Note PowerDAQ boards acquire channels sequentially at the

rated speed that is referenced as the aggregate rate. When the

channel list contains two channels, per channel rate is a half of

aggregate rate.

Maximum per channel rate can be calculated as:

Aggregate_rate / Number_of_channels (kS/s).

Depending on certain MFS models, maximum per channel rate is slower

because of the hold delay time.

The MF board (fig. 10) acquires input signals with a small delay

between acquisitions. If the input signal frequency is relatively low (510 times lower then acquisition rate), the difference in the acquired

signal level is minimal. Data acquisition is

input signal has a fairly high frequency, sequential acquisition can cause

significant error in the digitized signal levels. MFS board would be

more suitable for such an application.

virtually simultaneous

. If the

The MFS (Fig. 11) board holds the signal at the same level while

digitizing all of the channels in the channel list. There is no difference

in the acquired signal level among the channels. Data acquisition is

simultaneous

have a unique exact timing feature. SHAs have a negative delay. In

other words the signal captured by switching them into the hold mode

is the signal 15ns previously. MFS board control logic delays external

hold signals for the same amount of time. This guarantees that the

board acquires a signal level at the exact time of the external pulse.

require true difference between input channels levels and

working with signals close to nyquist frequency.

regardless of the input signal frequency. The MFS boards

Note Always use PowerDAQ MFS series of board if you

truly

41

Page 54

Chapter 3: Architecture

2

Note Complete timing tables for all PowerDAQ boards are

located Appendix A.

Input Modes

Single Ended

The PowerDAQ boards operate with either a single-ended or a

differential input configuration. Single-ended inputs allow up to 64

channels and share a common low side, which is the analog ground.

Single ended inputs are shown diagrammatically in figure 12.

5 for complete wiring instructions.

Note Unused channels should be shorted to ground using a 0

to 1KOhm resistor.

See Table

+

V1

-

Figure 17: Single-Ended Inputs

4

Ain

Agnd

+

-

Page 55

Chapter 3: Architecture

Differential Inputs

Differential inputs allow up to 32 channels. (Differential inputs use two

analog input channels. One channel connects to the positive input of

the programmable gain amplifier and the other to the negative of the

instrumentation amplifier).

Note Both inputs must remain in AGND ±14V rails; otherwise

input multiplexors lookup may occur.

+

V1

-

Ain (RETURN)

Ain(+)

+

-

Agnd

Figure 18: Differential Inputs

Example: For a 16 channel PowerDAQ board in differential mode,

channels 0 and 8 form the high and low inputs of input channel 0,

channels 1 and 9 that of input channel 1. Differential inputs are shown

diagrammatically below.

See Table 6 for complete wiring instructions.

Note PowerDAQ MFS boards with DG option installed have

the same number of differential and single-ended channels.

43

Page 56

Chapter 3: Architecture

Input Ranges

The PowerDAQ boards have four possible input ranges. These are global

settings.

UNIPOLAR BIPOLAR

0V to +10V - 10V to + 10V

0V to +5V* -5V to +5V

* Not Available on PDL-MF board.

Table 15: Input Range Table

Gain Settings

You can set a gain for each channel prior to acquisition. Depending on

your board, there are three gain ranges.

MF L Gains MF H Gains PDL-MF/

MFS DG-option Gains

1, 10, 100, 1000 1, 2, 4, 8 1, 2, 5, 10

Table 16: Programmable Gains

Note For low-level signals, you need high gains and you

should use a L model. For high level signals, you need a low gain

board and you should use the H model.

44

Page 57

Chapter 3: Architecture

Channel List

The Channel List contains sequences of channels to be acquired and

their per channel gains. This sequence is known as the SCAN. The ADC

Channel List can contain 1 to 256 channel entries (64 entries on PDLMF). Configuration data for each channel will include the channel

selection, gain, and slow bit setting. Each Channel List block written

clears and overwrites the previous settings.

The Slow Bit is a special marker which guaranties longer settling time

for a particular channel. It is very useful when the signal is acquired has

a high (100 or 1000) gain.

The Channel list has the following format:

Bit 8 Bits 7 and 6 Bits 5 to 0

Slow bit Gain Channel to acquire

Table 17: Channel List Format

Gain coding

(bits 7,6)

00 1 1 1

01 10 2 2

10 100 4 5

11 1000 8 10

On PDL-MF channel list may have up to 64 entries.

MF L Gains MF H Gains MFS DG-option

Gains

Table 18: Programmable Gain Codes

45

Page 58

Chapter 3: Architecture

Clocking

The PowerDAQ board has two selectable base frequencies (11 MHz and

33 MHz) to clock acquisition. Lower frequencies are obtained by

dividing the base frequency by a 24-bit number (from 1 to 16M). To

calculate the result frequency use following formula:

Timebase = Base Frequency / (divisor + 1)

Acquisition is clocked by two signals: conversion start (CV Start) and

channel list start (CL Start). There are four selectable sources for these

clocks:

• Software command

• Internal timebase

• External clock

• Continuous clocking (or self-retriggerable clock)

Additionally for internal or external clocks, an active edge (rising or

falling) can be selected.

Note The PowerDAQ board will generate an error condition

each time a clock signal is applied, before the board is ready to

process it. For example, if you clock the board with a clock

frequency higher than the rated aggregate rate, the board

reports a CV/CL start error.

