Page 1

http://www.omega.com

@

r

e-mail: info

omega.com

PCL10 / PCL11

Hand-Held Pressure

Indicator-Calibrato

Page 2

OMEGAnetSM On-Line Service

Internet e-mail

http://www.omega.com

info@omega.com

Servicing North America:

USA:

ISO 9001 Certified

Canada:

One Omega Drive, Box 4047

Stamford, CT 06907-0047

Tel: (203) 359-1660

e-mail: info@omega.com

976 Bergar

Laval (Quebec) H7L 5A1

Tel: (514) 856-6928

e-mail: info@omega.ca

FAX: (203) 359-7700

FAX: (514) 856-6886

For immediate technical or application assistance:

Usa and Canada:

Mexico and

Latin America:

Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Customer Service: 1-800-622-2378 / 1-800-622-BEST

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Tel: (95) 800-826-6342

En Español: (95) 203-359-7803

e-mail: espanol@omega.com

SM

SM

SM

FAX: (95) 203-359-7807

Servicing Europe:

Benelux:

Czech Republic:

France:

Germany/Austria:

United Kingdom:

ISO 9002 Certified

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that apply. OMEGA is constantly

pursuing certification of its products to the European New Approach Directives. OMEGA will add the CE mark to every

appropriate device upon certification.

The information contained in this document is believed to be corrected but OMEGA Engineering Inc. accepts no liability for any errors it

WARNING: These products are not designed for use in, and should not be used for, patient connected applications.

Postbus 8034, 1180 LA Amstelveen, The Netherlands

Tel: (31) 20 6418405

Toll Free in Benelux: 0800 0993344

e-mail: nl@omega.com

ul. Rude armady 1868, 733 01 Karvina-Hranice, Czech Republic

Tel: 420 (69) 6311899

Toll free: 0800-1-66342

e-mail: czech@omega.com

9, rue Denis Papin, 78190 Trappes

Tel: (33) 130-621-400

Toll Free in France: 0800-4-06342

e-mail: france@omega.com

Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: 49 (07056) 3017

Toll Free in Germany: 0130 11 21 66

e-mail: info@omega.de

One Omega Drive , River Bend Technology Centre

Northbank, Irlam, Manchester

M44 5EX, England

Tel: 44 (161) 777-6611

Toll Free in United Kingdom: 0800-488-488

e-mail: info@omega.co.uk

contains, and reserves the right to alter specifications without notice.

FAX: (31) 20 6434643

FAX: 420 (69) 6311114

FAX: (33) 130-699-120

FAX: 49 (07056) 8540

FAX: 44 (161) 777-6622

2

Page 3

INTRODUCTORY NOTE

This publication contains operating instructions, as well as a description of the principles of operation, of

PCL10 and PCL11 pressure calibrators.

OMEGA has used the best care and efforts in preparing this book and believes the information in this

publication are accurate. The OMEGA products are subjected to continuous improvement, in order to pursue

the technological leadership; these improvements could require changes to the information of this book.

OMEGA reserves the right to change such information without notice.

No part of this document may be stored in a retrieval system, or transmitted in any form, electronic or

mechanical, without prior written permission of OMEGA Engineering Inc.

PCL10 and PCL11 units use sophisticated analogic and digital technologies. Any maintenance operation

must be carried out by qualified personnel

ONLY. We recommend to contact our technicians for any support

requirements.

.

PCL10 and PCL11 is fully tested in conformity with the directive n°89/336/CEE Electromagnetic

Compatibility. OMEGA shall not be liable in any event, technical and publishing error or omissions, for any

incidental and consequential damages, in connection with, or arising out of the use of this book.

3

Page 4

TABLE OF CONTENTS

1 PERFORMANCE.................................................................................................................................. 6

1.1 Specifications................................................................................................................................................... 7

1.1.1 Ranges and resolution ................................................................................................................................ 9

2 GENERAL FEATURES...................................................................................................................... 10

2.1 Input and output flexibility............................................................................................................................... 10

2.2 Self calibration................................................................................................................................................10

2.3 Keyboard........................................................................................................................................................ 10

2.4 Display ...........................................................................................................................................................10

2.5 Digital interface .............................................................................................................................................. 10

2.6 Scale factor function.......................................................................................................................................10

2.7 Square root function....................................................................................................................................... 10

2.8 Pressure measurement damping................................................................................................................... 10

2.9 Case............................................................................................................................................................... 10

3 PHYSICAL DESCRIPTION ................................................................................................................ 11

4 FUNCTIONAL DESCRIPTION........................................................................................................... 12

4.1 Power supply..................................................................................................................................................12

4.2 Operative keyboard........................................................................................................................................ 12

4.3 Pressure Module............................................................................................................................................ 13

4.4 Microcontroller................................................................................................................................................13

4.5 Firmware ........................................................................................................................................................ 13

4.6 Digital display................................................................................................................................................. 13

4.7 Battery charger...............................................................................................................................................13

4.8 Digital interface .............................................................................................................................................. 14

5 UNPACKING ...................................................................................................................................... 15

6 PRE-OPERATIONAL CHECK ........................................................................................................... 16

7 OPERATION & APPLICATIONS ....................................................................................................... 17

7.1 Rechargeable batteries..................................................................................................................................17

7.2 Battery charger...............................................................................................................................................17

7.3 How to maximize the life span of the battery.................................................................................................. 17

7.5 Start-up ..........................................................................................................................................................17

7.6 Instrument Configuration review (Status) ....................................................................................................... 18

7.7 Display contrast and backlight adjustment..................................................................................................... 19

7.8 Normal operative mode.................................................................................................................................. 19

7.9 Zero adjustment ............................................................................................................................................. 20

7.10 Pressure measurement damping ...................................................................................................................20

7.10.1 Averaged Value Calculation Algorythm ..................................................................................................... 21

7.11 Technical unit selection.................................................................................................................................. 22

7.12 Voltage and Current measurements ..............................................................................................................23

7.13 Peak & Valley measurement.......................................................................................................................... 23

7.14 Scale factor program...................................................................................................................................... 23

7.15 Alarm setting and operative mode..................................................................................................................25

7.16 Pressure switch test....................................................................................................................................... 26

7.17 Leak test.........................................................................................................................................................27

7.18 User’s Calibration........................................................................................................................................... 27

8 INSTRUMENT CONFIGURATION..................................................................................................... 29

9 CALPMAN APPLICATION PC SOFTWARE .................................................................................... 30

9.1 Introductory note ............................................................................................................................................ 30

9.2 Software Installation....................................................................................................................................... 30

9.3 General structure of the CalpMan software.................................................................................................... 30

9.4 Pressure gauges test ..................................................................................................................................... 33

9.5 Pressure transmitter test ................................................................................................................................33

9.6 Test result printout from PCL10/11 ................................................................................................................ 34

9.7 Test result printout from PC ........................................................................................................................... 35

10 DIGITAL INTERFACE........................................................................................................................ 36

10.1 Digital output wiring practice .......................................................................................................................... 36

10.2 TTL to RS 232 adapter...................................................................................................................................36

10.2.1 Communication protocol from PCL10/11 to a PC...................................................................................... 37

10.2.2 Computer request for PCL10/11 settings .................................................................................................. 38

4

Page 5

10.2.3 Communication programs ......................................................................................................................... 39

11 MAINTENANCE ................................................................................................................................. 41

11.1 General recommendations............................................................................................................................. 41

11.2 Safety recommendations ............................................................................................................................... 41

11.3 Protection fuses replacement.........................................................................................................................41

11.4 Faulty operating conditions ............................................................................................................................41

11.5 Storage .......................................................................................................................................................... 42

5

Page 6

1 PERFORMANCE

PCL10/11 is a portable instrument for relative (gauge) and differential pressure measurement.

When connected to an auxiliary device such as a pump, a volume adjuster and a ventilation valve it can be used as a

pressure calibrator.

A complete system testing, measuring and calibrating built in a single, compact portable instrument.

Thanks to its compactness, roughness and user friendly operative mode, PCL10/11 is the ideal instrument for field

measurements, tests and calibrations.

Accurate, compact, rugged, easy to use; the ideal solution to measure and simulate:

• Volts (only measurements)

• milliAmperes (only measurements)

• gauge pressure

• differential pressure

PCL10/11 has been developed using the most advanced microcontroller technique to provide high accuracy on

extended ranges and a powerful operating flexibility.

The calibration uses computerized procedures and the relevant calibration data are memory stored to ensure high

accuracy.

The pressure/differential pressure measurement uses a base piezoresistive sensor individually and fully characterized for

linearity and temperature coefficient.

In addition to pressure measurement the instrument is equipped with a second channel designed for voltage (up to 30 V)

and current (up to 22 mA) measurements.

