Page 1

CAUTION!

is not intended for

or

use

I

use on human8

-

This product

medkd

L

Am

OME6.4

Teekmdoglea

http://www.omega.com

e-mail:

info@omega.com

lhquy

J

OS65 SERIES

Infrared Pyrometers

Page 2

OMEGAneP

On-Line Service

http://www.omega.com

Servicing North America:

Internet e-mail

info@omega.com

USA:

IS0

900 1

Certified

Canada:

For immediate technical or application assistance:

USA and Canada:

Mexico and

Latin America:

Benelux:

Czech Republic:

France:

Germany/Austria:

United Kingdom:

IS0

9002 Certified

One

Omega Drive, Box 4047

Stamford, CT 06907-0047

Tel: (203) 359-1660 FAX: (203) 359-7700

e-mail:

976

Lava1 (Quebec)

Tel: (514) 856-6928 FAX: (514) 856-6886

e-mail:

Sales Service: l-800-826-6342

Customer Service: l-800-622-2378

Engineering Service: l-800-872-9436

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Tel: (95)

En Espariol: (203) 359-1660 ext: 2203

info@omega.com

Bergar

H7L

canada@omega.com

800-TC-OMEGASM

5Al

l-800-TC-OMEGA ’”

I

1-800-622-BEST’L”

/

l-800-USA-WHENSM

/

FAX: (95) 203-359-7807

e-mail:

espanol@mega.com

Servicing Europe:

Postbus

Tel: (31) 20 6418405

Toll Free in Benelux: 06 0993344

e-mail:

Ostravska 767,733 01 Karvina

Tel: 42 (69) 6311899

e-mail:

9, rue

Tel: (33) 130-621-400

Toll Free in France: 0800-4-06342

e-mail:

Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: 49 (07056) 3017

Toll Free in Germany: 0130 11 2166

e-mail:

25 Swannington Road,

Broughton Astley, Leicestershire,

LE9

Tel: 44 (1455) 285520

FAX: 44 (1455) 283912

8034, 1180 LA Amstelveen, The Netherlands

FAX: (31) 20 6434643

nl@mega.com

FAX: 42 (69) 6311114

czech@mega.com

Papin,

Denis

france@@mega.com

germany@bmega.com

6TU, England

78190 Trappes

Toll Free in England: 0800-488-488

e-mail:

uk@?omega.com

FAX: (33) 130-699-120

FAX: 49 (07056) 8540

P.O. Box

Irlam, Manchester,

M44

Tel: 44 (161) 777-6611

FAX: 44 (161) 777-6622

7,

Omega Drive,

5EX,

England

It

is

the policy of OMEGA to comply with all worldwide safety and

apply. OMEGA is constantly pursuing certification of its products to the European New Approach

Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct but OMEGA Engineering, Inc. accepts

no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient connected applications.

EMC/EMI regulations that

Page 3

Table of Contents

OS65 Series

section

Section 1: Introduction

1.1

General Description

1.2 Available Models

1.3 Accessories

Section 2:

2.1 Unpacking

2.2 Dimensions

23 Wiring

Section 3: Operation

3.1 Emissivity

3.2 Emissivity Adjustment

3.3 Emissivity Tables

3.4

Comparison

35

Maintenance

..................

Iustalhtion

..“...“m....“...“.“.......~-.“-..~..~....-..................-”-”..~....“..“~........”

..

..~.H.....“...“..~~~..~....~.~~..~........~”~...~~“~.~~...~..~........“.....”

.

..H.........................~“~.”..”..~.”.~..~...“...“~~.~””~..~.~~.....“..~.“......““..“..”

.“I.“.-“...“....“...““....~...“........~...”~.~..“........~..~.~..~...“~.“........“....~

Measurements

--...-.--...“..“.....~.....“.~~~.”

..~...................._._.....“....~......................”_.....“....~.“_.......”

.

..................

..-..-......HI.“ W..““.~““.-....“”.....-........-.““~.-“.....”..-.“-..”

..“...““.“..“-.....~..“...-......................~.“..--“”....-.-

..“.....“.“.~.~“.m.“....“.~..............~....”...““~~..~.....~.-..................”

..

..“w....m....................““.....”~...~.”.””....-“-“-“”-”-.....“....“...”

wt.......~.“.~.~...“~~.~....~.““~..~~..”.~...........~.....~..”....~”

..........

“.“.........UI.

..“.......~..~...~~...............”.......~.-.”~.~

“~“..“..N......“...~.~.....“..~.~....”..””.~-”.~.“.~..........”...”

~.UlltUll_U.“..“.”

-.

.

...

...-........U....

._.

..-.““- m-....=.....“......“.-“.“-.

O...-..

-

........

....................

..........

..........

.H..

“.._

....

-.

..

Page

1

1

1

2

2

..

2

3

..

4

.

6

6

.

6

..-

.

7

..

8

“oo.“”

8

Section 4: Specifications

4.1 Specifications

4.2 Field of View Diagrams

4.3 Accessories Dimensions

4.4

Digital Output

~“..“.H~.........“~..~“.~.~.~““..~..”~~...”..~...~“...~-.~”..~”.“~.~“”

Option

..~.......~........~....“..“~..“”~~....~.~”~...“.....“....~.....“.~..“.”

-.

.m........“..“..“...-~.~-..-..“.....””......~....“-..“-.-”.-”

......

“._“...___

...

“................“............

-.

U.“IH~.mm”...“ W..“-...~“..““..““.-

...

.

--.-“UIIIIIIII

S.““.rm...rn

.

..m....

.

.

..”

”

”

..”

8

8

9

10

14

Page 4

Section 1: Introduction

1.1

General Description

The OMEGA@ OS65 Series

Infi-ared

Pyrometers are

designed to measure the temperature

of

targets rapidly and accurately. This includes difficult targets that are moving, inaccessible,

f@ile, or

to touch. The

OS65 Series can be

installed in your existing equip ment or

uflsafe

mounted with its own hardware for continuous monitoring of a process line. Since the OS65

Series instru m ents do not use chopper mo tors or vibrator m echanis m s, they can be mounted

in any position and in hostile environ m ents without

suffering

any loss in perfor m ance. This

includes installations that are moving, vibrating, or subject to m echanical shock. This

rugged design, coupled with their relatively s m all di mensions, make these instru m ents

ideally suited for a w ide variety of applications where durability, size, and low cost are

important.

