Page 1

Page 2

Trademark Notice

Registered trademarks belong to their respective owners.

COPYRIGHT – 2001 OMEGA Engineering

All Rights Reserved

2

Page 3

CONTENTS

INTRODUCTION _____________________________ 7

1.1 STANDARD FEATURES _______________________8

1.2 STANDARD KIT ITEMS ________________________9

1.3 SUMMARY OF PARTS________________________10

1.4 PRECAUTIONS______________________________11

1.5 USING THIS MANUAL ________________________13

1.5.1 Warnings ____________________________________ 13

1.5.2 Names ______________________________________ 13

1.5.3 Instruction Sequences __________________________ 14

1.5.4 Instruction Types ______________________________ 14

BASIC OPERATION _________________________ 15

2.1 GENERAL__________________________________16

2.1.1 Powering Up__________________________________ 16

2.1.2 Accessing Main Menu __________________________ 16

2.1.3 Selecting a Main Menu Item______________________ 17

2.1.4 Selecting an Option ____________________________ 17

2.1.5 Editing Names ________________________________ 19

2.1.6 Editing Numerical Values ________________________ 22

2.2 SETTING UP INPUTS_________________________23

2.2.1 Channel Selection & Setup ______________________ 24

2.2.2 Channel Types ________________________________ 25

2.2.3 Matching Inputs to Sensors ______________________ 26

2.2.4 Modifying the Input boxes _______________________ 27

2.2.5 Modifying the Output boxes ______________________ 29

2.2.6 Modifying the Units_____________________________ 29

2.3 SETTING UP CHANNELS _____________________30

2.3.1 Setting Up Your Recording (The Trigger Menu) ______ 30

2.3.2 Setting Display Options _________________________ 36

2.3.3 Graph Controls ________________________________ 37

2.4 RECORDING DATA __________________________39

2.4.1 Setting Up the Filename_________________________ 39

2.4.2 Choosing a Folder _____________________________ 39

2.4.3 Starting a Recording____________________________ 40

3

Page 4

2.4.4 Auto-Repeating Recordings ______________________ 40

2.4.5 Chained Recordings____________________________ 41

2.5 PLAYING BACK _____________________________42

2.6 FILE UTILITIES______________________________43

2.7 OUTPUTTING SAMPLES FROM RS232 __________44

UTILITIES__________________________________ 45

3.1 RESETTING THE INSTRUMENT ________________46

3.2 ADJUSTING LCD ____________________________47

3.2.1 Adjusting Contrast _____________________________ 47

3.2.2 Turning Backlight On ___________________________ 47

3.3 SETTING CLOCK ____________________________48

3.3.1 Checking Date and Time ________________________ 48

3.3.2 Setting Date and Time __________________________ 48

3.4 MANAGING BATTERY________________________49

3.4.1 Instrument Battery _____________________________ 49

3.4.2 Checking Battery Capacity_______________________ 50

3.4.3 Charging Powered-up instrument__________________ 50

3.4.4 Charging Powered-down instrument _______________ 50

3.4.5 Reconditioning Batt ery Pack _____________________ 51

3.4.6 Power Saver__________________________________ 51

3.4.7 Replacing Battery Pack _________________________ 52

3.5 ERASING MEMORY__________________________53

3.6 TROUBLESHOOTING ________________________54

3.6.1 Power Problems_______________________________ 54

3.6.2 Data Problems ________________________________ 54

3.6.3 Data-Transfer Problems_________________________ 55

3.6.4 Other Problems _______________________________ 55

ANALYSIS SOFTWARE______________________ 57

4.1 INSTALLING OM-3000

4.1.1 License Agreement ____________________________ 58

4.1.2 PC System Requirements _______________________ 58

4.1.3 Installing OM-3000

4.2 STARTING UP

4.2.1 Starting up ___________________________________ 60

4.2.2 Configuring PC COM port _______________________ 60

4

MAS

___________________________60

MAS

____________________58

MAS

on PC ___________________ 59

Page 5

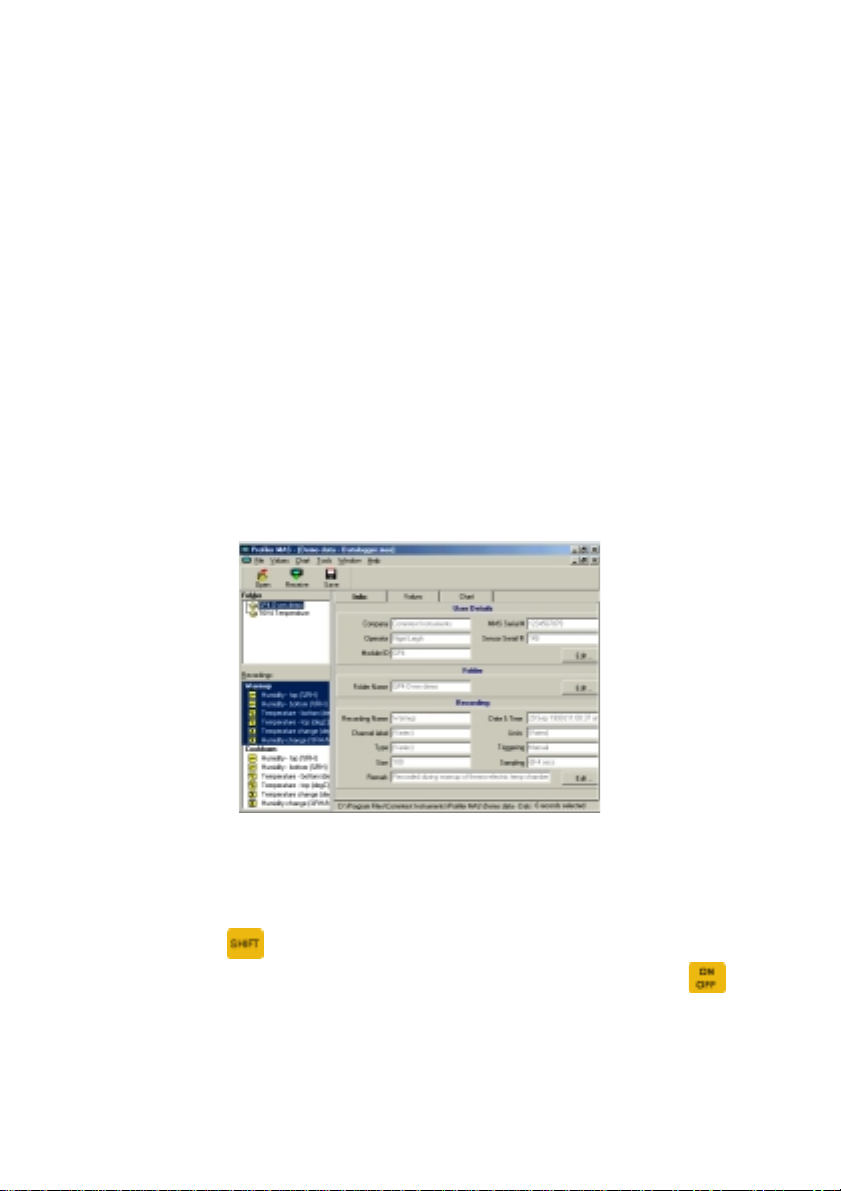

4.3 TRANSFERRING DATA TO THE PC_____________61

4.4 MANAGING DATA ___________________________62

4.4.1 Opening a File ________________________________ 62

4.4.2 Merging Two Files _____________________________ 62

4.4.3 Using the Navigator ____________________________ 62

4.4.4 Deleting Data from a Folder ______________________ 62

4.4.5 Editing Recording Details________________________ 63

4.4.6 Viewing and Printing Data Values _________________ 63

4.4.7 Exporting data ________________________________ 64

4.5 CALCULATING DATA ________________________65

4.6 PLOTTING DATA ____________________________66

4.6.1 Plotting Single and Individual Charts _______________ 66

4.6.2 Zooming & Panning ____________________________ 67

4.6.3 Printing Charts ________________________________ 67

4.6.4 Reading and Comparing Values __________________ 68

4.6.5 Plotting Waterfall Charts_________________________ 70

4.7 UPGRADING FIRMWARE _____________________71

Appendix SPECIFICATIONS __________________ 73

Appendix Application Notes__________________ 75

6.1 Application Note 1___________________________75

6.2 Application Note 2___________________________80

Appendix Optimizing Temperature Accuracy____ 83

Appendix OM-3000

8.1 FUNCTIONS ________________________________86

8.1.1 Mathematical Functions _________________________ 86

8.1.2 Iterative Functions _____________________________ 88

8.1.3 Logical Functions ______________________________ 88

8.1.4 Conditional Functions___________________________ 89

8.1.5 Date and Time Functions ________________________ 89

8.2 OPERATORS _______________________________90

8.2.1 Logical Operators______________________________ 90

8.2.2 Arithmetic Operators ___________________________ 90

MATH ________________ 85

MAS

MAS

MASMAS

5

Page 6

6

Page 7

INTRODUCTION

MAS

Windows

OM3000

OM3000-T6V4

o

C (-418 to +2498oF)

based software sup plied

.

.

temperature

±

5VDC or

Congratulations on purchasing the

T6V4

The

measurement ranging from –250 to +1370

depending on the thermocouple type, and up to four channels of

voltage

±

30VDC. Collected data can be transf erred to a PC where it can be

analyzed in detail using the

in the kit.

This manual has been f ormatted to a llow you to quic kly learn ho w to

use your

read it before operating your

module allows up to six channels of

measurement with user-selectable settings of

OM3000

. Please keep this manual for futur e reference and

7

Page 8

1.1 STANDARD FEATURES

• 24-bit A/D converter providing high-precision measurements

• 512kB non-volatile memory capable of storing up to 400,000

sample points

• Time and date stamped recordings

• Temperature compensated graphical L CD (liquid-cr ystal displa y)

with 240x128 pixels

• Electro-luminescent LCD backlight

• Built-in battery charger and conditioner

• 1500mAh Ni-Cad (Nickel-Cadmium) battery pack

• Upgradeable firmware

• RS232 interface to communicate with a PC (personal computer)

• Windows

8

based Measurment Analysis Software (

MAS

)

