Page 1

650-467-8671

OM-CP-Bridge120

Bridge/Strain Gauge

Data Logger

Page 2

GageFactor

R

R

ainsmi

000,000,1

)(crostr

×

∆

=µε

µε397

1.2

000,000,1

120

1.0

=

×

OM-CP-Bridge120

Product Notes

The OM-CP- Bridge120 data logger is designed to interface with and measure strain gauges and load

cells. The device provides an excitation voltage of 2.5V’s and is available in the following millivolt input

ranges: ±10mV, ±25mV, ±100mV, ±1000mV. The Bridge120 features a

sampling rate of up to 20Hz.

LEDs

Once started, the LED will flash at the selected reading rate to indicate the device is running.

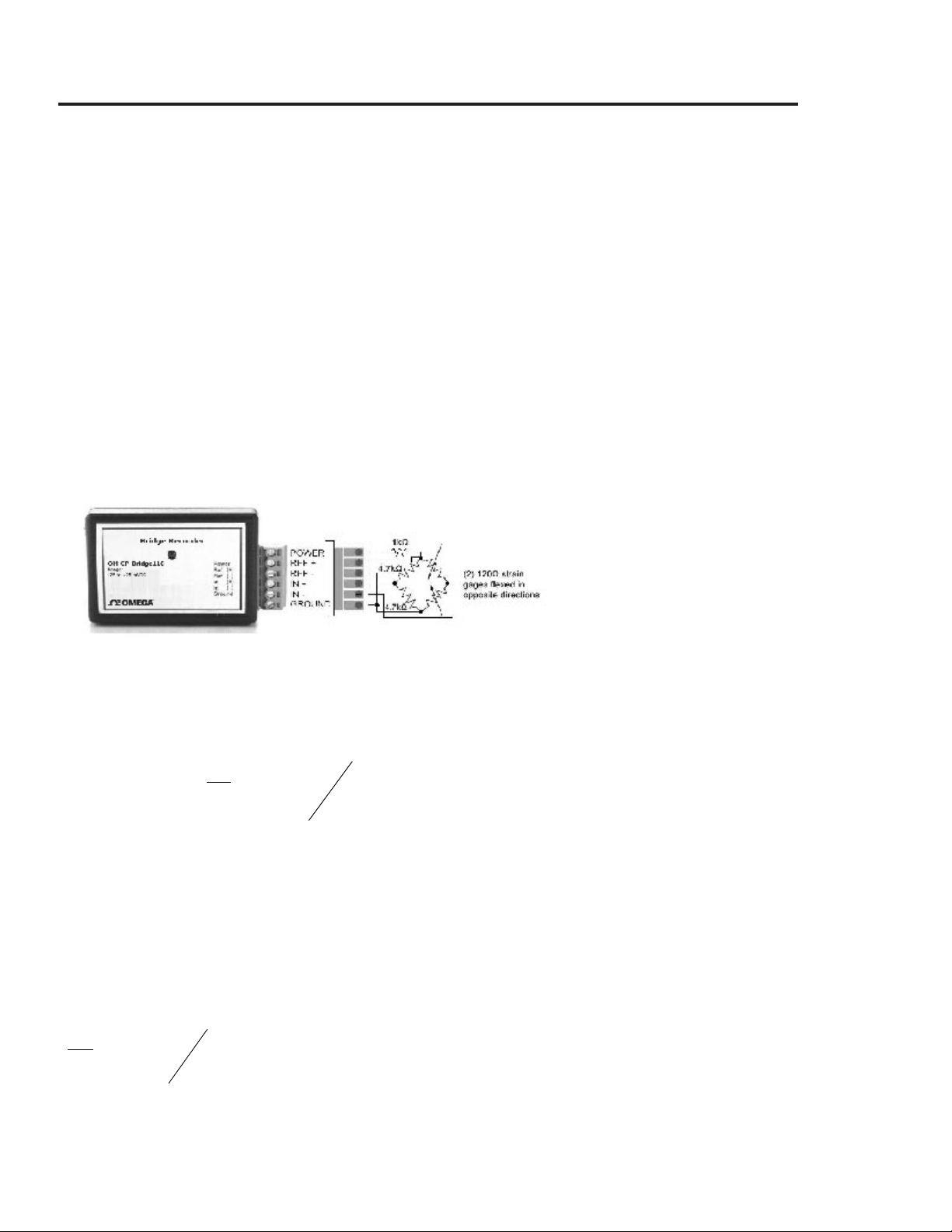

Wheatstone Bridge Configuration

If it is desired to make strain gage measurements with better signal integrity and not requiring

matching the thermal expansion coefficient to the material, then a Wheatstone Bridge configuration

ought to be considered. While there are several versions of the Wheatstone Bridge, the least complex

configuration that has these desirable qualities is the One-half bridge.

ONE-HALF WHEATSTONE BRIDGE

Note 1: The two strain gages need to bend in the opposite direction when stressed. Under this arrangement, the non-linear error

is nulled out and temperature coefficients between the sensors and the material do not have to match.

Note 2: The tolerance of the 120Ω resistors and the “matched” values of the strain gages affect the “null”

reading which theoretically ought to be 0V. It is recommended to use 1% or better resistors and identical strain gages.

EXAMPLE:

A common unit of strain gage measurement is microstrains (μ). Microstrain is mathematically

expressed as such: Where R/R is the ratio between the change in strain gage resistance (under stress)

and the nominal strain gage resistance. The Gage Factor (GF) is specified by the manufacturer or

vendor of the particular gage. Typically, GF values are 2 to 4.5 for metal and 50 to 200 for

semiconductor strain gages. A 120Ω strain gage measures, under stress, 120.1Ω. The GF is 2,1.

Convert to microstrains:

Page 3

GF

V

