Page 1

TABLE OF CONTENTS

Introduction..........................................................................................................................................iv

• Terms used in this Manual...........................................................................................................iv

• Product Symbols..........................................................................................................................iv

Operator Safety Information .................................................................................................................v

1.0 GENERAL INFORMATION AND FEATURES...................................................................................1

1.1 INTRODUCTION & SYSTEM OPERATION..............................................................................1

1.1.1 LOGGER MAINFRAME....................................................................................................2

1.1.2 MULTIPLEXER.................................................................................................................3

1.2 LOGGER EXTERIOR FEATURES............................................................................................4

2.0 PREPARATION AND SET-UP ..........................................................................................................6

2.1 UNPACKING..............................................................................................................................6

2.2 QUICK HOOK UP......................................................................................................................8

2.3 ATTACHING A OM-5200 TO THE WALL..................................................................................8

2.4 CONNECTING TRANSDUCER INPUTS TO MULTIPLEXER..................................................9

2.4.1 CONNECTING TRANSDUCERS TO THE TV-10/40 MUX............................................11

2.5 CONNECTING IN THE AC POWER ADAPTER.....................................................................12

2.6 CONNECTING OPTIONAL DC POWER CABLE ...................................................................12

2.7 GROUNDING THE ENCLOSURE...........................................................................................13

2.8 PAPER INSTALLATION ..........................................................................................................13

2.9 RS-232 FUNCTIONS...............................................................................................................14

2.9.1 DATA PORT CONNECTION..........................................................................................15

OM-5000 uiu

Page 2

3.0 OPERATION...................................................................................................................................16

3.1 FRONT PANEL........................................................................................................................16

3.1.1 DISPLAY.........................................................................................................................17

3.1.2 PRINTOUTS...................................................................................................................17

3.1.2.1 POWER UP.......................................................................................................17

3.1.2.2 LOGGER CONFIGURATION............................................................................18

• CONFIGURATION UNITS TABLE ..............................................................18

• CONFIGURATION ALARM TABLE.............................................................18

3.1.2.3 CHANNEL CONFIG...........................................................................................19

• LOG INTERVAL...........................................................................................19

• PRINT OPTIONS.........................................................................................20

• CHANNELS/DWELL....................................................................................20

• VOLTAGE SCALING...................................................................................20

• TADJUST.....................................................................................................20

• CHANNEL / ALARMS..................................................................................20

3.1.2.4 NORMAL LOGGING..........................................................................................21

3.1.2.5 MANUAL PRINT................................................................................................21

3.2 PROGRAMMING.....................................................................................................................22

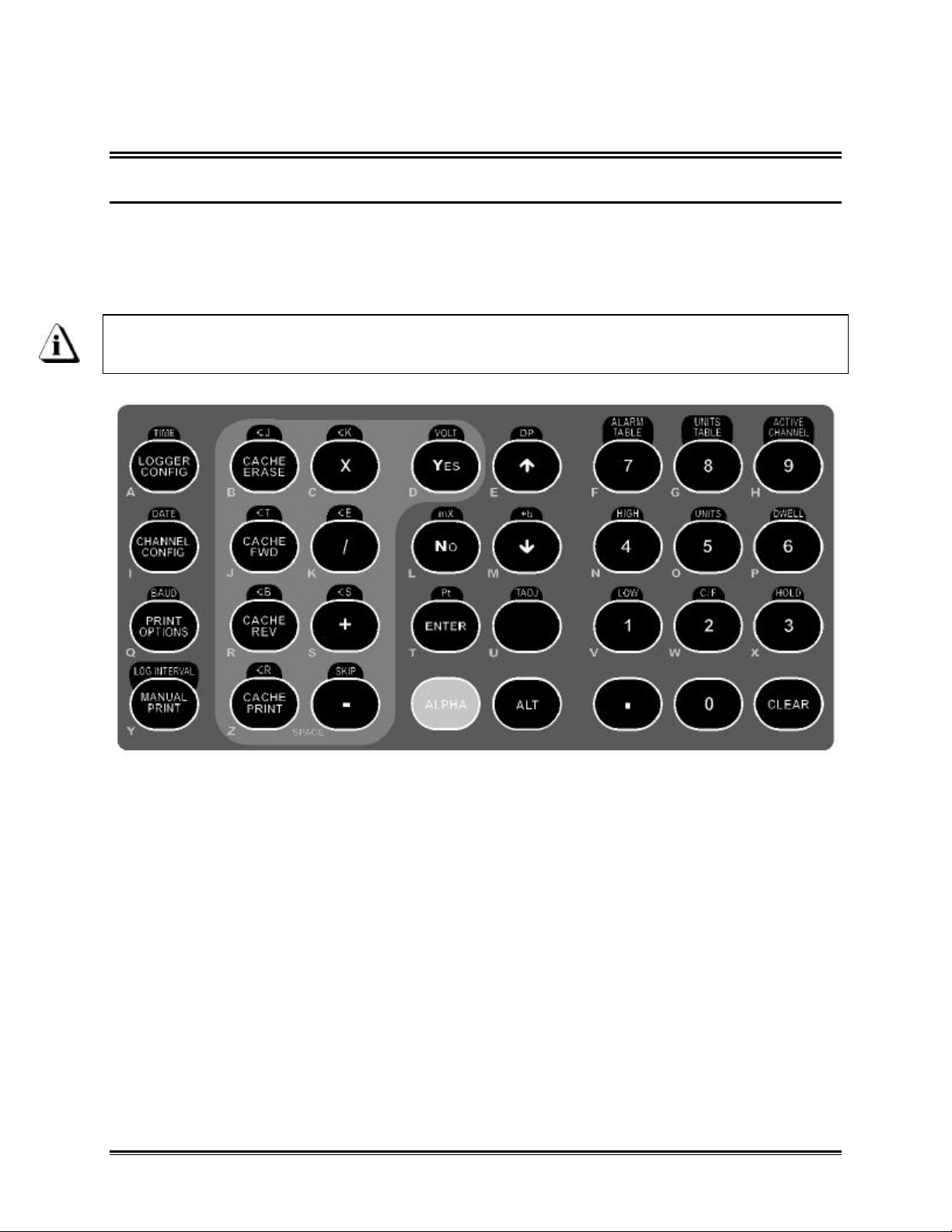

3.2.1 KEYPAD INTRODUCTION.............................................................................................22

3.2.1.1 THE ALPHA KEY...............................................................................................23

3.2.1.2 THE ALT KEY....................................................................................................23

3.2.1.3 THE CLEAR KEY...............................................................................................24

3.2.2 PROGRAMMING MAINFRAME FUNCTIONS ..............................................................25

3.2.2.1 MAINFRAME PROGRAM STORAGE...............................................................25

3.2.2.2 TIME...................................................................................................................25

3.2.2.3 DATE..................................................................................................................25

3.2.2.4 BAUD RATE ......................................................................................................26

3.2.2.5 LOG INTERVAL.................................................................................................26

3.2.2.6 CHANNEL LOGGING KEYS.............................................................................27

• ACTIVE CHANNEL......................................................................................27

• DWELL.........................................................................................................27

• HOLD...........................................................................................................27

OM-5000 uiiu

Page 3

3.2.3 PROGRAMMING MULTIPLEXER FUNCTIONS...........................................................28

3.2.3.1 MUX PROGRAM STORAGE ............................................................................28

3.2.3.2 CHANNEL TYPE KEYS (J,K,T,E,B,S,R,Volts, Pt & SKIP)................................28

3.2.3.3 VOLTAGE SCALING KEYS...............................................................................29

• VOLTAGE INPUT SCALING .......................................................................29

• MATCHING TRANSDUCERS TO THE LOGGER......................................29

• MATCHING A VOLTAGE TRANSDUCER..................................................29

• MATCHING A CURRENT TRANSDUCER.................................................30

• DATA SCALING (mX + b calculation).........................................................30

• EXAMPLE - VOLTAGE TRANSDUCER .....................................................31

• EXAMPLE - CURRENT TRANSDUCER.....................................................33

• PROGRAMMING EXAMPLE.......................................................................34

• DECIMAL POINT.........................................................................................34

3.2.3.4 TADJUST (TEMPERATURE ADJUSTMENT) ..................................................35

3.2.3.5 ALARM KEYS....................................................................................................36

• ALARM TABLE ............................................................................................36

• HIGH and LOW............................................................................................37

3.2.3.6 UNIT KEYS........................................................................................................38

• UNITS TABLES............................................................................................38

• UNITS ..........................................................................................................38

• C/F ...............................................................................................................39

3.3 DATA CACHE FUNCTIONS....................................................................................................40

3.3.1 CACHE KEYS.................................................................................................................41

3.3.1.1 CACHE ERASE KEY.........................................................................................41

3.3.1.2 CACHE FWD KEY.............................................................................................41

3.3.1.3 CACHE REV KEY..............................................................................................42

3.3.1.4 CACHE PRINT KEY ..........................................................................................42

APPENDIX A: CALIBRATION ..............................................................................................................43

• CALIBRATION INTERVAL..........................................................................................................43

• TV-10 and TV-40 MUX CALIBRATION.......................................................................................43

• VOLTS...................................................................................................................................44

• THERMOCOUPLES.............................................................................................................44

• COLD JUNCTION COMPENSATION CHECK....................................................................44

APPENDIX B: SPECIFICATIONS.........................................................................................................45

APPENDIX C: CONNECTING ACCESSORIES ....................................................................................49

THE ACCESSORY CARD.............................................................................................................49

• USING GLOBAL ALARM RELAYS ......................................................................................49

• USING THE EXTERNAL PRINT TRIGGER.........................................................................49

CONNECTING THE 20-RELAY ALARM CARD (OPTION)..........................................................50

CHANGING FIRMWARE EPROMS..............................................................................................51

OM-5000 uiiiu

Page 4

Introduction

This User’s Guide explains how to use Omega’s OM-5000 series Dataloggers.

This manual is written for users of varied experience. If a section covers information

you already know, feel free to skip to the next section.

•• Terms used in this Manual

In this manual, the following definitions are used for special terms and symbols.

• Informs the user that the note identifies conditions or practices that

could result in personal injury or damage to property other than the

equipment.

• Informs the user that the note identifies conditions or practices that

could result in damage to the equipment.

• Informs the user that the note includes important information.

• Thermocouple may be referred to as T/C.

• Both the OM-5100 and OM-5200 may be referred to as “Logger”.

•• Product Symbols

The following symbols may be present on the Product:

• Direct Current (DC) Power

• Alternating Current (AC) Power

• CAUTION: Whenever this internationally recognized symbol is used

on the product, additional information concerning that particular

feature or function appears in the manual.

• Frame or Chassis Terminal

• Battery Charger protected throughout by double or reinforced

insulation.

• Indoor use only. For electric-shock protection, always operate the

battery charger in a protected, indoor location.

• Thermocouple connection

OM-5000 uivu

Page 5

Operator Safety Information

The safety information in this summary is for the benefit of operating personnel.

Warnings and Cautions will also be found throughout the manual where they apply.

PRODUCT USAGE WARNINGS:

For fire and electric shock protection, DO NOT connect the input channels to objects at

elevated electrical potential. The common terminal of each measurement input channel

is not isolated from the common terminal of the input power connector and the RS-232

serial data port while that channel is being measured.

This interconnected common circuitry is not connected to ground or to the

enclosure of the Logger. If the Logger is interconnected to a desktop computer,

its internal circuitry very likely could be connected to ground through the serial

data port of the computer. The Logger enclosure and the measurement circuitry

provide functional isolation of the measurement and data circuitry sufficient to

allow for small electrical noise-related potentials to occur. This functional

isolation is not intended for electrical safety isolation. Therefore for electricshock protection and to prevent fire and damage to data interconnect wiring due

to high currents, the input channels must not be connected to objects at elevated

electrical potential.

• Do not operate the Logger in flammable or explosive atmospheres. Such usage

constitutes a fire or explosion risk.

• For electric-shock protection, only operate the AC power adapter indoor

location.

• For continued fire and electric shock protection, use only the specified power

adapter.

• For continued fire protection, use only the specified optional DC power cable,

which incorporates a two-ampere fuse.

A two-ampere fuse is incorporated in the cigarette lighter plug which is part of

the DC power cable. This fuse provides overcurrent protection should a short or

overload circuit occur in the Logger or the DC power cable.

OM-5000 uvu

Page 6

For protection of the Logger itself, observe the following:

• Do not immerse the Logger in liquids.

• Do not subject the Logger to sharp impacts or drops.

• Do not expose the Logger to corrosive environments.

• Extended exposure to temperatures below the specified minimum may

damage the battery (optional external rechargeable battery pack only).

• Extended exposure to temperatures above the specified maximum may

damage the Logger itself or its optional external rechargeable battery pack.

• Do not excessively stress the power input, the RS-232 serial data, and the

accessory port connections.

The warranty will not cover damage caused by neglect or abuse of this product.

To maintain the safety features incorporated in this product, operation must be in

strict compliance with the requirements specified herein.

OM-5000 uviu

Page 7

1.0 GENERAL INFORMATION AND FEATURES

This section explains the Features for the OM-5100 (Bench Top) and OM-5200 (Wall

Mount) Systems.

1.1 INTRODUCTION & SYSTEM OPERATION

Omega's digital Logger can be furnished with a variety of multiplexers and other

circuitry for various logging tasks.

The Logger is completely self-contained and equipped with a built-in 24-column

thermal printer, an alphanumeric keyboard, a 16-digit vacuum-fluorescent display, a

real-time clock (with rechargeable 30-day battery backup), and an RS-232 serial data

port for connection to a computer serial port.

An AC Power Adapter provides 12 V DC for powering the Logger. North American and

selected international configurations of this power adapter are available.

The Logger includes a Data Cache memory that provides temporary storage of logged

data for reviewing before printing or uploading to a remote computer. RS-232 cable for

connecting to a computer, Accessory board with an external print trigger input; Relay

contact signal outputs for high and low alarms; and an optically isolated serial interface

for use with optional accessories such as the 20-relay alarm card. Also available are:

carrying case, and cables for operating from an automotive 12V DC source.

The Logger can be programmed directly from the keyboard or from a remote computer.

Programmable functions include:

1. Current date, time, and log interval.

2. The contents and format of the printout.

3. The configuration of each channel to match the kind of sensor to be used, such

as thermocouple type, voltage input, and pH probes.

4. The number of channels scanned and which channels are to be skipped. Also

the dwell time between channels and a hold command for continuous logging of

one selected channel.

5. Scaling the display reading to accommodate various input sensors by

multiplying, adding, or subtracting (mX+b).

6. High and low alarm points.

7. Engineering units.

8. Default unit of temperature (C or F).

9. Nonvolatile storage of the configuration for your system in an electrically

programmed ROM.

OM-5000 u1u

Page 8

1.1.1 LOGGER MAINFRAME

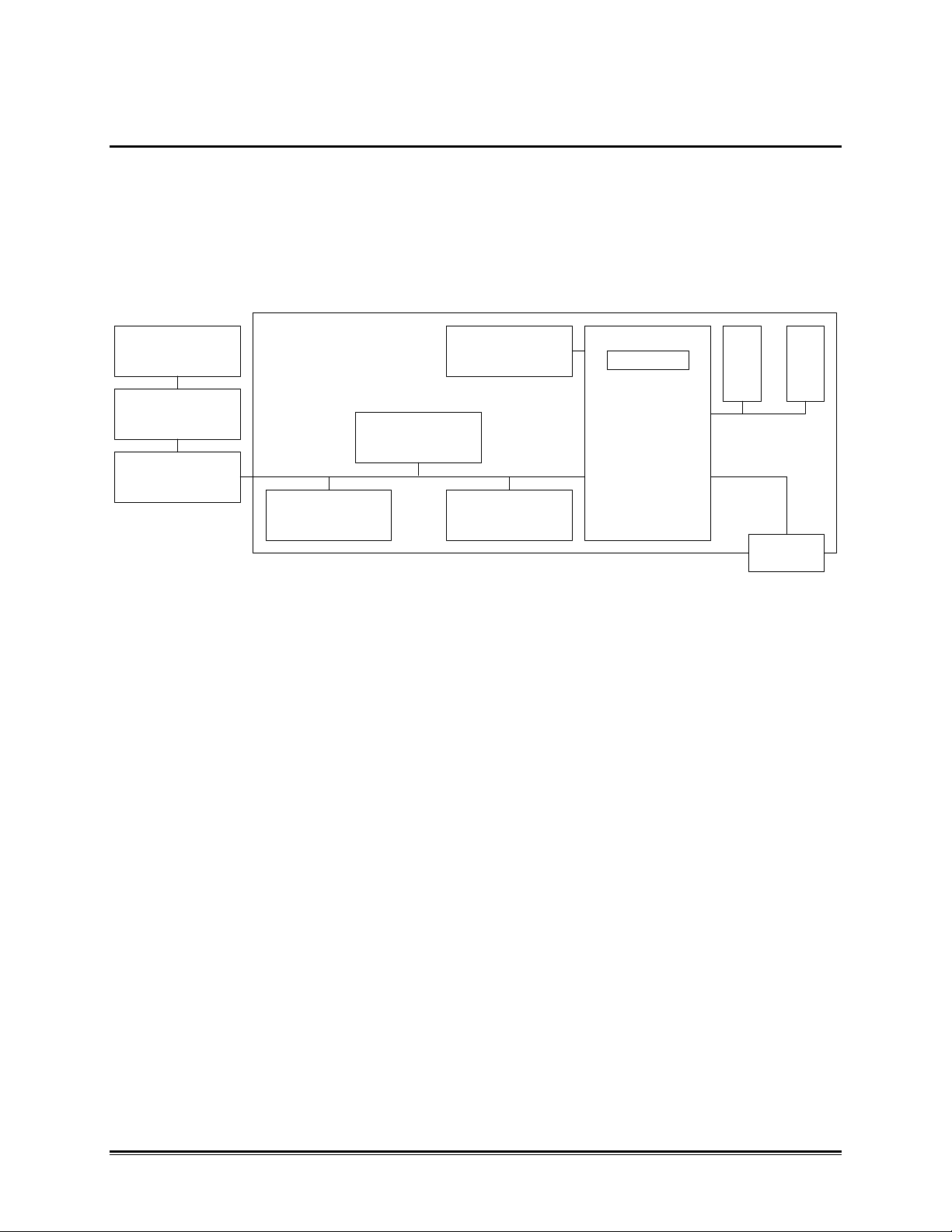

The Logger Mainframe, as diagramed in Figure 1-1 consists of a microprocessor with

internal EEPROM and external RAM and ROM. The printer, display, and real-time clock

subsystems communicate with the CPU over a serial bus. The processor also receives

data from a 24-key keyboard and is capable of communication to external computers or

devices through the RS-232 port. The serial (SPI) bus is also used to communicate

control and input information to the MUX, Accessory, and Alarm cards.

