Page 1

User's Guide

http://www.omega.com

e-mail: info@omega.com

PCI-DDA02

PCI-DDA06

PCI-DDA08

Page 2

Table of Contents

1.0 INTRODUCTION

............................................

2.0 PRODUCT DESCRIPTION

......................................

3.0 INSTALLATION

................................................

3.1 WINDOWS 95, 98 & NT

.........................................

3.2 DOS AND/OR WINDOWS 3.X

...................................

4.0 CONNECTIONS

................................................

4.1 CONNECTING EXTERNAL LINES

..............................

4.2 ANALOG CONNECTIONS

......................................

4.3 DIGITAL CONNECTIONS

......................................

4.3.1 Pull Up and Pull Down Resistors

...............................

5.0 PROGRAMMING & APPLICATIONS

...........................

5.1 PROGRAMMING LANGUAGES

.................................

5.2 PACKAGED THIRD-PARTY APPLICATIONS PROGRAMS

6.0 SELF-CALIBRATION

.......................................

6.1 CALIBRATION CONFIGURATION

.............................

7.1 REGISTER OVERVIEW

.......................................

7.2 BADR2

......................................................

7.3 BADR3

......................................................

8.0 ELECTRICAL SPECIFICATIONS

..........................

.........

Page 2

Page 2

Page 5

Page 5

Page 6

Page 7

Page 7

Page 8

Page 8

Page 8

Page 9

Page 9

Page 9

Page 10

Page 10

Page 11

Page 11

Page 13

Page 26

Page 3

1.0 INTRODUCTION

Thank you for purchasing a top quality PC data acquisition and control boards. The

PCI-DDA0x/12 family of boards represent the latest technology. As there is not a single

switch or jumper on the board, you will find the PCI-DDA0x/12 boards very easy to install and use.

All configuration, cal ibration, and range settings a re done solely through software, making inst allation simple and

quick. The PCI-DDA0x/12 family is supported by the innovative Universal Library, VIX

Components, and DAS-Wizard software, as well as by most third-party, high-level data acquisition software, so you

have all the tools you need to accomplish your data acquisition task.

Go ahead and install the PCI-DDA0x/12 into your computer and then turn your computer on. Welcome to the future!

PLEASE NOTE: If you have a PCI-DDA08/12, all instructions in this manual apply. If you have a PCI-DDA04/12,

you should ignore all references to D/A channels 4 through 7; and if you have a PCI-DDA02/12, you should ignore

all references to D/A channels 2 through 7. In all other respects, the three models are identical.

Page 2

Page 4

2.0 PRODUCT DESCRIPTION

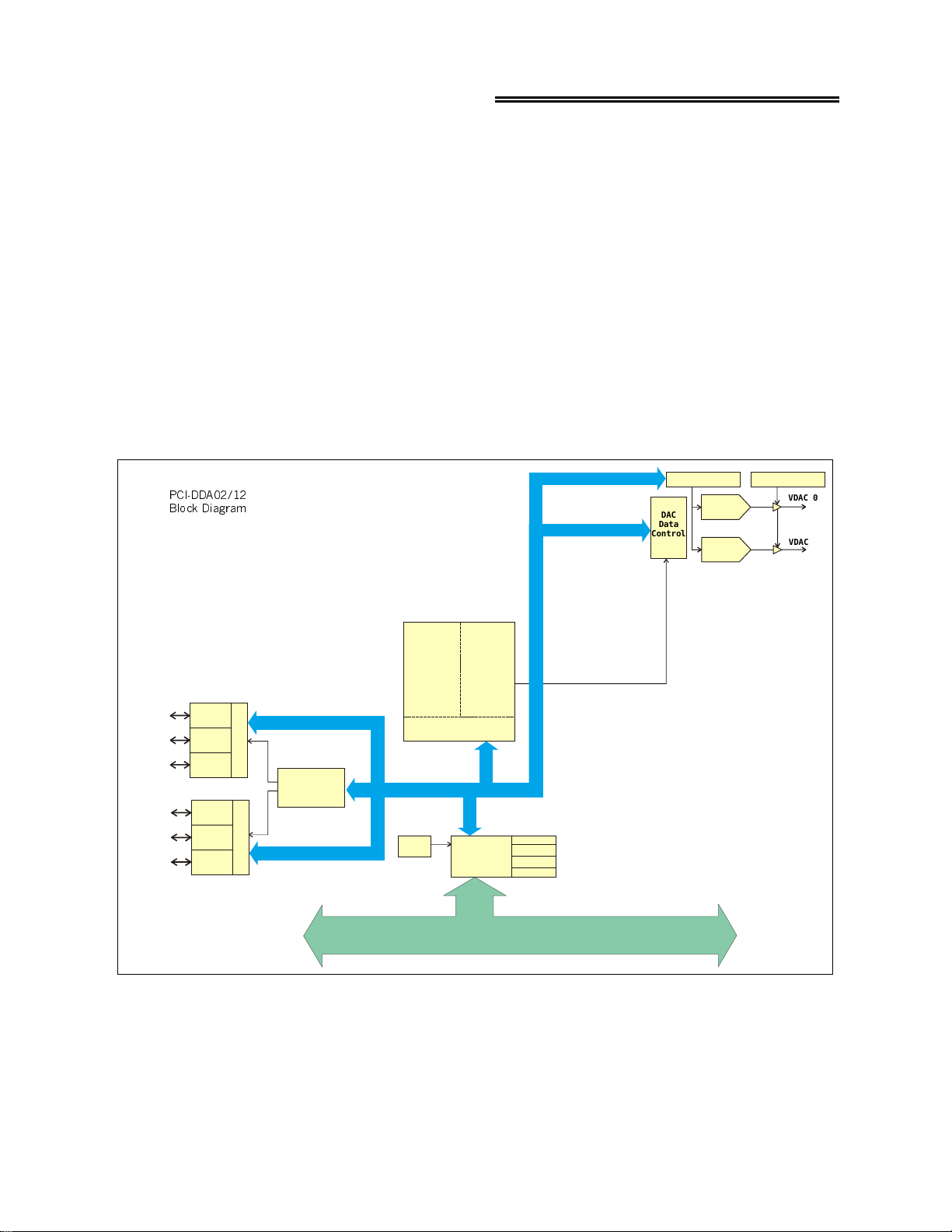

The PCI-DDA0x/12 family comprises three PCI bus plug-in board models: PCI-DDA02/12, PCI-DDA04/12, and

PCI-DDA08/12, with 2, 4, and 8 12-bit analog output channels, respectively. In addition, each model has 48 digital

I/O lines.

The D/A converters can be independently configured for either bipolar or unipolar 2.5V, 5V, and 10V ranges. The

outputs may be updated individ ually or simultaneously. All calibration and range setti ngs are done through software.

The digital I/O ports are configured as two 8255 mode 0 emulations; A (8 bits), B (8 bits), C high (4 bits), and C low

(4 bits). The digital outputs are capable of sinking 64 ma and sourcing 15 ma utilizing standard "S" logic.

The PCI interface uses the PLX 9052 IC which is a low-cost slave-only device. The PCI interface for the analog

output is configured in a 16 bit, multiplexed address/data bus, I/O access mode. The PCI interface for the digital I/O

is configured in an 8 bit, multiplexed address/data bus, I/O access mode to be register compatible with the

PCI-DIOxxH and PCI-DIO48/CTR15 boards. For an idea of how the PCI-DDA0X/12 is logically constructed, refer

to the block diagram below according to your particular model.

