Page 1

omega.com

e-mail: info@omega.com

For latest product manuals:

omegamanual.info

User’s Guide

OM-DN SERIES

Wireless Intelligent

Data Logging System

Shop online at

Extended Warranty

Program

SM

OM-DNR-900

REPEATER

OM-DNL-910

TEMPERATURE

LOGGER

OM-DNL-920

RH/TEMPERATURE

LOGGER

Page 2

Servicing North America:

U.S.A.: One Omega Drive, Box 4047

ISO 9001 Certified Stamford, CT 06907-0047

Tel: (203) 359-1660

FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1, Canada

Tel: (514) 856-6928

FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

U.S.A. and Canada: Sales Service: 1-800-826-6342/1-800-TC-OMEGA

®

Customer Service: 1-800-622-2378/1-800-622-BEST

®

Engineering Service: 1-800-872-9436/1-800-USA-WHEN

®

Mexico: En Espan˜ol: (001) 203-359-7803

FAX: ( 001) 203-359-7807

e-mail: espanol@omega.com

info@omega.com.mx

Servicing Europe:

Czech Republic: Frystatska 184, 733 01 Karviná, Czech Republic

Tel: +420 (0)59 6311899

FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342

e-mail: info@omegashop.cz

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: +49 (0)7056 9398-0

FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9001 Certified Northbank, Irlam, Manchester

M44 5BD United Kingdom

Tel: +44 (0)161 777 6611

FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

OMEGAnet®Online Service Internet e-mail

omega.com info@omega.com

It is the policy of OMEGA Engineering, Inc. to comply with all worldwide safety and EMC/EMI

regulations that apply. OMEGA is constantly pursuing certification of its products to the European New

Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA accepts no liability for any

errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, human applications.

Page 3

Table of Contents

CHAPTER 1: DATANET OVERVIEW 1

1.1. DataNet Introduction 1

1.2. What is ZigBee? 3

1.3. The ZigBee Concept 3

1.3.1. ZigBee Mesh Network Operation 4

1.3.2. Why is ZigBee Technology Key for Data Logging?

4

1.4. The DataNet System 5

1.4.1. The Data Logger 5

1.4.2. The Receiver/Repeater 6

1.4.3. Hardware Accessories 8

1.4.4. DataNet Software 8

CHAPTER 2: DATANET IMPLEMENTATION GUIDE 10

2.1. DataNet Network Architecture 11

2.2. Pre-setup Requirements 13

2.3. Launching the Software 13

2.4. Connecting the Receiver 15

2.5. Adding the Data Logger to the Network 16

2.5.1. Charging DataNet Loggers 17

2.5.2. Connecting the OM-DNL-910 and OM-DNL-920

Loggers to the Network 18

2.5.3. Loading Map View Background 20

2.6. Configuring the Logger 21

Page 4

2.7. Viewing Data 23

2.7.1. Online Data Views 24

2.7.2. Logger Tooltip 25

2.7.3. Sensor View 26

2.8. Optimizing the Network 27

2.8.1. Signal Test Utility 27

2.8.2. Overcoming RF Obstacles 28

2.8.3. Showing the Network Path 29

2.8.4. Adding Repeaters to the Network 30

2.8.5. Short Range Repeater 31

2.9. Recommended Approach to Deploying DataNet

Units

32

CHAPTER 3: DATANET HARDWARE OVERVIEW 35

3.1. Data Logger Front Panel Layout 35

3.1.1. OM-DNL-910 and OM-DNL-920 35

3.2. Data Logger External Connections 36

3.2.1. OM-DNL-910 and OM-DNL-920 36

3.3. OM-DNR-900 Receiver/Repeater Front Panel

Layout

37

3.4. OM-DNR-900 Receiver/Repeater External

Connections 38

3.5. Data Logger Sensor Overview 39

3.5.1. Internal Sensor Types 39

3.5.2. External Sensor Types 39

3.5.3. Sensor Connection 41

3.5.4. External PT-100 and NTC Sensor Connection 41

3.5.5. Programming Limitations for OM-DNL-910 and

OM-DNL-920 41

Page 5

3.5.6. External Alarm Output 42

3.5.7. Polarity 44

3.5.8. Frequency/Pulse Counter 45

3.5.9. User Defined Sensors 45

3.5.10. Sensor Alarms 45

3.5.11. Sensor Calibration 46

3.6. Unit Serial Number and Comment 46

3.7. Power Supply 47

3.7.1. OM-DNR-900 in Receiver Mode 47

3.7.2. OM-DNR-900 in Repeater Mode 47

3.7.3. OM-DNL-910 and OM-DNL-920 Data Loggers 48

3.7.4. Power Adapter 49

3.7.5. Data Logger Battery Life 49

3.8. USB Communication Cable 50

3.9. DataNet Keypad Overview 51

3.9.1. OM-DNL-910, OM-DNL-920 and OM-DNR-900

Keypad

51

3.10. Operating the OM-DNL-910 and OM-DNL-920 52

3.10.1. Turning on the Unit 52

3.10.2. Display Shutdown 52

3.10.3. Joining a Network 52

3.10.4. Main Menu Options 55

3.10.5. Additional Logger Screens 62

3.11. Operating the OM-DNR-900 in Receiver Mode 64

3.11.1. Turning on the Unit 64

3.11.2. Receiver Menus 64

3.11.3. Changing Receiver to Repeater 65

3.11.4. Additional Receiver Screens 66

3.12. Operating the OM-DNR-900 in Repeater Mode 67

3.12.1. Turning on the Unit 67

Page 6

3.12.2. Joining a Network 67

3.12.3. Menu Options 70

3.12.4. Additional Repeater Screens 74

CHAPTER 4: USING THE DATANET SOFTWARE 76

4.1. Installing DataNet Software 76

4.1.1. System Requirements 76

4.1.2. Installation Procedure 77

4.1.3. Installation Troubleshooting 80

4.2. DataNet Software Layout 80

4.2.1. Map View 81

4.2.2. Sensor View 82

4.2.3. History View 84

4.2.4. Data Map 85

4.2.5. DataNet Toolbar Icons 86

4.3. File Menu Items 92

4.3.1. Open 92

4.3.2. Open Project File 92

4.3.3. Save Project 92

4.3.4. Save Project As 93

4.3.5. Exit 93

4.4. Network Menu Items 93

4.4.1. Detect Receiver 93

4.4.2. Lock Network 93

4.4.3. Form New Network 94

4.4.4. Refresh Network Connections 94

4.4.5. Show Network Paths 95

4.5. Tools Menu Items 96

4.5.1. Define Sensor 96

4.5.2. Switch Sensor View Mode 97

4.5.3. Lock Map View 97

4.5.4. Options Menu 98

4.5.5. Email Alarm Notifications 98

Page 7

4.5.6. SMS Alarm Notifications 98

4.5.7. Firmware Update Center 98

4.6. Tools > Options Menu Items 98

4.6.1. Preferences Tab 99

4.6.2. Email Settings Tab 101

4.6.3. SMS Settings Tab 102

4.6.4. Analysis Menu Items 103

4.7. Data Recovery 104

4.8. Saving Data 105

4.9. Viewing Archived (Offline) Data 106

4.10. Viewing Online Data 108

4.10.1. Showing/Hiding the Data Sets 109

4.11. Working in Map View 111

4.11.1. Loading Map View Wallpaper 111

4.11.2. Moving Icons around the Screen 111

4.11.3. Logger Icon Context Menu 112

4.11.4. Viewing Logger Status 115

4.11.5. Receiver Icon Context Menu 116

4.11.6. Viewing Receiver Status 117

4.11.7. Repeater Icon Context Menu 118

4.11.8. Viewing Repeater Status 119

4.12. Configuring the Logger 120

4.12.1. Device Setup Tab 121

4.12.2. Alarm Setup Tab 123

4.13. Alarm Notifications Setup 125

4.13.1. Contacts Tab 127

4.13.2. Groups Tab 128

4.13.3. Notifications Setup Tab 129

4.13.4. Email and SMS Notification Formats 131

Page 8

4.14. Calibration 132

4.14.1. Introduction to DataNet Calibration 133

4.14.2. Calibrating the Data Logger 135

4.14.3. Performing a Two-point Calibration 136

4.14.4. Performing an Offset Calibration 137

4.14.5. Setting the Offset to a Specific Input 138

4.14.6. Calibrating the Internal Temperature Sensor on

the OM-DNL-910 139

4.14.7. Calibrating the External PT-100 Sensor Input 139

4.14.8. Saving Calibration Settings 139

4.14.9. Loading Calibration Settings 140

4.15. Analyzing the Data 140

4.15.1. Using the Graph Features 140

4.15.2. Statistical Analysis 146

4.16. Exporting Data to Excel or CSV Formats 147

4.17. Printing the Data 148

4.18. System Password 149

CHAPTER 5: UPDATING DATANET SOFTWARE AND

FIRMWARE

150

5.1. Using the Uptodata Client 150

5.2. Updating DataNet Firmware 155

5.2.1. Downloading the Firmware File 155

5.2.2. Firmware Update from the Update Center 156

5.2.3. Firmware Update from the Map View Icon 159

APPENDIX A: DATANET SPECIFICATIONS 161

A.1. Data Logger Input Types 161

Page 9

A.2. OM-DNL-910 and OM-DNL-920 Outputs 161

A.3. Logger Input Specifications OM-DNL-910 and OM-

DNL-920 162

A.4. General Specifications 163

A.5. System Requirements 165

APPENDIX B: SAFETY INFORMATION AND FCC IDS

166

APPENDIX C: FIGURES AND TABLES 169

Page 10

Chapter 1:

DataNet Overview

This chapter provides a general overview of the DataNet

system as well as the concept behind the ZigBee RF protocol.

1.1. DataNet Introduction

The Wireless Intelligent Logging Network

The DataNet system is a 16-bit, mobile data acquisition

network based on the innovative and reliable ZigBee

technology. This solution provides an intelligent sensor mesh

system with 100% data receipt and no data loss.

The DataNet system is comprised of a family of data logging

units, as well as a Receiver to manage the intelligent network

and Repeaters to extend the transmission range. The data

loggers measure a broad range of parameters and include

models that feature between one and four inputs for direct

measurement and recording of PT-100, thermocouple, 0-1 V,

4-20 mA, contact, frequency and pulse sensors, as well as

internal temperature and relative humidity sensors. These

models range from loggers with graphic display, AC or battery

power supply, to models with no display and battery power

only.

Data is transmitted from the end units to a Receiver

connected to a central computer. The system leverages the

ZigBee protocol, a 2.4 GHz license-free frequency RF band,

to ensure full data integrity. By adding DataNet Repeater units

to the network, you can extend the transmission range and

form a reliable mesh network of up to 65,000 units.

With its high resolution and fast Analog to Digital converter

(ADC), DataNet data loggers meet the majority of data

acquisition requirements in most industrial applications. Every

1

Page 11

DataNet logger unit is embedded with a unique serial number

and can be loaded with a descriptive comment for safe

identification. An internal clock and calendar keeps track of

the time and date of every sample measured.

DataNet loggers can automatically activate external alarm

events when data is outside a specified range. Email and

SMS notifications can be sent to predefined contacts.

The DataNet system is powered by the powerful DataNet

software. The Windows ™ based software is the central

management interface of the DataNet network. Data is

monitored online and can be displayed in graphs or tables.

You can analyze data with various mathematical tools, or

export data to a spreadsheet.

The software also enables you to configure, calibrate or

update the firmware of DataNet units wirelessly.

Key DataNet benefits include:

• Reliable transmission ensuring no data loss

• Long-range monitoring

• Ability to constantly expand transmission range by adding

additional Repeaters, or turning loggers into Repeaters

• Portable units facilitating easy deployment in various

environments

• Remote programming and firmware updates

• 65,000+ possible end units

• 16-bit resolution

• Low-power consumption

• Long battery life

• Minimal costs thanks to wireless infrastructure

2

Page 12

1.2. What is ZigBee?

ZigBee is a standards-based protocol built around the IEEE *

802.15.4 wireless protocol, providing the network

infrastructure required for wireless, low power network

applications.