ALARM

CARD

ACCESSORY

POD

MULTIPLEXOR

DISPLAY

SPI BUS

PRINTER CLOCK

Figure 1-1: Mainframe Block Diagram

KEYBOARD

EEPROM

CPU

R

A

M

RS-232

R

A

M

OM-5000 u2u

Page 9

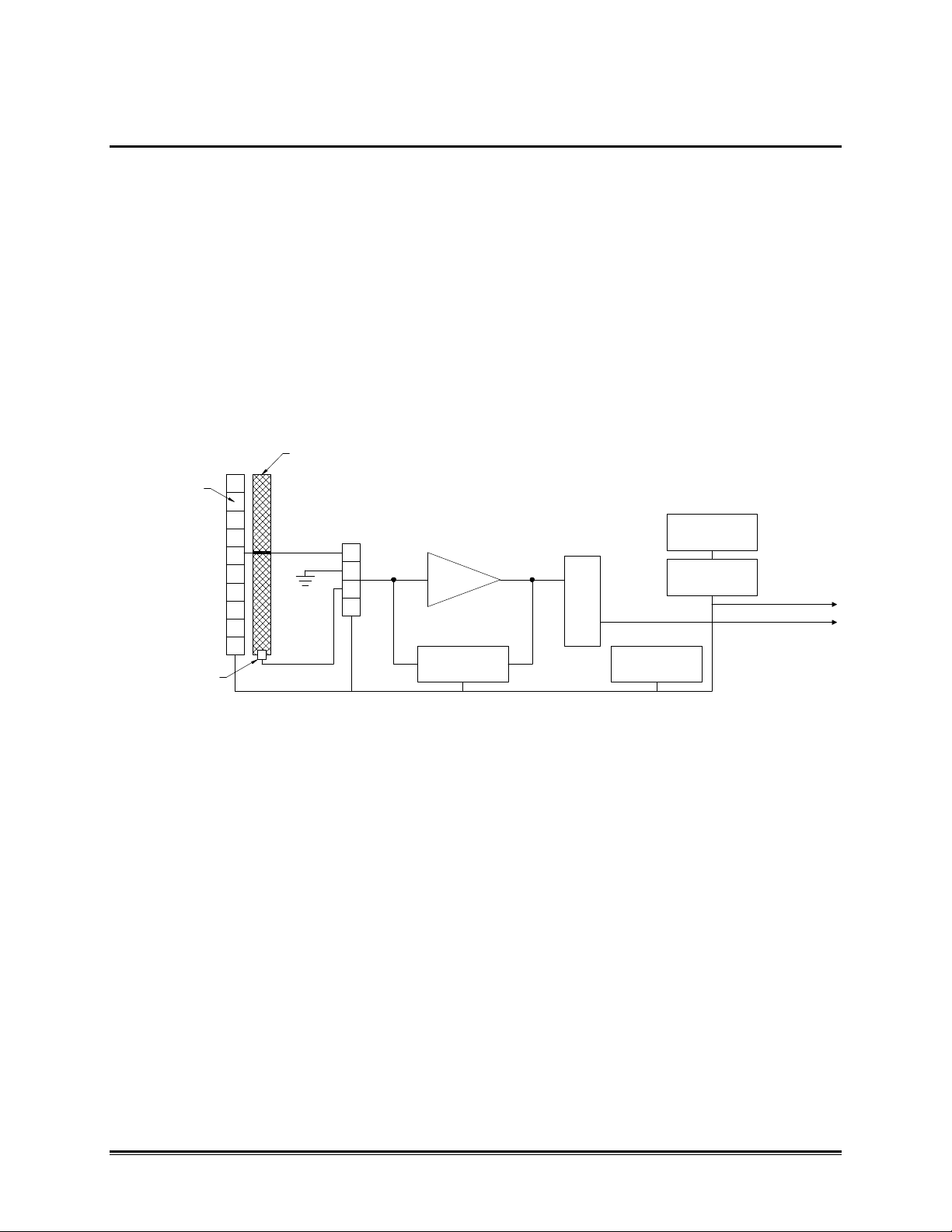

1.1.2 MULTIPLEXER

Multiplexers perform the signal conditioning functions for the Logger. The multiplexer

shown in the block diagram below is designed for use with thermocouple and voltage

inputs. Relays select which input (voltage or thermocouple) is to be read. The input

signals are amplified and digitized by the A/D converter. Provision is also made for

measuring the temperature at the thermocouple attachment point and the system zerovoltage input. Using these parameters, thermocouple readings are compensated for

junction temperature, and offset zero drifts are canceled. The CPU controlled range

switch is set according to the type of input that is selected. Information as to the

channel type, display units, and alarm points is stored in EEPROM in the multiplexer,

allowing you to change multiplexers without losing channel configuration information.

The plug-in accessory board and optional Alarm Cards can be plugged into the

multiplexer.

THERMAL BAR

RELAY MUX

COLD JUNCTION

SENSOR

SS MUX

AMP

A/D

RANGE

SWITCH

EEPROM

Figure 1-2: Typical Multiplexer Block Diagram

ALARM

CARD

ACCESSORY

SPI BUS

TO CPU

OM-5000 u3u

Page 10

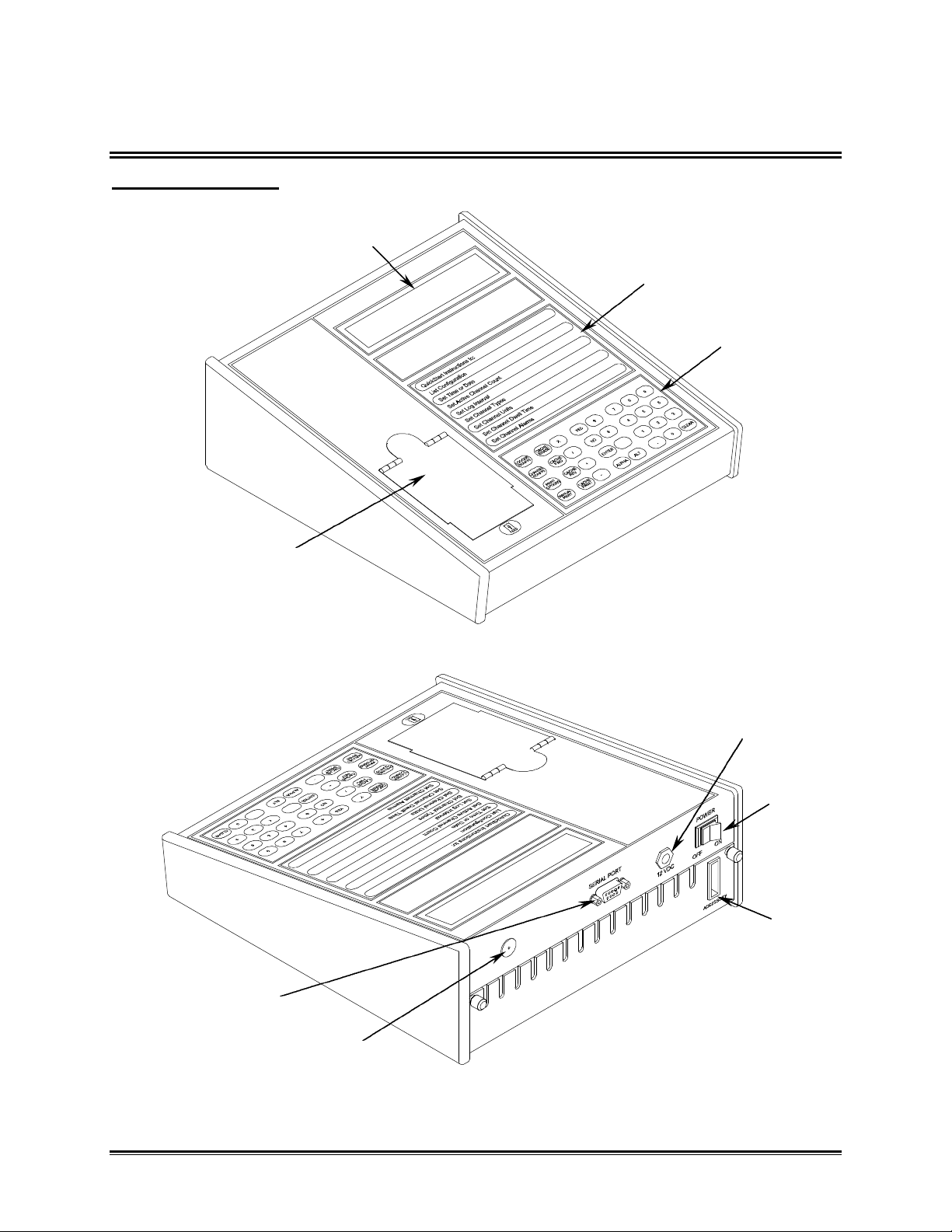

1.2 LOGGER EXTERIOR FEATURES

OM-5100 Features:

DISPLAY

PAPER COVER

QUICKSTART

INSTRUCTIONS

KEYPAD

RS-232 CONNECTOR

Figure 1-3

12V POWER

JACK

POWER

SWITCH

OPTIONAL

ACCESSORY

CONNECTOR

HORN

Figure 1-4

OM-5000 u4u

Page 11

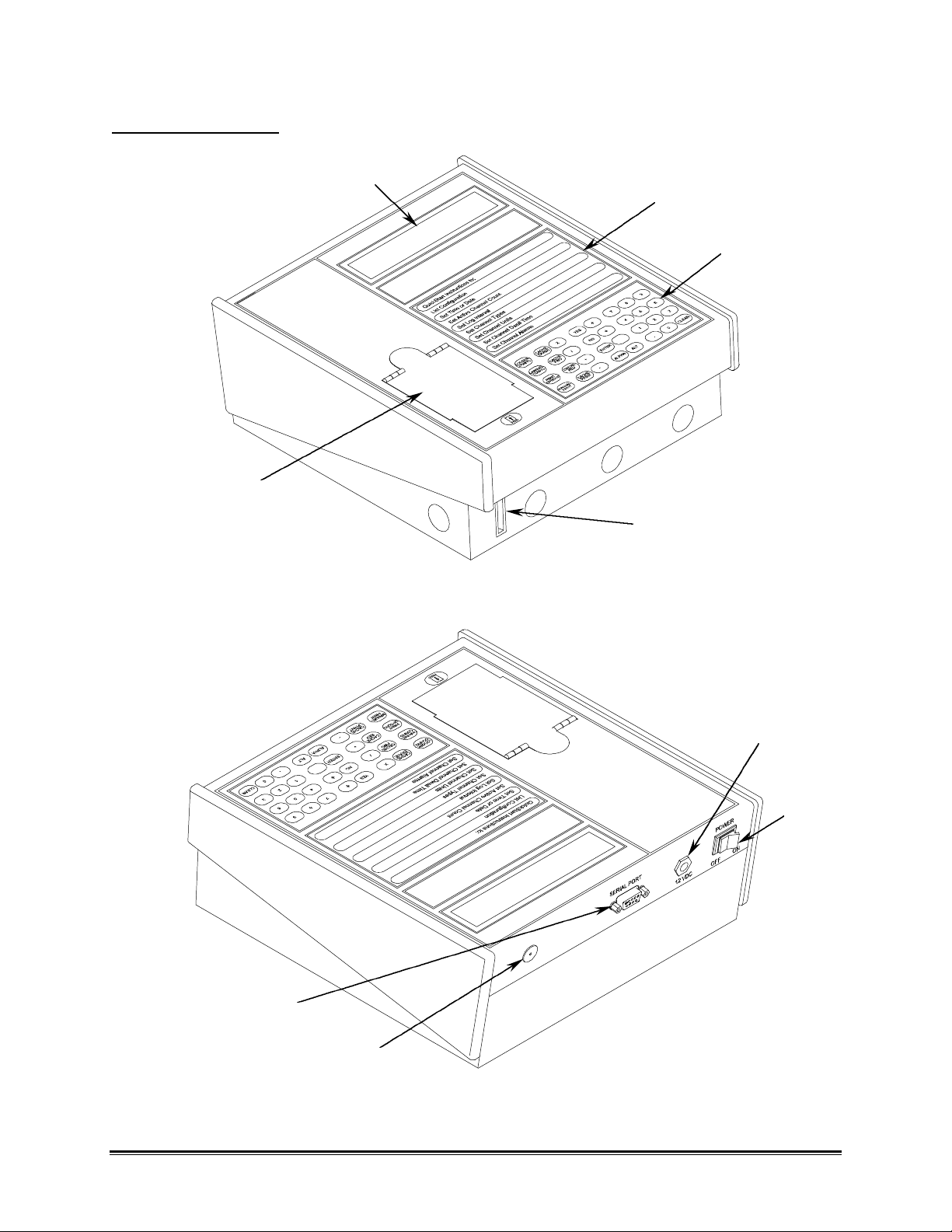

OM-5200 Features:

PAPER COVER

DISPLAY

QUICKSTART

INSTRUCTIONS

KEYPAD

OPTIONAL

ACCESSORY

CONNECTOR

Figure 1-5

12V POWER

JACK

POWER

SWITCH

RS-232 CONNECTOR

HORN

Figure 1-6

OM-5000 u5u

Page 12

2.0 PREPARATION AND SET-UP

This section provides the necessary information to set the Logger up for proper

operation.

2.1 UNPACKING

Unpack the unit carefully. Check for options and accessories that may have been

packed separately. Retain the shipping carton for reshipment (for recalibration or any

other purpose).

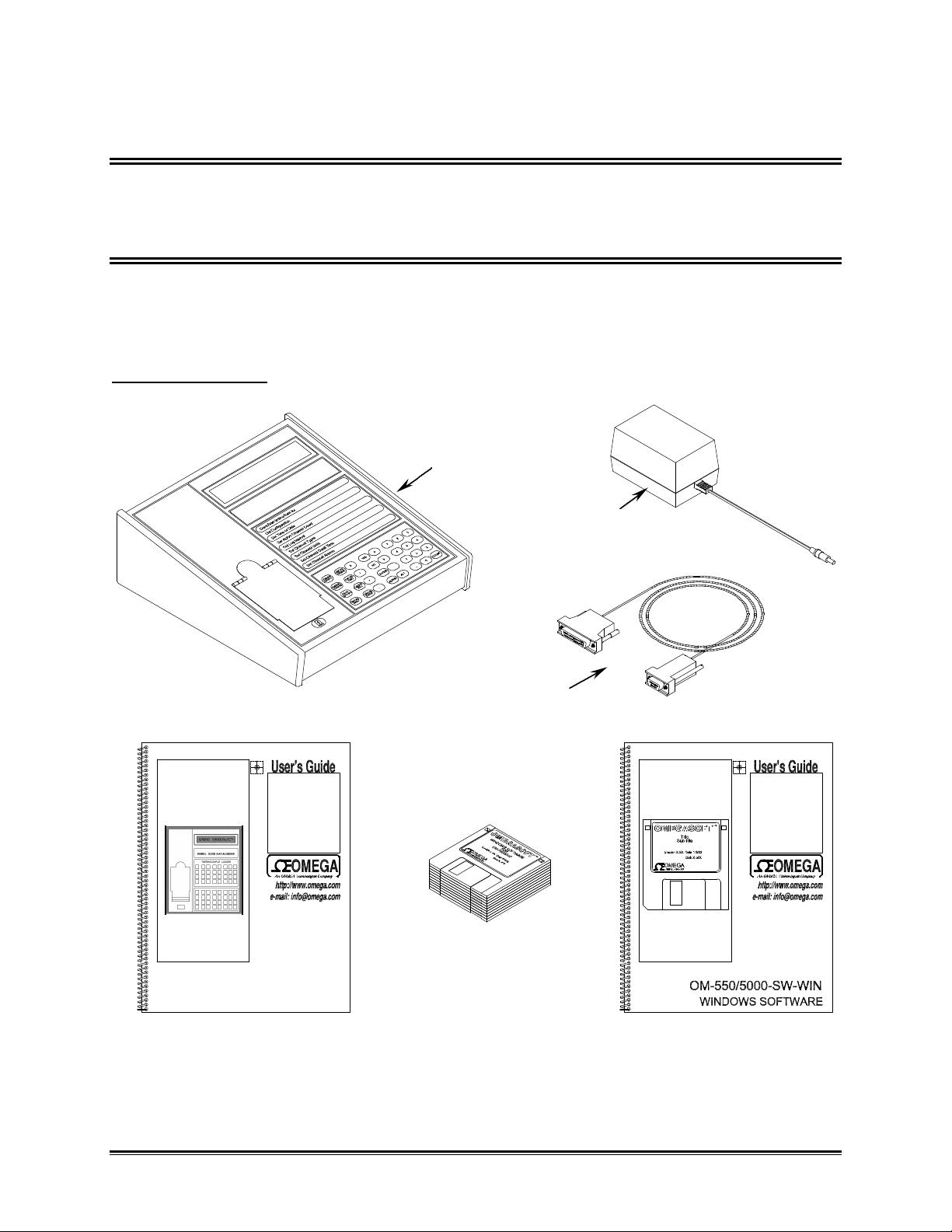

OM-5100 System:

OM-5100

AC POWER

ADAPTER

OM-5100 and OM-5200

Programmable Dataloggers

OM-5000SERIES

USERS GUIDE

RS-232 CABLE

OM-550/5000

WINDOWS SOFTWARE

OM-550/5000 WINDOWS

SOFTWARE USERS GUIDE

Figure 2-1: OM-5100 System

OM-5000 u6u

Page 13

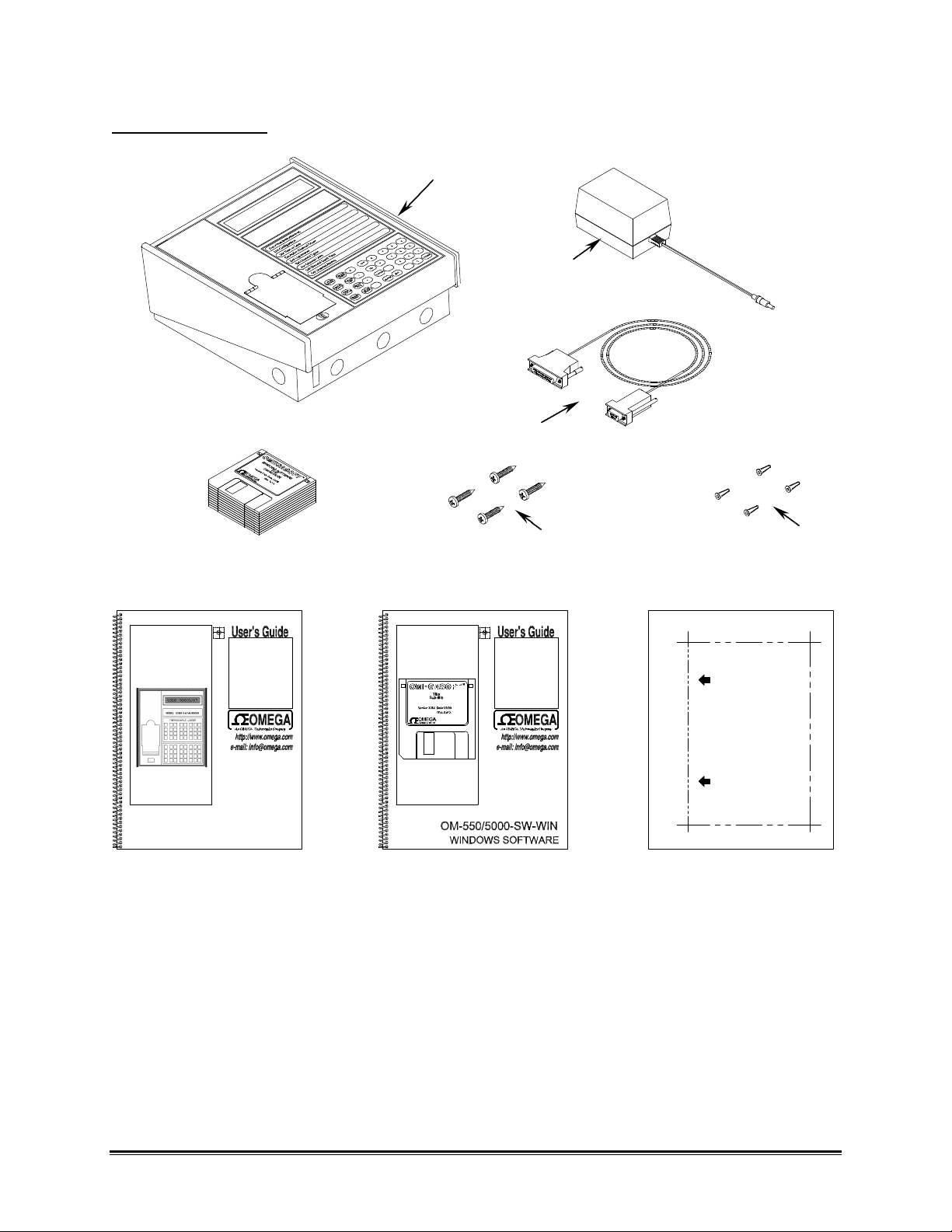

OM-5200 System:

DATAWORKER 10/40 WALL TEMPLATE

OM-5200

AC POWER

ADAPTER

RS-232 CABLE

OM-550/5000

WINDOWS SOFTWARE

OM-5100 and OM-5200

Programmable Dataloggers

OM-5000SERIES

USERS GUIDE

WALL MOUNT

SCREWS (4)

OM-550/5000 WINDOWS

SOFTWARE USERS GUIDE

Figure 2-2: OM-5200 System

WALL MOUNT

PLUGS (4)

THIS SIDE UP

OM-5200

WALL MOUNT TEMPLATE

OM-5000 u7u

Page 14

2.2 QUICK HOOK UP

If you have an OM-5200 System or do not want to attach your Logger to the wall, go directly to

the section 2.4 CONNECTING TRANSDUCER INPUTS TO MULTIPLEXER.

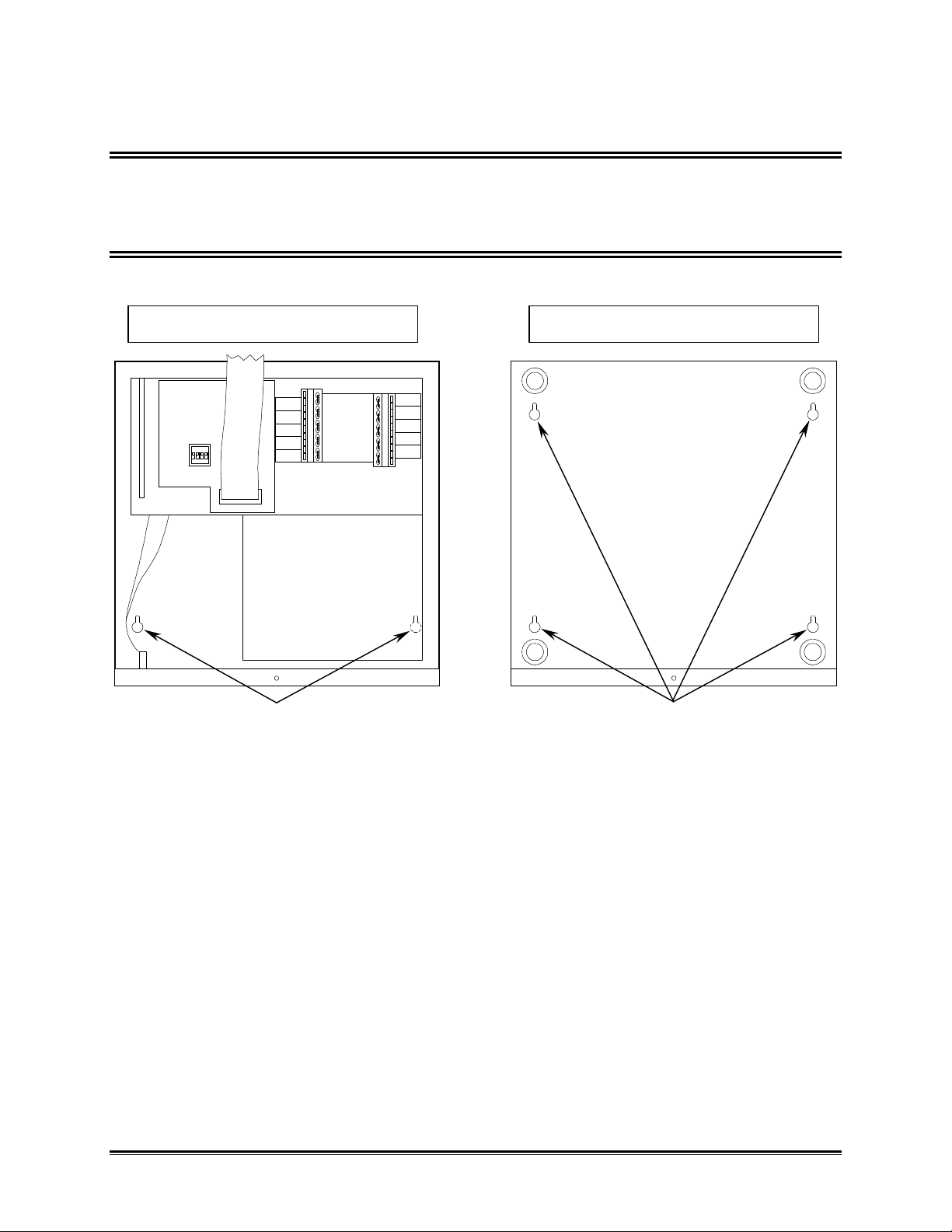

2.3 ATTACHING A OM-5200 TO THE WALL

This procedure is for the OM-5200 ONLY.

INTERNAL VIEW EXTERNAL VIEW

MOUNTING

HOLES

Figure 2-3: Mounting Holes

MOUNTING

HOLES

Locate the Wall Mount template. Observe the indicated setbacks from obstructions

when placing the template. Mark four mounting hardware locations on the wall. Drill

holes for the hardware and insert the anchors into the drilled holes. Tighten the screws

into the anchors until only about 1/4 inch is exposed. Slide the key-hole-shaped

mounting holes in the bottom of the Logger over the screws. It is important that there be

space around the Logger for the printout paper.

The Knock-out tabs in the base may be used for conduit entry if more permanent

installation is desired.

OM-5000 u8u

Page 15

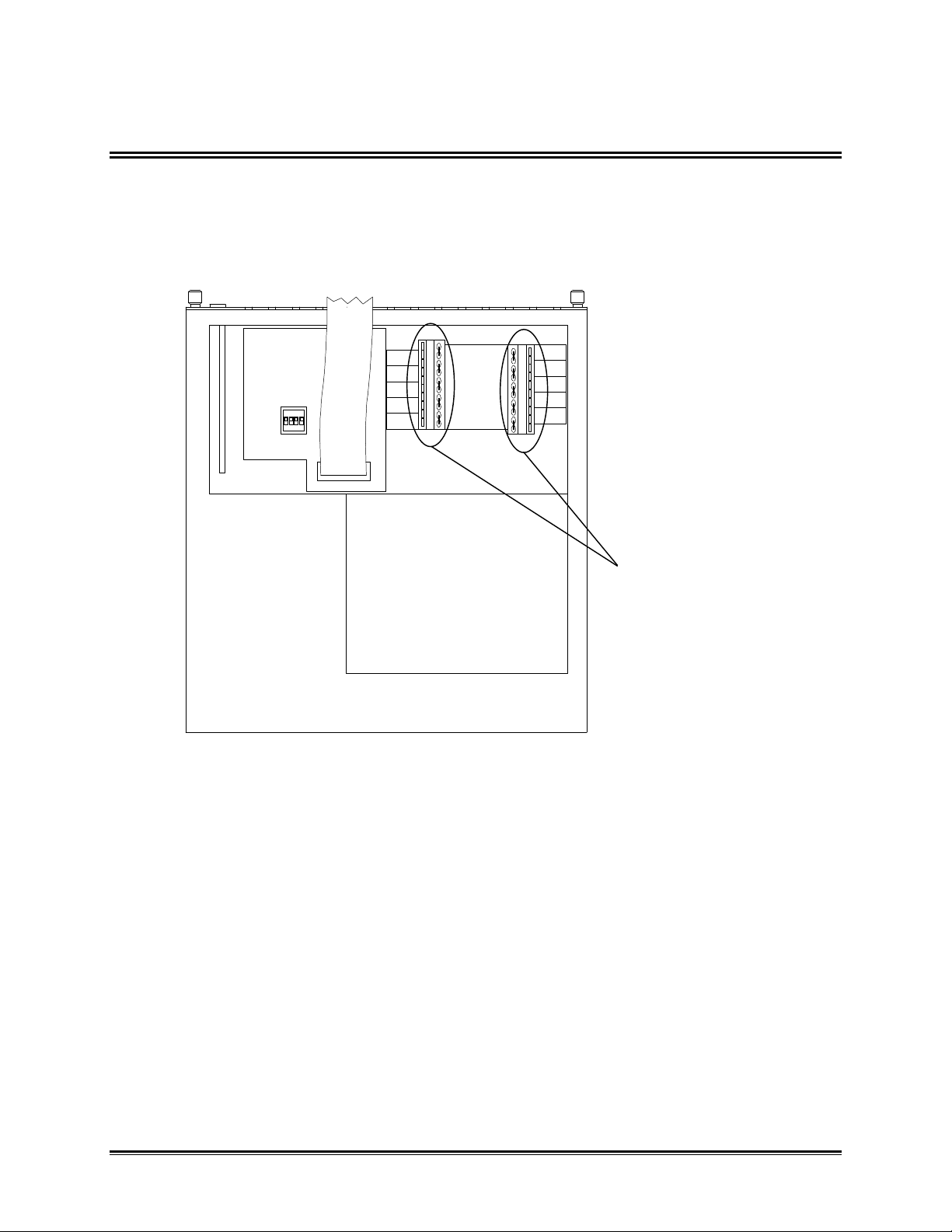

2.4 CONNECTING TRANSDUCER INPUTS TO MULTIPLEXER

1. If you have an OM-5100, place it on a bench in the normal operating position

and loosen the two MUX attachment thumbscrews on the rear panel. Carefully

slide the Mainframe forward exposing the green quick-disconnect terminal strips.

Now proceed to step #3.

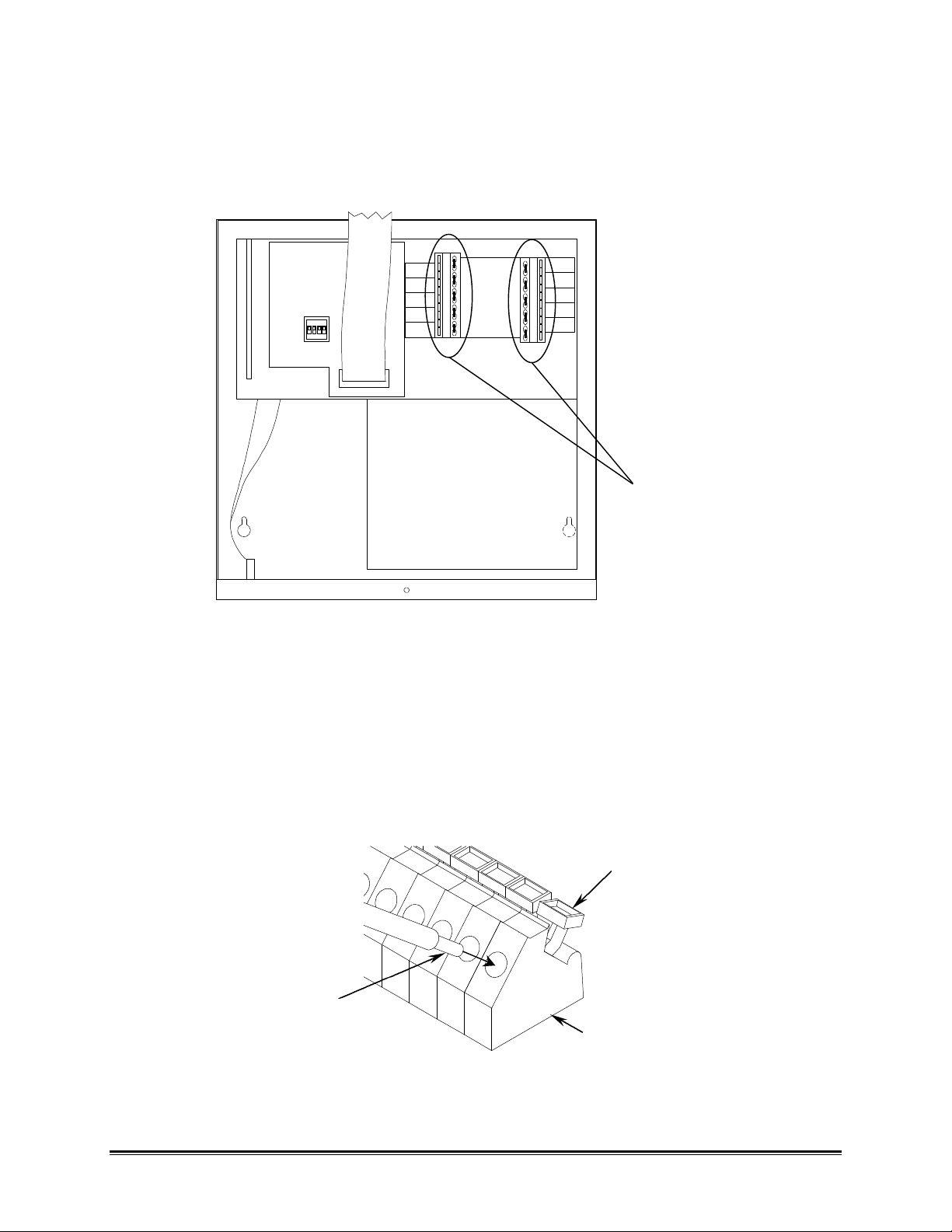

CHANNEL

NUMBER

QUICK-DISCONNECT

TERMINALS

Figure 2 4: Quick-Disconnect Terminals

OM-5000 u9u

Page 16

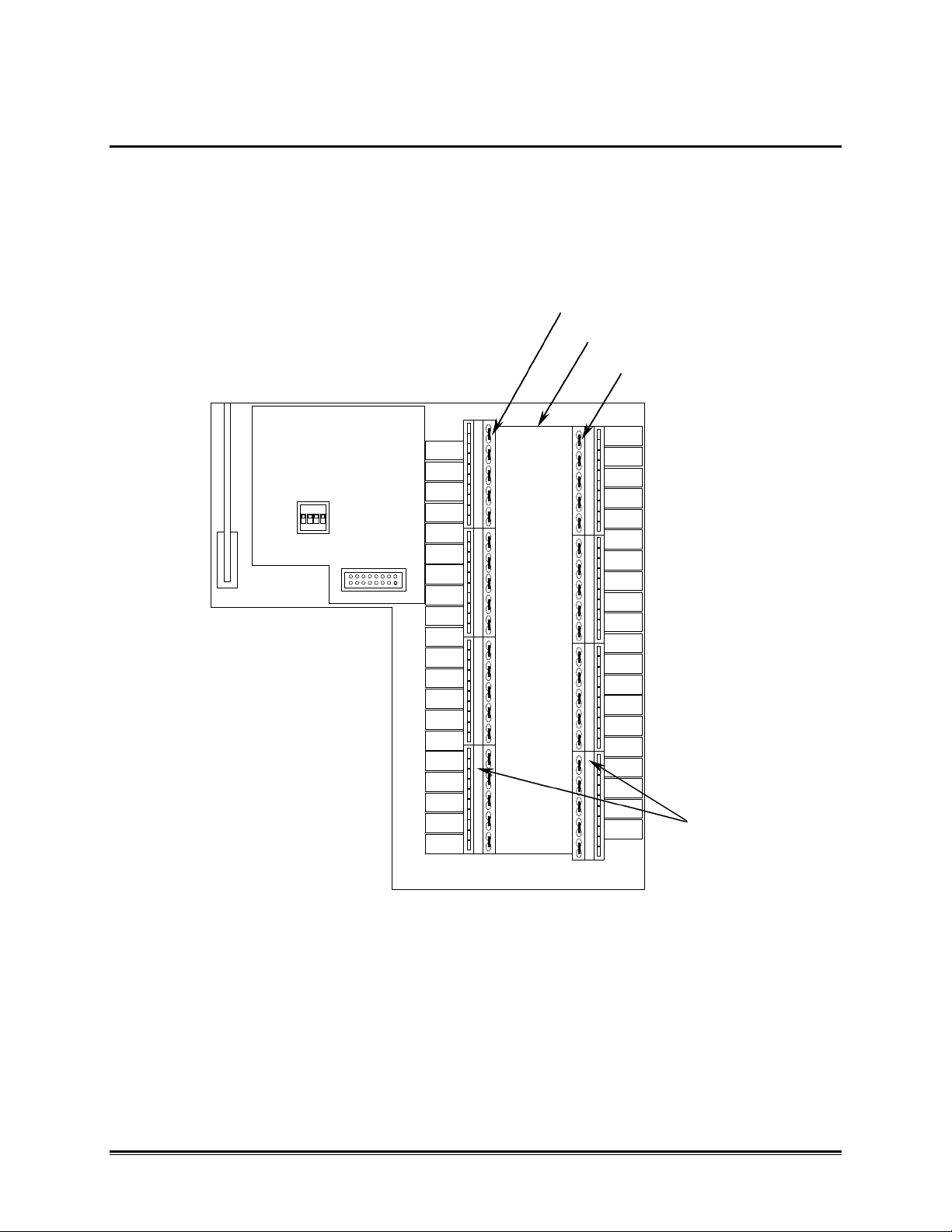

2. If you have a OM-5200, first loosen the thumbscrew on the front of the

mainframe and carefully lifting the Mainframe up, exposing the green quickdisconnect terminals.