Page 9

1.2 STANDARD KIT ITEMS

9

Page 10

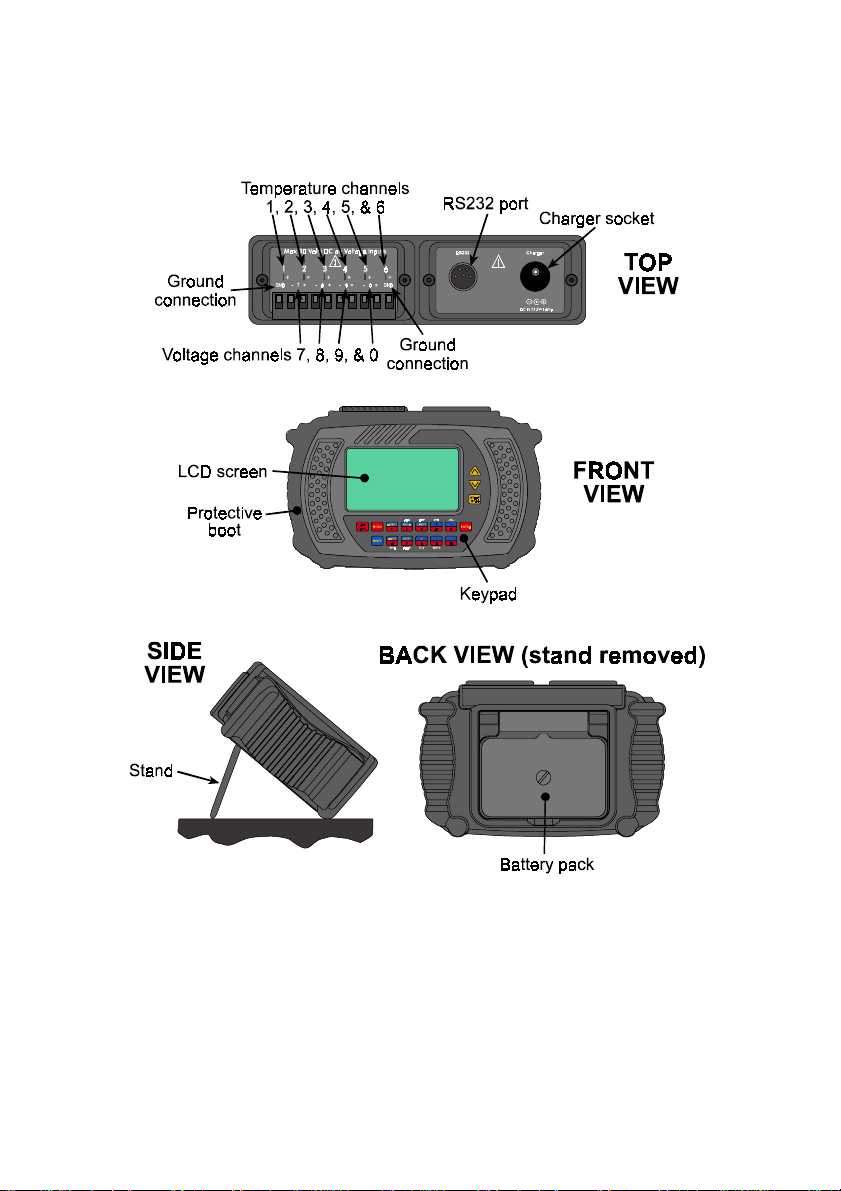

1.3 SUMMARY OF PARTS

10

Page 11

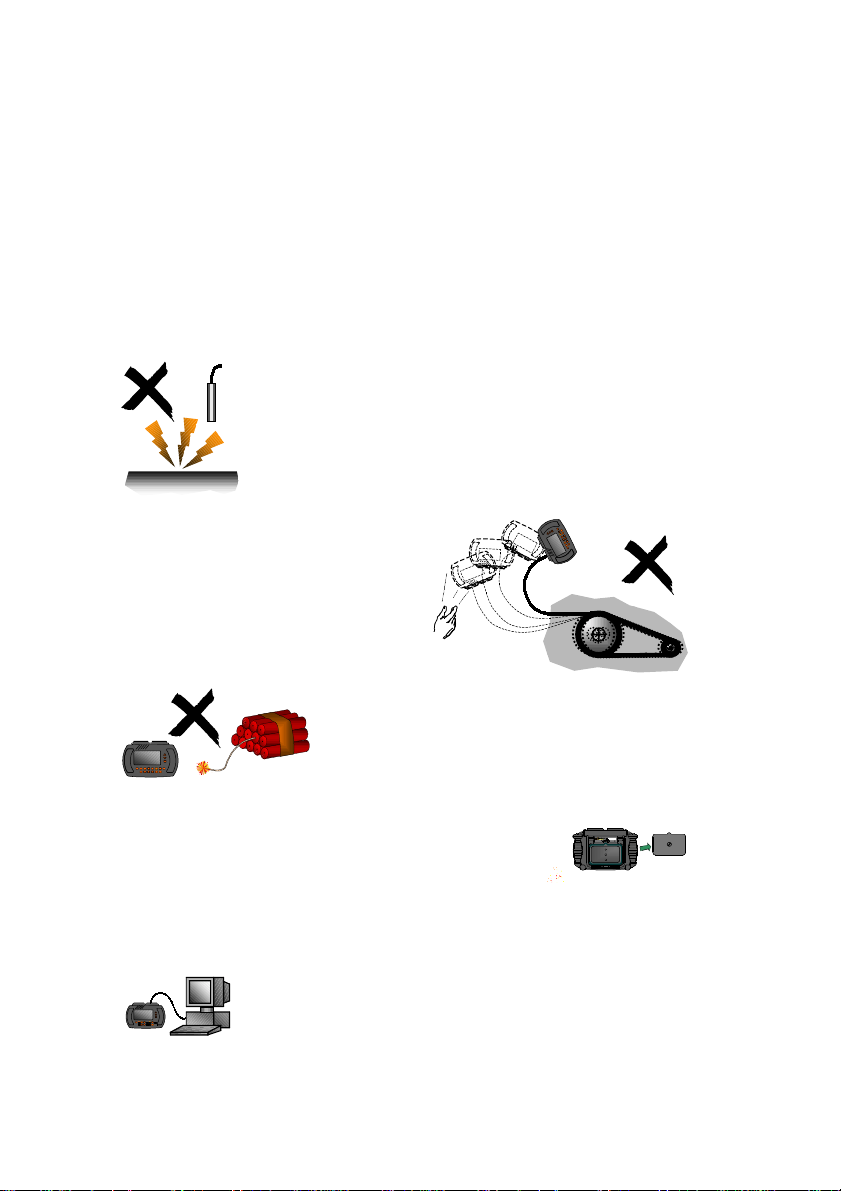

1.4 PRECAUTIONS

WARNING

operating your instrument. Not heeding the warnings or

recommendations c ould res ult i n data loss, data inaccuracy, dam age

to the instrument, or injury to yourself.

WARNING

transfer cable and bootstrap

cannot be entangled with any

moving or rotating machinery.

: Please read and understand this section fully before

WARNING

connect any sensor to a high voltage i.e. a vo ltage

that exceeds 50VDC or 32VAC or the “safety extra

low voltage” (SELV) defined by your local power

authority.

: Ensure the data-

: To avoid electrical shock, do not

WARNING

an explosive environment.

: Do not operate the instrument in

WARNING

the instrument for more than 2 hour s as data and

settings may be lost.

: Do not detach the battery pack from

WARNING

a PC before reprogram ming the instrum ent with new

firmware – reprogramming the instrument erases all

data stored in the instrument (see section 4.6).

: Transfer data stored in t he instrument to

<

2 hours

11

Page 12

WARNING

: Charge the battery pack up to at leas t 30%

capacity before taking a recording. If using the

instrument for 4 hours or more, first ensure that the

battery pack is fully charged.

30%

>

WARNING

: Constantly charging the battery when it is not fully

drained will create a "Memory" effect and eventually shorten the

amount of charge that the battery can hold. Please read

Managing Battery

to learn how to prevent this.

WARNING

: Do not expose the instrument to large

3.4

impacts or pressure.

WARNING

solvent to clean the instrument.

: Do not use alcohol or any organic

WARNING

: Do not expose the instrument to wet

Kero

conditions or store it in a dam p place where the relati ve

humidity exceeds 80% RH.

WARNING

: Do not place the instrument in a hot

place where the tem perature exceeds 140°F (60°C).

Otherwise, the battery pack will degrade.

WARNING

: Ensure that the battery pack is securely

fastened – but not over-tightened – to the instrument

before operating the instrument.

WARNING

: If the instrument malf unctions, return it

to an authorized dealer. Do not try to repair it

yourself, as this will invalidate the warranty.

WARNING

: Use only an approved power transformer

and ensure its voltage and frequency rating matches

that of your mains AC power.

12

DEALER

AUTHORIZED

Page 13

1.5 USING THIS MANUAL

1.5.1 Warnings

In this manual, the word

actions may lead to dam aging consequences. Please he ed all such

warnings.

WARNING

is displayed where certain

1.5.2 Names

In this manual, window and screen names are italicized. These

names refer to the names appearing at the top of windows/screens.

MAS

Window

The PC key names ar e shown as norm al tex t, e.g. Shif t ref ers to the

Shift key on the PC keyboard.

Keys on the instrument are shown as they appear on the instrum ent

keypad, e.g.

Some instrument keys have more than one function, e.g. the

key which is used as either t he ON k e y or the OFF key depending on

the state the instrument is operating in.

refers to the Shift key on the instrument.

13

Page 14

1.5.3 Instruction Sequences

The ! symbol is used to indicate the sequence of menu selections.

Instruction Meaning

Click File ! Save. Select the File menu and t hen

select Save.

1.5.4 Instruction Types

The word “press” refers to key presses or menu selections on the

instrument.

The word “click” refers to menu selections on the PC, and “push”

refers to key presses on the PC keyboard.

Instruction Meaning

Click File ! Export.

Push the Esc key.

Some operating instructions are illustrated with examples. Such

instructions are marked with the word

14

Select File and then Export in

MAS

software.

Push the Esc key on the PC

keyboard.

EXAMPLE

.

Page 15

BASIC

OPERATION

This section outl ines the procedure for perform ing basic operations

on your instrument. You will learn to:

• use the instrument menu system;

• record data; and

• playback recorded data.

WARNING

: Read section 1.4 before operating your instrument.

15

Page 16

2.1 GENERAL

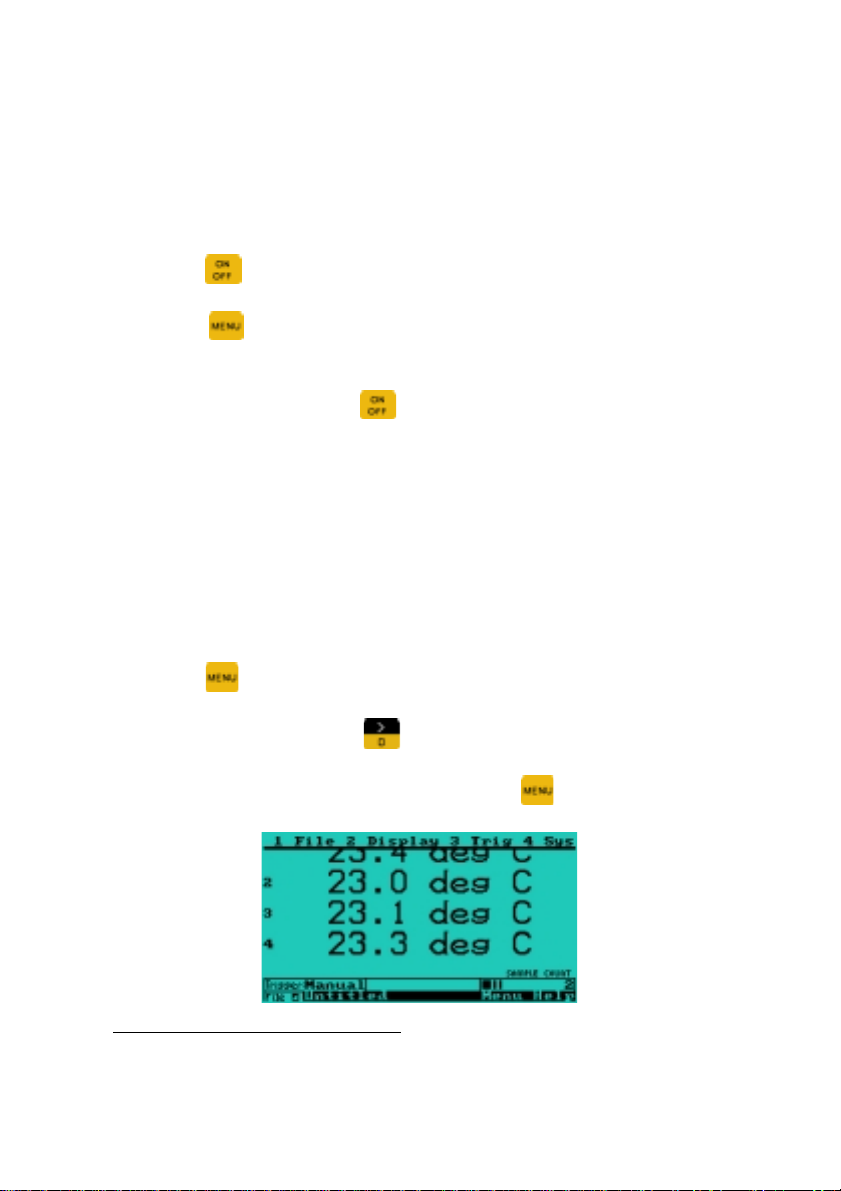

2.1.1 Powering Up

• Press

• Press

that is being measured (using previous settings).

• To power down, press

the instrument does not respond to any key press, reset it (see

section 3.1).

. The Initialization screen is displayed.

. Measurement begins and the screen displays data

*

and follow on-screen instructions. If

2.1.2 Accessing Main Menu

To perform instrument operations, you need to access the main

menu. To access the main menu:

• Press

You can alternativel y press

top of the screen and consis ts of four items: File, Display, Trig(ger),

and Sys(tem). To cancel the main menu, press

.

. The main menu is dis played at the

again.

Every time the instrument is powered up, the power saver (a power-saving feature)

*

is automatically turned on. See section 3.4.6 for more details.

16

Page 17

2.1.3 Selecting a Main Menu Item

• Press the number preceding the menu item.

Alternativel y, press

or .

