Page 1

MADE IN

OS550A/OS550AM/

OS550A-BB Series

Industrial Infrared

Thermometer/Transmitter

STANDARD PLASTIC CASE - OS550A

ALUMINUM CASE - OS550AM

(OPTIONAL)

omega.com

e-mail: info@omega.com

For latest product manuals:

omegamanual.info

User’s Guide

Shop online at

Page 2

Servicing North America:

U.S.A.: Omega Engineering, Inc., One Omega Drive, P.O. Box 4047

ISO 9001 Certified

Stamford, CT 06907-0047

Toll-Free: 1-800-826-6342 Tel: (203) 359-1660

FAX: (203) 359-7700 e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec), Canada H7L 5A1

Toll-Free: 1-800-826-6342 TEL: (514) 856-6928

FAX: (514) 856-6886 e-mail: info@omega.ca

For immediate technical or application assistance:

U.S.A. and Canada: Sales Service: 1-800-826-6342/1-800-TC-OMEGA

®

Customer Service: 1-800-622-2378/1-800-622-BEST

®

Engineering Service: 1-800-872-9436/1-800-USA-WHEN

®

Mexico: En Español: 001 (203) 359-7803 FAX: (001) 203-359-7807

info@omega.com.mx e-mail: espanol@omega.com

Servicing Europe:

Benelux: Managed by the United Kingdom Office

Toll-Free: 0800 099 3344 TEL: +31 20 347 21 21

FAX: +31 20 643 46 43 e-mail: sales@omega.nl

Czech Republic: Frystatska 184

733 01 Karviná, Czech Republic

Toll-Free: 0800-1-66342 TEL: +420-59-6311899

FAX: +420-59-6311114 e-mail: info@omegashop.cz

France: Managed by the United Kingdom Office

Toll-Free: 0800 466 342 TEL: +33 (0) 161 37 29 00

FAX: +33 (0) 130 57 54 27 e-mail: sales@omega.fr

Germany/Austria: Daimlerstrasse 26

D-75392 Deckenpfronn, Germany

Toll-Free: 0 800 6397678 TEL: +49 (0) 7059 9398-0

FAX: +49 (0) 7056 9398-29 e-mail: info@omega.de

United Kingdom: OMEGA Engineering Ltd.

ISO 9001 Certified

One Omega Drive, River Bend Technology Centre, Northbank

Irlam, Manchester M44 5BD England

Toll-Free: 0800-488-488 TEL: +44 (0)161 777-6611

FAX: +44 (0)161 777-6622 e-mail: sales@omega.co.uk

OMEGAnet®Online Service Internet e-mail

omega.com info@omega.com

It is the policy of OMEGA Engineering, Inc. to comply with all worldwide safety and EMC/EMI

regulations that apply. OMEGA is constantly pursuing certification of its products to the European New

Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA accepts no liability for any

errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, human applications.

Page 3

NOTE

i

Unpacking Instructions

Remove the Packing List and verify that you have received all equipment, including

the following (quantities in parentheses):

OS550A or OS550A-BB Series Infrared Thermometer with Sensor Head (1)

RS-232 Cable with connector/adapter (OS552A, thru OS555A) only (1)

CD Software ( OS552A, thru OS555A) only (1)

User’s Guide (1)

Optional Accessories:

From the Technical Library of ____________________________________

Model No. Description

OS550-MN Mounting Nut

OS550-MB Mounting Bracket

OS550-AP Air Purge Collar

OS550-MF Mounting Flange

OS550-WC Water Cool Jacket

OS550-LS Laser Sight

PSS-12 Power Supply, 12V regulated

PSR-24S Reg. 24 Vdc Power Supply

Screw Terminals

PSR-24L Reg. 24 Vdc Power Supply

Stripped Leads

WRS232-USB Wireless RS-232 Transceiver

OS550A-PCAB-15 Power/output cable connector 15 ft

OS550A-PCAB-100 Power/output cable connector 100 ft

If you have any questions about the shipment, please call the Customer Service

Department at

1-800-622-2378 or 203-359-1660. We can also be reached on the Internet at

omega.com

e-mail: cservice@omega.com

When you receive the shipment, inspect the container and equipment for signs of

damage. Note any evidence of rough handling in transit. Immediately report any

damage to the shipping agent.

The carrier will not honor damage claims unless all shipping material

is saved for inspection. After examining and removing contents, save

packing material and carton in the event reshipment is

necessary.

Page 4

ii

OS550A Series

Industrial Infrared Thermometer

This page is intentionally blank

Page 5

TABLE OF

CONTENTS

OS550A/OS550A-BB Series

Industrial Infrared Thermometer

iii

Page

Unpacking Instructions ...................................................................... i

Chapter 1 General Description .................................................... 1-1

1.1 Introduction ......................................................................................... 1-1

1.2 Thermometer Features ....................................................................... 1-2

1.2.1 Display Details...................................................................................... 1-3

1.2.2 Parts of the Thermometer .................................................................. 1-4

Chapter 2 Installing the Handheld Infrared Thermometer ............. 2-1

2.1 Installation ............................................................................................ 2-1

2.2 Sensor Head Dimensions ................................................................... 2-2

2.3 Main Display Housing Dimensions .................................................. 2-3

2.4 OS550A-BB Dimensions ..................................................................... 2-5

2.5 Mounting Bracket Dimensions (OS550-MB) .................................... 2-6

2.6 Mounting Nut Dimensions (OS550-MN) ......................................... 2-6

2.7 Mounting Flange Dimensions (OS550-MF)...................................... 2-7

2.8 Air Purge Collar Dimensions (OS550-AP) ....................................... 2-7

Chapter 3 Using the Infrared Thermometer .................................. 3-1

3.1 Using the Infrared Thermometer ...................................................... 3-1

3.1.1 Water Cool Jacket Accessory ............................................................. 3-1

3.2 How To Wire the Thermometer......................................................... 3-2

3.3 Operating the Thermometer............................................................... 3-3

3.3.1 Field of View Charts ............................................................ 3-4, 3-5, 3-6

3.4 Measurement Techniques ................................................................... 3-7

3.5.1 Adjusting Emissivity ......................................................................... 3-10

3.5.2 Calculating Temperature Values ..................................................... 3-11

3.5.3 Changing the Temperature for °F to °C.......................................... 3-11

3.5.4 Turning the Display Backlighting ON/OFF .................................. 3-11

3.5.5 Using the Alarm Functions............................................................... 3-12

3.5.6 Using Ambient Target Temperature Compensation .................... 3-14

3.5.7 PC Interface Software ........................................................................ 3-16

3.5.7.1 PC Interface Commands .................................................................. 3-21

3.5.8 Storing Temperature Data On Command ..................................... 3-23

3.5.9 Reviewing Stored Temperature Data ............................................. 3-23

3.5.10 Logging Temperature Data In Real Time ...................................... 3-24

3.5.11 Erasing The Temperature Data From Memory ............................ 3-25

Chapter 4 Laser Sight Accessory .................................................. 4-1

4.1 Warnings and Cautions ...................................................................... 4-1

4.2 Description ........................................................................................... 4-2

4.3 Operating the Laser ............................................................................. 4-3

4.3.1 Installing the Laser Sight onto the Thermometer............................ 4-3

4.3.2 Powering the Laser Sight Accessory ................................................. 4-3

Page 6

iv

TABLE OF

CONTENTS

OS550A/OS550A-BB Series

Industrial Infrared Thermometer

Page

Chapter 5 Maintenance ............................................................... 5-1

5.1 Cleaning the Lens ................................................................................ 5-1

5.2 Calibrating the Thermometer ............................................................ 5-1

Chapter 6 Troubleshooting Guide ................................................ 6-1

Chapter 7 Specifications .............................................................. 7-1

Chapter 8 Glossary of Key Strokes ............................................. 8-1

Appendix A How Infrared Thermometry Works .......................... A-1

Appendix B Emissivity Tables ...................................................... B-1

Appendix C Determining an Unknown Emissivity ........................ C-1

Index ............................................................................................. I-1

Page 7

v

List of Figures

Figure Description Page

1-1 Display and Keypad View ................................................ 1-3

1-2 OS550A/OS550AM/OS550A-BB Series Industrial

Infrared Thermometer Front View .............................. 1-4

2-1 Sensor Head Dimensions .................................................. 2-2

2-2 Plastic Housing Dimensions ............................................ 2-3

2-2A OS550AM Aluminum Housing Dimensions ................ 2-4

2-3 OEM Style Main Display

with Mounting Plate (OS550A-BB) .............................. 2-5

2-4 Mounting Bracket Dimensions

(OS550-MB) ......................................................................2-6

2-5 Mounting Nut Dimensions

(OS550-MN) .................................................................... 2-6

2-6 Mounting Flange Dimensions

(OS550-MF) ...................................................................... 2-7

2-7 Air Purge Collar Dimensions

(OS550-AP) ...................................................................... 2-7

3-1 Water Cool Jacket Dimensions

(OS550-WC) .................................................................... 3-1

3-2 OS550A-BB Wire Connection .......................................... 3-2

3-3 External Relay Wiring Diagram ...................................... 3-3

3-4 Typical Transmission Installation .................................... 3-3

3-5 Field of View Positions ...................................................... 3-3

3-6 OS550A Series (-1 FOV) .................................................... 3-4

3-7 OS550A Series (-2 FOV) .................................................... 3-4

3-8 OS550A Series (-3 FOV) .................................................... 3-5

3-9 OS550A Series (-4 FOV) .................................................... 3-5

3-10 OS550A Series (-5 FOV) .................................................... 3-6

3-11 OS550A Series (-6 FOV) .................................................... 3-6

3-12 OS555A FOV ...................................................................... 3-7

3-13 Visual Function Flow Chart ............................................ 3-9

3-14 Personal Computer Connection .................................... 3-16

4-1 Laser Sighting Accessory (OS550-LS) ............................ 4-2

A-1 Infrared Temperature ...................................................... A-1

A-2 Blackbody Spectral Distribution ......................................A-2

A-3 Field of View of a Thermometer/Transmitter ..............A-4

C-1 Determining Emissivity With Masking Tape ................ C-2

C-2 Determining Emissivity with a Drilled Hole ................ C-3

LIST OF

FIGURES

OS550A/OS550A-BB Series

Industrial Infrared Thermometer

Page 8

vi

This page is intentionally blank

OS550A/OS550A-BB Series

Industrial Infrared Thermometer

Page 9

vii

CAUTION & SAFETY INFORMATION

If the equipment is used in a manner not specified in this manual, the

protection provided by the equipment may be impaired.

The Installation category is one (1).

The output terminals of this product are for use with equipment (digital

meters, chart recorders, etc.) which have no accessible live parts. Such

equipment should comply with all the applicable safety requirements.

Do not operate the equipment in flammable or explosive environments.

The unit comes with two 4.6 m (15') shielded multi-conductor cables. The

sensor cable is a five conductor, 24 AWG stranded wire with a rating of 600

Vdc, 205 °C (401 °F) PTFE insulation. The power/output cable is an eight

conductor 24 AWG stranded wire with rating of 300 Vdc, 105°C (221 °F)

PVC insulation.

Power must be disconnected before making any electrical connections.

The recommended power supply should be VDE or UL approved. Rating: 824 Vdc @ 100 mA minimum power with overload protection, current limited

to 500 mA.

The supply voltage to the transmitter should not exceed 24 VDC.

There is only one fuse in the OS550A. Disconnect power before replacing the

fuse. The fuse must be replaced with one of identical size and rating. Fuse

Specifications: 125 mA/250 Vac, Time-lag, 5 x 20 mm with UL and/or VDE

Approvals such as Wickmann No. 19195-028.

All connections made to the thermometer should be made via a stranded

wire, shielded cable, 24 AWG (min), such as OMEGA Engineering's Model

TX4 or TX8 series. Wiring requirements for this unit are Class II.

SAFETY WARNINGS AND IEC SYMBOLS

This device is marked with international safety and hazardous symbols in

accordance with IEC1010. It is important to read and follow all the

precautions and instructions in this manual before operating or

commissioning this device as it contains important information relating to

safety and EMC. Failure to follow all the safety precautions may result in

injury and/or damage to your equipment.

IEC Symbol Description

Caution - Refer to the accompanying

document(s).

Direct Current

Laser Symbol

LIST OF

FIGURES

OS550A/OS550A-BB Series

Industrial Infrared Thermometer

Page 10

viii

Notes

Page 11

1-1

General Description

1

1.1 Introduction

The OS550A Series Industrial Infrared (IR) Thermometers provide

non-contact temperature measurement up to 4500°F (2482°C). They

offer effective solutions for many non-contact temperature

applications, including the following:

• Predictive Maintenance: Tracking temperature shifts which

indicate pending failure in solenoid valves.

• Energy Auditing: Locating wall insulation voids to reduce

building heating costs.