Gain Autocal Offset Autocal

3&,''$

%ORFN 'LDJUDP

DAC

Data

Control

12-Bit

DAC0

12-Bit

DAC1

VDAC 0

VDAC 1

PA0 (7:0)

PB0 (7:0)

PC0 (7:0)

PA1 (7:0)

PB1 (7:0)

PC1 (7:0)

Digital I/O

Port A

Port B

Port C

Digital I/O

Port A

Port B

Port C

Control

Control

PAL

Digital I/O

Controller

Decode/Sta tu s

CONTROLLER

Calibration

Control

Decode/Status

33 MHz LOCAL BUS

Boot

EEPROM

PLD

Output

DAC

Control

BADR0

PCI

CONTROLLER

PCI BUS (5V, 32-BIT, 33MHZ)

BADR1

BADR2

BADR3

Page 3

Page 5

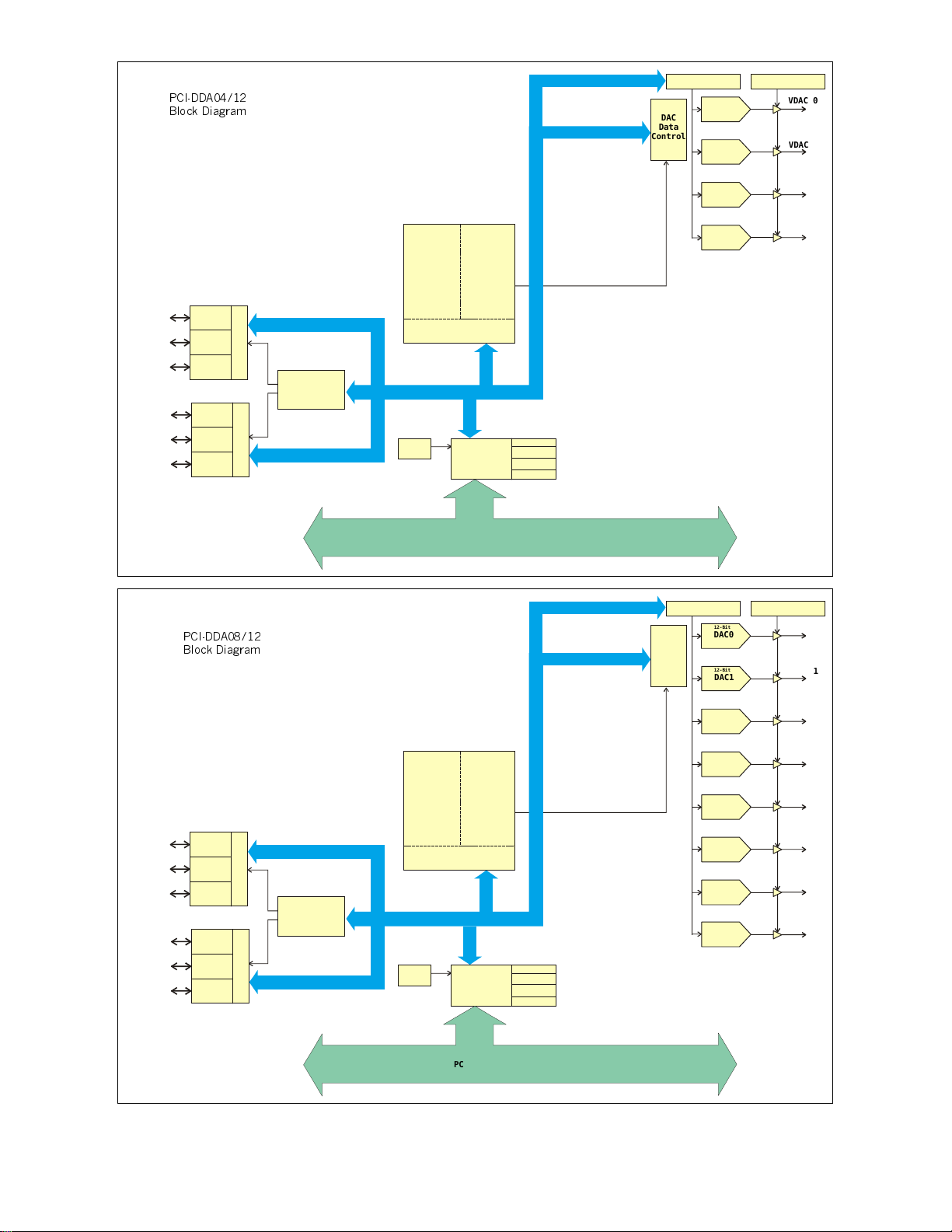

3&,''$

%ORFN 'LDJUDP

Gain Autocal Offset Autocal

12-Bit

DAC

Data

Control

DAC0

12-Bit

DAC1

VDAC 0

VDAC 1

PA0 (7:0)

PB0 (7:0)

PC0 (7:0)

PA1 (7:0)

PB1 (7:0)

PC1 (7:0)

Digital I/O

Port A

Port B

Control

Port C

Digital I/O

Port A

Port B

Control

Port C

3&,''$

%ORFN 'LDJUDP

PAL

Digital I/O

Controller

Decode/Sta tu s

CONTROLLER

Calibration

Control

Decode/Status

33 MHz LOCAL BUS

Boot

EEPROM

PLD

Output

DAC

Control

BADR0

PCI

CONTROLLER

BADR1

BADR2

BADR3

PCI BUS (5V, 32-BIT, 33MHZ)

12-Bit

DAC2

12-Bit

DAC3

Gain Autocal Offset Autocal

12-Bit

DAC

Data

Control

DAC0

12-Bit

DAC1

VDAC 2

VDAC 3

VDAC 0

VDAC 1

PA0 (7:0)

PB0 (7:0)

PC0 (7:0)

PA1 (7:0)

PB1 (7:0)

PC1 (7:0)

Digital I/O

Port A

Port B

Port C

Digital I/O

Port A

Port B

Port C

Control

Control

PAL

Digital I/O

Controller

Decode/Sta tu s

CONTROLLER

Calibration

Control

Decode/Status

33 MHz LOCAL BUS

Boot

EEPROM

PLD

Output

DAC

Control

BADR0

PCI

CONTROLLER

BADR1

BADR2

BADR3

PCI BUS (5V, 32-BIT, 33MHZ)

Page 4

12-Bit

DAC2

12-Bit

DAC3

12-Bit

DAC4

12-Bit

DAC5

12-Bit

DAC6

12-Bit

DAC7

VDAC 2

VDAC 3

VDAC 4

VDAC 5

VDAC 6

VDAC 7

Page 6

3.0 INSTALLATION

3.1 HARDWARE INSTALLATION

The PCI-DDA0x/12 products are completely plug and play. Simply follow the steps shown below to install your PCI

hardware.

1.

Turn your computer off, unplug it, open it up and insert the PCI board into any available PCI slot.

2.

Close your computer up, plug it back in and turn it on.

3.

Windows will automatically detect the board as it starts up. If the board's configuration file is already on the

system, it will load without user interaction. If the configuration file is not detected, you will be prompted to

insert the disk containing it. The required file is on the InstaCal or Universal Library disk you received with

your board. Simply insert the CD (or Disk 1 if your software is on floppy disk) into an appropriate drive and

click on

appear in the Device Manager under DAS Component.

If the file is not found on the first attempt, use the browse function to select the drive that contains the

InstaCAL or Universal Library disk, select the CBxx.INF file and then click on

CONTINUE

. The appropriate file should then be automatically loaded and the PCI board will

CONTINUE.

3.2 SOFTWARE INSTALLATION

3.2.1 INTRODUCTION

Insta

Cal is the installation, calibration and test software supplied with your data acquisition hardware. The complete

Insta

Cal package is also included with the Universal Library. If you have ordered the Universal Library, the Universal Library CD/disks install both the library and

the various pieces of compressed software. To install

the SETUP.EXE file contained on your CD, (or Disk 1 of the floppy disk set) and follow the on-screen instructions.

3.2.2 INSTALLATION OPTIONS

The Universal Library provides example programs for a wide var i ety of programming languages. If you are installing

the Universal Library, an "Installation Options" dialog box will allow you to select which languages' example

programs are loaded onto your computer. Select the desired example programs by checking the appropriate box(s).

3.2.3 FILE DEFAULT LOCATION

Insta

Cal will place all appropriate files in "C:CB" If you change this default location remember where the installed

files are placed as you may need to access them later.

3.2.4 INSTALLATION QUESTIONS

At the end of the installation process the installation wizard will ask a series of questions updating your startup files.

Unless you have knowledge to the contrary, simply accept the default (YES) when prompted. You will also be asked

if you would like to read an updated README file. If possible, please choose yes and take a look at the information

in the file. It will include the latest information regarding the software you are installing.

, WINDOWS

Insta

Cal. The installation will create all required files and unpack

Insta

Cal (and the Universal Library if applicable), simply run

95, 98 & NT

3.2.5 INSTALLATION COMPLETION

After the installation of

the system.

Insta

Cal is complete you should restart your computer to take advantage of changes made to

Page 5

Page 7

3.3 RUN INSTACAL

Run the InstaCal progr am in order to test your bo ard and co nfigure it for run-time use. By confi guring the boar d,

you add information to the configuration file, cb.cfg, that is used by the Universal Library and other third-party data

acquisition packages that use the Universal Library to access the board.