The OS65 Series are advanced non-contact m easure m ent syste m s. They utilize

m icroprocessor-based electronic

circuitry

that insures accuracy and repeatability. There are

six different outputs available, wh ich can feed directly into co mputers, data loggers, or other

instru m entation.

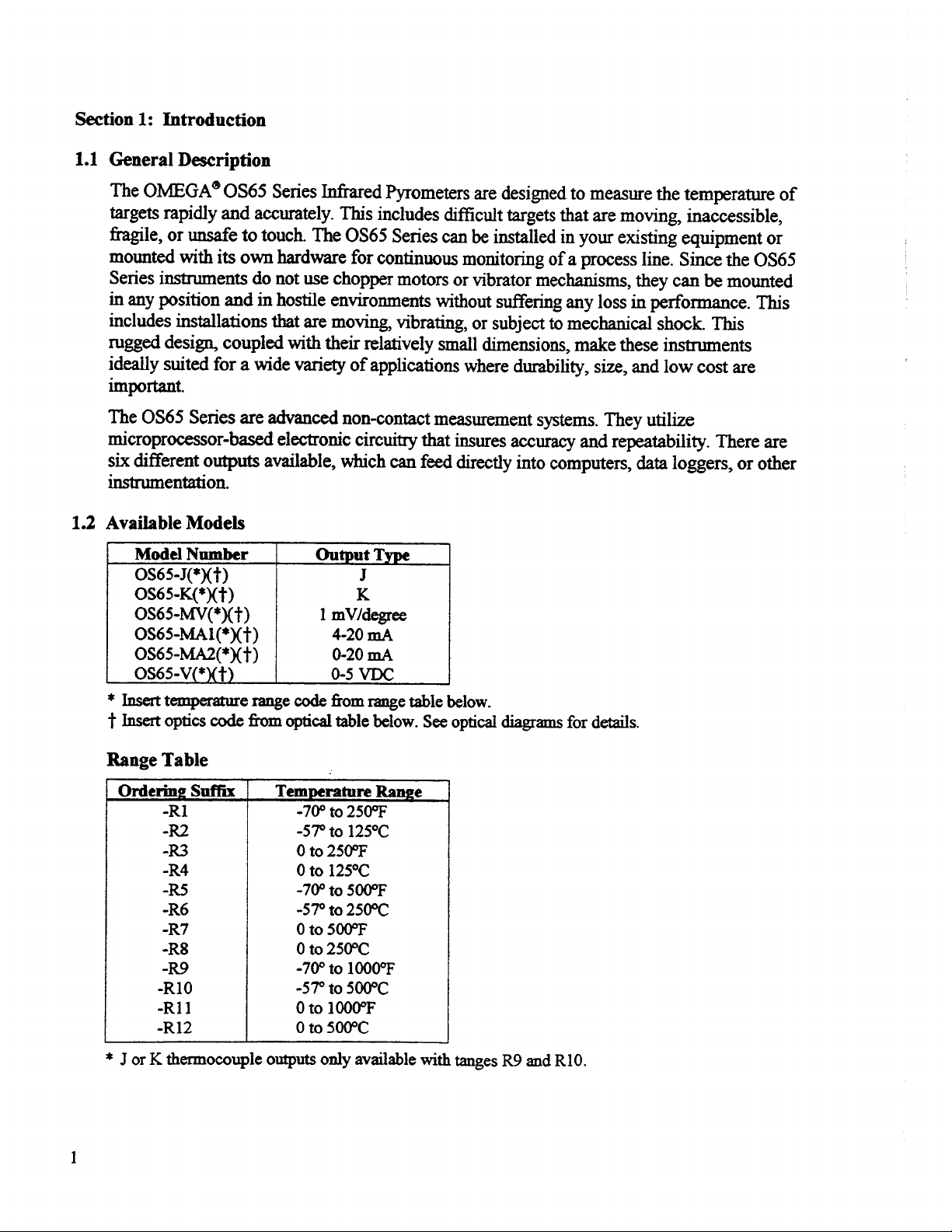

Available Models

1.2

ModelNumber

OS65-J(*)(*)

OS65-K(*)(t)

OS65- M v(*)(t)

OS65-MAl(*)(t)

OS65-h&Q(*)(t)

OS65-V(*)(t) o-5

Output Type

J

K

mV/degree

1

mA

4-20

mA

O-20

V-DC

*

Insert

t

Insert optics

tempemmre

Range Table

ordering

* J

or

SufIix

-Rl

-R2

-R3 0

-R4

-R5

-R6

-R7

-R8

-R9

-RlO

-Rll

-R12

the mocouple outputs only available with

K

range

f&n optical table

code

Temperature

-70“

-57”

0

-700

-570

oto5OOT

0

-700

-570

0 to

0 to

from

to

to

25OT

to

125OC

to

to

to

25O “C

to

to

to

1OOooF

5OOT

range table below.c&e

below.

he

250°F

125°C

5ooOF

250°C

1OOOT

5OOT

See

optical

tanges

diagrams

R9

for details.

RlO.

and

Page 5

Optical Table

Each unit is supplied with sensor mounting bracket and

nut,

15-foot

interconnecting cable

and electronics housed in NEMA 4 (IEC529, IP66) enclosure.

To order a bare bones operating system, including just the

infrared

sensing head and

electronics card (without NEMA 4 enclosure and sensor mounting bracket and nut), add

suffix

“BB” to model number.

1.3 Accessories

OS65-APC

OS65-AWC

OS65-MF

OS65-RAB

OS65-MN

OS65-NEMA4

OS65-NEMA12

Air Purge

Air/water Cooling Jacket

Mounting Frame

Right Angle Mounting Bracket

Mounting Nut

NEMA 4 Electronics Enclosure

NEMA 12 Electronics Enclosure

Collar

Options

c50

NIST

50-foot

cable (in place of the

15-foot

NIST Traceable Calibration Certificate

cable)

Section 2: Installation

2.1

Unpacking

veri@

Remove the Packing List

and

that you have received all equipment. If you have any

questions about the shipment, please call the OMEGA Customer Service Department at

l-800-622-2378 or 203-359-1660.