v

nsmicrostrai

p

000,000,1

2

)(

×

∆×

=µε

Quick Start Manual

If you wish to convert to microstrains from the differential bridge voltage, you can use the

following equation (assumes you are using the one-half Wheatstone Bridge as shown previously)

Where:

V = measured differential bridge voltage

Vp = bridge excitation voltage

GF = Gage Factor provided by the gage manufacturer

In some circumstances you may wish to plug in a packaged Wheatstone Bridge sensor such as

the Omega® PX170 differential pressure gage or Omega® LCGC series Load Cell gages. In these

circumstances, the internal resistive bridge cannot be altered.

When using a packaged Bridge sensor, check the specified bridge resistance. If it is less than 1kΩ then

add a 1kΩ resistor between the power and bridge. You may use values higher than 1kΩ to conserve

battery power, but it will diminish the signal to noise ratio. If the bridge resistance is greater than 1kΩ

then no additional resistor is required.

PACKAGED WHEATSTONE BRIDGE SENSOR LESS THAN 1KΩ RESISTANCE

PACKAGED WHEATSTONE BRIDGE SENSOR GREATER THAN 1KΩ RESISTANCE

Page 4

OM-CP-Bridge120

Installation Guide

Installing the Interface cable

- OM-CP-IFC200

Insert the device into a USB port. The drivers will install automatically.

- OM-CP-IFC110

Plug the serial cable into the port and verify it is secure.

Installing the software

Insert the Software CD in the CD-ROM Drive. If the autorun does not appear, locate the drive on the

computer and double click on Autorun.exe. Follow the onscreen instructions.

Connecting the data logger

- Once the software is installed and running, plug the interface cable into the data logger.

- Click the Communication Menu, then Auto Configure Port.

- After a moment, a box will appear stating a device has been found.

- Click OK. The Device Status box will appear. Click OK.

- At this point, communications have been configured for your logger. These settings can be found

under the Communication Menu.

Device Operation

Starting the data logger

- Click Device Menu then Start Device.