3.3.1 LAUNCHING InstaCAL

Launch InstaCal by going to your Start Menu then to Programs, then to ComputerBoards, and finally choosing Insta-

Cal. You may also launch the program by going to START >RUN and typing INSCAL32, or by finding the file

named "inscal32.exe" in your installation directory and double clicking it.

InstaCal will display a dialog box indicating the boards that have been detected in the system. If there are no other

boards currently installed by InstaCal, then the PCI-DDA0x/12 board will be assigned board number 0. Otherwise it

will be assigned the next available board number.

You can now view and change the b oa r d c o nfigur ati on b y clic king t he p ro p er ti es i co n o r se le cti ng the I nsta ll\Co nfigure menu.

3.3.2 TESTING THE INSTALLATION

After you have run the install program, it is time to test the installation. The following section describes the InstaCal

procedure to test that your board is properly installed.

With InstaCal running:

1. Select the board you just installed.

2. Select the "Test" function.

Follow the instructions provided to test for proper board operation.

3.4 DOS AND/OR WINDOWS 3.1

Most users are now installing PCI Bus boards in systems with 32-bit operating systems (e.g., Windo ws 95, 98 or

NT). The PCI-DDA0x/12 is not currently supported by the 16-bit library required to run under DOS or Windows

3.x.

Please contact us if your application is running under DOS or Windows 3.x.

Page 6

Page 8

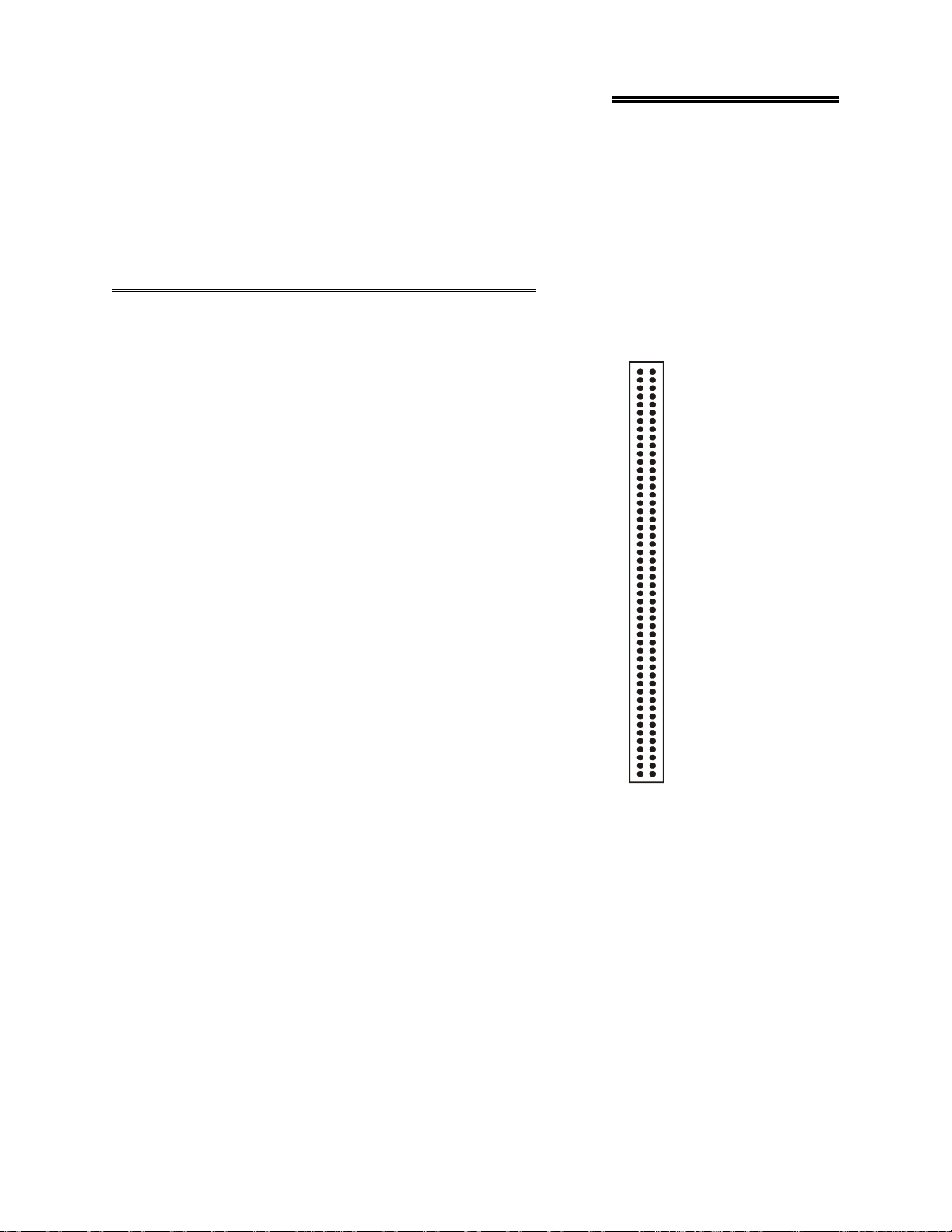

4.0 CONNECTIONS

The PCI-DDA0x/12 uses a single 100-pin connector on the back plate of the board to bring out all required digital

and analog lines and grounds.

PLEASE NOTE: If you have a PCI-DDA08/12, all instructions in this manual apply. If you have a PCI-DDA04/12,

you should ignore all references to D/A channels 4 through 7; and if you have a PCI-DDA02/12, you should ignore

all references to D/A channels 2 through 7. In all other respects, the three models are identical.

4.1 CONNECTING EXTERNAL LINES

The 100-pin connector provides a far greater signal density

than the traditional 37 pin D type connector. The ideal means

for breaking out the 100 lines from the PCI-DDA0X/12 are a

combination of one C100-FF-X series cable

and either one CIO-TERM100 screw terminal board or a pair of CIO-MINI50 screw

terminal boards.

Each of the C100-FF-x cable series consists of a ribbon cable

that is terminated at one end with a 100 pin connector that

mates with the connector on the PCI-DDA0x/12 board. The

100-conductor ribbon cable splits into two 50 pin ribbon

cables which are terminated with standard 50 pin header

connectors that connect to the CIO-TERM100

or

CIO-MINI50 screw terminal boards. The C100-FF-x is available in lengths of 1, 2, 3, 4, 5, 10, 15, 20, 25, and 50 feet,

where x is the length in feet. For example, a two-foot model

is designated C100-FF-2.

Vout 0 1

Analog Ground

Analog Ground

Analog Ground

Analog Ground

Analog Ground

Analog Ground

Analog Ground

Analog Ground16

Digital Ground 50

2

Vout 1 3

4

Vout 2 5

6

Vout 3 7

8

Vout 4 9

10

Vout 5 11

12

Vout 6 13

14

Vout 7 15

NC

17

NC

18

NC

19

NC

20

NC

21

NC

22

NC

23

NC

24

NC

25

NC

26

NC

27

NC

28

NC

29

NC

30

NC

31

NC

32

NC

33

NC

34

NC

35

NC

36

NC

37

NC

38

NC

39

NC

40

NC

41

NC

42

NC

43

NC

44

NC

45

NC

46

NC

47

NC

48

NC 49

PCI-DDA0x/12 Connector Diagram

51 P2-A7

52 P2-A6

53 P2-A5

2-

54 P A4

2-

55 P A3

2-

56 P A2

2-

57 P A1

2-

58 P A0

2-

59 P B7

2-

60 P B6

2-

61 P B5

2-

62 P B4

2-

63 P B3

2-

64 P B2

2-

65 P B1

2-

66 P B0

2-

67 P C7

2-

68 P C6

2-

69 P C5

2-

70 P C4

2-

71 P C3

2-

72 P C2

2-

73 P C1

2-

74 P C0

-

75 P1A7

1-

76 P A6

1-

77 P A5

1-

78 P A4

1-

79 P A3

1-

80 P A2

1-

81 P A1

1-

82 P A0

1-

83 P B7

1-

84 P B6

1-

85 P B5

1-

86 P B4

1-

87 P B3

1-

88 P B2

1-

89 P B1

1-

90 P B0

1-

91 P C7

1-

92 P C6

1-

93 P C5

1-

94 P C4

1-

95 P C3

1-

96 P C2

1-

97 P C1

1-

98 P C0

99 +5V

100 Digital Ground

Page 7

Page 9

4.2 ANALOG CONNECTIONS

The analog output connections on the PCI-DDA0x/12 series are two-wire hookups, one end of which is the signal

labeled Voutx, with x being the channel number from 0 to 7 (PCI-DDA08/12), 0 to 3 (PCI-DDA04/12), and 0 to 1

(PCI-DDA02/12). The other end is the associated analog ground. In software you may select analog ranges of ±10V,

±5V, ±2.5V, 0 - 10V, 0 - 5V, and 0 - 2.5V. Each port may be reconfigured easily and quickly.