The mesh network eliminates single points of failure by

providing multiple pathways for data to travel.

* IEEE is the Institute of Electrical and Electronics Engineers,

a non-profit organization dedicated to furthering technology

involving electronics and electronic devices.

1.3. The ZigBee Concept

The Coordinator: This device creates and maintains the

network. Once the network is up and running, the coordinator

behaves as just another device on the network. There is only

one Coordinator in a ZigBee network.

The Router: A router relays data packets/messages between

devices on the network and increases the distance between

these devices.

The End Unit: This device sends and receives information to

other devices on the network. It is usually a control or a

sensor unit, often battery operated. A ZigBee end unit cannot

relay messages.

ZigBee Terminology DataNet Terminology

Coordinator Receiver

Router Repeater

End Unit Data Logger

ZigBee enables mesh networking which supports a wireless,

yet integrated environment with communication between

3

Page 13

many coordinators, routers and end units in environments

where multiple applications are being monitored.

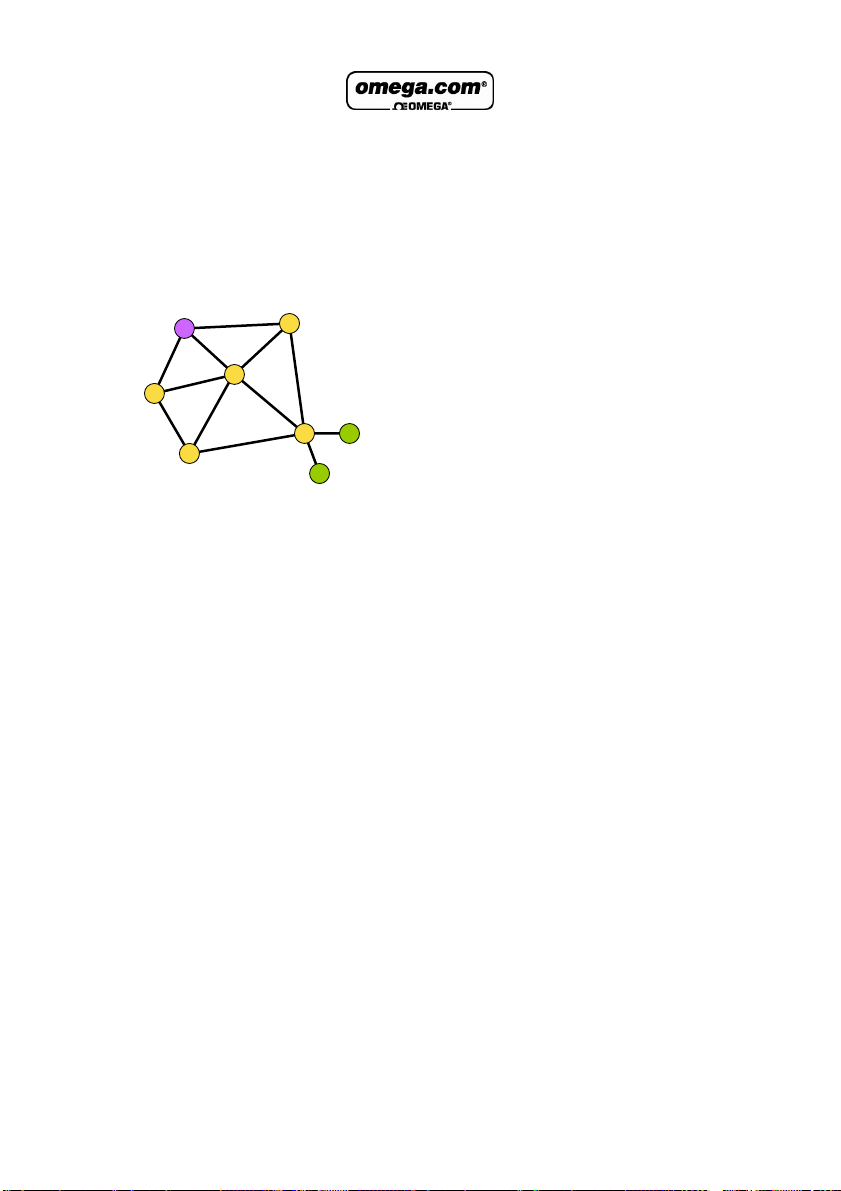

1.3.1. ZigBee Mesh Network

Operation

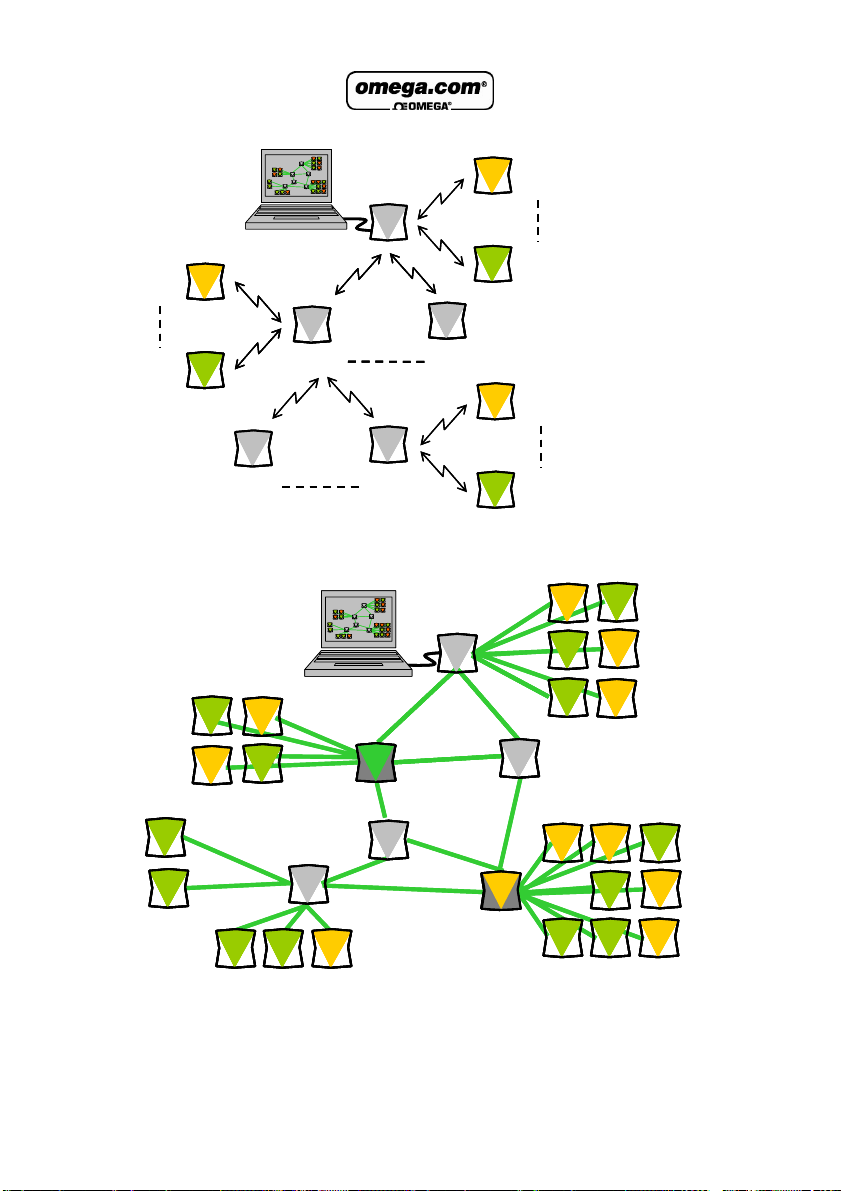

Figure 1: ZigBee network diagram

In a mesh network, all the router units are aware of their

environment meaning a router knows with units are close by.

When a router sends a message to a specific unit, it relays the

message until it gets to the destination.

Network recovery from a unit failure

In a mesh network, when a router fails, the network

automatically finds a different path via a different router for the

message relay.

This ensures maximum protection against a network

breakdown.

1.3.2. Why is ZigBee Technology Key

for Data Logging?

ZigBee technology has proved to be ideal for data acquisition

networks which require meter reading, parametric display of

data such as temperature or humidity and responsive action

when parameters are crossed. This is due to the fully

automated, flexible and reliable nature of the protocol. With

the Mesh Network system, the ZigBee standard redresses

4

Page 14

misbalances in any data logging system, responding to

weaknesses, inefficiencies, new network structure (with the

additional or removal of devices) through self correction.

1.4. The DataNet System

The basic DataNet system will contain at least one of the

following units:

• DataNet data logger – Part Number OM-DNL-910 or OM-

DNL-920

• Receiver/Repeater unit – Part Number OM-DNR-900

• Mini-USB cable

• Power adapter (one per DataNet unit ordered)

• DataNet Software CD

1.4.1. The Data Logger

There are two data logger models compatible with the

DataNet system. These are the so-called end units of the

system. These loggers support up to four external sensors

and two internal sensors, temperature and humidity,

depending on the specific model. Data is recorded and stored

to the logger’s internal memory and transmitted over the

network to the DataNet software running on the PC.

The data logger is programmed to consume as little power as

possible during operation, in order to conserve the battery life.

When not transmitting or recording data the units are in sleep

mode and they wake up when needed.

The battery is rechargeable and can run up to several months

on one charge, depending on the logger configuration. Refer

to section 3.7.5 for more information.

Note: Battery life depends on the logger sampling rate,

transmission rate, type of sensor, network architecture and

number of measured sensors.

5

Page 15

DataNet Loggers

Part Number: OM-DNL-920 Part Number: OM-DNL-910

Four external channel RF data logger

with two internal sensors, Humidity and

Temperature

Transmission Range: Up to 80 m line

of sight

Memory Capacity: ~59,000 samples

Power supply: AC or battery operated

Four external channel RF data logger

with internal Temperature sensor

Transmission Range: Up to 80 m line

of sight

Memory Capacity: ~59,000 samples

Power supply: AC or battery operated

1.4.2. The Receiver/Repeater

The OM-DNR-900 Receiver/Repeater unit can be

programmed by the user to work in either mode.

The Receiver acts as a bridge between the DataNet network

and the PC. It is connected to the PC via USB cable and is

used to create the network to which you add your data

loggers. The Receiver is externally powered but also includes

a rechargeable battery for back up (in case the external power

fails).

6

Page 16

Note: Each Receiver can detect up to 8 data loggers and 16

Repeaters. To detect more data loggers, Repeaters are

required.

The Repeater is externally powered via the USB port but also

includes a rechargeable battery for back up (in case the

external power fails). These units are considered the

backbone of the network, as they enhance the network range

by receiving and transmitting the data from Repeater to

Repeater until the data reaches the designated end unit or the

PC.

The Repeaters are the end units’ parent units, meaning each

Repeater has specific end units under their responsibility

(their children). They route the transmissions to and from the

end units to the Receiver (or other Repeaters in the network).

Each Repeater holds the data sent to the end units while the

end units are in sleep mode. At a specific interval the end unit

wakes up and receives the data from its parent (Repeater).

Note: Each Repeater can detect up to 24 data loggers and 16

Repeaters including the parent unit. If the number of loggers

exceeds this capability, additional Repeaters are required.

7

Page 17

Part Number: OM-DNR-900

Repeater Transmission Range: 800 m line of sight

End Units per Receiver: ~65,000

1.4.3. Hardware Accessories

The DataNet system includes the following accessories:

• Mini-USB cable for connecting PC to DataNet Receiver

• Power adapter to power DataNet Receiver, Repeater and

data loggers

1.4.4. DataNet Software

The user interface for the DataNet system, the DataNet

software CD is provided together with the DataNet hardware

and includes the following features:

• Network management

• Data display, management, storage and data diagnostics

• Alarm settings: Email and SMS notifications, visual and

audible alarms

8

Page 18

• Wireless sensor definition

• Wireless sensor calibration

• Wireless firmware update (boot over the air)

• Automatic software update (via Omega server)

The software interface is described in detail in Chapter 4:.