EXAMPLE

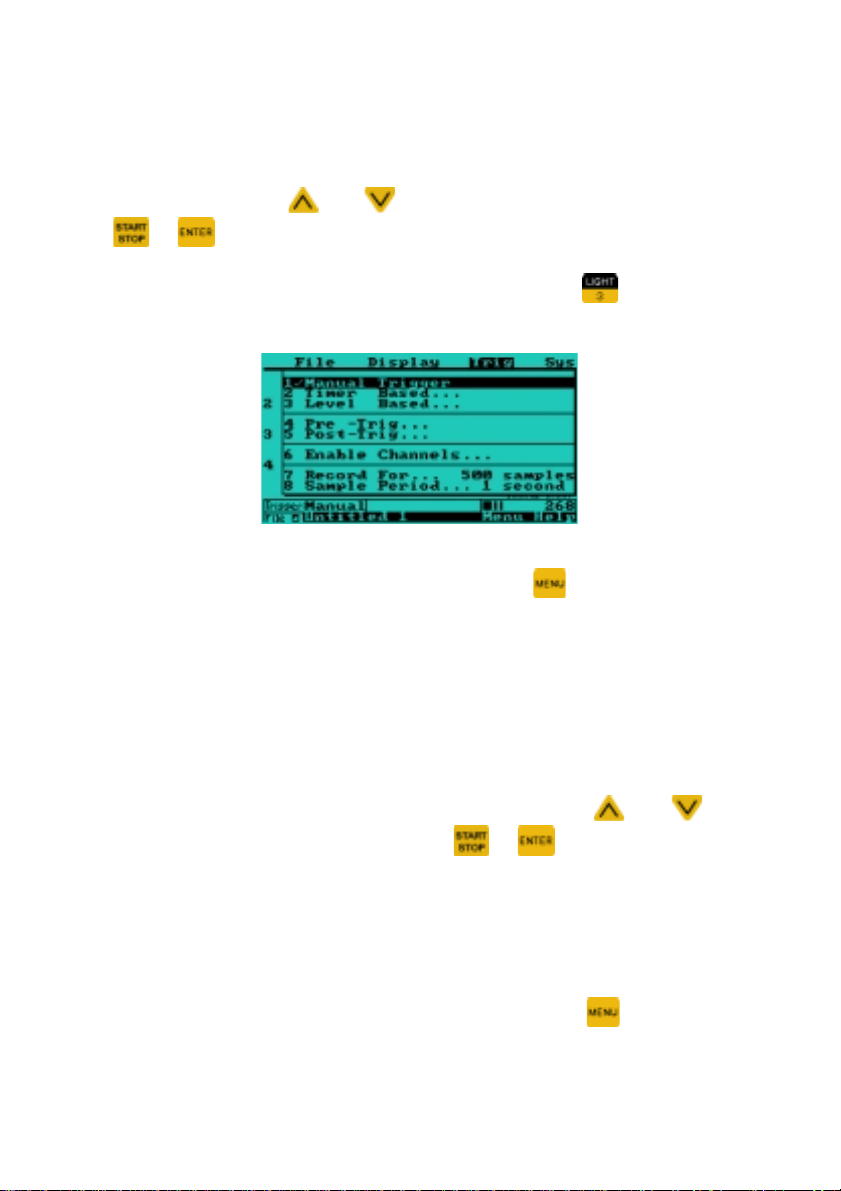

The drop down menu above shows the available options for the

Trigger menu. To c a n c e l a d r opdown menu, press

: to select the main menu item Trig, press

and to cycle to the menu it em then pr ess

.

.

2.1.4 Selecting an Option

The procedure for s electing an option in a dropdown m enu is similar

to selecting a main menu item i.e.

• Press the num ber preceding the opti on, or press

cycle to the option and then press

Selected options, where appropriate, are checked (!). Selecting

options with names ending with “…” br ings up windows that pr ovide

more options. These o ptions, and any further options they provide,

can be selected in the same manner. Most windows have selfexplanatory instruc tions. If more than one window is displayed, the

topmost is the one active. To cancel a window, press

or .

and to

.

17

Page 18

EXAMPLE:

to select Level Based… in the example below, press

18

Page 19

2.1.5 Editing Names

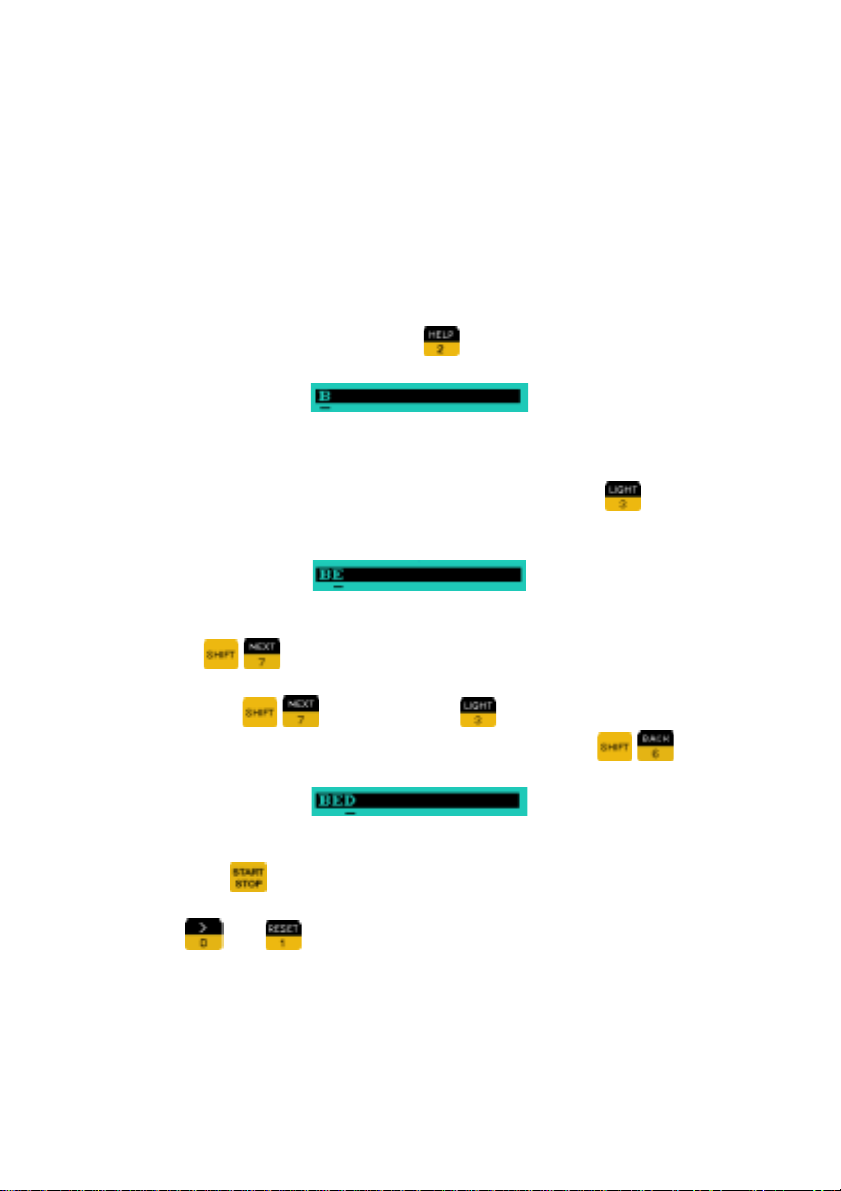

To enter characters in the text editing window:

• Select Display from the m ain m enu an d then se lect Edit Ch annel

Units or Edit Channel Names.

• Pres s the ke y with the character you want un til it appears above

the flashing cursor.

e.g. to enter the letter B, press

• The cursor advances automatically when you press the next key.

e.g. if the next letter you want to enter is E, press

displayed.

• If the next letter of the word is on the same key just pressed,

press

e.g. press

(The cursor can be moved backwards by pressing

• More editing options (and their shortcut keys) are available by

pressing

to advance the cursor position.

then press key until the letter D appears .

.

until the B is displayed.

until E is

).

Note

:

and can be used to enter the space character.

19

Page 20

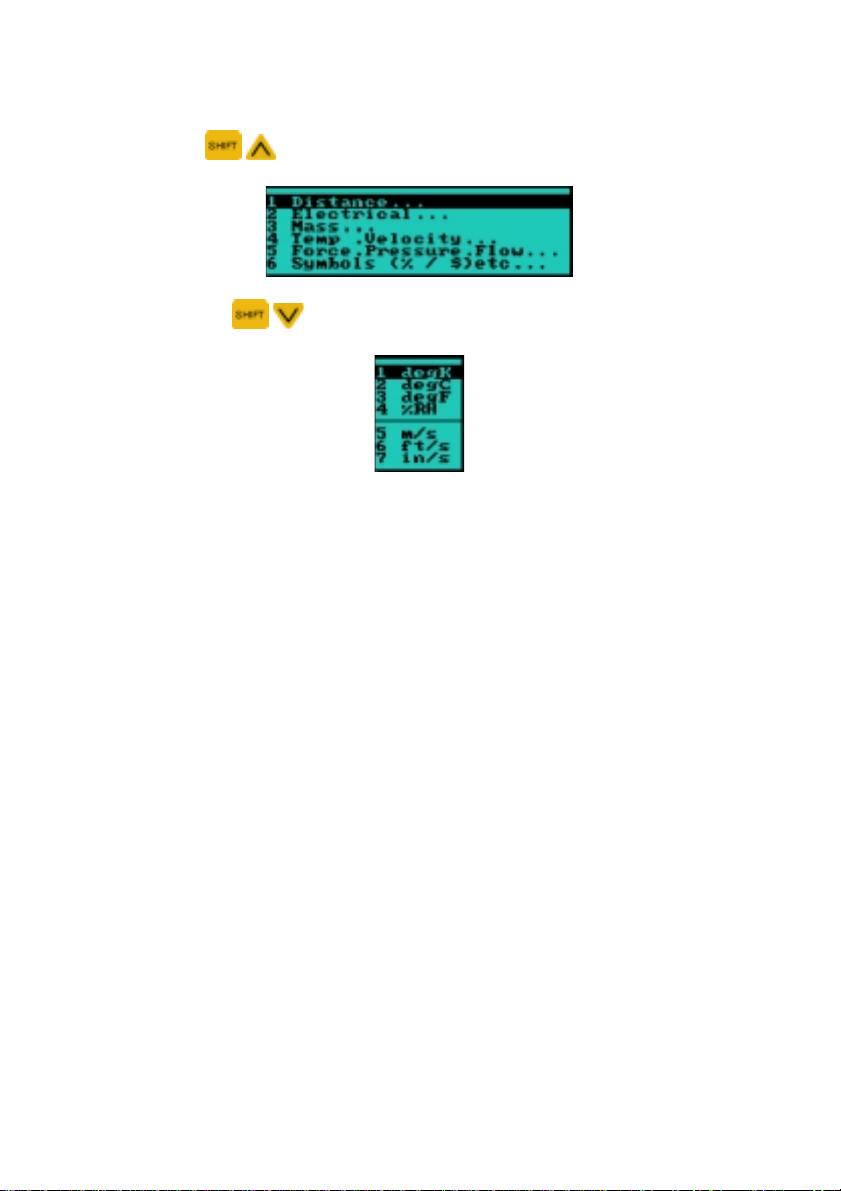

Libraries are available to make entering text easier.

• Press

• Pressing

to access the library categories.

will show the last text library selected.

