Page 1

reduced to any electronic medium or machine-readable form, in whole or in part, without prior written consent of OMEGA ENGINEERING, INC.

(C) Copyright 1999 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied, reproduced, translated, or

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

technology and engineering.

OMEGA's policy is to make running changes, not model changes, whenever an improvement is possible. This affords our customers the latest in

the product.

the product.

3. Repair instructions and/or specific problems relative to

2. Model and serial number of product, and

1. P.O. number to cover the COST of the repair,

available BEFORE contacting OMEGA:

current repair charges. Have the following information

FOR NON-WARRANTY REPAIRS, consult OMEGA for

3. Repair instructions and/or specific problems relative to

under warranty, and

2. Model and serial number of the product

PURCHASED,

1. P.O. number under which the product was

contacting OMEGA:

following information available BEFORE

FOR WARRANTY RETURNS, please has the

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent breakage in transit.

then be marked on the outside of the return package and on any correspondence.

CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID PROCESSING DELAYS). The assigned AR number should

PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN (AR) NUMBER FROM OMEGA'S

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE RETURNING ANY

RETURN REQUESTS / INQUIRIES

whatsoever arising out of the use of the Product(s) in such a manner.

language, and additionally, purchaser will indemnify OMEGA and hold OMEGA harmless from any liability or damage

humans, or misused in any way, OMEGA assumes no responsibility as set forth in our basic WARRANTY/DISCLAIMER

humans. Should any Product(s) be used in or with any nuclear installation or activity, medical application, used on

under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical applications or used on

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a ”Basic Component”

consequential, incidental or special damages.

purchase price of the component upon which liability is based. In no event shall OMEGA be liable for

based on contract, warranty, negligence, indemnification, strict liability or otherwise, shall not exceed the

purchaser set forth herein are exclusive and the total liability of OMEGA with respect to this order, whether

FOR A PARTlCULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATlON OF LIABILITY: The remedies of

OF TITLE, AND ALL IMPLIED WARRANTlES INCLUDING ANY WARRANTY OF MERCHANTABILITY AND FITNESS

WARRANTIES OR REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT

that the parts manufactured by it will be as specified and free of defects. OMEGA MAKES NO OTHER

products in accordance with information provided by OMEGA, either verbal or written. OMEGA warrants only

responsibility for any omissions or errors nor assumes liability for any damages that result from the use of its

OMEGA is pleased to offer suggestions on the use of its various products, However, OMEGA neither assumes

fuses, and triacs.

outside of OMEGA's control. Components which wear are not warranted, including but not limited to contact points,

or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating conditions

shows evidence of having been tampered with or shows evidence of being damaged as a result of excessive corrosion;

operation outside of design limits, improper repair, or unauthorized modification. This WARRANTY is VOID if the unit

defects resulting from any action of the purchaser, including but not limited to mishandling, improper interfacing,

the unit is found to be defective it will be repaired or replaced at no charge. OMEGA's WARRANTY does not apply to

issue an Authorized Return (AR) number immediately upon phone or written request. Upon examination by OMEGA, if

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA's Customer Service Department will

coverage on each product.

year product warranty to cover handling and shipping time. This ensures that OMEGA's customers receive maximum

months from date of purchase. OMEGA’s Warranty adds an additional one (1) month grace period to the normal one (1)