CHANNEL

NUMBER

QUICK-DISCONNECT

TERMINALS

Figure 2- 5: Quick-Disconnect Terminals

3. Strip 1/4" of insulation from wire ends.

4. Connect each transducer input by pressing down the corresponding small

orange terminal tab on the green terminal strip, inserting the wire into the hole

(approx. 1/2") and releasing the tab. Make sure the wire is pushed far enough

into the hole to engage the locking device. This can be tested by lightly pulling

on the wire after insertion. A problem will occur if the wire is not stripped back far

enough (1/4"), and insulation interferes with the connection.

TERMINAL TAB

WIRE

TERMINAL STRIP

Figure 2-6: Connecting a Terminal

OM-5000 u10u

Page 17

2.4.1 CONNECTING TRANSDUCERS TO THE TV-10/40 MUX

CHANNEL NUMBERS

The TV-10 and TV-40 multiplexers are designed to accept any of type J,K,B,S,R, or T

thermocouples. Channels are numbered from top to bottom and labeled on the Thermal

bar. For best accuracy the thermocouple leads should be placed as close as possible

to the thermal bar and covered to eliminate any drafts or thermal gradients. Channel

type (either J,K,B,S,R, o or V) must be programmed from the front panel (refer to

section 3.2.3.2 CHANNEL TYPE KEYS (J,K,T,E,B,S,R,Volts, Pt & SKIP)).

CHANNEL #2

THERMAL BAR

CHANNEL #1

QUICKDISCONNECT

TERMINALS

Figure 2-7: TV-40 Multiplexer Quick-Disconnect Terminals and Thermal Bar

OM-5000 u11u

Page 18

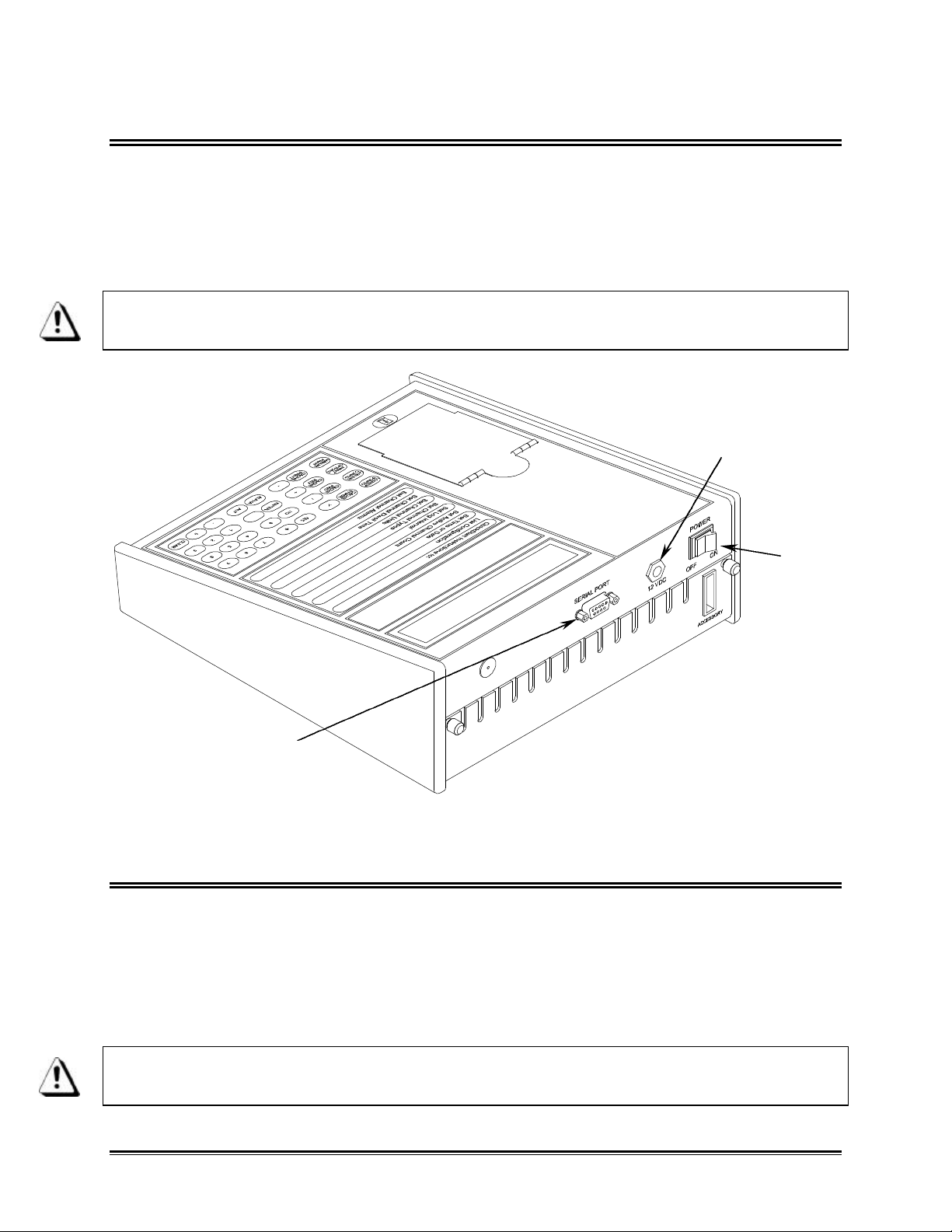

2.5 CONNECTING IN THE AC POWER ADAPTER

1. Turn the power switch on the rear panel of the Logger to the “OFF” position.

2. Plug the small DC connector of the power supply into the 12V power connector

on the rear panel.

3. Plug the AC Power Adapter into the wall outlet.

For continued fire and electric-shock protection, use only the specified AC Power

Adapter.

12V POWER JACK

POWER

SWITCH

RS-232 SERIAL PORT

Figure 2-8: OM-5100 Rear Panel

2.6 CONNECTING OPTIONAL DC POWER CABLE

1. Turn the power switch on the rear panel to the “OFF” position.

2. Plug the small DC connector of the 12V DC Cable into the DC connector on the

rear panel.

3. Plug the large DC cable connector into a 12V DC cigarette lighter power outlet,

whether in the optional rechargeable battery pack or in a motor vehicle.

For continued fire protection, use only the specified DC power cable which

contains a two-ampere fuse.

OM-5000 u12u

Page 19

2.7 GROUNDING THE ENCLOSURE

WINDOW

The rear panel incorporates a threaded chassis-connection point, identified with the "chassis

connection" symbol, which may be used for grounding the enclosure should the user desire to do so.

This terminal is not required to be used for "protective grounding" because the unit is only powered

by the low-voltage Power Adapter or optional rechargeable battery pack. Also, the measurement

circuits must not be connected to hazardous circuits. The enclosure is functionally isolated from the

internal circuits.

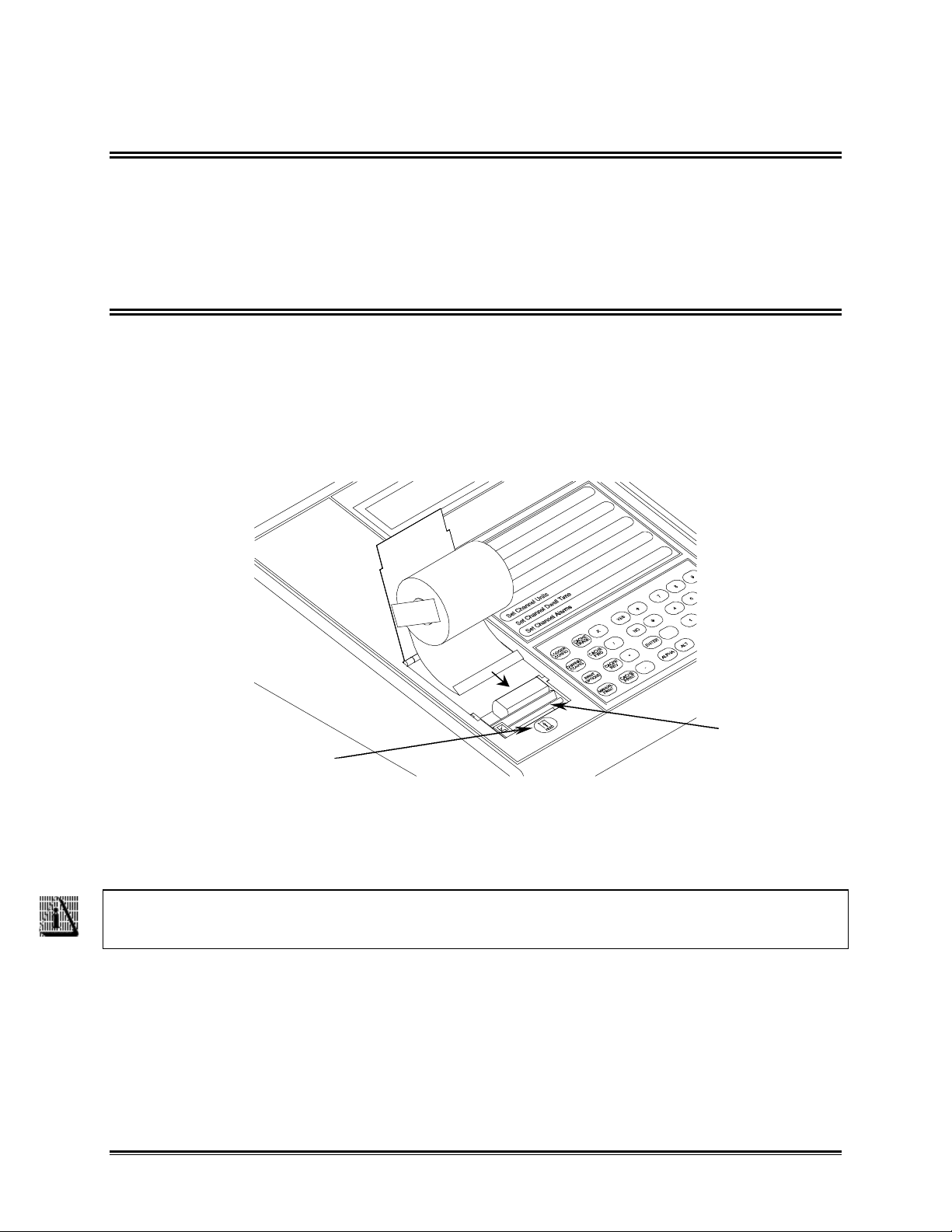

2.8 PAPER INSTALLATION

1. Unwind several inches of paper from the paper roll.

2. Fold the end of the thermal paper over creating a straight flat edge. This creates

a strong paper edge and allows the paper properly center in the printer when

inserting it into the rear paper slot on the printer. As shown in Figure 2-9 the

thermally sensitive side (printing side) of the paper is down.

FRONT

PAPER “FEED” KEY

Figure 2-9

3. Insert the paper into the rear printer slot as shown in Figure 2-9. Turn the Logger

“ON”, then press and hold the FEED key to feed the paper through the printer.

Paper orientation is important because only one side is coated for thermal

printing.

4. After the paper appears in the front window, pull several inches through.

5. Test the operation of the printer & paper-feed mechanism by turning the unit

“OFF” and back “ON”. When finished examine the printed messages for clarity.

OM-5000 u13u

Page 20

2.9 RS-232 FUNCTIONS

The Logger is equipped with an RS-232 communication interface. The RS-232 port is configured 8

bits, 1 stop, 1 start and no parity. Baud rate is selected from the front panel. (Refer to section

3.2.2.4 BAUD RATE).

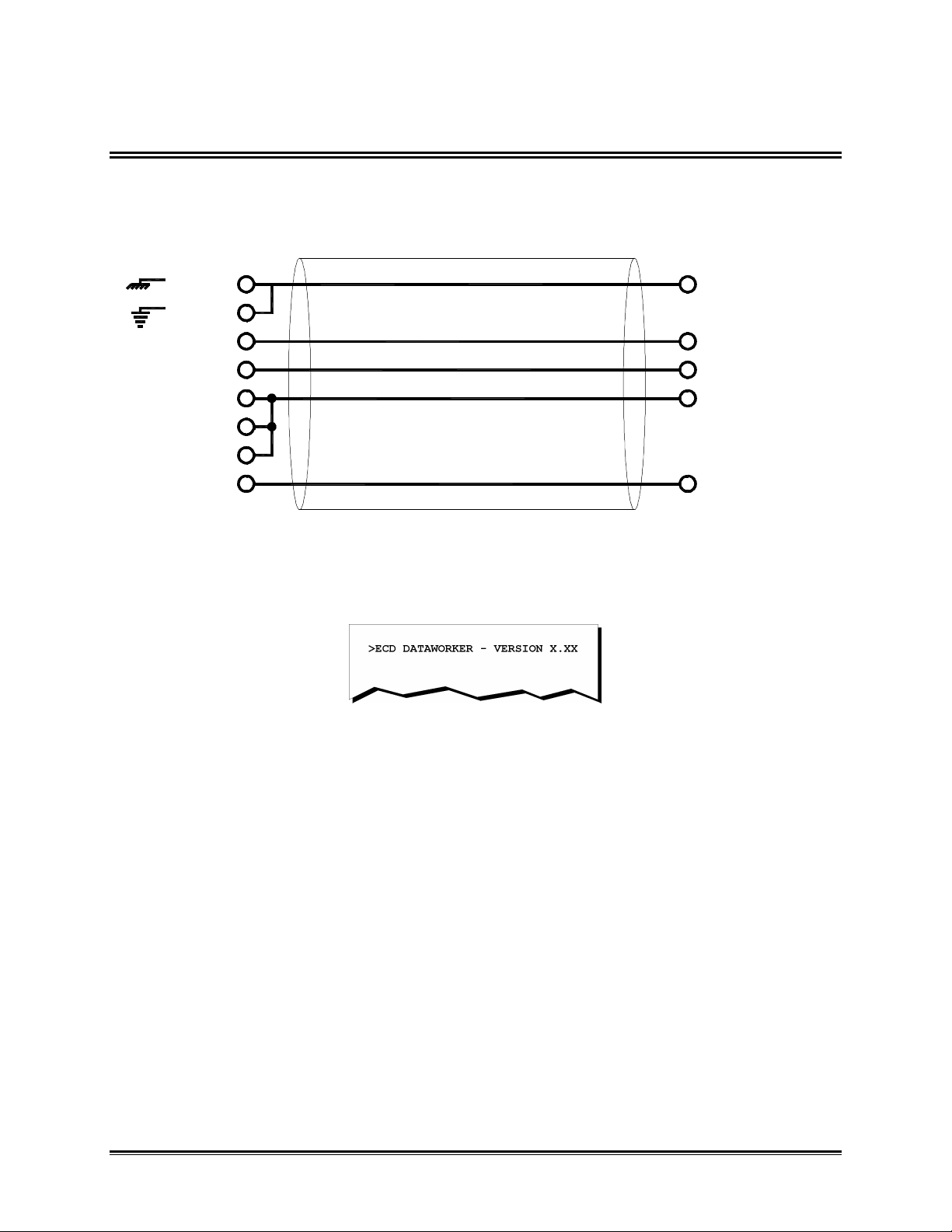

1

5 GND

7

RXD

TXD

DSR

CTS

DCD

DTR 4 DTR

Interface operation can be tested by connecting the terminal, then turning on the Logger. A sign-on

message similar to the following should appear:

3

2

6

5

8

20

TXD2

RXD3

DSR6

Figure 2-10: R2-232 Cable Wiring

Figure 2-11: Sign on Message

OM-5000 u14u

Page 21

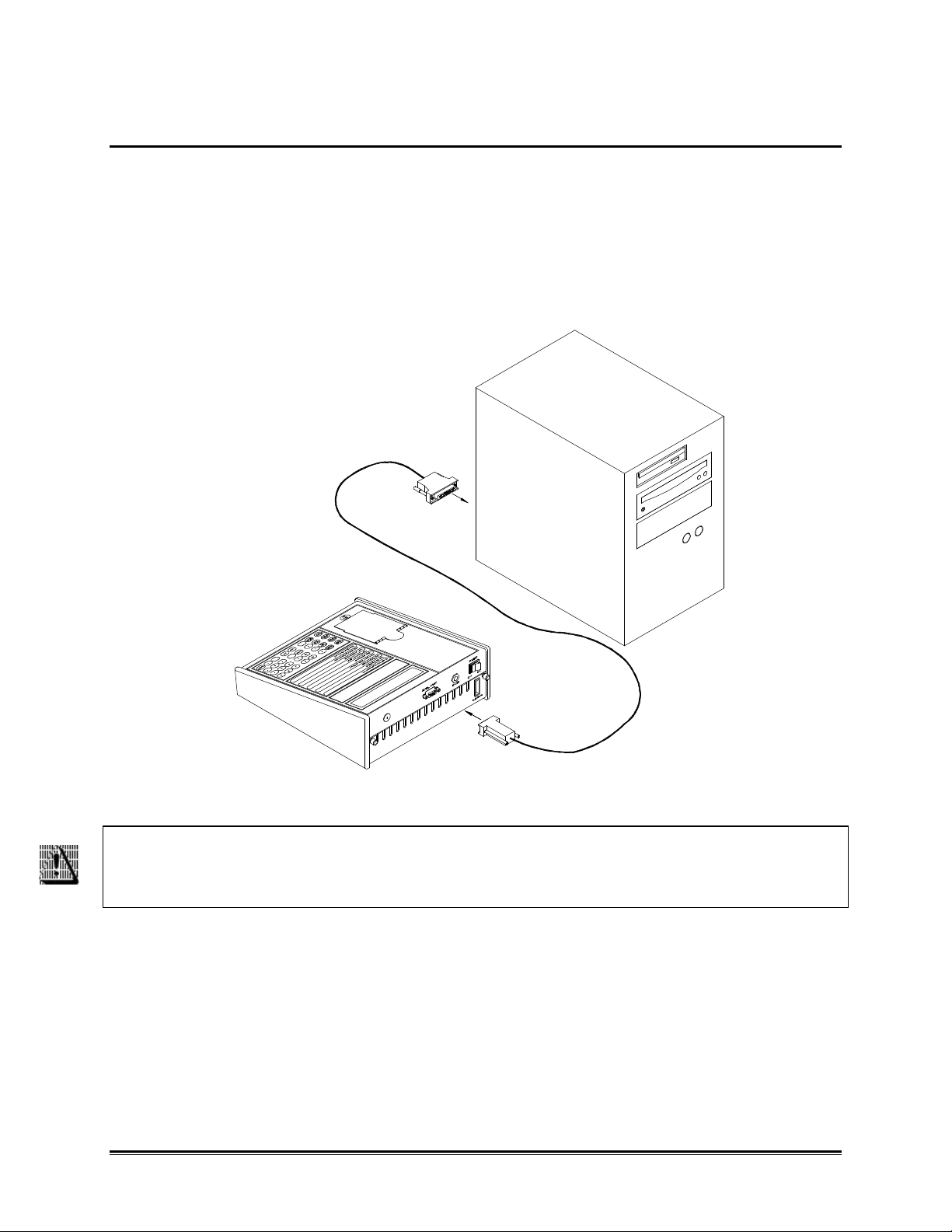

2.9.1 DATA PORT CONNECTION

When the Logger is logging, data is saved in the internal cache RAM. The OM550/5000 Windows software supplied with the Logger is used to transfer this data

through the RS-232 Serial Port to a PC for analysis and storage. Prior to transferring

data, the Logger must be connected to a PC with the supplied RS-232 cable assembly.

The cable is fitted with a 9-pin connector for the Data Port on Logger and a 25-pin

connector for the PC COM port.

Figure 2-12

To minimize danger to personnel, and to avoid ground loops which could affect

measurement accuracy, never connect the Logger to a PC and to the signal

inputs simultaneously!

OM-5000 u15u

Page 22

3.0 OPERATION

DISPLAY

The following section covers the functionality and programming of the Logger for proper operation.

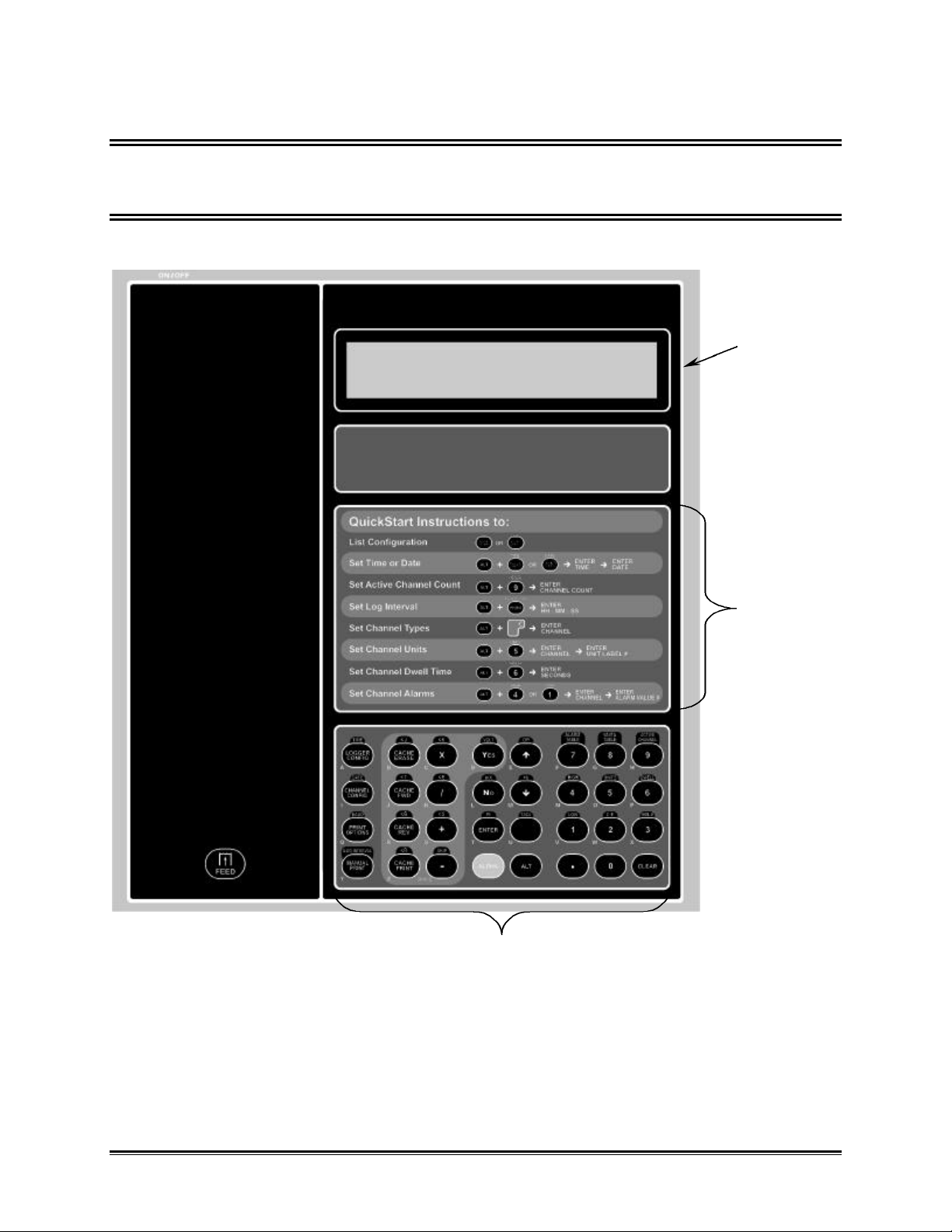

3.1 FRONT PANEL

The front panel includes a Display, Keypad, and Quick Start Instructions.

KEYPAD

Figure 3-1

QUICK START

INSTRUCTIONS

OM-5000 u16u

Page 23

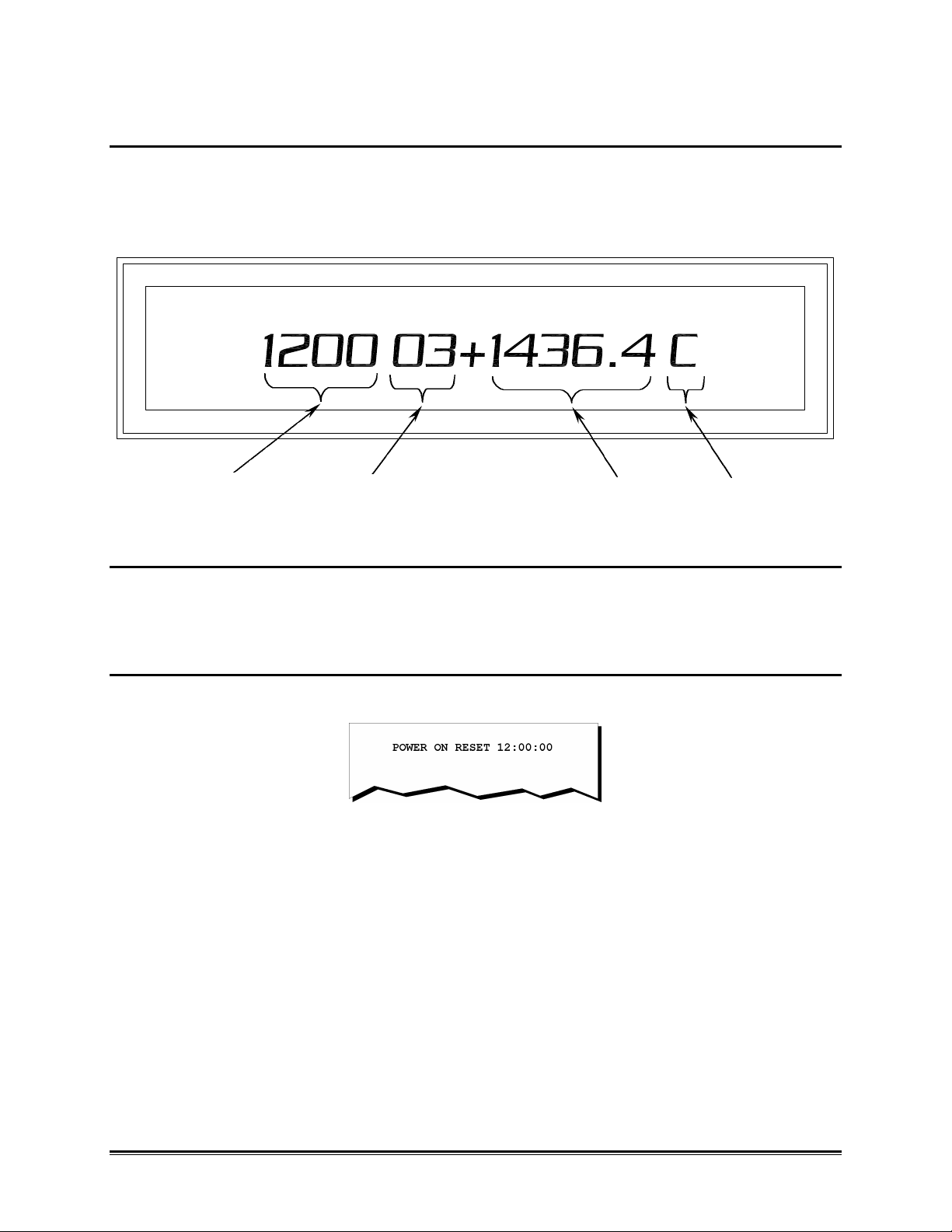

3.1.1 DISPLAY

The Logger display is used for displaying current channel data and prompting programming. When

logging, the display indicates the current time of day, channel number sign, channel data value, and

engineering units of the data. During programming the operator is prompted by the display for

information about the function being programmed.

DATE

CHANNEL

DATA UNITS

Figure 3-2

3.1.2 PRINTOUTS

The Logger incorporates a built-in 24 column printer that is an integral part of the

operation, The printer records data, prints out Logger program configuration and alarm

messages.

3.1.2.1 POWER UP

When the Logger is initially turned on, the power up message is printed.

Figure 3-3: Power Up Printout

OM-5000 u17u

Page 24

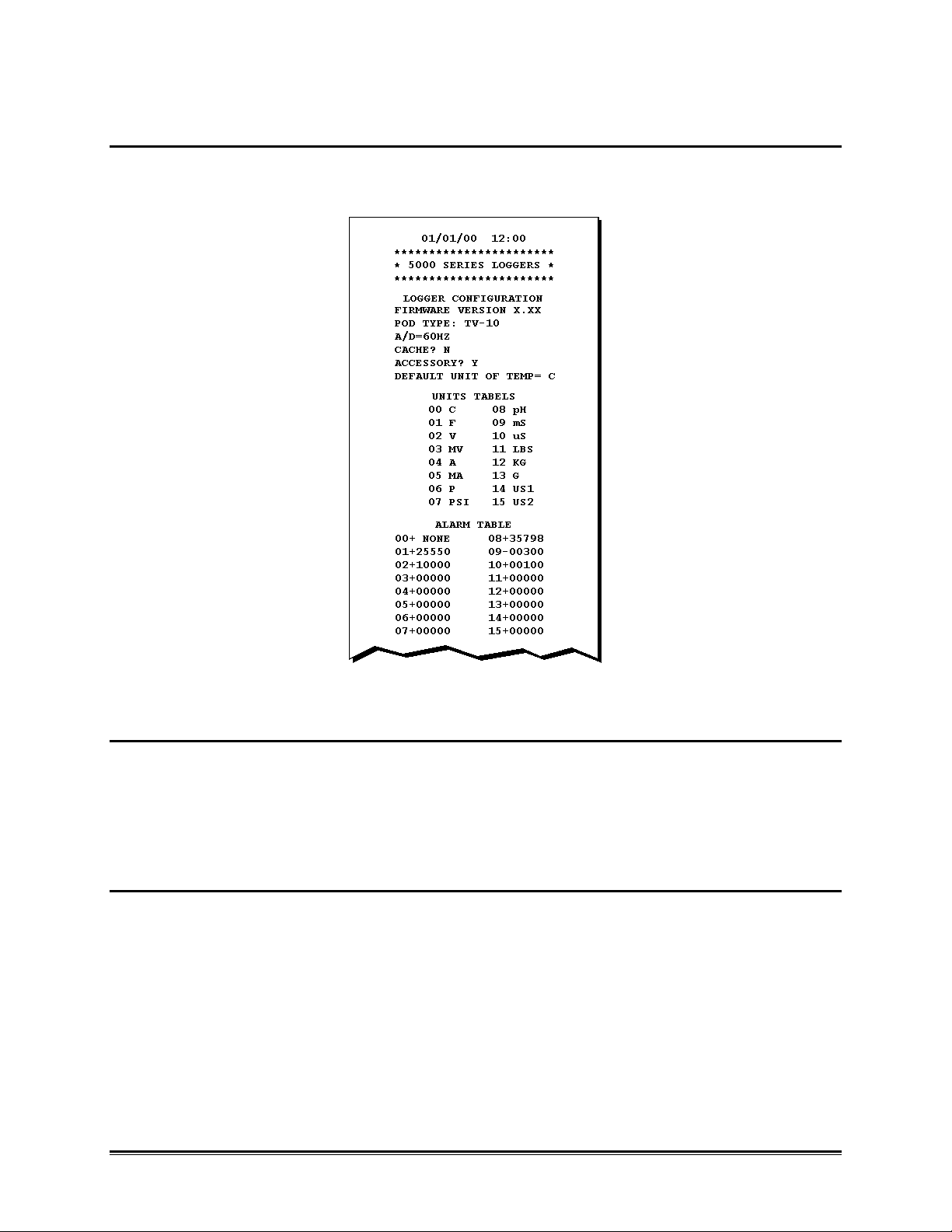

3.1.2.2 LOGGER CONFIGURATION

Pressing the LOGGER CONFIG key causes the Logger configuration to be printed out

on the printer. An example of a configuration printout is shown in Figure 3-4.

Figure 3-4: Configuration Printout

•• CONFIGURATION UNITS TABLE

16 unit labels are listed in a table and may be assigned to any of the Logger channels.

For example, if unit label 04 is assigned to a channel, an "A" will be displayed and

printed following the data on the channel. Unit labels 14 and 15 are user

programmable, and up to a three-character label may be programmed into these table

positions (refer to section• CONFIGURATION UNITS ).

•• CONFIGURATION ALARM TABLE

In a manner similar to the system used for Units Tables shown in Figure 3-4 the Alarms are

assigned to channels by selection from a table of possible numbers. All alarm values except 00

(NONE) are user programmable, and may be either positive or negative. Alarm values are numbers

only and assume the format or decimal printing position of the channel to which they are assigned.

After alarm values are assigned to channels a complete list of channels and alarms can be printed

out by pressing the ALARM TABLE key.