20

Page 21

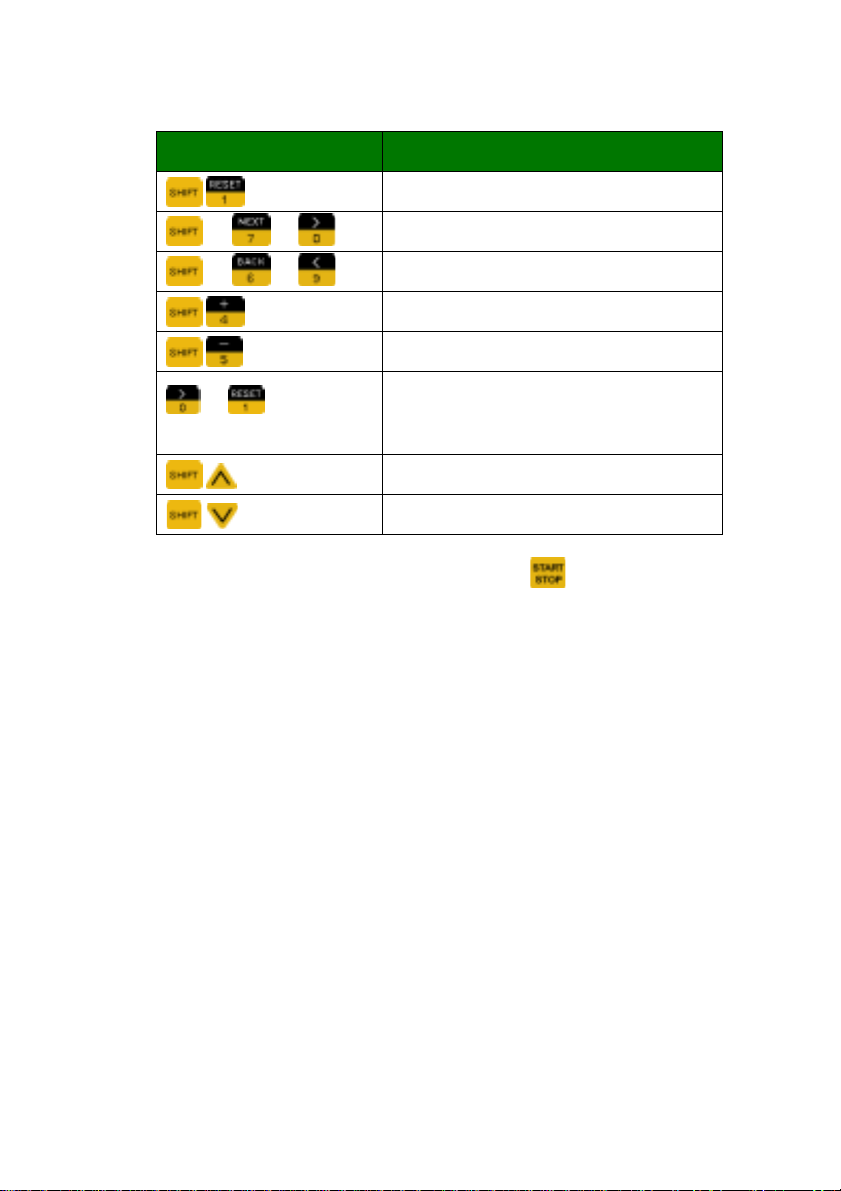

Table of Short Cut Keys

Short Cut Key Meaning

! or

! or

or

(press twice)

To toggle from upper to lower case press and choose the

desired case from the pop-up menu.

Folder, Recording and Channel names can have a maximum of 16

characters. Unit Names can have a maximum of 8 characters.

Clear all text

Move cursor forward

Move cursor back

Insert a space

Delete character

Can be used to enter a space

Text Library

Last Text Library

21

Page 22

2.1.6 Editing Numerical Values

• Select the numeric field to be edited (using the normal option

selection procedure outlined in section 2.1.4).

• Press the appropriate digit keys to enter the desire d value. Ent er

a decimal point by pressing

• To make the number negative/positive press

• Clear floating point num bers by pressing

point numbers can sometimes be incremented or decremented

by pressing

SAMPLING PERIOD.

or

, e.g. This is possible when setting the

.

.

. Non-floating

22

Page 23

2.2 SETTING UP INPUTS

T6V4

The

eight channels of data at a time. Due to the sharin g of channels 5

and 9, and of channels 6 and 0, the following conditions apply:

WARNING

1. Ensure that when using these shared channels, that only the

2. Never allow voltages of more than 10V between any two

3. Thermocouple channels 5 and 6 have a low input impedance

module is capable of sim ultaneous m easurem ents of up to

• Channels 5 and 9 cannot be simultaneously selected

• Channels 6 and 0 cannot be simultaneously selected

selected sensor type is connected. If a voltage source and

thermocouple of shared chan nels are sim ultaneous ly connected,

measurements will be erroneous.

thermocouple inputs, or 5V between an input and module

ground. This may damage the instrument.

due to the fact that the y are shared with voltage channe ls 9 and

0. If thermocouples of a resist ance higher than a few Ohms (eg.

Thermocouples with wire lengths longer than typically 2 to 3

meters) are used in these channels a small error will be

introduced. This error is proportional to the ratio of the

thermocouple resistance to the input impedance.

4. For best accuracy, all sources being measured should be

perfectly isolated from each other (including thermocouple

inputs)

† See Appendix Optimizing Temperature Accuracy.

†

.

23

Page 24

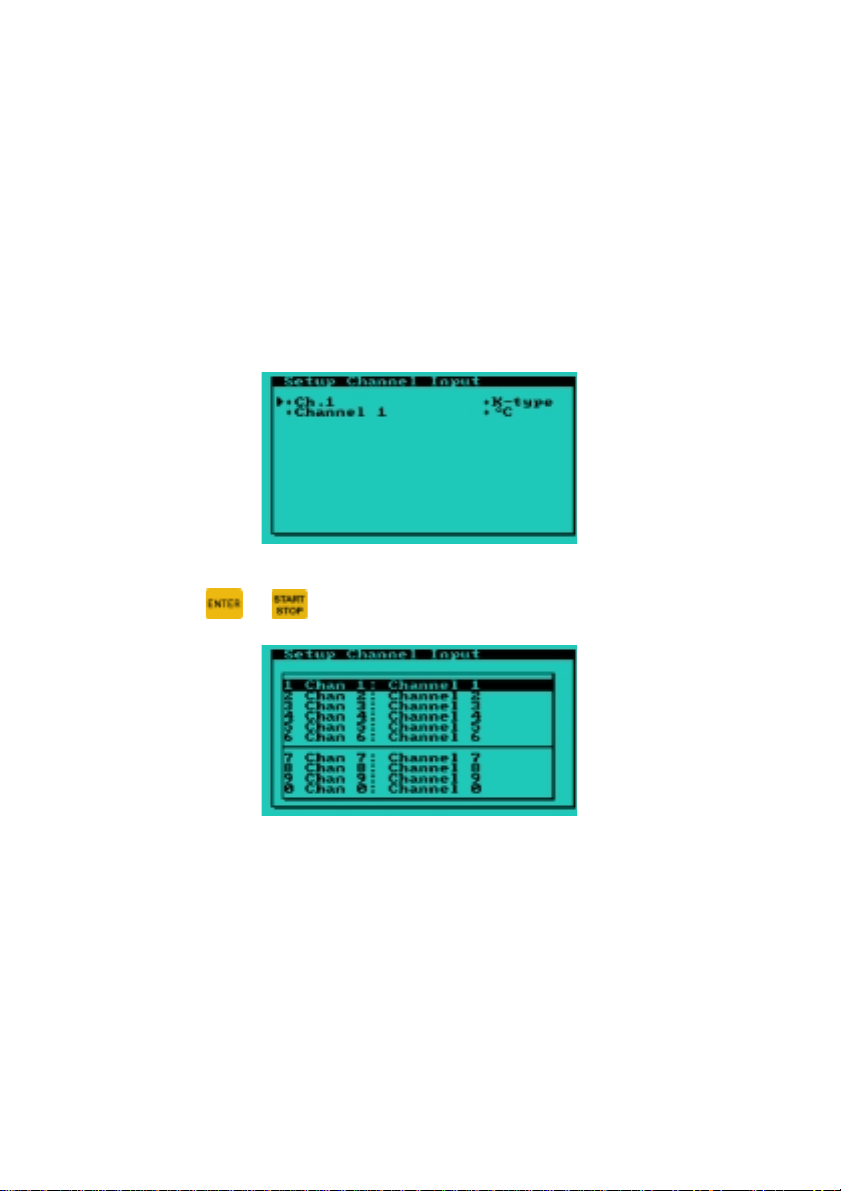

2.2.1 Channel Selection & Setup

The instrument needs to know what type of sensor is attached to

each input channel. You must set up the input channels one at a

time.

• Access the main menu (see section 2.1.2).

• Press Sys ! Setup Inputs… to display the “Setup Channel

Input” window.

• Press

• Select the channel you would like to setup.

Note:

24

or to display the channel drop down menu.

Channels can be named b y choosing “Edit/Names” from the

”Display” menu on the main menu bar (see section 2.1.2).

These names appear when downloading to a PC.

Page 25

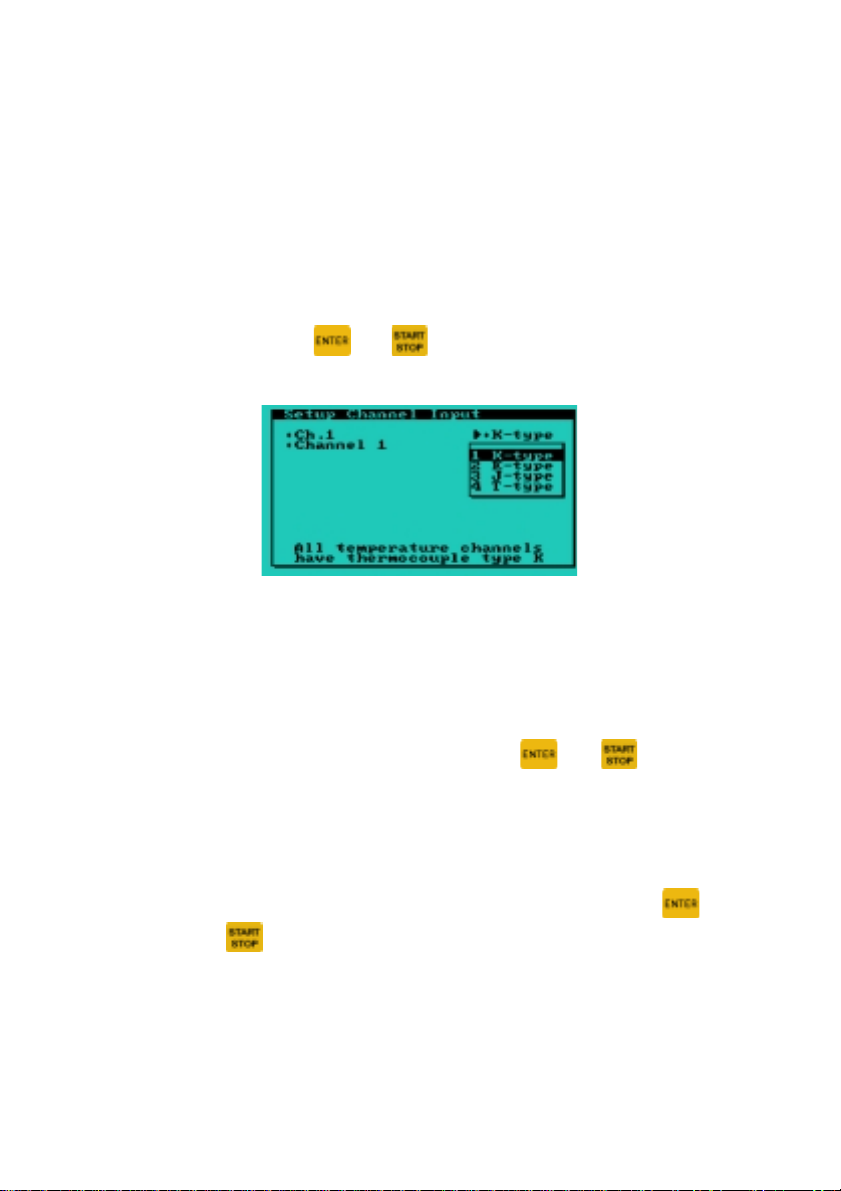

2.2.2 Channel Types

There are two types of channels on th e instrum ent, tem perature and

voltage. Each t ype of channel has differ ent configuration options as

follows:

Temperature Channels

Thermocouple type can be selected

• This can be done b y moving the cursor to the “K-type”

option in the “Setup Channel Input” window and

pressing

displayed.

• All thermocouples attac hed to the instrum ent m u st be of

the same type.

Units can be selected

• Move the cursor to the units displayed below the

thermocouple type and press

through the units, “

Voltage Channels

Voltage range can be selected

• Move the cursor to the “+/- 30V” and pressing

will toggle between “+/- 30V” and “+/- 5V”.

or . The following screen will be

o

C”, “oF”, and “User”.

or to cycle

or

Any change made to the voltage range will reset t he input a nd

output ranges to the default setup values.

