Page 1

http://www.omega.com

e-mail: info@omega.com

®

User’s Guide

LVU800 Series

Ultrasonic Transmitter

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a

period of 13 months from date of purchase. OMEGA Warranty adds an additional one (1) month grace

period to the normal one (1) year product warranty to cover handling and shipping time. This ensures

that OMEGA’s customers receive maximum coverage on each product.

If the unit should malfunction, it must be returned to the factory for evaluation. OMEGA’s Customer Service

Department will issue an Authorized Return (AR) number immediately upon phone or written request. Upon

examination by OMEGA, if the unit is found to be defective it will be repaired or replaced at no charge.

OMEGA’s WARRANTY does not apply to defects resulting from any action of the purchaser, including but not

limited to mishandling, improper interfacing, operation outside of design limits, improper repair, or unautho-

rized modification. This WARRANTY is VOID if the unit shows evidence of having been tampered with or

shows evidence of being damaged as a result of excessive corrosion; or current, heat, moisture or vibration;

improper specification; misapplication; misuse or other operating conditions outside of OMEGA’s control.

Components which wear are not warranted, including but not limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However, OMEGA neither

assumes responsibility for any omissions or errors nor assumes liability for any damages that result

from the use of its products in accordance with information provided by OMEGA, either verbal or writ-

ten. OMEGA warrants only that the parts manufactured by it will be as specified and free of defects.

OMEGA MAKES NO OTHER WARRANTIES OR REPRESENTATIONS OF ANY KIND WHATS0EVER,

EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE, AND ALL IMPLIED WARRANTIES INCLUDING ANY

WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DIS-

CLAIMED. LIMITATION OF LIABILITY: The remedies of purchaser set forth herein are exclusive and the

total liability of OMEGA with respect to this order, whether based on contract, warranty, negligence,

indemnification, strict liability or otherwise, shall not exceed the purchase price of the component

upon which liability is based. In no event shall OMEGA be liable for consequential, incidental or spe-

cial damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic

Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical

applications or used on humans. Should any Product(s) be used in or with any nuclear installation or activity,

medical application, used on humans, or misused in any way, OMEGA assumes no responsibility as set forth

in our basic WARRANTY/ DISCLAIMER language, and additionally, purchaser will indemnify OMEGA and

hold OMEGA harmless from any liability or damage whatsoever arising out of the use of the Product(s) in

such a manner.

RETURN REQUESTS / INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE

RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN (AR)

NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID PROCESSING

DELAYS). The assigned AR number should then be marked on the outside of the return package and on

any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent

breakage in transit.

FOR WARRANTY

RETURNS, please have the fol-

lowing information available BEFORE contacting

OMEGA:

1. P.O. number under which the product

was PURCHASED,

2. Model and serial number of the product under

warranty, and

3. Repair instructions and/or specific

problems relative to the product.

FOR NON-WARRANTY REPAIRS,

consult OMEGA

for current repair charges. Have the following

information available BEFORE contacting OMEGA:

1. P.O. number to cover the COST

of the repair,

2. Model and serial number of product, and

3. Repair instructions and/or specific

problems relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible.

This affords our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 1996 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied,

photocopied, reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without prior

written consent of OMEGA ENGINEERING, INC.

Servicing North America:

USA: One Omega Drive, Box 4047

ISO 9001 Certified Stamford, CT 06907-0047

Tel: (203) 359-1660

Fax: (203) 359-7700

e-mail: infor@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1

Tel: (514) 856-6928

FAX: (514) 856-6886

email: canada@omega.ca

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

SM

Customer Service: 1-800-622-2378 / 1-800-622-BEST

SM

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

SM

Mexico En Espanol: (001) 203-359-7803

e-mail: espanol@omega.com

FAX: (001) 203-359-7807

info@omega.mx

Servicing Europe:

Czech Republic: Frystatska 184, 733 01 Karvina, Czech Republic

Tel: +420 (0)59 6311899

FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342

e-mail: info@omegashop.cz

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: +49 (0)7056 9398-0

FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

United Kingdom: One Omega Drive, River BendTechnology Centre

ISO 9002 Certified Northbank, Irlam, Manchester

M44 5EX, England

Tel: +44 (0)161 777-6611

FAX: +44 (0)161 777-6622

Toll Free in England: 0800-488-488

e-mail: sales@omega.co.uk

omega.com

OMEGAnet

SM

On-Line Service Internet e-mail

http://www.omega.com info@omega.com

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that apply. OMEGA is constantly

pursuing certification of its products to the European New Approach Directives. OMEGA will add the CE mark to every

appropriate device upon certification.