The selection of operating functions is made on a polycarbonate thermoformed membrane keyboard which assures up to

one million operations per key.

Both pressure and electrical parameter readings are indicated on a high quality LCD dot matrix display equipped with a

backlight device for easy readings also in poor light conditions.

The case, made in shock-resistant ABS, is ergonomically designed for an easy practical use.

The instrument is powered by four Ni-MH rechargeable batteries; an external battery charger is supplied as a standard

accessory.

6

Page 7

1.1 Specifications

• Pressure and ∆P ranges:

see instrument codes

• Vacuum ranges:

-10% of the measuring range

(10 bar and 20 bar ranges only are limited to -0.8 bar)

• Keyboard selectable technical units:

mbar, bar, psi, mmwc (mmH

matm, atm, torr, Lbin

2

, kgm2, kgcm2

• Scale factor and square root:

for direct flow measurement

• Pressure media:

compatible with most common non-corrosive, non-reducing, non-condensing and non explosive gases

• Pressure ports:

1/8” BSPPF

• Accuracy:

Table A = 1 ±(0.1% of reading + 0.03% of f.s.)

Table A = 2 ±(0.05% of reading + 0.02% of f.s.)

The relative accuracy shown above are stated for 90 days and the operative conditions are from +5°C to +45°C.

Outside the above temperature band the temperature drift is ±0.004% rdg/°C

• Position effect:

negligible (excluded 20 mbar range)

• Electrical ranges:

0 to 30.000 V

0 to 22.000 mA

• Electrical ranges accuracy:

± (0.05% of reading + 0.01% of f.s.)

The relative accuracy shown above is stated for 90 days and the operative conditions are from +18°C to +28°C.

Outside the above temperature band the temperature drift is ±0.002% of rdg/°C

• Common mode rejection:

>140 dB at 50/60 Hz ± 1 Hz

• Normal mode rejection:

> 60 dB at 50/60 Hz ± 1 Hz

• Shunt (current channel):

< 110 Ω

• Impedance (voltage channel):

> 1 MΩ

• Maximum voltage input (voltage channel):

50V

• Maximum current input (current channel):

50 mA

• Short-circuit protection (loop power supply):

Fuse + Electronic

• Overcurrent protection (current channel):

Fuse

• Maximum load (passive loop):

900 Ω at 20 mA

• Display:

dot matrix LCD (2 lines of 16 characters each) with backlight device.

• Operative life:

8 hours without printing and without load on 20 mA passive current loop

4 hours without printing and with load on 20 mA passive current loop

O), cmwc (cmH2O), mwc (mH2O), inwc (inH2O), mmHg, mHg, inHg, kPa, hPa,

2

7

Page 8

• Data memory:

up to 50 group of data

• Working temperature limits:

from -5°C to 50°C

• Storing temperature:

from -20°C to 60°C

• Power supply:

Ni-MH batteries package

• Case:

Injection moulded ABS with internal metal coating in compliance with EMC

• External dimensions:

100 x 60 x 240 mm (without pressure module)

100 x 60 x 285 mm (with pressure module)

• Weights:

net 1 Kg (instrument + pressure module)

gross with packing 1,5 Kg

8

Page 9

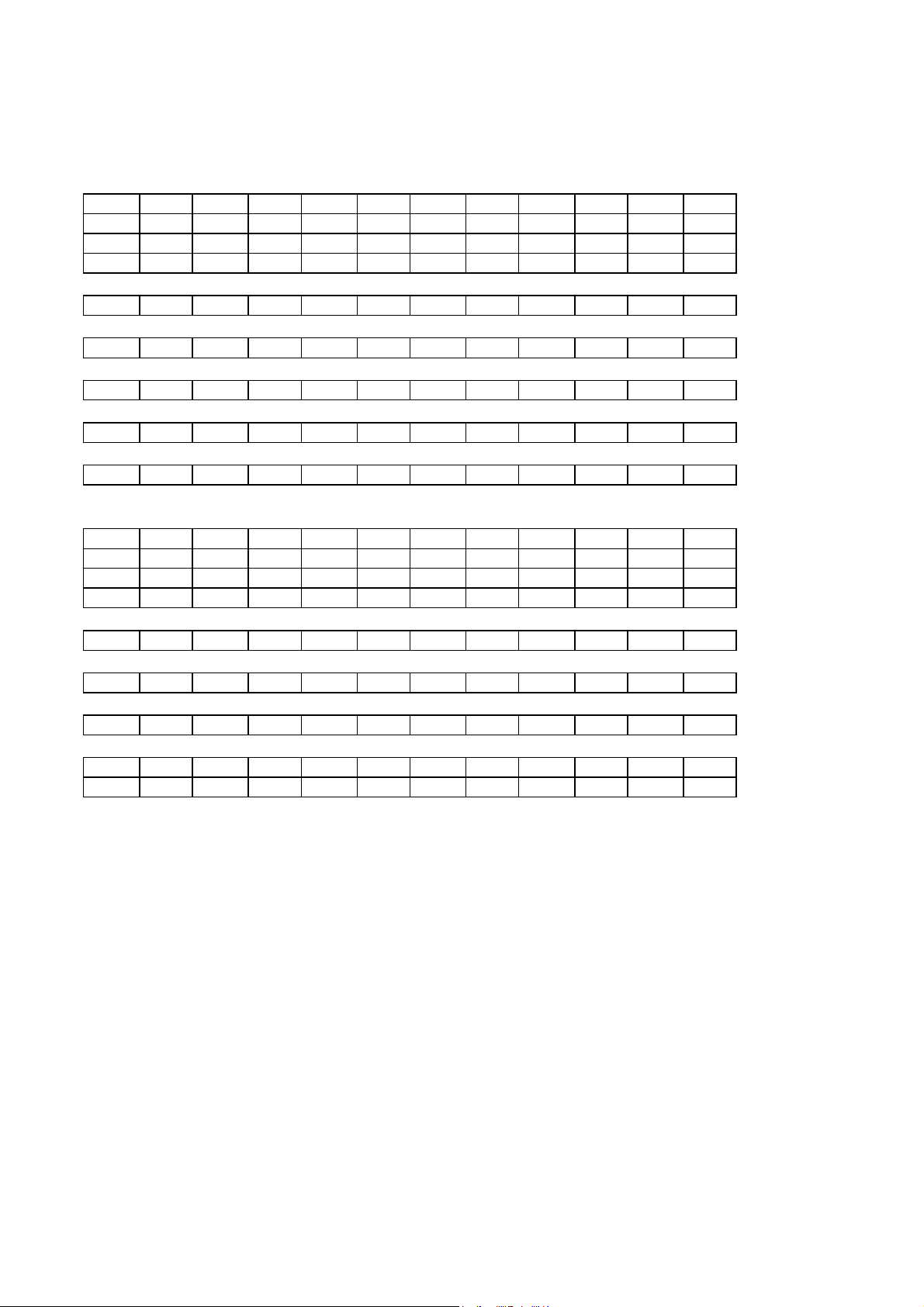

1.1.1 Ranges and resolution

Bar

-0,880 22,000 -12,76 319,08 -8,97 224,34 -8,80 2200,0 -353 8832 -12,76 319,08

-0,880 11,000 -12,76 159,54 -8,97 112,17 -8,80 1100,0 -353 4416 -12,76 159,54

-0,550 5,500 -7,98 79,77 -5,61 56,08 -5,50 550,0 -220,8 2208,1 -7,98 79,77

-0,2200 2,2000 -3,191 31,908 -2,243 22,434 -2,200 220,00 -88,3 883,2 -3,191 31,908

Bar

-0,1100 1,1000 -1,595 15,954 -1,122 11,217 -1,100 110,00 -44,2 441,6 -1,595 15,954

mBar

-55,0 550,0 -0,798 7,977 -56,1 560,8 -5,50 55,00 -22,08 220,81 -0,798 7,977

mBar

-22,00 220,00 -0,3191 3,1908 -224,3 2243,4 -2,200 22,000 -8,83 88,32 -0,3191 3,1908

mBar

-11,00 110,00 -0,1595 1,5954 -112,2 1121,7 -11,00 110,00 -4,42 44,16 -0,1595 1,5954

mBar

-2,200 22,000 -31,91 319,08 -22,43 224,34 -2,200 22,000 -0,883 8,832 -0,0319 0,3191

