Page 1

PCL432

Voltage Calibrator

Operator’s Manual

M1891/0994

GENERAL DESCRIPTION

The OMEGA®PCL432 Hand-Held Voltage Calibrator is designed to be a complete process voltage

calibrator delivering high accuracy in a small, easy to use package. Its microprocessor based circuitry

gives the user a large number of input/output options and operating modes without unnecessary

complexity.

Commonly used outputs (up to 3) can be stored in the PCL432’s non-volitile memory for quick recall. In

addition, an auto-step mode allows the calibrator to step through the selected setpoints at a user defined

dwell time of 5 to 60 seconds.

INSTALLATION

UNPACKING

Remove the Packing List and verify that you have received all equipment. If you have any questions about

the shipment, please call the OMEGA Customer Service Department at 1-800-622-2378 or (203) 359-1660.

When you receive the shipment, inspect the container and equipment for any signs of damage. Note any

evidence of rough handling in transit. Immediately report any damage to the shipping agent.

NOTE: The carrier will not honor any claims unless all shipping material is saved for their

examination. After examining and removing contents, save packing material and carton in the

event reshipment is necessary.

Check to see if your calibrator kit is complete. It should include:

1. Carrying case (Qty=1)

2. Test leads (Qty=1 set)

3. 9V battery (Installed)

4. Operator’s Manual (Qty=1)

SET-UP

Before beginning, become familiar with the keypad layout and the configuration of the input/output jacks.

Remember, these jacks are used in multiple configurations so pay careful attention to how the test leads

are connected for the specific application.

CJS0994RAF2BA

Page 2

OPERATING PROCEDURE

1. Turn on power and select the desired range by depressing the “RANGE SELECT” key, then place the

slide switch in the desired position (Read or Source).

2. Connections are made as follows:

Red Jack - Positive Input/Output

Black Jack - Negative Input/Output

3. The and keys adjust the output value up or down. Holding the ramp keys continuously for

several seconds will increase the scroll rate. Going beyond the endpoints will cause the output to wrap

around, thus allowing a quick return to either end of the scale.

4. Three calibration points can be stored in non-volatile memory by scrolling to the desired output,

depressing the Store key, and then the desired setpoint key.

5. The auto step will automatically step through the stored setpoints at pre-defined intervals. When the

auto-step key is first depressed, the display will indicate the dwell time (in seconds) between steps.

The factory set value is 15 seconds but you can set this value, from 5 to 60 seconds, by using

the and keys when the dwell time is being displayed. Once you have scrolled to the desired

dwell time, release the or key and wait approximately 3 seconds until the calibrator begins to

automatically step through the 3 setpoints. The calibrator will continue the stepping process until any

key is pressed. Your chosen dwell time will remain in a non-volatile memory location until you choose

to change it.