25

Page 26

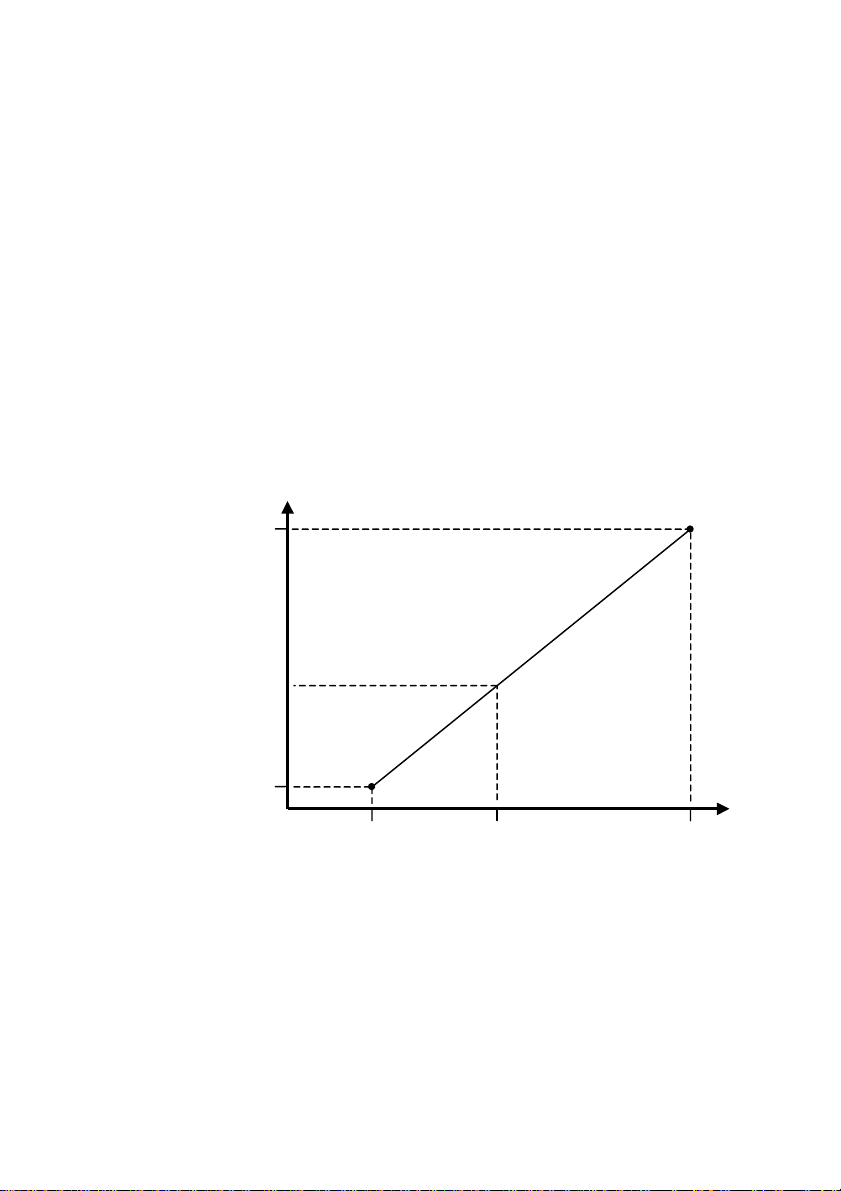

2.2.3 Matching Inputs to Se n sors

If you are using standard thermocouple or voltage inputs, then no

further setup is required. Ho wever for using other sensor s, you need

to match the inputs from the sensor to the values you would like

displayed.

EXAMPLE

: If you have a 0V – 24V proximity probe connected to

channel 8 that outputs:

0V at 1 mm

and 24V at 3.4 mm

then the following linear relationship is assumed:

3.4 mm

Measurement

to display

(mm)

2.0 mm

1.0 mm

10V = 2.0 mm

0 V

10 V

Sensor output-voltage

(V)

24 V

26

Page 27

2.2.4 Modifying the Input boxes

In this example we will setup the channel to match the following

sensor inputs:

• From the main menu, press Sys ! Setup Inputs… and select

the channel to be setup.

• Use the

input box you wish to edit.

• Press

or

or to display a list of edit options.

arrows to move the flashing cursor to the

Editing the Input Value:

• Select “Edit Input…” to enter the sensor input voltage in V.

• Press

or to accept the entered value.

27

Page 28

Sampling the Input value

:

It is also possible to s et the input boxes by sam pling the voltage or

temperature being monitor ed b y the instrument.

This is very useful if you know what you’re measuring, but do not

know what voltage / temperature your input sensor is providing.

e.g.

You have a sensor that can

measure the depth of water

based on pressure readings but

have no data that relates the

6ft

sensor output voltage to the

actual depth. However, you do

know that the present depth =

6ft.

• To match the input box follow the steps from the previous

example, but choose “Sample Input”.

• The input box will update with the sample taken being displayed

in the selected input box.

• If you are not happy with the sampled value keep selecting

“Sample Input” until you are, then press

to close the options

menu.

Note

: • The first input box reading must be lower than the

second input box.

28

• Input box readings must be more than 50

temperature and more than 1V apart for voltage.

o

apart for

Page 29

2.2.5 Modifying the Output boxes

• Use the

output box to be altered.

• Press

become highlighted, with its pr e v ious va lue c leare d. N ow enter in

the value, and press

• Now press

should flash beneath it).

• Press

or to accept this value.

Note

: Output box values • Can be positive or negative.

or

or to edit the value in this box. The box will

to begin editing. T ype in the number 3.4, and press

arrows to move the flashing cursor to the

or to accept this value.

arrow to select the nex t output box (The cursor

• Can contain decimal places.

• Can be in any order (i.e. box 1 can be

greater than box 2).

2.2.6 Modifying the Units

• To change the units (e.g. to mm), press

flashing cursors appear below the unit boxes.

• Press

window will appear (see section 2.1.5).

to begin editing the unit. The “Enter Channel Unit”

arrow until two

29

Page 30

2.3 SETTING UP CHANNELS

2.3.1 Setting Up Your Recording (The Trigger

Menu)

Most of the important information involved in your recording is

entered under the trigger menu. Trigger T ype, which Channels are

enabled, Sample Period, and Recording length/time.

Below are examples of all the trigger menu item s. Each item can be

configured by follo wing the pop-up m enus as per previous sections.

Timer and level b ased trigger optio ns can be selected by t he

arrows and pressing or .

The Trigger Type (how recordings are started).

or

There are three main types of trigger available:

•

Manual Trigger

•

Time Based Trigger

•

Level Based Trigger

30

Page 31

1 Manual Trigger

button.

- recording started and stopped by pressing

2 Timer Based Trigger

e.g. • Log data every day

Starting at 10:05:00am

• Record 5 samples

• Sample Period = 1 second

• After Recording

Power Down

(30 sec sensor warm up)

10:05:00am

Recording Period

W

Sample Period

= 1 second

Logging Period = 1 day

= 5 Samples

10:05:00am 10:05:00am

Warm up time

= 30 seconds

- data is recorded at regular intervals.

Log Period

Recording Period

Sampling Period

Stay Awake or Power

Down and Warm Up

Instructions

The user selectable warm

up time can be used to

allow sensors to stabilize

before recording begins.

W

Recording

W

Waiting

31

Page 32

3 Level Based Trigger

specified level.

- data is recorded if a sensor reaches a

6 m -

e.g. Trigger if lake level is

above 6m or below 2m.

2 m -

Outside Window Level

Available level trigger opt ions .

Trigger if signal is: Above Below Inside Outside

Level(s)

The Level based triggering option also allows for two more

types of triggering to be used:

•

Pre-Triggering

•

Post-Triggering

32

Page 33

4 Pre-Trigger

- record data for a specified time before a level

trigger occurs (level trigger must also be selected).

Chan 1

e.g.

Acidity

Crater Lake

Chan 2

Vibration

sensor

Instrument Settings

Channel 1 – No trigger setting

Channel 2 – Trigger if quake level is

above 6 on the Richter’s

scale

Pre-Trigger set to 1 hour

Sample period = 1 second

Record for 2 hours

Days/weeks etc. 1 hour data

Press

What is the acidity of a crater

lake 1 hour before an earth

quake?

“Quake”

signal

Quake triggers data logger

Pre-trigger Data after quake

recorded before

quake

2 hours data recorded

after quake

Once Pre-trigger is set, the d ata logger can be left for da ys, weeks

etc. When the specified trigger level occurs, pre-trigger data is

already saved in memory.

33

Page 34

5 Post Trigger

- start recording data to mem ory after a specified

time has elapsed once a level trigger has occurred.

Trigger occurs

Data recorded

Press

6 Enable Channels

record.

Note

: • Faster sampling rates are available if fewer channels

are selected.

• Less memory is used if few channels are enabled.

7 Sampling Period

Water level

Channel 1

Sample

recorded to

memory

Post-trigger time

- select the channels you would like to

- the amount of time between samples.

1 second

sampling

period

Note

: There is a fraction of a sec ond de lay bet ween chann el

1 second

sampling

period

1 second

sampling

period

1, 2, 3 etc. recordings.

34

Page 35

7 Record For…

of samples to take before recording automatically stops.

Note

:If “Auto Repeat Recordings” (under the file menu) is

- the amount of time to record for, or the number

selected and level trigger is also selected, a new file will

be created as soon as the recording time has finished.

This way you can get a separate file every time a lake

level goes into flood for example.

35

Page 36

2.3.2 Setting Display Opti ons

To specify how measured data is to be displayed:

• Access the main menu (see section 2.1.2).

• To display measured data in the form of text, press Display !

Text. The real-time readings are displayed for each enabled

channel.

• To display measured data in a text with minimum and maximum

values, press Display ! Min/Max.

• The min and max values are reset whenever a new recording is

started, or

• To edit the measurement unit for a channel, press Display !

Edit Units… In the Enter Channel Unit window, select the

channel by pressing

unit (see section 2.1.5).

• To edit the name of a channel, press Display ! Edit Names…

In the Enter Channel Name window, select the channel by

pressing

section 2.1.5).

is pressed.

or and then edit the name of the

or , and then edit the name of the channel (see

• To swap temperature units between degrees Celsius, degrees

Farenheit and User defined setup, pres s Display ! Temperature

Units:

Note

: It is possible to change the displayed Temperature units

during a recording by using the Display menu, but any

triggers that have been applied to Temperature channels

may accidentally trigger. The trigger levels that have been

set for any of the temperature channels are not converted

when you change your selection of Temperature units.

36

Page 37

2.3.3 Graph Controls

To view an xy-graph:

• Press Display ! Graph.

The following controls are available wh en viewing a graph. When a

file is being played back, additional cursor and zoom controls are

available.

Option Meaning

Active cursor moves right

(Playback only)*

Active cursor moves left

(Playback only)*

Toggle active cursor (Playback only)*

Zoom In and Out between cursors

(Playback only)*

KEYS 1 – 9, 0

(quick key press)

(quick key press)

(continuous key press)

(continuous key press)

Select channel 1 to 0

Increase y-axis scale

Decrease y-axis scale

Scroll graph up

Scroll graph down

Resets graph settings to default

37

Page 38

*(Playback only) - Cursors are available only when playing back a

file. For more inf orm ation on Playback mode please s ee sec tions 2.5

and 2.6.

o

Ch1 123.8

C !! 257

Channel being

examined

Note

: To leave the “Playback ” environment either press

Value at

active cursor

or select Display ! Exit Playback.

Sample

number at

active cursor

38

Page 39

2.4 RECORDING DATA

2.4.1 Setting Up the Filename

The data recorded in a single recordi ng session is stor ed as a file.

The name of the f ile into which data wil l be recorded is d isplayed at

the bottom of the data-display screen.

• T o edit the nam e of the file, pr ess File ! New Recording. In the

New Recording Setup window, select Filename and edit the

filename in the New File Name window (see section 2.1.5).

• File nam es are automatically num bered after the first recording

e.g. Lake level, Lake level 1, Lake level 2… etc.

2.4.2 Choosing a Folder

For identification purposes, it is convenient to group files that are

related under a common folder.

• To choose the folder under which the recording file is to be

grouped, press File ! New Recording. In the New Recording

Setup window, select Folder, and in the Save Recording in

Folder… window, select the folder.

• If a new folder is require d, pr ess Folder in the Save Recording in

Folder… window, sel ect the new f older, and then press Rename

to edit its name. Then select the newl y created folder in order to

place the recording file in it.

39

Page 40

2.4.3 Starting a Recording

• From the main display screen press

Data will be recorded and displayed according to how the inputs,

trigger, and display options were set up. The sample number is

updated on the bottom right of the screen as the samples are

collected.

