Page 1

M-3581 for

OMR-6520

OMR-6510

RS-232 to RS-422/RS -485 Converter

RS-422/RS -485 Repeater

User’s Guide

Page 2

Contents

1. INTRODUCTION............................................................................................1-1

1.1 WHAT IS OMR ?..................................................................................1-1

1.2 OUTSTANDING FEATURES OF OMR.................................................1-1

1.3 OMR-6000 SERIES PRODUCTS OVERVIEW........................................1-3

1.4 EIA RS-485 STANDARD ......................................................................1-3

1.5 RS-485 ON OMR...................................................................................1-4

1.6 OMR RS-485 NETWORK CONFIGURATIONS...................................1-4

1.7 CONSTRUCTING A OMR NETWORK.................................................1-5

1.8 TERMINATION BUS.............................................................................1-6

1.9. SHIELDING............................................................................................1-6

1.10. HOW TO CALCULATE CHECKSUM V ALUE........................................1-7

2. OMR-6520........................................................................................................2-1

2.1. OVERVIEW............................................................................................2-1

2.2. SETUP ....................................................................................................2-6

2.3. INSTALLATION....................................................................................2-7

2.4 PROGRAMMING....................................................................................2-8

3. OMR-6510........................................................................................................3-1

3.1. OVERVIEW............................................................................................3-1

3.2. SETUP ....................................................................................................3-5

3.3 INSTALLATION....................................................................................3-6

3.4 PROGRAMMING....................................................................................3-7

4. INSTALL A BRAND-NEW OMR ................................................................4-1

4.1 INITIALIZE A BRAND-NEW OMR.....................................................4-1

4.2 INSTALL A NEW OMR TO A EXISTING NETWORK........................4-3

5. SOFTWARE UTILITY ....................................................................................5-1

5.1 SOFTWARE INSTALLATION...............................................................5-1

5.2 HOW TO EXECUTE THE OMR ADMINISTRATION........................5-1

5.3 OMR ADMINISTRATION FUNCTION OVERVIEW...........................5-2

6. TROUBLESHOOTING AND MAINTENANCE........................................6-1

Contents i

Page 3

1. Introduction

1.1 What is OMR ?

OMR is a series of data acquisition modules. It provides a total solution of the data acquisition network and

control system. You can remotely control up to 256 OMR modules on RS-485 network. All you need is to use

a host computer, like a PC (Personal Computer), with one RS-232 serial port for controlling the whole system.

The maximum communication distance is 4000 feet from the host computer.

OMR is based on the RS-485 multi-drop network system, each module has a unique address ID. Using simple

ASCII command & response protocol through standard RS -485 interface can control all the OMR modules in

the RS -485 network.

The OMR modules provide direct linkage to a wide variety of sensors and perform all signal conditioning,

scaling, linearization and conversion. The modules can be used to measure temperature, pressure, flow,

voltage, current and numerous types of digital signals.

1.2 Outstanding Features of OMR

• Industry standard networking

All OMR modules use the RS -485 communication protocol for transmitting and receiving at high rates

and over long distance.

• Two-wire and multi -drop communication

A single twisted pair of wires is used to transmit and receive data between modules. Multi-drop capability

makes system configuration more flexible and easy set -up of a network.

• High transfer speed

OMR modules provide up to 115.2K bps data / command transfer rate. It can promote system bandwidth.

• Simple command / response protocol

All communications are performed with printable ASCII characters. This allows the information to be

processed with string functions common to the most high-level languages.

• Industrial design

The screw terminal plug connectors on every OMR module ensure simple installation and easy

modification. The compact size allows the modules to be mounted on DIN rail, back-panel wall-mount,

etc.

• Watch-dog supervisory

OMR contains a watch-dog supervisory circuitry that will automatically reset the module when the

system fails. In addition, a user-programmable software timer provides a ‘safe’ output signal in the event

of host computer failure.

• High isolation voltage

OMR provides photo -isolators, which ensure high isolation voltage, between the data acquisition circuits

and the communication port. The fatal electric-shock won‘t go through and damage all the modules on

the network.

• Noise immunity

The OMR provide extra noise immunity capability. An electrode, which is coated inside the ABS case,

can reduce electro-magnetic interference (EMI) and noise.

• Harsh environmental protection

Introduction 1-1

Page 4

A surface coating covers on the PCB and electronic components of the OMR. It allows superior

resistance to harsh environment such as humidity, salt spry and mos t harsh chemicals.

1-2 Introduction

Page 5

1.3 OMR-6000 series products overview

The OMR-6000 series provides the complete sets of data acquisition modules, including the communication

modules, the analog input modules, the analog output modules, and the digital I/O modules.

Communication Module

• OMR-6510: RS -422/RS-485 Repeater

• OMR-6520: RS -232 to RS-422/RS-485 Converter

• OMR-6530: USB to RS -422/RS-485 Converter

Analog Input Modules

• OMR-6011: Multifunction High Gain Analog Input

Module (with DI/O)

• OMR-6011D: Multifunction High Gain Analog Input with

5 ½ digit LED Display (with DI/O)

• OMR-6012: Analog Input Module (with DI/O)

• OMR-6012D: Analog Input Module with 5 1/2 digit LED Display (with DI/O)

• OMR-6013: 3-channel RTD Input Module

• OMR-6014D: Analog (Transmitter) Input Module with

5 1/2 digit LED Display

• OMR-6017: 8-channel Analog Input Module

• OMR-6018: 8-channel Thermocouple Input Module

Analog Output Modules

• OMR-6021: Single Channel Analog Output Module

• OMR-6024: 4-channel Analog Output Module (with DI)

Digital I/O Modules

• OMR-6050: Module with 7 DI channels and 8 DO channels

• OMR-6052: Isolated Digital Input Module

• OMR-6053: 16-channel digital Input Module

• OMR-6054: 15-channel digital Input Module

• OMR-6056: 15-channel digital Output Module

• OMR-6058: 28-channel programmable digital I/O Module

• OMR-6060: 4-channel Relay Output & Digital Input Module

• OMR-6063: 8-channel Relay Output Module

• OMR-6080: Counter/Frequency Input Module

1.4 EIA RS-485 Standard

The EIA RS-485 interface is a communication standard developed for multi-dropped systems that can

communicate at high rate over long distance. The standard RS-485 can operate at speed up to 10 M bps over

cable length up to 4000 feet.

