Page 1

22 mm PILOT DEVICES

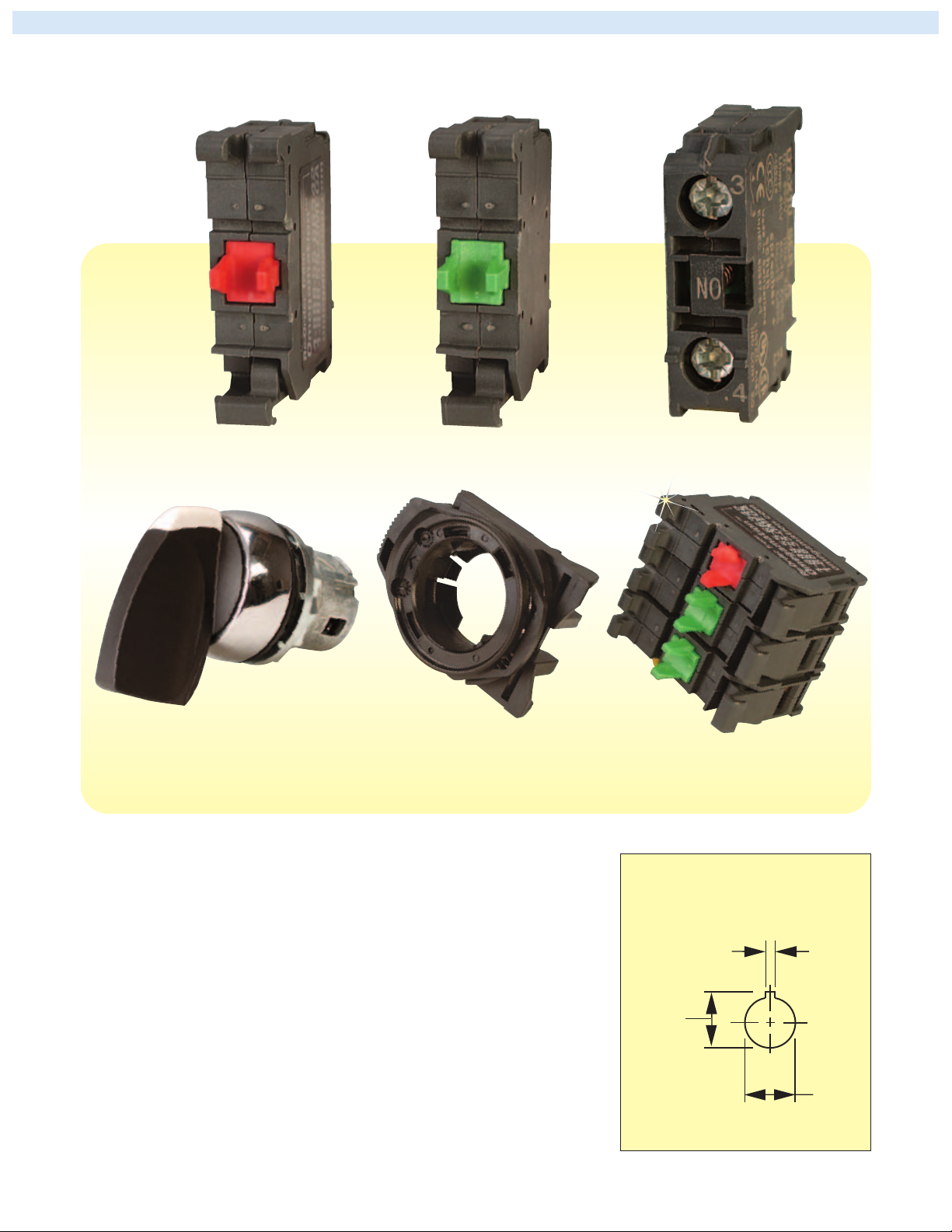

OMPBD7 SERIES

PUSHBUTTONS AND SELECTOR SWITCHES

Omegas rugged OMPBD7 pilot devices offer

maximum flexibility and a wide choice for all

applications. This 22 mm line is aesthetically

appealing and modularly designed to make

assembly and interchangeability easy.

The OMPBD7 operators are available in

two different body styles to meet every

application need. Both operators exhibit a

new lower profile stylish appearance while

maintaining the rugged performance

necessary for demanding environments.

