Page 1

OMEGABOND® High Temperature

Chemical Set Cements

OMEGABOND

HIGH TEMP

CC High Temperature

Cement Binder

U Heat Conductive

U Thermal Shock

Resistant

U Insulate Electricity

U Resists Oils,

Solvents,

Most Acids

U Adhere To

Practically

All Clean

Surfaces**

Chemical set cements set or cure

by an internal chemical action which

does not require exposure to air.

Chemical set cements can be used

in thick applications (applied in

thicknesses greater than 1⁄4")*.

Selection Criteria

for Cements

1. Type of Application—

Potting, sealing, encapsulating,

assembling, bonding. Is a thick

or thin film of cement required?

This dictates whether or not an

air set or a chemical set cement

can be used.

2. Thermal Considerations—

What is the maximum

temperature that the cement

must withstand? What degree

of thermal conductivity is

needed? What degree of thermal

expansion is allowed? These

properties are then matched to

the appropriate cement.

3. Solvent—10% Sodium

Hydroxide. However it’s difficult to

remove cured cement.

4. Substrate—What materials will

the cement be in contact with?

5. Application Consideration—

Pot life, set time, method of

dispensing, batch size, cure

procedure.

CC High

Temperature

Cement Filler

6. Miscellaneous

Considerations—Porosity,

moisture absorption, electrical

resistance, volume stability,

clearances/tolerances.

To Order

Model No. Description

OB-600 OMEGABOND® 600 powder, 8 fluid oz

(1 part cement; just mix with water)

OB-700 OMEGABOND® 700 powder, 8 fluid oz

(1 part cement; just mix with water)

CC HIGH TEMP CC high temperature cement kit, contains

2.25 oz powder and 0.75 oz liquid by weight

CC FILLER CC high temperature cement powder, 8 oz by weight

(2 part cement; mix liquid with CC binder)

CC BINDER CC high temperature cement liquid, 8 oz by weight

(2 part cement; mix liquid with CC filler)

OB - K IT-2 Chemical set cement kit, ideal for research purposes;

includes 2 fluid oz each of OB-600 and OB-700 and

also one CC high temp kit

OB-TL OMEGABOND® thinning liquid, 8 fluid oz used to

dampen porous substrates before application of

mixed OB-300 or OB-400 cements

See next page for footnotes.

*, **

Ordering Example: OB-KIT-2, chemical set cement kit containing OB-600, OB-700, and