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a period of 13

WARRANTY/DISCLAIMER

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

TEMPERATURE

] Thermocouple, RTD & Thermistor Probes, Connectors,

Panels & Assemblies

] Wire: Thermocouple, RTD & Thermistor

] Calibrators & Ice Point References

] Recorders, Controllers & Process Monitors

] Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

] Transducers & Strain Gauges

] Load Cells & Pressure Gauges

] Displacement Transducers

] Instrumentation & Accessories

FLOW/LEVEL

] Rotameters, Gas Mass Flowmeters & Flow Computers

] Air Velocity Indicators

] Turbine/Paddlewheel Systems

] Totalizers & Batch Controllers

pH/CONDUCTIVITY

] pH Electrodes, Testers & Accessories

] Benchtop/Laboratory Meters

] Controllers, Calibrators, Simulators & Pumps

] Industrial pH & Conductivity Equipment

DATA ACQUISITION

] Data Acquisition & Engineering Software

] Communications-Based Acquisition Systems

] Plug-in Cards for Apple, IBM & Compatibles

] Datalogging Systems

] Recorders, Printers & Plotters

HEATERS

] Heating Cable

] Cartridge & Strip Heaters

] Immersion & Band Heaters

] Flexibie Heaters

] Laboratory Heaters

ENVIRONMENTAL MONITORING AND CONTROL

] Metering & Control Instrumentation

] Refractometers

] Pumps & Tubing

] Air, Soil & Water Monitors

] Industrial Water & Wastewater Treatment

] pH, Conductivity & Dissolved Oxygen Instruments

User’s Guide

OSP 100 series

Portable Infrared Thermometer

http://www.omega.com

e-mail: info@omega.com

M-3269/00

Page 2

General

The OSP100 is the ideal tool for periodic process monitoring and for measuring

temperature quickly and easily, by contact with the target or from distance. An optional

laser pinpointing method simplifies the identification of the measuring surface area.

The OSP100 is the essential tool for the prevention of a variety of temperature related

equipment or process malfunctions. It can prevent serious damage to bearings, motors,

valves, electrical switches and distribution conductors, cooling or steam traps, thermal

insulation deterioration, hot spots, engine performances, extrusion heads, depleted

refrigeration system, etc.

The instrument is rugged, accurate and compact for fast and easy periodic process

monitoring, to control quality and/or supervise production phases of cooked and

refrigerated foods.

Specifications

! Spectral band: 8-14 mm

! Display: 3 ½ digit custom backlighted LCD plus labels for max, min, emissivity, Hold, °C, °F,

low battery.

! Resolution: 0.1°C up to 199.9°C. 1°C otherwise.

! Response time: 500 ms

! Target pinpointing: sight dot or circular laser sighting (L and XL models only)

! Emissivity: adjustable from 0.30 to 1.00

! Auto Power Off: Automatic power Off if no key is pressed for more than 40 sec.

! Alarm: low and high alarm with visual and acoustic beeper

! Signal processing: °C/°F, average, hold, max, min (where applicable)

! Accuracy IR channel:

range from 23°C to f.s. : ±1% of reading or ±1°C whichever is greater

range from -32°C to 23°C : ±1.5°C

! RTD channel: Pt100 IEC751 a385 (probe excluded)

Input range: from -32°C to 520°C

Accuracy: ±0.3% of rdg or ±0.3°C whichever is greater

! Laser sight::

Wavelength: 650nm, Beam diameter: 3mm, Beam divergence: <0.5mrad;

Laser indicator: asterisk on display

! FDA Classification: Class II, Complies with 21CFR Chapter 1, Subchapt.er J

! Safety Classification: Class 2

! Power supply: alkaline or rechargeable battery

! Battery life: 60 h (back light & laser off)

! Ambient temperature: -10 to +45°C / 10-95% RH non condensing

! Storage temperature: -30°C to +60°C

! Dimensions and weight: 180x140x45 mm 380g nett

When alkaline batteries are used, DO NOT connect power module to input jack.

CE certifications

This instrument conforms to the following standards:

