Page 1

Bearings

There are no sleeve

bearings in our entire line of

general purpose motors. We

use nothing but heavy-duty oversized ball

bearings on both the DE (drive end) and the

ODE (opposite drive end). It is exactly for

this reason that we can mount our motors in

the “shaft up” or “shaft down” position with

no derating. A shaft slinger keeps moisture

and contaminants from the drive end

bearing. And all of our AC motors have a

high tensile strength steel shaft.

Windings/Insulations

All of our motors have copper windings and

are manufactured with Class F insulation.

End Bells and Fan Covers

All of our end bells are heavy duty burnished

(polished) aluminum. Our fan covers are

steel, not plastic.

Junction Boxes

Our large, easy-to-wire junction boxes have

rubber dust curtains designed to keep

foreign particles from entry. These covers

are designed to come apart at an angle to

permit ease of wiring. Most motors are

convertible F1 to F2 and all are rotatable at

90 degree intervals. Conduit holes are

provided per NPT standards.

Motor Leads

All of our leads are both color coded and

numbered per NEMA MG1 Standards.

Capacitor Covers

Each motor comes equipped with a large

steel capacitor cover with a protective

rubber gasket and oversized capacitors.

The oversized start capacitor gives the

motor a much higher starting torque and

voltage range.

OMT Series

Starts at

$

97

OMT13-18-56CB,

$97, shown smaller

than actual size.

Rolled Steel AC Motors:

0.33 to 2 HP

NEMA 56C Frame

NEMA Design B

115/208 to 230 Volt

TEFC (Totally Enclosed

Fan Cooled)

Single-Phase

Class F Insulation

Premium-Grade Quality

1.15 Service Factor

Heavy Gauge Bolt-On,

Bolt-Off NEMA 56-Frame

Removable Base

Motor Slide Base for

Adjustable Mounting

Replacement Start/Run

Capacitors Available

Omegamation™ general purpose AC motors

are made by one of the leading motor

manufacturers for over 45 years, a worldclass accredited supplier with a long history

of quality testing procedures and standards

performed by the finest independent testing

laboratories in the world. Our motors are

made in high quality ISO9001-certified

facilities using only the highest quality

material and manufacturing processes.

All motors are electrically tested in

sub-assembly production and again after

final assembly, and come with an ironclad

2-year warranty.

Features and Benefits of AC

Motors from Omegamation

Following are a few of the many reasons

why our AC motors provide the best

combination of quality and performance at

the lowest prices.

Nameplates

Nameplates are said to be the “Window Of

Quality” of a motor. Our AC motor

nameplates are stainless steel to reduce

corrosion and laser etched to provide

permanent markings, and include an

easy-to-read wiring diagram.

Paint

We use an electrostatically applied, rust

proof and scratch resistant paint. The paint

almost seems to become part of the steel

enclosure itself.

Certification

Our motors are CCSAUSCertified. Note the

US stamp. It means that our motor has not

only passed the Canadian Standard

Association requirements, but also the

USA’s UL and ANSI standards, thus giving

them the highest certification standards

you can have for North America. Our

certifications also include CE, CC006A,

and of course ISO9001.

Warranty

Our warranty matches the motors quality in

that it leads the industry in guaranteeing

customer satisfaction. All of our AC motors

have an ironclad two-year warranty and it is

a nameplate-only warranty. That is to say,

the customer sends us the nameplate and

we send him a new motor. No paperwork—

no delay—no waiting for credit based on a

factory inspection—and no questions

asked! Simply call our customer service

department to obtain an AR number for the

nameplate return.

Wide Range

of Motor

Sizes!