9

Page 19

Chapter 2:

DataNet

Implementation Guide

First time users of the DataNet system should read this

chapter before drilling down into the many features of the

system described later in the user guide. The Implementation

Guide will give you a clear understanding of the basic aspects

of setting up the system, and getting your network up and

running.

Once you are familiar with the technical aspects of setting up

the network as outlined in this chapter, please consult section

2.9 for the recommended approach to initial deployment of the

system.

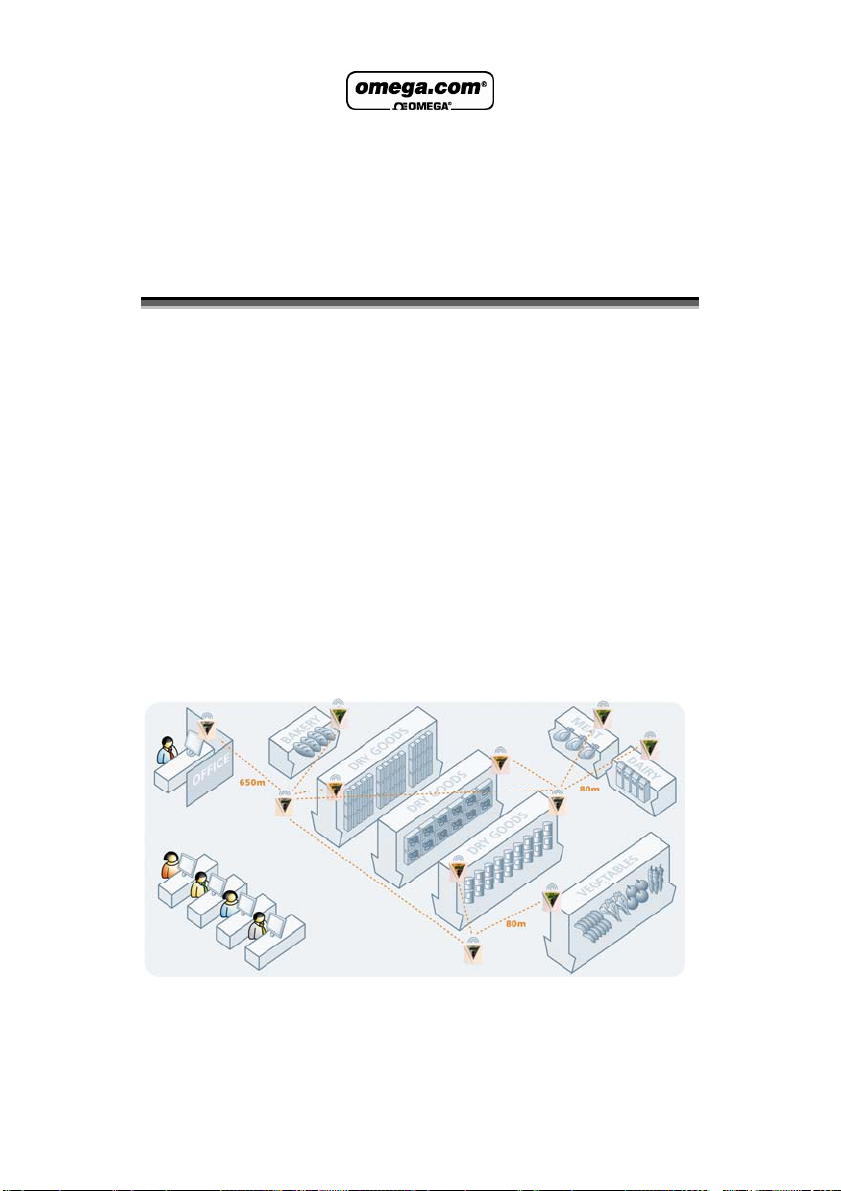

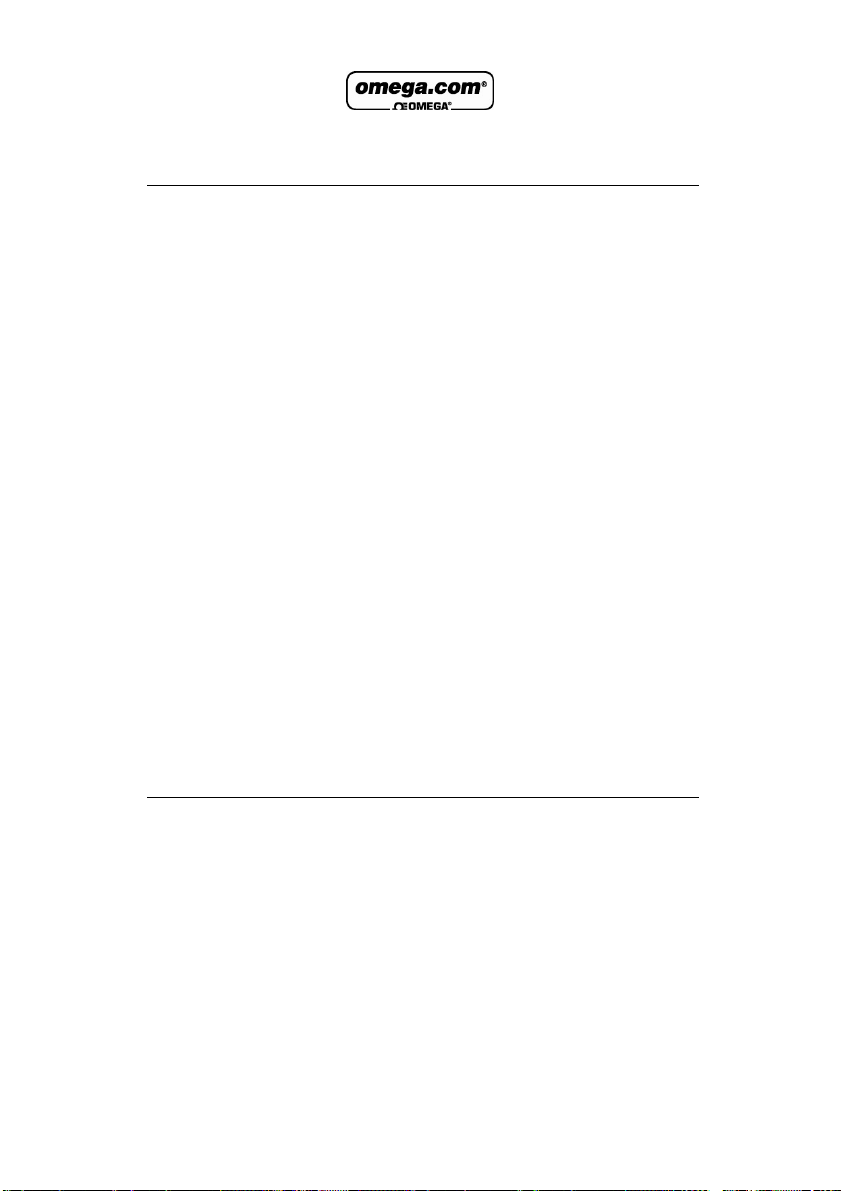

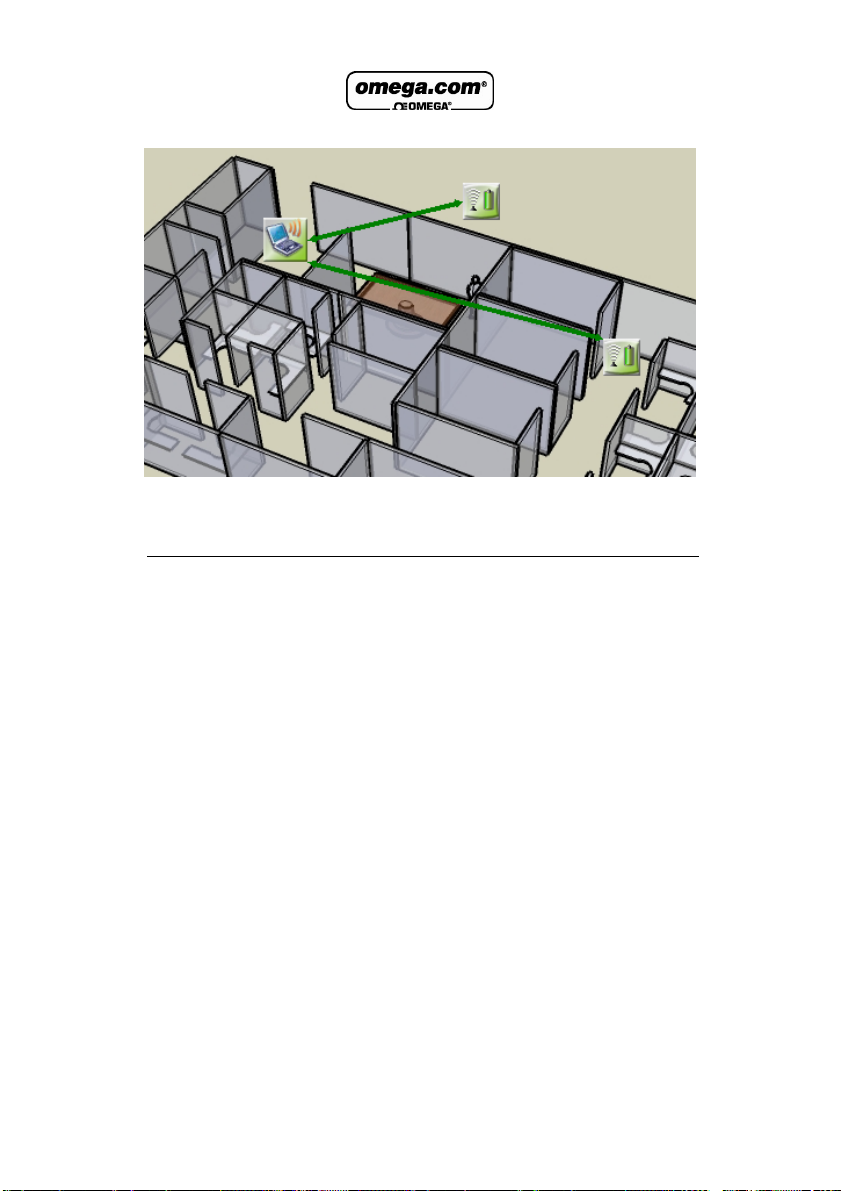

Example

Below is a diagram depicting a supermarket deployment of a

DataNet system, illustrating how the devices may be

positioned to provide full coverage within the facility.

Figure 2: Example of DataNet network application

10

Page 20

2.1. DataNet Network

Architecture

The DataNet network architecture consists of layers of loggers

and Repeaters, forming a mesh network monitored by the

Receiver unit connected to the workstation PC.

The basic architecture is as follows:

• Maximum nodes on network: 65,000

• OM-DNR-900 Receiver recognizes up to 8 loggers and 16

Repeaters

• OM-DNR-900 Repeater recognizes up to 24 loggers and

16 Repeaters (including parent unit)

• OM-DNL-910 and OM-DNL-920 in Short Range Repeater

mode (refer to section 2.8.5) recognizes up to 24 loggers

and 16 Repeaters

The diagrams below show the architecture of a typical

DataNet mesh network. Repeaters and loggers, which are

being used as Short Range Repeaters in Figure 4 (see

section), can be added to the network in order to extend the

range and improve its robustness. Each such device has end

units communicating with it, but this route may change as the

RF environment changes. This is the ZigBee’s self correcting

mechanism at play.