EN 50081-1: 1992, Electromagnetic emissions

EN 50082-1: 1992, Electromagnetic susceptibility

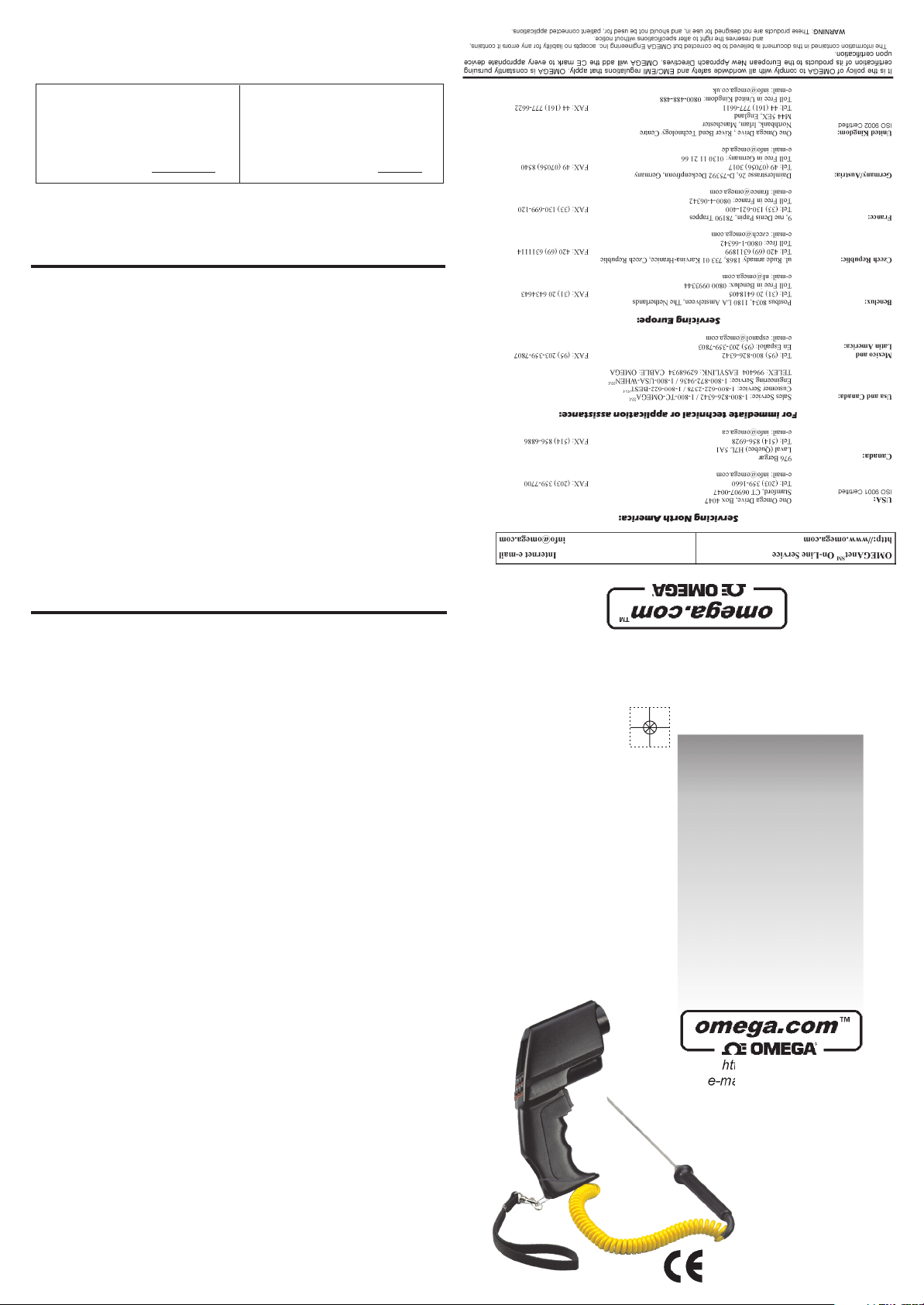

Operational Flow Chart

NORMAL MODE KEYPAD

+ -+ -

Laser pointer enable/disable

Probe

Lamp

Hold

Min/Max

SET MODE KEYPAD

Display external probe/infrared measurements

Backlight ON/OFF

Hold measurements in lower display. Refresh hold.

Circular switch between Average, Minimum or Maximum measurements on lower display.

2nd

2nd

2nd

2nd

2nd

2nd

Activate 2nd function keys.

+

Probe

+

+

Min/Max

+

Lamp

+

Increase digit.

Decrease digit.

Store value and return in normal mode.

Hold

Laser beam mode: Continuous / Flashing (economy mode).

°C/°F

=

=

=

Set e

=

Switch engineering temperature units.

Set mode for HIGH alarm.

HI

Set mode for LOW alarm.

LO

Set mode for Emissivity.

Probe

°C/°F

Lamp Hold Min/Max

Set e

Set

HAL

Lock

e

OSP100 uses a

High Quality custom display

HI

Set Alarm

Applications

FOOD (HACCP) To control and supervise production phases, handling, transport, and

conservation of cooked and refrigerated foods.

AUTOMOTIVE To check engine, bearings, muffler, brakes, etc.

INDUSTRIAL & ELECTRICAL Bearings, motors, valves, switches, insulation, etc.

HVAC/R Heating & cooling systems, thermal insulation, radiators, ducts, etc.

LAL

2nd

°F

°C

LO

Basic functions

To take a temperature reading, point the unit at the target you wish to measure. Push and

keep the trigger pushed. The current temperature reading is displayed. Last reading before

previous switching-off is displayed in lower display. Release the trigger. A “Lock” symbol on

the LCD will be displayed and the Hold value is refreshed. OSP100 will remain switched on

for 40 seconds. The time will reset if a key is pressed or a serial communication message is

sent.. Press and release quickly the trigger to switch the instrument off.