The RS-485 interface can support up to 32 drivers / receivers on the same line. This allows actual networking

applications on a parity line system (sometimes called multi-drop).

The RS -485 uses differential transmission on a balance line. Its easy wiring makes it popular to use in

industrial applications.

Introduction 1-3

Page 6

Converter

Converter

Terminator

1.5 RS-485 on OMR

The OMR improves the RS-485 capability for minimizing the user‘s cost. On each OMR module, a half-duplex

RS-485 transceiver is used to communicate with other modules. A single twisted pair of wires, which provides

standard differential transmission, is used to transmit and receive data between modules. The high input

impedance of each OMR receiver allows up to 128 OMR modules on the same RS -485 bus without using a

signal repeater.

The maximum transfer rate of OMR is 115.2Kbps, which is lower than the maximum speed of the RS -485

standard. The slew-rate limiter on every RS -485 transceiver of OMR is very useful for transmitting error-free

data, minimizing EMI, and reducing reflections caused by improperly terminated cables.

The OMR on a network may not use the same power supply. Therefore, the voltage difference between

grounds of the modules may exist.

Excessive output current and power dissipation caused by faults or by bus contention are prevented by the

current limiter and the thermal shutdown circuitry inside the OMR.

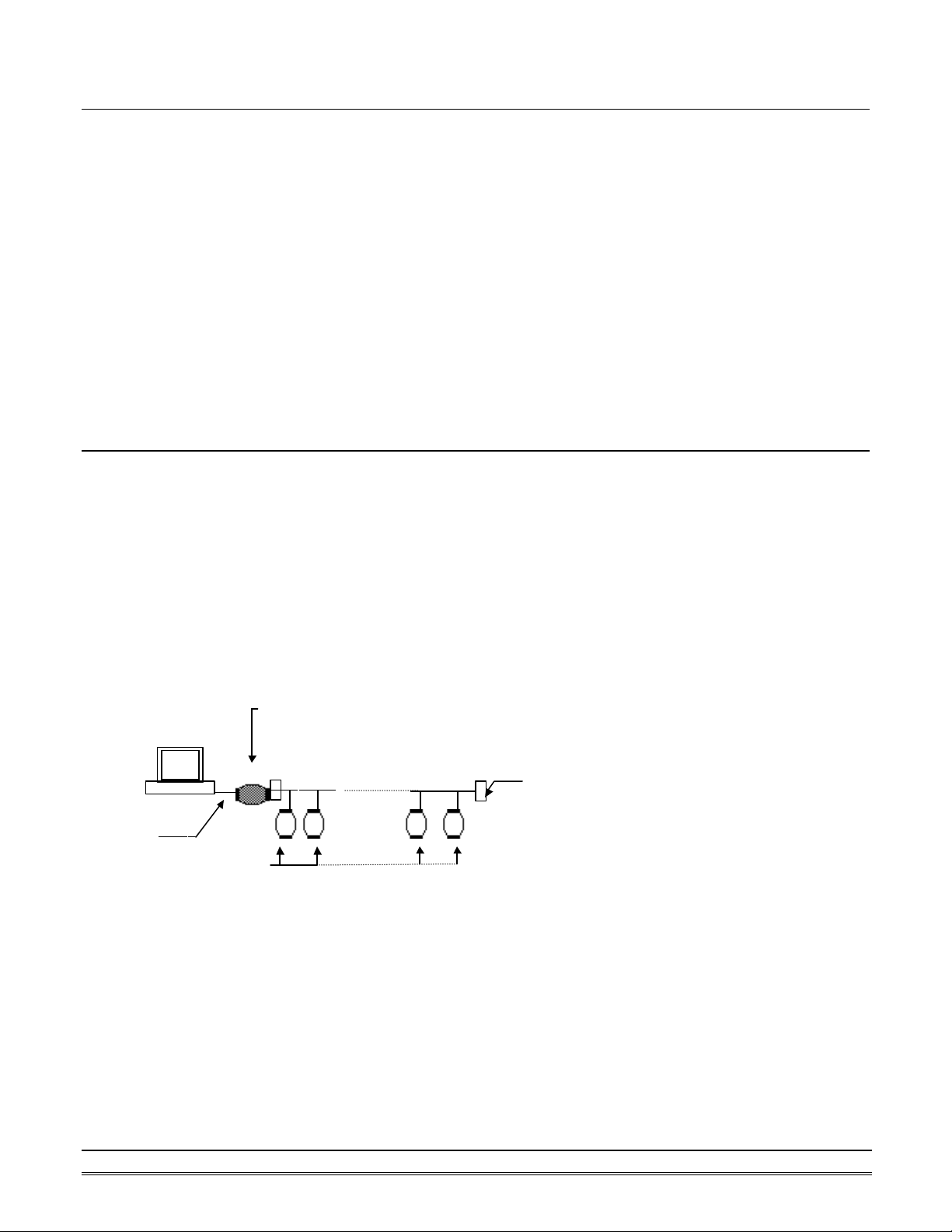

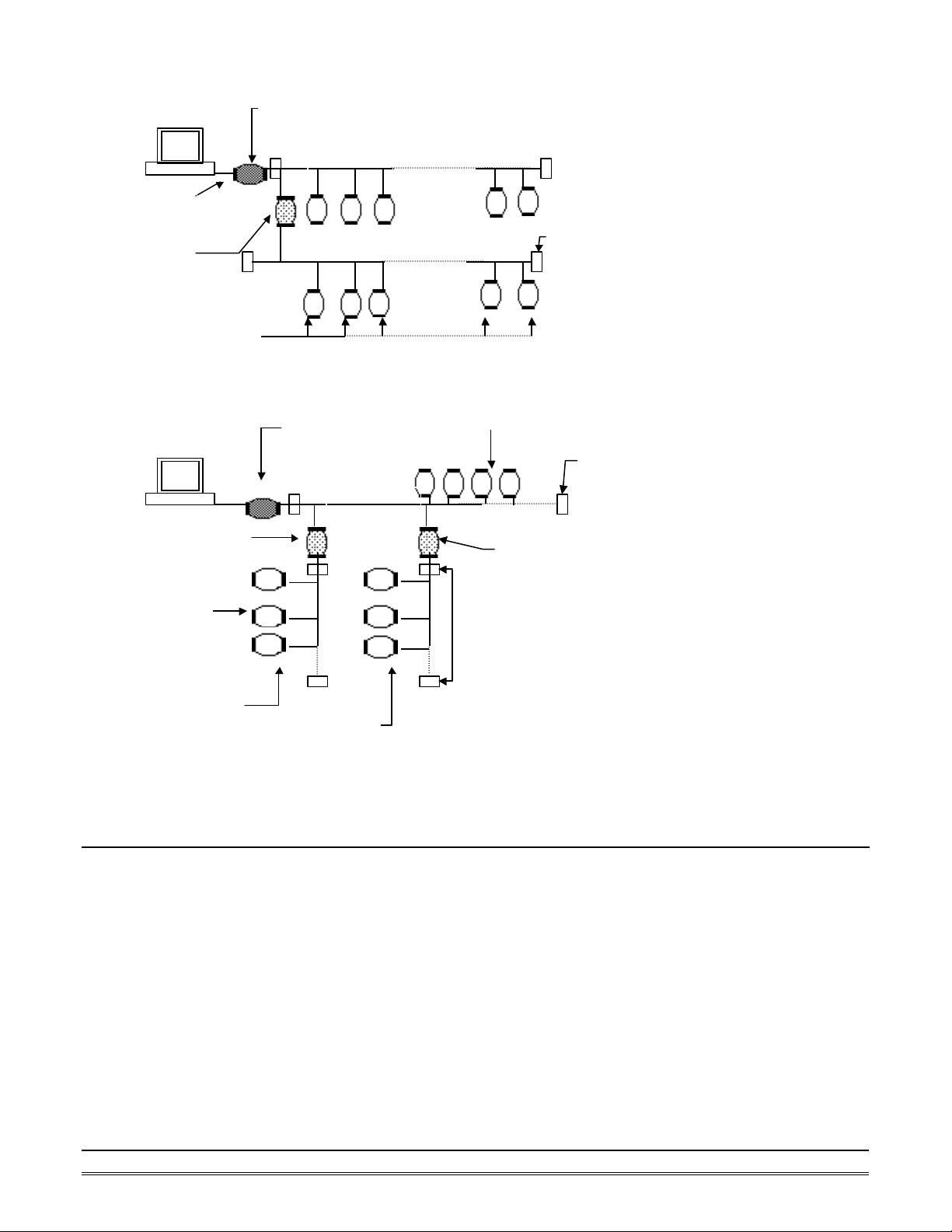

1.6 OMR RS-485 Network Configurations