GENERAL PURPOSE

AC MOTORS

56C FLANGE, SINGLE PHASE

FRACTIONAL AND INTEGRAL HP

D-43a

Page 2

D-43b

56C FLANGE MOTORS

SINGLE PHASE—115/208 TO 230 VOLT

INVERTER DUTY WITH CLASS “F” INSULATION

All ratings

Totally enclosed

Fan cooled

Steel fan

cover

Large

easy-to-wire

junction box with

rubber gasket

Manual

overload also

available for

farm

applications

Heavy gauge

bolt-on, bolt-off

NEMA 56-frame

removable base

Rolled steel

(shell) frame

Cast aluminum

end bells

Heavy duty

oversized ball

bearings and high-

tensile strength

steel shaft

Shaft slinger

keeps moisture

and contaminents

from the drive

end bearing

NEMA 56C

flange mount

Large metal nameplate with

easy-to-read wiring diagram

Large steel capacitor cover

with rubber gasket and

oversized capacitors

OMT13-18-56CB, $97, shown smaller than actual size.

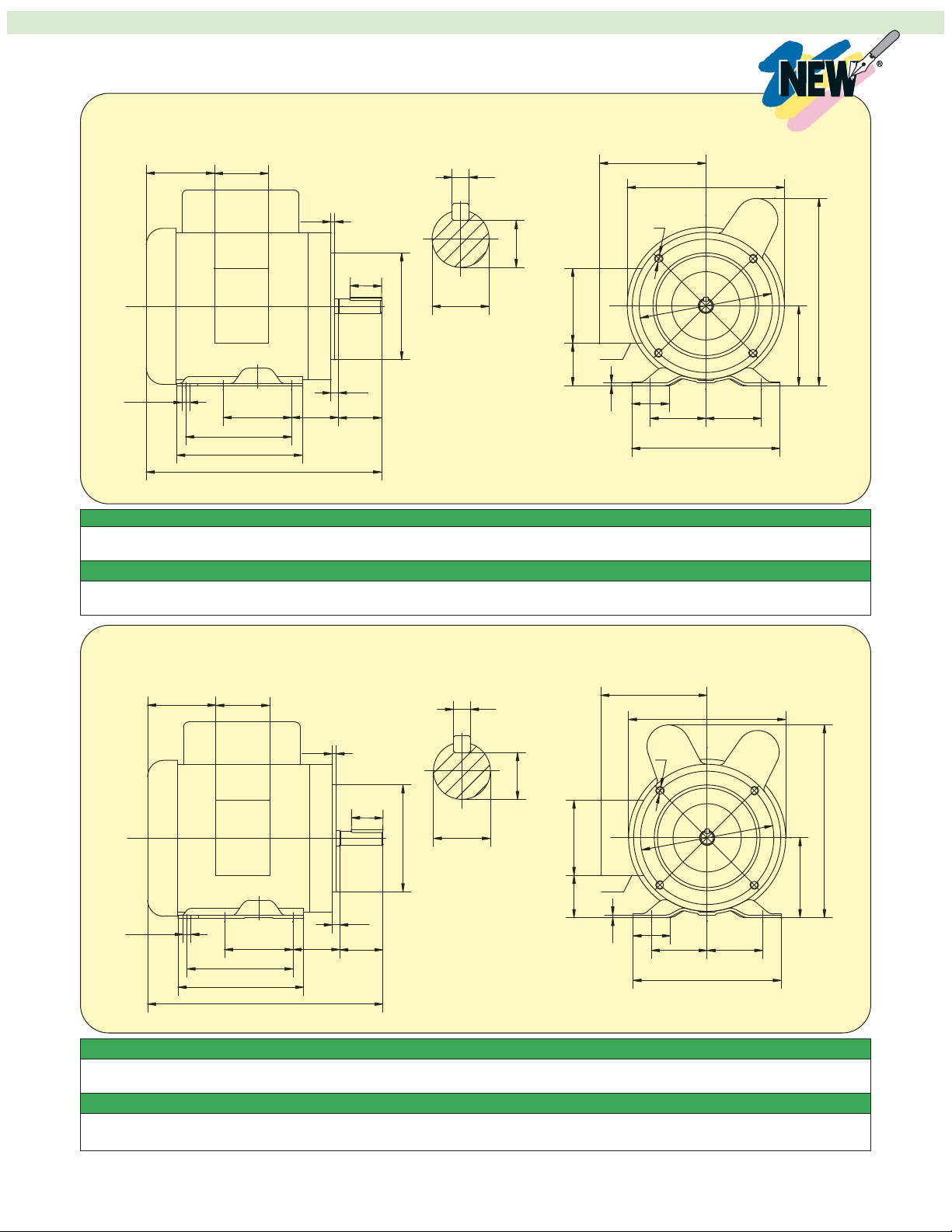

Page 3

D-43c

N-W

U

R

S

ES

XE

XD

EE

AB

XC

A

XB

G

D

H(SLOT)