Two Operator Types

OMPBD7P is a plastic operator with a

captive black plastic front bezel. Constructed

of high-grade thermoplastics, the OMPBD7P

is the corrosion resistant solution for harsh

environments. For super tough applications,

the OMPBD7M has a die-cast zinc housing

and mounting ring for a rugged durability.

Both are finished with corrosion resistant

chrome plating. The OMPBD7M also

features a captive shiny metal bezel for

a polished appearance.

Quick, Easy Installation

A standard anti-rotation tab keeps

front elements from turning or falling

off the control panel, making it possible

for one person to install all OMPBD7

components even if the front and rear

panel are not accessible at the same

time. A central mounting ring allows

for quick installation and removal of

all OMPBD7 operators. All back-of-panel

components including contact blocks

and power module elements snap-on and

are readily accessible and interchangeable

without removing the pilot device from

the panel.

Tool-Less Mounting Latch

The OMPBD7 “tool-less” mounting latch

mates the front element with the contact

blocks and other back-of-panel components.

The mounting latch is available in a plastic

and metal design. The latches are easily

installed with a “click” and removed by

pushing a rotating collar to the right. Quick,

reliable and strong, it’s the best pilot device

mounting latch available in the industry.

Long Electrical and

Mechanical Life

Most OMPBD7 operators have a mechanical

of ten million operations… five million

contact blocks. Electrical life ranges from

500,000 cycles at 3 A to ten million at 0.1 A.

The OMPBD7 line is also electronics

compatible with self cleaning contacts.

Environmental Ratings

Front elements, including pushbuttons,

mushroom operators and selector switches,

are IP66 rated against submersion,

oil and dirt, making them reliable in the

toughest industrial environments. Metal

operators are NEMA 4/13 rated and plastic

operators are rated NEMA 4/4X/13.

OMPBD7M-F3PX10,

$24, metal pushbutton,

flush button, green,

momentary operation

with 1 NO contact.

OMPBD7P-E4PX10,

$24, plastic pushbutton,

extended button, red,

momentary operation

with 1 NO contact.

OMPBD7P-MT34PX01, $45,

plastic pushbutton, 30 mm

mushroom, red, maintained

operation with 1 NC contact.

Each pushbutton includes

one contact block. Units

shown with two additional

blocks (pushbuttons may be

used with up to 6 contacts)

see page I-26.

I-23

l Heavy-Duty/Oil Tight

Pushbuttons

l Quick Installation with Tool-Less

Mounting Latch

l Plastic Operators: NEMA 4/4X/13

and IP65/66 Rated

l Metal Operators: NEMA 4/13 and

IP65/66 Rated

l Touch-Safe Contact

Blocks–with IP20 Recessed

Screw Terminals

l Heavy-Duty Current Rating

(10A Continuous)

All models shown

larger than actual size.

Page 2

Additional Features

and Options

Heavy-Duty Ratings—The OMPBD7 line

is UL 46E, NEMA A600 and Q600 listed.

All components carry a 10 Amp continuous

current rating, covering all industrial

control needs.

All Major Approvals—OMPBD7 front

elements are UL Recognized, while all

OMPBD7 assemblies are UL Approved.

The line is also approved by every major

international agency making them

ideal for export requirements.

H-Bridge & Gold Plated Contacts—

By doubling the available paths for current

to pass through the contacts, the standard

H-bridge design provides a cleaner current

flow. Gold plated contacts quadruple the

current paths for increased contact reliability

in low voltage applications.

Touch-Safe—Back of panel components

are finger safe, with IP20 protection.

Long Lasting Integral LED Assemblies—

Our new LED lamps last up to 11 years!

They are conveniently offered as a complete

unit for all illuminated operators which

include the one piece Integral LED Module.

They come in five different colors: amber,

blue, green, red and white.

I-24

24.1

(0.95)

+0,4

–0

22.3

(0.88)

3.2

(0.126)

+0,2

–0

+0,4

–0

Panel Hole Dimensions: mm (in)

OMPBD7M-HM22PX01, two way metal selector switch with long knob.

Each unit includes tool-less mounting latch and one normally closed contact block.

Shown with two additional (up to 6 total per operator possible) normally open

contact blocks, model OMPBD7-X10, $8.50 each.

All shown larger

than actual size.