The OSP100L and 100XL models can be supplied with a laser sighting with either a “laser

dot” to read the target area center or with a “laser circle” to read the target area. Press the

[*] key to enable/disable the laser. The message “LAS EN” or “LAS DIS” will be displayed.

When enabled, the laser can be switched on by pressing the trigger button for more than

1 sec. The laser will automatically switch off when the trigger button is released. The

emission indicator symbol (*) will appear on lower display.

Press in sequence the [2 ] and [*] keys to change the laser beam mode between

Continuous and Flashing (to increase battery expected life) mode.

Press the [Lamp] key to switch back-light on or off.

Press in sequence the [2 ] and [°C/°F] keys to change the engineering units between °C

and °F.

nd

nd

Enhanced functions

External probe operation. Connect the Pt100 resistance thermometer to the appropriate

connector. Switch the unit on and press the [Probe] key. The “EXT” message will be

displayed on the lower display for Pt100 readings.

Hold measurement. Press the [HOLD] key to freeze the displayed temperature. The hold

value will be displayed in lower display. On the main display the temperature is that actually

measured. Press the key again to refresh the Hold indication.

The Hold indication is refreshed by pressing the trigger for more than 1 sec with the unit in

measuring mode and releasing the trigger. Switch the OSP100 off by pointing the unit to

the target to recall the last value when you switch the unit on.

Select Average (AVG), Minimum (MIN) and Maximum (MAX) values. Press the [Min/Max]

key until the appropriate message is displayed. The unit will refresh the values of each

measurement from the power on. To reset the values, press the [2 ] key or switch the unit

off and on.

Emissivity adjustments. Press in sequence the [2 ] and [Set e] keys to change the emissivity

from 0.30 to 1.00 with 0.01 resolution. On the lower display the set value is shown. Press

the [UP] and [DOWN] keys to increase and decrease the emissivity. Press the [ENTER] key to

store and return on the normal mode measurement.

Set low (LAL) and high (HAL) alarms. Press in sequence the [2 ] and [HI] keys to change

the High alarm set point.. “HAL” will be seen on the display. The stored High alarm will be

displayed. The High alarm level is to be set by adjusting the [UP] or [DOWN] keys. Press the

[HI] key to enable/disable the acoustic alarm. Press the [ENTER] key to store the displayed

value and return to normal mode. Press in sequence the [2 ] and [LO] keys to change the

Low alarm set point..“LAL” will be seen on the display. The Low alarm level is to be set by

adjusting the [UP] or [DOWN] keys. Press the [LO] key to enable/disable the acoustic alarm.

Press the [ENTER] key to store the displayed value and return in normal operation mode.

When the measurement is inside the programmed alarm band, the “LAL” or “HAL” symbol

will be lit and an intermittent beep will be emitted.