1 CC high temp kit.

Visit omega.com/ob_bond_chem_set for Pricing and Details

OMEGABOND

®

700

OMEGABOND

®

600

F-25

Page 2

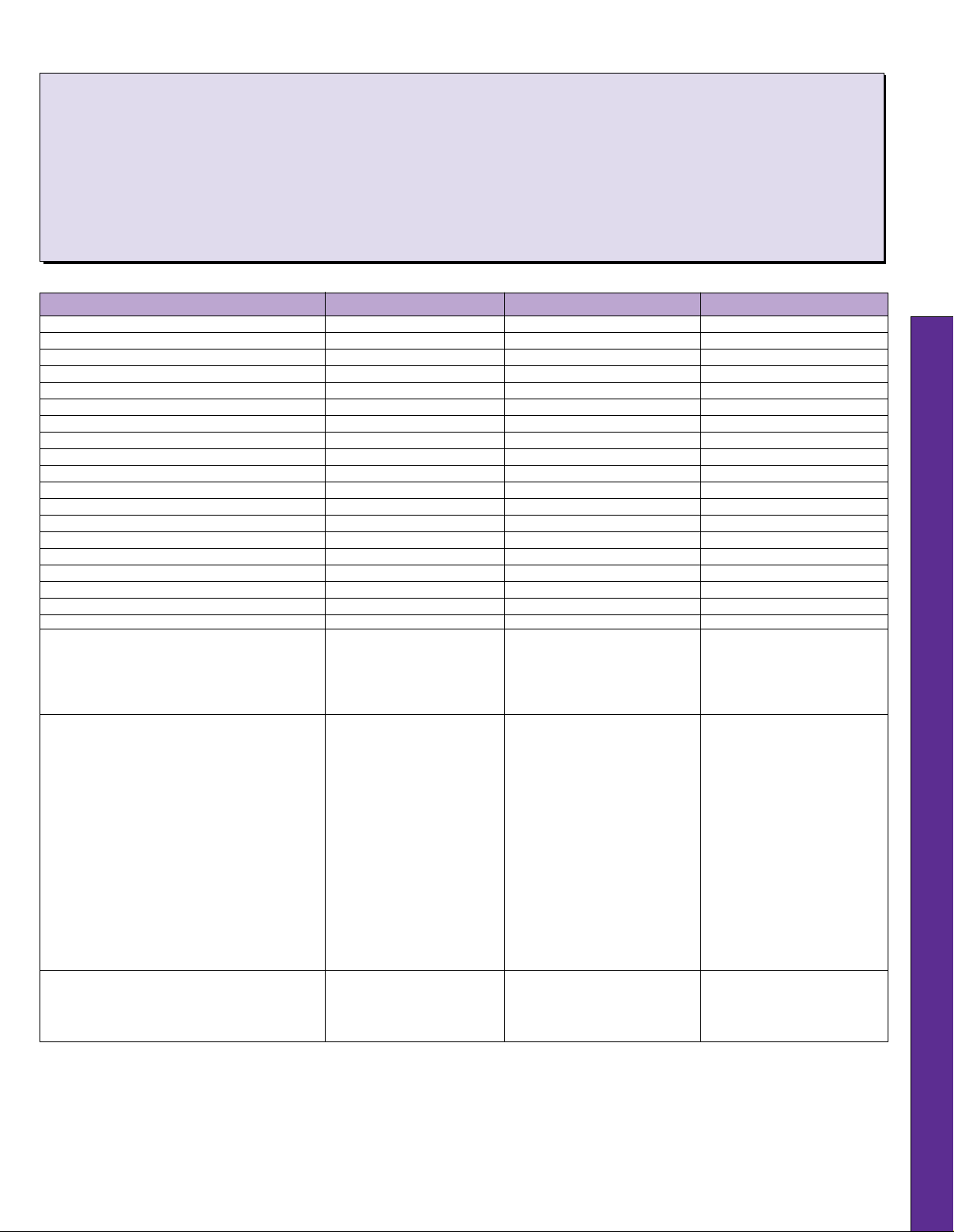

High Temperature Chemical Set Cements

APPLICATIONS

OMEGABOND® 600 OMEGABOND® 700 CC High Temperature Cement

U Potting U Coating U Cementing on and Insulating

U Bonding U Assembling Thermocouples for Surface

U Insulating U Sealing Temperature Measurement

U Embedding

U Coating

Physical Properties

†

Cement OMEGABOND 600 OMEGABOND 700 CC High Temperature

Type of cement (1 or 2 Part) 1 part 1 part 2 part

Coefficient of thermal expansion, in/in/°F 2.6 x 10

Color Off white White Tan

-6

12.4 x 10-6 4.6 x 10

-6

Compressive strength, psi 4500 to 5500 3500 3900

3

Density, lb/ft

160 141

Dielectric constant 3.0 to 4.0 5.0 to 7.0

Dielectric strength at 20°C (70°F), V/mil 76.0 to 101.0 25.0 to 51.0

Dielectric strength at 400°C (750°F), V/mil 25.0 to 38.0 12.5 to 25.0

Dielectric strength at 795°C (1475°F), V/mil 12.5 to 25.0 ≤1.3

Maximum service temperature, °C (°F) 1426 (2600) 871 (1600) 843 (1550)

Modulus of rupture, psi 450

Tensile strength, psi 250 425

10

Volume resistivity at 20°C (70°F), Ω-cm 10

Volume resistivity at 400°C (750°F), Ω-cm 109-1010

-1011

Volume resistivity at 795°C (1475°F), Ω-cm 108-109

Flexural strength, psi

Absorption, %

Shrinkage, %

Thermal conductivity, Btu-in/ft

2

-hr-°F 10 to 12 4.5 to 5.9 8

435

9

107-10

6

104-10

3

102-10

10 - 12

0.5

Mix ratio Mix 100 parts powder with Mix 75 to 80% powder with Mix 3 parts powder to 1 part

13 parts water by weight 20 to 25% water by weight liquid by weight, or 2 parts

filler to 1 part liquid by

volume

Curing schedule OMEGABOND 600

®

OMEGABOND 700® CC high temperature

cures at room cures at room temperature cement hardens with an

temperature by internal with a chemical set action in internal chemical-setting

chemical action in 18 to 24-hr, cure time can be action with an initial set in

18 to 24-hr, cure time accelerated by low approximately 30 min;

can be accelerated by temperature oven drying the final set is reached in

low temperature oven at 82°C (180°F); if the 18 to 24-hr when cured

drying at 82°C (180°F); if cement is to be exposed at room temperature;

the cement is to be exposed to elevated temperatures, if it is desired to accelerate

to elevated temperatures, cure for 18 to 24-hr at the curing time, set the

cure for 18 to 24-hr at ambient temperature, drying oven to 65°C (150°F)

ambient temperature, then oven dry for 4-hr and the cement will cure in

then oven dry for 4-hr at 82°C (180°F) and for 4-hr; if the drying oven

at 82°C (180°F) and for an additional 4-hr at is set to 105°C (220°F), the

an additional 4-hr at 105°C (220°F); this helps cement will cure in 3 hours

105°C (220°F); this helps to prevent spilling

to prevent spilling

F

Distinguishing characteristics High dielectric strength, Used on metals or other Used to cement on and

and applications used to pot nickel materials which have a insulate thermocouples for

chromium resistance high coefficient of thermal surface temperature

heating wire; won’t expansion; excellent measurement

stick to smooth quartz bonding characteristics

†These physical properties were determined under laboratory conditions using applicable ASTM procedures. Actual field data may vary.

Do not use physical properties data for specifications.

Air set cements are also available, see OMEGABOND® 300, OMEGABOND® 400 and OMEGABOND® 500. These cements set or cure through

*

loss of moisture by evaporation. Atmospheric conditions therefore affect the drying rate. Air set cements are used mainly in the thin film applications

(less than 1⁄4" thickness.)

Porous substrates may require dampening with thinning liquid before application of mixed cement. For OMEGABOND® 600 and

**

OMEGABOND® 700 (1 part cement), order OMEGABOND® thinning liquid (8 fluid oz), OB -TL. For CC high temperature cement,

use CC high temperature cement liquid binder to dampen porous substrates.

F-26

Loading...

Loading...