When you receive the shipment, inspect the container and equipment for any

signs

of

damage. Note any evidence of rough handling in transit. Immediately report any damage to

the shipping agent.

Note:

examination. After examining and removing contents,

the event reshipment is necessary.

The carrier will not honor any claims unless all shipping material is saved for their

save

packing

material and carton in

Page 6

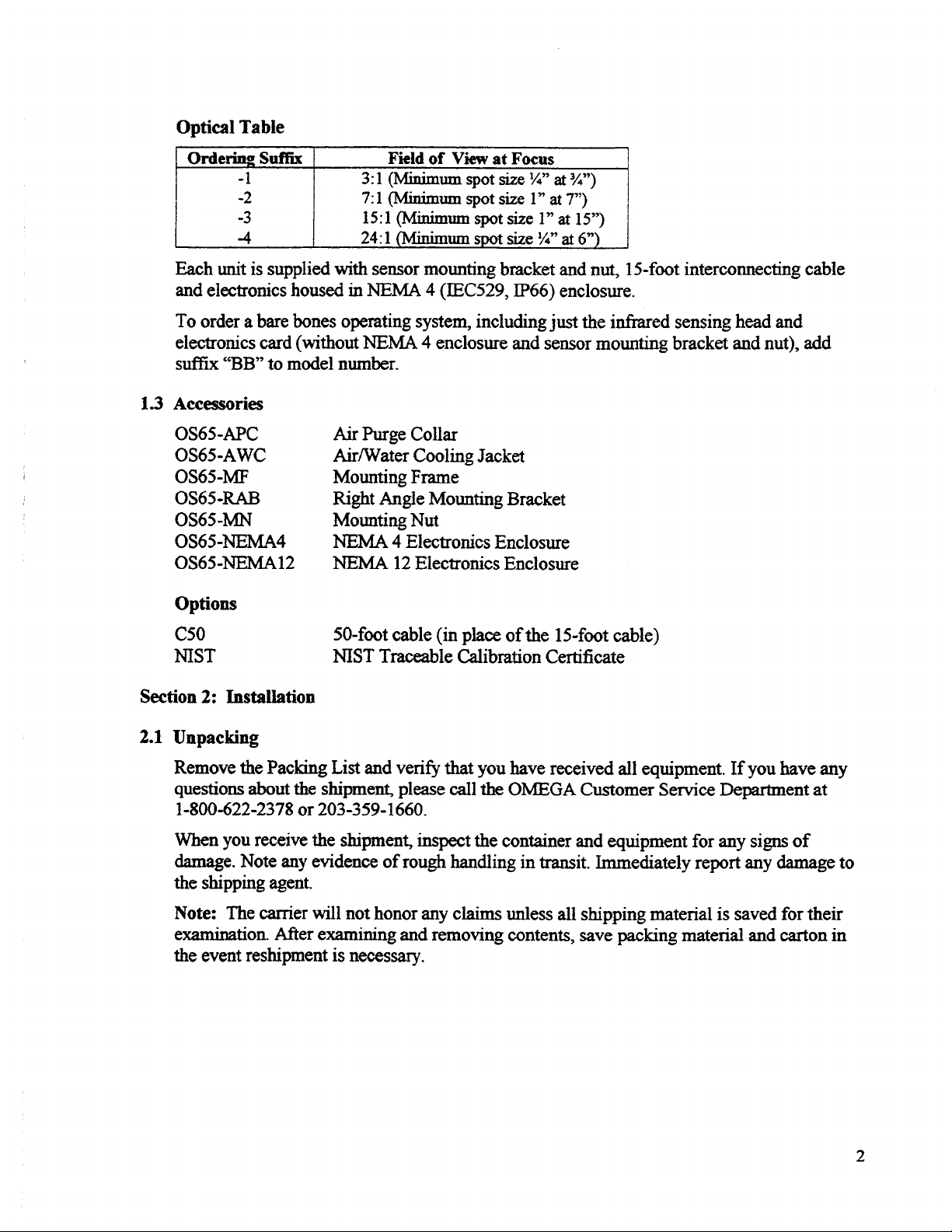

DlMENSIONS

t

@

1.625”

(164.1)

__-.--

J

.____._-

- -

f

--

1

l/2

-

20

THD

\

0.205 HOLE

THRU

It

-..-

(13.3)

5.2”

4.25” (10.8)

--

----.

II

4

(2:54)

.-._-_.__

L

OSB5

4.3 ”

SENSlNC

(1o.g)~--

HEAD

(2.54)

15FT (460)

CABLE

OS65 ELECTRONICS

_...__

..