nd

nd

nd

nd

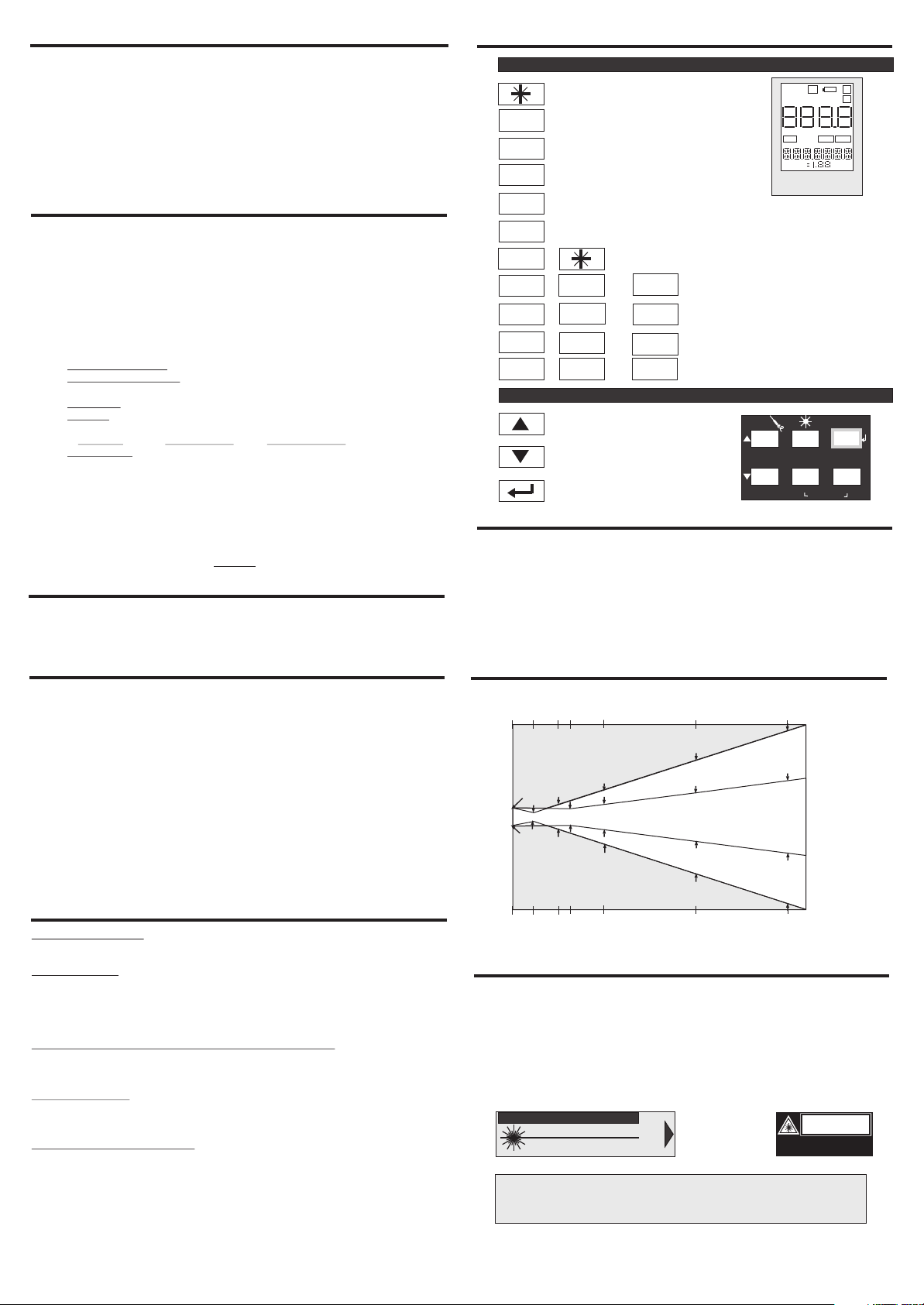

Optics

Distance: Sensor to Object (in)

9

0

1

Spot DIA* (in)

.5

12

25

* Spot size measured

Spot DIA* (mm)

at 90% energy

0

225

500

40

25

20

.9

23

625

3

1.4

35

75

1000

1.4

35

Distance: Sensor to Object (mm)

Warnings and Cautions

! USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE OF

PROCEDURES OTHER THAN THOSE SPECIFIED HERE MAY RESULT IN

HAZARDOUS RADIATION EXPOSURE.

! DO NOT LOOK AT THE LASER BEAM COMING OUT OF THE LENS OR VIEW

DIRECTLY WITH OPTICAL INSTRUMENTS - EYE DAMAGE CAN RESULT.

! USE EXTREME CAUTION WHEN OPERATING THE LASER.

! NEVER POINT THE LASER BEAM AT A PERSON.

! KEEP OUT OF REACH OF ALL CHILDREN.

C A U T I O N

LASER RADIATION - DO NOT STARE INTO BEAM

MAX.OUTPUT<1mW, WAVELENGTH 630-670nm

CLASS I I LASER PRODUCT

COMPLIES WITH 21CFR CHAPTER 1, SUBCHAPTER J

DO NOT ATTEMPT TO OPEN THE LASER SIGHT MODULE.

(THERE ARE NO USER SERVICEABLE PARTS IN THE MODULE).

PATENT NOTICE: U.S. PAT. B1 5,368,392; 5,524,984; 5,727,880; 5,465,838; 5,823,678; 5,823,679.

Other U.S. and Foreign Patents and Applications Pending. Manufactured in Italy. Licensed by Omega

Engineering, Inc.

THIS APERTURE

LASER RADIATION

AVOID EXPOSURE

IS EMITTED FROM

WARNING

80

6.2

2.7

67

157

2000

120

9.4

4.0

OSP100XL

100

Nominal D:S = 30:1

238

OSP100, OSP100L

Nominal D:S = 12:1

3000

OSP100L and OSP100LX models only

LASER RADIATION DO NOT STARE

INTO BEAM OR VIEW DIRECTLY

WITH OPTICAL INSTRUMENTS.

MAX.OUTPUT<1mW, WAVELENGTH 630-

670nm, CLASS 2 LASER PRODUCT

CONFORMS TO IEC825-1:1993

Loading...

Loading...