OMR-6000 series is designed under RS-485 multi-drop network architecture. Up to 256 OMR modules can be

controlled in a multi-drop network. The limit of 256 is due to command code. The network can be connected

by simple topology (Figure 1-1) or branch topology (Figure 1-2) or free topology (Figure 1-3).

The OMR -6520 and OMR -6510 are the two basic communication modules to construct a RS-485 network. The

OMR-6520 is a RS-232 to RS-485/RS-422 converter. The OMR -6520 is used to build a RS-485 port for the host

computer by converting standard RS -232 signal into RS-485 signal.

The OMR -6510 is the RS-485 signal repeater, which is used to extend or to lengthen the network distance. An

OMR bus can connect up to 256 modules, each segment is up to 128 modules. Whenever the numbers of the

modules excess 128, the repeater should be used. In addition, the length of a standard RS -485 bus is up to

4000 feet, the repeater should be used whenever the length of a signal bus is more than 4000 feet.

Host

RS-232

OMR Modules

ND-6520

OMR-6520

RS-232/RS-485

RS-232 to RS-485/RS-422

RS-485 bus

Figure 1-1 Simple Topology

1-4 Introduction

Page 7

Converter

Converter

Repeater

Terminator

Terminat

Terminat

Host

RS-232

OMR-651

0

Host

OMR Modules

OMR I/O modules

OMR Modules

OMR-6510

OMR-6520

RS-232 to RS-485/RS-422

RS-485 bus

RS-485 bus

Figure 1-2 Branch Topology

OMR-6520

RS-232 to RS-485/RS-422

OMR I/O modules

RS-485 bus

Figure 1-3 Free Topology

OMR Modules

OMR-6510

Repeater

1.7 Constructing a OMR Network

Go through the following steps, the user can construct an OMR network easily.