__

..--

__-._.

.---

.--

Page 7

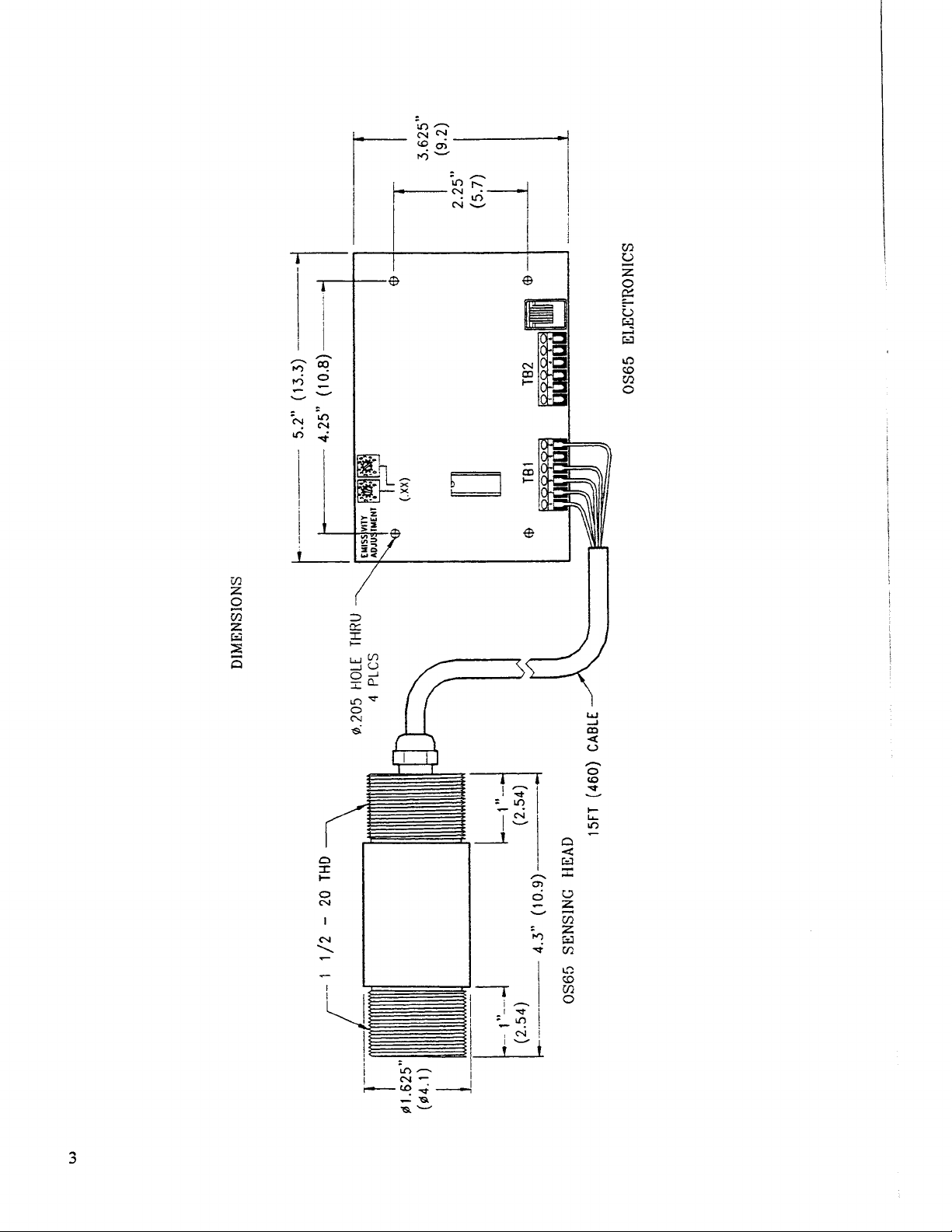

OS65J,OS6!bK,

OS6HAV

WIRING DIAGRAM FOR

and OS65V

TERMNALTBI

1. WHITE

I::kFK

4. GREEN

5. N/C

6. SHIELD GROUND

Terminals

TERMINAL

IR SENSOR

XF

AME SENSOR

&

5 do not share common

1

+

“6:~F%F

+

TB2

+

ground. The output on TB2 is a floating

differential output.

WIRING DIAGRAM FOR

+3

L

-- Bm -

WHITE

BLACK

OS65MAl

TBl

SENSOR INPUT

OS6!i-MA2

and

II

CZM%

TERMlNALTEll

l.Wl+TE

4. GREEN

5.

6. SHIELD GROUND

*See

wiring to meters with

built-in power supplies,

referred to as sensor

excitation

IR SENSOR

I;“,“”

EK $:

AMB

Nc

SENSOR

next page for

POWER

+

+

VDC

9-30

CONNECTlON

TERMINAL

%DCPOWER-

&DCPOWER+

ma

NouPowEl?Eo

TB2

091

SENSOR INPUT

PoaPowEREDwoPsuPPLY

)

Y6RuNuTBl

l.-wNlIs)

(PLUS)

*

3.

4

~DeJ iI

-

L

-

LOOPSUPPLY

lERulNuY62

FUJS)

2.

??

(MlNU6)

-

3.

GREEN

SHIELD

-

Page 8

Meter with internal power

supply for sensor excitation

SENSOR

CONNECTION POWER

TERMINALTBl

1. WHITE

;&A&K

4.

5.

SlilELD GROUN D

GFtEEh

N.c

!R SENSOR +

:2V& ‘C

AMBSENS~R

I

.-_.”

+

3

VDI

S-30

_I^..

CONNtr;

TERMINALTB2

%DCPOWER-

6. DC POWER +

POWER60 LOOP SUPPLY

FOR

11111.

WN

1

IIIII

IIL_

YERMNAL lB2

l.-fbmJUs)

-(PLUS)

3.

I

I

I

OS65MA2

T62

DIGJTAL

R&%X466

I

OS65MA1 and WIRING DIAGRAM FOR

I

I

-

-

-,,‘

with

TEb2

(Note

for

wiring terminals. 1 and 3 are not at common ground

must have a separate isolated power supply from the power supply on terminals 5 and

terminal 5, and

6.)

Page 9

Section

3.1

3:

Operation

Emissivity

A blackbody is defined as an object that emits the maximum theoretical amount of radiation

at a given temperature and has an emissivity at 1.0. The name blackbody is misleading

because it is not the color of the object, as much as the material and the surface finish of the

material that determines the emittance value.

The emittance of most organic substances (wood, cloth, plastic, and most paints) is

approximately 0.95. Metals with smooth, polished surfaces will have emittance values much

lower than 1.0.

3.2

Emissivity Adjustment

When

using an OS65 Series model to measure shiny, metallic

objects, the proper emissivity

adjustment must be made. This is easily accomplished by adjusting the emissivity pots on

the electronics board. One of the pots allows a coarse adjustment of the emissivity and has

from

range

0.10 to 0.90 in 0.10 steps. The second pot allows a fine adjustment of the

emissivity and has a range of 0.00 to 0.09 in 0.01 steps. To make the adjustment, use a small

screwdriver to turn the pots until the

arrows

are aligned with the proper setting. Determining

the proper setting can be done as follows.

1.

Heat a sample of the material to a known temperature as determined by a precise sensor.

Using the emissivity control of your OS65 Series instrument, adjust the indicated

temperature until it matches the temperature measured by the contact sensor. This value

of emissivity can now be used whenever the same material is measured.

a

2.

For relatively low temperatures (to approximately

500°F,

250°C),

a piece of masking

tape can be placed on the object and its temperature measured with the OS65 Series

instrument. Since the masking tape has an emissivity of approximately 1

measurement you obtain from it can be considered a “true”

temperature

.O,

the

and the object ’s

emissivity can be determined using the method described as above.

usiug

3.

For high temperatures, measure the object temperature

a thermocouple. Adjust the ’

emissivity control until the OS65 Series reading equals that of the thermocouple. For

exceedingly high temperatures, determine the emissivity using the emissivity value table

on page 7 of this manual.