• Food Processing: Taking accurate temperature readings

without direct contact with the food or packaging material.

• Annealing Processing: Monitoring surface temperatures of

metals while it is inside an oven by seeing through glass

window.

The IR thermometer provides a custom backlit dual digital LCD that

displays both current and minimum, maximum, average or

differential temperatures. This versatile instrument provides:

• Measurable target distances from 5 inches (12.7 cm) to

approximately 200 feet (61 m)

• Emissivity adjustable from 0.1 to 1.00 in 0.01 steps provides

ease of use when measuring a variety of surfaces.

• Continuous temperature measurement up to 10 times per

second.

• Audible and visual alarms. The high and low alarm points

are set via the keypad.

• Analog output, 1 mV/degree,4-20mA or 0-5VDC

which allows interfacing with data acquisition equipment

(including chart recorders, data loggers and computers)

• Two way RS232 serial communication to a PC. This allows

downloading data for further analysis (OS552A, OS553A

and OS554A, OS555A).

• Ambient target temperature compensation. This provides

more accuracy for measuring low emissivity targets.

• Record up to 800 temperature data points either continuos or

on demand. Review the recorded data on the thermometer

LCD, as well as downloading the data to a PC (OS553A and

OS554A, OS555A).

• Backlit display useful in low ambient light conditions

• Laser Sighting is optional.

• High and Low Alarm outputs to drive external Mechanical

Relays

Page 12

General Description

1

1-2

General Description

1.2 Thermometer Features

The thermometer is easy to use:

• Temperature readings are switchable from °F to °C via the

keypad.

• Parameters, such as target material emissivity and alarm

setpoints, can be set and remain in non-volatile memory

until reset.

This instrument has a rugged and functional design, including:

• Sealed keypad display.

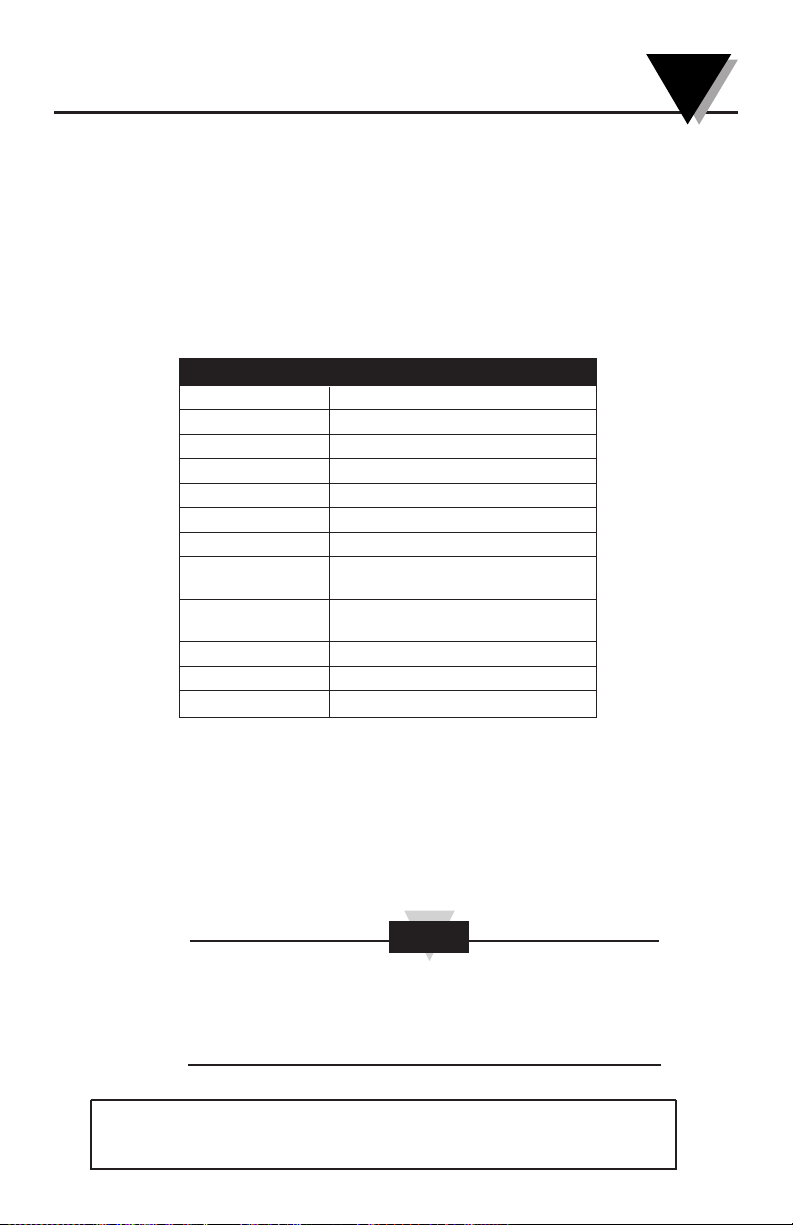

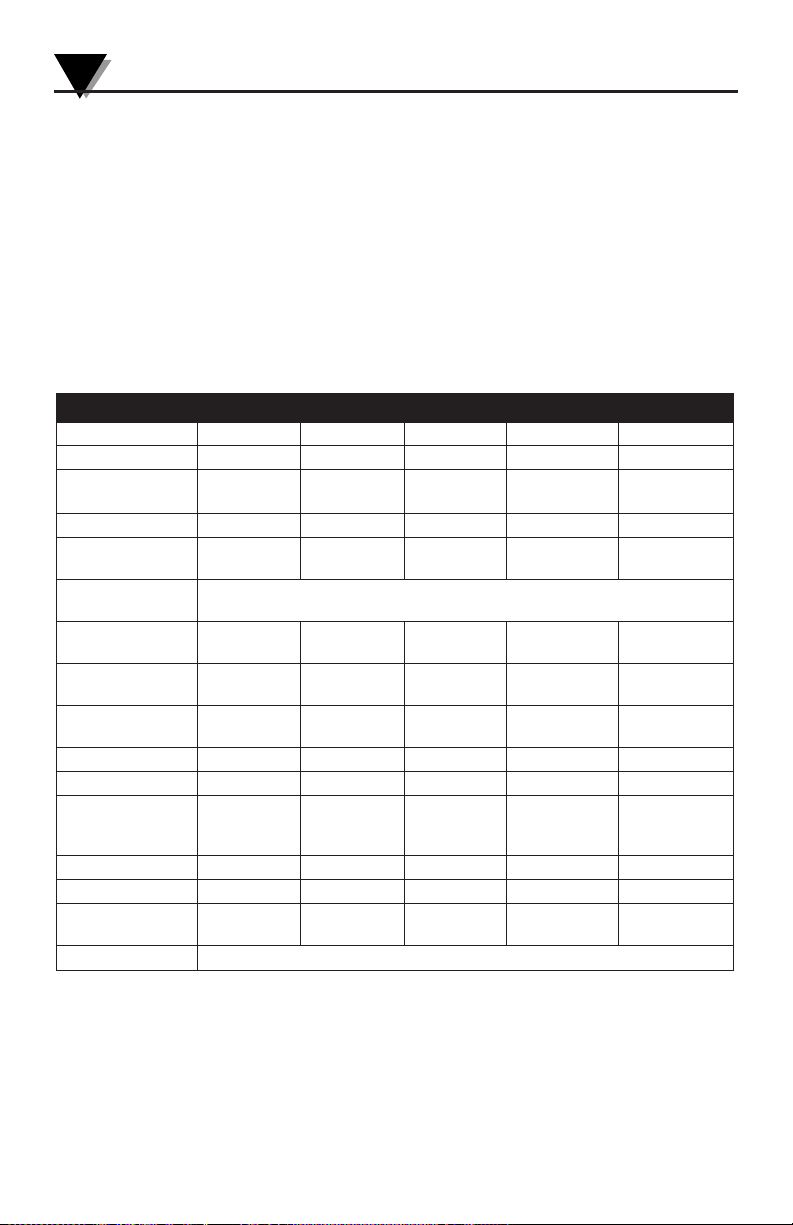

Table 1-1. OS550A Series Industrial Infrared Thermometer Features

*or 3°F whichever is greater - 2% of rdg for temps > 2000°F on OS555A

Features OS551A OS552A OS553A OS554A OS555A

Accuracy* ±1% rdg ±1% rdg ±1% rdg ±1% rdg ±1% rdg

Range -10 to 750°F -10 to 1000°F -10 to 1600°F 0 to 2500°F 1000 to 4500°F

(-23 to 400°C) (-23 to 538°C) (-23 to 870°C) (-18 to 1371°C) (538 to 2482°C)

Emissivity adjustable adjustable adjustable adjustable adjustable

Backlit Dual

standard standard standard standard standard

Display

Distance to

Spot Ratio

Differential

standard standard standard standard standard

Temperature

Min/Max

standard standard standard standard standard

Temperature

Average

standard standard standard standard standard

Temperature

High Alarm standard standard standard standard standard

Low Alarm – standard standard standard standard

Ambient Target

Temperature – standard standard standard standard

Compensation

RS-232 Interface – standard standard standard standard

Data Storage – – standard standard standard

Audible Alarm

standard standard standard standard standard

& Output

Analog Outputs 1 mV/Degree or 0/5 Vdc or 4/20 mA

See Field of View Charts, pages 3-4, 3-5, 3-6, 3-7

Page 13

1-3

General Description

1

General Description

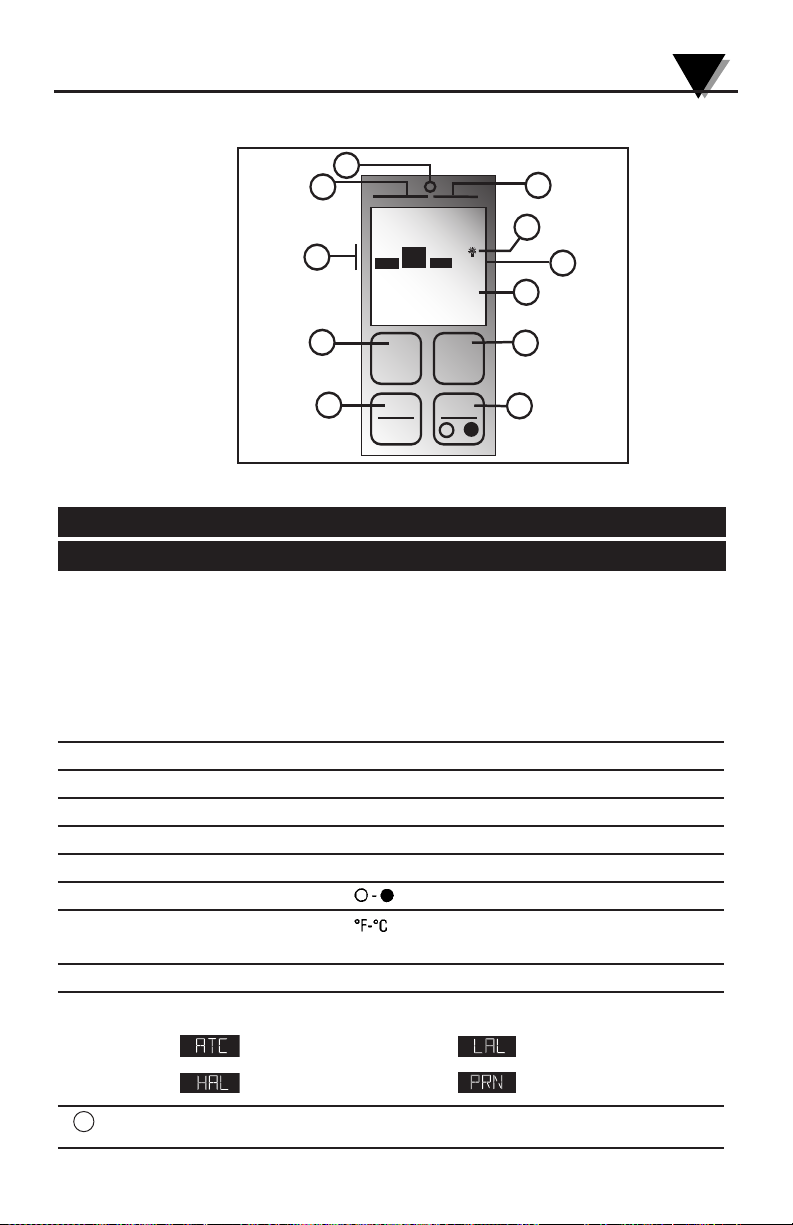

1.2.1 Display Details

Figure 1-1. Display and Keypad View

Table 1-2. Display Details

Key Description

¿

Display Mode displays one of the following:

E (Emissivity) HAL (High Alarm Setpoint)

MAX (Maximum Temperature) LAL (Low Alarm Setpoint - OS552A thru OS555A)

MIN (Minimum Temperature) AMB (Ambient Target Temp - OS552A thru OS555A)

dIF (Differential Temperature) PRN (Print Data - OS552A, thru OS555A)

AVG (Average Temperature) MEM (Store Temperature Data - OS553A thru OS555A)

LOG (Log Temp Data- OS553A thru OS555A)

¡

Data associated with one of the Display Modes

¬

Backlighting Icon - allows the display to be viewed under low ambient light

√

Displays the units of measure in either °F or °C

ƒ

Main display - displays the current temperature

≈

Enables or Disables alarms or LOG. Resets MAX, MIN, DIF,AVG, temperatures

∆

s for incrementing data; is for turning on/off the backlighting

«

t for decrementing data; is for changing the units of measure from

°F to °C or vice versa

»

Function key for scrolling through the display modes

…

Display Icons

Ambient Target Temperature Low Alarm

High Alarm Data Transmisson thru RS232

High or Low Alarm condition LED

MAX750

658

ATC

HAL

LAL

PRN

°F °C

SET

FUNC

F-C

▼

▼

-

2

1

10

11

9

8

3

4

5

6

7

11

Page 14

General Description

1

1-4

General Description

1

1.2.2 Parts of the Thermometer/Transmitter

Figure 1-2.