4.3 DIGITAL CONNECTIONS

The PCI-DDA0x/12 emulates two 82C55 chips, but offers much higher drive capability than the 82C55. The board

emulates only Mode 0 of the 82C55 (no strobed I/O or bi-directional I/O bits). The board is completely plug-andplay without any onboard user configurable switches or jumpers. The 48 CMOS/TTL compatible digital I/O lines are

configured in four banks of 8 and four banks of 4. Each group may be input or output.

All the digital outputs/inputs on the PCI-DDA0x/12 connector are TTL compatible. TTL is an electronics industry

term, short for Transistor Transistor Logic, which describes a standard for digital signals which are either at 0V or

5V. The binary logic inside the PC is all TTL or LSTTL (Low power Schottky TTL).

The outputs ar e cap a bl e o f sinking 6 4 mA or so urc ing 1 5 mA. All I/O is b r ought o ut to the 100-pin connector, which

also allows connection to the PC’s +5 Volt and Ground.

Keep in mind that unco nnected inputs flo at. If you are using a DIO bo ard for input, and have unconnecte d inputs,

ignore the data from those lines. In other words, if you connect bit A0 and not bit A1, do not be surprised if A1 stays

low, stays high or tracks A0. In the absence of a pull-up/down resistor, any input to a CIO-DIO which is unconnected is unspecified.

You do not have to connect all input lines, and unconnected lines will not affect the performance of connected lines.

Just make sure that you mask out any unconnected bits in software.

4.3.1 Pull Up and Pull Down Resistors

Whenever the board is powered on or reset, all ports are set to input mode. Inputs will typically float high, but will

not reliably supply enough output current to ensure that external d evices you have connected will “see” a logic 1.

Which way they float depends on the characteristics of the circuits connected and is unpredictable! If it is important

that your system go into a predetermined state on power up or reset, you need pull up/down resistors.

The pull-up resistor pulls the input to a high state (+5V) while its value of 2200 ohms requires only 2 ma of the 64

mA available from the output. A 2200 ohm pull-down resistor accomplishes the same task except that the line is

pulled low when the board is input mode (and uses only 2 mA of the available 15 mA output provided by the board).

The PCI-DDA0X boards are equipp ed with positions for pull-up/down resistors Single Inline Packages (SIPs). T he

positions are marked A, B and C and are located behind board’s I/O connector.

A 2.2K ohm, 9-resistor SIP is made of 9, 2.2K resistors all connected one side to a single common point and the

other, each to a pin protruding from the SIP. The common line to which all resistor are connected also protrudes

from the SIP. The common line is marked with a dot and is at one end of the SIP.

The SIP may be installed as pull-up or pull-down. At each SIP location, there are 10 holes in a line. One end of the

line is +5V, the other end is GND. They are so marked. The 8 holes in the middle are connected to the 8 lines of the

port.

Page 8

Page 10

5.0 PROGRAMMING & APPLICATIONS

Your PCI-DDA0x/12 is supported by the powerful Universal Library. We strongly recommend that

you take advantage of the Universal Library as your software interface. The complexity of the registers required for

automatic calibration combined with the dynamic allocation of addresses and internal resources makes the

PCI-DDA0x/12 series very challenging to program via direct register I/O operations. Direct I/O programming

should not be required.

5.1 PROGRAMMING LANGUAGES

The Universal Library provides complete access to the PCI-DDA0x/12 functions from a range of

Windows programming languages. If you are planning to write programs, or would like to run the example

programs for Visual Basic or any other language, please refer to the Universal Library manual.

The optional VIX Components package may greatly simplify your programming effort. VIX Components is a set of

programming tools based on a DLL interface to Windows languages. A set of VBX, OCX, and ActiveX interfaces

allows point and click construction of graphical displays, analysis and control structures. Please see a ComputerBoards product catalog or contact us for a complete description of VIX Components.

5.2 PACKAGED THIRD-PARTY APPLICATIONS PROGRAMS

In addition to DAS-Wizard, many packaged third-party application programs such as Labtech

Notebook and HP-VEE now have drivers for the PCI-DDA0x/12. If the package you own does not appear to have

drivers for the PCI-DDA0x/12 please fax or e-mail the package name and the revision number from the install disks.

We will research the package for you and advise how to obtain PCI-DDA0x/12 drivers.

Some application drivers that are included with Universal Library are not included with third-party application

packages. If you have purchased an application package directly from the software vendor, you may need to

purchase our Universal Library and drivers. Please contact us for more information on this topic.

Page 9

Page 11

6.0 Self-Calibration

The PCI-DDA0x/12 is shipped fully-calibrated from the factory with calibration coefficients stored in nonvolatile

RAM. When using the Universal Library, these calibration factors are read from nonvolatile RAM and are automatically written to the calibration DACS each time a different DAC range is specified. The user has the option to recalibrate with respect to the factory-measured voltage standards at any time by simply selecting the "Calibrate" option in

InstaCal. Instacal will calibrate all channels at all six ranges. Each channel takes less than a minute to calibrate.

6.1 CALIBRATION CONFIGURATION

The PCI-DDA0x/12 provides self-calibration of the analog source and measure systems thereby eliminating the need

for external equipment and user adjustments. Calibration factors are stored on the serial nonvolatile RAM.

The analog output circuits are calibrated for both gain and offset. Gain calibration of the analog outputs are

performed via DAC reference adjustments. Offset adjustments for the analog output are made in the output buffer

section. A block diagram of the PCI-DDA0x/12 series calibration circuitry is shown below.

VHULDO

*DLQ $GMXVW

&RDUVH

7ULP '$&V

)LQH

3UHFLVLRQ

9

VHULDO

3&,''$ &DOLEUDWLRQ %ORFN 'LDJUDP

2XWSXW '$&

AD78 37

9UHI

2IIVHW $GMXVW

VHULDO

&RDUVH

7ULP '$&V

)LQH

3URJUDPDEOH 9ROWDJH VRXUFH

0$;

5HIHUHQFH '$&

9RXW

3*$

;

2XWSXW

9ROWDJHV

6HWSRLQW 9ROWDJH

[

2XWSXW 9ROWDJH

3UHFLVLRQ

&RPSDUDWRU

&203

&RXQWHU

&/($5

Page 10

Page 12

6.2 "IN-SYSTEM" CALIBRATION

The PCI-DDA0x/12 is calibrated at the factory for the correct voltages at the I/O connector itself. For more precise

application of voltages at the "system end", we have provided a version of InstaCAL that allows you to calibrate the

board within your system, for correct voltages at your field connection. This calibration allows the user to remove

the effects of voltage drops caused by IR loss in the cable and connector for resistances up to 1 ohm. This calibration

will also allow the user to zero out errors in any external signal conditioning up to approximately ± 10 mV.

Please contact the factory for details regarding the use of this "in-system" calibration feature.

Page 11

Page 13

7.0 Register Description

We strongly urge users to take advantage of the Universal Library software package rather than attempt to write

register level software for the PCI-DDA0x/12 series. The register level programming information is provided as a

matter of completeness only. Register level programming of this or any other software calibrating PCI board is quite

complex and should only be attempted by highly experienced programmer.

7.1 REGISTER OVERVIEW

NOTE: please ignore references to D/A channels 4 through 7 on the PCI-DDA04/12, and references to channels 2

through 7 on the PCI-DDA02/12. Otherwise, the three boards are identical.

PCI-DDA0x/12 operation registers are mapped into I/O space. Unlike ISA bus designs, this board has several base

addresses, each corresponding to a reserved block of addresses in I/O space.

Of the six Base Address Regions (BADR) available per the PCI 2.1 specification, four are implemented in this

design and are summarized as follows.