4.

When a portion of the surface of the material can be coated, a dull black paint will have

emissivity of approximately 1 .O (other non-metallic coatings such as mold release may

be used also). Use this “true” temperature to determine the emissivity using the method

described in Example

1.

Standardized values of emissivity are available for most

materials.

A simplified table of emissivities is provided here. For a more detailed listing of

emissivities, refer

and D.P. Dewitt, published by

Publishing Company, 227 West

to

‘Thermal Radiative Properties ” (vol.

1FlKPlemu-n

17*

Data Corporation, subsidiary of Plenum

Street, New York, New York 10011.

7,8,

and 9) by Y.S. Touloukian

Page 10

Emissivity Tables

The following tables are provided as a guide for estimating the emissivity of various

that

materials. It is important to note

the actual emissivity, particularly for metals, can vary

greatly depending on surface finish oxidation, corrosion, or the presence of dirt, water, or

The best determination of emissivity can be made using the

oil.

techniques

described above.

Metals

Materials

Alumiuum

oxidized

uIloxidized

Polished

Brass

oxidized

Polished

Carbon

Graphite

chromium

Copper

oxidized

Polished

Gold

Polished

Iron

oxidize d

unoxidize d

Rusted

iron,

cast

oxidized

Unoxidized

Molten

Iron,

Wrought

Smooth

oxidized

Polished

Monel

Nickel

o?ddized

Unoxidized

PlatinIml

Polished

Black

silver

Steel

Cold-Rolled

(NiCu)

Emissivitv

0.20-0.55

0.09

0.05

0.50

0.03-0.05

0.40

0.10

0.40-0.80

0.03

0.02

0.50-0.90

0.15

0.50-0.70

0.60-0.95

0.20

0.20-0.30

0.70

0.30

0.40-0.60

0.05-0.10

0.10-0.40

0.20-0.50

0.10

0.30

0.09

0.03

0.70-0.90

Ground Sheet

Polished Sheet

oxidized

Stainless

zinc

o>ridized

Polished

Galvaoized

Non-Metals

Materials

Asbestos

Asphalt

Brick

Carbonmdum

GXi3LUiC

ClaY

Concrete

Cloth

Plate

Gravel

Grvp=

ICe

Limestone

Paint

Non-Metallic

Paper

Any

Color

Plastic

@asue

mils thickness)

Rubber

Sand

Snow

soil

Water

wood

Natural

(G=

20

0.40-0.60

0.20

0.70-0.90

0.20

0.10

0.03

0.20

Emissivity

0.95

0.95

0.95

0.90

0.95

0.95

0.95

0.95

0.85

0.95

0.80-0.95

0.98

0.95

0.90-0.95

0.95

0.90

0.95

0.90

0.90

0.90-0.98

0.93

0.90-0.95

7

Page 11

3.4

Comparison Measurements

When making comparison measurements on the same material, an approximation of the

emissivity will still give good results. Selecting a relatively low emissivity value will make

the difference in compared temperatures slightly larger than actual. When trying to locate a

slight temperature difference, setting the emissivity to 0.20 will provide the maximum

sensitivity, although the absolute temperature measurement will not normally be correct.

3.5 Maintenance

Due to its solid-state, sealed construction, the OS65 Series instruments require minimum

maintenance. The optics may require periodic inspection and cleaning if the sensor is in a

dirty environment. Use an optical cleaning solution (e.g. mild detergent) and a cotton swab.

Care

should be taken to prevent scratching the lens or its coating.

If

you are operating the

instrument in a dirty atmosphere, the optional lens air purge assembly is recommended.

Se&on

4:

Specifications

Accuracy:

Repeatability:

Spectral Response:

Emissivity

Response

Range:

Time:

Field of View

Power:

Environmental Ratings:

Ambient Operating

Sensing

EkCtl-OlliCS:

ComN!ction:

Max. Lead

(Ohms, Current Output Mode):

Load

@A,

Dimensions-

Sensing Head:

Electronics:

Weight-

Sensing Head:

Electronics

Electronics

Head:

Current-

Voltage Output Mode):

NEMA 4 enclosure):

NEMA 4 enclosure:

(FOV):

Wire

Resistance-

only (without

mounted

Range-

iu

(l°C),

+z?F

x&4

-

Hoc

185T)

7)/0.02

&O-50%

8-

0.10 to 0.99 digitally adjustable

300

3:1,minimumspotsize ’/4”at3/4”

7: 1, minimum spot size 1 ” at

15:1,

24: 1, minimum spot size

9-30

sensing

with either NEMA 4 electronics enclosure or

dust-tight

-180

32Oto

4.5 m

(Supply Voltage

1omAmaximum

10.9 cm x 4.1 cm (4.30 ” x 1.63”); l-112-20 thread

13.3 cm x 9.1 cm (5.25 ” x 3.62”)

0.3 kg (8 oz.)

0.1 kg (4 oz.)

1.2 kg (43.2 oz.)

of reading

14 microns

msec

(10 to 90%)

minimum spot size 1 ” at 15”

VDC,

40

head NEMA 4, dust-tight and water-tight

or drip-tight enclosure

85“C

to

(0 to

12OT

(15fi.

cable standard); Optional 15 m (50 ft. cable)

whichever is greater

+l% of reading or

T

s”

at 6”

NEh4A

12

8

Page 12

4.2

FIELD

OFVIEW DIAGRAMS

DISTANCE:

SENSOR

2

(II)

OWECT

TO

3

4

6

3:l

CLEAR

w

0

$

D

’

“,

6

83

?I?-

to

o-

a

(I)

DISTANCE: SENSOR TO OBJECT

DISTANCE: SENSOR TO

1’

4

2oan

toa

DISTANCE: SENSOR

DISTANCE:

E

,

DISTANCE: SENSOR TO

3om

SENSOR

TO

TO

OFklECT

06JEcT

OBJECT

6ocm 2ocm 4Ocm

(an)

lid

40fm

(CM

(in)

cfn

a.3

6Oa-n

(cm)OBJECT

4.1’

ld.5

15:l

z

iz-

‘og

a.

rn

CLEAR

APERTUR E

1’

ti

Z-

co

o -

%

MSTANCE:

12345678 9

U&

+

4

E

L

SENSOR TO OBJECT (in)

625

q

1.58Clll

5cm

10 cm

FOCUS

1/4’a:6’

15c m

OISTANCE: SENSOR TO

.w

4

1.7 cm

2Dcm

OBJECT (cm)

II I I ‘ I I r ,

24:l

Page 13

WATER

OS%-

COOL3NG

ACCESSORIES -

An%

JACKET

DIMENSIONS (INCHES)

MOUNTING FRAME

62.80

FOR 3

OS65-MF

l/8-27

BOLT CIRCLE

l/4”

OIA SCREWS

NPT

7

OS65MN

NOUNTING

!