OS550A/OS550AM/OS550A-BB Series Industrial Infrared Thermometer

Front View

The display is shown in more detail in Figure 1-1 and described in Table 1-2.

Note: There are no user-serviceable parts in the thermometer.

Shown with optional mounting bracket,

OS550-MB and mounting nut OS550-MN

Sensor Head

NEMA4 Plastic Housing, Keypad, Display

and Output Electronics (OS550A Series)

Sensor

Cable with

Quick

Disconnect

Power/

Output

Cable with

Quick

Disconnect

OEM Style

Keypad, Display,

and Electronics

(OS550A-BB Series)

NEMA4

Aluminum

Housing,

(OS550AM

Series)

Page 15

2-1

2

2.1 Installation

2.1.1 Sensor Head Installation

The OS550A’s sensor head is made of black anodized aluminum. Both ends

of the sensor head come with a 1

1

⁄2 - 20 standard threaded mounting

connection. The sensor head is connected to the main display electronics via

a 15' shielded cable and environmentally sealed twist lock connector.

Mounting accessories are available. See page 2-2 for sensor head

dimensions.

If the sensor head is used in an environment where the

ambient temperature is above 122°F (50°C), the water

cool jacket accessory (OS550-WC) must be used to

maintain accuracy and prevent damage to the sensor

head. See Chapter 3.1.

2.1.2 OS550A Series NEMA Plastic Housing Installation

The OS550A Series’ main display and electronic’s housing is

environmentally sealed and weather tight. Mounting ears are provided

making mounting easy. Mount the main electronics assembly in a location

that you can easily access to view the LCD and make program changes to

the unit. See case and mounting plate dimensions on page 2-3.

2.1.2A OS550AM Series NEMA Aluminum Housing

The OS550AM Series is available in a NEMA Aluminum Housing as an

option. Refer to figure 2-2A for case and mounting hole dimensions.

2.1.3 OS550A-BB OEM Style Display Installation

The main display and electronics assembly is provided with an aluminum

mounting plate making installation of this OEM style system economical

and easy to customize. Assembly should be mounted in a location that is

free of dirt, grease, oils, and other liquids. See mounting dimension

on page 2-5.

Installing the Infrared Thermometer

NOTE

Page 16

Installing the Infrared Thermometer

2

2-2

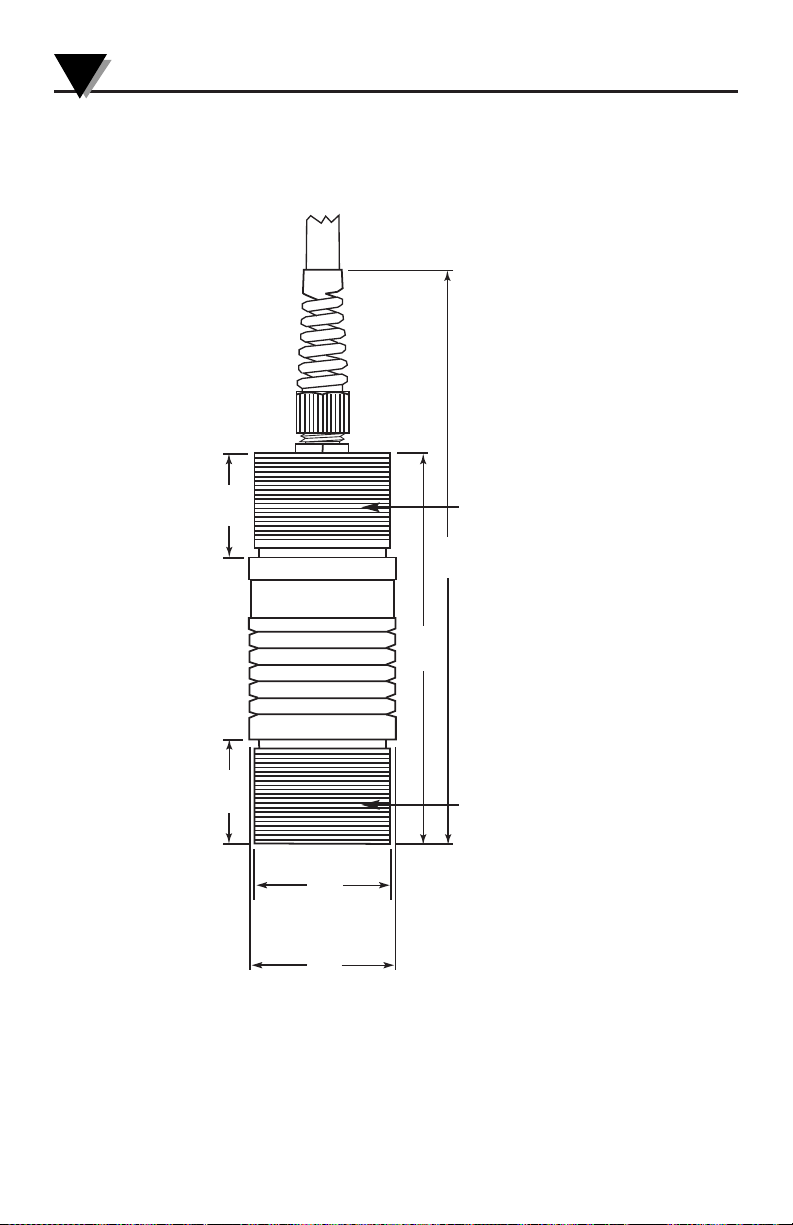

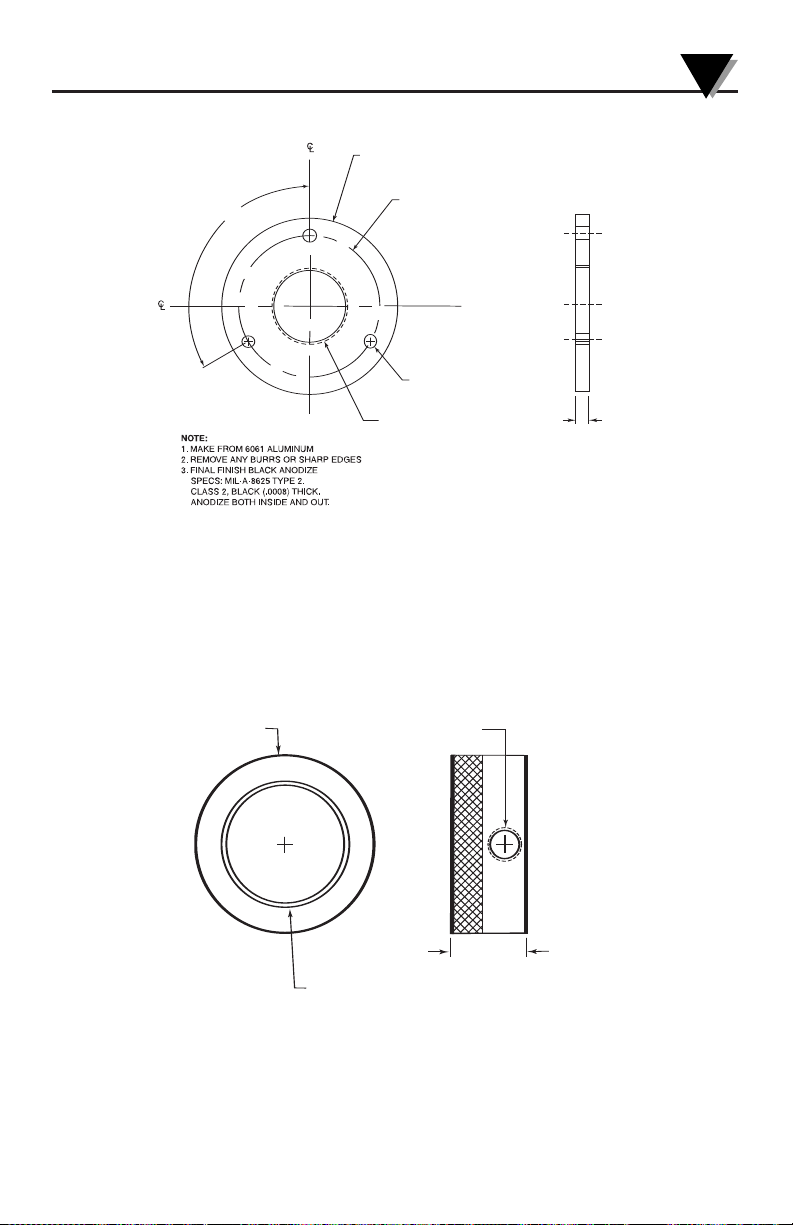

2.2 Sensor Head Dimensions

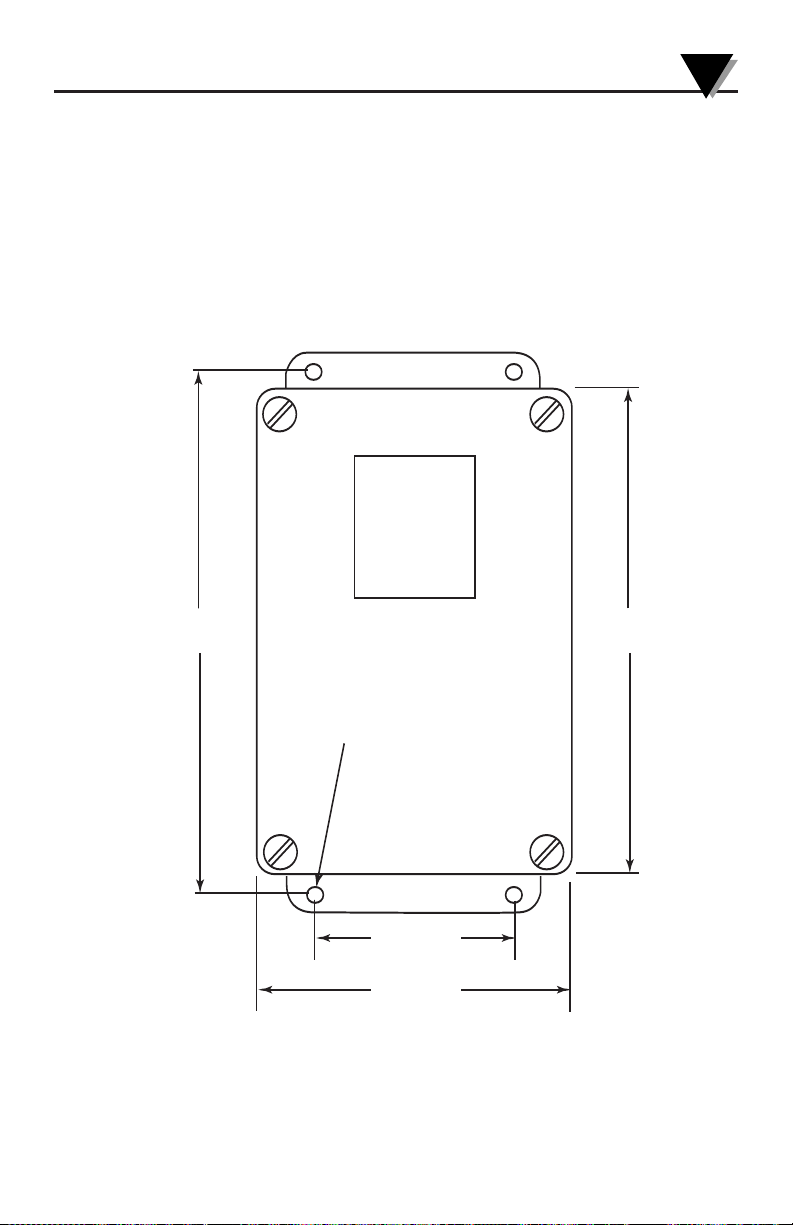

Fig. 2-1. Sensor Head Dimensions

29.2

(1.15)

29.2

(1.15)

41.1

(1.62) DIA.