PSI

PSI

PSI

PSI

PSI

mPSI

mH20 at 4°C kPa

mH20 at 4°C kPa

cmH20 at 4°C kPa

mmH20 at 4°C kPa

mmH20 at 4°C hPa

mmH20 at 4°C hPa

InH20 at 4°C Lb/In2

InH20 at 4°C Lb/In2

InH20 at 4°C Lb/In2

InH20 at 4°C Lb/In2

InH20 at 4°C Lb/In2

InH20 at 4°C Lb/In2

Bar

-0,880 22,000 -0,660 16,501 -660 16501 -0,897 22,434 -0,868 21,712 -25,99 649,7

-0,880 11,000 -0,660 8,251 -660 8251 -0,897 11,217 -0,868 10,856 -25,99 324,83

-0,550 5,500 -0,413 4,125 -413 4125 -0,561 5,608 -0,543 5,428 -16,24 162,42

-0,2200 2,2000 -0,1650 1,6501 -165,0 1650,1 -0,2243 2,2434 -0,2171 2,1712 -6,50 64,97

Bar

-0,1100 1,1000 -82,5 825,1 -82,5 825,1 -0,1122 1,1217 -0,1086 1,0856 -3,248 32,483

mBar

-55,0 550,0 -41,3 412,5 -41,3 412,5 -561 5608 -54,3 542,8 -1,624 16,242

mBar

-22,00 220,00 -16,50 165,01 -16,50 165,01 -224,3 2243,4 -21,71 217,12 -0,650 6,497

mBar

-11,00 110,00 -8,25 82,51 -8,25 82,51 -112,2 1121,7 -10,86 108,56 -0,3248 3,2483

-2,200 22,000 -1,650 16,501 -1,650 16,501 -22,43 224,34 -2,171 21,712 -0,0650 0,6497

mHg at 0°C torr

mmHg at 0°C torr

mmHg at 0°C torr

mmHg at 0°C torr

mmHg at 0°C torr

Kg/cm2

Kg/cm2

Kg/m2

Kg/m2

Kg/m2

Atm

Atm

mAtm

mAtm

mAtm

InHg at 0°C

InHg at 0°C

InHg at 0°C

InHg at 0°C

InHg at 0°C

9

Page 10

2 GENERAL FEATURES

2.1 Input and output flexibility

An advanced flexibility of performance has been achieved using the microcontroller technique. Each instrument, through

a menu-driven procedure, allows simultaneous measurement of pressure (gauge or ∆P) and of the typical loop signal in

current (up to 22 mA) or voltage (up to 30 V). The microcontroller performs linearization and temperature compensation

of the piezoresistive pressure sensor using the characterization data stored in the pressure module memory.

2.2 Self calibration

The hardware-firmware design allows the automatic calibration of the instrument. The calibration procedure is protected

by a security code.

2.3 Keyboard

A thermoformed metal-click tactile polycarbonate membrane keyboard, with a working life of one million operations per

key, seals the internal electronics from the surrounding environment. The contact closure of membrane keys is

acknowledged, as a coded signal, directly by the microprocessor.

2.4 Display

The high contrast alphanumeric LCD display with dot matrix (7x5 dots per character-16 characters ), in the normal

operative mode, simultaneously indicates pressure symbol and value, current or voltage symbol and value.

It is also used for operator’s messages, instrument configuration set-up, special operative modes, etc.

It is equipped with a backlight device to allow easy readings even in poor light conditions.

The method to adjust the display contrast is described in par. 8.7.

2.5 Digital interface

A digital interface with TTL logic levels is available as a standard for communication with external units. A serial data port

provides a communication capability at a logic level of 0-5 V (four wires: Tx, Rx, GND, Vcc). A TTL to RS 232 adapter is

available as an option.

2.6 Scale factor function

Easy menu-driven set-up to read or simulate electrical signal values in terms of engineering units. Four programmable

alphanumeric characters are available on the display to show the symbol of the parameter (i.e. mbar, etc.). The display

will indicate the scaled input value.

2.7 Square root function

It can be programmed during the set-up procedure to obtain direct readings of flow from a dP transmitter signal. The

display limits are -9999 and +30000.

2.8 Pressure measurement damping

To allow measurement of unstable input signals using a special algorithm based on a combination of working band and

average weight.

2.9 Case

The case is designed for an easy hand held operation and transportation. The body is injection molded, shock-resistant

ABS with internal metal coating. An ABS case for instrument + printer + pumps + accessories is available on request.

10

Page 11

3 PHYSICAL DESCRIPTION

The PCL10/11 palm-top indicator consists of a rugged and compact case, a replaceable pressure module, a mother

board with all basic functions, a daughter board for the auxiliary functions (mA and V readings), a tactile membrane

keyboard, a LCD display and a group of four nickel-metalhydride rechargeable batteries.

The internal surface of the case is metal coated to improve compliance with EMC.

The battery package is located on the lower back part of the case, and is accessible through a cover fastened by a

metal screw.

The two sections of the case are joined together by four metal screws located on the back side.

The optional leather case, with shoulder strap, assures a better protection of the instrument against mechanical knocks

or scratches.

11

Page 12

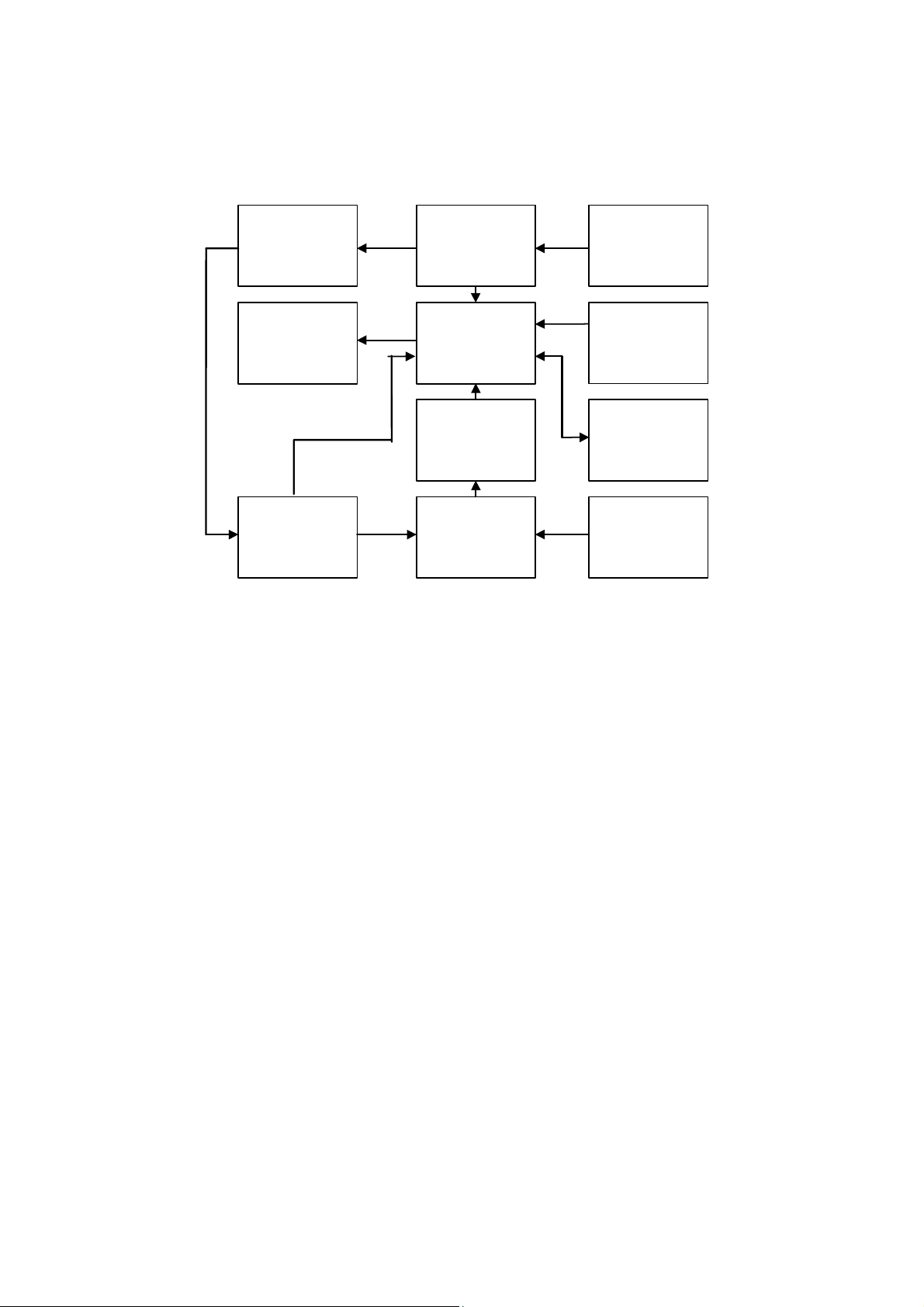

4 FUNCTIONAL DESCRIPTION

The PCL10/11 portable calibrator block diagram is shown below.