- Choose the desired start method.

- Choose the start parameters by selecting a Reading Rate suitable for your application.

- Enter in any other desired parameters and click Start.

- A box will appear stating the data logger has been started. Click OK.

- Disconnect the data logger from the interface cable and place it in the environment.

Downloading data from a data logger

- Connect the data logger to the interface cable.

- Click the Device Menu then Read Device Data. This will offload recorded data onto the PC.

Page 5

Part Number OM-CP-Bridge120

Range

Resolution

See Table Below*

Accuracy

Memory 32,767

Sample Rate 20Hz to 12 hours

Units

V, mV, μV, Engineering Units specied through software

Required Interface Package OM-CP-IFC110 or OM-CP-IFC200

Baud rate 57,600

Typical Battery Life 25 days

Operating Environment –40°C to +80°C (-40°F to 176°F),

0%RH to 95%RH (non-condensing)

Material ABS plastic

Dimensions 0.8” x 1.7” x 2.7” (20mm x 43mm x 69mm)

Approvals CE Pending

Nominal Range +10mV +25mV +100mV +1000mV

Measurement Range +15mV +37.5mV +120mV +1200mV

Resolution 1µV 2.5µV 5µV 50µV

Accuracy +0.25%FSR +0.10%FSR +0.05%FSR +0.01%FSR

Input Range 0 to 2.5V 0 to 2.5V 0 to 2.5V 0 to 2.5V

Reference Voltage 2.5V 2.5V 2.5V 2.5V

Battery Warning

WARNING: FIRE, EXPLOSION, AND SEVERE BURN HAZARD. DO NOT SHORT

CIRCUIT, CHARGE, FORCE OVER DISCHARGE, DISASSEMBLE, CRUSH, PENETRATE

OR INCINERATE. BATTERY MAY LEAK OR EXPLODE IF HEATED ABOVE 80˚C (176˚F).

Page 6

OMEGAnet

Servicing North America:

U.S.A.:

Omega Engineering, Inc., One Omega Drive, P.O. Box 4047

Stamford, CT 06907-0047

Toll-Free: 1-800-826-6342 Tel: (203) 359-1660

FAX: (203) 359-7700 e-mail: info@omega.com

Canada:

976 Bergar

Laval (Quebec), H7L 5A1 Canada

Toll-Free: 1-800-826-6342 TEL: (514) 856-6928

FAX: (514) 856-6886 e-mail: info@omega.ca

For immediate technical or application assistance:

U.S.A. and

Canada: Customer Service: 1-800-622-2378/1-800-622-BEST

Mexico/

Latin America

It is the policy of OMEGA Engineering, Inc. to comply with all worldwide safety and EMC/EMI regulations that apply. OMEGA is constantly pursuing

certification of its products to the European New Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA accepts no liability for any errors it contains, and reserves the

right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, human applications.

Sales Service: 1-800-826-6342/1-800-TC-OMEGA

Engineering Service: 1-800-872-9436/1-800-USA-WHEN

En Español: 001 (203) 359-7803 FAX: 001 (203) 359-7807

info@omega.com.mx e-mail:espanol@omega.com

®

Online Service Internet e-mail

omega.com info@omega.com

Servicing Europe:

Benelux:

Toll-Free: 0800 099 3344 TEL: +31 20 347 21 21

FAX: +31 20 643 46 43 e-mail: sales@omegaeng.nl

Czech

Republic:

Toll-Free: 0800-1-66342 TEL: +420-59-6311899

FAX: +420-59-6311114 e-mail: info@omegashop.cz

France: Managed by the United Kingdom Office

Toll-Free: 0800 466 342 TEL: +33 (0) 161 37 29 00

FAX: +33 (0) 130 57 54 27 e-mail: sales@omega.fr

®

®

Germany/

Austria

®

FAX: +49 (0) 7056 9398-29 e-mail: info@omega.de

United

Kingdom: One Omega Drive, River Bend Technology Centre, Northbank

ISO 9001

FAX: +44 (0) 161 777-6622 e-mail: sales@omega.co.uk

Managed by the United Kingdom Office

Frystatska 184

733 01 Karviná, Czech Republic

Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Toll-Free: 0800 6397678 TEL: +49 (0) 7056 9398-0

OMEGA Engineering Ltd.