The information contained in this document is believed to be correct but OMEGA Engineering, Inc. accepts no liability for any errors it con-

tains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient connected applications.

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

Shop online at omega.com

TEMPERATURE

Thermocouple, RTD & Thermistor Probes,

Connectors, Panels & Assemblies

Wire: Thermocouple, RTD & Thermistor

Calibrators & Ice Point References

Recorders, Controllers & Process Monitors

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

Transducers & Strain Gauges

Load Cells & Pressure Gauges

Displacement Transducers

Instrumentation & Accessories

FLOW/LEVEL

Rotameters, Gas Mass Flowmeters & Flow Computers

Air Velocity Indicators

Turbine/Paddlewheel Systems

Totalizers & Batch Controllers

pH/CONDUCTIVITY

pH Electrodes, Testers & Accessories

Benchtop/Laboratory Meters

Controllers, Calibrators, Simulators & Pumps

Industrial pH & Conductivity Equipment

DATA ACQUISITION

Data Acquisition & Engineering Software

Communications-Based Acquisition Systems

Plug-in Cards for Apple, IBM & Compatibles

Datalogging Systems

Recorders, Printers & Plotters

HEATERS

Heating Cable

Cartridge & Strip Heaters

Immersion & Band Heaters

Flexible Heaters

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

Metering & Control Instrumentation

Refractometers

Pumps & Tubing

Air, Soil & Water Monitors

Industrial Water & Wastewater Treatment

pH, Conductivity & Dissolved Oxygen Instruments

M-4463/0707

OMEGA

®

TM

Page 2

Step One

SPECIFICATIONS

40

30

20

10

00

-40 -20 00 20 40 60 80

Acceptable

Range

Unacceptable

Range

Temperature/Pressure Derating

Operating Pressure (psi)

Temperature ( C)

12 16 20 24 28

Unacceptable

Range

Maximum Loop Resistance

Max. Series Resistance (Ohms)

Supply Voltage (VDC)