• power supply

• reference voltage signal

Reference

Voltage

Pressure sensor

Module + Memory

Power

Supply

Microcontroller LCD Display

Analog to Digital

Converter

Multiplexer

External

Battery Charger

Operator

Keyboard

Digital

Interface

Auxiliary Voltage &

Current Input

• microcontroller (central unit + memory)

• input circuit

• LCD display

• operative keyboard

• replaceable pressure module with characterisation data memory

4.1 Power supply

The instrument is powered by four internal batteries that can be recharged through an external charger module supplied

as a standard accessory. The internal batteries are Ni-MH rechargeable AA type with a nominal voltage of 1.25 V.

The voltage of the four batteries in series (approximately 5 V) is connected to the input of a switching circuit to generate

the voltages for the pressure transducer, the analog and digital circuits. The power supply circuit, is also configured as a

voltage multiplier to generate a voltage of 24 Vdc for the final output stage operating both into active or passive loops.

The above voltage levels are required to work with an external load up to 900Ω to supply the external current loop (see

par. 7.8).

4.2 Operative keyboard

The front panel is a tactile polycarbonate membrane keyboard, and has a working life of one million operations per key.

The contact closure of the membrane keyboard is acknowledged as a coded signal by the microprocessor that

recognizes the operator’s instructions .

Keys are interconnected on a 4 x 3 matrix; the microprocessor identifies the active key directly.

The values of the <▲> and <▼> keys ( membrane slidewires ) are acknowledged through the converters built in the

microprocessor chip.

<ON> Power ON switch

<OFF> Power OFF switch

<Lamp> Switches -On- the LCD back-light display

12

Page 13

<PAGE> Scrolls display/menu pages

<PRINT> Enables printout of data

<▲> <▼> Data selection

<STATUS> Instrument configuration review and set-up data storage

<ZERO> Pressure channel zero reset

<HOLD> To freeze and temporary memory store data

<DAMP> Pressure measurement signal damping

<STORE> Memory load / Operator’s message acknowledgements

<SET-UP> Instrument configuration

<PEAK> Maximum value identification and measurement

<VALLEY> Minimum value identification and measurement

<CONV> Convert displayed data to electrical data (scale factor only)

<LCD-> Adjust the LCD contrast

<LEAK> Leak test procedure to allow the test of leak in terms of pressure decay over time

<ALARM RESET> Switch -Off- the acoustic alarm

<ENTER> Memory load key

4.3 Pressure Module

The replaceable Pressure Module incorporates a fully characterised piezoresistive sensor and communicates with basic

unit via a 15 pin connector.

Temperature/pressure characterisation data are stored in a non volatile EEPROM, resident in the replaceable module.

An extended number of Pressure Module units are available in a wide variety of pressure measurement ranges (see

table B Par. 1.1).

Any Pressure Module can be used in any basic unit and the measurement system will provide measurement accuracy in

conformance with the declared specifications.

4.4 Microcontroller

The microcontroller handles all the logic functions of the instrument, performs the linearization for pressure transducers,

compensates for the reference junction temperature, drives the digital display and acknowledges all the operator’s

instructions.

The core of the circuit is a single-chip microcomputer that utilises HCMOS technology to provide the low power

characteristics and high noise immunity of CMOS plus the high speed operation of HMOS.

The microcomputer provides highly sophisticated, on- chip peripheral functions including: 256 bytes of static RAM, an 8

channel analog to digital (A/D) converter (used to read the battery package voltage, the analog keyboard, the battery

charger, the short-circuit and the overload on the external current loop), a serial communication interface (SCI)

subsystem, and a serial peripheral interface (SPI) subsystem.

The microprocessor works with an 8/16 bit communication bus to EPROM and EEPROM memories and is interfaced

with a decoder, a latch of address and an inverter-driver.

4.5 Firmware

The operating system firmware handles all logic instructions to the internal peripheral circuits and performs the

computation of the linearization equations.

The application system firmware is resident on the non-volatile memory (EEPROM) of the microprocessor chip.

It is used to store the installation parameters (autocalibration data, program data, etc.)

4.6 Digital display

The digital display, mounted on an auxiliary board, uses high contrast LCD technology (STN liquid ).

The character generation is made by a secondary dedicated microprocessor driven by two integrated circuits with signal

input from the bus of the main microprocessor.

The 16 characters are displayed with a 7x5 dot matrix.

PCL10/11 is standard equipped with a backlight device for easy readings in poor light conditions.

4.7 Battery charger

The auxiliary module, supplied as a standard accessory, allows operations from 100-120 Vac or 230-240 Vac 50/60 Hz.

The calibrator, if needed, can be operated directly from a line source through the charger.

The plastic case of the battery charger incorporates the line voltage plug and a cable with a connector for interconnection

to the instrument.

13

Page 14

The charger circuit is designed with an insulating transformer and a voltage stabiliser circuit. The step-down transformer

reduces the power line (100, 115 or 230 Vac nominal) to a value of 10 Vac. The above voltage is full wave rectified,

filtered and stabilised. The output voltage of 6,66 V is the ideal value to recharge the internal Ni-MH batteries.

4.8 Digital interface

The digital interface circuit is essentially based on the serial communication interface subsystem (SCI) on the chip of the

microprocessor at 0 up to +5V level.

An adapter to convert TTL to RS 232 voltage levels can be obtained on request.

14

Page 15

5 UNPACKING

Remove the instrument from its packing case and remove any shipping ties, clamps, or packing materials.

Carefully follow any instructions given on any attached tags.

Inspect the instrument against scratches, dents, damages to case corners etc. which may have occurred during

shipment.

If any mechanical damage is noted, report the damage to the shipping carrier and then notify OMEGA directly or its

nearest agent, and retain the damaged packaging for inspection.

A label, on the bottom, indicates the serial number of the instrument.

Refer to this number for any inquiry for service, spare parts supply or application and technical support requirements.

OMEGA will keep a data base with all pieces of information regarding your instrument.

15

Page 16

6 PRE-OPERATIONAL CHECK

The PCL10/11 portable calibrator is powered by four Ni-MH rechargeable batteries.

The external battery charger, supplied as a standard , can be ordered for either 100/120 Vac or 230/240 Vac power

source.

Before using the instrument carefully verify the nominal voltage value of the charger with the available mains power line.

The instrument should be used in environments where the temperature does not exceed the specified limits (from -5°C to

+50°C) and where the relative humidity is lower than 95%.

In case of “low” battery condition (voltage lower than 4.6 V ) the display will show the symbol

A battery symbol means that the battery package has enough energy for about 30 minutes’ operation.

In this condition the instrument batteries must be recharged.

WARNING :

THE INSTRUMENT IS SUPPLIED WITH NI-MH RECHARGEABLE BATTERIES.

DO NOT USE NORMAL ALKALINE BATTERIES.

ALKALINE BATTERIES, WHEN CONNECTED TO A DC VOLTAGE SUPPLY UNDERTAKE AN OVERHEATING PROCESS WITH A RISK OF

EXPLOSION.

–.

16

Page 17

7 OPERATION & APPLICATIONS

PCL 10/11

The PCL10/11 portable calibrator is factory calibrated before shipment.

During the start-up the operator should only select and load the pertinent application parameter as described below.

7.1 Rechargeable batteries

The PCL10/11 portable calibrator is powered by a built-in rechargeable battery package .

The instrument is shipped with an average level of charge.

After unpacking, a full charge of the batteries is recommended; connect the instrument to the charger module (“OFF”

condition) for a period of 10 hours minimum.

The Ni-MH rechargeable batteries do not suffer when used in cyclic operations.

The cyclic operation is understood as a method of operation by which the battery is continually charged and discharged.

Note that a battery, at its lower limit of discharge, risks a non uniform cell polarization: this condition makes it difficult to

recharge it with the charger supplied.

Avoid leaving the instrument, with batteries totally or partially discharged, for a long time without recharging them.

To charge the batteries use only the original supplied charging module. The module incorporates protection and current

limiting devices not normally found in other commercial chargers.

7.2 Battery charger

The external battery charger is configured, before shipment, for a supply voltage of 100, 115 or 230 Vac, upon order

specification. The nominal voltage value is indicated on the front label of the battery charger.

7.3 How to maximize the life span of the battery

Disconnect the ac mains supply when the battery is charged. Use the battery until it is completely discharged.

Leaving the ac mains supply plugged in will decrease the life of the battery. It's possible to leave the AC mains supply

plugged-in 2 or 3 more days after the normal (10 hours) charge without batteries damages.

Note that the operating time decreases at low temperatures.

A Ni-MH battery can be recharged about 500 times when used with the recommended instructions.

7.5 Start-up

PCL10/11 can perform a wide variety of simple and complex pressure based measurements, tests and calibrations.

Using the menu driven set-up procedures the system can be easily configured for the required measurement mode.

The present paragraph describes, step by step, the use of PCL10/11 to perform basic pressure measurements.