11

Page 21

1

1

DL

DLDL

RC

RCRC

DL

DLDL

8

DL

DLDL

DL

DLDL

8

24

24

1

1

24

24

24

1

1

1

DL

DL

DLDL

RP

RP

RP

RPRP

15

15

RPRP

16

16

16

DL

DL

DLDL

RP

RPRP

RP

RP

RPRP

1

1

1

1

1

Figure 3: Standard DataNet mesh network architecture

DL

DL

DLDL

DL

DL

DLDL

USB

USB

RC

RC

RCRC

DL

DL

DLDL

DL

DL

DLDL

DL

DL

DLDL

DL

DL

DL

DL

DLDL

DL

DL

DLDL

DL

DL

DLDL

DL

DL

DLDL

DL

DL

DLDL

DL

DL

DLDL

DL DL DL

DL DL DL

DLDL DLDL DLDL

RP

RP

RPRP

SRR

SRR

DL

DLDL

RP

RP

RPRP

RP

RP

RPRP

SRR

SRR

DL

DLDL

RP

RP

RPRP

RP

RP

RPRP

DL

DL

DLDL

DL

DL

DLDL

DLDL

DLDLDL

DLDLDL

DLDL

DLDL

DL

DL

DLDL

Figure 4: DataNet network with Short Range Repeaters

12

DLDL

DL

DL

DLDL

DL

DL

DLDL

Page 22

2.2. Pre-setup Requirements

Prior to commencing with the DataNet implementation you

must have the following requirements in place:

PC

• 24/7 availability

• Reliable AC power

• Sufficient hard disk space to store loggers’ data

• One free USB port

DataNet devices

• One OM-DNR-900 DataNet Receiver

• At least one DataNet logger OM-DNL-910 or OM-DNL-

920

• At least one OM-DNR-900 DataNet Repeater, depending

on your environment, for extended transmission

Mini-USB cable

The mini-USB cable connects the OM-DNR-900 Receiver to

the PC (and is supplied with the PC Suite software kit).

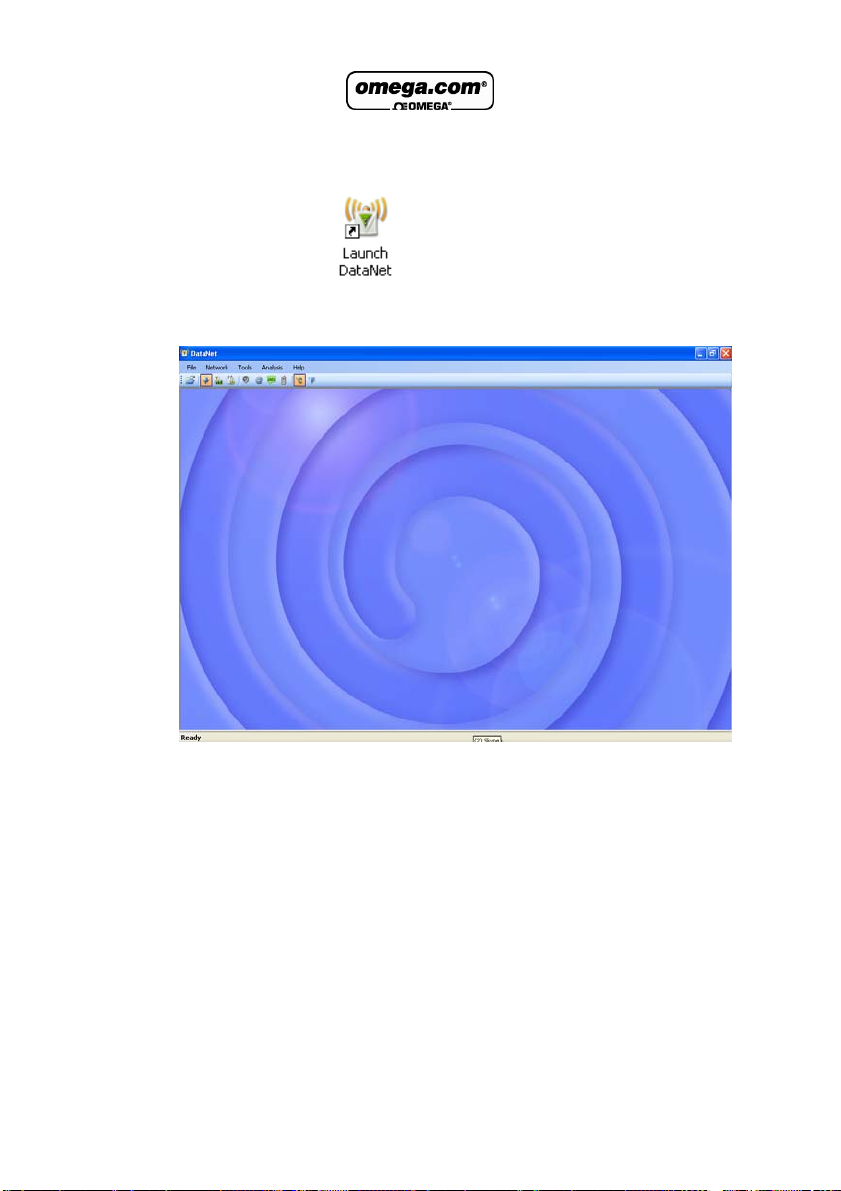

2.3. Launching the Software

1. Install the DataNet software on the PC workstation. Refer

to section 4.1: Installing DataNet Software on page 76 for

more details.

13

Page 23

2. Once the software and associated components have

been installed, launch DataNet from your DataNet

desktop shortcut

3. The main DataNet window is launched. The default view

is called Map View.

Figure 5: Main DataNet window

4. Check for DataNet updates. Go to Help > Check for

Updates from the DataNet main menu to check for newer

versions of DataNet software and firmware released since

you purchased your system. For more details on the

Update feature go to Chapter 5: Updating DataNet

Software and Firmware.

.

14

Page 24

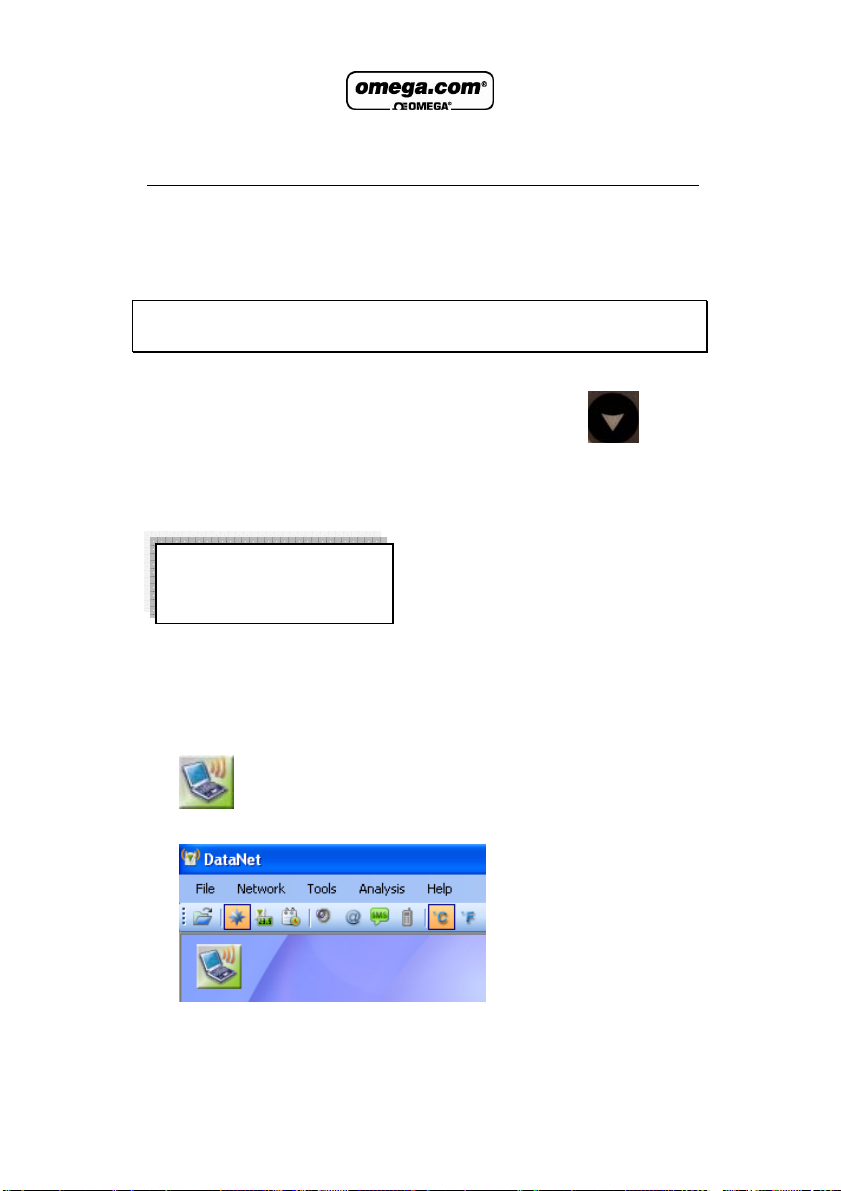

2.4. Connecting the Receiver

1. Only once the DataNet software has been installed,

connect the DataNet Repeater unit (OM-DNR-900) to the

Omega-supplied power adapter.

Note: Only use adapters provided by Omega Engineering.

Use of the wrong adapter could damage your DataNet units.

2. Turn on the unit by pressing the Scroll button on

the front keypad. The unit will beep when turned on.

3. Verify that the unit is in Receiver mode by seeing the

following screen on the LCD:

DataNet Receiver

ID: 123.456.789

The ID will be unique to your Receiver network. If the unit

is in Repeater mode, switch it to Receiver mode. Go to

section 3.12 for more details.

4. Connect the mini-USB cable to the computer and to the

Receiver’s mini-USB port. The DataNet Receiver icon

will immediately appear in the top left corner of the

Map View.

Figure 6: Adding Receiver icon to Map View

15

Page 25

A green icon indicates that the Receiver is online.

Note: If the Receiver is not recognized by the software try

connecting the mini-USB cable to another USB port on the

PC. Or select Network > Detect Receiver in the main menu.

Should you disconnect the Receiver’s USB cable or

power adapter (and the battery eventually dies), the

Receiver icon will be grayed out:

5. Go to Network > Form New Network. The Receiver will

then form a new network based on your RF environment

rather than use the network formed in the factory. This will

ensure optimal network performance. Refer to section 2.8:

Optimizing the Network for more details.

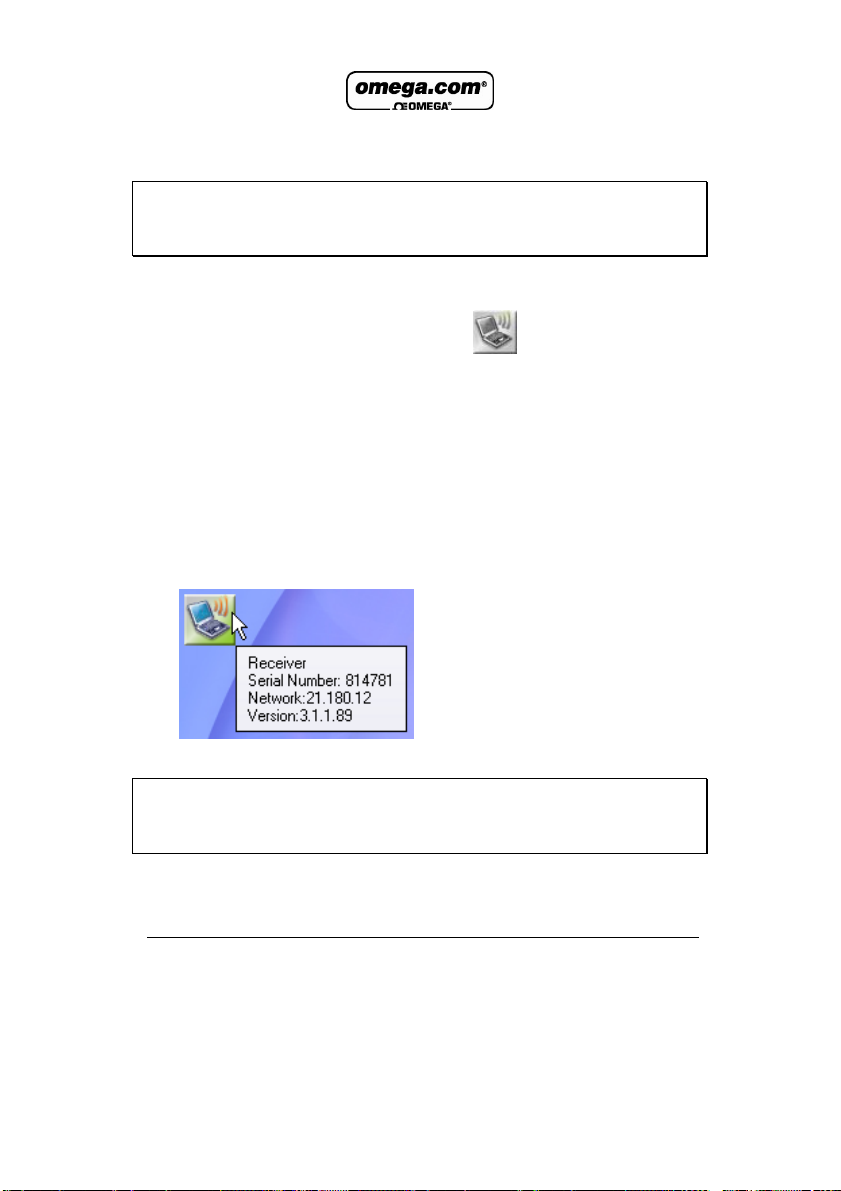

Check the DataNet network ID that was formed by the

Receiver by placing the mouse cursor over the Receiver

icon. The network ID as well as Receiver firmware version

and unit serial number is displayed.