38.1

(1.50) DIA.

109.2

(4.30)

160.3

(6.31)

11⁄2x 20 THREAD

11⁄2x 20 THREAD

Page 17

2-3

Installing the Infrared Thermometer

2

131.3

(5.17) TYP.

120.6

(4.75) TYP.

Ø 4.37 (0.172) MOUNTING HOLE

(4 PLACES)

50.0

(1.97) TYP.

80.10

(3.15) TYP.

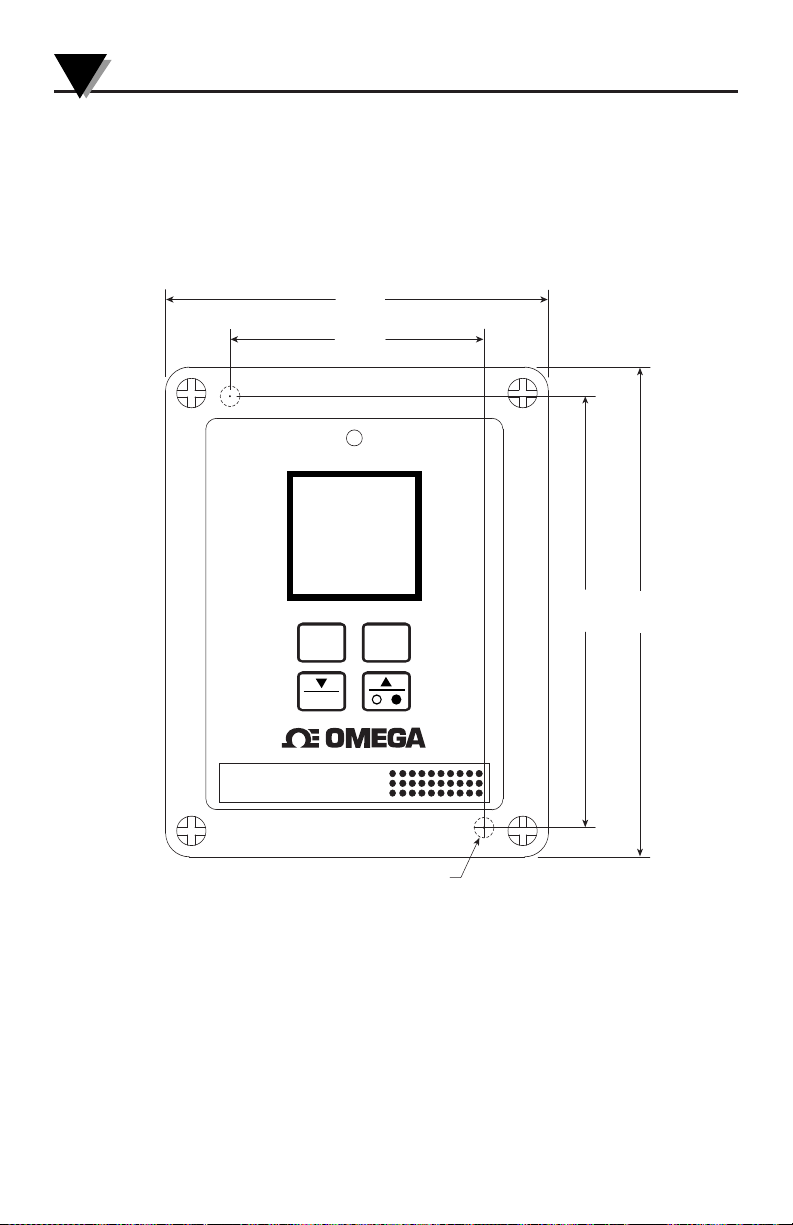

Fig. 2-2. Plastic Housing Dimensions

2.3 OS550A Main Display Standard Plastic Housing Dimensions

Page 18

Installing the Infrared Thermometer

2

2-4

FUNC SET

°F-°C

-

90.0

(3.54)

60.0

(2.36)

100.8

(3.97)

115.3

(4.54)

4.7 (0.187) DIA.

MOUNTING HOLES

2 PLCS

High/Low Alarm

®

OS550A SERIES INFRARED

INDUSTRIAL PYROMETER

2.3A OS550AM Aluminum Housing Dimensions

Fig. 2-2A. Aluminum Housing Dimensions

Page 19

2-5

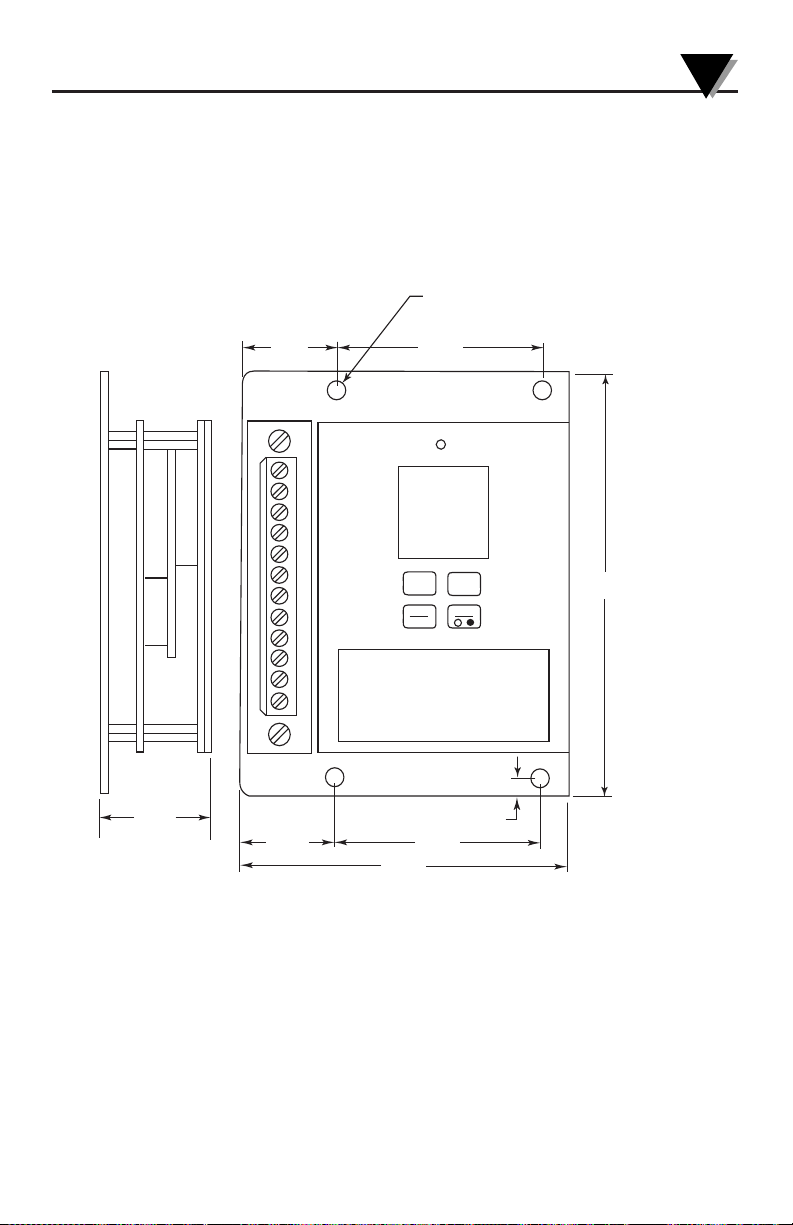

2.4 OS550A Display Electronics Dimensions

Fig. 2-3. OEM Style Main Display with Mounting Plate

SET

FUNC

F-C

▼

▼

-

26.4

(1.04)

31.0

(1.22)

57.4

(2.26)

Ø 5.16 (0.203) THRU TYP. (4 PLACES)

WILL FIT UP TO A

#10 SCREW OR BOLT

118.4

(4.66)

26.4

(1.04)

57.4

(2.26)

5.1

(.20) TYP.

91.4

(3.60)

Installing the Infrared Thermometer

2

Page 20

2-6

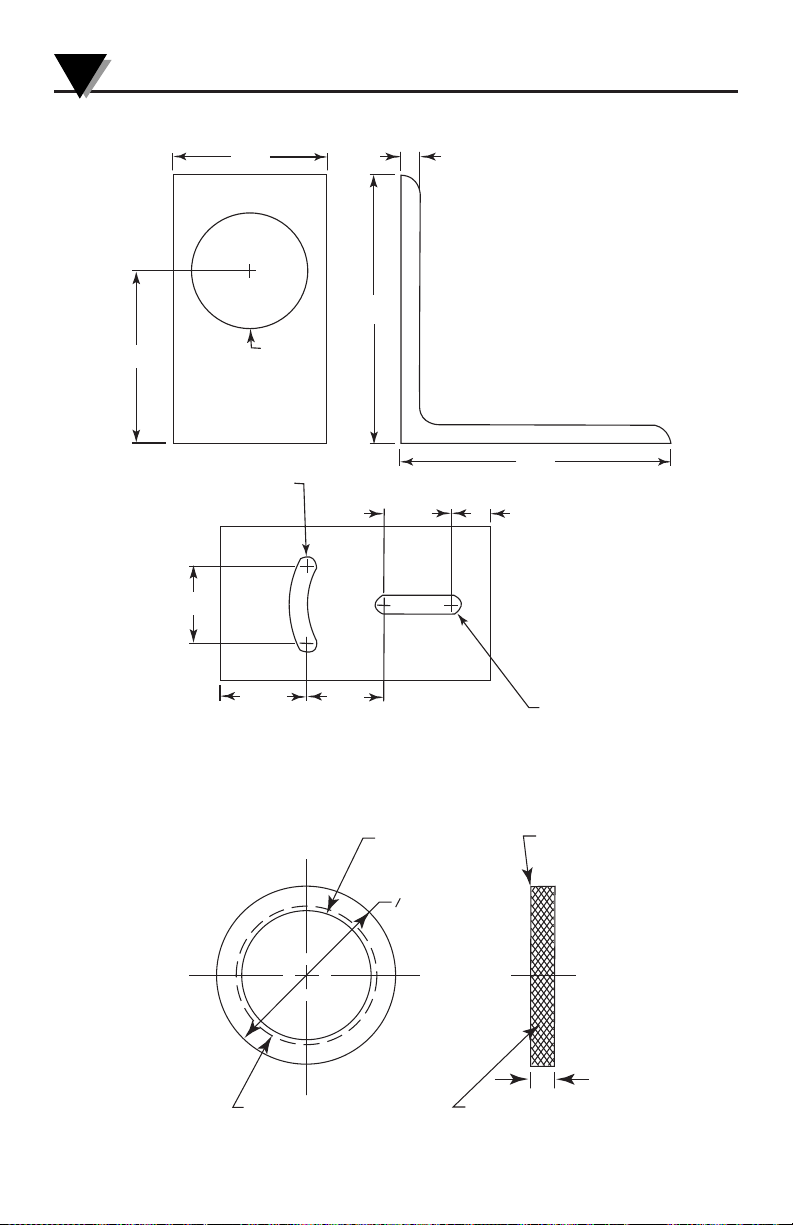

2.4 Mounting Bracket Dimensions (OS550-MB)

Fig. 2-4. Mounting Bracket Dimensions

2.5 Mounting Nut Dimensions (OS550-MN)

Fig. 2-5 Mounting Nut Dimensions

50.8

(2.00)

57.2

(2.25)

38.61

Ø (1.520)

88.9

(3.50)

6.4

(.25) REF

88.9

(3.50)

12.7

(.50)

25.4

(1.00)

28.58

(1.125)

22.23

(.875)

25.4

(1.00)

3.18

R (.125)

3.18

R (.125)