CONTACT BLOCKS

Red = normally closed.

OMPBD7-X01, $8.50.

OMPBD7-X10, $8.50.

Green = normally open.

Rear view.

Page 3

I-25

OMPBD7M-F3PX10, $24,

metal pushbutton, flush button,

green, momentary operation

with one NO contact.

22 mm PUSHBUTTONS

NON-ILLUMINATED PUSHBUTTONS AND E-STOPS

OMPBD7-NL

Series

Start at

$

22

OMPBD7P-MT64PX10, $45,

plastic pushbutton, 60 mm

mushroom, red, maintained

operation with one NO contact.

OMPBD7P-E4PX10, $24,

plastic pushbutton, extended

button, red, momentary

operation with one NO contact.

OMPBD7M-MM43PX01, $36,

metal pushbutton, 40 mm

mushroom, green, momentary

operation with one NC contact.

To Order

(Specify Model Number)

MOST POPULAR MODELS HIGHLIGHTED!

NON-ILLUMINATED PUSHBUTTONS—COMPLETE WITH LATCH AND ONE CONTACT BLOCK

METAL OPERATOR PLASTIC OPERATOR BUTTON

MODEL NO. PRICE MODEL NO. PRICE STYLE OPERATION CONTACT

OMPBD7M-E(*)PX01 $26 OMPBD7P-E(*)PX01 $24 Extended Momentary 1 NC

OMPBD7M-E(*)PX10 26 OMPBD7P-E(*)PX10 24 Extended Momentary 1 NO

OMPBD7M-F(*)PX01 24 OMPBD7P-F(*)PX01 22 Flush Momentary 1 NC

OMPBD7M-F(*)PX10 24 OMPBD7P-F(*)PX10 22 Flush Momentary 1 NO

OMPBD7M-FA(*)PX01 28 OMPBD7P-FA(*)PX01 26 Flush Maintained 1 NC

OMPBD7M-FA(*)PX10E 28 OMPBD7P-FA(*)PX10E 26 Flush Maintained 1 NOEM

OMPBD7M-MM4(*)PX01 36 OMPBD7P-MM4(*)PX01 31 40 mm Momentary 1 NC

mushroom

OMPBD7M-MM4(*)PX10 36 OMPBD7P-MM4(*)PX10 31 40 mm Momentary 1 NO

mushroom

OMPBD7M-MM6(*)PX01 39 OMPBD7P-MM6(*)PX01 34 60 mm Momentary 1 NC

mushroom

OMPBD7M-MM6(*)PX10 39 OMPBD7P-MM6(*)PX10 34 60 mm Momentary 1 NO

mushroom

OMPBD7M-MP4(*)PX01 51 OMPBD7P-MP4(*)PX01 47 40 mm Maintained 1 NC

push-pull

OMPBD7M-MP4(*)PX10 51 OMPBD7P-MP4(*)PX10 47 40 mm Maintained 1 NO

push-pull

All models shown

larger than actual size.

*

Insert number for color selection, 2 = black, 3 = green, 4 = red, 5 = yellow, 6 = blue, 9 = no caps for inscription caps on flush models only.

Each pushbutton includes

one contact block. Units shown

with two additional blocks

(pushbuttons may be used with

up to 6 contacts), see page I-26.

Page 4

I-26

To Order

(Specify Model Number)

MOST POPULAR MODELS HIGHLIGHTED!