Figure 7: Receiver tooltip

Note: You can move the Receiver icon elsewhere on the

screen by going to Tools > Lock Map View and unselecting

this option.

2.5. Adding the Data Logger to

the Network

Once you have connected your Receiver and established a

network you are ready to add data loggers and build your

system.

16

Page 26

2.5.1. Charging DataNet Loggers

Note: Only use adapters provided by Omega Engineering.

Use of the wrong adapter could damage your DataNet units.

If the loggers will run from the battery supply make sure to first

charge each of the loggers for 16 hours before use in order

maximize the battery life. A fully charged battery can last

several months, depending on your logger configuration.

Refer to section 3.7.5 or more details on battery life.

If the loggers will run from the AC power supply, when first

connected to the AC adapter the logger will always initiate the

16 hour charge cycle.

Note: For loggers measuring data with the internal

temperature sensor, it is critical to note that during the charge

cycle the logger will heat up thereby causing the internal

temperature sensor reading to rise up to 10 ˚C above ambient

temperature. Once the charging process is complete, the

logger will cool down and the internal temperature sensor

readings will return to normal.

For loggers remaining connected to AC power, to prevent the

logger from heating up again following the initial charge cycle,

the logger will receive a one minute trickle charge each day

rather than stay continually charged. This is sufficient to

ensure the logger doesn’t self-discharge and will maintain the

logger’s full charge status.

Refer to section 3.7.3 for more details on the DataNet loggers’

power supply.

17

Page 27

2.5.2. Connecting the OM-DNL-910

and OM-DNL-920 Loggers to

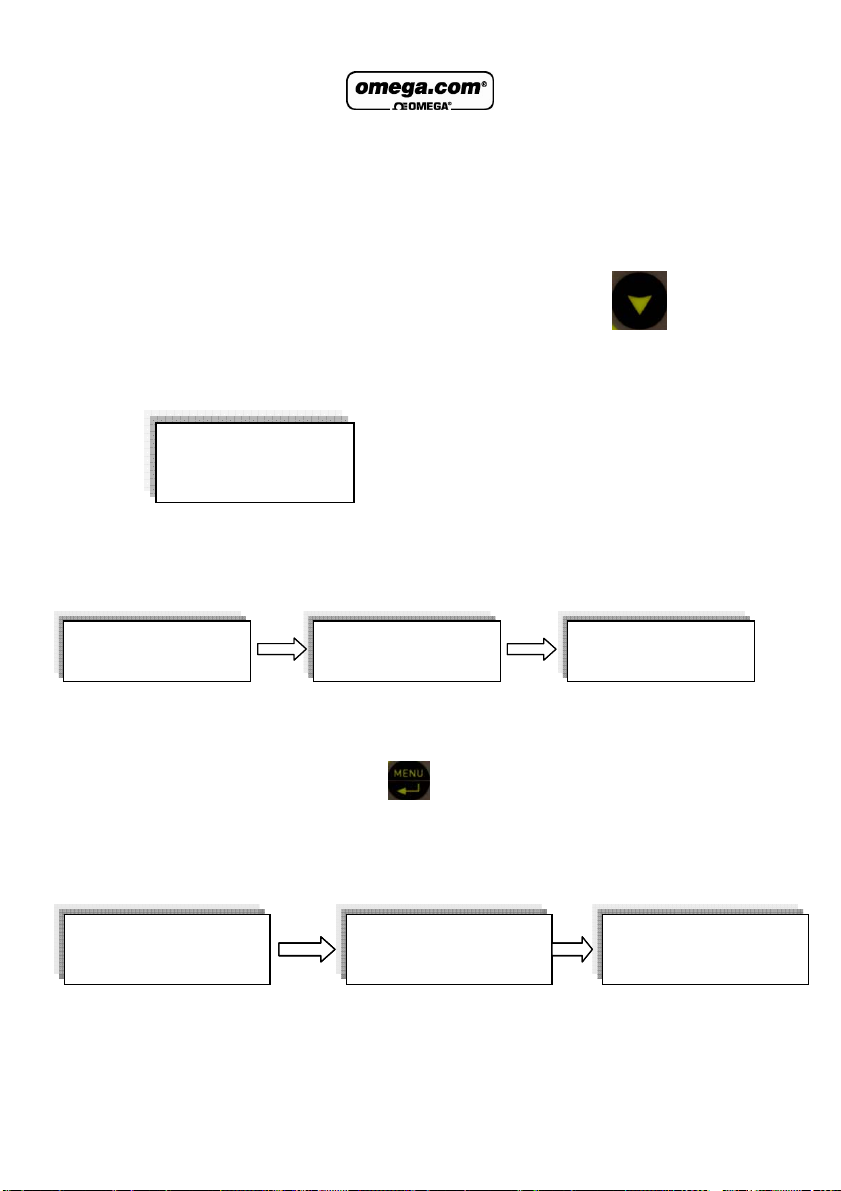

the Network

1. Turn on the logger by pressing the Scroll button .

The unit will beep when turned on. As soon as the unit is

turned on, the LCD screen will display the following

message:

DataNet - OM

DataNet Logger

2. The logger will then start scanning for networks. The LCD

will indicate how many networks were found in range, and

will announce when the scan is complete. Locked

networks will not be listed.

Scan for network Scan for network

Found 2 networks

Found 2 networks

To join the network created by your Receiver (there may be

other networks created by your colleagues) scroll through the

found networks on the LCD (using the logger Scroll button)

and press the Enter button

network. In the example below, the network required is the

second network found. You can also rescan the networks by

pressing Enter on the Rescan networks screen, which is

reached by scrolling through all the found networks.

Network 1:

Network 1:

ID: 014.061.082

ID: 014.061.082

ID: 014.061.082

Network 2:

Network 2:

Network 2:

ID: 026.167.85

ID: 026.167.85

ID: 026.167.85

when you reach the required

18

Scan complete Scan for network Scan for network

Scan complete

Rescan networksNetwork 1:

Rescan networks

Page 28

Note: If the logger did not detect a network, the unit will turn

off in order to conserve the battery.

3. Once you select the network, the logger will automatically

join that network and a new message will be displayed on

the LCD:

Joined network:

ID: 026.167.85

Note: If the message Join failed appears on the LCD, then

rescan for the network and try again. If the logger continually

fails to join, then form a new network on the Receiver.

4. The LCD will then indicate the following status message:

DataNet - OM

Ready

If the Receiver is disconnected for any reason, the following

message is displayed:

DataNet - OM

No Receiver

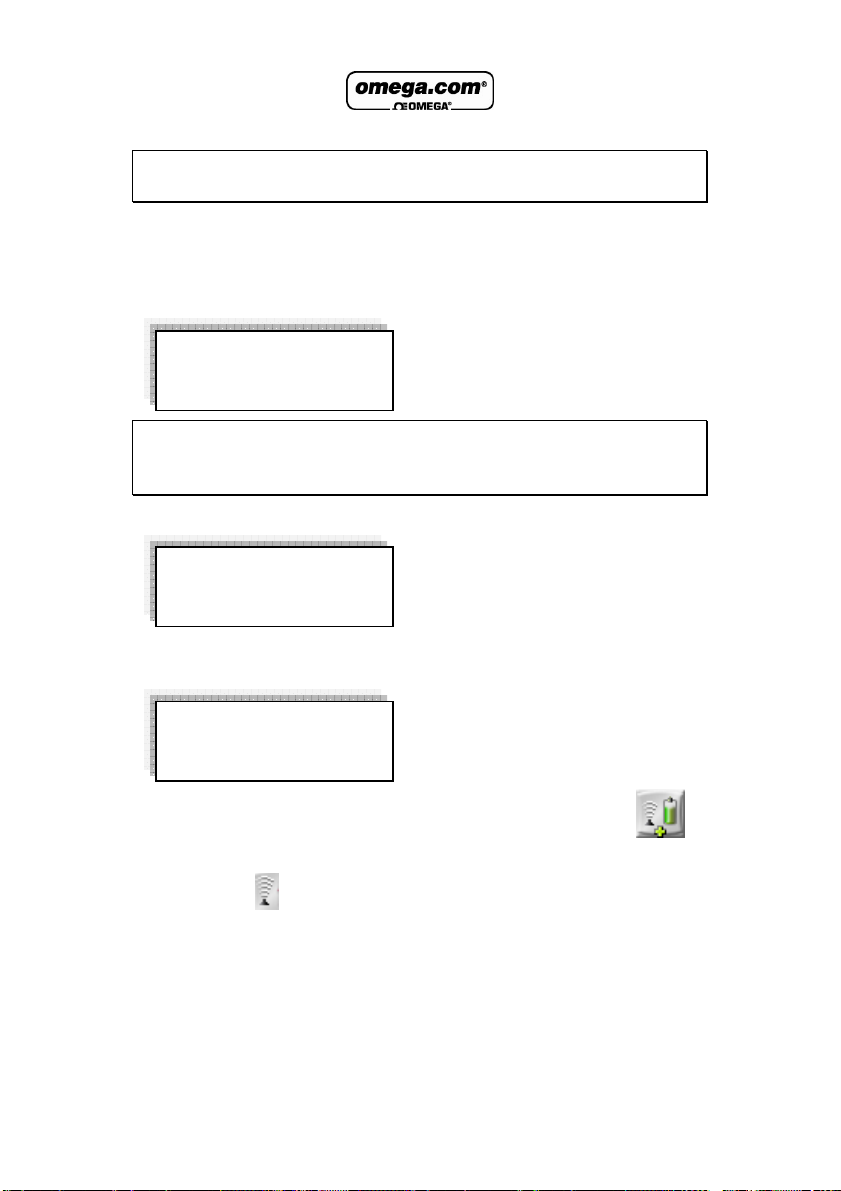

5. When the logger joins the network, the Logger icon

will automatically appear in the Map View.

a. The

symbol indicates the signal strength of the

logger in the network.

19

Page 29

b. The

from internal battery supply. The

that the logger is running from external power supply.

c. The

addition to the network and has not yet been

configured (setup).

6. Repeat steps 1-3 for every logger in your system.

7. In order to find the physical location of the logger you can

right-click on the Logger icon in Map View and select Call

Unit (Beep). The logger will then beep.

symbol indicates that the logger is running

symbol indicates

symbol indicates that the logger is a new

2.5.3. Loading Map View Background

Load an image into DataNet showing a map of your facility in

order to place the Receiver and Logger icons in their relative

positions. As you add more loggers to the system, this will

prove very helpful.