OperationsFunctionI/O Region

32-bit DOUBLE WORDPCI memory mapped configuration registersBADR0

32-bit DOUBLE WORDPCI I/O mapped configuration registersBADR1

8-bit BYTEDigital I/O registersBADR2

16-bit WORDDAC registersBADR3

BADR0 and BADR1 are used for PCI configuration and should be used only by experienced programmers familiar

with the PCI interface. BADR2 is an 8-bit data/address bus for compatibility with our other digital I/O PCI cards.

BADR3 is a 16-bit data/address bus for software ease when writing to the 12-bit DACs.

7.2 BADR2

Write FunctionRead FunctionRegister

Output Port 1A DataInput Port 1A DataBADR2 + 0

Output Port 1B DataInput Port 1B DataBADR2 + 1

Output Port 1C DataInput Port 1C DataBADR2 + 2

Control Register 1Control register readback 1BADR2 + 3

Output Port 2A DataInput Port 2A DataBADR2 + 4

Output Port 2B DataInput Port 2B DataBADR2 + 5

Output Port 2C DataInput Port 2C DataBADR2 + 6

Control Register 2Control register readback 2BADR2 + 7

The Digital I/O ports simulate the 8255 Mode 0 function

PORT 1A DATA

BADR2 + 0hex

READ/WRITE

.

01234567

A0A1A2A3A4A5A6A7

Page 12

Page 14

PORT 1B DATA

BADR2 + 1hex

READ/WRITE

01234567

B0B1B2B3B4B5B6B7

PORT 1C DATA

BADR2 + 02hex

READ/WRITE

01234567

CL0CL1CL2CL3CH0CH1CH2CH3

CONTROL REGISTER 1

BADR2 + 03hex

READ/WRITE

01234567

D0D1-D3D4---

The operating mode of the Digital I/O port is set to Mode 0. The control register therefore is used to enable the ports

for input/output to the connector. For example, to set all ports to output, write the value 0hex to BADR2 + 3. To set

all ports to input, write the value 1Bhex to Base + 3. T he user is able to read the current state of the output por t by

simply reading that port when set to be output. D7, D6, D5, and D2 are ‘don’t care’. ‘CU’ is PORT C upper nibble,

‘CL’ is PORT C lower nibble.

Table 1.0

DIO PortValuesProgramming Codes

CUBADecHexD0D1D3D4

CL

OUTOUTOUTOUT000000

INOUTOUTOUT111000

OUTOUTINOUT220100

INOUTINOUT331100

OUTINOUTOUT880010

ININOUTOUT991010

OUTININOUT10A0110

INININOUT11B1110

OUTOUTOUTIN16100001

INOUTOUTIN17111001

OUTOUTININ18120101

INOUTININ19131101

OUTINOUTIN24180011

ININOUTIN25191011

OUTINININ261A0111

ININININ271B1111

Page 13

Page 15

PORT 2A DATA

BADR2 + 04hex

READ/WRITE

PORT 2B DATA

BADR2 + 05hex

READ/WRITE

PORT 2C DATA

BADR2 + 06hex

READ/WRITE

01234567

A0A1A2A3A4A5A6A7

01234567

B0B1B2B3B4B5B6B7

01234567

CL0CL1CL2CL3CH0CH1CH2CH3

CONTROL REGISTER 2

BADR2 + 07hex

READ/WRITE

See BADR2 + 03hex and TABLE 1.0 for full description of the Control Register.

7.3 BADR3

WRITE FUNCTIONREAD FUNCTIONREGISTER

D/A Control RegisterInitiate a simultaneous updateBADR3 + 0

reservedBADR3 + 2h

D/A Calibration Register 1 D/A Calibration Register 1 DataBADR3 + 4h

D/A Calibration Register 2BADR3 + 6h

D/A 0 DATA BADR3 + 8h

D/A 1 DATABADR3 + Ah

D/A 2 DATABADR3 + Ch

D/A 3 DATABADR3 + Eh

D/A 4 DATABADR3 + 10h

D/A 5 DATABADR3 + 12h

D/A 6 DATABADR3 + 14h

D/A 7 DATABADR3 + 16h

01234567

D0D1-D3D4---

Page 14

Page 16

D/A CONTROL REGISTER

BADR3 + 0hex

WRITE

SU

This bit enables simultaneous update for the DAC pair specified by D2 and D1 (see table below). Setting the simultaneous update bit inhibits updating the DAC output until a simultaneous update is initiated (see READ below). The

DACs are paired as follows; DACs 0 and 1, DACs 2 and 3, DACs 4 and 5, and DACs 6 and 7. Setting simultaneous

update for either DAC in the pair will set it for both.

The power on status of this bit is 0

EN

This bit enables the DAC specified by D2, D1, D0.

The power on status of this bit is 0. A disabled DAC is held at 0v.

D[2:0]

These bits specify the DAC that is being configured.

0123456789101112131415

SUEND0D1D2XR0R1R2XXXXXXX

0 = Simultaneous update disabled

1 = Simultaneous update enabled

0 = DAC disabled

1 = DAC enabled

R[2:0]

These bits select the gain/range for the DAC specified by D2, D1, and D0.

The power on setting is Bipolar 2.5V.

DAC ChannelD0D1D2

0000

1100

2010

3110

4001

5101

6011

7111

LSB SizeRANGER0R1R2

1.22mVBipolar 2.5VX00

2.44mVBipolar 5V010

4.88mVBipolar 10V110

611uVUnipolar 2.5VX01

1.22mVUnipolar 5V011

2.44mVUnipolar 10V111

Page 15

Page 17

READ

Reading this register initiates a simultaneous update for all DACs.

D/A CALIBRATION REGISTER 1

BADR3 + 4hex

WRITE

01234567

SDIMA0MA1MA2XXXX

SDI

This is the serial data in bit for the calibration EEPROM, the 16-bit reference DAC, and the 8-bit trim DACs.

Writing to this register will automatically generate the correct serial clock.

NOTE: You must preserve the status of MA2:MA0 when adjusting the offset and gain calibration DACs.

MA[2:0]

These bits select the DAC to be calibrated

DAC ChannelMA0MA1MA2

0000

1100

2010

3110

4001

5101

6011

7111

READ

01234567

D0D1D2D3D4OVERFLOWCOMPSDO

D[4:0]

These bits are the output of the 5 bit calibration counter. D0 is the LSB. Each time you initiate a read, the counter is

first cleared and then gated (allowed to count) for a fixed period. This ensures that all count periods are identical.

OVERFLOW

This bit indicates that a 5-bit calibration counter overflow.

0 = no counter overflow

1 = counter overflow

Page 16

Page 18

COMP

This bit comes from the output of the calibration comparitor.

0 = DAC voltage is greater than the calibration reference voltage

1 = DAC voltage is less than the calibration reference voltage

SDO

This is the serial data out bit for the calibration EEPROM. Reading this register will automatically generate the

correct serial clock.

D/A CALIBRATION REGISTER 2

BADR3 + 6hex

WRITE ONLY

01234567

SEL_EEPROMSEL_542SEL8800_01SEL8800_23SEL8800_45SEL8800_671X

SEL_EEPROM

This bit is the chip select for the calibration EEPROM. It is active high and should be initialized to 0. Make sure that

none of the DACs discussed below are enabled at the same time as the EEPROM because they share common serial

data and clock lines. The calibration EEPROM is the NM93C56 which is divided into 128 16-bit words. The

memory map is listed in the tables below. Data is clocked in and out on the rising edge of the serial clock. The

decoding logic on the board drives the serial clock automatically so no additional programming is required. You

must send a WREN (write enable) command to the device before trying to write to it.