TWIST-TO-RELEASE E-STOP PUSHBUTTONS —COMPLETE WITH LATCH AND ONE CONTACT BLOCK

METALOPERATOR PLASTIC OPERATOR BUTTON

MODEL NO. PRICE MODEL NO. PRICE STYLE OPERATION CONTACT

OMPBD7M-MT34PX01 $48 OMPBD7P-MT34PX01 $45 30 mm mushroom Maintained 1 NC

OMPBD7M-MT34PX10 48 OMPBD7P-MT34PX10 45 30 mm mushroom Maintained 1 NO

OMPBD7M-MT34PX01S 58 OMPBD7P-MT34PX01S 55 30 mm mushroom Maintained 1 GCB

OMPBD7M-MT44PX01 51 OMPBD7P-MT44PX01 47 40 mm mushroom Maintained 1 NC

OMPBD7M-MT44PX10 51 OMPBD7P-MT44PX10 47 40 mm mushroom Maintained 1 NO

OMPBD7M-MT44PX01S 61 OMPBD7P-MT44PX01S 57 40 mm mushroom Maintained 1 GCB

OMPBD7M-MT64PX01 56 OMPBD7P-MT64PX01 52 60 mm mushroom Maintained 1 NC

OMPBD7M-MT64PX10 56 OMPBD7P-MT64PX10 52 60 mm mushroom Maintained 1 NO

OMPBD7M-MT64PX01S 66 OMPBD7P-MT64PX01S 62 60 mm mushroom Maintained 1 GCB

OMPBD7M-MK44PX01 95 OMPBD7P-MK44PX01 91 Keyed 40 mm Maintained 1 NC

OMPBD7M-MK44PX10 95 OMPBD7P-MK44PX10 91 Keyed 40 mm Maintained 1 NO

OMPBD7M-MK44PX01S 105 OMPBD7P-MK44PX01S 101 Keyed 40 mm Maintained 1 GCB

MODEL NO. PRICE DESCRIPTION

OMPBD7-N2 $4.00 22.5 mm (0.89") hole plug

OMPBD7-AW2 5.50 Mounting ring wrench for plastic or metal operators.

OMPBD7-AKR3825 9.50 Additional set of keys

CONTACT BLOCKS, UP TO 6 PER OPERATOR

MODEL NO. PRICE DESCRIPTION

OMPBD7-X01 $8.50 One NC contact block

OMPBD7-X10 8.50 One NO contact block

OMPBD7-X01L 8.50 One NCLB, late break contact block

OMPBD7-X10E 8.50 One NOEM, early make contact block

OMPBD7-X01V 13.00 One NC low voltage contact block

OMPBD7-X10V 13.00 One NO low voltage contact block

OMPBD7-X01S 16.00 GCB—Guardian Contact Block for E-stops

INSCRIPTION CAPS FOR NO CAP PUSHBUTTONS

MODEL NO. PRICE DESCRIPTION

OMPBD7-AF301 $2.75 Green “START” cap for flush momentary pushbuttons

OMPBD7-AF306 2.75 Green “I” cap for flush momentary pushbuttons

OMPBD7-AF402 2.75 Red “O” cap for flush momentary pushbuttons

OMPBD7-AF405 2.75 Red “STOP” cap for flush momentary pushbuttons

OMPBD7-AF3CE166 2.75 Green “ON” cap for flush momentary pushbuttons

OMPBD7-AE402 2.75 Red “O” cap for flush momentary pushbuttons

OMPBD7-AE405 2.75 Red “STOP” cap for flush momentary pushbuttons

LEGENDS—BLACK WITH WHITE LETTERS

MODEL NO. PRICE LEGEND MODEL NO. PRICE LEGEND

OMPBD7-34BE101 $4 AUTO OMPBD7-34BE163 $4 OFF

OMPBD7-34BE107 4 CLOSE OMPBD7-34BE166 4 ON

OMPBD7-34BE110 4 DOWN OMPBD7-34BE170 4 OPEN

OMPBD7-34BE113 4 FAULT OMPBD7-34BE188 4 REVERSE

OMPBD7-34BE114 4 FAST OMPBD7-34BE193 4 RUN

OMPBD7-34BE120 4 FORWARD OMPBD7-34BE201 4 SLOW

OMPBD7-34BE126 4 HAND OMPBD7-34BE208 4 START

OMPBD7-34BE129 4 HIGH OMPBD7-34BE212 4 STOP

OMPBD7-34BE148 4 LOW OMPBD7-34BE223 4 UP

ACCESSORIES

Come complete with one operator, one tool-less latch and one contact block.

Up to 6 contact blocks can be used per operator.