BA

2F

AK

AJ

BF

2F

B

BB

BC

C

L

AA

J

P

N-W

U

R

S

ES

XE

XD

EE

AB

XC

A

XB

G

D

H(SLOT)

BA

2F1

AK

AJ

BF

2F2

B

BB

BC

C

L

AA

J

P

AB CD E2F12F2G H J L P R S U

165 165 330 89 62 76 127 3 9 44 208 175 13 5 16

(6.5) (6.5) (13) (3.5) (2.44) (3) (5) (0.12) (0.34) (1.73) (8.19) (6.9) (0.517) (0.188) (0.625)

ES AA AB AH AJ AK BA BB BC BF XB XC XD XE

36

1

⁄2" NPT

136 49 149 114 70 4 5 10 42 94 82 72

(1.41) (5.35) (1.91) (5.875) (4.5) (2.75) (0.16) (0.19) (

3

⁄8-16) (1.65) (3.7) (3.23) (2.85)

AB CD E2F12F2G H J L P R S U

165 165 351 89 62 76 127 3 9 44 216 175 13 5 16

(6.5) (6.5) (13.8) (3.5) (2.44) (3) (5) (0.12) (0.34) (1.73) (8.5) (6.9) (0.517) (0.188) (0.625)

ES AA AB AH AJ AK BA BB BC BF XB XC XD XE

36

1

⁄2" NPT

136 49 149 114 70 4 5 10 42 94 82 72

(1.41) (5.35) (1.91) (5.875) (4.5) (2.75) (0.16) (0.19) (

3

⁄8-16) (1.65) (3.7) (3.23) (2.85)

Dimensions: mm (in)

Dimensions: mm (in)

OMT1-18-56CB

OMT1.5-18-56CB

56C FRAME MOTORS—1 PHASE

Page 4

N-W

U

R

S

ES

XE

XD

EE

AB

XC

A

XB

G

D

H(SLOT)

BA

2F1

AK

AJ

BF

2F2

B

BB

BC

C

L

AA

J

P

D-43d

N-W

U

R

S

ES

XE

XD

EE

AB

XC

A

XB

G

D

H(SLOT)

BA

2F1

AK

AJ

BF

2F2

B

BB

BC

C

L

AA

J

P

Dimensions: mm (in)

AB CD E2F12F2G H J L P R S U

165 165 315 89 62 76 127 3 9 44 208 175 13 5 16

(6.5) (6.5) (12.4) (3.5) (2.44) (3) (5) (0.12) (0.34) (1.73) (8.19) (6.9) (0.517) (0.188) (0.625)

ES AA AB AH AJ AK BA BB BC BF XB XC XD XE

36

1

⁄2" NPT

136 49 149 114 70 4 5 10 42 94 82 72

(1.41) (5.35) (1.91) (5.875) (4.5) (2.75) (0.16) (0.19) (

3

⁄8-16) (1.65) (3.7) (3.23) (2.85)

OMT12-18-56CB

Dimensions: mm (in)

AB CD E2F12F2G H J L P R S U

165 165 371 89 62 76 127 3 9 44 216 175 13 5 16

(6.5) (6.5) (14.6) (3.5) (2.44) (3) (5) (0.12) (0.34) (1.73) (8.5) (6.9) (0.517) (0.188) (0.625)

ES AA AB AH AJ AK BA BB BC BF XB XC XD XE

36

1

⁄2" NPT

136 49 149 114 70 4 5 10 42 94 82 72

(1.41) (5.35) (1.91) (5.875) (4.5) (2.75) (0.16) (0.19) (

3

⁄8-16) (1.65) (3.7) (3.23) (2.85)