3.50

Y -

2.k

j

I

I

NUT

c

E

-

2.00

01.52r

OS65-RAB

RIGHT ANGLE MOUNTING BRACKET

.25

HEX

OS65

APC

j---

I

COUAR

.2s

6.250

AIR PURGE

.125

R

4

b

I

7

/

i

3.00

--+.5

_!

10

Page 14

OS65”SV

1.5

2C

118

27

(3.81)

(C.32)

NP T

/

I - + -

1.15

(29.2)

WRENC H

FLAT S

iii

I

I

RIGdT

;o’;;i~;

THR U

ANGLE ADAPTOR

OS65-PA

(3.81)

1 .5

20

UN-2 B

THR U

_j

1.1 5

(29.2 )

i.5

N?T

(3.81)

ADA?TilR

PIPE

OS65-CA

(3.81)

l/2 1

112

NP T

UN-2929

11

CGNDiJ:T

SCALE.

A3APTC],?

i/2

Page 15

f-z- - \

/--

COVER

--- 6.75

I--

F

B

(171)

VIEW SHOWING CLAMP END (4 TOTAL)

USED ON NEMA-4,

N4-UX

---_-__

------_-_

--+--“.-_--_-_----_c__

I

--- _ -- __

------ -

=P

_._i

6.00

,-

(152)

SECTlON

L2.364

(60)

A- A

t;;

7.50 ---

(191)

N&MA

_

P

I

@ F -

-4

b-

75

19)

POL l CS lt R

&

NEMA 12 ENCLOSURE

1

PANELS

FTC FEET

INYOE

14

ANY 61

POwCR

ANO

CAUCE

12

GAUGE

CnAV

COA ll HC

UJ ,

sll.

7.50

-p-

-

(191)

-

4 . 00-- -

( 102 )

VIEW B-B

VIEW SHOWING HINGE END

USED ON NEMA-12,

Page 16

Sensor (Air/Water-Cooled Housing)

The

air/water-cooled housing (AWC) option allows the sensor to be used in ambient tempera-

tures up to 250°F

77°F

(25OC)

of 2 to 5

should be 3 to 5 cfm (1.4 to 2.4

PSID

liters) per minute; water temperature should be

Chilled water, below

(121°C)/3500F

(0.14 to 0.35

50°F

(

(175°C). It is supplied with two

liter&c)

Kg&

cm). Water flow should be approximately 0.5 gallons (2

50°

10°C),

is not recommended. To avoid condensation and lens dam-

with a pressure drop across the housing

to 80°F (10 ” to 27°C) for efficient cooling.

l/8”

NPT threads. Air flow

age, it is required to use the APC with the AWC.

PIACES

2

OS&j-AWC

WATER COOLING JACKET

Air Purge Collar (APC)

from

The APC accessory is used to keep dust, moisture, airborne particles and vapors away

the

lens. It may be installed before or after the bracket (see drawing) and screwed in fully. Air

flows into the

cfm

of 1 to 3

inants

(0.5 to 1.5

from

settling on the lens.

l/S”

NPT thread port and out the

I

&---

liter&z).

2.25

HEX

Clean or “instrument ” air is recommended to avoid contam-

1

!

--+

AlR

aperture.