TTENTION: ALL THE VALUES IN THE FOLLOWING FIGURES ARE ONLY LISTED AS AN EXAMPLE.

A

During set-up and load memory remember that the instructions of the manual related to key operation have the following

meaning:

<A> + <B> Press the <A> key and keeping the pressure on it, press then the <B> key.

<A> , <B> Press in sequence, first the <A> key and then the <B> key.

To power-on the instrument, press the <ON> key; the indication

will appear for a few seconds.

The instrument runs an autodiagnostic routine for the self-checking of critical circuits and components.

A positive check will be shown eg. with the following indication :

for about one second.

The number in the “Code” line indicates that some memory data have been lost.

The paragraph of this manual points out of the different type of lost data can be notified.

• Press the <PAGE> key to obtain the following indication relevant with the type of pressure module installed.

Error Checksum

Code : 0010

17

Page 18

10 Bar 0.05%

Press (PAGE)

The example indicates that a pressure module 0 to 10 bar fs with an accuracy of 0.05% of the reading has been

installed.

• Press the <PAGE> key to enter the operative mode and to obtain eg. the following pages indicating that the auxiliary

measurement channel (second line of the display) is respectively Voltage (V) with a resolution of 1 mV or Current

with a resolution of 1 µA:

P1 0.000 Bar

V1 0.000 V

The instrument is ready for pressure measurement and simultaneously voltage or current measurement.

If a low battery condition is present a “Battery” symbol '

If the “Pressure Module” is not installed the following message will be shown :

or eg.

P1 0.000 Bar

mA1 0.000 mA

–' will be displayed in all operative pages.

!! NO Module !!

Turn Off & insert

• To insert the Pressure Module switch first the instrument -Off- to avoid any possible damage ;

• Insert the required Pressure Module ;

• Switch the instrument “On” again.

7.6 Instrument Configuration review (Status)

To review the configuration of the instrument on the display press the <STATUS> key.

The indication will be as it follows:

Batt. 18/08/96

5.3 10:45:20

An “AC” symbol (on the above display : below on the left) will be displayed when the instrument is connected to a battery

charger to confirm that the charging voltage level is present in the instrument power supply circuit.

The “low” limit of the battery voltage, for the correct operation of the instrument, is +4.6V.

Any date and time information will be displayed only when the memory module with the real time clock is installed in the

instrument (see table D=1 on Par. 1.1).

Without any memory module and real time clock the above indication will be as it follows :

or eg.

Batt. 04/03/97

5.3 18:12:51

• When the real time clock is installed to change the time and date format (eg. European to USA) press <ENTER> +

<PAGE> keys. The displayed indication will change as it follows :

or eg.

Batt. 18/08/96

5.3 10:45:20

from “day/month/year” to “month/day/year” and about time from 0 to 24 :00 :00 using an am (“a”) or pm (“p”) indication.

• Press the <STATUS> key to review the type of Pressure Module installed and to obtain ie. the following indication :

<ENTER> + <PAGE>

2 Bar 0.1%

S/N 10000 V1

The Pressure Module installed in this example has a full scale range of 2 bars with an accuracy of 0.1% of the reading

and is identified by the Serial number 10000.

Batt. 18/08/96

AC 5.3 10:45:20

Batt. --------

5.3 --------

Batt. 08/18/96

5.3 10a45:20

18

Page 19

The “V1” message indicates that the characterization matrix used is version n. 1.

• Press the <STATUS> key to obtain the configuration (status) of the instrument with ie. the following indication :

Adjust:ZERO CAL

#20000 V1.000

The “ZERO” message, when displayed, indicates that an autozero procedure was carried out.

The “CAL” message, when displayed, indicates that the “user's calibration” has been activated.

• Press <ENTER> + <PAGE> keys if you require to remove the user's calibration.

• Press <ENTER> + <PAGE> keys if you require to remove the zero correction obtaining the following indication :

Adjust:---- ----

#20000 V1.000

In the second line are displayed the serial number of the instrument and the identification code of the version of firmware

installed.

The above information is extremely useful to understand the update status of the instrument and to simplify information

exchange with OMEGA engineers during repair or service activities.

7.7 Display contrast and backlight adjustment

The high contrast alphanumeric LCD display is equipped with a backlight device to allow easy readings even in poor light

conditions.

The backlight can be switched -On- using the <LAMP> key.

The contrast of the display can be adjusted using

<ENTER> + <▲> key to increase or

<ENTER> + <▼> key to decrease the contrast.

7.8 Normal operative mode

In the normal operative mode the instrument shows ie. the following indication :

P1 0.000 Bar

mA1 0.000 mA

The number “1”, marked on the right side of “P” and “mA”, indicates that the page n.1 is displayed. The above page

number refers to the possibility of freezing/memory store the measured value using the <HOLD> key.

Five pages of memory stored data are available.

An asterisk “*” will mark the memory stored parameters :

*P1 0.000 Bar

*mA1 0.000 mA

The operator can make additional measurements, while keeping in to memory the previously memory stored data,

pressing the <PAGE> key obtaining ie. the following indication :

P2 0.000 Bar

mA2 0.000 mA

The operator can review all memory stored data pages using the <PAGE> key in repeated sequence.

When displayed the operator can cancel the displayed memory stored page (marked with an asterisk) pressing the

<HOLD> key.

Current measurement on active and passive loops.

The mA input channel of PCL10/11 can operate directly on active and passive loops. This means that the instrument has

an internal power supply able to compensate for the voltage level present into the loop.

If the internal power supply is connected to a short circuit or the load requires more then 20 mA, a message “PS ovc”

(power supply overcurrent) will be displayed.

The internal power supply uses an electronic circuit to limit the maximum output current to 25 mA and a fuse, F2 (see

Par. 11.2), to preserve itself from external overvoltage and overcurrent.

19

Page 20

ACTIVE EXTERNAL LOOP

PASSIVE EXTERNAL LOOP

Trx P.S.

- mA +

ACTIVE

- mA +

PASSIVE

- mA +

ACTIVE

TRX

- mA +

PASSIVE

7.9 Zero adjustment

The pressure sensor installed into the Pressure Module is temperature compensated. However, the pressure transducer

could present zero drifting due to a temperature variation exceeding the characterization limits or to a long term working

time. Any time the operator requires accurate pressure measurement or to run a leak test, a zero adjustment of the

pressure transducer is strongly recommended.

During the normal operative mode the display indication is eg. the following :

P1 0.008 Bar

mA1 0.000 mA

To run the autozero procedure remove tubings from the pneumatic connector and start the autozero procedure pressing

the <ZERO> key. The instrument will display an “Autozero” message and a four second countdown :

Autozero

Please wait ..4

At the end of the countdown the display will confirm that the pressure measurement is now reset to zero as it follows :

P1 0.000 Bar

mA1 0.000 mA

If the correction required is too high (this can be caused by pneumatic tubes connected to the input terminals) the

instrument will display the following message :

P1 Zero Er

mA1 0.000 mA

Review the pneumatic input connection and try the autozero procedure again through the <ZERO> key.

To disable the 'zero correction' switch-OFF the PCL10/11 (see also Par. 7.6).

If unsuccessful see the indication at Par. 7.6 “Review instrument configuration (Status)”.

7.10 Pressure measurement damping

When measuring a very unstable pressure process, there is a great need of a reading stabilization.

PCL10/11 is equipped with a combination of :

working band

average weight

The working band is used to define the maximum and minimum values between which the process which is being

analyzed has to oscillate. The average weight is a value obtainable from the practical use. It is used to define the

number of fluctuations into the working band where the average value is to be calculated. The working band, in addition

to the weighted average, is used not to have long response times when the oscillations are extremely high. At first the

working band should be excluded. Then the entity of the oscillation (in digits) with an average weight set at zero (and

working band = Off) should be verified and extimated. This is to say that the maximum value of the pressure oscillation

plus the 20% is the value of the working band to be programmed. The weighted average will be increased progressively

from 0 to 7 according to the operative requirements.

During the normal operative measurement mode eg. as it follows :

P1 0.000 Bar

mA1 0.000 mA

20

Page 21

• Press the <DAMP> key to enable the above described operative mode. A “d” is marked on the right side of the “P”

symbol as it follows :

P1d 0.000 Bar

mA1 0.000 mA

• Press again the <DAMP> key to disable this special operative mode.

To install the required calculation data

With the instrument in the normal operative mode eg. with the following indication :

of the “Damp” routine follow the below indicated procedure :

P1 0.000 Bar

mA1 0.000 mA

• Press the <ENTER> + <STATUS> key to enter the configuration procedure

• Press the <STATUS> key several times to obtain the following indication :

Damp P 5 -

Band P Off

• Press the <ENTER> key to select the parameter to be adjusted.

• Press <▲> and <▼> keys to adjust the required value. Remember that with a 0 (zero) setting the parameter will be

excluded and the message “Off” will be displayed.