DescriptionAddress

+9.99756V Reference DAC 16-bit word 00h

+9.99512V Reference DAC 16-bit word 01h

+4.99878V Reference DAC 16-bit word 02h

+4.99756V Reference DAC 16-bit word03h

+2.49939V Reference DAC 16-bit word04h

+2.49878V Reference DAC 16-bit word05h

0V Reference DAC 16-bit word06h

Table 2.0 EEPROM Memory Map for the Reference DAC

Page 17

Page 19

Lower ByteUpper ByteAddress

Bipolar 10V Trim DAC0 Fine OffsetBipolar 10V Trim DAC0 Coarse Offset07h

Bipolar 10V Trim DAC0 Fine GainBipolar 10V Trim DAC0 Coarse Gain08h

Bipolar 5V Trim DAC0 Fine OffsetBipolar 5V Trim DAC0 Coarse Offset09h

Bipolar 5V Trim DAC0 Fine GainBipolar 5V Trim DAC0 Coarse Gain0Ah

Bipolar 2.5V Trim DAC0 Fine OffsetBipolar 2.5V Trim DAC0 Coarse Offset0Bh

Bipolar 2.5V Trim DAC0 Fine GainBipolar 2.5V Trim DAC0 Coarse Gain0Ch

Unipolar 10V Trim DAC0 Fine OffsetUnipolar 10V Trim DAC0 Coarse Offset0Dh

Unipolar 10V Trim DAC0 Fine GainUnipolar 10V Trim DAC0 Coarse Gain0Eh

Unipolar 5V Trim DAC0 Fine OffsetUnipolar 5V Trim DAC0 Coarse Offset0Fh

Unipolar 5V Trim DAC0 Fine GainUnipolar 5V Trim DAC0 Coarse Gain10h

Unipolar 2.5V Trim DAC0 Fine OffsetUnipolar 2.5V Trim DAC0 Coarse Offset11h

Unipolar 2.5V Trim DAC0 Fine GainUnipolar 2.5V Trim DAC0 Coarse Gain12h

Bipolar 10V Trim DAC1 Fine OffsetBipolar 10V Trim DAC1 Coarse Offset13h

Bipolar 10V Trim DAC1 Fine GainBipolar 10V Trim DAC1 Coarse Gain14h

Bipolar 5V Trim DAC1 Fine OffsetBipolar 5V Trim DAC1 Coarse Offset15h

Bipolar 5V Trim DAC1 Fine GainBipolar 5V Trim DAC1 Coarse Gain16h

Bipolar 2.5V Trim DAC1 Fine OffsetBipolar 2.5V Trim DAC1 Coarse Offset17h

Bipolar 2.5V Trim DAC1 Fine GainBipolar 2.5V Trim DAC1 Coarse Gain18h

Unipolar 10V Trim DAC1 Fine OffsetUnipolar 10V Trim DAC1 Coarse Offset19h

Unipolar 10V Trim DAC1 Fine GainUnipolar 10V Trim DAC1 Coarse Gain1Ah

Unipolar 5V Trim DAC1 Fine OffsetUnipolar 5V Trim DAC1 Coarse Offset1Bh

Unipolar 5V Trim DAC1 Fine GainUnipolar 5V Trim DAC1 Coarse Gain1Ch

Unipolar 2.5V Trim DAC1 Fine OffsetUnipolar 2.5V Trim DAC1 Coarse Offset1Dh

Unipolar 2.5V Trim DAC1 Fine GainUnipolar 2.5V Trim DAC1 Coarse Gain1Eh

Bipolar 10V Trim DAC2 Fine OffsetBipolar 10V Trim DAC2 Coarse Offset1Fh

Bipolar 10V Trim DAC2 Fine GainBipolar 10V Trim DAC2 Coarse Gain20h

Bipolar 5V Trim DAC2 Fine OffsetBipolar 5V Trim DAC2 Coarse Offset21h

Bipolar 5V Trim DAC2 Fine GainBipolar 5V Trim DAC2 Coarse Gain22h

Bipolar 2.5V Trim DAC2 Fine OffsetBipolar 2.5V Trim DAC2 Coarse Offset23h

Bipolar 2.5V Trim DAC2 Fine GainBipolar 2.5V Trim DAC2 Coarse Gain24h

Unipolar 10V Trim DAC2 Fine OffsetUnipolar 10V Trim DAC2 Coarse Offset25h

Unipolar 10V Trim DAC2 Fine GainUnipolar 10V Trim DAC2 Coarse Gain26h

Unipolar 5V Trim DAC2 Fine OffsetUnipolar 5V Trim DAC2 Coarse Offset27h

Unipolar 5V Trim DAC2 Fine GainUnipolar 5V Trim DAC2 Coarse Gain28h

Unipolar 2.5V Trim DAC2 Fine OffsetUnipolar 2.5V Trim DAC2 Coarse Offset29h

Unipolar 2.5V Trim DAC2 Fine GainUnipolar 2.5V Trim DAC2 Coarse Gain2Ah

Table 3.0 Calibration EEPROM Memory Map for Trim DACs

Page 18

Page 20

Lower ByteUpper ByteAddress

Bipolar 10V Trim DAC3 Fine OffsetBipolar 10V Trim DAC3 Coarse Offset2Bh

Bipolar 10V Trim DAC3 Fine GainBipolar 10V Trim DAC3 Coarse Gain2Ch

Bipolar 5V Trim DAC3 Fine OffsetBipolar 5V Trim DAC3 Coarse Offset2Dh

Bipolar 5V Trim DAC3 Fine GainBipolar 5V Trim DAC3 Coarse Gain2Eh

Bipolar 2.5V Trim DAC3 Fine OffsetBipolar 2.5V Trim DAC3 Coarse Offset2Fh

Bipolar 2.5V Trim DAC3 Fine GainBipolar 2.5V Trim DAC3 Coarse Gain30h

Unipolar 10V Trim DAC3 Fine OffsetUnipolar 10V Trim DAC3 Coarse Offset31h

Unipolar 10V Trim DAC3 Fine GainUnipolar 10V Trim DAC3 Coarse Gain32h

Unipolar 5V Trim DAC3 Fine OffsetUnipolar 5V Trim DAC3 Coarse Offset33h

Unipolar 5V Trim DAC3 Fine GainUnipolar 5V Trim DAC3 Coarse Gain34h

Unipolar 2.5V Trim DAC3 Fine OffsetUnipolar 2.5V Trim DAC3 Coarse Offset35h

Unipolar 2.5V Trim DAC3 Fine GainUnipolar 2.5V Trim DAC3 Coarse Gain36h

Bipolar 10V Trim DAC4 Fine OffsetBipolar 10V Trim DAC4 Coarse Offset37h

Bipolar 10V Trim DAC4 Fine GainBipolar 10V Trim DAC4 Coarse Gain38h

Bipolar 5V Trim DAC4 Fine OffsetBipolar 5V Trim DAC4 Coarse Offset39h

Bipolar 5V Trim DAC4 Fine GainBipolar 5V Trim DAC4 Coarse Gain3Ah

Bipolar 2.5V Trim DAC4 Fine OffsetBipolar 2.5V Trim DAC4 Coarse Offset3Bh

Bipolar 2.5V Trim DAC4 Fine GainBipolar 2.5V Trim DAC4 Coarse Gain3Ch

Unipolar 10V Trim DAC4 Fine OffsetUnipolar 10V Trim DAC4 Coarse Offset3Dh

Unipolar 10V Trim DAC4 Fine GainUnipolar 10V Trim DAC4 Coarse Gain3Eh

Unipolar 5V Trim DAC4 Fine OffsetUnipolar 5V Trim DAC4 Coarse Offset3Fh

Unipolar 5V Trim DAC4 Fine GainUnipolar 5V Trim DAC4 Coarse Gain40h

Unipolar 2.5V Trim DAC4 Fine OffsetUnipolar 2.5V Trim DAC4 Coarse Offset41h

Unipolar 2.5V Trim DAC4 Fine GainUnipolar 2.5V Trim DAC4 Coarse Gain42h

Bipolar 10V Trim DAC5 Fine OffsetBipolar 10V Trim DAC5 Coarse Offset43h

Bipolar 10V Trim DAC5 Fine GainBipolar 10V Trim DAC5 Coarse Gain44h

Bipolar 5V Trim DAC5 Fine OffsetBipolar 5V Trim DAC5 Coarse Offset45h

Bipolar 5V Trim DAC5 Fine GainBipolar 5V Trim DAC5 Coarse Gain46h

Bipolar 2.5V Trim DAC5 Fine OffsetBipolar 2.5V Trim DAC5 Coarse Offset47h

Bipolar 2.5V Trim DAC5 Fine GainBipolar 2.5V Trim DAC5 Coarse Gain48h

Unipolar 10V Trim DAC5 Fine OffsetUnipolar 10V Trim DAC5 Coarse Offset49h

Unipolar 10V Trim DAC5 Fine GainUnipolar 10V Trim DAC5 Coarse Gain4Ah

Unipolar 5V Trim DAC5 Fine OffsetUnipolar 5V Trim DAC5 Coarse Offset4Bh

Unipolar 5V Trim DAC5 Fine GainUnipolar 5V Trim DAC5 Coarse Gain4Ch

Unipolar 2.5V Trim DAC5 Fine OffsetUnipolar 2.5V Trim DAC5 Coarse Offset4Dh

Unipolar 2.5V Trim DAC5 Fine GainUnipolar 2.5V Trim DAC5 Coarse Gain4Eh

Table 3.0 (cont.) Calibration EEPROM Memory Map for Trim DACs

Page 19

Page 21

Lower ByteUpper ByteAddress

Bipolar 10V Trim DAC6 Fine OffsetBipolar 10V Trim DAC6 Coarse Offset4Fh

Bipolar 10V Trim DAC6 Fine GainBipolar 10V Trim DAC6 Coarse Gain50h

Bipolar 5V Trim DAC6 Fine OffsetBipolar 5V Trim DAC6 Coarse Offset51h

Bipolar 5V Trim DAC6 Fine GainBipolar 5V Trim DAC6 Coarse Gain52h

Bipolar 2.5V Trim DAC6 Fine OffsetBipolar 2.5V Trim DAC6 Coarse Offset53h

Bipolar 2.5V Trim DAC6 Fine GainBipolar 2.5V Trim DAC6 Coarse Gain54h

Unipolar 10V Trim DAC6 Fine OffsetUnipolar 10V Trim DAC6 Coarse Offset55h

Unipolar 10V Trim DAC6 Fine GainUnipolar 10V Trim DAC6 Coarse Gain56h

Unipolar 5V Trim DAC6 Fine OffsetUnipolar 5V Trim DAC6 Coarse Offset57h

Unipolar 5V Trim DAC6 Fine GainUnipolar 5V Trim DAC6 Coarse Gain58h

Unipolar 2.5V Trim DAC6 Fine OffsetUnipolar 2.5V Trim DAC6 Coarse Offset59h

Unipolar 2.5V Trim DAC6 Fine GainUnipolar 2.5V Trim DAC6 Coarse Gain5Ah

Bipolar 10V Trim DAC7 Fine OffsetBipolar 10V Trim DAC7 Coarse Offset5Bh

Bipolar 10V Trim DAC7 Fine GainBipolar 10V Trim DAC7 Coarse Gain5Ch

Bipolar 5V Trim DAC7 Fine OffsetBipolar 5V Trim DAC7 Coarse Offset5Dh

Bipolar 5V Trim DAC7 Fine GainBipolar 5V Trim DAC7 Coarse Gain5Eh

Bipolar 2.5V Trim DAC7 Fine OffsetBipolar 2.5V Trim DAC7 Coarse Offset5Fh

Bipolar 2.5V Trim DAC7 Fine GainBipolar 2.5V Trim DAC7 Coarse Gain60h

Unipolar 10V Trim DAC7 Fine OffsetUnipolar 10V Trim DAC7 Coarse Offset61h