1. Setup an OMR-6520.

2. Connect the host computer with the OMR-6520.

3. Setup one or more OMR-6510 if necessary.

4. Connect the OMR-6510 to extend to RS -485 bus if necessary.

5. Install the OMR utility software from disk.

6. Initialize the brand-new OMR modules.

7. Add the new OMR modules into RS -485 network.

Refer to chapter 2 for executing step 1 and 2. Refer to chapter 3 for executing step 3, 4 and for understanding

the time to install OMR -6510. The knowledge about the software for operating the OMR is in chapter 5. For

executing the step 6 and step 7, refer to chapter 4.

Introduction 1-5

Page 8

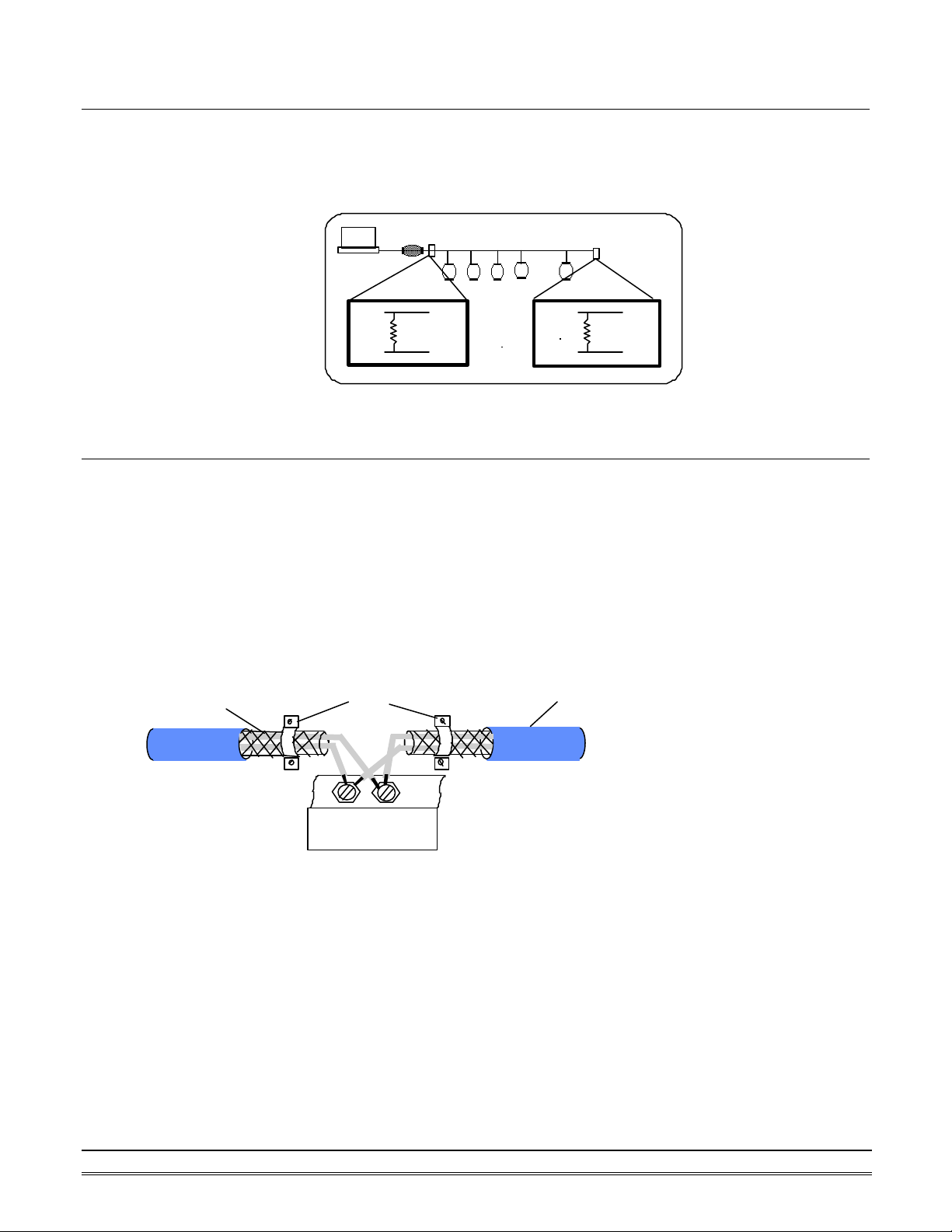

1.8 Termination Bus

In order to avoid signal reflections on the bus, each bus segment has to be blanked off at its physical beginning

and at its end with the characteristic impedance. A termination resister (Rt) is installed for this purpose. The Rt

value - 120Ω ± 2% is recommended, and the detailed connection of Rt can be referred from the “Terminator

Connection” diagram below.

Host

1.9. Shielding

In case of increased interference, a shielded bus cables is recommended to use for wiring between module and

modules. In addition, a shielding also should be done for the cable of power supply and for the signal cables.

Some experiences and recommendations are concerning for shield connection.

1. The shield should be connected with protective earthing at each bus connection.

2. The shield should be applied additionally several times along the course of the cable.

3. The Computer should be applied the shield directly to the appliance or to separate shield rails.

braided shield

Data+

120 ohms

Data-

Terminator Connection

EarthingPoint

Data+

120 ohms

Data-

Isolation

RS-485 Connection

1-6 Introduction

DA

TA

+

DA

TA

-

OMR-Module

Page 9

Response :

Response :

1.10. How to Calculate Checksum Value

Format of OM R Commands

(LeadingCode)(Addr)(Command)(Data)[Checksum]<CR>

When checksum is enable then [Checksum] is needed, it is

2-character.