The data is recorded into the file and f older you chose earlier (the

name of the file is displayed at the bottom of the screen).

to start the recording.

2.4.4 Auto-Repeating Recordings

If recordings are le vel-triggered, the ins trument can be instr ucted to

take recordings repeatedl y. This is us eful for captur ing the next level

trigger event.

To auto-repeat level-triggered recordings:

• Press File ! Auto Repeat Recordings to check (!) the option.

• To stop a recording press the

key.

40

Page 41

2.4.5 Chained Recordings

The instrument has a maximum capability of approx 60,000 data

points per individual recording. When this size is reached, another

file is created and recording c ontinues witho ut intervention or loss of

data.

Note

: Each sample of each channel uses up a data point, e.g. a 4

channel recording of length 10,000 samples uses up

40,000 data points.

Chained recordings are denoted with an x/ y extens ion. Which can be

interpreted as the xth number part of a total of y parts.

e.g. Untitled 1/2

Untitled 2/2

When transferring to

then the chained recordings will be recombined into a single long

recording.

MAS

, if the entire folder is selected and sent,

41

Page 42

2.5 PLAYING BACK

To play back a recording:

• Press File ! Examine files…

• In the Playback File window, select the recording to be played

back and press

Note

: Recordings can be played back in either the text, bar or

graph display modes, irrespec ti ve of the mode that the y were

recorded in.

• In the data-display screen, press

the samples and

the beginning of the recording ( the sample number is dis played

at the bottom right of the screen). The instrument beeps when

you have reached the first and last samples.

• T he display type and units can be altered i n the playback, any

changes made during p layback are only for the durati on of the

playback. This allows recordings to be viewed in an alternative

view from the way that they were recorded.

• T o exit Playback mode either press

Playback.

Note

: In the Playback File window, there are also options to

rename or erase a folder or recording, create a new folder

and collapse or expand the data tree.

42

.

to move forward through

to move backwards. Press to return to

or Display! Exit

Page 43

2.6 FILE UTILITIES

In the file selection window (File!Examine Files) the following

utilities are available:

Option Meaning

1. Shrink /

Expand

2. Folder

3. Rename

4. Copy

5. Lock

6. Erase

7. Snd to PC

or

Shrinks or Expands the File Folder structure to

make selecting a folder easier and quicker.

Creates a NEW FOLDER.

Renames a file or a folder.

Copies the selected file’s s etup (channel names,

units, trigger type etc.) so that the next

recording’s setup is the same.

Prevents a file from being erased with the

“ERASE” option. T his option can be used to loc k

your recordings so th eir setups are protected a nd

can then be copied at a later date. WARNING:

File! Erase All Memory will erase a locked file.

Erases the selected f ile or folder (does not erase

locked files/folders).

Sends the selected file or folder to the PC (see

section 4).

Selects a file for playback or selects the active

FOLDER to record int o (if Window Title is “Save

Recordings in Folder…”).

43

Page 44

2.7 OUTPUTTING SAMPLES

FROM RS232

Press File!Output Samples to RS232 to send real time data in

ASCII format from the instrument’s RS232 port.

This data can be captured by a PC (e.g. using HyperTerminal).

Channel Number Values

14.5000

6.8251

100.02

99.800

4.6000

6.8252

100.00

200.00

Format of Data

<channel number><space><channel value><CR><LF>

(8 data bits, no parity bit, 1 stop bit)

The default bit rate is 9600 bits/secon d, but it is p ossible to ha ve the

instrument send data at 57600 or 19200 bits/second.

Approximately 200ms between

channel readings

Cycle continuously repeats

To select a higher rate, send the instrument approximately 20 ’Q’

characters (e.g. pres s Q in HyperTerminal 20 times ) at the bit rate

you desire.

Note

: • ‘∗’ characters will be echoed while the ‘Q’ characters are

being transmitted.

• Operating the instrument’s menus may temporary

disrupt the transmission of samples from the RS232

port.

• Transferring files to

transmission.

• When using Timer Trigger, COMs will default to 9600

bits/second after the first wakeup.

44

MAS

cancels RS232 sample

Page 45

UTILITIES

This section outlines the procedure f or perform ing utility funct ions on

your instrument . You will learn to:

• reset the instrument ;

• adjust the instrument LCD;

• set the instrument clock;

• manage the instrument battery pack;

• manage memory usage on the instrument ; and

• troubleshoot the instrument .

WARNING

: Read section 1.4 before operating your instrument .

45

Page 46

3.1 RESETTING THE

INSTRUMENT

Sometimes, due to electrostatic discharge exceeding 8kV, the

instrument may not respond to any key presses (including

presses). In such cases, it is important to reset the instrument as

soon as possible. To reset the instrument :

• Press

simultaneously, once the initialization screen has been

displayed.

Once reset, the instrument displays the Initialization screen and

resumes normal operation. Res etting the instrument does no t erase

data or settings stored in the instrument .

while holding down and then release th em both

46

Page 47

3.2 ADJUSTING LCD

3.2.1 Adjusting Contrast

• Press Sys ! LCD-Contrast…

• To darken the LCD, press

• To restore the default contrast, press

If the screen flickers when cursors are moved, make the LCD darker.

. To lighten it, press .

then .

3.2.2 Turning Backlight On

To toggle the backlight ON and OFF press then .

47

Page 48

3.3 SETTING CLOCK

3.3.1 Checking Date and Time

• Press Sys !Clock.

All recordings are date and time stamped according to the clock

shown in the Date & Time window.

3.3.2 Setting Date and Tim e

• Press Sys ! Clock.

• To cycle to a particular field, press

• To edit the value of a field, press

• Press

If the am/pm hour f ormat is chosen, the hour s witches back to 1 at

the thirteenth hour. If the 24h format is chosen, the hour c ontinues

incrementing until 23 before switching back to 0.

48

when you have finished.

.

and .

Page 49

3.4 MANAGING BATTERY

3.4.1 Instrument Battery

The instrument is powered by a rechargeable Nickel-Cadmium (NiCad) batte ry pack. The normal operating voltage is 6.0 to 8.5 Volts.

Some automatic features have be en built into the inst rument to help

ensure that the battery pack is alwa ys suf f ic ientl y charge d. Be lo w 6.6

Volts, the instrument displays a flashing

corner of the screen and beeps once every minute as a reminder

that the battery pack needs to be charged. Below 6.1 Volts, the

instrument automatically turns off the backlight to prevent further

power draining. Below 80% battery capacity, the instrument

automatically begins to charge the batter y pack (if external power is

supplied). At 5.5 Volts, the instrument automatically powers down.

The power saver is anot her f eatur e tha t he lps c o nser ve po wer on the

instrument – see section 3.4.6.

There is also an internal backup battery that backs up data and

settings in the instrument in the event that the battery pack is

detached from the instrum ent . The backup battery is kept char ged

by the battery pack if the battery pack is functioning normally.

icon at the bottom right

WARNING

more than 2 hours as this will drain the backup battery, thereby

causing data and settings to be lost.

The battery pack can be charged by supplying 13.5 ± 1.5VDC, 1A

power to the instrument charger socket. The power transformer

supplied in the k it provides t his DC voltage . The optio nal car ad apter

charging lead may also be used to charge the battery pack in a

vehicle with a 12-Volt negative-chassis power system.

WARNING

transformer used is an approved ins trument po wer transform er (13.5

± 1.5VDC, 1A output) and that the voltage and frequency of your

mains AC power match that of the power transformer.

: Do not detach the ba ttery pack from the instrument for

: Before charging the batter y pack, ensure that th e power

49

Page 50

3.4.2 Checking Battery Capacity

• Press Sys

The remaining battery capacity and voltage are displayed.

3.4.3 Charging Powered-up instrument

WARNING

• Plug the instrument power transformer into a standard power

outlet and its connector to the instrum ent charger socket. If the

battery capacity is less than 80%, charging begins automatically.

• If charging does not begin automatically, press Sys ! Charge

Batt Charging, as ind icated b y the

begins.

If the

on. Charging stops automatically when complete or you can press

Sys ! Charge Batt to stop it. A full charging cycle takes

approximately 150 m inutes. All other functions are usable while the

battery pack is being charged.

: See the warnings in section 3.4.1.

icon in the dropdo wn menu,

icon is not displayed, ch eck that the mains power is turned

3.4.4 Charging Powered-down instrument

WARNING

• Plug the instrument power transformer into a standard power

outlet and its connector to the instrument charger socket. The

instrument powers up and charging, as indicated by the flashing

“CHARGING” message beside the Charge Batt option in the Sys

dropdown menu, begins.

: See the warnings in section 3.4.1.

If the instrument does not power up, reset the instrument (see

section 3.1), or unplug the power transformer connector and re-plug

it in. See also section 3.4.3 notes.

50

Page 51

3.4.5 Reconditioning Battery Pack

WARNING

Battery reconditioning is the process of first discharging and then

charging batteries. It reduces the undesirable memory effect in NiCad batteries. The batter y pack should be reconditioned when it is

first used (for its capacity to be displayed correctly) and monthly

thereafter (to prevent battery d egr adatio n). T o recondi tion th e batter y

pack:

• Plug the instrument power transformer into a standard power

outlet and its connector to the instrument charger socket.

• Press Sys ! Recondition Batt.

After discharging the battery pack, the instrument automatically

proceeds to charge it. See also section 3.4.3 notes.

: See the warnings in section 3.4.1.

3.4.6 Power Saver

Everytime the instrum ent is powered up, the power sa ver – a power

saving feature – is automatically turned on. With the power saver

turned on, the following occurs autom atically if no keys are pr essed

for a period of time, after 8 minutes the LCD is turned off (but any

key press will turn it on a ga in) a nd af ter 1 5 minutes, the instrument is

powered down. To turn the power saver on or off:

• Press Sys ! Power Saver.

51

Page 52

3.4.7 Replacing Battery Pack

• Lift the boot stand.

• Unscrew the battery pack and screw in the new one using a

suitable screwdriver or coin.

WARNING

not over-tightened – to the instrument .

: Ensure that the battery pack is securely fastened – but

52

Page 53

3.5 ERASING MEMORY

WARNING

ALL

recordings in the instrument .

Before erasing data, you may wish to archive it on your PC (see

section 4.3). To erase all folders and recordings:

• Press File ! Erase ALL Memory…

• In the Erase All ! window, press

for the data to be erased.

To erase only one particular recording or folder, see section 2.5.

WARNING:

default settings. All locked folders and files will be erased.

: Following the proce dure below erases

and together and wait

Erase All Memory will reset the instrument to factory

ALL

folders and

53

Page 54

3.6 TROUBLESHOOTING

3.6.1 Power Problems

Symptom Cause Remedy

Instrument cannot powerupLow battery capacity

Electrostatic discharge

(ESD) exceeding 8kV

Instrument powers down

when backlight turned on

Instrument powers down

shortly after powering up

Flashing icon and

beeping every minute

Low battery capacity Charge battery pack

Low battery capacity Charge battery pack

Low battery capacity Charge battery pack

Charge battery pack

Reset instrument

3.6.2 Data Problems

Symptom Cause Remedy

Data lost when battery

pack detached for more

than 2 hours

Data lost when battery

pack detached for less

than 2 hours

Flat backup battery Charge battery pack

Faulty backup battery Send instrument

authorized dealer for

servicing

to

“Insufficient memory”

displayed

Measured data seems

incorrect

54

No memory sp ace left

for recordings

Sensor wired wrongly

Faulty sensor

Erase obsolete

recordings (transfer to

PC first if necess a r y)

Wire as recommended

Replace sensor

Page 55

3.6.3 Data-Transfer Problems

Symptom Cause Remedy

“No PC ?” displayed, and

data cannot be transferred

to PC

MAS

-3000 unable to

transfer data and “Transfer

failed” or “

Dialog” displayed on PC

MAS

Error

Data-transfer cable not

properly connected

Data-transfer cable

connected to wrong PC

COM port

Baud rate setting in OM-

MAS

3000

Baud rate setting in OM3000

MAS

too high

too high

Re-secure cable

connections

Test COM port

availability and use

available port

Select a lower baud rate

in OM-3000

Select a lower baud rate

in OM-3000

MAS

MAS

3.6.4 Other Problems

Symptom Cause Remedy

Instrument does not

respond to any key press

“Module fault” displayed Module‡ damaged Send instrument to

Electrostatic discharge

exceeding 8kV

Reset instrument

authorized dealer for

servicing

“Switch off then connect

module” displayed

Module not properly

plugged into instrument

Power down instrument

then re-secure module,

making sure not to bend

the connection pins

The “module” is the measurement hardware unit of the instrument . It has the six

‡

temperature measurement channels and 4 voltage measurment channels att ached to

it and is fastened to the rest of the instrument

by means of two M3x0.5x12mm screws.