Unipolar 10V Trim DAC7 Fine GainUnipolar 10V Trim DAC7 Coarse Gain62h

Unipolar 5V Trim DAC7 Fine OffsetUnipolar 5V Trim DAC7 Coarse Offset63h

Unipolar 5V Trim DAC7 Fine GainUnipolar 5V Trim DAC7 Coarse Gain64h

Unipolar 2.5V Trim DAC7 Fine OffsetUnipolar 2.5V Trim DAC7 Coarse Offset65h

Unipolar 2.5V Trim DAC7 Fine GainUnipolar 2.5V Trim DAC7 Coarse Gain66h

Table 3.0 (cont.) Calibration EEPROM Memory Map for Trim DACs

Page 20

Page 22

Read word programming sequence

1.

Select the EEPROM by writing 127 (7Fh) to BADR3 + 6hex (D/A CALIBRATION REGISTER 2).

2.

Write 01h to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

3.

Write 01h to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

4.

Write 00h to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

5.

Write address bit 7 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

6.

Write address bit 6 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

7.

Write address bit 5 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

8.

Write address bit 4 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

9.

Write address bit 3 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

10.

Write address bit 2 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

11.

Write address bit 1 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

12.

Write address bit 0 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

13.

Read BADR3 + 4hex (D/A CALIBRATION REGISTER 1). Data bit 15 will be in register bit 7.

14.

Read BADR3 + 4hex (D/A CALIBRATION REGISTER 1). Data bit 14 will be in register bit 7.

15.

Read BADR3 + 4hex (D/A CALIBRATION REGISTER 1). Data bit 13 will be in register bit 7.

16.

Read BADR3 + 4hex (D/A CALIBRATION REGISTER 1). Data bit 12 will be in register bit 7.

17.

Read BADR3 + 4hex (D/A CALIBRATION REGISTER 1). Data bit 11 will be in register bit 7.

18.

Read BADR3 + 4hex (D/A CALIBRATION REGISTER 1). Data bit 10 will be in register bit 7.

19.

Read BADR3 + 4hex (D/A CALIBRATION REGISTER 1). Data bit 9 will be in register bit 7.

20.

Read BADR3 + 4hex (D/A CALIBRATION REGISTER 1). Data bit 8 will be in register bit 7.

21.

Read BADR3 + 4hex (D/A CALIBRATION REGISTER 1). Data bit 7 will be in register bit 7.

22.

Read BADR3 + 4hex (D/A CALIBRATION REGISTER 1). Data bit 6 will be in register bit 7.

23.

Read BADR3 + 4hex (D/A CALIBRATION REGISTER 1). Data bit 5 will be in register bit 7.

24.

Read BADR3 + 4hex (D/A CALIBRATION REGISTER 1). Data bit 4 will be in register bit 7.

25.

Read BADR3 + 4hex (D/A CALIBRATION REGISTER 1). Data bit 3 will be in register bit 7.

26.

Read BADR3 + 4hex (D/A CALIBRATION REGISTER 1). Data bit 2 will be in register bit 7.

27.

Read BADR3 + 4hex (D/A CALIBRATION REGISTER 1). Data bit 1 will be in register bit 7.

28.

Read BADR3 + 4hex (D/A CALIBRATION REGISTER 1). Data bit 0 will be in register bit 7.

29.

Deselect the EEPROM by writing 127 (7Eh) to BADR3 + 6hex (D/A CALIBRATION REGISTER 2).

Page 21

Page 23

Write enable programming sequence

1.

Select the EEPROM by writing 127 (7Fh) to BADR3 + 6hex (D/A CALIBRATION REGISTER 2).

2.

Write 01h to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

3.

Write 00h to bit 0 of BADR1 + 4hex (D/A CALIBRATION REGISTER 1).

4.

Write 00h to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

5.

Write 01h to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

6.

Write 01h to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

7.

Write 01h to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

8.

Write 01h to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

9.

Write 01h to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

10.

Write 01h to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

11.

Write 01h to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

12.

Write 01h to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

13.

Deselect the EEPROM by writing 126 (7Eh) to BADR3 + 6hex (D/A CALIBRATION REGISTER 2).

Write word programming sequence

1.

Select the EEPROM by writing 127 (7Fh) to BADR3 + 6hex (D/A CALIBRATION REGISTER 2).

2.

Write 01h to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

3.

Write 00h to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

4.

Write 01h to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

5.

Write address bit 7 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

6.

Write address bit 6 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

7.

Write address bit 5 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

8.

Write address bit 4 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

9.

Write address bit 3 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

10.

Write address bit 2 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

11.

Write address bit 1 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

12.

Write address bit 0 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

13.

Write data bit 15 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

14.

Write data bit 14 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

15.

Write data bit 13 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

Page 22

Page 24

16.

Write data bit 12 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

17.

Write data bit 11 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

18.

Write data bit 10 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

19.

Write data bit 9 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

20.

Write data bit 8 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

21.

Write data bit 7 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

22.

Write data bit 6 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

23.

Write data bit 5 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

24.

Write data bit 4 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

25.

Write data bit 3 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

26.

Write data bit 2 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

27.

Write data bit 1 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

28.

Write data bit 0 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

29.

Deselect the EEPROM by writing 126 (7Eh) to BADR3 + 6hex (D/A CALIBRATION REGISTER 2).

30.

Delay 10 ms before selecting the EEPROM again.

SEL_542

This bit is the chip select for the 16 bit serial reference DAC.

sure that the EEPROM and the trim DACs are not enabled at the same time as the reference DAC because they share

common serial data and clock lines. The reference DAC is the MAX542 which is a 16-bit voltage output serial

DAC. The reference voltage range is +/-10V (created by using the MAX542 in bipolar mode and amplifying its

output with a x4 precision amplifier.) Data is clocked in and out on the rising edge of the serial clock. The decoding

logic on the board drives the serial clock automatically so no additional programming is required. The calibration

values for the reference DAC have been set at the factory and can be read from the EEPROM, see table 1 above.