TYP. 2 PLACES

.020 x 45

CHAMFER

BOTH SIDES

.020 x 45

CHAMFER

BOTH SIDES

1 1/2-20-2B THRU MED. DIAMOND NURL

.250

C

L

o

2.00

Installing the Infrared Thermometer

2

Page 21

2-7

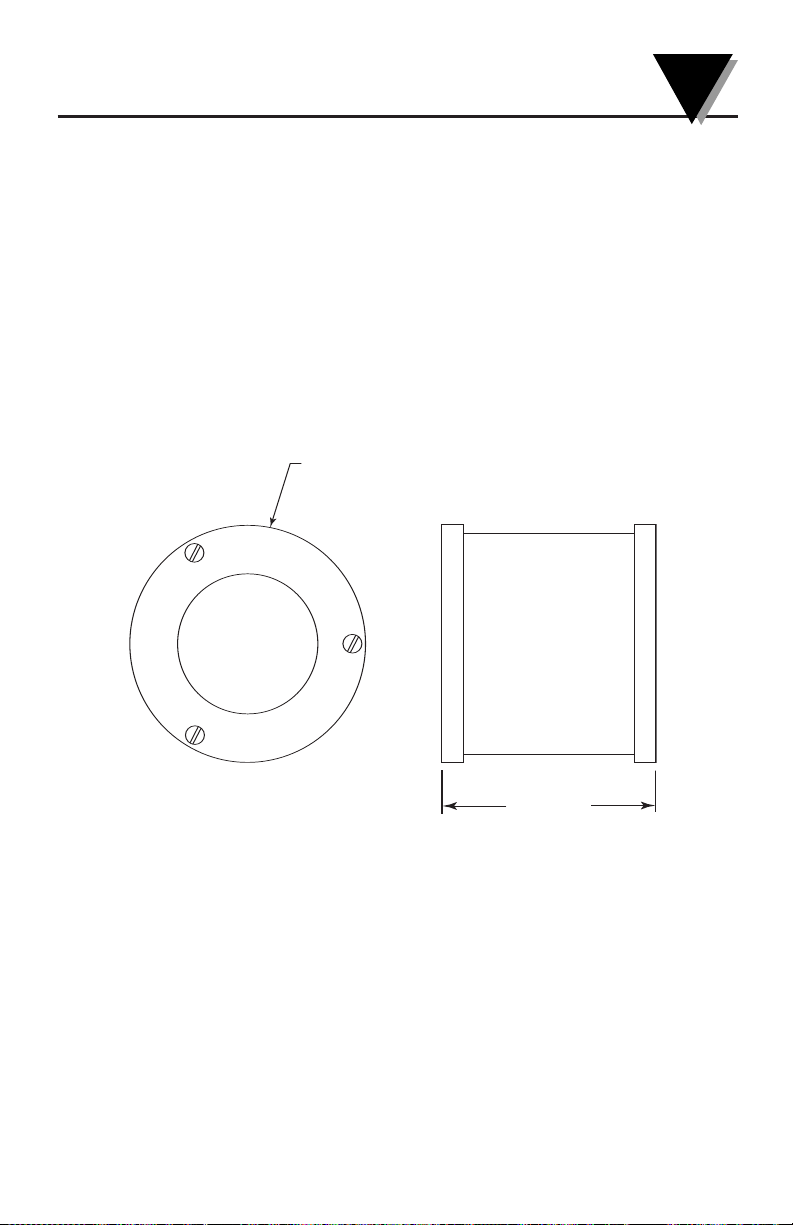

2.6 Mounting Flange Dimensions (OS550-MF)

2.7 Air Purge Collar Dimensions (OS550-AP)

6.35

(.250)

38 (1.5) - 20 THREAD

6.35 (.250)

THRU TYP. (3 PLACES)

3 HOLES ON Ø 71.1 (2.80)

BOLT CIRCLE

TYP. 3 PLACES

120

Ø 89 (3.5)

21.59

(.850)

1/8 N.P.T. TAP THRU

51 (2.0) DIA.

38 (1.5) – 20 THREAD

Fig. 2-6 Mounting Flange Dimensions

Fig. 2-7 Air Purge Collar Dimensions

Installing the Infrared Thermometer

2

Page 22

Installing the Infrared Thermometer

2

2-8

Notes

Page 23

3-1

Using the Infrared Thermometer

3

3.1 Using the Infrared Thermometer

3.1.1 Water Cool Jacket Accessory

When using the OS550A sensor head in an ambient temperature

environment above 50°C (122°F), the OS550-WC Water Cooling Jacket

option must be used to maintain the accuracy and response time of the

unit. Two 1⁄8" N.P.T. compression fittings are provided for connection to

copper water lines. A constant flow of approx. 0.5 GPM of clean, room

temperature water is sufficient to protect the instrument and maintain

accuracy up to 85°C (185°F). This option can be installed in the field.

Fig 3-1. Water Cool Jacket Dimensions (OS550-WC)

Ø 70.4 (2.77)

63.5 (2.50)

Page 24

Using the Infrared Thermometer/Transmitter

3

3-2

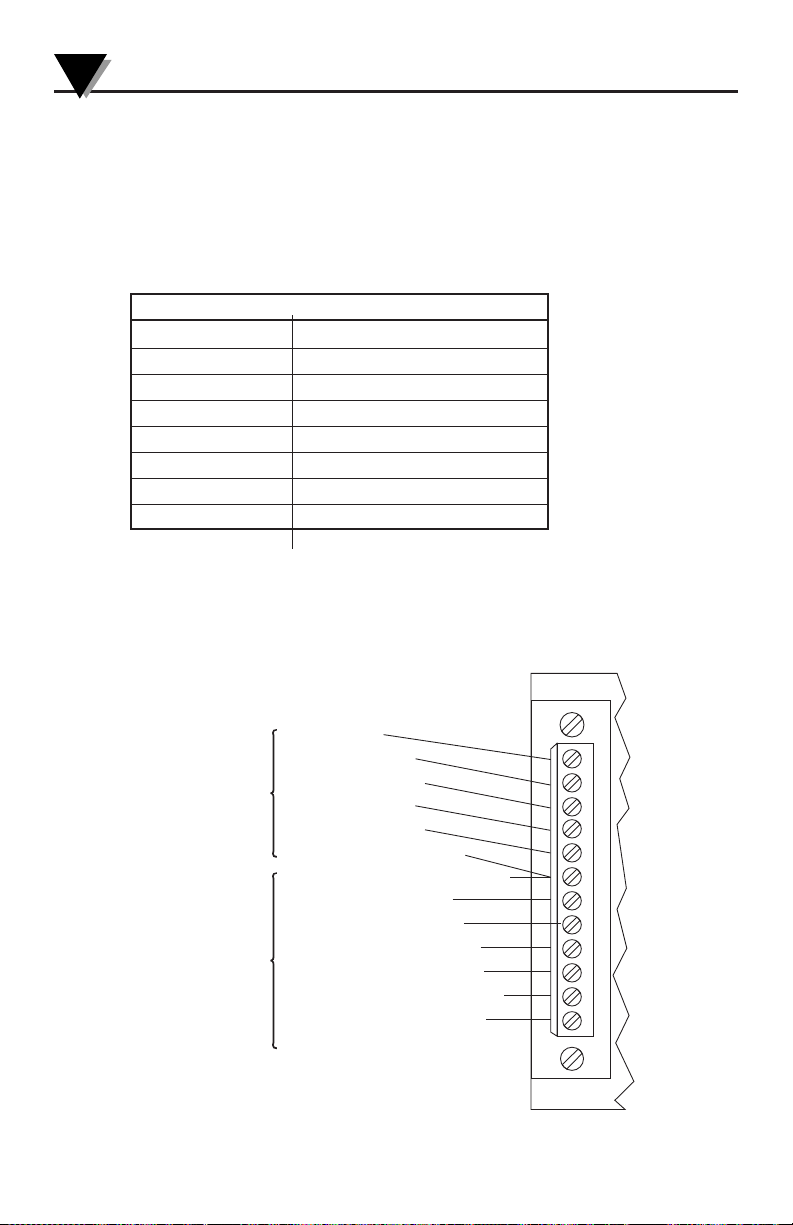

3.2 How To Wire the Thermometer

3.2.1 OS550A Series Cable Connection

The OS550A Series thermometer comes with a built-in 4.5 m (15') sensor

cable and power/output cable. Plug in the two cables to the mating

connectors on the Enclosure. Power and output connections are made to the

cable via stripped wire ends located at the other end of the cable. The

power/output cable can be shortened or extended in the field if needed. See

table 3-1 below for wire Connection.

Note: Power Input and Analog output share the same common ground.

Table 3-1 Power/Output Cable Connection

3.2.2 OS550-BB Series Terminal Block Wire Connections

Figure 3-2. OS550A-BB Wire Connection

Cable Wire Connection

Red + Power Input

Black – Power Input

White + Analog Output

Green – Analog Output

Yellow High Alarm Output

Blue Low Alarm Output

Orange No Connection

Shield Earth Ground

5

4

3

2

1

6

7

8

9

10

11

12

RED WIRE (+5V)

WHITE WIRE (CHAN 1)

GREEN WIRE (CHAN 2)

YELLOW WIRE (TAMB)

BLACK WIRE (GROUND)

SHIELD WIRE - SENSOR CABLE

SHIELD WIRE - POWER/OUTPUT CABLE

RED WIRE (+ POWER INPUT)

BLACK WIRE (– POWER INPUT)

WHITE WIRE (+ ANALOG OUTPUT)

GREEN WIRE (– ANALOG OUTPUT)

YELLOW WIRE (HIGH ALARM OUTPUT)

BLUE WIRE (LOW ALARM OUTPUT)

ORANGE - NO CONNECTION

SENSOR

CABLE

CONNECTION

POWER

OUTPUT/

CABLE

CONNECTION

8-24 Vdc

1mV/Deg, 0/5 Vdc

4/20 mA

}

}

Page 25

Figure 3-3. External Relay Wiring Diagram

Figure 3-4. Typical Transmitter Installation

3.3 Operating The Thermometer

1. After installing the thermometer (see section 2.1) and connection for

sensor cable and power/output (see section 3.2), your unit is ready

for use.

2. The optical field of view of the thermometers sensor head should fall

within the area of the target being measured. See Figure 3-2. Figures 33 through 3-8 show the fields of view vs. distance for the various

thermometers.

Figure 3-5. Field of View Positions

3. The target temperature and emissivity are displayed on the LCD.

Determine the emissivity of the target (refer to Appendix B).

Press the key to increment the target emissivity.

Press the key to decrement the target emissivity

Field of View

Target

(ACCEPTABLE)

(UNACCEPTABLE)

YELLOW WIRE

OUTPUT

CABLE

BLACK OR GREEN WIRE

BLUE WIRE

HIGH ALARM

LOW ALARM

+

–

–

+

MECHANICAL

RELAY

8-24 VDC

MECHANICAL

RELAY

8-24 VDC

3-3

Using the Infrared Thermometer/Transmitter

3

SENSOR HEAD

SENSOR CABLE

POWER/OUTPUT

CABLE

8-24 VDC

POWER

SUPPLY

DIGITAL

VOLTMETER,

AMMETER,

RECORDER

(EARTH GND)

FIELD REPLACEABLE FUSE

(+ PWR) RED

+

+

–

–

(+ OUTPUT) WHITE

(– OUTPUT) GREEN

(– PWR) BLACK

SHIELD

OS550A

OS550AM

5 CONDUCTOR SHIELDED CABLE

8 CONDUCTOR SHIELDED CABLE

Page 26

Using the Infrared Thermometer/Transmitter

3

3-4

Figure 3-6. OS550A Series (-1 FOV)

Figure 3-7. OS550A Series (-2 FOV)

7.0

.35" @ 24"

1.6

9mm @ 610 mm

.8

21

42

181

.9

22

4.0

101

0

3

16102 5

SPOT DIA.* (MM)

*SPOT DIAMETER MEASURED

AT 90% ENERGY

5.0

0

.61

1.5

1.0

3.0

SPOT DIA.* (IN)

DISTANCE: SENSOR TO OBJECT (FT)

DISTANCE: SENSOR TO OBJECT (M)

D:S = 68:1

3.3.1 Field of View Charts

Page 27

3-5

Using the Infrared Thermometer/Transmitter

3

Figure 3-8. OS550A Series (-3 FOV)

Figure 3-9. OS550A Series (-4 FOV)

4.8"

1.0" @ 0" to 20"

2.5cm @ 51cm

1.2"

1.0"

2.5

6.0

4.0

8.0

10.0

12.2

1601208040

1.0"

1.8"

2.4"

3.0"

3.6"

4.2"

1' 2'

200

8'6'

0**

DISTANCE: SENSOR TO OBJECT (FT)

DISTANCE: SENSOR TO OBJECT (CM)

SPOT DIA.* (IN)SPOT DIA.* (CM)

*SPOT DIAMETER MEASURED

AT 90% ENERGY

D:S = 20:1

4'

244

3' 5' 7'

20"

Page 28

Using the Infrared Thermometer/Transmitter

3

3-6

2.9

0.9" @ 0

1.9

22mm @ 0

1.2

1.0

31

26

48

75

0.9

0

3

1610

*SPOT DIAMETER MEASURED

AT 90% ENERGY

D:S

=

60:1

5

5.0

0

1.0 3.01.5

SPOT DIA.* (MM)

SPOT DIA.* (IN)

DISTANCE: SENSOR TO OBJECT (FT)

DISTANCE: SENSOR TO OBJECT (M)

.45"

11.5

3"

SPOT DIA.* (MM)

A

*SPOT DIAMETER MEASURED

T 90% ENERGY

7.6

SPOT DIA.* (IN)

DISTANCE: SENSOR LENS TO OBJECT (in.)