Page 5

SPECIFICATIONS FOR

SERIES OMPBD7— HEAVY

DUTY/OIL TIGHT

Front-of-Panel (Operators)

DESCRIPTION PLASTIC (OMPBD7P) METAL (OMPBD7M)

MECHANICAL RATINGS

Vibration [G] Tested at 10 ...2000 Hz, 1.52 mm displacement (peak-to-peak)

(assembled to panel) max/10 G max for 3 hr duration, no damage

Shock [G] Tested at 1/2 cycle sine wave for 11 ms; no damage at 100 G

Degree of Protection

Mechanical Durability 10,000,000 Cycles Momentary push buttons, momentary mushroom

per EN 60947-5-1 (Annex C) 1,000,000 Cycles Multi-function, Selector Switch, Key Selector Switch,

Operating Forces (typical [N] Flush/extended = 5N; E-stop = 36N; Mushroom = 9N

with one contact block)

Operating Torque (typical

application with one [N·m] Selector switch = 0.25 N·m (2.2 lb-in.)

contact block)

Mounting Torque [N·m] 1.7 N•m (15 lb-in) 4.4 N•m (40 lb-in)

MECHANICAL RATINGS

2

1

UL Type 3/3R/4/4X/12/13 (IP65/66) UL Type 3/3R/4/12/13 (IP65/66)

500,000 Cycles Selector Jog Non-illuminated Push-Pull E-Stop

300,000 Cycles Twist-to-Release E-Stop, Illuminated Push-Pull E-Stop,

Maintained Push Buttons, selector switches

100,000 Cycles Potentiometer, Toggle Switch

Temperature Range [°C] -25 to 70°C (-13 to 158°F)

(operating)

Temperature range [°C] -40 to 85°C (-40 to 185°F)

(short-term storage)

Humidity [%] 50...95% RH from 25 to 60°C (77 to 140°F) per:

Notes:

1 Performance data given in this publication is provided only as a guide for the user in determining suitability and do not constitute a

performance warranty of any kind. Such data may represent the results of accelerated testing at elevated stress levels, and the user is

responsible for correlating the data to actual application requirements. ALL WARRANTIES AS TO ACTUAL PERFORMANCE, WHETHER

EXPRESS OR IMPLIED, ARE EXPRESSLY DISCLAIMED.

2 Momentary mushroom operators are IP65, multi-function operators have no Type 13 rating. Plastic operators with keys have no Type 4X rating.

3 Operating temperatures below 0°C (32°F) are based on the absence of freezing moisture and liquids, UL recognized to 55°C (131°F) -

incandescent module, max 40°C (104°F).

3

Procedure IV of MIL-STD-810C, Method 507.1 cycling test

I-29

Page 6

Back-of-Panel Components

1

DESCRIPTION PLASTIC (OMPBD7P) METAL (OMPBD7M)

ELECTRICAL RATINGS

Standard Contact A600, Q600,

Block Ratings 600 Vac,

AC15, DC 13 to EN 60947-5-1 and UL 508, 17V, 5mA min

Low Voltage Contact 5V, 1mA DC min.

Block Ratings

4

C300, R150, AC 15, DC 13 to EN 60947-5-1 and UL 508

Nominal Voltage Range Current Draw Frequency

24 Vac 0...29 Vac 31 mA 50/60 Hz

LED Module Ratings 24 Vdc 10...30 Vdc 24 mA DC

120 Vac 70...132 Vac 25 mA 50/60 Hz

240 Vac 180...264 Vac 22 mA 50/60 Hz

Thermal Current [A] 10 A max enclosed (40°C ambient) to UL 508, EN 60947-5-1

Wire Capacity

Screw terminal

5

[AWG] #18...12 AWG (0.75...2.5 mm2) Max (2) #14 AWG or (1) #12 AWG

Spring-clamp terminal [AWG] #18...14 AWG (0.75...1.5 mm2)

Recommended Tightening

Torque on Screw Terminals [N] 0.7...0.9 N • m (6...8 lb-in)

Insulation Voltage [Ui] Ui = 690 V (screw terminal)

Ui = 300 V (screwless terminal)

Dielectric Strength (Min) [V] 2500 V for one minute

External Short Circuit

Protection

Standard blocks

10 A type gL/gG cartridge fuse to EN 60269-2-1 or gN (Class J to UL 248-8 or Class C to UL 248-4)

Low voltage

contact blocks

6 A type gL/gG cartridge fuse to EN 60269-2-1 or gN (Class J to UL 248-8 or Class C to UL 248-4

)

Electrical Shock Protection Finger-safe conforming to IP2X

MECHANICAL RATINGS

Vibration [G] 10...2000 Hz, 1.52 mm displacement (peak-to-peak) max/10 G max 6 hr

(assembled to panel)