[Checksum] = ((LeadingCode)+(Addr)+(Command)+(Data)) MOD 0x100

Example 1: checksum is disable

User Command : $012<CR>

!01400600

Example 2: checksum is enable

User Command : $012B7<CR>

!01400600AC

‘$’ = 0x24 ‘0’ = 0x30 ‘1’ = 0x31 ‘2’ = 0x30

B7 = ( 0x24 + 0x30 + 0x31 + 0x32 ) MOD 0x100

‘!’ = 0x24 ‘0’ = 0x30 ‘1’ = 0x31 ‘4’ = 0x34

‘6’ = 0x36

AC = ( 0x24 + 0x30 + 0x31 + 0x34 + 0x30 + 0x30 + 0x36 + 0x30 + 0x30 ) MOD 0x100

Introduction 1-7

Page 10

Page 11

2. OMR-6520

2.1. Overview

What is OMR-6520 ?

OMR-6520 is a RS -232 to RS-422/RS-485 converter, it converts the RS -232 signal to the RS-422/RS-485

signals. The OMR -6520 can be considered as an extension RS-422/RS-485 serial port for the host computer.

A standard 9-pin D-type connector is used to connect the host computer and the OMR-6520. Hence, the

OMR-6520 can connect with all kinds the PC, IPC or Notebook PC, which install a standard RS-232 interface.

Features of OMR-6520

• RS-422/RS-485 transceiver

• Differential 2-wire half-duplex RS -485

• Easily setup and installation

• Auto direction flow control

• Maximum 128 OMR on a bus without using repeaters

• Maximum 256 addressable OMR modules

• High transfer speed

• High isolation voltage

• Lower power consumption

OMR-6520 2-1

Page 12

Specifications of OMR-6520

² Input

• Interface : standard RS -232 9 pin female D-type connector

• Speed (bps) : 1200(115.2K1), 2400, 4800, 9600, 19.2K,

38.4K, RTS

• Data Format : 9 bits, 10 bits, 11 bits, or 12 bits

² Output

• Interface : RS-485, differential, 2 half-duplex wires

RS-422, differential, 4 full-duplex wires

• Speed (bps) : 1200(115.2K1), 2400, 4800, 9600, 19.2K,

38.4K, RTS

• Max RS -485 network bus distance : 4000 ft. (1200m)

² Isolation

• Isolation voltage : 5000 Vrms(between RS -422/RS-485

network and host computer)

² Bus

• Max loading : 128 OMRs on a RS -485 network

• Max modules : 256 OMRs with one OMR-6510 repeater

² Power

• Power Supply : +10V to +30V

• Power Consumption : 0.95 W

Note 1: 115.2K is supported by version A1.2 or later.

2-2 OMR-6520

Page 13

SW1: ON

SW2: ON

SW7: ON

A Look at OMR-6520 & Pin Assignment

(RS-232 IN)

RS-232 to RS-485

OMR-6520

Switch Position

SW4: ON

SW5: ON

SW6: ON

/RS-422Converter

Baud Rate

RTS CTRL

115.2K bps

2400 bps

4800 bps

9600 bps

19.2K bps

38.4K bps

(Y) DATA+

(G)DATA-

TX+

TX-

RX+

TX-

(R)+Vs

(B)GND

OMR-6520 2-3

Page 14

Pin Definitions

Pin # Signal Name Description

1 (Y)DATA+ RS-485 transmission line, positive

2 (G)DATA- RS-485 transmission line, negative

4 TX+ RS-422 transmission line, positive

5 TX - RS-422 transmission line, negative

6 RX+ RS-422 receiving line, positive

7 RX - RS-422 receiving line, negative

9 (R)+VS OMR power supply, +10V~+30V

10 (B)GND OMR ground

-- RS-232 IN 9-pin RS -232 connector

Connection Between Host and OMR-6520

Host RS -232

RTS ’

GND •

TXD Ž

RXD •

Host

Computer

RS-232

OMR-6520 RS-232

‡ RTS

… GND

ƒ TXD

‚ RXD

OMR-6520

RS-232/RS-485

DATA +

DATA -

+Vs GND

2-4 OMR-6520

Page 15

Power Regulator

& Filter

Power Input

+10V ~ +30V

+5V

GND

Isolation +5V

Isolation GND

DC to DC

Converter

TXD

RXD

RTS

GND

Receiver

RS-232

/ Driver

SW1

Switching

Communication

Controller

PTC : Positive Temperature Coefficient

Receiver/Driver

Data+

Data-

Rx+

Rx-

Tx+

Tx-

Functional Block Diagram

RS-422/RS-485

Opto-Isolation

Communication

Direction Control

TVS : Transient Voltage Suppresser

OMR-6520 2-5

Page 16

2.2. Setup

Objective of Setup

In normal condition, it is not necessary to setup the OMR-6520. The default configuration of this

communication module is 9600 bps and data format of 8 data bits with 1 start bit, 1 stop bit, and no parity

check. Note that the data format is reserved to be compatible with other brand‘s communication port; it should

not be modified if only OMR is used in a system. The baud rate can be configured according applications’

requirement.

Setup Equipments

Only screwdriver is used to open the case. Software, power supply, and wiring are not necessary.

Setup Procedure

Only hardware switch setting can be setup in OMR-6520. The user can set the speed of the serial interface

(RS-232 and RS-422/RS-485), and the serial data format. The speed and the data format on the whole RS-485

network must be identity otherwise the communication will be not correct.