OMT2-18-56CB

Page 5

N-W

U

R

S

ES

XE

XD

EE

AB

XC

A

XB

G

D

H(SLOT)

BA

2F1

AK

AJ

BF

2F2

B

BB

BC

C

L

AA

J

P

N-W

U

R

S

ES

XE

XD

EE

AB

XC

A

XB

G

D

H(SLOT)

BA

2F1

AK

AJ

BF

2F2

B

BB

BC

C

L

AA

J

P

Dimensions: mm (in)

OMT34-18-56CB

D-43e

Dimensions: mm (in)

OMT13-18-56CB

AB CD E2F12F2G H J L P R S U

165 165 315 89 62 76 127 3 9 44 208 175 13 5 16

(6.5) (6.5) (12.4) (3.5) (2.44) (3) (5) (0.12) (0.34) (1.73) (8.19) (6.9) (0.517) (0.188) (0.625)

ES AA AB AH AJ AK BA BB BC BF XB XC XD XE

36

1

⁄2" NPT

136 49 149 114 70 4 5 10 42 94 82 72

(1.41) (5.35) (1.91) (5.875) (4.5) (2.75) (0.16) (0.19) (

3

⁄8-16) (1.65) (3.7) (3.23) (2.85)

AB CD E2F12F2G H J L P R S U

165 165 315 89 62 76 127 3 9 44 208 175 13 5 16

(6.5) (6.5) (12.4) (3.5) (2.44) (3) (5) (0.12) (0.34) (1.73) (8.19) (6.9) (0.517) (0.188) (0.625)

ES AA AB AH AJ AK BA BB BC BF XB XC XD XE

36

1

⁄2" NPT

136 49 149 114 70 4 5 10 42 94 82 72

(1.41) (5.35) (1.91) (5.875) (4.5) (2.75) (0.16) (0.19) (

3

⁄8-16) (1.65) (3.7) (3.23) (2.85)

Page 6

D-43f

56C FRAME MOTORS—1 PHASE

OMT13-18-56CB OMT12-18-56CB OMT34-18-56CB

HP

1

⁄3

1

⁄2

3

⁄4

RPM/POLES 1800/4 1800/4 1800/4

VOLTAGE/PHASE 115/208 to 230V 1 115/208 to 230V 1 115/208 to 230V 1

FRAME 56C 56C 56C

FREQUENCY 60 HZ 60 HZ 60 HZ

RATED SPEED 1725 RPM 1725 RPM 1725 RPM

DUTY CYCLE Continuous Continuous Continuous

SERVICE FACTOR 1.15 1.15 1.15

AMBIENT TEMP 40°C 40°C 40°C

ALTITUDE 3300' ASL 3300' ASL 3300' ASL

INSULATION CLASS FFF

FULL LOAD AMPS 6.6/3.3 A 8.8/4.4 A 11.0/5.5 A

TEMP RISE @

FULL LOAD

80K at SF 1.15 80K at SF 1.15 100K at SF 1.15

OVERLOAD None None None

DESIGN BBB

RATED TORQUE 1.02 ft-lb 1.52 ft-lb 2.29 ft-lb

LOCKED ROTOR

TORQUE

300% 300% 275%

BREAKDOWN TORQUE 275% 275% 250%

LOCKED ROTOR

AMPS (STARTING)

31/18 A 37/21 A 55/32 A

SLIP 4.17% at full load 4.17% at full load 4.17% at full load

NO LOAD CURRENT 4.82 A 7.23 A 8.67 A

BEARINGS Ball Ball Ball

DE BEARING 6203-ZZ 6203-ZZ 6203-ZZ

ODE BEARING 6203-ZZ 6203-ZZ 6203-ZZ

ENCLOSURE TEFC TEFC TEFC

MOUNTING F-1 F-1 F-1

ROTATION CW/CCW CW/CCW CW/CCW

MOMENT OF

INERTIA (lb-ft

2

)