DISTANCE: SENSOR LENS TO OBJECT (cm.)

15.2

6"

9" 12"

15"

.15"

.39"

.78"

1.17"

3.9

9.9

19.9

29.9

D:S = 40:1

22.9

30.5

38.1

0.9"

22

0

0

Fig. 3-10. OS550A Series- (-5FOV)

Figure 3-11. OS550A Series- (-6FOV)

Page 29

3-7

3

Using the Infrared Thermometer/Transmitter

Figure 3-12. OS555A FOV

3.4 Measurement Techniques

You can use the IR Thermometer to collect temperature data in any

one of five different ways:

• Spot Measurement — Measures the temperature of discrete objects

such as motor bearings, engine exhaust manifolds, etc.:

1. Aim the sensor head at the desired target.

2. If necessary, adjust the emissivity using the and keys.

3. Read the temperature.

• Differential Measurement — Measures the temperature differential

between two spots (the maximum and minimum temperatures viewed)

1. Aim the thermometer at the first spot.

2. If necessary, adjust the emissivity.

3. Aim at the second spot.

4. Adjust the emissivity of the second spot if required.

5. To display the differential temperature, press the key until

“dIF” appears on the display.

6. Read the differential temperature from the upper display.

• Static Surface Scan – Measures the temperature across a static surface:

1. Aim the thermometer’s sensor head at a starting point.

2. If necessary, adjust the emissivity.

3. Slowly move the thermometer’s sensor head so that the line of

sight sweeps across the surface. The thermometer measures the

temperature at each point on the surface.

4. To record the temperature profile across the surface, connect

the IR thermometer to a strip chart recorder that will accept an

analog input matching the analog output of the model OS550

that you have selected.

8.7"

0.5"@ 0

5.1"

13mm @ 0

1.5"

38

130

221

0.9"

0' 16' 82'50'

*SPOT DIAMETER MEASURED

AT 90% ENERGY

D:S

=

110:1

25

0

5 15

DISTANCE: SENSOR TO OBJECT (FT)

SPOT DIA.* (MM)

SPOT DIA.* (IN)

DISTANCE: SENSOR TO OBJECT (M)

Page 30

3-8

Using the Infrared Thermometer/Transmitter

3

Table 3-2. Functional Flow Chart

Display

Mode:

Press to...

Go to

Go to

Go to

Go to

Go to

Go to

or

Go to

Go to

Go to

or

Go to

Go to

Press to...

ACTIVATE / DEACTIVATE

ACTIVATE / DEACTIVATE

ACTIVATE / DEACTIVATE

ACTIVATE / DEACTIVATE

Store

temperature data

Turn ON/OFF

Logging

Reset MAX,

MIN, DIF,

AVG, temperatures

Press or to...

Set Emissivity

Press to change

between °F/ °C

Press to turn LCD

backlight ON or OFF

Set

High alarm value

Set

Low alarm value

Set target ambient

temperature

Set data transmission

interval

Review stored data

Display shows:

Current temperature

Emissivity

Current temperature

Maximum temperature

Current temperature

Minimum temperature

Current temperature

Differential temperature

Current temperature

Average temperature

Current temperature

High alarm setpoint

Current temperature

Low alarm setpoint

Current temperature

Ambient target temperature

Current temperature

Print interval

Current temperature

Memory location

Current temperature

Logging

OS551A

OS552A

OS553A, OS554A, OS555A

Real T ime Mode

_ _

Page 31

Figure 3-13 Visual Function Flow Chart

LC K

°F

°F

LAL

°F

AT C

°F

PR N

°F

°F

°F

°F

°F

°F

HA L

°F

MODE MODE DISPLA Y DISPLA Y

☞

☞

☞

☞

☞

☞

☞

☞

☞

☞

☞

(Model OS551A)

(Model OS552A)

(Model OS553A,

OS554A,

OS555A)

3-9

3

Using the Infrared Thermometer/Transmitter

* While in these 4 modes:

Use key to change temperature from °F to °C or vice versa.

Use key to turn on/off the display backlighting.

*

*

*

*

Note: This flow-chart can also

be found on the back of the

label inside the main display

housing clear plastic lid.

Page 32

Using the Infrared Thermometer/Transmitter

3-10

3

3.5.1 Adjusting Emissivity

Refer to Appendices B and C for information on emissivity

before making your adjustment.

1. When the thermometer is powered up, the default

emissivity setting will be set to 0.95.

2. If necessary, press the key to increment the target

emissivity or press the key to decrement the target

emissivity.

The unit maintains the emissivity value even when the

power is removed.

At the Power Up, Display shows the Model No.

(OS553A, OS552A, etc.) then the firmware revision,

then the analog output, before going to

MV 1

V0-5

MA 4-20

real time operation.

NOTE

NOTE

°F

Page 33

3-11

Using the Infrared Thermometer/Transmitter

3

3.5.2 Calculating Temperature Values

The thermometer calculates the MAX, MIN, dIF, and AVG

temperatures based on the current temperature.

To clear the “AVG ---” display, press the key to reset or turn off the

thermometer.

Pressing the key resets the MAX, MIN, dIF and AVG

temperatures while in the same Display modes.

3.5.3 Changing the Temperature from °F to °C (or vice versa)

During the time that the thermometer displays either MAX, MIN,

dIF, or AVG temperatures, press the key to change all the

temperatures from °F to °C or vice versa.

3.5.4 Turning the Display Backlighting ON/OFF

During the time that the thermometer displays either MAX, MIN,

dIF, or AVG temperatures, press the key to turn the display

backlighting ON/OFF.

°F

°F°F°F

°F

NOTE

“AVG ---” is displayed when either of the following

conditions occur:

1.

When the average temperature measurement reaches its

time period as stated in the specifications.

2.

When the thermometer is trying to measure a target

temperature which is outside of its measuring temperature

range.

is the maximum temperature

since the temperature

measurement session starts

(pulling the trigger).

is the minimum

temperature since the

temperature measurement

session starts.

is the difference between

the MAX and MIN

temperatures.

is the true average temperature since the temperature

measurement session starts. The average temperature under

continuous operation is accurate for a limited period of time

(refer to the specifications). However, the AVG temperature

function can be used indefinitely when the thermometer is

operating intermittently.

Page 34

Using the Infrared Thermometer/Transmitter

3-12

3

3.5.5 Using the Alarm Functions

The thermometer provides audible and visible alarm

indications, as well as alarm outputs.

• To set the high alarm value:

1. Press the key until the High Alarm Display Mode

(HAL) appears.

2. Press the key to increment the high alarm value. Press

the key to decrement the high alarm value.

3. Press the key to enable the high alarm function. The

icon appears.

If the temperature exceeds the high alarm setpoint,

you will hear a beep and the icon on the

display flashes. The high alarm output voltage goes

high. The alarm LED turns on.

4. To disable the high alarm, press the key again,

and the icon disappears.

If you are not in High Alarm Display Mode (HAL) when

the high alarm goes off, you must press the key to

get into the High Alarm Display Mode. Then press the

key to disable the high alarm.

The unit maintains its high alarm set point value even

when the power is removed.

Default Values of high alarm set points are:

OS551A 750°F

OS552A 1000°F

OS553A 1600°F

OS554A 2500°F

OS555A 4500°F

NOTE

NOTE

°F

HAL

Page 35

3-13

Using the Infrared Thermometer/Transmitter

3

• To set the low alarm value (OS552A thru OS555A):

1. Press and hold the key until the Low Alarm Display

Mode (LAL) appears.

2. Press the key to increment the low alarm value. Press

the key to decrement the low alarm value.

3. Press the key to enable the low alarm function. The

icon appears.

If the temperature drops below the low alarm

setpoint, you will hear a beep and the icon on

the display flashes. The low alarm output voltage

goes high. The alarm LED turns on.

4. To disable the low alarm, press the key again, and

the icon disappears.

If you are not in Low Alarm Display Mode (LAL) when

the low alarm goes off, you must press

the

key to get into the

Low

Alarm Display Mode.

Then press the key to disable the low alarm.

The unit maintains its low alarm set point value even

when the power is removed.

Default values of Low alarm set points are:

OS551A, 552A, 553A -10°F

OS554A 0°F

OS555A 1000°F

NOTE

NOTE

°F

LAL

Page 36

Using the Infrared Thermometer/Transmitter

3-14

3

3.5.6 Using Ambient Target Temperature Compensation

(OS552A thru OS555A)

Use the Ambient Target Temperature Compensation

(AMB) Display Mode when high accuracy readings under

both of these conditions are required:

• The target has a low emissivity.

• The ambient temperature around the target is much

higher than the ambient temperature around the

infrared thermometer.

To set and activate the Ambient Target Temperature

Compensation Mode:

1. With power applied to the unit, set the emissivity to 1.0

2. Press and hold the key until the Average Display

Mode (AVG) appears.

3. Slowly move the thermometer so that the line of sight

sweeps across the area surrounding the target. The

thermometer measures the temperature at each point on

the surrounding area.

4. Read the average temperature value from the upper

display and record it here __________.

5. Press and hold the key until the Ambient

Temperature Display Mode (AMB) appears.

6. Set the AMB temperature found in Step 4 by pressing the

key or the key.

7. Press the key to enable the ambient target

temperature compensation. The icon appears

on the display.

To disable this mode, press the key again.

The icon disappears.

NOTE

°F

AT C

Page 37

3-15

Using the Infrared Thermometer/Transmitter

3

8. Press and hold the key until the Emissivity Display

Mode (E) appears.

9. Change the emissivity to the proper value for the target

being measured (refer to Section 3.5.1).

10. Aim at the target. The target temperature and emissivity

are displayed on the LCD.

To disable the Ambient Target Temperature

Compensation at a later time, you must press the

key to get into the Ambient Target

Temperature Display Mode. Then press the

key to disable it.

The unit maintains its target ambient temperature

value even when the power is removed.

NOTE

NOTE

°F

ATC

Page 38

Using the Infrared Thermometer/Transmitter

3

3-16

3.5.7 PC Interface Software (OS552A thru OS555A)

Software Installation:

In order to install the PC interface software (IRTM), the PC should have the

following minimum requirements:

Operating System: Windows 98SE, 2000, NT4.0, XP, Vista

32 MB RAM

Hard disk with a minimum of 20 MB free space

Place the CD into the CDROM drive. Click Start Run… from the start

menu. Click Browse to find setup program from the CD and then click OK

to run setup program. The setup program will guide you through the

installation process.

Figure 3-13 Personal Computer Connection

Sending temperature data to PC in Real Time:

1. From Windows Operation System, Go to Start Program Omega

Infrared Temperature Measurement IRTM then click.

2. Check the RS232 connection between the infrared thermometer and the

PC. Select your serial COM Port number from the Communication Port

Setting menu on the menu bar. Turn on the infrared thermometer. From

the program screen, click the Start button. This initiates data transmission

from the thermometer to the PC.

RS-232

Digital Cable

NOTE

Bottom hole is

the RS-232 jack

Personal

Computer

9-Pin 'D'

Connector

6-Pin

Phone Jack

To the

Computer

To the

Pyrometer

Page 39

3-17

Using the Infrared Thermometer/Transmitter

3

The data will fill in the screen as shown. If no data appears, you need to check

the COM port number or the RS232 connection. Here is a list of data sent:

Distance and thermocouple measurements are not

applicable on this transmitter.

Current Temperature = 74ºF

E=0.95 (Emissivity) HAL=1000ºF

(High alarm set point)

MAX = 85ºF LAL = -10ºF

(Maximum Temperature) (Low alarm set point)

MIN = 72ºF

(Minimum Temperature)

DIF = 13ºF PRN = 2 second

(Differential Temperature) (Data Transmission interval)

AVG = 73ºF AMB = 75ºF

(Average Temperature) (Target Ambient temperature)

You can also start the data transmission from the thermometer side by

going to the PRN display menu, and pressing the key. The icon

will appear on the LCD and data transmission starts. You can stop the data

transmission from the PC side by clicking the Stop button. You can also stop

the data transmission from the thermometer side by pressing the

key again while in the PRN display menu. The icon will disappear

from the LCD, and data transmission stops.

NOTE

Page 40

Using the Infrared Thermometer/Transmitter

3

3-18

The transmitted temperature data is the average temperature for

the specified data transmission interval. The data transmission

interval (PRN) can be set any where from 1 to 1999

seconds.

You can save the data into a file by going into the File menu.

Download Stored Temperature data to PC

• Run the IRTM program.

• If you are already in the IRTM program and sending temperature data

from the thermometer to the PC in real time, click the Stop button to stop

data transmission.

• Go to Tool menu, and click on Download stored temperature data.

• A new Download Storage Data Window will pop up, and stored data will

fill in.

• When downloading data is complete, you will hear a beep.