OM-5000 u18u

Page 25

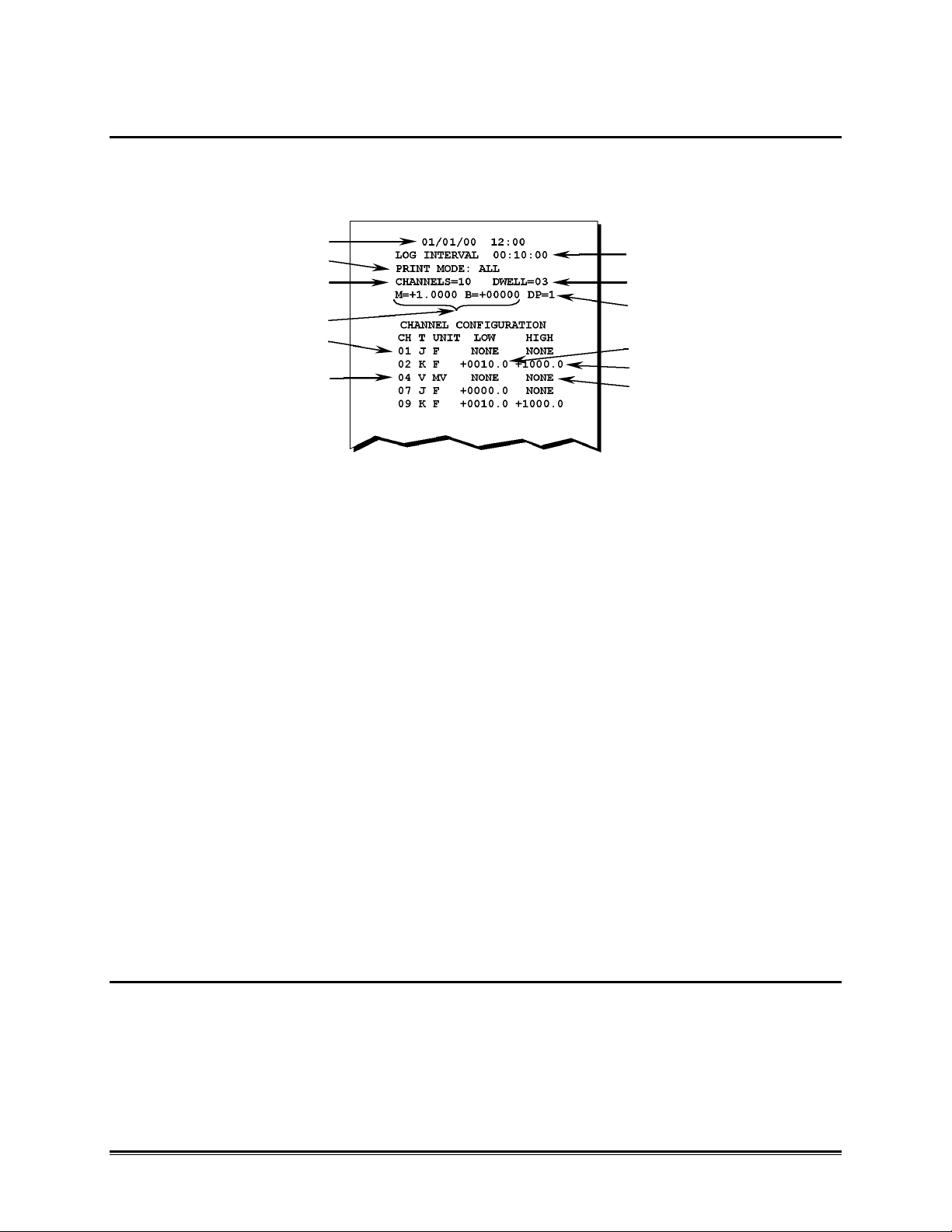

3.1.2.3 CHANNEL CONFIG

(1)

(2)

(3)

(5)

(6)

Pressing the CHANNEL CONFIG key causes the Logger Channel configuration to be

printed out on the printer. An example of a Channel configuration printout is shown in

Figure 3-5.

(4)

(7)

(8)

(11)

Figure 3-5: Channel Configuration Printout

(1) Date & Time

(2) Log Interval is 10 minutes

(3) All channels will print

(4) 10 channels are configured for scanning

(5) Dwell is 3 seconds

(6) Voltage scaling

(7) DP is number of places to right of decimal point

(8) Channels 1 & 7 are Type J Thermocouple

(9)

(10)

(12)

(9) Low alarm for channel 2& 9 is 10.0

(10) High alarm for channel 2 & 9 are 1000.0

(11) Channel 4 is a voltage channel with units = MV

(12) Channel 4 has no alarms

*Channels 3, 5, 6, 8, & 10 are skipped

•• LOG INTERVAL

The Log Interval listed in Figure 3-5 is the time between printouts of all currently enabled channels.

OM-5000 u19u

Page 26

•• PRINT OPTIONS

The Print Options shown in Figure 3-5 determines the amount of data that is sent to the printer. If

the Print Options are set to ALL, all data and alarm information goes to the printer. If the Print

Options are set to ALARMS, only out-of-range alarms are printed. If the Print Options are set to

NONE, no data is printed. In all cases data is sent to the cache memory. If the MANUAL PRINT key

is pressed or an external print trigger is initiated through the accessory port, the Print Options setting

is ignored and normal channel data will be printed.

•• CHANNELS/DWELL

The Channel Configuration information shown in Figure 3-5 documents the maximum channel

number that will be logged. The Dwell is the time in seconds that the Logger sits on a channel before

testing alarm points or saving or printing data.

•• VOLTAGE SCALING

The m, b and DP parameters shown on the Channel Configuration printout indicate the current

scaling and format constants used for channels configured as Voltage. The voltage reading from the

MUX is multiplied by the m constant and then the b constant is added before displaying. The DP

determines how many places will appear to the right of the decimal point when printing voltage

alarms.

•• TADJUST

The Tadjust portion of the Channel Configuration printout shows the number of degrees that

thermocouples are adjusted before printing or displaying.

•• CHANNEL / ALARMS

The Channel Alarm portion of the Channel Configuration printout shows the number, sensor type,

units and alarm points programmed for all active channels.

OM-5000 u20u

Page 27

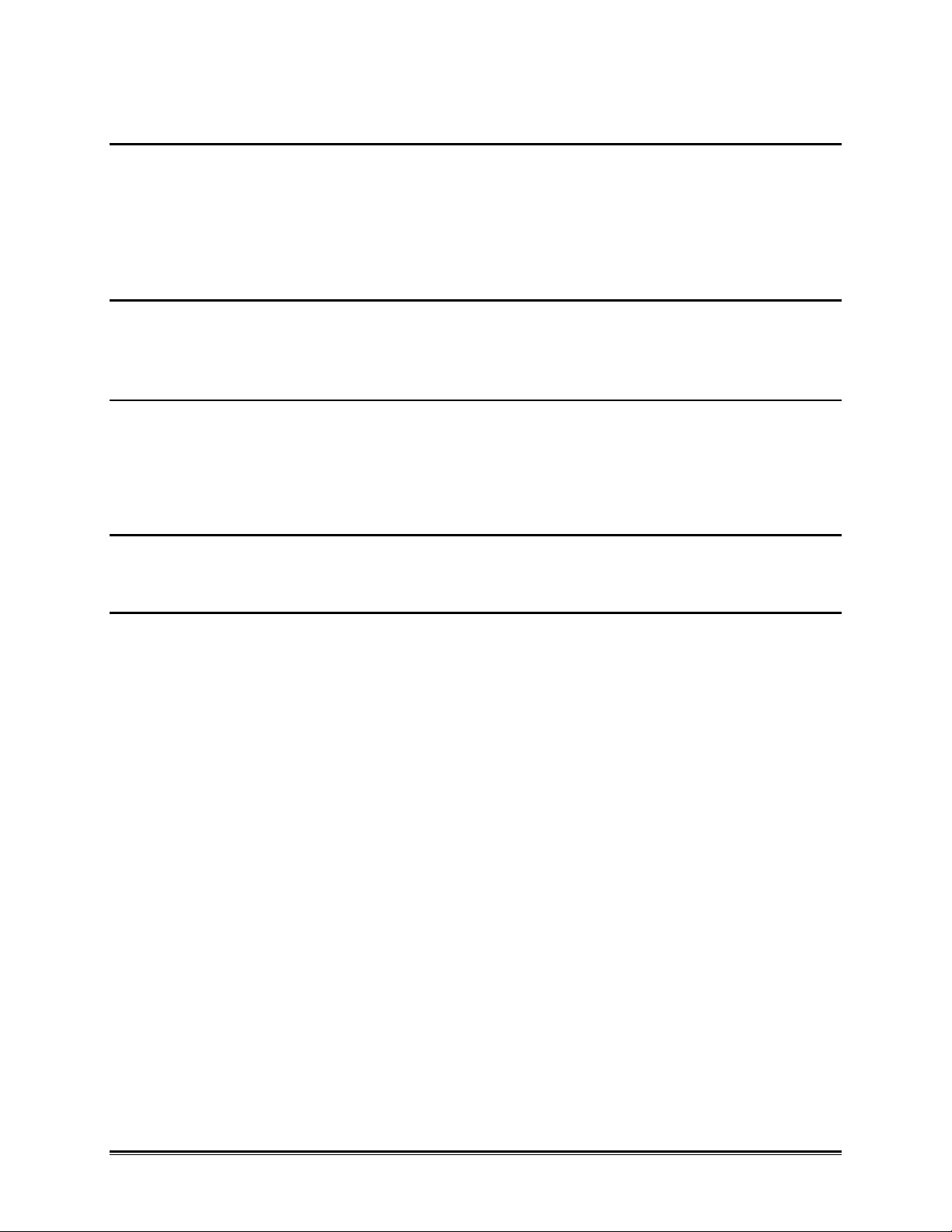

3.1.2.4 NORMAL LOGGING

When operating the Logger in a normal logging mode the printout appears similar to

the one shown in Figure 3-6.

(1)

(2)

(3)

Figure 3-6: Normal Logging Printout

(1) Date & Time

(2) Channel 1 has an open Thermocouple

(3) Channel 4 reads 100.2MV

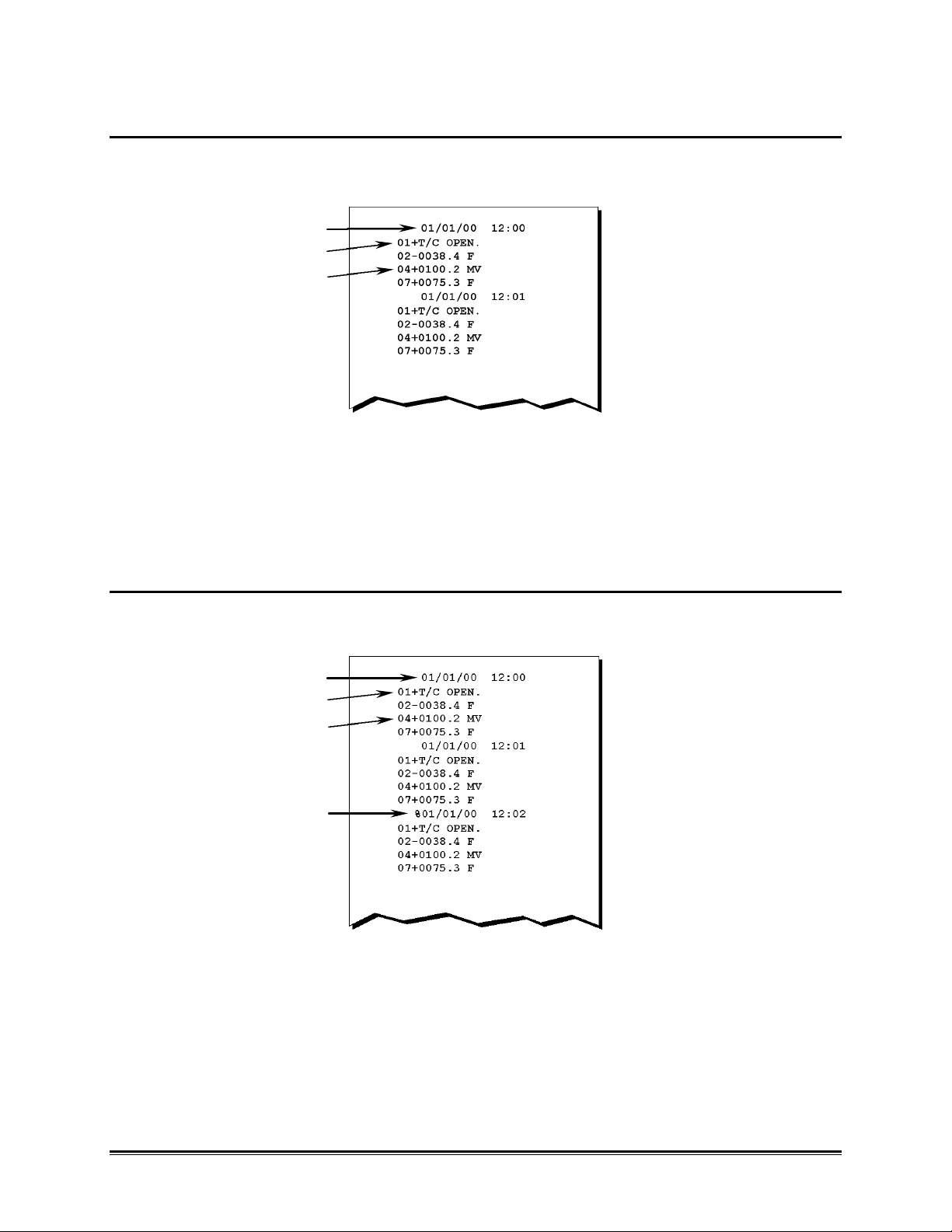

3.1.2.5 MANUAL PRINT

Pressing the MANUAL PRINT key on the front panel initiates a printout similar to the normal logging

printout except that the time line is marked with a "%" character.

(1)

(2)

(3)

(4)

Figure 3-7: "MANUAL PRINT" Printout

(1) Date & Time

(2) Channel 1 has an open Thermocouple

(3) Channel 4 reads 100.2MV

(4) Printing was initiated by the Manual Print key or external print trigger.

OM-5000 u21u

Page 28

3.2 PROGRAMMING

3.2.1 KEYPAD INTRODUCTION

When programming data into the Logger, be certain that a beep is heard when pressing a key to

insure that the CPU has responded to the keystroke. Most keys perform one primary, one alpha, and

one alternate function. Program data entry is done by displaying an example of how the data is to be

entered and flashing the position at which the data is to be entered. If data out of range for the

function being programmed is entered, the Logger will not accept the data.

In the following instructions and examples, MSD means most significant digit and

LSD means least significant digit.

Figure 3-8: Keypad

OM-5000 u22u

Page 29

3.2.1.1 THE ALPHA KEY

Alpha characters are entered by pressing the ALPHA key, which shifts the key functions to the letters

at the top left of each key. The keyboard remains in the Alpha mode until the Alpha key is pressed

again.

Figure 3-9: Alpha Keys

3.2.1.2 THE ALT KEY

The alternate legends for keys are activated by pressing the ALT key to shift the key functions to the

upper keyboard legend. The Alternate key functions are engaged for one keystroke only.

Figure 3-10: Alternate Key Legend

OM-5000 u23u

Page 30

3.2.1.3 THE CLEAR KEY

The CLEAR key may be pressed at any time to return to the normal operating mode. The Keypad

then returns to its primary function and all keystrokes for the current operation are canceled. All

program entries are automatically stored in memory after the last digit or character is entered for that

operation.

OM-5000 u24u

Page 31

3.2.2 PROGRAMMING MAINFRAME FUNCTIONS

3.2.2.1 MAINFRAME PROGRAM STORAGE

Mainframe program variables are stored in either the real-time clock, or the CPU electrically

alterable RAM. The variables stay with the mainframe even if Multiplexers are changed.

3.2.2.2 TIME

The Logger keeps time in the 24-hour format HH:MM:SS. To enter the time, press the ALT key

followed by the LOGGER CONFIG key. The time currently programmed will appear for 3 seconds,

then Time (HH:MM:SS) appears with the digit ready for entry flashing. If the time is correct, pressing

the CLEAR key will preserve it. To set the time to 14:20:00 enter as follows:

FUNCTION KEY PRESSED DISPLAY

Shift to ALT keyboard ALT SELECT ALTERNATE

Select time LOGGER CONFIG TIME (HH:MM:SS)

Enter MSD hour (tens) 1 TIME (1H:MM:SS)

Enter LSD hour (units) 4 TIME (14:MM:SS)

Enter MSD minutes (tens) 2 TIME (14:2M:SS)

Enter LSD minutes (units) 0 TIME (14:20:SS)

Enter MSD seconds (tens) 0 TIME (14:20:0S)

Enter LSD seconds (units) 0 TIME (14:20:00)

3.2.2.3 DATE

When the DATE key is pressed, the date currently entered in memory will appear for 3 seconds after

which a new date may be entered. If the displayed date is correct, pressing the CLEAR key will

preserve it. Dates are incremented when the time passes from 23:59:59 to 00:00:00. Leap years are

accommodated. The new date is entered in the form MM:DD:YY.

Follow the procedure and example below to enter a new date of 01/01/97:

FUNCTION KEY PRESSED DISPLAY

Shift to alt. keyboard ALT SELECT ALTERNATE

Select DATE CHANNEL CONFIG DATE (MM-DD-YY)

Enter MSD month 0 DATE (0M-DD-YY)

Enter LSD month 1 DATE (01-DD-YY)

Enter MSD day 0 DATE (01-0D-YY)

Enter LSD day 1 DATE (01-01-YY)

Enter MSD year 9 DATE (01-01-9Y)

Enter LSD year 7 DATE (01-01-97)

OM-5000 u25u

Page 32

3.2.2.4 BAUD RATE

The RS-232 port baud rate is selectable as either 9600, 1200, or 600 and is selected by pressing the

YES or NO key in response to the baud rates as they appear.

Follow the procedure below to set the baud rate to 600 baud:

FUNCTION KEY PRESSED DISPLAY

Shift to alt. keyboard ALT SELECT ALTERNATE

Select BAUD PRINT OPTIONS BAUD=9600Y/N ?

NO BAUD=1200Y/N ?

NO BAUD= 600Y/N ?

YES

3.2.2.5 LOG INTERVAL

The Log Interval is a 6-digit entry in the form HH:MM:SS. Logging intervals can range from 1 second

to 23 hours, 59 minutes and 59 seconds, however the log interval should be chosen to log all active

channels before the next log interval starts.

If the log interval is set shorter than the total scan time, the log interval will be “overrun”. The effect of

overrunning the log interval is twofold. First is that your data will not be recorded at the desired time.

Second is that only data is stored in the cache, not time. The Logger calculates the event time using

the time of the last data taken and the log interval. Therefore the time stamp on the printout and

cache printout will not agree.