• Double click the Map View background to browse to the

image directory and load the image. Remember to unlock

the Map View in order to move the icons around.

• Right-click the Map View background and two options will

be available: Load Wallpaper and Reset Wallpaper,

which resets to the default Omega wallpaper.

20

Page 30

Figure 8: Map View background image example

2.6. Configuring the Logger

Once you connected your DataNet loggers to the network,

you must configure them in order to start acquiring data.

1. Right-click on the Logger icon you wish to configure.

Select Setup from the context menu.

The Setup window will be launched.

21

Page 31

Figure 9: Logger Setup window

This dialog provides non-editable information such as the

serial number, battery level, reception level and firmware

version of the current unit.

On the Device Setup and Alarm Setup tabs, the user is

able to configure the following parameters:

Unit's comment

Sampling rate

Transmission interval

Samples averaging

Temperature units °C/°F (on the logger LCD)

22

Page 32

Active sensors

Custom sensors' names

Alarm levels

Alarm duration

Alarm delay

Alarm pre delay

2. Select the sensors you wish to connect to the logger for

data acquisition. It doesn’t matter which order you select

the sensors. You may only have Input 4 selected, for

example, and Inputs 1 to 3 left unselected.

3. Select the sampling rate and transmission interval (rate at

which the data is transmitted from the logger to the

Receiver).

4. Unless you have Alarm levels you wish to edit (see the

Alarms Setup tab), click either Setup and Run (to send

the setup and immediately log data), or Setup Only (to

send the setup but only log data at your command).

5. If you selected Setup Only in step 4, right-click the

Logger icon and select Run from the context menu to

start logging data.

6. To stop the logger, right-click the Logger icon and select

Stop from the context menu.

Note: Running the logger clears the logger memory. All

previously recorded data will be erased when you begin a new

logging session.

2.7. Viewing Data

Once you run the logger, you have several ways of viewing

the online data that is being acquired.

• Online graph/table/statistics views

• Logger icon tooltip

23

Page 33

• Sensor view

2.7.1. Online Data Views

Double clicking the Logger icon or selecting Display Data in

the Logger icon context menu will open the online graph.

This graph is updated in real-time with the newly recorded

data.

You can switch between Graph, Table and Statistics views to

view the data in different formats.

Figure 10: Online data – Graph view

24

Page 34

Figure 11: Online data – Table view

Figure 12: Online data – Statistics view

2.7.2. Logger Tooltip

Close the online data window and return to Map View. Scroll

over the Logger icon and you will see a tooltip displaying the

relevant logger information, including real-time data.

25

Page 35

Figure 13: Logger tooltip

This tool-tip is updated with every newly recorded sample.

2.7.3. Sensor View

Click the Sensor View icon in the tool bar to switch to

this view. Here, you can monitor the data by viewing data

display of each individual sensor, rather than of each logger.

Figure 14: Sensor view

• If the sensor is in alarm, the sensor box will change color

from green to red (just as the Logger icon would).

• Double-clicking the individual sensor window will open the

data in the online Graph view.

26

Page 36

Note: By going to Tools > Switch Sensor View Mode you

can reduce the size of the sensor window to display only the

sensor type and sensor data. Recommended for networks

with many loggers.

2.8. Optimizing the Network

This section outlines a number of features and suggestions for

optimizing the DataNet network and getting the best

performance out of the end units and parent units.

For example, when you first setup your network, you want to

ensure that the loggers are placed in the optimum position in

order to receive and transmit data to/from the DataNet

software.

Refer to the DataNet specifications to guide you on the range

of the DataNet units. With this knowledge, and based on the

layout of your facility, you should have a good idea of the

likely positional layout of your units.

2.8.1. Signal Test Utility

Rather than setup the system on a trial and error basis,

DataNet has a Signal Test utility built in to the logger

firmware, which gives you a clear idea of the strength of the

signal of each logger to the Receiver, and the quality of the

data link between Receiver and logger.

Perform the following test on each logger in your system while

deciding where to position the logger:

1. Using the Scroll button, scroll through the main menu on

the logger until you reach the following display:

Signal level:

Run test -> Menu

27

Page 37

2. Press the Menu button to run the test.

The signal level and link quality will be displayed. As you

move the logger further away from the Receiver, you will

see these two parameters drop from a maximum of 100%.

When the logger is out of range of the Receiver, you will

see the following screen:

Out of range

3. To exit the Signal test, press the Scroll button.

2.8.2. Overcoming RF Obstacles

A universal issue concerning any wireless system is how to

overcome a hostile RF environment. DataNet’s ZigBee RF

protocol has been designed for these hostile RF environments

that routinely exist onsite. ZigBee can overcome competing

wireless noise and other problems communicating the data.

Its mesh networking capabilities allows it to re-route signal

traffic around temporary or permanent physical obstacles,

radio-frequency interference, Repeater error or other such

failures.

The robustness of the system is such that there is no single

point of failure, ensuring data recovery from end units on the

network.

Tips on overcoming RF barriers

• When first creating the network in the environment where

the loggers will be deployed, form a new network on the

Receiver. There may be local interference on the 2.4 GHz

free bandwidth. The ZigBee protocol, when forming a new

network, selects the least noisy channel (out of 16

available channels). Within this channel the units can

change RF slots (by hopping) but cannot move to other

28

Page 38

channels while running. By running on a channel on a

network created in another environment e.g. in the office,

this channel may become noisy and therefore

transmission range may be less than expected.

• When placing units in an indoor or outdoor environment,

bear in mind that walls, furniture, metal objects, etc. limit

the RF coverage thereby reducing the range of the units.

• Add Repeaters (OM-DNR-900) in range of end units and

parent unit to enhance RF coverage and improve

robustness of network. Have as many alternative

transmission routes as possible in order to eliminate

single points of failure.

• When placing Repeater ensure it is not on the limit of its

range to the end unit or parent unit (Repeater or

Receiver), to avoid periods of unavailability due to

changing RF conditions.

• Add Short Range Repeaters (OM-DNL-910 or OM-DNL-

920) to overcome RF interference nearby to the loggers.

• The higher the Receiver is positioned the better reception

quality it will obtain.

2.8.3. Showing the Network Path

By going to Network > Show Network Paths in the DataNet

main menu, the software will show the actual path that the

system uses to communicate between Receiver and logger,

for all units in the system.

Figure 15: Showing network paths – Example 1

You can also select Show Path from the logger context menu

to display the individual path from the unit to the Receiver.

Using this option you can see exactly how the system is built.

29

Page 39

Figure 16: Showing network paths – Example 2

The screenshot above shows a system of three loggers (red

squares) and two Repeaters (blue circles) transmitting to the

Receiver.

The arrows show the path between the units. Note that they

are bi-directional, meaning that the system is a two-way

system with units both transmitting and receiving data.

• A green path indicates a strong signal

• A yellow path indicate a medium strength signal

• A red path indicates a weak signal

2.8.4. Adding Repeaters to the

Network

Loggers which aren’t in range of the Receiver can transmit to

the Receiver via a Repeater/Short Range Repeater, which is

30

Page 40

in range. As DataNet is built using mesh networking

technology Repeaters (OM-DNR-900) can be added to the

system to enhance the network range.

The Receiver/Repeater is the same device, just configured

differently from the main menu when turned on. Refer to

section 3.11.3 to learn how to switch the OM-DNR-900 unit

type to Repeater.

2.8.5. Short Range Repeater

You may also enable a logger (OM-DNL-910 or OM-DNL-920)

to operate as a Repeater in addition to its logging capabilities.

In this mode the logger is referred to as a Short Range

Repeater (SRR) as the unit’s range specification stays at 80

m line of sight and is not increased to the longer range spec of

the Repeater.

To switch a logger to SRR mode, simply right-click the logger

icon in the DataNet software Map View and select Enable

Short Range Repeater Mode.

Note: In SRR mode the logger must be connected to AC

power at all times as the power consumption is much greater.

31

Page 41

2.9. Recommended Approach to

Deploying DataNet Units

Now that you have a general understanding of how the

DataNet system functions, you may wish to follow the

recommended approach for initial deployment of the system.

This approach will ensure a smooth and efficient deployment

of your DataNet units and you may then tweak this approach

based on experience you gain while using the system.

Note: When deploying the system bear in mind that several

factors could cause interference with the system, such as

electromagnetic pulses, metal shielding in the vicinity of the

transmissions, other devices using the same 2.4 GHz band,

etc. Be familiar with your environment before deploying the

system. Also refer to section 2.8.

1. After you have charged the DataNet units and are ready

to deploy them in your facility, collect all units - data

logger end units, Receiver and Repeaters (if relevant) –

and bring them to your PC workstation.

2. Connect the Receiver to the PC and form a network. Turn

on the units and one by one bring them online so you can

view their icons in the DataNet software’s Map View.

3. Configure each of the units via the Setup feature. At this

stage it is not necessary to configure the type of sensors

you will be using, or sample rate, alarm levels, etc. The

point of this step is to configure each of the units with a

logger or Repeater name that indicates where in your

facility they will be deployed. For example, Room 15

Freezer or Floor 2 Bio Lab. This will make it much easier

for you to recognize the units in the Map View once you

have deployed them. Once in place, you can reconfigure

the units however you like.

32

Page 42

4. It is also recommended, if possible, to change the Map

View default background to a diagram or map of your

facility. You can then move the logger or Repeater icons

accordingly so you can have a visual representation of

their location in the facility.

5. Take each logger and begin to distribute in your facility in

the precise location you would like them to be based.

Once in position you can then run the Signal Test on each

logger to verify that you have a good signal to the

Receiver. If you are out of range and there is no

alternative location for the logger, you will most likely have

to add at least one Repeater to the network.

6. Once each of the loggers is in position return to the PC

and in Map View, verify that each of the loggers is online.

You can also use the Show Network Paths feature to

see the path of the logger to the Receiver, and the

strength of the transmission.

7. If you determine that you need to add Repeater/s to the

network in order to bring end units online or enhance the

transmission where the signal is weak, then deploy the

Repeater/s with the following points in mind:

a. There must be an electrical socket accessible at the

location of the Repeater as they must be powered

externally in order to run for more than a few hours.

b. Place the Repeater/s as high from the ground as

possible in order to enhance the wireless signal from

its antenna.

c. Expose the Repeater/s to as many end units as

possible. For example, if there is a room with several

offline end units requiring a Repeater, position the

Repeater next to the room so that it is in range of as

many of these end units as possible, so you don’t

have to add more Repeaters.

8. After you have deployed the Repeater/s return to the

software and using the Show Network Paths feature verify

that all end units are now successfully transmitting to the

33

Page 43

Receiver, either on their own or via a parent Repeater.

You can continue to tweak the position of the units until

you are satisfied with the quality of the transmission.

9. Now that the units are in place the last step of initial

deployment is to reconfigure each unit to start data

acquisition. Configure the sensor setup, sample rate,

transmission rate, alarm levels, Email/SMS notifications,

etc. as you see fit.

34

Page 44

Chapter 3:

DataNet Hardware

Overview

This chapter details the hardware features of the DataNet

system components: the data loggers and the

Receiver/Repeater.

3.1. Data Logger Front Panel

Layout

3.1.1. OM-DNL-910 and OM-DNL-920

LCD screen

LCD screen

Menu/Enter button

Menu/Enter button

Scroll button

Scroll button

Figure 17: OM-DNL-910 data logger front panel

LCD screen

Displays logger status, logger data, Min/Max values and

network information.

Menu/Enter button

Use to enter logger menu options and to execute logger

commands.

35

Page 45

Scroll button

Use to scroll though menu items and to power on unit.

3.2. Data Logger External

Connections

3.2.1. OM-DNL-910 and OM-DNL-920

External connections of the OM-DNL-910 and OM-DNL-920

are exactly the same.