• You can save this data into a file by going to the File menu of this

window. Data can be saved as an Excel, Text or data file format.

• You can also Erase the stored data in the thermometer by going to File

menu, and click on Erase stored data at thermometer.

• You can exit or close this window and go back to the previous window.

Communicating through Hyper terminal

You can get temperature data in real time or download stored data to Hyper

terminal of the PC as follows:

• From Start Programs Accessories Hyper terminal

• Create a name for your communication

• Set the communication settings as follows (In the Properties menu):

- COM port (1,2,3)

- Baud rate (9600)

- Data Bits (8)

- Parity (None)

- Stop bit (1)

- Flow control (None)

If you are sending data in real time, turn on the thermometer. Press

key until reaching the PRN display mode. Press the key to

start data transmission to the PC. The PRN icon will appear on the

thermometer’s LCD.

NOTE

Page 41

3-19

Using the Infrared Thermometer/Transmitter

3

Menu Description

File

Save Data As...

Save the collected temperature data in one of the formats:

Excel File (.xls), Text File (.txt), Data File (.dat)

Exit

Do you want

to save your

temperature data?

No

Exit the program

Ye s

Save the data then

Exit the program

without saving data

Cancel

Go back to Program

View

Show (Hide) Data File

Show or Hide the Data Table on the screen. The data

table shows the last 10 temperature data points.

View All

Show the data table and parameter settings

Hide the data table and parameter settings

Shrink All

Page 42

Using the Infrared Thermometer/Transmitter

3

3-20

Stop Data Transmission to Change Parameters

Tool

Stop data transmission to be able to change parameter settings

like E, HAL, LAL, etc. Any change of parameter settings will reflect

on the thermometer's display. When done with parameter settings,

click the Start button to restart data transmission.

Change Temperature Display between °F<-> °C

You can change the temperature display from °F to °C or

vise versa. It gets reflected on the thermometer's display as well.

Reset MAX, MIN, DIF, and AVG Temperatures

Download stored temperature data

Reset the MAX, MIN, DIF, AVG temperatures which will get

Save as

Erase the stored data from thermometer

Exit

reflected on the thermometer's display.

Resume Data Storage

Ta bl e

Continue saving temperature data in the table.

Pause saving temperature data in the table.

Pause Data Storage

Delete the saved data from the table.

Clear data

File

COM1

Communication Port Setting

COM2

COM4

COM3

Select an available serial

port on your PC.

Help

°F <-> °C Calculator

Convert temperature Engineering unit from °F to °C or vise versa.

About IRTM

Shows the software version & copyright information.

Page 43

3-21

Using the Infrared Thermometer/Transmitter

3

3.5.7.1 PC Interface Commands

You can communicate directly from the PC to the infrared thermometer. Here

are the Comm port settings and communication commands from the PC:

Baud rate: 9600

Data: 8 Bits

One Stop Bit

No Parity

All the PC commands to the infrared thermometer are case sensitive and

terminates with a carriage return (CR). You can change parameter settings

from the PC when data transmission is stopped.

Here is a typical data strings from the infrared thermometer to the PC when

the “T” command is activated:

OS534, OS553A; E:95; MAX:78; MIN:65; DIF:13; AVG:72; HAL:900; LAL:20;

AMB:125; PRN:5; PRNF:1; IR:73; CF:0; FF:1; LF: 0:

End

Command Description

(ASCII)

IR Get the current infrared temperature from the thermometer

TStart sending Data stings from the thermometer to the PC

P Stop sending data to the PC

SReset Min, Max, Diff, Avg temperature values on the thermometer

F1 or F0 F1 = Set Engineering unit to °F , F0 = Set Engineering unit to °C

E95 Set Emissivity to 0.95 (Thermometer sends “E:95” back as

confirmation)

H500 Set High Alarm set point (HAL) to 500 (It sends “HAL:500” back as

confirmation)

L20 Set Low Alarm set point (LAL) to 20 (It sends “LAL:20” back as

confirmation)

A125 Set Target ambient temp (AMB) to 125(It sends “AMB:125” back as

confirmation)

t Get the data transmission interval (PRN) from thermometer

t5 Set data transmission interval (PRN) to 5 seconds. Thermometer sends

back “PRN:5” as confirmation.

p Get the data transmission flag from the thermometer.

PRNF:0 means no data transmission (PRN is disabled)

PRNF:1 means data transmission (PRN is enabled)

D0 Start to download stored data from IR thermometer memory

De Erase the data from the IR thermometer memory

Page 44

Using the Infrared Thermometer/Transmitter

3

3-22

String Description

E:95; Emissivity is 0.95

MAX:78; Maximum temperature is 78

MIN:65; Minimum temperature is 65

DIF:13; Differential temperature is 13

AVG:72; Average temperature is 72

HAL:900; High alarm set point (HAL) is 900

LAL:20; Low alarm set point (LAL) is 20

AMB:125; Target ambient temperature is 125

PRN:5; Data transmission interval is every 5 seconds

PRNF:1; PRN Flag (0: PRN disabled, No data transmission, 1: PRN enabled,

Data communication active)

IR:73;Current Infrared temperature is 73

CF:0; Temperature engineering unit (CF:1 in Degree C, CF:0 in Degree F)

FF:1; Temperature engineering unit (FF:1 in Degree F, FF:0 in Degree C)

LF:0 Temperature over range flag

xxxx0xxx : In Range, Top

xxxxIx xx : Out of Range, Top

xxxxx0xx : In Range, Bottom

xxxxxIxx : Out of Range, Bottom

End End of data string

Page 45

3-23

Using the Infrared Thermometer/Transmitter

3

3.5.8 Storing Temperature Data on Command

(OS553A, OS554A, OS555A)

The thermometer can store up to 800 temperature data

points on command. This data is stored in the non-volatile

memory, so removing power will not affect or erase this

data. To store temperature data:

1. Aim at the target and turn on the transmitter.

2. If necessary, press the key to increment the target

emissivity or press the key to decrement the target

emissivity.

3. Press and hold the key until the Memory Display

Mode (MEM) appears.

4. Press the key to store the target temperature at the

memory location indicated. You will hear a beep to

verify that the data is stored. Then the memory location is

incremented by one.

5. After all data is taken, press and hold the key

until the Emissivity Display Mode (E) appears.

3.5.9 Reviewing Stored Temperature Data (OS553A,

OS554A, OS555A):

1.

Press the key to go to the MEM display mode.

2 The upper display shows the next memory location to

store temperature data.

3. Press the key to go to previous memory locations.

The lower display will show the corresponding stored

temperature data at that location.

4. Press the key to go to the last memory location. The

lower display will show the current temperature. You can

now store temperature data by pressing the key.

°F

Page 46

Using the Infrared Thermometer/Transmitter

3

3-24

5. If you do not press any key for 5 seconds, the display

goes back to real time showing current temperature

and the last memory location.

3.5.10 Logging Temperature Data in Real Time

(OS553A, OS554A, OS555A)

The thermometer can log temperature data in real time. The

logged data is stored in the non-volatile memory, so

removing the power will not affect or erase the data. The

data is logged based on the data recording interval (PRN)

which can be set anywhere from 1 to 1999 seconds. The

thermometer can log up to 800 data points. Therefore, the

logging period can be anywhere from 13 minutes (1 second

recording interval) up to 18.5 days (1999 second recording

interval). To log temperature in real time:

1. Aim at the target and turn on the transmitter.

2. Press the or keys to adjust the Emissivity value

for the target.

3. Press the key until the display mode

appears.

4. Set the data recording interval (seconds) by pressing the

or keys.

5. Press the key until the LOG display mode appears.

6. Press the key to start logging temperature data in

real time. The display will show LOG on, and the unit starts

logging data based on the recording interval set in the

display menu. Press the key again, and the

unit stops logging data. The display will show LOG off.

°F

on

LCK

Page 47

3-25

Using the Infrared Thermometer/Transmitter

3

3.5.11 Erasing the Temperature Data from Memory

The user can erase all 800 temperature data points in

memory at any time by using the following procedure:

1. Turn on the transmitter.

2. Press the

key until reaching the MEM or LOG

display mode.

3. Press the then keys in rapid sequence. The

display shows ERASE on the top and it will beep to

indicate that the stored data is erased.

Erasing the temperature data does not erase or

reset Emissivity, High and Low Alarm setpoints,

printing interval and Ambient Target Temperature

compensation

NOTE

Page 48

Using the Infrared Thermometer/Transmitter

3

3-26

Notes

Page 49

4-1

4.1 Warnings and Cautions

When using the laser sight accessory OS550-LS, you may

receive harmful laser radiation exposure if you do not adhere to

the warnings listed below:

• USE OF CONTROLS OR ADJUSTMENTS OR

PERFORMANCE OF PROCEDURES OTHER

THAN THOSE SPECIFIED HERE MAY RESULT

IN HAZARDOUS RADIATION EXPOSURE.

• DO NOT LOOK AT THE LASER BEAM COMING

OUT OF THE LENS OR VIEW DIRECTLY WITH

OPTICAL INSTRUMENTS — EYE DAMAGE

CAN RESULT.

• USE EXTREME CAUTION WHEN OPERATING THE

LASER SIGHT ACCESSORY.

• NEVER POINT THE LASER SIGHT AT A PERSON.

• KEEP OUT OF REACH OF ALL CHILDREN.

DO NOT ATTEMPT TO OPEN THE LASER SIGHT ACCESSORY.

(There are no user-serviceable parts in the unit.)

Refer to the inside back cover of this manual for product

warning label.

4

Laser Sight Accessory

CAUTION

WARNING

Page 50

Laser Sight Accessory

4

4-2

4.2 Description

A laser sighting accessory is available to aid in the sensor head

installation process. When installing a line of sight Infrared

transducer with a small spot size and long target distance, it is

sometimes difficult to locate the center of the focused spot and the

material to be measured. To solve this problem, we offer a laser

sighting accessory OS550-LS that will install onto the front of the

OS550 series sensor head. This compact tool provides the installer

with a true line of sight laser dot up to a distance of 12.2 meters

(40') in the center of the IR optical path taking the guess work out of

proper alignment during the installation. The laser is powered by a

power pack with replaceable batteries and interconnect cable.

Fig. 4-1 Laser Sighting Accessory (OS550-LS)

Page 51

4-3

Laser Sight Accessory

4

4.3 Operating the Laser Sight

4.3.1 Installing the Laser Sight onto the Thermometer

The laser sight accessory (OS550-LS) screws onto the front of the

sensor head. Do not over tighten the laser sight accessory onto the

sensor head. This accessory is only used during sensor head

installation and then removed.

4.3.2 Powering the Laser Sight Accessory

The laser sight head is powered by a small compact battery pack

supply provided with this accessory. Connections are made between

the laser sighting head and the power pack via a 24" cable with mini

mating connectors. Power is turned on and off to the sighting head

by a slide switch on the power pack.

Page 52

Laser Sight Accessory

4

4-4

Notes

Page 53

5.1 Cleaning the Sensor Head Lens

Although all lenses are quite durable, take care to prevent scratching

when cleaning them. To clean the lens:

1. Blow off loose particles, using clean air.

2. Gently brush off remaining particles, using a camel hair brush.

Alternatively, clean any remaining contaminants with a damp, soft,

clean cloth. Be careful not to rub too hard.

Do not use any ammonia or cleaners with ammonia on the lens,

as damage may result. Do not wipe the surface dry, as this may

cause scratching.

5.2 Calibrating the Thermometer

The thermometer can not be calibrated by the user. For precise

calibration of the thermometer, call our Customer Service

Department. It is recommended that the Infrared Thermometer be

sent to the factory once a year for recalibration.

Maintenance

5

CAUTION

5-1

Page 54

Maintenance

5

5-2

Notes

Page 55

THERMOMETER

Problem Solution

The thermometer does a. Check for proper wiring

not turn on (No Display) connections, see Section 3.2

b.

Contact our Customer Service

Department, unit requires service.

a. Make sure you have entered the

correct emissivity setting.

b. Make sure you are not trying to

measure a temperature above the

maximum temperature range of

your model.

The thermometer is a. Try to remove and then re-apply

“locked up” (the power to reset the unit.

display is “frozen”).

b. Contact our Customer Service

Department, unit requires service.

Troubleshooting Guide

6

The thermometer is

showing an incorrect

temperature

6-1

Page 56

Troubleshooting Guide

6

6-2

Problem Solution

The display is either 1. Clean the thermometer lens.

erratic or stays at Refer to Section 5.1.

one reading.

2.

Activate the Diagnostic routine of the

thermometer as follows (while looking

at room temp):

a. Turn on the transmitter.

b. Press the key and key at the

same time.

You can expect to see and hear the following:

• You will see the model and version

number “VER X.X” of the software for

about 1 second.

• You will hear a beep, “TST” is displayed.

• Soon after, all of the segments of the

display including the backlighting will

light up for about 1 second.