front

.28

l/2-20-

OS65-APC

PURGE COLLAR

Air flow should be a maximum

l/8-27

NPT

-_Ikl.28

13

Page 17

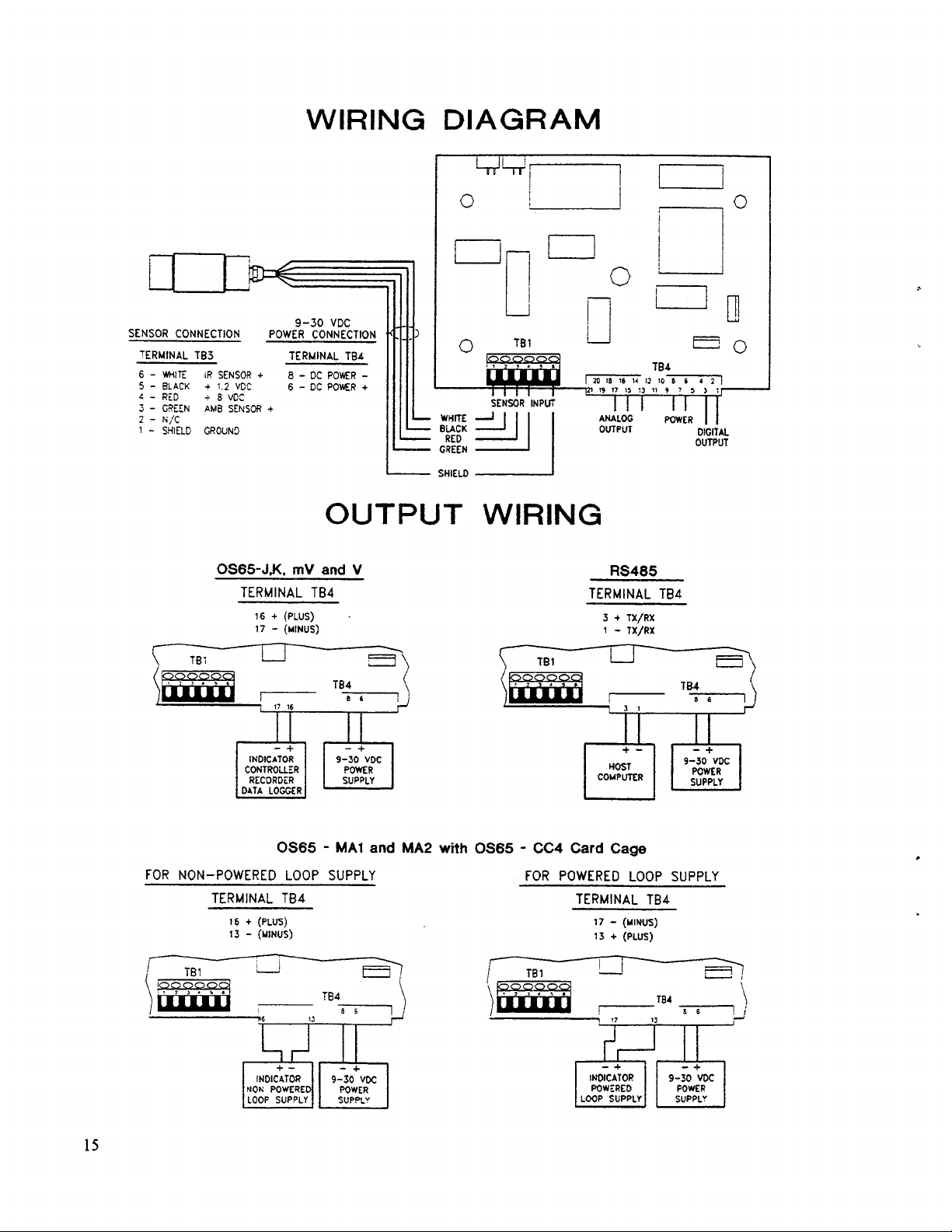

DIGITAL OUTPUT WIRING (not field installable)

RS

232

TERMINAL TB3 TERMINAL TB3

2

TX0

2

RX0

3

5

CND BLACK

YELLOW

GREEN

TX/RX

3

TX/RX

ANALOG POWER

DIGITAL

OUTPUT

RS

48 5

YELLOW

GREEN

TOP VIEW

Protocol

9600

no

parity

8databits

1 start bit

1

stop bit

9600, N, 8,

FRONT VIEW

I

YELLOW

Interrogation

Format:

A one character command followed by a two character address and

possibly an additional two character address or a two character baud rate code.

Both

The address

required: i.e.,

I

commands: #AA

Baud Rate Code:

Reset:

is two characters between 00 and

FF hex.

OA rather than just A.

Unit at address AA responds with the IR temperature

@AABB

0/oAAo5

01

03

05

Turn

unit on with emissivity set at 00.

Unit at address AA gets new address BB

Unit at address

300 baud

1200 baud 04

4800 baud 06

AA is

02 600 baud

characters are

assigned

4800 baud

2400 baud

9600 baud

Default Conditions: Address:

Baud Rate:

A4

9600

14

Page 18

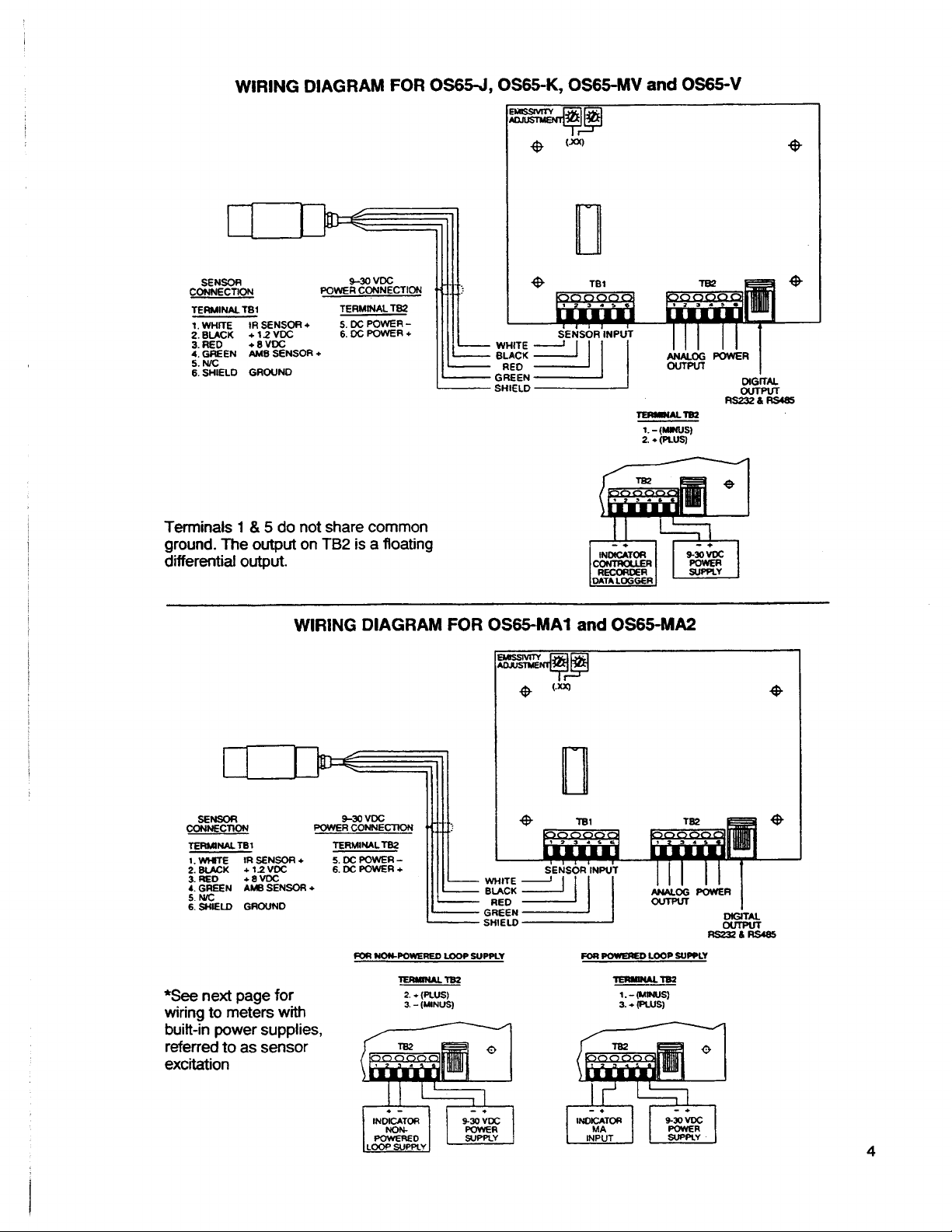

WIRIN G

DIAGRA M

SENSOR CONNECTION

TERMINAL

6

5

4

3

2

1

783

MilTi-

-

BLACK +

-

RED

GRiEN

-

-

N/ C

-

SHIELD GROUND

IR

SENSOR +

1.2

OS65-JX.