Mini USB port

Mini USB port

12 V power socket

12 V power socket

Negative Center

Negative Center

Excitation

Excitation

Four sensor

Four sensor

inputs

inputs

Figure 18: OM-DNL-920 data logger external connections

Mini USB Port

Functional in future models only – to enable data download direct

to PC via USB port.

12 V Power Socket

To connect logger to external power supply (negative center).

Sensor Inputs

Pluggable screw terminal blocks marked In-1 to In-4 (from left to

right), to connect wide range of sensor types for data acquisition.

All four inputs can be used simultaneously. Sensors can be

36

Page 46

connected in any order.

To connect a sensor to the DataNet data logger, unplug the

screw terminal, connect the sensor’s wires to the terminals, and

then plug the terminal back to the corresponding socket on the

input block.

Excitation socket

Output power socket used to power external sensors, power

derived directly from the external power supply adaptor.

3.3. OM-DNR-900

Receiver/Repeater Front

Panel Layout

LCD screen

LCD screen

Menu/Enter button

Menu/Enter button

Scroll button

Scroll button

Figure 19: Receiver/Repeater front panel

LCD screen

Displays Receiver/Repeater status and network information.

Menu/Enter button

Use to enter logger menu options and to execute logger commands.

Scroll button

Use to scroll though menu items and to power on unit.

37

Page 47

3.4. OM-DNR-900

Receiver/Repeater

External Connections

Mini USB port

12 V power socket

Negative Center

External Alarm

Figure 20: Receiver/Repeater external connections

Mini USB Port

To connect Receiver to PC and be detected by DataNet software.

Connect the mini USB Type B plug (rectangle plug) of the supplied

USB communication cable to the Receiver and the USB Type A

plug (flat plug) to the computer.

Refer to section 3.8.

12 V Power Socket

To connect unit to external power supply. Plug in an AC/DC 9-12 V

adaptor to power the unit. To use as a Receiver or Repeater and

maintain network integrity, the unit should be powered at all times.

Connecting external power to the unit automatically charges the

internal back-up battery. The adaptor should meet the required

specifications. Refer to Appendix A: DataNet Specifications.

External Alarm

Connect external alarm e.g. siren, audible alarm, to this input.

Whenever a logger on the network is in alarm status, the external

alarm will be activated. Refer to section 3.5.6 for more details.

38

Page 48

3.5. Data Logger Sensor

Overview

This section provides an overview of the hardware

specifications of the DataNet data loggers.

3.5.1. Internal Sensor Types

The OM-DNL-910 and OM-DNL-920 loggers include internal

sensors, depending on the logger model.

Sensor Measurement

Range

Digital Humidity 5% to 95% ±3% (in DataNet

Digital Temperature -20 ºC to 50 ºC ±0.5 ºC OM-DNL-920

Temperature

PT100 -20 ºC to 50 ºC ±0.3 ºC

Accuracy Logger

Model

OM-DNL-920

software)

±4% (on logger LCD)

OM-DNL-910

3.5.2. External Sensor Types

OM-DNL-910 and OM-DNL-920

Each of the four input channels of these data logger models

are multi-purpose and can be individually configured to any of

the following types and ranges.

Sensor Measurement

Range

Current 4 – 20 mA ± 0.5 % In-1 to In-4

Contact Open (0) /

Close (1)

N/A In-1 to In-4

39

Accuracy Available

Inputs

Page 49

Sensor Measurement

Range

Accuracy Available

Inputs

Frequency 20 Hz – 4 KHz N/A In-4 only

Pulse Counter 1 – 65,536 pulses

N/A In-4 only

0 to 4 KHz

Temperature

PT100 (2-wire)

-200 to 400 ºC -200 to -60 ºC ±0.5 %

60 to 400 ºC ±0.5 %

In-1 to In-4

-60 to 60 ºC ±0.3 ˚C

Temperature TC-J -200 ºC to 1,000 ºC -200 to -60 ºC ±0.5 %

In-1 to In-4

60 to 1,000 ºC ±0.5 %

-60 to 60 ºC ±0.5 ˚C

Temperature TC-K -200 ºC to 1,000 ºC -200 to -60 ºC ±0.5 %

In-1 to In-4

60 to 1,000 ºC ±0.5 %

-60 to 60 ºC ±0.5 ˚C

Temperature TC-T -200 ºC to 400 ºC -200 to -60 ºC ±0.5 %

In-1 to In-4

60 to 400 ºC ±0.5 %

-60 to 60 ºC ±0.5 ˚C

Voltage 0 – 1 V ± 0.5 % In-1 to In-4

Voltage 0 – 50 mV ± 0.5 % In-1 to In-4

40

Page 50

3.5.3. Sensor Connection

Connect the sensor/s to the terminal block/s at the top of data

logger:

Figure 21: DataNet logger sensor inputs

Sensors do not have to be added successively. You may only

configure In-4, or configure In-1 and In-3, for example, when

setting up the logger via the software.

3.5.4. External PT-100 and NTC

Sensor Connection

The PT-100 positive polarity (red) and ground (white) wires

are connected to the + input of the terminal block. The

negative polarity (black) wire is connected to the – input on

the terminal block.

3.5.5. Programming Limitations for

OM-DNL-910 and OM-DNL-920

The standard sampling rate for all sensors on all inputs is from

a maximum of one sample every second to a minimum of one

sample every two hours. However, there are certain

limitations using a specific combination of sensors, which

41

Page 51

must be taken into account when programming the DataNet

data loggers.

Note: The software integrates all programming limitations

automatically when configuring the loggers.

Please refer to the table below for DataNet programming

limitations, where:

PT100, Thermocouple J, K or T = A

Internal Digital Temperature (on OM-DNL-

920)

Sensor

Combination

3 x A

4 x A

A + B

(2 x A) + B

(3 x A) + B

(4 x A) + B One sample every

Table 1: Data Logger programming limitations

Maximum

Sampling Rate

One sample every

three seconds

One sample every

four seconds

five seconds

= B

Example Setup

In-1: PT-100

In-2: TC-J

In-3: TC-J

Internal: Temp

In-1: TC-T

In-2: PT-100

Internal: Temp

In-1: TC-T

In-2: TC-J

In-3: PT-100

In-4: PT-100

3.5.6. External Alarm Output

The DataNet system supports connection of an external alarm

e.g. siren, audible alarm, to the Receiver external alarm input

or to In-1 of the OM-DNL-910 and OM-DNL-920 data loggers.

42

Page 52

When connected to the Receiver, the external alarm will be

activated whenever a logger on the network is in alarm status.

When connected to the data logger, the external alarm will be

activated only when that specific logger is in alarm status.

Once there is no alarm status, the external alarm will be

deactivated.

Data Logger External Alarm

In-1 of the OM-DNL-910 and OM-DNL-920 serves either as a

standard sensor input or as an external alarm output.

Configure In-1 as Alarm Normally Open or Alarm Normally

Closed in the logger Setup window in the DataNet software.

Normally Open will result in the alarm being activated during

alarm status (the circuit will be closed).

Normally Closed will result in the alarm being activated when

logger is not in alarm and therefore deactivated when there is

an alarm (the circuit will be opened).

Connect In-1 to your external alarm device.

Use the Alarm Setup tab in the Setup dialog to define the

logger alarm settings. If these settings are breached then the

alarm will be activated.

Receiver External Alarm

By connecting the external alarm to the Ext Alarm input on

the Receiver, any alarm on the entire network will activate the

external alarm.

Use the Alarm Setup tab in the Setup dialog to define the

logger alarm settings. Whenever the Receiver receives an

alarm status from any logger on the network, the external

alarm will be activated. No additional configuration in the

software is required.

External Alarm Schematic

See the schematic below explaining how to hook up an

external alarm to the DataNet unit.

43

Page 53

-

-

+

+

-

-

+

+

+

+

3-4 V battery

Relay

Relay

-

-

+

+

Alarm device

Alarm device

(e.g. siren)

(e.g. siren)

Figure 22: External alarm schematic

• + from OM-DNR-900 goes to – of the Relay inputs

• + of Relay input goes to battery that powers the Relay

• Load inputs of the Relay go to the Alarm device e.g. siren,

lights, etc.

• - of the battery goes to – of OM-DNR-900.

3-4 V battery

to power relay

to power relay

-

-

Note: Maximum load of the Relay is 50 mA, 3 V.

Refer to Appendix A: DataNet Specifications for the full

external alarm output specification.

3.5.7. Polarity

Current, voltage, thermocouples and user defined sensors

have distinct polarity. Be careful to connect them in the right

polarity.

44

Page 54

3.5.8. Frequency/Pulse Counter

Connect the signal wires to In-4 terminal blocks, and select

Frequency or Pulse counter for Input 4 from the logger

Setup window in the DataNet software. Inputs 1 to 3 are still

available for other sensors.

The Frequency/Pulse counter is optically isolated from the

internal circuitry and can simultaneously measure a signal

source, together with another input.

3.5.9. User Defined Sensors

DataNet provides a simple and straightforward tool for

defining a limited number of custom sensors. Almost any

sensor or transducer with 0 – 1 V or 4 – 20 mA output is

accepted by the DataNet logger and its electrical units are

automatically scaled to meaningful user-defined engineering

units.

The sensor definitions are stored in the logger’s memory and

are added to the sensors list. The sensor’s readings are

displayed in the user defined units only in the DataNet

software. Future versions will also support displaying the user

defined engineering units on the logger LCD.

Refer to section 4.5.1 for more details.

3.5.10. Sensor Alarms

Via the software, users can define minimum and maximum

alarm levels for each input individually. Users can define prelow and pre-high alarm levels, for an additional level of safety

in case the logger is approaching an actual breach of alarm.

45

Page 55

The DataNet logger display indicates when the sensor reading

is in alarm of any type. The symbols AL-H, AL-L, AL-P-H or

AL-P-L are visible next to the corresponding input readings.

Refer to section 4.13 for more details.

3.5.11. Sensor Calibration

The DataNet data logger is shipped fully calibrated. However,

further calibration can be applied via the DataNet software.

The calibration parameters are sent to the data loggers

wirelessly and stored in the logger’s memory.

Users may calibrate individual input as well as all inputs at

once. Calibration settings may be saved and then loaded into

the logger at a later date if the calibration settings have

changed.

Refer to section 4.13.4 for more details.

3.6. Unit Serial Number and

Comment

Every DataNet data logger and Receiver/Repeater unit is

embedded with a unique serial number.

The data logger only can be loaded with a descriptive

comment to identify its task and location. You may add or edit

the comment of any logger on the network via the DataNet

software.

Every time data is transferred to the computer it is labeled

both with the logger’s serial number and comment and is

displayed in the graph or data table view.

The unit serial number is also marked on a sticker on the back

of the product.

46

Page 56

3.7. Power Supply

3.7.1. OM-DNR-900 in Receiver Mode

The Receiver unit is powered via the USB port of the PC,

when connected via the mini USB cable. In addition, the unit

can run for a limited time (up to three hours) from an internal

NiMh rechargeable battery. To charge the internal battery,

connect the unit to the AC power supply supplied with the

OM-DNR-900. The internal battery pack is generally used as

a back up power supply in the event the external power

supply fails.

Note: When in Receiver mode, the unit must be connected to

external power at all times. While running on internal power,

the unit will run for only several hours before shutting down

and therefore shutting down the DataNet network which the

Receiver is managing.

3.7.2. OM-DNR-900 in Repeater Mode

When in Repeater mode, the OM-DNR-900 must be

connected to external AC power at all times using the

supplied AC charger. Otherwise, when the internal backup

batteries drains and shuts down the unit, all the end units

dependent on the Repeater to transmit to the Receiver, will

not be detected by the software. The user won’t be able to

monitor data readings from these units until the Repeater

comes back online.

When connected to external power supply, the Repeater

battery will not be charged when the unit is turned off. This will

allow the system to protect the battery from overheating.