The CV Start clock starts the A/D conversion. The CL Start clock starts

the channel list execution. The CV Start clocks are ignored until the CL

Start pulse is sensed. If any clock is switched to continuous clocking, it

re-triggers itself immediately after board is ready to process it.

Note On the PDL-MF board only one clock may be used at

the time. If CV clock is specified as internal or external, CL clock

must be set to continuous, if CL clock set to internal/external,

CV clock is ignored and board is running A/D on maximum

speed.

46

Page 59

Chapter 3: Architecture

Clock combination Typical use

CL Clock

source

SW Continuous Acquire one set of data points (one

Internal Continuous Continuous acquisition with accurate

External Continuous Continuous acquisition when each run of

Continuous Continuous Performs acquisition at maximum speed

Continuous

or SW

Continuous External MF boards only. Useful when one

Internal Internal Rarely used. MF boards only. Useful with

External External Rarely used. Gives full control of the

SW SW Rarely used. Gives full control of the

CV Clock

source

Internal MF boards only. You can select the

scan). SW clock causes channel list to be

executed once. The board will wait until

next CL clock comes before restarting.

timebase. After each CL Clock pulse, the

channel list is executed at the maximum

acquisition rate. This is the most useful

mode.

the channel list is triggered by the

external signal. This mode is used to

synchronize external events with scans.

possible. Less accurate than using the

timebase.

specific time between conversions. Use

this type of clocking when you want to

increase settling time between

acquisitions especially when your signal

source has high output impedance.

channel is acquired and you want to

start acquisition exactly at the external

pulse edge.

slow scan rates and you need to provide

exact time between conversions.

boards timing to the external device

boards timing to your software

Table 19: Different Clocking Combinations

47

Page 60

Chapter 3: Architecture

Triggering

The Analog input subsystem needs a trigger signal to start and stop

acquisition. The Trigger signal is selectable. It can be either software

command or an external pulse. External trigger is edge-sensitive. You

can select rising or falling edge to be active. If the board is set up to

start on an external trigger, all clocks will be ignored until the pulse

comes. Acquisition continues until the stop trigger comes.

Note If CV Start clock is set to continuous start/stop, the

trigger is guaranteed to start and stop acquisition at the

beginning of channel list. If CV Start is external, it’s up to

external equipment settings.

Note The PDL-MF board provides gated mode on the

external clock, when external trigger line used as a gate for the

internal/external clock. On the MF/MFS boards gated mode may

be implemented using the 8254 counter-timers.

48

Page 61

Start

trigger

edge

Rising Rising

Rising Falling

Falling Falling

Falling Rising

Stop

trigger

edge

External TTL signal

Acquisition started

Acquisition stopped

Chapter 3: Architecture

Table 20: External Trigger Modes

ADC FIFO

The PowerDAQ boards have an on-board FIFO. The FIFO could contain

from 1kS (default) up to 64 kS depending on the FIFO option

purchased.

When the PowerDAQ board acquires data in continuous mode, data is

written into the ADC FIFO. When the FIFO becomes half-full, the DSP

initiates data transfer from the ADC FIFO into the host memory. When

a minimal amount of data is to be transferred to the host memory in

continuous acquisition mode, it is 512 samples for 1kS FIFO, 2048

samples for 4kS FIFO, etc.

49

Page 62

Chapter 3: Architecture

Data format

Data in the data stream has the following format. Each two

consecutive bytes contain a single sample from the A/D converter.

Data is stored repeatedly sample by sample for all channels in the

channel list. (Table 19 shows a PowerDAQ 16-bit board data format.

For PowerDAQ 12-bit boards, only 12 LSBs (Least Significant Bits) are

valid. PowerDAQ II boards automatically place zeroes in any unused bit

locations.)

1st channel 2nd channel … last channel 1st channel …

sample sample sample sample

bit15 bit14 bit13 bit12 bit11 bit10 bit9 bit bit7 bit6 bit5 bit4 bit3 bit2 bit1 bit0

Table 21: Data Format Table for a 16-bit Board

bit15 bit14 bit13 bit12 bit11 bit10 bit9 bit8 bit7 bit6 bit5 bit4 0x0 0x0 0x0 0x0

Table 22: PowerDAQ II 12-bit data format

bit15 bit14 bit13 bit12 bit11 bit10 bit9 bit8 bit7 bit6 bit5 bit4 bit3 bit2 0x0 0x0

Table 23: PowerDAQ II 14-bit data format

bit15 bit14 bit13 bit12 bit11 bit10 bit9 bit8 bit7 bit6 bit5 bit4 bit3 bit2 bit1 bit0

Table 24: PowerDAQ II 16-bit data format

50

Page 63

Chapter 3: Architecture

The following calculations should be performed to convert the raw,

stored hexadecimal data to scaled (Voltage) data:

1. Determine the value of a single bit (“bit weight”) in Volts

depending on the input range.

PowerDAQ II (span)/65535

0 - 5V unipolar (5V span) 0.000076295 Volts/bit

0 - 10V unipolar (10V span) 0.000152590 Volts/bit

+/-5V bipolar (10V span) 0.000152590 Volts/bit

+/-10V bipolar (20V span) 0.000305180 Volts/bit

Table 25: Bit Weight vs. Input Range

2. Determine the “zero offset” which depends on the input

range selected.