The adjustment can be as it follows :

• Damp P : from 0 (no damp effect) to 7 (high damp effect- high average weight)

• Band P : from 0 (Off = excluded) to 200

• If the instrument is not equipped with the internal data memory the above selection can be memory stored using

<ENTER> + <PAGE> keys. In this case the data will be kept also when the instrument is switched “Off”.

• Press the <PAGE> key to return to the normal operative mode

7.10.1 Averaged Value Calculation Algorythm

The working band and the Weighted average allows to measure very unstable processes. In order to use parameters in

a correct way, it's useful to understand their working way, which is explained in the following figures:

a) If all the successive acquisitions are always comprised in the working band, the average value will be calculated

according to the weighted average programmed.

b) If during the acquisition, the process is subdued to variations exceeding the working band, the algorithm will move

the working band (always considering the programmed limits), ensuring a fast response and displaying time.

Wheighted average effect

Input pressure

fluctuations

Indicated values with

wheighted average = 0

Indicated values with

wheighted average = 2

Indicated values with

wheighted average = 7

21

Page 22

Working band effect

Input pressure

fluctuation

Measured value with wheighted

average=7 and working band excluded

Measured value with wheighted

average=7 and working band included

7.11 Technical unit selection

The required technical unit can be selected as it follows.

With the instrument in the normal operative mode ie. see the following indication :

P1 0.000 Bar

mA1 0.000 mA

• Press <ENTER> + <STATUS> keys to abilitate the technical unit selection :

Unit P : Bar ß

In mA/V : V --

The arrow on the right side marks which parameter can be modified.

• Press the <ENTER> key to select the required line

• Press <▲> or <▼> key to select the required parameter

• Press the <PAGE> key to confirm and to memory store the new selection. The instrument will return to the main

operative page

The pressure technical units that can be selected are the following :

PSI

mmwc (mmH

Bar / mBar

KPa / hPa/MPa

inwc (inH

lbi2 (lb/in2)

mmHg / mHg at 0°C

2

(kg/cm2) / kgm2 (kg/m2)

kgc

Atm

The electrical technical units that can be selected are the following :

---- the indication of the second line of the display is disabled.

mA 0 - 20 mA

V 0 - 30 V

X mA 0 - 20 mA with scale factor mode

X V 0 - 30 V with scale factor mode

SWno test switch normally open

SWnc test switch normally closed

The selection Bar/mBar, mmwc/mwc, kPa/hPa/Mpa depends on the type of Pressure Module installed.

O) / mwc (mH2O) at 4°C

2

O) at 4°C

2

22

Page 23

7.12 Voltage and Current measurements

m

V

H

L

PCL11 is equipped for direct current and voltage measurements.

The ranges are :

• Volt : 0 ... 30 V with 1 mV resolution

• mA : 0 ... 22 mA with 1 µA resolution

7.13 Peak & Valley measurement

From the start-up the instrument will continuously update the identified maximum (peak) and minimum (valley) values.

The above data can be displayed using respectively :

<ENTER> + <PEAK> keys for the maximum value

<ENTER> + <VALLEY> keys for the minimum value.

The display indication will be eg. as it follows :

PK 2.828 Bar

PK 1.824 mA

Val 0.120 Bar

Val 0.088 mA

PK ----- Bar

PK 0.000 mA

The message “----“ indicates that a computation error was present therefore no data are available.

The memory stored and displayed minimum and maximum values can be reset using <ZERO> + <HOLD> keys.

• Press the <PAGE> key to return to the normal operative mode.

7.14 Scale factor program

The “scale factor” function is a method with a view to read or to simulate electrical signal values in terms of engineering

units.

• From the normal operative mode :

P1 0.000 Bar

mA1 0.000 mA

• Press <ENTER> + <STATUS> keys and then the <ENTER> .

• Press <▲> key several times to obtain one of the following indications :

P1 0.000 Bar

A1 0.000 X mA

P1 0.000 Bar

1 0.000 X V

• Press <STATUS> key to obtain the following indication :

o X : 0.0000-

i X : 0.0000

• The two parameters refer to the technical value required scaled from a linear input electrical signal.

• Press <ENTER> key to move the arrow to the right column to mark the required parameter to be adjusted

• Press <▲> and <▼> keys to set the required value. The limits of the setting are -9999 and +30000.

• Press <STORE> key to adjust the decimal point position (0.0000 - 0.000 - 0.00 - 0.0 - 0).

23

Page 24

• Press <SET UP/STATUS> key to confirm the above setting and to memory store the new data. A new display page

T

will be obtained :

Input : 1-5 V -

ype : Linear

The following input ranges and type of Xscaling are available :

0 - 20 mA

4 - 20 mA

0 - 10 V

1 - 5 V

Linear

Square

• Press <ENTER> key to move the arrow to the right column to mark the required parameter to be adjusted

• Press <▲> and <▼> keys to set the required value.

• Press the <SET UP/STATUS> key to confirm the above setting and to memory store the new data. A new display

page will be obtained :

Word : -

I

This page allows to load the symbol of the required technical unit to be displayed in this scale factor operative mode.

Four alphanumeric characters are available.

• Press <ENTER> key to move the arrow to the second line in order to mark the position of the character to be set or

modified

• Press <▲> and <▼> keys to set the required character in each of the four position.

• Press <SET UP/STATUS> key to confirm the above setting and to memory store the new data. An example of the

loaded symbol is the following :

Word : mBar -

I

• If the instrument is not equipped with the internal data memory the above selection can be memory stored using

<ENTER> + <PAGE> keys. In this case the data will be kept also when the instrument is switched “Off”.

• Press <PAGE> key to return to the normal operative mode

The available procedure alphanumeric characters that can be used as a symbol of the measured or simulated parameter

are the following :

24

Page 25

Library of characters

HIL

.

.

....

7 8 O P g h

! 6 9 N Q f i

.

....

.

.

.

.

.

" 5 : M R e j )

# 4 ; L S d K |

$ 3 < k T c l )

% 2 = J U b m z

& 1 > I V a n y

' 0 ? H W \ o x

( / @ G X _ P w

) . A F Y ^ q v

* - B E Z ] r u

. .

..

.....

.

.

.....

+ , C D [ s t

When the Scale Factor mode is operative press <ENTER> + <CONV> keys to obtain the electric signal equivalent to the

actual displayed technical unit.

Scale factor principle of operation

The Xscaling mode operates as it follows :

Input mA V LO HIx LOx

Display linear

(./ )( )

=

Input mA V LO HIx LOx

Display square

(./ )( )

=

In the above equations the different combinations can be as it follows :

LO HI

0 - 20 mA 0 20

4 - 20 mA 4 20

0 - 10 V 0 10

1 - 5 V 1 5

The display page will be eg. as it follows :

−•−

O

−

−•−

HI LO

−

LOx()

+

2

LOx()

+

.

.

P1 0.000 Bar

mA1 0.000 xxxx

The indication “xxxx” will be “XmA” if no alphanumeric symbol or the previously loaded symbol (up to four alphanumeric

characters) has been selected.

7.15 Alarm setting and operative mode

This procedure allows to set the required alarm level.

With the instrument in the normal operative mode with eg. the following indication :

P1 0.000 Bar

mA1 0.000 mA

• Press the <ENTER> + <STATUS> key to enter the procedure

• Press the <STATUS> key several times to obtain the following indication :

25

Page 26

A

A

l P: 0.00-

U

l mA/V: Off

• Press the <ENTER> key to move the arrow to the required line of the display

• Press <▲> and <▼> keys to set the required alarm level value. Remember that when the set is 0 (zero) the alarm is

excluded and the message “Off” will appear

• Press the <SET UP/STATUS> key to confirm the above setting and to memory store the new data.

• Press the <PAGE> key to return to the normal operative mode

During the normal operative mode the presence of an alarm condition will be announced by an acoustic signal and a

message “Al” eg. as it follows :

P1 Al 0.000 Bar

mA1 0.000 mA

The acoustic signal can be cancelled with the <ALARM RESET> key. The message “Al" will be kept in the display. Both

the acoustic signal and the message “Al” will automatically disappear when the signal returns below the alarm level.

7.16 Pressure switch test

The instrument can be used to test pressure switch but the availability of a pressure pump equipped with a needle valve

is required.

When in the normal operative mode with eg. the following indication :

P1 0.000 Bar

mA1 0.000 mA

• Press <ENTER> + <STATUS> keys to enter the general installation procedure

nit P : Bar -

In mA/V : V

• Move the arrow on the left side of the display to the second line using the <ENTER> key

• Press <▲> or <▼> key to select one of the two indications as it follows :

Unit P : Bar

In mA/V : SWno -

Unit P : Bar

In mA/V : SWnc -

• Press the <PAGE> key to acknowledge the selection and to return to the normal operative mode

When a SWno (Switch normally open) has been selected connect the pressure switch to the terminals “mA Passive” on

the right side of the instrument. The pressure switch under test opened the contact. When the pressure switch

commutates its contact the pressure displayed value will be frozen and marked with an “*”.