0.07458 0.07956 0.09505

CONNECTION DIAGRAM 115/208 to 230V—6 leads 115/208 to 230V—6 leads 115/208 to 230V—6 leads

TYPE WIRING Loose wire Loose wire Loose wire

WIRE/HOUSING Junction box Junction box Junction box

SHAFT Keyed Keyed Keyed

CAPACITOR(S) 111

CAPACITOR SIZE Ø42 x 80 mm

2

Ø42 x 80 mm

2

Ø42 x 80 mm

2

CAPACITOR INFO 200µF/125V 250µF/125V 250µF/125V

BASE/TYPE Rigid removable Rigid removable Rigid removable

PAINT COLOR Black Black Black

APPROX WEIGHT 26 lb 27 lb 31 lb

POWER FACTOR 0.62 0.63 0.65

EFFICIENCY (%) 56.0 at full load 57.0 at full load 65.0 at full load

Page 7

D-43g

OMT1-18-56CB OMT1.5-18-56CB OMT2-18-56CB

11.5 2

1800/4 1800/4 1800/4

115/208 to 230V 1 115/208 to 230V 1 115/208 to 230V 1

56C 56C 56C

60 HZ 60 HZ 60 HZ

1725 RPM 1725 RPM 1725 RPM

Continuous Continuous Continuous

1.15 1.15 1.15

40°C 40°C 40°C

3300' ASL 3300' ASL 3300' ASL

FF F

13.6/6.8 A 15.2/7.6 A 20.0/10.0 A

100K at SF 1.15 110K at SF 1.15 110K at SF 1.15

None None None

BB B

3.04 ft-lb 4.57 ft-lb 6.09 ft-lb

275% 250% 250%

250% 225% 225%

75/43 A 120/65 A 150/86 A

4.17% at full load 4.17% at full load 4.17% at full load

10.84 A 12.40 A 14.21 A

Ball Ball Ball

6203-ZZ 6203-ZZ 6203-ZZ

6203-ZZ 6203-ZZ 6203-ZZ

TEFC TEFC TEFC

F-1 F-1 F-1

CW/CCW CW/CCW CW/CCW

0.1195 0.1418 0.1823

115/208 to 230V—6 leads 115/208 to 230V—6 leads 115/208 to 230V—6 leads

Loose wire Loose wire Loose wire

Junction box Junction box Junction box

Keyed Keyed Keyed

12 2

Ø42 x 80 mm

2

Ø42 x 80 mm2to Ø45 x 90 mm

2

Ø42 x 80 mm2to Ø45 x 90 mm

2

300µF/125V 250µF/165V, 40µF/450V 200µF/165V, 40µF/450V

Rigid removable Rigid removable Rigid removable

Black Black Black

34 lb 37 lb 43 lb

0.66 0.75 0.77

68.0 at full load 71.0 at full load 73.0 at full load

Page 8

D-43h

MODEL NO. PRICE DESCRIPTION

OMSCFM13 $12 Start capacitor, for OMT13-18-56CB

OMSCFM12 12 Start capacitor, for OMT12-18-56CB

OMSCFM34 12 Start capacitor, for OMT34-18-56CB

OMSCFM1 12 Start capacitor, for OMT1-18-56CB

OMSCFM1.5 12 Start capacitor, for OMT1.5-18-56CB

OMSCFM2 12 Start capacitor, for OMT2-18-56CB

OMRCFM1.5 12 Run capacitor, for OMT1.5-18-56CB

OMRCFM2 12 Run capacitor, for OMT2-18-56CB

OMW56 8 Motor slide base, 56 frame

OMCSWITCHFM 12 Centrifugal switch, single-phase motors

ACCESSORIES

Ordering Example: OMW56, motor slide base for 56 frame, $8.