Set log intervals as follows (the example is for 1 hour, 30 minutes, and

15 seconds):

FUNCTION KEY PRESSED DISPLAY

Shift to alt. keyboard ALT SELECT ALTERNATE

Select log interval LOG INTERVAL INTRVL (HH:MM:SS)

Enter MSD hour 0 INTRVL (0H:MM:SS)

Enter LSD hour 1 INTRVL (01:MM:SS)

Enter MSD minute 3 INTRVL (01:3M:SS)

Enter LSD minute 0 INTRVL (01:30:SS)

Enter MSD second 1 INTRVL (01:30:1S)

Enter LSD second 5 INTRVL (01:30:15)

OM-5000 u26u

Page 33

3.2.2.6 CHANNEL LOGGING KEYS

•• ACTIVE CHANNEL

The Logger allows setting the maximum number of channels to be scanned from 1 to the capability

of the multiplexer (up to 40 in a 40-channel MUX). Enter the desired maximum channels to be

scanned with the following procedure and example (8 channels):

FUNCTION KEY PRESSED DISPLAY

Shift to alt. keyboard ALT SELECT ALTERNATE

Select Maximum channels 9 MAX CHANNELS CC

Enter MSD channel 0 MAX CHANNELS 0C

Enter LSD channel 8 MAX CHANNELS 08

•• DWELL

Dwell time is a 2-digit entry, which can range from 1 to 9 seconds. Enter the desired time using the

following procedure and example (05 seconds dwell):

Dwell time is used to allow the Logger needed time to settle on a channel. The

total time needed is dependent on the input type and is best determined by

experience. Dwell is part of the total scan time and must be taken into

consideration along with Active Channels and Log Interval to get a scan time that

will not be longer than the Log Interval.

FUNCTION KEY PRESSED DISPLAY

Shift to alt. keyboard ALT SELECT ALTERNATE

Select dwell time 6 DWELL SEC NN

Enter MSD second 0 DWELL SEC 0N

Enter LSD second 5 DWELL SEC 05

•• HOLD

The Hold function allows the user to continuously scan on any individual channel. The channel hold

continues until the CLEAR key is pressed.

In the following example: Channel 10 is designated to be put on Hold:

FUNCTION KEY PRESSED DISPLAY

Shift to alt. keyboard ALT SELECT ALTERNATE

Select hold function 3 HOLD CHANNEL CC

Enter MSD of channel 1 HOLD CHANNEL 1C

Enter LSD of channel 0 HOLD CHANNEL 10

OM-5000 u27u

Page 34

3.2.3 PROGRAMMING MULTIPLEXER FUNCTIONS

3.2.3.1 MUX PROGRAM STORAGE

Mainframe program variables are stored in electrically alterable RAM located on the MUX. These

variables are retained even if power is disconnected.

3.2.3.2 CHANNEL TYPE KEYS (J,K,T,E,B,S,R,Volts, Pt & SKIP)

Each channel in the Logger can be individually programmed for measuring voltage (±2.000 volts), or

thermocouples. The availability of thermocouples depends on the type of multiplexer you have.

When programming channels as a thermocouple the default unit of temperature will be assigned to

it. Channels may also be skipped when no logging is desired. Different thermocouple types are

selected from the front panel as J,K,B,S,R or T:

In the following example:

Channel 1 is for a type T thermocouple (Note: Thermocouple-10/40 Mux only)

Channel 4 is for a type K thermocouple (Note: Thermocouple-10/40 Mux only)

Channel 10 is set to read voltage (V) (±2.000 volts max.)

Channel 12 is to be skipped.

FUNCTION KEY PRESSED DISPLAY

Shift to alt. keyboard ALT SELECT ALTERNATE

Select T/C type T CACHE FWD CHANNEL T CC

Enter MSD channel 0 CHANNEL T 0C

Enter LSD channel 1 CHANNEL T 01

Shift to alt. keyboard ALT SELECT ALTERNATE

Select T/C type K X CHANNEL K CC

Enter MSD channel 0 CHANNEL K 0C

Enter LSD channel 4 CHANNEL K 04

Shift to alt. keyboard ALT SELECT ALTERNATE

Select voltage YES CHANNEL V CC

Enter MSD channel 1 CHANNEL V 1C

Enter LSD channel 0 CHANNEL V 10

Shift to alt. keyboard ALT SELECT ALTERNATE

Select skip - CHAN SKIP CC

Enter MSD channel 1 CHAN SKIP 1C

Enter LSD channel 2 CHAN SKIP 12

Shift to alt. keyboard ALT SELECT ALTERNATE

OM-5000 u28u

Page 35

3.2.3.3 VOLTAGE SCALING KEYS

mX + b effects all voltage channels

•• VOLTAGE INPUT SCALING

Any of the Logger input channels may be programmed as Voltage channels. Voltage channels

include m and b constants for "scaling" all voltage data to your application. The following sections

include examples for common transducers.

•• MATCHING TRANSDUCERS TO THE LOGGER

Some transducers provide a "voltage" output others provide a "current" output.

This section explains how to use resistors to “Match” either output to the Logger input.

Currents must be converted to a voltage and voltages must be attenuated (reduced) if they can

exceed the Logger maximum input (±2.0000 VDC). This process is called Matching, which means

converting or attenuating the transducer's output to an acceptable level without overloading it.

•• MATCHING A VOLTAGE TRANSDUCER

Use two resistors to attenuate a voltage without overloading the transducer. The method shown here

will draw approximately half of the transducer's maximum current at full-scale.

I

TRANSDUCER

OUTPUT

+

R2

R1V LOGGER INPUT

-

Figure 3-11

V = transducer maximum output voltage

I = 1/2 transducer's maximum output current

R1 = 2 / I

R2 = (V-2) / I

OM-5000 u29u

Page 36

•• MATCHING A CURRENT TRANSDUCER

Use one resistor to develop the necessary voltage at the Logger input:

I

+

TRANSDUCER

OUTPUT

-

R1 V DATAWORKER INPUT

Figure 3-12

V = Logger maximum input voltage

= 2.0000 VDC

= R1 * I

I = 1/2 transducer's maximum output current

R1 = 2 / I

•• DATA SCALING (mX + b calculation)

The Logger can read the output voltage of a properly matched transducer but the data will be in

"volts" and you might prefer data in units that reflect your application. Programming the Logger to

produce data in terms of the actual parameter being measured is called Scaling.

The linear slope-intercept formula (Y = mX + b) shows how to do this. Given input "X", careful choice

of m and b can scale the output "Y" to any value, with some restrictions:

• The m and b values you choose must be within the allowable ranges:

-9.99999 < m < +9.99999 -999999 < b < +999999

The following equations show how to scale your data to the actual value of the parameter you are

measuring. They assume that an increasing transducer output indicates an increasing parameter. If

your system is inversely proportional, just change the sign of the m value. Remember that m and b

can be positive or negative.

X1 = minimum voltage expected at the Logger input

X2 = maximum voltage expected at the Logger input

Y1 = minimum parameter value for your application

Y2 = maximum parameter value for your application

m = (Y1-Y2) / (X1-X2) b = Y2 - (m * X2)

OM-5000 u30u

Page 37

•• EXAMPLE - VOLTAGE TRANSDUCER

EXAMPLE:

Given a 20 - 90 % RH (Relative Humidity) transducer with a 0 - 10 VDC output and a maximum

current of 3 mA.

Program the Logger to indicate 20.00 %RH to 90.00 %RH (that is, to indicate %RH with 0.01%

resolution).

1. First, find the Matching resistors:

I = 1/2 maximum current

= 0.003 / 2

= 0.0015 Amps

R1 = 2 / I R2 = (V - 2) / I

= 2 / 0.0015 = (10 - 2) / 0.0015

= 1333 Ω = 5333 Ω

2. Check:

V = (R1 + R2) * I V = R2 * I

= (1333+5333)*1.5 mA = 1333*1.5 mA

= 9.999 = 1.9995

= 10 = 2

When the transducer output is 10 VDC, the Logger will see 2 VDC.

OM-5000 u31u

Page 38

3. Next, find m & b:

X1 = 0 VDC ç minimum expected Logger input

= 0 A/D counts

X2 = 2.0000 VDC ç Logger maximum allowable input

= 20000 A/D counts

Y1 = 20.00 %RH ç choose decimal point = 2

= 2000 A/D counts

Y2 = 90.00 %RH ç keep decimal point = 2

= 9000 A/D counts

m = (Y1 - Y2) / (X1 - X2)

= (2000 - 9000) / (0 - 20,000)

= 0.35000

b = Y2 - (m * X2)

= 9000 - (0.350 * 20,000)

= 002000

Notice the decision to indicate with 0.01% resolution determined a decimal

position of 2.

OM-5000 u32u

Page 39

•• EXAMPLE - CURRENT TRANSDUCER

EXAMPLE:

Given a 0 - 150 PSI transducer with a 4-20 mA output.

Program the Logger to indicate 0 - 150 PSI with 0.01 PSI resolution.

1. First, find the Matching resistor:

R1 = 2 / I

= 2 / 20 mA

= 2 / 0.02

= 100 Ω

When the transducer output is 4 mA, the Logger will see 0.4 VDC and when the transducer output is

20 mA, the Logger will see 2 VDC.

2. Next, find m & b:

X1 = 0.4000 VDC ç minimum expected Logger input

= 4000 A/D counts

X2 = 2.0000 VDC ç Logger maximum allowable input

= 20000 A/D counts

Y1 = 0 VDC ç minimum transducer output

= 0.00 PSI ç choose decimal point = 2

Y2 = 150.00 PSI ç maximum transducer output

= 15000 A/D counts ç keep decimal point = 2

m = (Y1 - Y2) / (X1 - X2)

= (0 - 15000) / (4000 - 20000)

= 0.93750

b = Y2 - (m * X2)

= 15000 - (0.93750 * 20000)

= -003750

Notice the decision to indicate with 0.01 PSI resolution determined a decimal

position of 2

OM-5000 u33u

Page 40

•• PROGRAMMING EXAMPLE

mX + b effects all voltage channels

In the following example: The mX+b equation is set so that m = +.6666 and b = -00010. (Range of

allowable values for b are -32767 to +32767 and allowable values for m are -9.9999 to 9.9999)

FUNCTION KEY PRESSED DISPLAY

Shift to alt. keyboard ALT SELECT ALTERNATE

Select m coefficient NO M COEF +N.NNNN

Select the positive sign + M COEF +N.NNNN

Enter the MSD 0 M COEF +0.NNNN

Enter the NSD 6 M COEF +0.6NNN

Enter the NSD 6 M COEF +0.66NN

Enter the NSD 6 M COEF +0.666N

Enter the LSD 6 M COEF +0.6666

Shift to alt. keyboard ALT SELECT ALTERNATE

Select b coefficient DOWN ARROW B COEF +NNNNN

Select the negative sign - B COEF -NNNNN

Enter the MSD 0 B COEF -0NNNN

Enter the NSD 0 B COEF -00NNN

Enter the NSD 0 B COEF -000NN

Enter the NSD 1 B COEF -0001N

Enter the LSD 0 B COEF -00010

•• DECIMAL POINT

The decimal point may be set at any position. In the following example, any number from 0 to 5 may

be entered when the display shows DECIMAL POS=N with the N flashing. The number entered

determines the number of places from the right that the point will appear.

In the following example: The decimal point is set to the hundredths position (000.00), that is 2

places from the right. The range of possible locations are .nnnnn to nnnnn.

FUNCTION KEY PRESSED DISPLAY

Shift to alt. keyboard ALT SELECT ALTERNATE

Select decimal point (flashing) UP ARROW DECIMAL POS=N

Enter position 2 2 DECIMAL POS=2

OM-5000 u34u

Page 41

3.2.3.4 TADJUST (TEMPERATURE ADJUSTMENT)

The Logger permits adjustment of the temperature readings to accommodate various thermocouple

sensors. This correction is accomplished by adding the value of Tadjust to actual sensor readings.

The value of Tadjust is cumulative and the number entered adds (or subtracts if negative) to the

Tadjust value already stored in the MUX EEPROM. The accumulated value of Tadjust is shown on

the "Channel Configuration" printout (refer to Figure 3-5: Channel Configuration Printout)

In the following example: Tadjust is increased by 22.5 degrees. The Range of allowable values for

Tadjust is -99.9 to +99.9.

Tadjust effects all channels the same.

FUNCTION KEY PRESSED DISPLAY

Shift to alt. keyboard ALT SELECT ALTERNATE

Select Tadjust TADJUST TADJUST +00XX.X

Select the positive sign + TADJUST +00XX.X

Enter the MSD 2 TADJUST +002X.X

Enter the NSD 2 TADJUST +0022.X

Enter the LSD 5 TADJUST +0022.5

If a channel's type is such that the temperature readings are only accurate to one

degree resolution (e.g. B,S or R thermocouple), only the integer portion of

Tadjust ahead of the decimal point is added.

OM-5000 u35u

Page 42

3.2.3.5 ALARM KEYS

•• ALARM TABLE

The Logger permits assignment of up to 15 alarm values. These alarm values are put in a table, and

may be assigned to any channel as a high or low alarm (refer to section• HIGH and LOW). Alarm

values are of fixed format (only whole numbers) and may be either positive or negative. Alarm

values may be printed by pressing the LOGGER CONFIG key.

In the following example: We will assign a value of +100 to alarm number 01, and a value of -100 to

number 02:

FUNCTION KEY PRESSED DISPLAY

Shift to alt. keyboard ALT SELECT ALTERNATE

Select alarm value 7 ALARM NN+XXXXX

Enter the channel MSD 0 ALARM 0N+XXXXX

Enter the channel LSD 1 ALARM 01+XXXXX

Select the positive sign + ALARM 01+XXXXX

Enter the MSD 0 ALARM 01+0XXXX

Enter the NSD 0 ALARM 01+00XXX

Enter the NSD 1 ALARM 01+001XX

Enter the NSD 0 ALARM 01+0010X

Enter the LSD 0 ALARM 01+00100

Shift to alt. keyboard ALT SELECT ALTERNATE

Select alarm value 7 ALARM NN+XXXXX

Enter the channel MSD 0 ALARM 0N+XXXXX

Enter the channel LSD 2 ALARM 02+XXXXX

Select the negative sign - ALARM 02-XXXXX

Enter the MSD 0 ALARM 02-0XXXX

Enter the NSD 0 ALARM 02-00XXX

Enter the NSD 1 ALARM 02-001XX

Enter the NSD 0 ALARM 02-0010X

Enter the LSD 0 ALARM 02-00100

OM-5000 u36u

Page 43

•• HIGH and LOW

The Logger offers 16 alarm values that can be assigned to any channel as either a high or low alarm.

The channels are assigned first, then the alarm value (HH or LL). If no alarm is desired on a channel,

it may be assigned alarm value 00. The default tag for high and low alarm values is NONE.

In the following example: Channel 01 is assigned a high alarm value of +100, which was assigned

to Alarm Value 01 in the Alarm Value section.

Channel 05 is assigned a low alarm value of -100 as assigned to Alarm Value number 02 in Section

Alarm Value section.

FUNCTION KEY PRESSED DISPLAY

Shift to alt. keyboard ALT SELECT ALTERNATE

Select HIGH for high alarm 4 HI ALM CH CC HH

Enter MSD of channel 0 HI ALM CH 0C HH

Enter LSD of channel 1 HI ALM CH 01 HH

Enter MSD of alarm value no. 0 HI ALM CH 01 0H

Enter LSD of alarm value no. 1 HI ALM CH 01 01

Shift to alt. keyboard ALT Select Alternate

Select LOW for low alarm 1 LO ALM CH CC LL

Enter MSD of channel 0 LO ALM CH 0C LL

Enter LSD of channel 5 LO ALM CH 05 LL

Enter MSD of alarm value no. 0 LO ALM CH 05 0L

Enter LSD of alarm value no. 2 LO ALM CH 05 02

OM-5000 u37u

Page 44

3.2.3.6 UNIT KEYS

•• UNITS TABLES

The Logger has a total of 16 unit labels. The last two, 14 and 15, are programmable with up to 3

characters each. Once the label number is entered numbers maybe entered or by using the ALPHA

key the Keypad shifts to the alpha mode, in which the keys select the alpha characters denoted in

red at the top left of each affected key.

Only labels 14 and 15 can be customized.

In the following example:

Unit label 14 is programmed to read RPM

Unit label 15 is programmed to read MG

FUNCTION KEY PRESSED DISPLAY

Shift to alt. keyboard ALT SELECT ALTERNATE

Select unit label 8 UNIT LABEL NN CCC

Enter MSD unit label no. 1 UNIT LABEL 1N CCC

Enter LSD unit label no. 4 UNIT LABEL 14 CCC

Enter unit label char R UNIT LABEL 14 RCC

Enter unit label char P UNIT LABEL 14 RPC

Enter unit label char M UNIT LABEL 14 RPM

Shift to alt. keyboard ALT SELECT ALTERNATE

Select unit label 8 UNIT LABEL NN CCC

Enter MSD unit label no. 1 UNIT LABEL 1N CCC

Enter LSD unit label no. 5 UNIT LABEL 15 CCC

Enter unit label char SPACE UNIT LABEL 15 CC

Enter unit label char M UNIT LABEL 15 MC

Enter unit label char G Unit LABEL 15 MG

•• UNITS

The Logger offers 16 unit labels that can be assigned to any channel. The list of units available can

be printed out by pressing the LOGGER CONFIG key.

In the following example: We will assign unit label 03 (MV) to channel 01:

FUNCTION KEY PRESSED DISPLAY

Shift to alt. keyboard ALT SELECT ALTERNATE

Select UNIT 5 UNIT CH CC UU

Select channel number MSD 0 UNIT CH 0C UU

Select channel number LSD 1 UNIT CH 01 UU

Select unit number MSD 0 UNIT CH 01 0U

Select unit number LSD 3 UNIT CH 01 03

OM-5000 u38u

Page 45

•• C/F

The C/F key is used to set the default unit of temperature, Celsius or Fahrenheit. This default unit of

temperature is automatically assigned to any new channel that is programmed as a thermocouple.

Changing the default unit of temperature does not change any temperature units

already set. To change a channel’s temperature unit you must reprogram the

channel as a thermocouple or actually change the channel’s units.

The default unit of temperature is programmed by pressing the YES or NO key in response to the

options as they appear.

Use the following procedure to set the default to Fahrenheit:

FUNCTION KEY PRESSED DISPLAY

Shift to alt. keyboard ALT SELECT ALTERNATE

Select C/F 2 TEMP UNIT C Y/N?