*P1 1.000 Bar

*SW1 Open(no)

• Press the <HOLD> key to reset the instrument

An opposite status will be active when operating with normally closed type of pressure switch.

If instead of selecting “SWno” or “SWnc” the operative mode “SW” is selected the instrument can be used to identify the

hysteresis value of the pressure switch displaying both sides of the contact switchover.

26

Page 27

7.17 Leak test

T

P

P

U

PCL10/11 provides the ability to detect and quantify leaks in terms of pressure decay over a programmable time.

The instrument will monitor the actual pressure for the programmed time interval and, at the end of the monitoring time

period, display the measured change in pressure.

The leak test can be made in vessel, operative gas network or non operative network.

The operative gas network can be checked directly where other applications require the availability of a pump and

adaptors.

The leak test mode can be abilitated with keys <ENTER> + <LEAK> obtaining the following indication :

Leak Test

ime: 60 s -

Press the <▲> or <▼> key to adjust the required test time

Press the <LEAK/STORE> key to start the test. A new displayed page with a countdown indication will be shown :

Leak Test -58s

: 1.880 Bar

• At the end of the test the following displayed page will indicate the total pressure decay (pressure value at the start

of the procedure minus the pressure value at the end of the test).

Leak Test Result

0.804 Bar

7.18 User’s Calibration

The procedure described below allows PCL10/11 recalibration by using an external pressure reference source. The

value that can be used for this purpose must be between 10% and 100% of the span.

The internal microprocessor will align the zero and span values to the reference pressure value.

To recalibrate the unit proceed as follows:

• Switch <ON> keeping the <Page> key pressed. The display will show :

! CALIBRATION !

ENTER PASSWORD

• Enter password pressing <DAMP>, <HOLD>, <DAMP> in sequence.

• Press three times the <STATUS> key. The display will show the following indication :

User Cal xxx%

X X X X X X X X X

( The value indicated above is just an example. You can find a different value.)

• Press <▲> or <▼> keys to set the reference pressure value (in % of the span). If you want to read the reference

pressure value in engineering units, press the <ZERO> key. For example the display will show :

User Cal 85%

X X X X X X X X X

The second line shows the actual value measured by A/D converter in digital units.

• Press the <ZERO> key to return to the previous page.

• Leave inputs HP/LP at zero pressure and press <PAGE> to run the zero calibration. On the display a countdown will

start :

<ZERO>

ser Cal 8.500 Bar

hNCal : X X X X X

Please Wait ...1

_ _ _ _ _ _ _ _ <

If the zero calibration procedure is inside the limits, you will have the message :

27

Page 28

User Cal Z xxx%

_ _ _ _ _ _ _ _ _

You can proceed with the next step.

If the zero calibration procedure is out of limits, you will have the message :

User Cal F xxx%

_ _ _ _ _ _ _ _ _

In this case check connections for zero input pressure and restart zero calibration.

• Press <ENTER> to put the cursor on the second line, to generate the reference pressure value and wait for few

seconds to stabilize the system. Press <PAGE> to start the calibration. The following message will appear on

display :

Please Wait ...1

_ _ _ _ _ _ _ _ <

If the calibration is inside the limits, the display will show :

User Cal * xxx%

_ _ _ _ _ _ _ _ <

You can proceed with the next step. This means that the User’s calibration is accepted.

If the span calibration procedure is out of limits, you will have the message :

User Cal ? xxx%

_ _ _ _ _ _ _ _ <

In this case, check the connections to the reference pressure source and repeat the calibration procedure by

pressing the <PAGE> key.

To enable and disable the User’s calibration follow the procedure described below :

• With the instrument in operative mode press the <STATUS> key until the display shows :

Adjust : ________

Keeping pressed the <ENTER> key press the <STATUS> key to enable the User’s calibration. The display will

show the following message :

X X X X X X X X X

User's calibration disabled

Adjust : ____ Cal

Repeat the same procedure to disable the User’s calibration.

The User’s calibration won’t erase OMEGA factory calibration. When enabled, it can be used

by the customer to define a personal work range. When disabled the instrument will work with the

factory calibration ignoring the other.

X X X X X X X X X

User's calibration enabled

28

Page 29

8 INSTRUMENT CONFIGURATION

The configuration of the instrument can be modified using the following procedure :

• The procedure starts with the instrument switched -Off-.

• To enter the configuration procedure keep the <STATUS> key pressed and press the <ON> key to obtain the

following indication :

INSTALL Proc

Enter Password

• Press <ENTER>, <STORE>, <ENTER> in sequence to obtain the following indication :

12-:38-:00 Clock

18 / 8 /96 Set

If the real time clock is not installed all the above numbers are replaced with 0.

• Press the <ENTER> key to select the parameter to be modified

• Press the <▲> or <▼> key to adjust the new value

• Press the <STATUS> key to confirm and to memory store the new data. A new display page will be shown as it

follows :

Text ENG -

Baud Rate 9600

The digital communication speed can be selected from : 300, 600, 1200, 2400, 4800, 9600, 19200

• Press the <STATUS> key to confirm and to memorize the new data.

• Switch the instrument -Off- to exit from the configuration procedure.

29

Page 30

9 CalpMan Application PC Software

9.1 Introductory note

Standard Agencies and Quality Auditors require the collection, the organization and analysis of traceability documents for

all the equipments installed in the process or used in laboratory.

A supporting software for Windows Calpman (Calibration Procedure Manager) is available, and supplied together with a

memory module installed into the instrument and a digital interface cable when the Table D=1 option is specified, to

transfer a selection of calibration routines from a PC to the internal memory of the instrument in order to simplify field

calibrations selecting the appropriate tag number.

Test and calibration data can be memory stored and downloaded to a PC to document the calibration activity that allows

to build a quality control chart/data bank from a single calibration sheet to a detailed historical report.

Each instrument, called “Tag”, to be calibrated/inspected is identified by a 16 alphanumeric characters.

Three additional lines of 16 characters are available for a more detailed description of the instrument to be calibrated. A

typical example is shown below :

Tag = Pressure Trx 128

Auxiliary information = High temp trap

Area n.21T68

Stafford Station

The overall capabilities of the combination PCL10/11 + CalpMan software are the following :

PCL10/11 can store up to 50 Tags

Each Tag can be tested at up to 5 different calibration steps (P Test Point)

Each Tag can be identified with an alphanumeric code of 16 characters

Plant location/Plant section can be identified with three additional lines every 16 alphanumeric characters

The Operator/Inspector’s name can be written with up to 16 alphanumeric characters

Test procedure can be prepared on a PC and downloaded to a PCL10/11 when required

Test procedure can be eventually directly loaded in the field and downloaded to the PC

Direct test of Pressure gauges or pressure analog/digital indicators

Direct test of Pressure Transmitters with comparison P inlet to electrical signal output

Direct test of Pressure Transmitters with comparison P inlet to scaled pressure technical unit

Direct test of Pressure Transmitters at actual programmed Pressure test point or with automatic calculation of

actual error with inlet pressure in an acceptable deviation band from the Pressure Test Point level.

9.2 Software Installation

Calpman runs on IBM PC under WINDOWS 3.1. Minimum requirements are a 386 CPU with 2Mbyte Ram and 1 Mbyte

on hard disk, Monochromatic or colour monitor and a Microsoft mouse or a compatible one.

In order to install Calpman for Windows, follow the below procedure:

• Place the Calpman disk in a 3.5" diskette drive;

• From the Windows Program Manager's File Menu, select <RUN>;

• Enter the filename A:SETUP.EXE (substitute the letter A for the disk drive that contains Calpman diskette)

• Follow the on screen instructions making sure to provide the correct path to your Calpman directory when prompted.

Once installed, the CalpMan icon will appear on your Windows screen and it will be possible to boot it by clicking on the

icon as usual.

9.3 General structure of the CalpMan software

The general structure of the CalpMan software can be easily explained taking into consideration the following PC “Tag”

main page and the auxiliary page relevant to “Other” parameters.

30

Page 31

The understanding of the above page content requires the explanation of the terminology used and of the objective (or

result) of each parameter taken into consideration.

Tag

16 alphanumeric characters are available to load the identification code of each component/equipment/instrument that

has to be periodically inspected.

eg. Pressure Trx 128 or P Trx 128/21/T68

Note

Three lines, each of 16 alphanumeric characters, are available to load additional identification information eg. relevant

with the section of the process, the area and the name of the plant as it follows :

High Temp Trap

Area n. 21/T68

Stafford Station

Operator

16 alphanumeric characters to identify the name of the operator/inspector responsible for the practical inspection and/or

reallignement

eg. J.H.Bellamy

Date

Actual date or inspection or verification. The date is automatically loaded from the internal real time clock of the

instrument.