47

Page 57

3.7.3. OM-DNL-910 and OM-DNL-920

Data Loggers

The OM-DNL-910 and OM-DNL-920 data loggers run from an

internal NiMh rechargeable battery as well as from external

AC power supply. Depending on the logger configuration,

from a fully charged battery, the data logger can run for up to

several months. Refer to section 3.7.5 for more details on

battery life.

Note: Charge the data logger units for 16 hours before using

them for the first time.

When connected to external power supply, the data logger

battery will not be charged when the unit is turned off. This will

allow the system to protect the battery from overheating.

First Time Charging

From a fully drained battery, you must charge the battery for

16 hours to bring it to a full charge. Once the charge cycle is

complete, the logger will run from the external power supply,

without draining (or charging) the internal battery. In order to

maintain a fully charged battery and ensure the battery

doesn’t self-discharge, the battery charger will daily charge

the unit for a minute to maintain the battery capacity.

Note: Before storing the DataNet units make sure you have

unplugged all the sensors and turned the units off via the

keypad.

Standard Charging

Whenever a logger is reconnected to the charger it will begin

the 16-hour charge cycle, no matter what the status of the

battery. Once the charging cycle is complete the logger will

run from external power supply.

48

Page 58

Effect of Charging Battery on Temperature

Sensor

For loggers measuring data with the internal temperature

sensor, it is critical to note that during the charge cycle the

logger will heat up thereby causing the internal temperature

sensor reading to rise by up to 10 ˚C above ambient

temperature. Once the charging process is complete, the

logger will cool down and the internal temperature sensor

readings will return to normal.

For loggers remaining connected to AC power, to prevent the

logger from heating up again following the initial charge cycle,

the logger will receive a one minute trickle charge each day

rather than stay continually charged. This is sufficient to

ensure the logger doesn’t self-discharge and will maintain the

logger’s full charge status.

3.7.4. Power Adapter

The DataNet power adapter is used to power the OM-DNR900 and OM-DNL-910 and 920 units. The mains adaptor

(AC/DC adaptor) converts mains power (from a wall outlet) to

a voltage suitable to the DataNet hardware unit.

• Output: Capacitor filtered 9 to 12 VDC, 300 mA

• Female plug, center negative

Note: Only use Omega-supplied power adapters to avoid

damaging the units with incorrect power supply.

3.7.5. Data Logger Battery Life

Battery life depends on the logger sampling rate, transmission

rate, type of sensor, network architecture and number of

measured sensors.

• OM-DNL-910 and OM-DNL-920 can last up to six months

on a charged battery.

49

Page 59

The table below provides two example scenarios of standard

logger configurations and expected battery life.

Logger

Model

OMDNL910

OMDNL910

Table 2: Data logger battery life scenarios

Sensor Setup Sample

• Internal

Temperature

• 4 x Thermocouple

1 x PT-100 15

15

minutes

minutes

Rate

Transmission

Rate

15 minutes Five

15 minutes Six

3.8. USB Communication Cable

A mini USB communication cable is supplied as part of the

DataNet PC Suite. This cable connects the Receiver to the

DataNet PC workstation. When connected to the PC the

Receiver can communicate with the DataNet software and

manage the DataNet network.

The USB cable also powers the Receiver when connected to

the PC but it does not charge the internal battery.

Battery

Life

months

months

Note: The USB driver is installed as part of the software

installation process. Without this driver the PC won’t detect

the Receiver. To avoid compatibility problems do not connect

the Receiver to the PC before installing the USB driver.

Type B plug

Connect to PC USB port

Type A plug

Connect to Receiver USB port

Figure 23: USB communication cable

50

Page 60

3.9. DataNet Keypad Overview

3.9.1. OM-DNL-910, OM-DNL-920 and

OM-DNR-900 Keypad

The OM-DNL-910, OM-DNL-920 and OM-DNR-900 units

each have two buttons on the keypad, which are used to

navigate through the LCD menu options, as well as turn on

the units.

Refer to section 3.10 to learn how to operate the data loggers

and sections 3.11 and 3.12 to learn how to operate the

Receiver and Repeater.

The Menu button

functionalities:

Navigate to the main menu. When

pressed from within a submenu, the

display will take you back to the

main menu.

Selecting an option from one of

the menus. When pressed on one

of the main menu items, it will take

you to the sub menu options.

The Scroll button

functionalities:

When the unit is off, pressing this

button will power the unit on.

Scrolls through the menu options.

51

has two

has two

Page 61

3.10. Operating the OM-DNL-910

and OM-DNL-920

This section explains how to operate the OM-DNL-910 and

OM-DNL-920 loggers and provides an overview of the menu

options on the units’ LCD screen.

3.10.1. Turning on the Unit

In order to view the logger menu options, the unit must be

powered on by pressing the Scroll button

Ensure the logger is charged or connected to the AC adapter.

Once the unit is switched on it will emit a short beep and the

screen will display a welcome message:

DataNet - OM

DataNet Logger

on the keypad.

3.10.2. Display Shutdown

If the logger screen is inactive for thirty seconds it will turn off.

However the logger will continue to operate in the

background. Press the Scroll button to enable the LCD

screen again. The screen will not turn off during firmware

upgrade.

3.10.3. Joining a Network

When a logger is powered on or reset, it will automatically

scan for a network after the welcome message has appeared.

There are three scenarios that can occur while scanning for a

network:

52

Page 62

Scenario 1: The logger can’t find the last network that it was

connected to. For example, the logger is a new unit which was

never previously joined a network.

Scenario 2: The logger scans and finds the last network it

was connected to, and joins that network.

Scenario 3: The logger can’t find any networks at all.

Scenario 4: The logger found a network but failed to join. The

unit will try to reconnect nine times before scanning for the

network again. Moving the unit closer to the Receiver can help

the logger to join successfully. If the logger still can’t join, form

a new network.

Scenario 1

If the unit can’t find the last network that it was connected to

(for example, it’s a new unit), the unit will display all the

networks that are in range:

Scan for network

Where # is the number of networks found

Once the scan has been completed the following screen

appears:

Scan complete

Scan for network

Found # network

If more than one network was found, the user will need to

select the network ID that he wants to connect to. The user

uses the Scroll button to scroll through the Network IDs. The

relevant network is selected using the Enter button.

53

Page 63

Network 1:

Network 1:

ID: 014.061.082

ID: 014.061.082

Once the network has been selected the following screen will

be displayed.

Joined network:

ID: 021.207.175

To rescan the networks, simply select the Rescan Networks

option and the logger will start the scanning process again.

If only one network was found the system will automatically

connect to that network without the user needing to select the

network manually.

Scan for network

Scan for network

Scan for network

Found 1 network

Found 1 network

Found 1 network

The logger display will return to the welcome message, which

consists of the logger name (editable via the software) and the

network status:

• Ready - If connection to the DataNet software is

established.

• Software is down - If established connection to the

Receiver but the DataNet software is down (PC is off,

software is not open, etc.)

• No Parent Signal – The parent unit, either the Receiver

or Repeater, is not detected by the logger therefore the

logger is not transmitting its data to the network.

Network 2:

Network 2:

ID: 021.207.175

ID: 021.207.175

Rescan networks

Scan complete Joined to network:

Scan complete Joined to network:

Scan complete Joined to network:

ID: 021.207.175

ID: 021.207.175

ID: 021.207.175

54

Page 64

DataNet – OM

DataNet – OM

Software Down

Software Down

Scenario 2

When the system scans for networks and finds the last

network that it was connected to it will automatically connect

to the last known network.

Joined Network:

ID: 021.207.175

As in Scenario 1, the logger display will then return to the

welcome message displaying the unit name and status.

Scenario 3

The system can’t find any networks at all.

If no networks were found, the unit will display the following

screens.

Scan for network

Found 0 network

DataNet – OM

DataNet – OM

Ready

Ready

DataNet – OM

DataNet – OM

No Receiver

No Receiver

Scan complete No found networks:

Rescan networks

3.10.4. Main Menu Options

There are three menu categories on the data logger:

• View Data

• Status

• Min/Max Values

55

Page 65

Note: If the unit is not in Run mode only the Status menu

options will be available.

Press the Menu button to reach the main menu display. Scroll

through the main menu options (View Data, Status and

Min/Max Values) using the Scroll button. Once you reach the

main menu option you need, press Enter to select that option

and enter the sub menus.

View Data Menu

View Data

Note: View Data is the default page when the unit is running.

If there is more than one sensor running, the screen will auto

scroll between the sensors showing the sensor name and

senor value. These are real-time displays.

The display will switch back to the View Data screen after five

minutes if none of logger buttons have been pressed.

If the sensor breached any of the predefined alarm levels,

then the alarm symbol will be displayed alongside the data

reading.

For example:

In-TMP

24˚C AL-Lo

The logger display alarm symbols are:

• AL-HI : Alarm High

• AL-Lo : Alarm Low

56

Page 66

• AL-P-H : Pre Alarm High

• AL-P-L : Pre Alarm Low

Status Menu

Status

The Status menu contains the following sub menus, all

reachable by using the Scroll button.

The sub menus are outlined below in the order in which they

appear on the logger display.

Name and Status

As explained previously, the unit name (or Comment) is

displayed on the first row and the second row indicates the

logger status.

If the logger is running, then the following screen is displayed.

DataNet - OM

Logger running

Mark Unit on PC

To indicate the logger icon in the software’s Map View, press

the Enter button when this screen is displayed. The logger’s

icon located in the Map View will blink a number of times.

Batt Level (battery level)

If the power adapter is not connected the battery percentage

will be displayed.

If the power adapter is connected External power will be

displayed.

57

Page 67

Batt Level: 67%

Signal Level Test

The Signal Level test allows the user to check the signal

strength and quality of the link between the logger and its

parent unit. This test is used to determine optimal positioning

of the logger during deployment.

Signal level:

Run test -> Menu

By pressing the Menu button the unit will show the signal level

and link quality in percentage terms.

If there is no connection with a parent unit, an Out of range

message will be displayed.

Link quality: 95

Batt Level:

External power

Out of range Signal level: 80

• Signal level: Indicates the reception level between end

unit and parent unit. If the level falls below 20% then the

logger should be placed in a better location or a Repeater

should be added.

• Link quality: Calculation of the data transmitted with no

errors from the logger to the parent unit. If the level falls

between 85% then the logger should be placed in a better

location or a Repeater should be added. The lower the

link quality %, the more retries are needed in order for the

logger to send all of its data.

58

Page 68

Note: The signal level may be low but the link quality can still

be 100%.

You will not be able to run the Signal Level test when the

logger has lost its connection to the network. If you tried, then

the following screens are displayed:

No Parent signal DataNet - OM

No Parent found

Logger Version

This menu informs the user of the logger firmware version.

This is helpful when you need to upgrade the system

firmware, to check the current version. Or when contacting

Omega technical support, with any technical issues.

Logger version:

2.03.00.01.89.00

The firmware version is commonly referred to by the numbers

in bold in the screen above. For example, the firmware

version which is supported by this user guide is v1.89.

S/N

This menu displays the unit’s eight digit SN.

S/N 12345678

Network Data

This menu displays the unique network ID to which the unit is

currently connected. This ID will match the network ID

59

Page 69

displayed in the software in the Receiver icon’s tooltip in the

Map View.

Network data:

ID: 014.061.082

Device Mode

There are two possible device modes:

• DataNet Logger

Device is operating as standard data logger

• Logger – SR RPTR

Device is operating as a Short Range Repeater. Refer to

section 2.8.5 for more details.

Leave Network

If this option is selected, the unit will first leave the network

and then reset itself. The scan network procedure described

in section 3.10.3 will begin. The only exception to this

procedure is that even if the last connected network is found

during the scan, the unit will not automatically connect to it.

Leave network

Note: If the logger was in Run mode prior to sending the

Leave Network command the software will download all data

from the unit first and then force it to leave the network.

Reset Unit

When the unit is reset, upon start up it will automatically scan

for networks. The unit will automatically connect to the

60

Page 70

previously connected network assuming it was found in the

network scan.

Following reset the unit will continue to operate according to