NO TEMP UNIT C Y/N? YES

TEMP UNIT F Y/N?

OM-5000 u39u

Page 46

3.3 DATA CACHE FUNCTIONS

The Logger contains a 14.5 K Byte data cache that retains logged data even when the unit is “OFF”.

The cache is a circular buffer; when full, each new data point overwrites the oldest data.

Each data point occupies two bytes of cache memory, so the total capacity of the cache depends

upon the quantity of active (unskipped) channels. To calculate the capacity, divide 7250 by the

number of active channels, as below:

ACTIVE CHANNELS CACHE CAPACITY

1 7250 scans of all active channels

2 3625 scans of all active channels

3 2416 scans of all active channels

4 1812 scans of all active channels

5 1450 scans of all active channels

To calculate the time required to “Fill” the cache, multiply the capacity (above) by the current Log

Interval.

Although the Logger continuously scans all channels, data is written to the cache only once during

each log interval, at the completion of the first scan. The Logger then merely scans the channels and

displays the readings until the next log interval has passed.

The data cache will be erased when the Logger is reprogrammed or the CACHE ERASE key

pressed. If the cached data is valuable, DO NOT reprogram the Logger until the data has been

transferred to a PC!

The cache can be erased in several ways: From the Keypad, by performing a Power-Up Reset or by

reprogramming the channel definitions or Log Interval.

During a Power-Up Reset, the Logger can fill the cache with "phony" data. The artificial data is a

functional test of the unit and can also be used to ensure that the RS-232 Port connection to a PC is

functioning properly.

The actual data values will vary with the pod's programming.

OM-5000 u40u

Page 47

3.3.1 CACHE KEYS

Four keys give access to the cached data. One erases it and three let you review or (optionally) print

it.

CACHE KEYS

Figure 3-13: Cache keys

The CACHE FWD and CACHE REV keys position a pointer into the cache. Data at the pointer is

displayed, with the time it was acquired. The CACHE PRINT key prints the displayed data.

3.3.1.1 CACHE ERASE KEY

The CACHE ERASE key clears the cache and resets the Review pointer to the earliest data (none, in

this case). This key prompts the operator for yes or no confirmation to avoid accidental erasure.

Refer to section 3.3 DATA CACHE FUNCTIONS for other ways to erase the cache.

3.3.1.2 CACHE FWD KEY

The CACHE FWD key displays the cached data in the order it was acquired, from earlier too later.

Hold the key down to increase the rate at which the data scrolls through the display. Press any non

cache-related key to end this Forward review and resume logging.

OM-5000 u41u

Page 48

3.3.1.3 CACHE REV KEY

The CACHE REV key displays the cached data in reverse-acquisition order, from later too earlier.

Hold the key down to increase the rate at which the data scrolls through the display. Press any non

cache-related key to end this Reverse review and resume logging.

3.3.1.4 CACHE PRINT KEY

The CACHE PRINT key prints the cached data from the review pointer to the end of the cache in

forward-sequence.

Figure 3-14: Cache Printout

OM-5000 u42u

Page 49

APPENDIX A: CALIBRATION

CHANNEL NUMBERS

•• CALIBRATION INTERVAL

Six months is the recommended calibration interval.

•• TV-10 and TV-40 MUX CALIBRATION

R9

R32

ACCESSORY CARD

SW1

J50

J14

Figure A-1: TV-40 MUX

SETUP

1. Turn the Logger “OFF”.

2. Press and Hold the CLEAR key down and turn Logger back “ON”.

3. Answer "Yes" to the Clear CPU and Clear POD prompts.

4. Press the CHANNEL CONFIG key on the to verify that M=1.0000, B=+00000

and that channel #1 is configured as type V and channel #2 is configured as

type J thermocouple with F units. Also verify that Tadjust =0.00 and verify that

operating line frequency (50/60 Hz) is set to your particular application.

Consult factory for 50/60 Hz conversion.

OM-5000 u43u

Page 50

•• VOLTS

1. Hold the Logger on channel #1 Hold, by pressing the ALT then HOLD keys and

selecting 01.

2. Apply a 2.00000 volt ±10 microvolts standard voltage to channel 1.

3. Adjust R32 until the mainframe display reads exactly 2.0000.

•• THERMOCOUPLES

This calibration should be made only after Voltage is calibrated.

1. Set SW1-1 to the "ON" position (this removes the CJC compensation from

temperature readings)

2. Connect a precision millivolt voltage standard to the channel #2 input and set

the standard to 35.999 millivolts ±2 uV.

3. Adjust R9 on the MUX until the mainframe display reads 1200.0 F.

4. Set SW1-1 to the "OFF" position and disconnect the voltage standard. Cold

junction compensation is now in effect.

•• COLD JUNCTION COMPENSATION CHECK

1. Short the Channel #2 input with a copper wire, the display should read room

temperature.

2. Measure the temperature of the Isothermal Bar near Q3

3. Temperatures measured in 1 and 2 should agree, within 5 degrees C

OM-5000 u44u

Page 51

APPENDIX B: SPECIFICATIONS

VOLTAGE MEASUREMENT INPUT:

RANGE: ±2 VOLTS

INPUT IMPEDANCE: 1 MEG-OHM

CMRR: >105 db at 50/60Hz

NMRR: >75 db at 50/60Hz

INPUT BIAS CURRENT: 7 nA

MAXIMUM OVERVOLTAGE PROTECTION: 120 VOLTS AC

ACCURACY: ±400 µV

RESOLUTION: 100 µV

THERMOCOUPLE MEASUREMENT INPUT:

TYPES: J,K,T,E,B,S,R

INPUT IMPEDANCE: 100 MEG-OHM

LEAD RESISTANCE EFFECT: Less Than 20 µV/400 OHM

OPEN THERMOCOUPLE INDICATION: "T/C OPEN"

COLD JUNCTION COMPENSATION: 0-50°C

COMMON MODE REJECTION RATIO (CMRR) at 50/60Hz: >140 db

NORMAL MODE REJECTION RATIO (NMRR) at 50/60Hz: >75 db

COLD JUNCTION ERROR: 0.5°C Max over range 10°C to 40°C

RESOLUTION: (SEE TABLE BY TYPE)

TEMPERATURE RANGE: (SEE TABLE BY TYPE)

LINEARIZATION CONFORMITY ERROR: (SEE TABLE)

°F °C Resolution Conformity

TYPE Range Range °F Error (°C)

J -265 -165 0.1 0.08

1400 760

K -150 -101 0.1 0.10

2282 1250

T -158 -105 0.1 0.10

752 400

E -220 -140 0.1 0.09

1225 660

B 600 315 1.0 1.00

3272 1800

S -58 -50 1.0 0.9

3029 1665

R -58 -50 1.0 0.9

3029 1665

OM-5000 u45u

Page 52

DIGITAL INTERFACE (RS-232 SERIAL DATA PORT):

BAUD RATE: 9600/1200/600 (Programmable)

OUTPUT VOLTAGE: ±9V

MINIMUM LOAD (OHMS): 3KΩ

CONNECTOR: 9 Pin "D" shell

A/D CONVERSION:

MAX SPEED (Conversions/sec) : 10

RESOLUTION (Counts) : ±20,000

TECHNIQUE: Dual Slope

CAPACITY:

MAXIMUM INPUT CHANNELS : 40

DISPLAY TYPE:

16 DIGIT ALPHANUMERIC VACUUM FLUORESCENT

OM-5000 u46u

Page 53

ENVIRONMENTAL:

OPERATING AND STORAGE ENVIRONMENT: Indoor use only

OPERATING TEMPERATURE RANGE: 0 to 50 °C (32° F to 122°F)

STORAGE TEMPERATURE RANGE: -25°C to 75°C (-13°F to 167°F)

OPERATING RELATIVE HUMIDITY RANGE: Maximum 80% R.H. for temperatures

up to 31°C decreasing linearly to maximum 50% R.H. at 40°C, remaining constant

from 40°C to 50°C.

STORAGE RELATIVE HUMIDITY RANGE: Maximum 95% R.H., non-condensing.

MAINS VOLTAGE FLUCTUATION RANGE: Maximum +10% of the nominal rated input

voltage for the specified AC Power Adapter.

POLLUTION DEGREE: Classed as Pollution Degree 2, per IEC Publication 664.

This means that normally only non-conductive pollution (in the form of dust)

occurs. Occasionally, however, a temporary conductivity caused by condensation

must be expected.

INSTALLATION CATEGORY (OVERVOLTAGE CATEGORY): Classed as Installation

Category II, which applies to products used on electric supply branch circuits.

This is an IEC Publication 664 classification of parts of installation systems or

circuits with standardized limits for transient overvoltages, dependent on the

nominal line voltage to earth.

POWER/CURRENT RATINGS:

AC POWER ADAPTER:

INPUT: 120 VAC or 230 VAC, model-specific

OUTPUT: 12 VDC, 1 A, 12 W

LOGGER

NON-PRINTING: 12 VDC, 300mA

PRINTING: 12 VDC, 700 mA

PHYSICAL:

DIMENSIONS

Bench top: OM-5100 10.5"D x 10.0"W x 3.5"H

Wall mount: OM-5200 10.5"W x 10.0"H x 4"D

WEIGHT: 9 Lbs.

CALIBRATION : NIST (USA) Traceability

RECALIBRATION CYCLE FREQUENCY (MONTHS): 6

WARRANTY PERIOD: 1 year

OM-5000 u47u

Page 54

CONNECTORS:

MUX INPUTS: Spring-loaded, press to release, 16AWG max.

DC POWER: 0.08" Pin x 0.218" Jack

RS-232 Serial Data Port: 9 Pin "D" Shell

ACCESSORY: 8 X 2 X 0.1" 0.025" Header

PAPER LIFE:

PAPER TYPE: Thermal

ROLL CAPACITY: 82 ± 1.6 Feet

LINE HEIGHT: 0.150 inches per printed line

LINES PER ROLL: 6,560±128

EXAMPLE: If 8 channels are being printed once every 10 minutes, the paper will last 136 hours or 5

days.

OM-5000 u48u

Page 55

APPENDIX C: CONNECTING ACCESSORIES

THE ACCESSORY CARD

The Logger comes with the Accessory Card installed, Accessory I/O options and typical applications

circuits are shown below:

Diagram of Accessory Board I/O Options

•• USING GLOBAL ALARM RELAYS

The Global Alarm high and low relays are available for switching external devices. The relay

contacts close whenever any channel is in an alarm condition.

•• USING THE EXTERNAL PRINT TRIGGER

The External Print Trigger input is used to initiate a channel data printing sequence. Printing occurs

even if the Logger Print Options are set to "NONE". If an external power supply is used, the input is

isolated from the Logger circuitry. You may optionally tap a small amount of power off the Accessory

Connector as shown in the above diagram.

OM-5000 u49u

Page 56

CONNECTING THE 20-RELAY ALARM CARD (OPTION)

In order to use a 20-Relay Alarm Card, you must have an Accessory card installed.

1. Turn the Logger and the 20-Relay Alarm Card power “OFF”.

2. Locate the 16-conductor cable supplied with the Alarm Card and connect the

Accessory output connector on the MUX rear apron to the connector labeled "IN"

or "Accessory" on the Alarm Card.

3. To test operation, turn the Logger and Alarm Card power “ON”, and cause a

High or Low alarm to occur on one of the first 10 channels. The appropriate LED

on the alarm card should light and the relay should close.

Up to 3 additional alarm cards may be "daisy chained" for access to High and

Low alarms on all 40 channels. No programming is necessary.

20-Relay Alarm Card

OM-5000 u50u

Page 57

CHANGING FIRMWARE EPROMS

1. Turn the power “OFF”, remove the Logger from the wall and loosen the

thumbscrew to open the Logger.

2. Lift up the protective cover over the CPU board by grasping it at the front, and

lifting up and out.

3. Locate U3 in the following diagram. This IC is mounted in a special low Insertion

Force socket. In order to release the socket, push in the bar at the top (OPEN).

Note pin #1 location and install the new EPROM.

4. To re-lock the socket, press in at the bottom (ACT).

Low Insertion Force EPROM Socket

CPU Board Parts Layout

OM-5000 u51u

Page 58

OM-5000DOS SOFTWARE

Page 59

TABLE OF CONTENTS

INTRODUCTION....................................................................................................................................iii

• HARDWARE REQUIREMENTS ..................................................................................................iii

INSTALLATION.....................................................................................................................................iv

• HARD DISK INSTALLATION....................................................................................................... iv

1.0 STARTING THE PROGRAM ............................................................................................................1

2.0 READING DATA FROM THE LOGGER ...........................................................................................2

3.0 LOADING EXISTING DATA FILES...................................................................................................3

4.0 MODIFYING THE SOFTWARE CONFIGURATION..........................................................................4

5.0 LIST DATA ON MONITOR ...............................................................................................................6

6.0 PRINTING DATA ON PRINTER........................................................................................................7

7.0 SAVING TEXT FILES.......................................................................................................................7

8.0 EDITING PLOT LABELS..................................................................................................................8

OM-5000 DOS Software uiu

Page 60

9.0 HOT PLOT...................................................................................................................................... 10

9.1 FILE NAME, PLOT TITLE, and TIME STAMP.........................................................................11

9.2 DATA PLOTS AND AXES .......................................................................................................12

9.3 X-DATA CURSORS.................................................................................................................13

9.4 X-CURSOR DATA TABLE.......................................................................................................14

9.5 CHANNEL SELECT AND LINK BUTTONS.............................................................................15

9.6 HELP MENU............................................................................................................................17

9.7 FUNCTION KEY INTERFACE.................................................................................................18

9.7.1 X-CURSOR SELECT KEYS (F1 thru F3).......................................................................18

9.7.2 CHANNEL SELECT KEYS (NUMBERS 1 thru 5)..........................................................19

9.7.3 CHANNEL LINK KEYS (ALT-1 thru ALT-5) ...................................................................19

9.7.4 SCALE PLOT KEYS (F5 and F6)...................................................................................20

9.7.5 PRINT SCREEN KEY (F7).............................................................................................21

9.8 MOUSE INTERFACE..............................................................................................................22

9.8.1 MOUSE AND MOUSE POINTER..................................................................................23

9.8.2 X-Y READOUT...............................................................................................................24

9.8.3 CHANNEL SELECT AND LINK BUTTONS...................................................................25

9.8.4 MAGNIFY TOOL.............................................................................................................27

10.0 QUITTING ..................................................................................................................................... 28

11.0 DISK FILE TYPES........................................................................................................................29

12.0 READINGS AND DATAPOINTS ................................................................................................... 29

OM-5000 DOS Software uiiu

Page 61

INTRODUCTION

The OM-5000 DOS Software requires an IBM PC or compatible, with 640K of

ram and 1 or 2 serial ports. Most monitors will work.

The software is supplied on a 3-1/2” disk, and requires a hard drive. It is not

copy protected and we recommend that you make at least one backup copy to

hold in reserve. Refer to your computer’s manual for copying instructions.

OM-5000 data can be saved to disk as experiment files. The files are

automatically named with the word LOG, followed by three numbers, like

LOG007. The numbers will increment as new experiments are saved or you can

choose the number.

In addition to the OM-5000 data, an experiment file can (optionally) contain

information describing the parameters of the experiment and the data.

The HOT PLOT display can be operated either from the keyboard or with an

optional mouse pointing device.

•• HARDWARE REQUIREMENTS

COMPUTER: IBM* PC, XT, AT, OR PS-2, Compaq*, or compatible, with

640K RAM

DISK DRIVE: At least one floppy drive (3.5” or 5.25”, 720K or 1.44M)

and a Hard Drive.

GRAPHICS CARD: CGA, EGA, VGA or Hercules

MONITORS: CGA, EGA, VGA or Hercules compatible

PRINTERS: 9-pin Epson compatibles

Star Rainbow Color

HP* PaintJet Color

HP Laserjet

SERIAL PORT: One, configured as either COM1: or COM2:

MOUSE: Microsoft or equivalent, with appropriate driver

(mouse.com, ect.)

*IBM is a registered trademark of International Business Machines Corporation.

COMPAQ is a registered trademark Compaq corporation.

HP is a registered trademark of Hewlett Packard.

OM-5000 DOS Software uiiiu

Page 62

INSTALLATION

The OM-5000 DOS Software will operate only from your hard disk. If you are

using a mouse, you must install the appropriate mouse driver software

(mouse.com or mouse.sys) supplied with your mouse. See your mouse manual

for instructions.

•• HARD DISK INSTALLATION

The OM-5000 DOS Software diskette contains an Install program. This program

creates a directory named M5000 on the root directory of you hard disk and

copies the necessary files to it. To run the Install program, place the source

diskette in drive A:, make it the currently logged directory (refer to your DOS

manual if necessary), and type “A:INSTALIT” or “B:INSTALIT”.

OM-5000 DOS Software uivu

Page 63

1.0 STARTING THE PROGRAM

To start the program, boot your computer from your hard drive. From the DOS

prompt, change to the directory where you have installed the OM-5000 DOS

Software. (e.g. CD C:\M5000).

TYPE: M5000C If you have a computer with CGA video card.

M5000E If you have a computer with EGA video card.

M5000V If you have a computer with VGA video card.

M5000H If you have a computer with Hercules video card.

To exit the program, type Q at the MASTER MENU.

When the program begins it will display the MASTER MENU.

Master Menu Screen

The MASTER MENU lists the options available to you: reading data from the

Logger, reading an existing experiment file, or modifying the software

configuration parameters (your custom labels and computer configuration).

The MASTER MENU options change to match what you are doing. For example,

if you have read new data from the Logger but have not saved it do disk, the

program will prompt you to save the data when you exit.

Experiment file LOG001 is always automatically loaded when the program starts.

This is the file used in all examples in this manual.

OM-5000 DOS Software u1u

Page 64

2.0 READING DATA FROM THE LOGGER

This selection presents instructions for transferring data from the Logger to the

PC.

Be sure the communication cable is properly installed and the Logger is “ON”

and set to 9600 baud before starting the read process. If you use the same

computer port for both the mouse and the Logger, be sure to reconnect the

mouse after the data has been read.