It is active low and should be initialized t o 1 .

Make

Write word programming sequence

1.

Select the MAX542 by writing 124 (7Ch) to BADR3 + 6hex (D/A CALIBRATION REGISTER 2).

2.

Write data bit 15 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

3.

Write data bit 14 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

4.

Write data bit 13 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

5.

Write data bit 12 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

6.

Write data bit 11 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

7.

Write data bit 10 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

8.

Write data bit 9 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

9.

Write data bit 8 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

Page 23

Page 25

10.

Write data bit 7 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

11.

Write data bit 6 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

12.

Write data bit 5 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

13.

Write data bit 4 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

14.

Write data bit 3 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

15.

Write data bit 2 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

16.

Write data bit 1 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

17.

Write data bit 0 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

18.

Deselect the MAX542 by writing 126 (7Eh) to BADR3 + 6hex (D/A CALIBRATION REGISTER 2).

SEL8800_xy

These bits are the load_dac controls for the offset and gain Trim DACs, DAC8800s, which are 8 channel, 8-bit,

voltage output, serial DACs.

and the reference DAC discussed above are not enabled at the same time as the trim DACs because they share

common serial data and clock lines. Each DAC8800 is used for the calibration of two output DACs, xy. For

example, bit 2, SEL8800_01, is the chip select for the DAC8800 that calibrates output DACs 0 and 1. There are

course and fine adjust DAC outputs for both offset and gain error calibration (see table below). Data is clocked in

on the rising edge of the serial clock. The decoding logic on the board drives the serial clock automatically so no

additional programming is required.

They are active low and should be initia lized to 1.

Make sure that the EEPROM

A0A1A2Cal FunctionTrim DAC Channel

000DACx Fine Gain0

100DACx Coarse Gain1

010DACx Coarse Offset2

110DACx Fine Offset3

001DACy Fine Gain4

101DACy Coarse Gain5

011DACy Coarse Offset6

111DACy Fine Offset7

Write byte programming sequence

1.

Write address bit A2 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1). See table

above for correct value of A2.

2.

Write address bit A1 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1). See table

above for correct value of A1.

3.

Write address bit A0 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1). See table

above for correct value of A0.

4.

Write data bit 7 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

5.

Write data bit 6 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

6.

Write data bit 5 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

Page 24

Page 26

7.

Write data bit 4 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

8.

Write data bit 3 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

9.

Write data bit 2 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

10.

Write data bit 1 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

11.

Write data bit 0 to bit 0 of BADR3 + 4hex (D/A CALIBRATION REGISTER 1).

12.

Assert the desired DAC8800s LDAC line by writing the correct value to BADR3 + 6hex (D/A

CALIBRATION REGISTER 2).

13.

Deassert the desired DAC8800s LDAC line by writing 126 (7Eh) to BADR3 + 6hex (D/A CALIBRATION REGISTER 2).

D/A 0 - D/A 7 DATA

The following 8 registers are the data registers for the eight 12-bit o utput DACs. D0 is the LSB. Writing to the

register will automatically update the DAC output unless the simultaneous update bit is set for that DAC (see the

D/A Control Register description for more information on simultaneous update.) The data format is mode dependent

as shown below.

Bipolar Mode:

Offset Binary Coding

000h = -FS

800h = Mid Scale (0V)

FFFh = +FS - 1LSB

Unipolar

Straight Binary Coding

000h = -FS (0V)

800h = Mid Scale (+FS/2)

FFFh = +FS - 1LSB

D/A 0 DATA

BADR3 + 8hex

WRITE ONLY

D/A 1 DATA

BADR3 + 0Ahex

WRITE ONLY

Mode:

0123456789101112131415

D0D1D2D3D4D5D6D7D8D9D10D11XXXX

0123456789101112131415

D0D1D2D3D4D5D6D7D8D9D10D11XXXX

D/A 2 DATA

BADR3 + 0Chex

WRITE ONLY

Page 25

Page 27

D/A 3 DATA

BADR3 + 0Ehex

WRITE ONLY

D/A 4 DATA

BADR3 + 10hex

WRITE ONLY

D/A 5 DATA

BADR3 + 12hex

WRITE ONLY

0123456789101112131415

D0D1D2D3D4D5D6D7D8D9D10D11XXXX

0123456789101112131415

D0D1D2D3D4D5D6D7D8D9D10D11XXXX

0123456789101112131415

D0D1D2D3D4D5D6D7D8D9D10D11XXXX

0123456789101112131415

D0D1D2D3D4D5D6D7D8D9D10D11XXXX

D/A 6 DATA

BADR3 + 14hex

WRITE ONLY

D/A 7 DATA

BADR3 + 16hex

WRITE ONLY

0123456789101112131415

D0D1D2D3D4D5D6D7D8D9D10D11XXXX

0123456789101112131415

D0D1D2D3D4D5D6D7D8D9D10D11XXXX

Page 26

Page 28

8.0 Electrical Specifications

Typical for 25°C unless otherwise specified.

Analog Output

D/A converter type AD7837B

Resolution 12 bits

Number of channels

PCI-DDA08/12 8

PCI-DDA04/12 4

PCI-DDA02/12 2

Output Ranges ±10V, ±5V, ±2.5V, 0 - 10V, 0 - 5V, 0 - 2.5V. Each channel

independently programmable.

Data transfer Programmed I/O.

Offset error (calibrated) ±(300µV +¼LSB)

Gain error (calibrated) ±(300µV +¼LSB)

Differential non-linearity ±1LSB max

Integral non-linearity ±1LSB max

Monotonicity 12 bits

D/A Gain drift ±2 ppm/°C

D/A Offset drift ±5µV/°C

Throughput PC dependent, software update

Settling time (20V step to ±½LSB) 6µs typ, 10µs max

Slew Rate 5V/µs

Current Drive ±5 mA

Output short-circuit duration 25 mA indefinite

Output coupling DC

Output impedance 0.1 Ohms max

Miscellaneous Double buffered output latches

Update DACs individually or simultaneously (software selectable)

Power up and reset, all DAC's cleared to 0 volts , ±210mV

Digital Input / Output

Digital Type (main connector) 8255 mode 0 emulation

Output: 74S244

Input: 74LS373

Configuration 4 banks of 8, 4 banks of 4, programmable by bank as input or

output

Number of channels 48 I/O

Output High 2.4 volts min @ -15mA

Output Low 0.5 volts max @ 64 mA

Input High 2.0 volts min, 7 volts absolute max

Input Low 0.8 volts max, -0.5 volts absolute min

Power-up / reset state Input mode (high impedance)

Page 27

Page 29

Power consumption

+5V Operating

PCI-DDA08/12 1.6A typical, 2.6A max

PCI-DDA04/12 1.5A typical, 2.4A max

PCI-DDA02/12 1.4A typical, 2.2A max

+12V

PCI-DDA08/12 24mA typical, 48mA max

PCI-DDA04/12 12mA typical, 24mA max

PCI-DDA02/12 6mA typical, 12mA max

-12V

PCI-DDA08/12 16mA typical, 25mA max

PCI-DDA04/12 8mA typical, 12mA max

PCI-DDA02/12 4mA typical, 6mA max

Environmental

Operating temperature range 0 to 70°C

Storage temperature range -40 to 100°C

Humidity 0 to 90% non-condensing

Page 28

Page 30

EC Declaration of Conformity

PCI bus analog output boards with 48-bits of digital I/OPCI-DDA0X/12

DescriptionPart Number

to which this declaration relates, meets the essential requirements, is in conformity with, and CE marking has been

applied according to the relevant EC Directives listed below using the relevant section of the following EC standards

and other normative documents:

EU EMC Directive 89/336/EEC

EU 55022 Class B

technology equipment.

EN 50082-1

IEC 801-2

IEC 801-3

IEC 801-4

Carl Haapaoja, Director of Quality Assurance

: EC generic immunity requirements.

: Electrostatic discharge requirements for industrial process measurement and control equipment.

: Radiated electromagnetic field requirements for industrial process measurements and control equipment.

: Electrically fast transients for industrial process measurement and control equipment.

: Limits and methods of measurements of radio interference characteristics of information

: Essential requirements relating to electromagnetic compatibility.

Page 29

Page 31

Loading...

Loading...