Mem#

Memory slot number automatically loaded during downloading procedure from the PC

Next Cal

Time interval for the next calibration (or calibration interval time) required by the considered “Tag”

S/N Instrument

Serial number of the PCL10/11 used.

P module

The full scale of the pressure module installed on PCL10/11 (eg. “10 bars” pressure module)

Can be selected using the installed library.

P unit

The technical unit to be used that can be selected from the installed library (eg. mbar, bar, psi, mmH2O, inH2O, inHg,

mmHg, kPa, atm)

mA/V In

The electrical parameter of the pressure transmitter output that can be selected between “V” and “mA”

P TP

Test Point value of pressure required for a full inspection of the relevant “Tag”.

Up to 5 test points are available (eg. for a pressure gauge 0-10 bars the test point could be 0 - 2.5 - 5 - 7.5 - 10 bars.

31

Page 32

P value

Actual pressure value recognized during the test and automatically loaded during the test procedure.

P error

Actual error automatically loaded during the test procedure

mA/V Value

Actual electrical signal measured at the relevant test point

mA/V TP

()

When full required pieces of information are loaded for the specific test point a “x” mark will confirm the instrument

acknowledgement

Three general buttons are present on the top right of the main page :

Quit

Press this button to exit the CalpMan procedure. The following subpage will be displayed :

- About

Gives general information relevant with the calpman - Calibration Procedure Manager software package.

- Config

Require the identification and the selection of the communication port COM 1 or COM 2 of the PC.

Instrument

Allows the selection of the below indicated activities :

- Load from instrument

To load a test procedure from the internal memory of the PCL10/11 to the PC memory.

- Save on Instrument

To save the active test procedure, relevant with a specific Tag code, into the PCL10/11 memory.

A further message requires confirmation.

- Clear Tag

To cancel one Tag from that installed in the PCL10/11 memory.

A further message requires confirmation.

- Clear All Tags

To cancel all Tag procedures installed in the PCL10/11 memory.

A further message requires confirmation.

Computer

Allows the selection of the below indicated activities :

- Load from file

To load on the CalpMan main page a test procedure memory stored on the PC.

- Print

Allows the printout of the specific PC data page.

- Clear tag

To clear the active Tag data page

- Clear Tag result

To clear data relevant to a specific Tag code.

- Other parameters

To display the “Other” parameter page

Other

Press this key to obtain the “Other” parameter page as indicated below, relevant with the scale factor data and auxiliary

parameters.

In X

To select and memory store the required input signal from the list of ranges installed into the library of the program (0-20

mA, 4-20 mA, 0-10 V, 1-5 V).

Type X

To select the scale factor mode “Linear” or “Square”.

Dp X

To select and memory store the required position of the decimal point among 0.0000-0.000-0.00-0.0-0.

This page allows the configuration of the digital communication data of the PC to be used with the CalpMan

software package.

Require the setting of the transmission rate of the PC that should be the same value used into the configuration of

PCL10/11 (19200 - 9600 - 4800 - 2400 - 1200 - 600 - 300)

32

Page 33

Lo X

To load the zero value of the technical unit range ( eg. 0 bar).

Hi X

To load the full scale value of the technical unit range (eg. 80 bar).

Word X

To load the technical unit symbol relevant with the scale factor mode (eg. bar)

Alarm P

To load the required pressure alarm value (if required).

Alarm mA/V

To load the required input signal alarm value (if required)

Damp

Damp Band

see paragraph 7.10 for a better understanding of the “Damp” operative mode useful to obtain a good reading in-situ in

presence of an unstable pressure process.

The use of the relevant “Damp” weight and “Damp Band” will allow repeatitive tests for higher accuracy.

Automatic Error

Enables or disables the automatic error mode

Error Band

To load the required error band value

Return

Press this key to return to the “Tag” main page

9.4 Pressure gauges test

This procedure allows to test pressure gauges or pressure digital indicators.

PCL10/11 must be connected to the pressure gauge and, using a tee adaptor, to a manual pump.

Pump pressure on the circuit to reach a pressure value below the Test point and then use the volume adjuster of the

pump to obtain, on the pressure gauge dial, the required Test Point value.

The CalpMan software is equipped with a special routine for the automatic recognition of the deviation of the actual

setting of the pressure gauge from the Test Point value setting compared with the preloaded error band.

9.5 Pressure transmitter test

This procedure allows the test of pressure transmitters.

This procedure can be programmed to be run comparing the input pressure with the electrical signal output or, using the

scale factor mode, through a direct comparison of homogeneous data (eg. bars against bars).

As an accurate setting of the pressure level with a manual pump is critical, to simplify the operation, the CalpMan

software is equipped with a special routine that allows to run a test and to identify the deviation error, on a specific Test

point value, using any pressure Test Point setting inside a stated and acceptable band.

The system will recognize the generated pressure level and automatically compare it with the appropriate proportional

deviation on the output signal.

33

Page 34

9.6 Test result printout from PCL10/11

Directly from PCL10/11, using the optional impact type printer, a Report of Calibration can be obtained pressing the

<PRINT> key.

A typical example is shown below :

PCL10/11

S/N B 65588

#C 65589 v 1.005

TAG Plant code

Pressure Trx 128

14 :42 28/11/96

Memory Report 0

TP1 -1.000 PSI

P1 -1.206 PSI

mA1 0.000emA

TP1 -1.000 mA

ErA 0.100 mA

TP3 3.000 PSI

P3 3.200 PSI

mA3 3.583 mA

TP3 3.000 mA

ErA 0.300 mA

ST4 4.000 PSI

P4 4.480 PSI

mA4 4.051 mA

TP4 4.000 mA

Er 0.051 mA

ST5 5.000 PSI

P5 5.588 PSI

mA5 5.388 mA

TP5 5.000 mA

Er 0.388 mA

High Temp Trap

Area n. 21T68

Stafford Station

Operator

J.H.Bellamy

................

34

Page 35

9.7 Test result printout from PC

A full Report of calibration per each specific Tag test can be obtained from the PC using CalpMan.

An example of a typical Report of Calibration is shown below.

Report of Calibration

OMEGA PCL10/11 S/N 65588B 65589

Module : 1 Bar

Pressure Unit : kpa

mA/V input : X mA

X scaling input : 4-20 mA

X scaling type : Linear

X scaling Lo : 10.0 mbar

X scaling Hi : 1000.0 mbar

Time : 22 :32 Date : 28/11/96

TAG : Pressure Trx 128

Description :

High temp trap

Area n. 21T68

Stafford Station

TP P Value TP mA/V Value Error

1.10 -8.31 3.0 -238.5 2.2 E

1.20 -8.31 3.1 -237.5 2.3 E

1.30 -8.31 3.2 -237.5 2.4 E

1.50 -8.32 3.4 -237.5 2.6 E

Error Method : Automatic

Operator : J.H.Bellamy

35

Page 36

10 Digital interface

The PCL10/11 portable indicator is equipped with a digital interface.

The interface circuit is essentially based on the serial communication interface subsystem (SCI) on the chip of the

microcontroller.

The output voltage levels are TTL at 0 to +5 V.

An optional adapter to convert the voltage level from 0 to +5 V, to the RS232 levels, can be supplied on request.

This adapter is required to interface PCL10/11 with a Personal Computer.

10.1 Digital output wiring practice

The wiring to the digital output signals is made through a mini DIN connector mounted on the lower end of the case.

The pertinent connections are indicated below.

Rx PCL10/11

Tx PCL10/11

ground

Female miniDIN connector

(case mounted - external view)

5 V

ground

For easy interconnections a miniDIN connector with cable can be supplied on request. The color codes of the conductor

can change with different suppliers; please check them before using.

4 5 6

8

7

Front view

3

1 2

LINDY CINCH

pin 1 : brown black

pin 2 : red green

pin 3 : green blue

pin 4 : gray gray

pin 5 : purple yellow

pin 6 : blue white

pin 7 : orange red

pin 8 : yellow brown

10.2 TTL to RS 232 adapter

The cat. BB530001, TTL to RS232 adapter, consists of a cable to which are connected a male mini DIN connector (for

PCL10/11) and a DB 25 connector, that contains the electrical circuitry (for the PC).

The basic circuit and connections are as follows:

36

Page 37

+ 5 V

10 µF, 16 V

10 µF, 16 V

10 µF, 16 V

TTL to RS 232 converter

10 µF, 16 V

+

+

6 2 16 10

11

Tx

12

Rx

ICL 232

1

+

TSC 232

3

4