To setup the OMR -6520, use the screwdriver to open the case, then change the switch setting. The new setting

is available after power on. The case must be put back and locked carefully. Note that do not scratch the

surface of the circuit while setting up, otherwise the surface coating or even the circuits will be damaged.

Default Setting

• 9600 baud rate

• 10 bits series data format : one start bit, eight data bits, one stop bit, no parity check

SW1 Setting

SW1 Default Setting (9600 bps)SW1 Default Setting (9600 bps)

ON

11 22 33 44 55 66 77

OFF

1 2 3 4 5 6 7 Baud Rate

ON OFF OFF OFF OFF OFF OFF RTS Control

OFF ON OFF OFF OFF OFF OFF 1200 or 115.2k1 bps

OFF OFF ON OFF OFF OFF OFF 2400 bps

OFF OFF OFF ON OFF OFF OFF 4800 bps

OFF OFF OFF OFF ON OFF OFF 9600 bps

OFF OFF OFF OFF OFF ON OFF 19200 bps

OFF OFF OFF OFF OFF OFF ON 38400 bps

Note 1: 115.2kbps is supported by version A1.2 or later.

2-6 OMR-6520

Page 17

ON

1

2

Data Bits : 8

Stop Bits : 1

SW2 Setting

SW2 Default Setting

Start Bits : 1

Parity : None

1 2 Start Bit Data Bits Stop Bit Parity Packet Data Bits

1 7 1 0 OFF OFF

9

1 6 1 1

1 8 1 0 OFF ON

10

1 7 1 1

1 9 1 0 ON OFF

11

1 8 1 1

1 10 1 0 ON ON

12

1 9 1 1

2.3. Installation

Software Utility

Software is not necessary for this module.

Equipments for Installation

A host computer wit h RS-232 port

RS-232 cable (DB-9 female)

DC Power supply (+10V~+30V) (NDP-243u is recommended)

Wires (shielded and grounded is recommended)

Installation Procedure

1. Make sure the host computer is power off.

2. Use RS-232 cable to connect OMR-6520 with host comp uter.

3. Wire the power supply to OMR. Note that the power supply should meet the specification.

4. Wire other OMRs.

Application Wiring

The Figure 2-1 shows the application wiring of OMR-6520.

Host

Computer

Local Power Supply

+10 V to +30 V

+Vs GND

RS-232

RS-232/RS-485

DATA +

DATA -

+Vs GND

OMR moduleOMR-6520

+ DATA

- DATA

+Vs GND

OMR-6520 2-7

Page 18

2.4 Programming

The OMR-6520 is a communication module, it is not necessary to be programmed.

Figure 2-1 Application wiring of OMR-6520

2-8 OMR-6520

Page 19

3. OMR-6510

3.1. Overview

What is OMR-6510 ?

The OMR-6510 is the RS -422/RS-485 signal repeater which is used to extend or to lengthen the network

distance. A OMR bus can connect up to 128 modules. The repeater should be used when the numbers of the

modules excess 128. In addition, the repeater should also be used when the length of a signal bus is more

than 4000 feet.

Features of OMR-6510

• RS-422/RS-485 signal transceiver & repeater

• Bi-directions signal transmission for both RS -422/RS-485 ports

• Automatic transmission direction control

• Easily setup and installation

• Maximum 128 OMR on a bus

• Maximum 256 addressable OMR modules

• High transfer speed

• Surge protection

• Lower power consumption

Specifications of OMR-6510

² Input / Output

• Interface : RS-485, differential 2 half-duplex wires

RS-422, differential, 4 full-duplex wires

• Speed (bps) : 1200(115.2K1), 2400, 4800, 9600, 19.2K, 38.4K

• Data Format : 9 bits, 10 bits, 11 bits, or 12 bits

• Max RS -485 network bus distance : 4000 ft. (1200m)

Note 1: 115.2k is supported by version A1.2 or later.

² Bus

• Max Loading : 128 OMRs on a bus

² Power

• DC Power Supply : +10V to +30V

• Power Consumption : 0.9 W

A Look at OMR-6510 & Pin Assignment

OMR-6510 3-1

Page 20

20

DATA+ (Y)

DATA- (G)

OMR-6510

Switch Position Baud Rate

SW1-1: ON 115.2K bps

SW1-2: ON

SW1-3: ON

SW1-4: ON

SW1-5: ON

SW1-6: ON

1

(Y)DATA+

(G)DATA-

Tx+

Tx+

Tx-

RS-422/RS-485

Repeapter

2400 bps

4800 bps

9600 bps

19.2 K bps

38.4 K bps

Tx-

Rx+

Rx+

Rx-

RX-

(R)+Vs

11

(B)GND

10

3-2 OMR-6510

Page 21

Pin Definitions

Pin # Signal Name Description

1 (Y)DATA+ RS-485 transmission line, positive

2 (G)DATA- RS-485 transmission line, negative

4 TXIN+ RS-422 transmission input line, positive

5 TXIN- RS-422 transmission input line, negative

6 RXOUT+ RS-422 receiving output line, positive

7 RXOUT - RS-422 receiving output line, negative

9 (R)+VS OMR power supply, +10V~+30V

10 (B)GND OMR ground

14 RXIN- RS-422 receiving input line, negative

15 RXIN+ RS-422 receiving input line, positive

16 TXOUT - RS-422 transmission output line, negative

17 TXOUT+ RS-422 transmission output line, positive

19 (G)DATA- RS-485 transmission line, negative

20 (Y)DATA+ RS-485 transmission line, positive

OMR-6510 3-3

Page 22

Power Regulator

& Filter

Power Input

+10V ~ +30V

+5V

GND

TVS : Transient Voltage Suppresser

PTC : Positive Temperature Coefficient

Data+

Data-

Rx+

Rx-

Tx+

Tx-

SW1

Communication

Switching

Controller

Communication

Data+

Data-

Rx+

Rx-

Tx+

Tx-

OMR-6510 Functional Block Diagram

RS-422/RS-485

Receiver/Driver

RS-422/RS-485

Receiver/Driver

Direction

Control

3-4 OMR-6510

Page 23

3.2. Setup

Objective of Setup

In normal condition, it only needs to setup the OMR-6510 when the OMR bus with more than 128 modules or