• The display will clear and a PAS (pass)

or ERR (error) code may be seen on the

display.

ERR1: Infrared temp reading is >150°F

or < 23°F.

ERR2: Ambient temp >122°F or < 32°F

ERR3: Can not read from EEPROM

memory

EER4: Can not write to EEPROM memory

Page 57

6-3

Troubleshooting Guide

6

The temperature reading

is erratic. The sensor

head has just been

moved from one extreme

temperature to room

temperature [0°C or

50°C (32°F or 122°F)] or

vice versa.

The temperature

reading is erratic. The

sensor head has just

been moved from room

temperature (ambient

temperature) to a

temperature 10°C

colder or warmer.

Problem Solution

The thermometer has to stabilize

before taking temperature

measurements. It takes up to

40 minutes for the thermometer

to stabilize.

The thermometer has to stabilize

before taking temperature

measurements. It takes up to

20 minutes for the thermometer

to stabilize.

No Laser Beam Check Battery pack voltage.

Page 58

Troubleshooting Guide

6

6-4

Notes

Page 59

(Specifications are for all models except where noted)

THERMOMETER

Measuring OS551A: –23°C to 400°C (-10°F to 750°F)

Temperature OS552A: –23°C to 538°C (-10°F to 1000°F)

Range: OS553A: –23°C to 871°C (-10°F to 1600°F)

OS554A: –18°C to 1371°C (0°F to 2500°F)

OS555A: 538°C to 2482°C (1000°F to 4500°F)

±1% of reading or

3°F whichever is greater

±2% of reading for temp > 2000°F, OS555A only

Distance to Spot Size Ratio: 10:1 (Figure 3-7) 60:1 (Figure 3-10)

20:1 (Figure 3-8) 40:1 (Figure 3-11)

30:1 (Figure 3-9) 68:1 (Figure 3-6)

110:1 (Figure 3-12)

Display Repeatability: ± (1% rdg + 1 digit)

Display Resolution: 1°F or 1°C

Display Response Time: 100 msec

Spectral Response: 8 to 14 microns - OS551A thru OS554A

2 to 2.5 microns - OS555A

Operating Ambient

Temperature:

Main Electronics: 0°C to 50°C (32°F to 122°F)

Sensor Head 0°C to 50°C (32°F to 122°F)

Sensor Head with 0°C to 85°C (32°F to 185°F)

OS550-WC

Water Flow rate for 0.5 GPM, room temperature

OS550-WC

Air Flow for OS550-AP 1 to 3 CFM (0.5 to 1.5 liters/sec.)

Operating Relative 95% or less without condensation

Humidity:

Display: Backlit LCD dual display

Power Requirements: 8-24 Vdc @ 100 mA

Main Electronics IP65, NEMA 12 & 13 rated

Standard Housing ABS Plastic

Metal Housing Die cast aluminum

Specifications

7

Accuracy @ 24°C or 75°F

Ambient Temperature and at

emissivity of 0.95 or greater:

7-1

Page 60

Specifications

7

7-2

Emissivity: 0.10 to 1.00 in 0.01 increments, set via keypad

Calculated Temperature Maximum (MAX), Minimum (MIN),

Values: Average (AVG), Differential (dIF)

Average Temp Accuracy 30 Days

Time Period

(Under Continuous Operations)

Ambient Target Temperature

Compensation: OS552A thru OS555A

set and enabled via keypad

RS-232 Output OS552A thru OS555A

set and enabled via keypad

9600 bits per second, 8 bits of data,

1 stop bit, no parity

RS-232 Cable: RJ12 to 9 pin D connector, Female

RJ12 Pin # 9 pin D connector Pin #

3 TX 2 RX

4 RX 3 TX

5 GND 5 GND

Power/Analog Output Cable: 15' long; 8-conductor, shielded 24 AWG

Sensor Head Cable 15' long; 5-conductor, shielded 24 AWG

Alarm: Set and enabled via keypad

All models: High alarm standard, with

audible and visual indication with red LED

OS552A, OS553A: Low alarm standard, with

OS554A, OS555A audible and visual indication

with red LED

Alarm Deadband 10°F (5°C)

Alarm Outputs Voltage; 100mA Drive

Data Storage: OS553A, OS554A, OS555A Up to 800 sets of

temperatures data points on command or

continuous data logging.

Dimensions:

Main Housing, Plastic: 120.6 x 80.0 x 50.8 mm (4.75 x 3.15 x 2.00")

Main Housing, Aluminum 115.0 x 90.0 x 55.5 mm (4.54 x 3.54 x 2.18")

Sensor Head: 41.1 dia. x 109.2 mm (1.62 dia. x 4.30")

Weight:

Main Electronics: 2.2 kg. (1 lb.)

Sensor Head: 1.87 kg. (0.85 lb.)

Page 61

7-3

Specifications

7

1 mV/degree C or F Analog Output:

Accuracy: ± 2 mV or 2 Deg referenced to the temperature display

0-5 Vdc Analog Output:

Accuracy: ± 0.25% of full scale (Referenced to temperature display)

Scaling: Fixed (scaled to match full temperature range of model

selected)

Minimum Load: 1 K ohms

4-20 mA Analog Output:

Accuracy: ± 0.25% of full scale (Referenced to temperature display)

Scaling: Fixed (scaled to match full temperature range of model

selected)

Maximum Load: 500 ohms

Page 62

7

7-4

Specifications

LASER SIGHT ACCESSORY (OS550-LS)

Wavelength (Color): 630-670 nanometers (red)

Operating Distance:

Laser Dot 152 mm to 12 m (6" to 40')

Max. Output Optical Power: <1mW at 75°F ambient temperature,

Class II, Laser Product

European Classification: Class 2, EN60825-1

Maximum Operating Current: 25mA at 3 V

FDA Classification: Complies with 21 CFR Chapter 1,

Subchapter J

Beam Diameter: 5 mm

Beam Divergence: <1mrad

Operating Temperature: 0°C to 50°C (32°F to 122°F)

Operating Relative Humidity: 95% or less without condensation

Power Switch: ON/OFF (slide)

Power Indicator: Red LED

Power: 3 Vdc

Identification Label: Located on head assembly circumference

Warning & Certification Label: Located on head assembly circumference

Page 63

Key(s) Key(s) Functions

• Selects one of the following Display

Modes:

E , MAX, MIN, dIF, AVG, HAL, LAL,

AMB, PRN, MEM or LOG.

• Enables/disables High and Low Alarms.

• Enables/disables Target Ambient

Temperature Compensation.

• Enables/disables sending data to the

personal computer or serial printer.

• Stores temperature data on command.

• Enables/disables Data Logging.

• Increments the data or value displayed.

• Turns on or off the backlighting (only in

MAX, MIN, dIF, or AVG Display

Modes).

• Decrements the data or value displayed.

• Changes the unit of measure from °F to

°C or vice versa (only in MAX, MIN, dIF,

or AVG Display Modes).

Press and hold down the

key and key at the

same time

and keys

pressed in rapid sequence

Glossary of Key Strokes

8

• Allows you to go to the Diagnostic

Routine.

• Allows you to erase all 800 stored

temperature data from the

memory.

8-1

Page 64

1

8-2

Notes

Glossary of Key Strokes

8

Page 65

Thermal Radiation

Heat is transferred from all objects via radiation in the form of

electromagnetic waves or by conduction or convection. All objects

having a temperature greater than absolute zero (-273°C, -459°F,

0 K) radiate energy. The thermal energy radiated by an object

increases as the object gets hotter. Measurement of this thermal

energy allows an infrared thermometer to calculate the object’s

temperature if the emissivity (blackness) is known. Generally, it is

convenient to measure the amount of radiated energy in the infrared

part of an object’s radiation spectrum.

Figure A-1 shows a block diagram of an infrared radiation

thermometer. Energy from the object is focused by the lens onto the

detector. As the detector heats up, it sends out an electrical signal,

which in turn is amplified and sent to the circuitry of the

thermometer. The thermometer software then calculates the

temperature of the object.

Figure A-1. Infrared Thermometer Block Diagram

OBJECT

LENS

DETECTOR

OR

SIGNAL OUTPUT TO SERIAL PRINTER

OR PERSONAL COMPUTER

AMPLIFIER

PYROMETER

CIRCUITRY AND

DISPLAY

Appendix: How Infrared Thermometry Works

A

A-1

Page 66

Appendix: How Infrared Thermometry Works

A

A-2

Blackbody

When thermal radiation falls on an object, part of the energy is

transmitted through the object, part is reflected and part is

absorbed. A blackbody is defined as an ideal object that absorbs all

the radiation incident upon it. The best example of a real object that

acts like a blackbody is a small hole drilled deep into a large opaque

cavity. Thermal radiation entering the cavity is internally reflected

and has little chance of escaping the cavity before it is fully

absorbed.

Emissivity is defined as the ratio of energy radiated by an object to

that of the energy radiated by a blackbody. By definition, the

emissivity of a blackbody is 1. Most objects are considered gray

objects with an emissivity between 0 and 1. Various emissivities for

common materials are shown in Appendix B.

Spectral Distribution

Objects radiate energy at different wavelengths, but not with

constant intensity at each

wavelength. Figure A-2

shows the energy radiated

by a blackbody at various

temperatures as a function

of wavelength. As a body is

heated, the intensity of the

radiated energy increases

and the peak of the curve

shifts towards the shorter

wavelength end of the

spectrum. The total area

under a spectral

distribution curve is

proportional to the total

energy radiated by the

blackbody at a given

temperature.

Figure A-2. Blackbody

Spectral Distribution

Relative emission from a blackbody versus wavelength.

The area under the curve corresponds to the total energy, and is proportional to the absolute temperature to

the 4th power. The peak of the spectral distribution

curve shifts to shorter wavelengths as the temperature

increases.

Page 67

Wien’s Displacement Law describes the exact mathematical

relationship between the temperature of a blackbody and the

wavelength of the maximum intensity radiation.

where λ

m

= wavelength measured in microns

T = temperature in Kelvin

Calculating Temperature

The net thermal power radiated by an object has been shown to

depend on its emissivity, its temperature and that of the ambient

temperature around the object. A very useful equation known today

as the Stefan-Boltzmann Law

has been shown both theoretically and

empirically to describe the relationship.

I = thermal power in watts/meter

2

ε = Emissivity

σ = 5.6703 x 10-8watts/meter2x K4(Stefan’s constant)

T = temperature of object in Kelvin

Ta= temperature of ambient surroundings in Kelvin

The infrared thermometer uses this equation directly in calculating

the temperature of an object. The incident power is measured by the

infrared detector. The emissivity of the object is determined by the

user. The ambient temperature is measured by a sensor inside the

thermometer. With all quantities known, the thermometer uses the

Stefan-Bolzmann Law

to calculate and output the temperature of the

object

A-3

Appendix: How Infrared Thermometry Works

A

Page 68

Appendix: How Infrared Thermometry Works

A

A-4

Optics Field of View

Accurate measurement of temperature via infrared means depends

strongly on the size of the object and the distance between the

thermometer and the object. All optical devices (e.g. cameras,

microscopes, infrared thermometers) have an angle of vision,

known as a field of view or FOV, within which they see all objects.

In particular, the thermometer will measure a fixed proportion

of

the energy radiated by all

objects within its FOV. The user must

guarantee that the distance between the thermometer and the object

is defined so that only that object fills the FOV of the instrument.

Referring to Figure A-3, Objects “X” and “Y” are within the FOV of

the thermometer. The measured temperature would fall somewhere

between the actual temperatures of the two objects. In order to

measure the temperature of Object “X” accurately, Object “Y” would

need to be removed. In order to measure the temperature of Object

“Y” accurately, the user would need to move closer to Object “Y”

until it completely filled the FOV of the thermometer. Alternatively,

the user could measure the temperature of Object “Y” with a

thermometer with a smaller FOV.

Figure A-3. Field of View of a Thermometer/Transmitter

The distance-to-spot size ratio (D⁄S) defines the field of view (FOV).

Thus, a

D

⁄S = 10 gives you approximately a 1' spot size at a distance of

10'. For accurate spot size values, refer to the Field of View diagrams

shown in Figures 3-3 through 3-8.

Page 69

B-1

Table B-1 provides guidelines for estimating the emissivity of various

common materials. Actual emissivity, especially of metals, can vary

greatly depending upon surface finish, oxidation, or the presence of

contaminants. Also, emissivity or infrared radiation for some materials

varies with wavelength and temperature. To determine the exact

emissivities for most applications, follow the procedures in Appendix C.

9

METALS

Material Emissivity (ε)

Aluminum – pure highly polished plate . . . . . . . . . . . . . . . . . . . . 0.04 – 0.06

Aluminum

– heavily oxidized . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.20 – 0.31

Aluminum

– commercial sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.09

Brass

– dull plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.22

Brass