r \&&$j

VC C

TERMINAL TB4

16 + (PLUS)

17

Q-30 VDC

TERMINAL TB4

-

DC POWER

8

mV

and V

-

(MINUS)

TBt

11111

111

-

I

iI

SHIELD

OUTPU T

ST

TBl

d

‘INPISEI;SOR

WIRIN G

TERMINAL TB4

3 + TX/RX

1

COUPliTER

RS485

-

TX/R X

+-

HOST

TEA

II , I

GO’VDC

POWER

-

SUPPLY

- MA1 and MA2 with OS65

OS65

- CC4 Card Cage

FOR NON-POWERED LOOP SUPPLY FOR POWERED LOOP SUPPLY

TERMINAL TB4

(PLUS)

16 +

-

(MINUS)

13

TERMINAL TB4

-

(MINUS)

17

13 + (PLUS)

Page 19

WARRANTY/DISCLAIME R

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a

period

period to the normal

ensures that OMEGA ’s customers receive maximum coverage on each product.

If the unit should malfunction, it must be returned to the factory for evaluation. OMEGA ’s Customer

Service Department will issue an Authorized Return (AR) number immediately upon phone or written

request. Upon examination by OMEGA, if the unit is found to be defective it will be repaired or replaced at

no charge. OMEGA ’s WARRANTY does not apply to defects resulting from any.action of the purchaser,

including but not limited to mishandling, improper interfacing, operation outside of design limits,

improper repair, or unauthorized modification. This WARRANTY is VOID if the unit shows evidence of

having been tampered with or shows evidence of being damaged as a result of excessive corrosion; or

current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating

conditions outside of OMEGA ’s control. Components which wear are not warranted, including but not

limited to contact points, fuses, and

OMEGA is pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or errors nor assumes liability for any

damages that result from the use of its products in accordance with information provided by

OMEGA, either verbal or written. OMEGA warrants only that the parts manufactured by it will be

as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR

REPRESENTATlONS

TITLE,

AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF

LIABILlTY

OMEGA with respect to this order, whether based on contract, warranty, negligence,

indemnification, strict liability or otherwise, shall not exceed the purchase price of the

component upon which liability is based. In no event shall OMEGA be liable for

consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic

Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or

applications or used on humans. Should any Product(s) be used in or with any nuclear installation or

activity, medical application, used on humans, or misused in any way, OMEGA assumes no responsibility

as set forth in our basic WARRANTY/DISCLAIMER language, and additionally, purchaser will indemnify

OMEGA and hold OMEGA harmless from any liability or damage whatsoever arising out of the use of the

Product(s) in such a manner.

of

13 months from date of purchase. OMEGA Warranty adds an additional one (1) month grace

one (1) year

OF ANY KIND WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF

AND AU IMPLIED

The remedies of purchaser set forth herein are exclusive and the total liability of

WARRANTlES

product warranty to cover handling and shipping time. This

triacs.

INCLUDING ANY WARRANTY OF

MERCHANTABIUTY

(2)

in medical’

/

RETURN REQUESTS

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE

RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN

(AR) NUMBER FROM OMEGA ’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID

PROCESSING DELAYS). The assigned AR number should then be marked on the outside of the return

package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent

breakage in transit.

FOR

WARRANTY

following information available BEFORE

contacting OMEGA:

1.

PO. number under which the product was

PURCHASED,

2. Model and serial number of the product under

warranty, and

3. Repair instructions and/or specific problems

relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords

our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

0

Copyright 1996 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied,

reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without prior

written consent of OMEGA ENGINEERING, INC.

RETURNS, please have the

FOR

for current repair charges. Have the following

information available BEFORE contacting OMEGA:

1. P.O. number to cover the COST

2. Model and serial number of product, and

3. Repair instructions and/or specific problems

INQUIRIES

NON-WARRANTY

of the repair,

relative to the product.

REPAIRS, consult OMEGA

Page 20

I

Were

Do I Find Everything

Need for

Process Measurement and Control?

OMEGA...Of Course!

TEMPERATURE

&

&

Thermistor Probes, Connectors, Panels

RTD

I_2

Thermocouple,

0 Wire: Thermocouple, RTD

0 Calibrators & Ice Point References

0 Recorders, Controllers

0 Infrared Pyrometers

&

Thermistor

&

Process Monitors

PRESSURE, STRAIN AND FORCE

&

G4’

Transducers

0 Load Cells

0 Displacement Transducers

0 Instrumentation

Strain Gauges

&

Pressure Gauges

&

Accessories

FLOW /LEVEL

&

b?

Rotameters, Gas Mass Flowmeters

0 Air Velocity Indicators

0 Turbine

0 Totalizers

/

Paddlewheel Systems

&

Batch Controllers

Flow Computers

Assemblies

pH/CONDUCTIVITY

&

pH

Electrodes, Testers

0’

0

Benchtop

0

Controllers, Calibrators, Simulators

0

Industrial

/

Laboratory Meters

&

Conductivity Equipment

pH

Accessories

&

Pumps

DATA ACQUISITION

&

@’

Data Acquisition

0

Communications-Based Acquisition Systems

0

Plug-in Cards for Apple, IBM

0

Datalogging Systems

0

Recorders, Printers

Engineering Software

&

Compatibles

&

Plotters

HEATERS

0

Heating

0

Cartridge

0

Immersion

0 Flexible Heaters

0

Laboratory Heaters

Cable

&

Strip Heaters

&

Band Heaters

ENVIRONMENTAL

MON ITORING AND CONTROL

&

Metering

Refractometers

Pumps

Air, Soil

Industrial Water

pH,

Conductivity

Control Instrumentation

&

Tubing

&

Water Monitors

&

Wastewater Treatment

&

Dissolved Oxygen Instruments

Ml770 0299

Loading...

Loading...