MODEL NO. PRICE DESCRIPTION

OMT13-18-56CB $97 56C flange rolled steel motor, 115/208-230 V, single-phase, 1/3 HP, 1800 RPM

OMT12-18-56CB 102 56C flange rolled steel motor, 115/208-230 V, single-phase, 1/2 HP, 1800 RPM

OMT34-18-56CB 111 56C flange rolled steel motor, 115/208-230 V, single-phase, 3/4 HP, 1800 RPM

OMT1-18-56CB 124 56C flange rolled steel motor, 115/208-230 V, single-phase, 1 HP, 1800 RPM

OMT1.5-18-56CB 157 56C flange rolled steel motor, 115/208-230 V, single-phase, 1.5 HP, 1800 RPM

OMT2-18-56CB 190 56C flange rolled steel motor, 115/208-230 V, single-phase, 2 HP, 1800 RPM

To Order

(Specify Model Number)

MOST POPULAR MODELS HIGHLIGHTED!

Ordering Example: OMT13-18-56CB, 56C flange rolled steel motor, 115/208 to 230 V single-phase, 1⁄3HP, 1800 RPM, $97.

OMT13-18-56CB, $97,

shown smaller than

actual size.

Page 9

One Omega Drive | Stamford, CT 06907 | 1-888-TC-OMEGA (1-888-826-6342) | info@omega.com

EPG05

www.omega.com

UNITED KINGDOM

www. omega.co.uk

Manchester, England

0800-488-488

UNITED STATES

www.omega.com

1-800-TC-OMEGA

Stamford, CT.

CANADA

www.omega.ca

Laval(Quebec)

1-800-TC-OMEGA

GERMANY

www.omega.de

Deckenpfronn, Germany

0800-8266342

Karviná, Czech Republic

FRANCE

www.omega.fr

Guyancourt, France

088-466-342

CZECH REPUBLIC

www.omegaeng.cz

596-311-899

BENELUX

www.omega.nl

Amstelveen, NL

0800-099-33-44

More than 100,000 Products Available!

Temperature

Calibrators, Connectors, General Test and Measurement

Instruments, Glass Bulb Thermometers, Handheld Instruments

for Temperature Measurement, Ice Point References,

Indicating Labels, Crayons, Cements and Lacquers, Infrared

Temperature Measurement Instruments, Recorders Relative

Humidity Measurement Instruments, RTD Probes, Elements

and Assemblies, Temperature & Process Meters, Timers and

Counters, Temperature and Process Controllers and Power

Switching Devices, Thermistor Elements, Probes and

Assemblies,Thermocouples Thermowells and Head and Well

Assemblies, Transmitters, Wire

Flow and Level

Air Velocity Indicators, Doppler Flowmeters, Level

Measurement, Magnetic Flowmeters, Mass Flowmeters,

Pitot Tubes, Pumps, Rotameters, Turbine and Paddle Wheel

Flowmeters, Ultrasonic Flowmeters, Valves, Variable Area

Flowmeters, Vortex Shedding Flowmeters

pH and Conductivity

Conductivity Instrumentation, Dissolved Oxygen

Instrumentation, Environmental Instrumentation, pH

Electrodes and Instruments, Water and Soil Analysis

Instrumentation

Data Acquisition

Auto-Dialers and Alarm Monitoring Systems,

Communication Products and Converters, Data

Acquisition and Analysis Software, Data Loggers

Plug-in Cards, Signal Conditioners, USB, RS232, RS485

and Parallel Port Data Acquisition Systems, Wireless

Transmitters and Receivers

Pressure, Strain and Force

Displacement Transducers, Dynamic Measurement

Force Sensors, Instrumentation for Pressure and Strain

Measurements, Load Cells, Pressure Gauges, Pressure

Reference Section, Pressure Switches, Pressure Transducers,

Proximity Transducers, Regulators,

Strain Gages, Torque Transducers, Valves

Heaters

Band Heaters, Cartridge Heaters, Circulation Heaters,

Comfort Heaters, Controllers, Meters and Switching

Devices, Flexible Heaters, General Test and Measurement

Instruments, Heater Hook-up Wire, Heating Cable

Systems, Immersion Heaters, Process Air and Duct,

Heaters, Radiant Heaters, Strip Heaters, Tubular Heaters

click here to go to the omega.com home page

Loading...

Loading...