Irlam, Manchester M44 5BD United Kingdom

Toll-Free: 0800-488-488 TEL: +44 (0) 161 777-6611

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a period of 61 months from

date of purchase. OMEGA’s WARRANTY adds an additional one (1) month grace period to the normal five (5) year product

warranty to cover handling and shipping time. This ensures that OMEGA’s customers receive maximum coverage on each

product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’sCustomer Service Department will issue an

Authorized Return (AR) number immediately upon phone or written request. Upon examination by OMEGA, if the unit is found to be

defective, it will be repaired or replaced at no charge. OMEGA’sWARRANTY does not apply to defects resulting from any action of the

purchaser, including but not limited to mishandling, improper interfacing, operation outside of design limits, improper repair, or

unauthorized modification. This WARRANTY is VOID if the unit shows evidence of having been tampered with or shows evidence of

having been damaged as a result of excessive corrosion; or current, heat, moisture or vibration; improper specification;

misapplication; misuse or other operating conditions outside of OMEGA’scontrol. Components in which wear is not warranted,

include but are not limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However, OMEGA neither assumes responsibility

for any omissions or errors nor assumes liability for any damages that result from the use of its products in accordance with

information provided by OMEGA, either verbal or written. OMEGA warrants only that the parts manufactured by the

company will be as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR REPRESENTATIONS OF ANY

KIND WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE, AND ALL IMPLIED WARRANTIES INCLUDING ANY

WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION

OF LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total liability of OMEGA with respect to this

order, whether based on contract, warranty, negligence, indemnification, strict liability or otherwise, shall not exceed the

purchase price of the component upon which liability is based. In no event shall OMEGA be liable for consequential,

incidental or special damages.

CONDITIONS: Equipment sold by OMEGAis not intended to be used, nor shall it be used: (1) as a “Basic

21 (NRC), used in or with any nuclear installation or activity; or (2) in medical applications or used on humans. Should any Product(s)

be used in or with any nuclear installation or activity, medical application, used on humans, or misused in any way, OMEGAassumes

no responsibility as set forth in our basic WARRANTY/ DISCLAIMER language, and, additionally, purchaser will indemnify OMEGAand

hold OMEGAharmless from any liability or damage whatsoever arising out of the use of the Product(s) in such a manner.

Component” under 10 CFR

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE RETURNING ANY

RETURN REQUESTS /INQUIRIES

PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN (AR) NUMBER FROM OMEGA’S CUSTOMER

SERVICE DEPARTMENT (IN ORDER TO AVOID PROCESSING DELAYS). The assigned AR number should then be marked on the

outside of the return package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent breakage in transit.

FOR WARRANTY

tion available BEFORE contacting OMEGA:

1. Purchase Order number under which the product was

PURCHASED,

2. Model and serial number of the product under warranty, and

3. Repair instructions and/or specific problems relative to the

product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords our customers the latest in

technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2011 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied, reproduced, translated, or

reduced to any electronic medium or machine-readable form, in whole or in part, without the prior written consent of OMEGA ENGINEERING, INC.

RETURNS, please have the following informa-

FOR NON-WARRANTY REPAIRS,

consult OMEGA for current repair charges. Have the following information available BEFORE contacting OMEGA:

1. Purchase Order number to cover the COST of the repair,

2. Model and serial number of the product, and

3. Repair instructions and/or specific problems relative to

the product.

MQS-5035/1011

MQS-5044/0412

Loading...

Loading...