the distance exceeds 4000 feet long. The default configuration of this communication module is 9600 bps and

data format of 8 data bits with 1 start bit, 1 stop bit, and no parity check. Note that the data format is reserved

to be compatible with other brand‘s communication port, it should not be modified if only OMR is used in a

system. The baud rate can be configured according user’s requirement.

Setup Equipments

Only screw driver is used to open the case. Software, power supply, and wiring are not necessary.

Setup Procedure

Only hardware switch setting can be setup in OMR-6510. The user can set the speed and the data format of

the RS-422/RS-485 interface. The speed and the data format on the whole network must be identity otherwise

the communication may be not correct.

To setup the OMR-6510, use the screw driver to open the case, then change the switch setting. The new

setting is available after power on. The case must be put back and locked carefully. Note that do not scratch

the surface of the circuit while setting up, otherwise the surface coating or even the circuits will be damaged.

Default Setting

• 9600 Baud rate

• 10 bits serial data format : one start bit, eight data bits, one stop bit, no parity check

SW1 Setting

SW1 Default Setting (9600 bps)SW1 Default Setting (9600 bps)

ON

11 22 33 44 55 66

OFF

1 2 3 4 5 6 Baud Rate

ON OFF OFF OFF OFF OFF 1200 or 115.2k1 bps

OFF ON OFF OFF OFF OFF 2400 bps

OFF OFF ON OFF OFF OFF 4800 bps

OFF OFF OFF ON OFF OFF 9600 bps

OFF OFF OFF OFF ON OFF 19200 bps

OFF OFF OFF OFF OFF ON 38400 bps

Note 1: 115.2kbps is supported by version A1.2 or later.

SW2 Setting

OMR-6510 3-5

Page 24

ON12

Start Bits : 1

Data Bits : 8

Stop Bits : 1

Parity : None

SW2 Default Setting

1 2 Start Bit Data Bits Stop Bit Parity Packet Data Bits

1 7 1 0 OFF OFF

9

1 6 1 1

1 8 1 0 OFF ON

10

1 7 1 1

1 9 1 0 ON OFF

11

1 8 1 1

1 10 1 0 ON ON

12

1 9 1 1

3.3 Installation

Software Utility

Software is not necessary.

Equipments for Installation

A 2-wire RS -485 network or 4-wire RS-422 network.

DC Power supply (+10V~+30V)

Wires

Installation Procedure

1. Make sure the original RS -422/RS-485 network is power off.

2. Wire the power supply to OMR-6510. Note that the power supply should meet the specification.

3. Wire other OMRs to the extend RS -485 bus.

3-6 OMR-6510

Page 25

+Vs GND

module

Application Wiring

OMR

module

DATA +

DATA -

+Vs GND

Local Power Supply

+10 V to +30 V

OMR-6510

Repeater

+DATA DATA+

-DATA DATA-

+Vs GND

OMR

+ DATA

- DATA

+Vs GND

Figure 3-1 OMR-6510 wiring.

3.4 Programming

The OMR-6510 is a communication module, it is not necessary to be programmed

OMR-6510 3-7

Page 26

Page 27

4. Install a Brand New OMR

4.1 Initialize a Brand-New OMR

Objective of Initializing a Brand-New OMR

All OMR modules. except OMR-6520 and OMR-6510, in a RS -485 network must have an unique address ID,

however, every brand-new OMR has a factory default setting as following:

• Baud rate is 9600 bps.

• Address ID is 01.

• Checksum is disable.

• Host watchdog timer is disable.

Therefore, to configure the brand-new OMR before using is necessary, otherwise the address ID will conflict

with others. The baud rate may also be changed according to user‘s requirements.

The following initialization procedures are need not only for a brand-new module, but also for a installed OMR

module. When the user want to change the setting, the initialization procedure can also be used.

Initial State

The OMR I/O modules must be set a Initial State when you want to change the default settings of the modules,

such as the ID address, baud rate, check-sum status etc. All OMR I/O modules have an special pin labeled as

Default*. “ The module will be set as Initial State if the Default* pin is shorted to ground.” Under this state,

the default configuration is set as following:

• Address ID is 00.

• Baud rate is 9600 bps.

• Checksum is disable.

• Host watchdog timer is disable.

In itialization Equipments

• Host computer with an RS -232 port.

• An installed RS -485 module (OMR-6520) with 9600 baud rate.

• The brand new OMR module

• DC Power supply (+10 to +30 VDC) for OMR modules

• A OMR-6510 if the connection distance is more than 4000 ft.

Initialization Procedure A

-- As Baud rate is 9600 bps and check-sum is disable

1. Power off the host computer and the installed OMR-6520. Be suring the baud rate of the OMR-6520 is

9600 bps.

2. Connect a brand new OMR module with the RS -485. Refer to Figure 4.1 for detail wiring.

3. Power on the host computer.

4. Power on the power supply for OMR modules.

5. Use the OMR Administrating utility to configure the address ID, Baud rate and check-sum status of the

module.