55

Page 56

56

Page 57

ANALYSIS

SOFTWARE

Recordings made on your instrument can be transferred to the

software running on a Windows

M

easurement Analysis Software.

analyse, print & export your recordings.

It is assumed that the user of

Windows

Windows

commands.

Note

WARNING

commands. Please ref er to the appropriate lit erature on

if clarification is needed on mouse and keyboard

Throughout

a comprehensive topic-specific

the right mouse but ton an ywhere in

up menu of the applicable commands.

: Read section 1.4 before operating your instrument .

MAS

, pressing F1 on your keyboard will bring up

based PC.

MAS

can be used to stor e, graph,

MAS

is already familiar with basic

Help screen

MAS

MAS

stands for

. Also, clicking

will bring up a po p-

MAS

57

Page 58

4.1 INSTALLING OM-3000

MAS

4.1.1 License Agreement

Please read the license and warrant y agreement printed on the CD

cover found in the jewel c ase that t he

MAS

is licensed for individual use and for installation on one

computer. The software contained on the CD-Rom remains the

intellectual proper ty of OMEGA Engineerin g who retain the tit le and

ownership of the software.

MAS

CD-Rom was suppli ed in.

4.1.2 PC System Requirements

The following are the minimum system requirements for installing

MAS

:

• Pentium or better

• 32MB RAM (64MB recommended)

• 10MB hard disk space

• CD-Rom drive

• Windows

• Windows

• Windows

• An unused COM Port for communication with the instrument

58

95, 98, Me, NT or 2000 operating system

compatible displa y and print er

compatible mouse or other pointing device

Page 59

4.1.3 Installing OM-3000

• Close all programs on your PC.

MAS

on PC

• Insert the

• Wait for the

OR

Run the

• Follow the instructions given to complete the installation.

MAS

CD-Rom into the CD-Rom drive.

MAS

Installation program to automatically start.

MAS

Install.exe program located on the CD-Rom.

59

Page 60

4.2 STARTING UP

MAS

4.2.1 Starting up

• Click Start ! Programs ! OM-3000 ! OM-3000 MA S 5.00

4.2.2 Configuring PC COM port

• To allow data transf er between the instrument and t he PC, you

must first configure your PC COM port as follows:

• Connec t the instrument to one of the COM ports usin g the data-

transfer cable and power up the instrument .

• Click Tools menu! Configure COM port.

• Select the COM port that the instrument is connected to.

• Select a baud rate. The baud rate is t he speed (in bits/secon d) at

which data is trans ferr ed. The lo wer t he baud rate, the less lik ely

are data-transfer err ors. Automatic is the default cho ice as it is

sufficient for normal transfers.

• Click Test port

• Click Yes in the Confirm window to test the connection.

Connection failure may be due to the selection of the wrong

COM port in

connectors being not p lugged in properly, or the PC serial port

being not set up properly. If the con nection is good, co ntinue as

follows:

• Click OK in the sec ond confirm windo w to acknowledge that t he

instrument is attached to the COM port.

• Click OK to leave the

60

MAS

, the instrument being not powered up,

MAS

Configuration window.

Page 61

4.3 TRANSFERRING DATA TO

THE PC

Data transferred to the PC is stored in

and have the .das extension.

To transfer data from the instrument to the PC:

• Turn on the instrument Check its battery capacit y and if less than

30%, charge the battery pack.

• Connect the RS232 por t of the instrument to the configured PC

COM port using the data-transfer cable. On the PC click the

Receive button.

• On the instrument , press File menu! Examine F iles… Use the

arrow keys to select the individual recording or folder to be

transfered. If a folder is highlighted, all recordings within the

folder will be transferred.

• Press

Once the data-transfer is complete, the data will appear in the

current file in

a new file.

• To append more data fr om the instrument to the c ur rent f i le, c lic k

the Receive button.

• Alt ernatively, to receive more data but in its own new file, click

File menu ! Receive from OM-3000 ! Transfer to a New File.

SndToPC to send the selected recording or folder.

MAS

or if no files wer e ope n, the d ata wi ll app ear i n

MAS

files. These are text files

• To save the data in the current file, click the Save button, nam e

the file and click Save. If the file was an already existing file,

clicking the Save button will autom aticall y save the fil e under th e

same name and in the same location on the PC.

61

Page 62

4.4 MANAGING DATA

4.4.1 Opening a File

• Click Open button and select the file.

4.4.2 Merging Two Files

• Open one of the files.

• Click File m enu! Import & Merge a file… and select the other

file to be merged into the open file.

The merged data can be viewed but is not autom atically saved on

the computer. To save it, click File menu! Save or Save As.

4.4.3 Using the Navigator

When a file is open, the navigator that consists of two boxes is

displayed on the left side of the s creen. The top box shows all the

folders in the file. The bottom box shows all the recordings in the

selected (highlighted) folder above.

4.4.4 Deleting Data from a Folder

• Select the folder in the Folder section of the navigator.

• Using the navigator, select the individual recordings and/or

channels to be deleted.

• Click File ! Delete, or press the Delete key. You will then be

prompted to confirm that you wish to delete the selected

recordings/channels

62

Page 63

4.4.5 Editing Recording De tails

• Select the folder, and th en the recordin gs and/or channels to be

edited.

• Click the Info tab to access the Info page wher e you can e dit the

User Details (eg. Company Name, instrum ent serial number…),

Folder Name, and the Recording Details (eg. recording name,

remarks, channel labels and un its …) .

• From the Edit User Details screen there is access to edit the

Default User Details. These values are written to all future

recordings, while they are being transferred from the instrument .

4.4.6 Viewing and Printing Da ta Values

• Open the file and using the navigator, select the recordings

and/or channels to be viewed and/or printed.

• Click the Values tab. T he data in the selec ted recordings and/or

channels can now be viewed.

• To change the value in a cell, clic k the cell and type in the new

value.

• To reduce the amount of data by averaging, click the Average

button.

• To print the data, click the Print button.

• To copy the values to a s preadshee t progr am , click the Copy (to

clipboard) button, go to the Spreadsheet program and use its'

"Paste" command.

• To print a report on the data, click File ! Summary Report

Full Report** and s elect the pr int option in the Data Summary or

Report Generator window that appears.

§ The Summary report produces a data summary about the selected

recordings/channels. For more information consult the MAS help file.

§

or

63

Page 64

4.4.7 Exporting data

• In the Navigator select the folders or r ecordings to be exported

as a .das file.

• Click File ! Export and select the option required.

• Provide the nam e and location of the export file t o be produced

and then click the Save button.

** The Full report produces an exact printout of the pages selected in the report

generator window. For more information consult the MAS help file.

64

Page 65

4.5 CALCULATING DATA

You can perform calculations on your r ecorded d ata b y creati ng ne w

"calculated" channels:

• Open the file and using the navigator, select the recordings

and/or channels to be used in calculations.

• Click the Values tab to displa y the data and click the Calculate

button to access the Calculate window.

• Each channel is automatically given a "

used to identif y the channel. It is a lett er of the alphabet t hat c an

be used to reference the values of a recording for use in

calculations.

• Expressions can then be derived using the provided functions

and the channel tags

eg. TempChange = ChangePerHr(B) with units degC/hr

This example will create a channel called

"TempChange" which is calculated as the rate of

change per hour of the channel which has tag 'B'.

• Constants can also be used in calculations. You may need to

use constants in your expressions, for example:

To find the "difference from the mean value" for a particular channel,

say the channel represented by "

A constant should be defined to provide the mean value of

channel 'D', "K0 = Mean(D)"

This constant is then used in the express ion,

"DiffFromMean = D – K0"

††

.

tag

" 'D'.

tag

" character that is

See Appendix OM-3000

††

MATH for a complete list of functions available.

MAS

65

Page 66

4.6 PLOTTING DATA

4.6.1 Plotting Single and Individual Charts

• Open the file and using the navigator, select the recordings

and/or channels to be plotted.

• Select the Chart tab and click the Plot button. You can also plot a

recording or channel by double-clicking it in the navigator.

• To display the selected recordings and/or channels on individual

charts, click the Individual button.

• To change the format of charts, click the Adjust button to access

the Adjust Axes & Colors window. This window allows for

changes to be made to the axes and colors of the plotted

recordings displa yed on the chart.

• To clear all plotted recordings, click Chart menu ! Clear Chart.

To retain existing plots when adding to the chart, click the Hold

button. A maximum of 16 plots can be displayed at a time

To enlarge a chart, you can hide the legend by clicking Chart menu

! Show Legend. You can also Hide the navigator by clicking

Window menu ! Show Navigator.

66

Page 67

4.6.2 Zooming & Panning

To zoom in on any part of a chart:

• Click a point to the left of that part of the chart and drag a

rectangle across and down to the right over the section to be

enlarged (while holding down the lef t mous e butt on) . Re le ase th e

mouse button to perform the zoom.

To zoom in horizontally:

• Proceed as above, but only move the m ouse direc tly up or down

to select the area to be enlarged. Two horizontal lines will be

displayed across the chart to indicate the selection.

To zoom in vertically:

• Proc eed as abov e, but onl y move the m ouse dir ectly lef t or ri ght

to select the area to be enlarged. Two vertical lines will be

displayed across the chart to indicate the selection.

To unzoom from any view:

• Left click on any point in the chart and drag a rectangle up and to

the left to display a rectangle with a cross in it. When the m ouse

button is released all zoom ing will be undone and the char t will

be returned to its original view.

Panning

• T he chart displayed can be dragged i n any direction to dis play

sections that are hidden from the current view. To pan around

the chart click and h old down th e right m ouse but ton in the chart

display. The curs or will turn into a pointing hand icon. Drag the

mouse pointer in the direction that you wish to move the chart.

Note:

If you move the cursor of f the chart, you will have to re lease

the right mouse button and return it to within the chart

boundaries to continue panning.

4.6.3 Printing Charts

• Click Print while the chart is displayed and choose the color

scheme for printin g (e.g. Black & White, Full Color or Color on

White bkgnd)

67

Page 68

4.6.4 Reading and Comparin g Values

To place cursors on charts to read the data values on curves:

• Plot the recordings and/or channels on a single chart.

• To place a cursor at a particular point on a curve, place the

mouse cursor at that point, follow the curve until a crosshair

appears, and then click the left mouse button. If the default

cursor options are used, the cursor com prises a hori zontal and a

vertical dashed l ine, and the values ind icated by the cursor are

displayed at the edge of the chart next to the dashed lines.

• To move the cursor to a differ ent point on t he sam e curve, pres s

the horizontal arro w k e ys. T o move in small steps , hol d d o wn the

Ctrl key when pressing t he horizontal arrow ke ys. You can also

move the cursor by clicking the left mouse button on the new

point (first allowing a crosshair to appear).

• To move the cursor t o a different curve, push the vertical arrow

keys. Alternativel y, click the left mouse button on the new curve,

or on the appropriate symbol on the legend.

• To place a second c ursor on the chart, place th e mouse cursor

at the point of interes t, foll ow the cur ve u ntil a cros shair ap pears ,

and then click the right mouse button. If the default cursor

options are used, the dif ference be tween th e values indicate d by

the cursors is shown at the t op right corner of th e char t. Curs or A

corresponds to left mouse button and cursor B to the right.

• To toggle the focus between t he cursors, push the spac e bar, a

cursor must be focused before it can be moved using th e arrow

keys. A cursor is focused if it has a rectangular target.

• To clear the cursors, push the Esc key.

• To change cursor options, click Chart menu ! Cursor Options....

68

Page 69

EXAMPLE

cursors displayed (using the default cursor options).

Each cursor displ ays the x and y axis va lues and the difference in

both the x and y axis values of the two cur sors in the top rig ht hand

side of the chart.

: a two-channelled temperature recording with both

69

Page 70

4.6.5 Plotting Waterfall Charts

• Plot the recordings and/or channels on a single chart.

• Click Chart menu ! Waterfall Chart and select the depth

required.

Waterfall charts are useful for trending data behaviour. As on

ordinary charts, cursor and zooming functions can be used on

waterfall charts.