OPERATING CONSIDERATIONS AND PRECAUTIONS

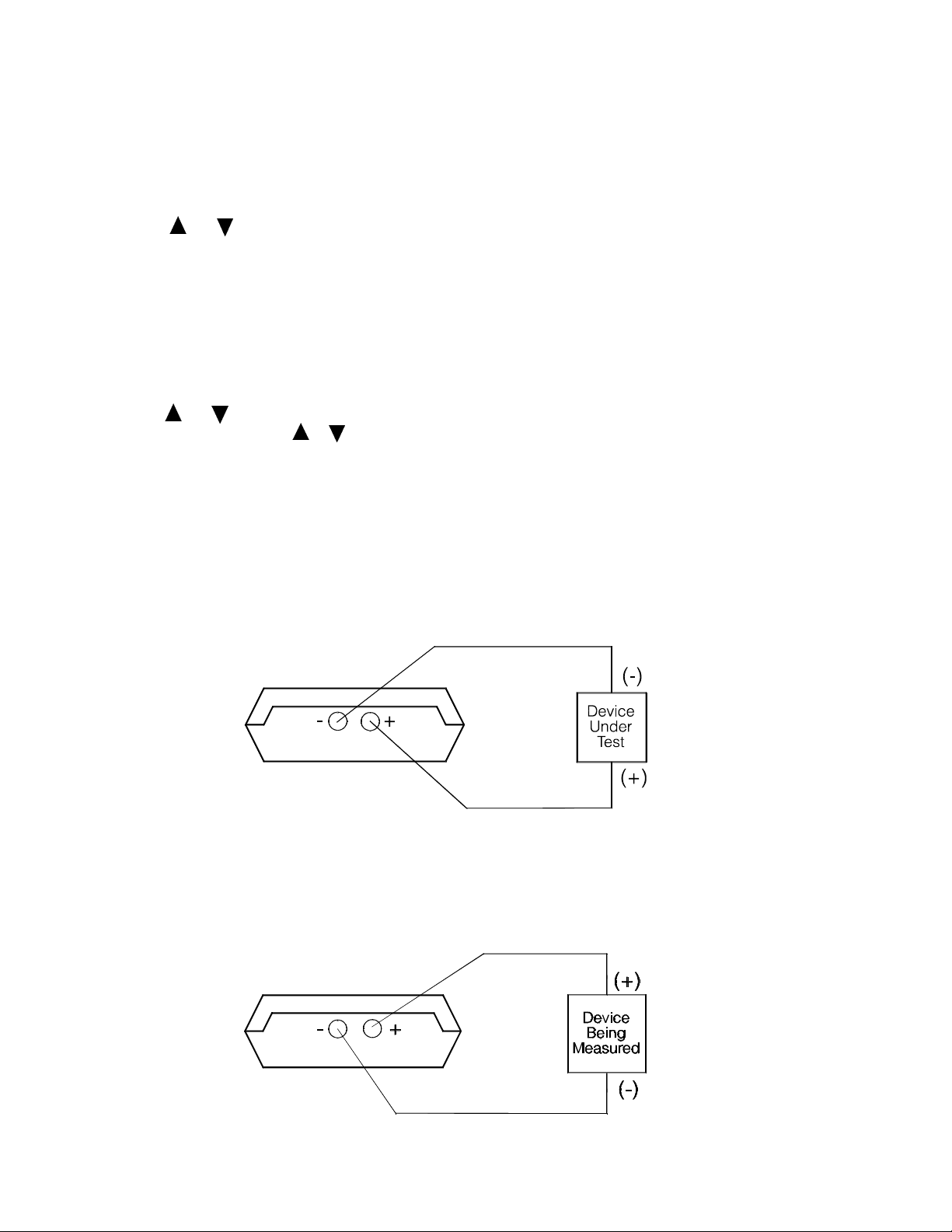

1. When operating in the voltage source mode, the PCL432 has the capability to drive loads up to 20 mA

as shown in Figure 1.

Figure 1 - Voltage Source Mode

2. When reading a voltage, the PCL432 can measure over a range of 0-200 mV or 0-20 Volts.

Connections are shown in Figure 2.

Figure 2 - Voltage Loop Readings

Minimum Resistance:

200 mV Range - 10 ohm

20 V Range - 1 Kohm

Page 3

ACCURACY

The PCL432 is checked against an NIST traceable reference before shipment to verify that each range falls

within the 0.05%, ±1 count, of full scale accuracy specification. Long term accuracy should remain within

0.1%, ±1 count, of FSR. All of these ratings are based on a 25°C ambient temperature. A change of 10°C

will cause approximately a 1000 ppm change (based on 100 ppm/C temp.) in the output or the equivalent

of a 0.1% output change. Therefore, allowances must be made for error caused by wide temperature

variations.

SPECIFICATIONS

Input/output Ranges 0 to 200 mV

0 to 20 Volts

Accuracy ±0.05% ±1 LSD

Maximum Load Driving ±20 mA

Operating Modes Read

or

Source

Operating Temperature 0 to 50°C (32 to 122°F)

Storage Temperature -20 to 60°C (-4 to 140°F)

Temperature Stability 0.01% F.S./°C

Setpoints 3 user programmed calibration points stored in non-volatile RAM.

Power 9V alkaline battery

Auto Step Function Toggle through SP1, SP2 and SP3 with user defined display.

Case Size 1.43” x 3.15” x 5.7” (36.3 x 80.0 x 144.8mm)

Weight 12 oz (340g)

MAINTENANCE

Generally, with normal usage, this calibrator should hold its rated specifications for at least 6 months.

Beyond this, it should remain within 0.05% of FSR over its useful life, provided it is not abused or tampered

with. If after the stated warranty period, the device falls out of calibration, it can be returned to OMEGA

Engineering, Inc. for re-calibration.

}

0-200.0 mV

0-20.00 V

Page 4

Page 5

Loading...

Loading...