Initialization Procedure B

-- As Baud rate is not 9600 bps or check-sum is not disable

1. Power off the host computer and the installed OMR-6520.

2. Connect a brand new OMR module with the RS -485. Refer to Figure 4.1 for detail wiring.

3. Configure the OMR-6520 to Baud rate 9600 bps.

4. Short the DEFAULT* pin of the brand-new module.

5. Power on the host computer.

Install a Brand -New OMR 4-1

Page 28

6. Power on the power supply for OMR modules.

7. Use the OMR Administrating utility to configure the address ID, Baud rate and check-sum status of the

module.

8. Power of the local power supply.

9. Disconnect the DEFAULT* pin.

10. Configure the OMR-6520 to desired Baud rate.

11. Power on the local power supply

12. Use OMR Administration utility to check the module‘s new setting.

4-2 Install a Brand -New OMR

Page 29

+Vs GND

Converter

Initialization Wiring

Host

Computer

RS-232

Local Power Supply

+10 V to +30 V

OMR-6520

RS-232/RS-485

DATA +

DATA -

+Vs GND

New

OMR

module

DATA+

DATA Default*

+Vs GND

Figure 4-1 Layout for Configuring the OMR module

4.2 Install a New OMR to a Existing Network

Equipments for Install a New Module

• A existing OMR network

• New OMR modules.

• DC Power supply (+10 to +30 VDC).

Installing Procedure

1. Configure the new OMR module according the initialization procedure in se ction 4.1.

2. The baud rate and check-sum status must be identity with the existing RS-485 network. The address ID must not

be conflict with other OMR modules.

3. Power off the OMR local power supply of the existing RS-485 network.

4. Power off the host computer.

5. Add the new module to the existing RS-485 network.

6. Power on the host computer.

7. Power on the OMR local power supply.

8. Use the OMR administration utility to check entire network.

Install a Brand -New OMR 4-3

Page 30

Page 31

5. Software Utility

5.1 Software Installation

1. Insert “ADLink All-in-one CD” into your CDROM driver.

2. Move cursor on OMR and click.

3. Move cursor on OMR 6000 Admin Utility and click.

4. Select the driver you want to install and follow the setup instructions on screen.

5.2 How to Execute the OMR Administration

What environment you needed?

1. At least one RS -232 communication port.

2. Microsoft Windows (version 3.1, 95/98/NT)

3. At least 2MB Hard Drive Space

4. A VGA monitor (optional)

5. Mouse (optional)

Execute the OMR Administration Utility

l Run “OMR Administration Utility” Icon.

Software Utility 5-1

Page 32

5.3 OMR Administration Function Overview

Default RS -232 Communication Port Setting.

l Communication Port : COM2

l Baud Rate : 9600

l Data Bits : 8

l Stop Bits : 1

l Parity : None

5.3.1 Change RS -232 Communication Port Setting.

Choose “Network -ComPort” to change setting.

5.3.2 Search all exist OMR modules

Choose “Network -Search” to search all exist OMR modules in the current RS-485 network.

You can change search addresses range from here.

5-2 Software Utility

Page 33

Terminal Emulation, user can input

Configuration :

Select one exist OMR module and

his module‘s

Monitor all the module’s function on the

5.3.3 Using Operations

Operation-Terminal :

Operation-

Operation-Monitor:

Operation-Diagnostic: Diagnostic module‘s function.

Operation-Calibration: Some A/D modules need do calibration

Operation-Model Number: Select Model Number

command and get response message.

select Configuration to do t

common and private setting .

network.

Term ICON for Operation-Terminal

You can remote control all moudles by directly using command mode, or testing your from this Terminal.

Software Utility 5-3

Page 34

Operation-Run Batch : Run batch command file in BATCH.CMD

user can edit this text file.

Operation-Step Batch : Run the batch command step by step.

Operation-Display Batch : Display content of BATCH.CMD

Operation-Repeat : Repeat one command n times

Diag ICON for Operation-Diagnostic

This dialog is different by different -fuction modules.

5-4 Software Utility

Page 35

Software Utility 5-5

Page 36

in the

Cal ICON for Operation-Calibration

This dialog is different by different -fuction modules.

5.3.4 Save and Print OMR modules’ information

File-Save : Save all exist OMR modules information as display as

listbox in the current RS -485 network.

File-Print : Print the OMR module information in the listbox.

File-Exit : Quit the OMR Administration Utility.

5-6 Software Utility

Page 37

5.3.5 Version Information

Help-About Version information

Software Utility 5-7

Page 38

5-8 Software Utility

Page 39

6. Troubleshooting and Maintenance

Preventive Maintain

• Periodic check for loose connection

ATTENTION: To avoid electircal shock or unintended operation of the module, remove incoming power before

checking connections.

Using the LED Indication

The LED provides status information on Modules operation. The troubleshooting about shows LED indicator. It

also shows how to use the LED to detect and correct common operating problems.

LED What it Means: What to do:

OFF 1. Module is not receiving input

power by loosing wiring.

ON(RED) 1. Normal receiving state. 1. No action required.

Flashing 1. Normal transmitting state. 1. No action required.

Other Malfunctions

Problem What it Means: What to do:

1.Check module wiring, cable

connections, and cable connections

on terminal block.

Do not

function

1.Loose wiring

2.Incorrect DIP switch setting

1. Check wiring and cable

connection

2. Check Baudrate and

data packet setting of

the DIP switch.

Troubleshooting and Maintenance 6-1

Loading...

Loading...