Shock [G] Tested at 1/2 cycle sine wave for 11 ms and no damage at 100 G max

Contact durability per

EN 60947-5-1 (Annex C) 10,000,000 cycles

NO Slow double make and break

NC Slow double make and break - positive opening

Contact OZ peration NOEM Double break / double make / early make

NCLB Double break / double make, late break - positive opening

NCEB Double break / double make, early break - positive opening

Push Button Travel to

NC and NOEM 1.5 mm (0.060 in)

Change Electrical State NO and NCLB 2.5 mm (0.1 in)

Operating Forces (Typical) [N] 3.4 N: each single circuit contact block

5...6.5 N: each dual circuit contact block

Notes:

1 Performance data given in this publication is provided only as a guide for the user in determining suitability and do not constitute a

performance warranty of any kind. Such data may represent the results of accelerated testing at elevated stress levels, and the user is

responsible for correlating the data to actual application requirements. ALL WARRANTIES AS TO ACTUAL PERFORMANCE, WHETHER

EXPRESS OR IMPLIED, ARE EXPRESSLY DISCLAIMED.

4 Low voltage contacts are recommended for applications below 17 V, 5 mA.

5 Wires less than #18 (0.75 mm2) may not hold in terminal securely.

I-30

Page 7

One Omega Drive | Stamford, CT 06907 | 1-888-TC-OMEGA (1-888-826-6342) | info@omega.com

EPG05

www.omega.com

UNITED KINGDOM

www. omega.co.uk

Manchester, England

0800-488-488

UNITED STATES

www.omega.com

1-800-TC-OMEGA

Stamford, CT.

CANADA

www.omega.ca

Laval(Quebec)

1-800-TC-OMEGA

GERMANY

www.omega.de

Deckenpfronn, Germany

0800-8266342

Karviná, Czech Republic

FRANCE

www.omega.fr

Guyancourt, France

088-466-342

CZECH REPUBLIC

www.omegaeng.cz

596-311-899

BENELUX

www.omega.nl

Amstelveen, NL

0800-099-33-44

More than 100,000 Products Available!

Temperature

Calibrators, Connectors, General Test and Measurement

Instruments, Glass Bulb Thermometers, Handheld Instruments

for Temperature Measurement, Ice Point References,

Indicating Labels, Crayons, Cements and Lacquers, Infrared

Temperature Measurement Instruments, Recorders Relative

Humidity Measurement Instruments, RTD Probes, Elements

and Assemblies, Temperature & Process Meters, Timers and

Counters, Temperature and Process Controllers and Power

Switching Devices, Thermistor Elements, Probes and

Assemblies,Thermocouples Thermowells and Head and Well

Assemblies, Transmitters, Wire

Flow and Level

Air Velocity Indicators, Doppler Flowmeters, Level

Measurement, Magnetic Flowmeters, Mass Flowmeters,

Pitot Tubes, Pumps, Rotameters, Turbine and Paddle Wheel

Flowmeters, Ultrasonic Flowmeters, Valves, Variable Area

Flowmeters, Vortex Shedding Flowmeters

pH and Conductivity

Conductivity Instrumentation, Dissolved Oxygen

Instrumentation, Environmental Instrumentation, pH

Electrodes and Instruments, Water and Soil Analysis

Instrumentation

Data Acquisition

Auto-Dialers and Alarm Monitoring Systems,

Communication Products and Converters, Data

Acquisition and Analysis Software, Data Loggers

Plug-in Cards, Signal Conditioners, USB, RS232, RS485

and Parallel Port Data Acquisition Systems, Wireless

Transmitters and Receivers

Pressure, Strain and Force

Displacement Transducers, Dynamic Measurement

Force Sensors, Instrumentation for Pressure and Strain

Measurements, Load Cells, Pressure Gauges, Pressure

Reference Section, Pressure Switches, Pressure Transducers,

Proximity Transducers, Regulators,

Strain Gages, Torque Transducers, Valves

Heaters

Band Heaters, Cartridge Heaters, Circulation Heaters,

Comfort Heaters, Controllers, Meters and Switching

Devices, Flexible Heaters, General Test and Measurement

Instruments, Heater Hook-up Wire, Heating Cable

Systems, Immersion Heaters, Process Air and Duct,

Heaters, Radiant Heaters, Strip Heaters, Tubular Heaters

click here to go to the omega.com home page

Loading...

Loading...