EXAMPLE

to three sets of data pertaining to the same measurement point. It

can be seen that the peak value has a rising trend.

: the four curves on the waterfall chart below correspond

70

Page 71

4.7 UPGRADING FIRMWARE

When an upgraded instr um ent firm ware versio n is a vaila ble, it wil l be

posted on the OMEGA website. Once you have obtained the

firmware file, the firmware can be upgraded using the

reprogramming procedure below.

WARNING

• Check the instrum ent battery capacity and if it is less than 30%

charge the battery pack.

• Connect the RS232 por t of the instrument to the configured PC

COM port using the data-transfer cable.

• Po wer up the ins trument and tr ansfer an y data you wish to keep

to

• In

Reprogram window click the Reprogram button! Automatic

search.

: Upgrading the firmware erases all data in the instrument.

MAS

on a PC.

MAS

click Tools menu! Reprogram OM-3000. In the

• Click Select Drive to Search a nd select the drive wher e the ne w

firmware version is located.

71

Page 72

• Click Start S earch, and when the sear ch is com pleted select the

new firmware file.

• Click Start Reprogram using this file.

Once the reprogramm ing is complete, the instrument will be ep and

the Initialisation scr een will appe ar. If an error oc curs, check that the

data-transfer cable has been connected properly and that the

instrument is powered up.

72

Page 73

Appendix

SPECIFICATIONS

The following are the specifications for:

• instrument firmware version 2.10

MAS

•

These specifications may be changed in future versions.

software version 5.00

73

Page 74

Model:

OM3000-T6V4

Specifications

Range

T Type Thermocouple

E Type Thermocouple

J Type Thermocouple

K Type Thermocouple

Voltage

Common Mode Range

Resolution

Temperature

Voltage

Accuracy

Temperature

Voltage

Common Mode Error

Minimum Sampling

Interval

Data Logging

Data Storage Format

Data Storage

Folder Name

Display

Resolution

Viewing Area

Backlight

Repro gram Allows internal firmware to be upgraded via built -i n serial port

Communications

Baud Rate

Channel Organiz a tion

Termination

Temperature

Voltage

Input Impedance

Temperature

Voltage

Isolation

Battery

Type

Voltage

Capacity

Operating Time

Charger & Conditioner

Fast Charge Rate

Discharge Rate

Mechanical

Size

Weight

Environmental

Temperature/Humidity

Operating

Storage

EMC

© 2000 Omega Engineering Ltd,. The manufacturer reserves the right to modify specifications

6 Temperature Chan n els

Incorporating 4 Voltage Channels

-418 to +743°F (-250 to +395°C)

-418 to +1823°F (-250 to +995°C)

-346 to +2183°F (-210 to +1195°C)

-418 to +2498°F (-250 to +1370°C)

±5VDC and ±30VDC (user-selectable)

±30VDC (voltage channels only)

Above -148°F (-100°C): 0.1°F or °C

At or below -148°F (-100°C): 1°F or °C

±5VDC: 200µV (0.0002V) ±30VDC: 1mV (0.001V)

Above -148°F (-100°C): ±0.1% of reading ±0. 9°F ( 0.5°C)

At or below -148°F (-100°C): ±1% of reading ±0.9°F (0.5°C)

±5VDC: ±0.3% of reading ±0.6mV

±30VDC: ±0.3% of reading ±3mV

0.1% of common mode voltage

Number of channels

selected (userselectable)

1

2

3

4

5

6

7

8

Up to 50 named folders

Multiple recordings per folder

Recording length: 1 sample … entire memory

512 kilobytes – approximately 400, 000 indiv idual data points

Up to 16 alphanumeric characters

LCD with graphic capabilities

240 x 128 pixels

4.3" x 2.3" (110mm x 60mm)

Electro-luminescent

RS232

9600, 19200, 57600 bits per second

Any combination of up to 8 channels for any recording

Sockets accept miniature thermoc ouple twin blade plug

Screw terminals

Channels 1, 2, 3, & 4: greater than 100k

Channels 5 & 6: 30k

Channels 7, 8, 9, & 0: 2M

50VDC minimum Between inputs and

Custom Nickel-Cadmium pack

7.2V nominal

1500mAh nominal

13 hours nominal with backlight off, 7 hours nominal wi th backlight on

Built-in dual rate charger – automatic and m anual c ontrol

0.7A nominal

0.5A nominal

9.7" W x 6.1" L x 3.0" H (247mm x 154mm x 75mm)

4.4lb (2kg)

32°F to 122°F (0°C to 50°C) / 80% RH 32°F to 86°F

70% RH 32°F to 122°F

14°F to 140°F (-10°C to 60°C) / 95% RH

EN50081-1

EN50082-1

Voltage channels

only selected

(seconds)

0.2

0.3

0.4

0.5

Ω

Ω

Ω

Temperature or

temperature and

voltage channels

selected (seconds)

0.2

0.3

0.5

0.6

0.7

0.8

0.9

1.0

Remarks

Operating temperature range is determined by operating

range of thermocouple.

Differential inputs.

Voltage allowed between channels and input ground.

Effective resolution decreases at or below -148°F ( - 100°C).

Temperature measurement accuracy depends on

and thermocouple accuracy. Only

T6V4

accuracy is given here.

(23 ± 5°C), charger off. See Appendix Optimizing Temperature

Accuracy.

Minimum time to scan all

channel.

Sampling interval is programmable from 0.2 seconds to 60

hours.

User-specified name entered from keypad.

Each recording has unique time/date stamp.

Supports long recordings by chaining 60,000 data point

recordings. Each ample contains one data point per channel.

Non-volatile memory (battery backup). Number of samples

depends on the number of recordings and the variability of the

readings.

Download firmware updates from the Omega website.

15kV ESD protected. Cable with DB9 connector included.

Automatic baud rate selection.

Channels 5 & 9 and 6 & 0 are shared.

Blades spaced 5/16" (7.9mm) center-to- c enter.

Terminal-to-terminal.

Terminal-to-terminal (channels 5 & 9 and 6 & 0 are shared).

1MΩ per terminal to input ground.

No isolation between channels.

Power transformer (13.5 ± 1.5VDC, 1A output ) included in kit.

2.5 hours for complete charge nominal.

Combats Ni-Cad battery memory effect.

Including protective boot.

Including protective boot and strap.

Non-condensing.

Non-condensing.

Radiated and conducted emissions.

RF field, ESD and fast transient immunity.

OM3000-T6V4

OM3000-T6V4

temperature 73 ± 9°F

selected channels - not each

outputs e.g. RS232 port.

OM3000-

OM3000-T6V4

74

Page 75

Appendix

Application Notes

6.1 Application Note 1

Using the

Description

The internal circuitry of the

one of eight differential input channels (8 channel multiplexed differential

input A/D converter).

Four of these multiplexed inputs are dedicated to measuring

•

thermocouple voltages (CH1 to CH4).

Two multiplexed inputs are dedicated to measuring voltages up to

•

30VDC through resistive dividers (CH7, CH8).

The remaining two multiplexed inputs share resistive dividers (CH9 and

•

CH0) with an additional two thermocouple channels (CH5 and CH6

respectively). These inputs can be used for either (but not both) voltage

or temperature measurement, depending on the channel number

selected.

All channels (and the module ground) are isolated from instrument

circuitry and the serial cable, battery etc. If only one channel is connected,

then there is no need to consider the effects of common mode voltage or AC

noise.

Module’s Common Mode Inputs

T6V4

T6V4

module measures low-level signals from

internal

75

Page 76

However, the channels are not isolated from each other. Each channel has

differential inputs (ie. they measure the voltage between +ve to -ve), which

allows non-isolated voltage sources to be measured provided:

common mode voltage restrictions are observed;

•

the effect of common mode voltage on accuracy is understood; and

•

channel-to-channel leakage current through the

•

allowed.

Restrictions

T6V4

module is

For safety:

respect to ground potential) to any input pin. This includes thermocouples

that are not isolated but measuring the temperature of a metallic object at

high voltage.

WARNING: The isolation within the

To avoid damage:

thermocouple input pins, or greater than 5V between any thermocouple input

pin and module ground. (This will damage the protection diodes in the

multiplexer – see the “

Example: To measure the temperatures of both terminals of a 12V battery it

is essential to use isolated thermocouples.

To avoid incorrect readings:

input to exceed + or - 5V with respect to the module ground. (This ground

will float to some intermediate value depending on the voltages present on

voltage and thermocouple input pins.) If any one input pin goes out of this

range, all inputs may read incorrectly. Example: Measuring voltage from a

12V battery on CH7 while measuring temperature on CH1 from a nonisolated thermocouple at a potential greater than the battery positive –

current will flow in through the thermocouple wire, through the input of the

multiplexer, and out through the resistive divider of channel 7. This may

cause either or both of the readings to be completely incorrect.

Do not apply voltages greater than SELV (see Section 5) (with

module is not intended to

T6V4

protect the user from hazardous voltages.

Do not apply more than 10V between any of the 12

T6V4

Module Equivalent Input Circuit” diagram below).

Do not allow any voltage on any multiplexer

To minimize common mode errors:

channels is as small as possible, or at least smaller than the voltages being

measured. The best way to do this is to isolate the input sources, in that way

the instrument

voltage. Sometimes this is not possible, for example when measuring motor

current with a shunt and motor voltage, or measuring the temperature of

both sides of a power diode (less than 1V across it) by directly soldering on

thermocouples. In these cases, common mode errors need to be kept in

mind or checked (see examples 1 and 3).

input circuitry itself holds all input sources to the same

Ensure the voltage difference between

76

Page 77

To avoid problems with common mode noise:

(See Application Note 2)

When isolating signal sources, ensure that the impedance of this isolation is

significantly higher than the

instrument's

input impedance (for AC signals

too). If this is not so, common mode voltages applied may be larger than

when they were not isolated. Example: long cable and thermocouple runs,

when isolated, may act as aerials and pick up large AC voltages (say

50VAC) which would overload the input of the multiplexer, resulting in

erroneous readings or even damage.

Module Equivalent Input Circuit

T6V4

Protection

Diodes

(CH7, CH8, CH9, CH0)

+5V

Four Voltage

Inputs Like This

Two Sha r ed

Thermocouples

Four More

Dedicated

Thermocouple

Inputs Like This

-5V

Protection

Diodes

+5V

-5V

Switch

Array

A/D

Inputs

150k

Equivalent Input

Structure

Switch

Array

Ω

77

Page 78

Examples on Application Note 1

Differential measurements can be confusing to understand. The best way of

explaining is with examples.

Example 1:

+24V

- +

Example 2:

Measuring supply current and supply voltage to a DC motor.

24-Volt Motor

+ -

Max 30 Volts DC on Volta ge Inputs

123456

GND-7+-8+-9+-0+GND

Measuring signals in a multi-channel 4-20mA system.

78

Max 30 Volts DC on Voltage Inputs

123456

GND-7+-8+-9+-0+GND

Page 79

Example 3:

Measuring case temperature of both sides of a forward

conducting power diode while it is operating at SELV (saf ety extra

low voltage).

Ma x 30 Vol t s D C o n Vol ta ge Inp ut s

123456

GND-7+-8+-9+-0+GND

79

Page 80

6.2 Application Note 2

Instrument Grounding

In an industrial environment it is common to have AC and/or DC

voltages between conductive surfaces that are not bonded together.

Conductors that are assumed to be isolated may in fact have a DC

leakage, a 50Hz/60Hz AC voltage from inductive or capacitive coupling,

or a continual presence or bursts of r.f. voltage (emc).

When using the instrument to measure DC voltages that are not referenced

to ground (ie. one point bonded to ground by a low impedance), then

connecting a thermocouple to another conductive surface can cause the

voltage readings to alter (i.e. become incorrect). It is necessary to check for

errors, by observing the voltages while connecting the thermocouple.

In such an environment it is recommended that the metal surface to which

the thermocouple is connected, is grounded or wired to the GND terminal of

T6V4

the

module, as shown in examples 1 or 2.

Note

: 1. Because the GND terminal on the

of the allowable differential voltage range, if the ground of a

grounded PSU is connected to the GND terminal, the PSU

voltage may not exceed 30V (e.g. do not connect a grounded

48V supply to the instrument

2. Uninsulated thermocouples cannot be used for measuring

temperatures of conductive surfaces that are of different

voltages.

80

T6V4

module is the center

as in example 3).

Page 81