1,000

800

600

400

200

000

- Enhanced

Performance

- Specified

Performance

- Limited

Performance

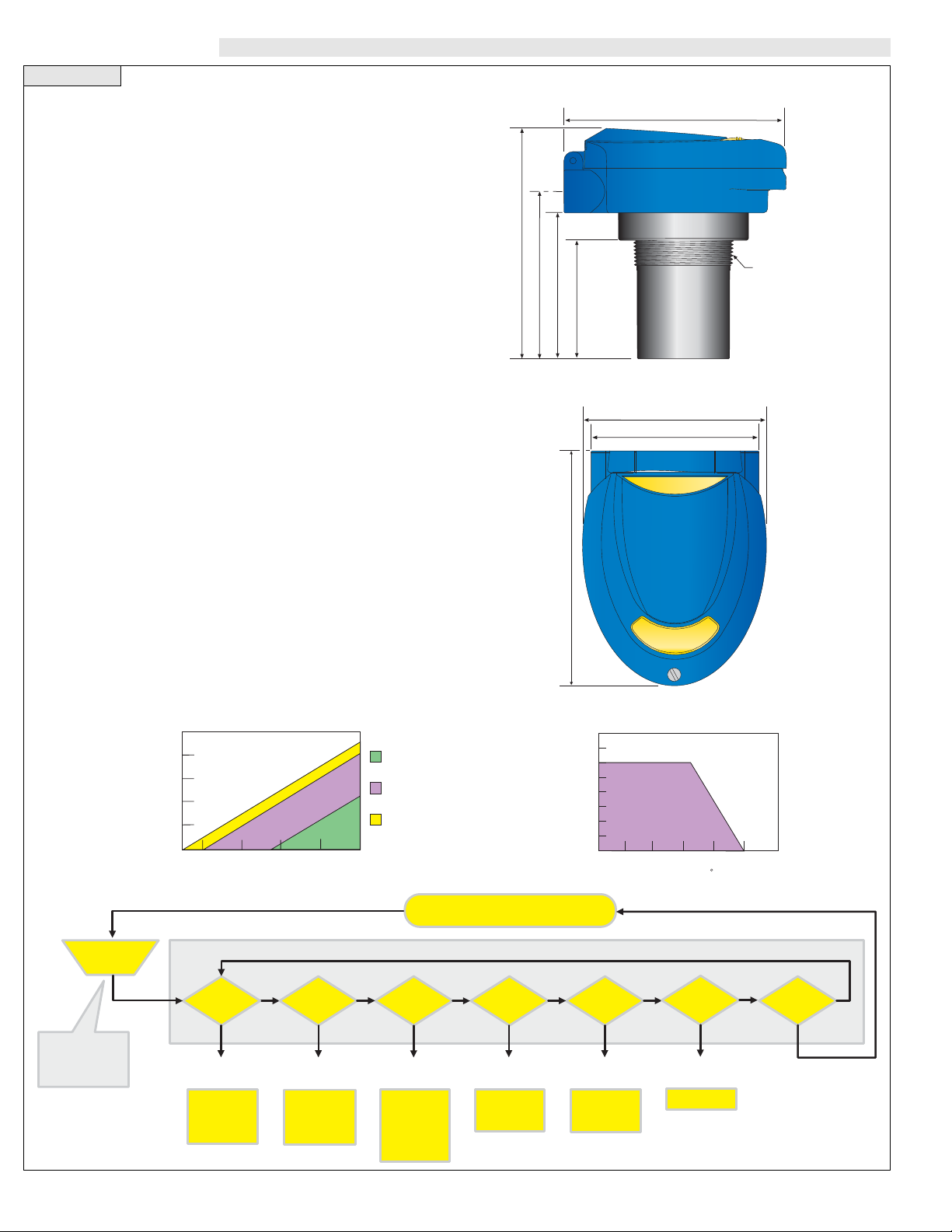

4.1"

(104 mm)

5.2"

(133 mm)

3.8"

(96 mm)

3.4"

(88 mm)

5.5"

(138 mm)

5.2"

(133 mm)

4.0"

(100 mm)

2.7"

(69 mm)

2" NPT

(2" G)

T op View

Range: LVU816: 8” to 16.4’ (10 cm to 5 m)

LVU826: 8” to 26.2’ (20 cm to 8 m)

LVU832: 12” to 32.8’ (30 cm to 10 m)

Accuracy: +/- 0.2% of span in air

Resolution: LVU816: 0.039 (1 mm)

LVU826: 0.039 (1 mm)

LVU832: 0.078: (2 mm)

Beam width: 3” (7.6cm) dia.

Dead band LVU816: 8” (10cm)

LVU826: 8” (20cm)

LVU832: 12” (30cm)

Display type: LCD, 6-digit

Display units: Inch, cm or percentage

Display mode: Air gap or liquid height

Memory: Non-volatile

Supply voltage: 12- 28 VDC

Loop resist,: 500 Ohms @ 24 VDC

Signal output: 4 - 20 mA, two -wire

Signal invert: 4-20 mA, 20-4 mA

Calibration: Push button

Fail-safety: Selectable: 4 mA, 20 mA, 21 mA,

22 mA or hold last value

Process temp.: F: -4° to 140°

C: -20° to 60°

Temp comp,: Automatic

Electronics temp.: F: -40° to 160°

C: -40° to 71°

Pressure: 30 psi (2 bar) @ 25 °C., derated @

1.667 psi (113 bar) per °C, above 25 °C

Enclosure rating: NEMA 4X (IP65)

Enclosure vent: Water tight membrane

Encl. material: PC/ABS FR

Trans. material: PVDF

Process mount: 2” NPT (2” G)

Mount. gasket: Viton®

Conduit entrance: Dual, 1/2” NPT

Classification: General purpose

CE compliance: EN 61326 EMC

SELECT / FAST

Button

DISPLAY

UNITS TANK SAFE TGCAL VALUES RUN

TOP MENU

Inches

Centimeters

Percentage

Display

Height (4 mA)

Fill H (20 mA)

Rev mA

Help

22 mA

21 mA

20 mA

4 mA

Hold

FULL

EMPTY

Help

To activate the top

menu, press and

hold SELECT / FAST

button for 5 seconds

SELECT

Display Units

SELECT

4-20 Span

SELECT

Fail-Safety

SELECT

Target-Cal

SELECT

Diagnostics

Setup

Diagnostics

Reset

HELP

SELECT

Diagnostics

Contact

Side View

Page 3

Step Tw o

SAFETY

Step Three

OVERVIEW

A. Application: The general-purpose ultrasonic transmitter pro-

vides non-contact level detection up to 32.8’ or 10m. The transmitter

is well suited for a wide range of corrosive, waste and slurry type

media, and is broadly selected for atmospheric bulk storage, day tank

and waste sump applications.

B. Part Number: The part and serial numbers are located on the

wrench flat. Check the part number on the product label and confirm

which of the below model configurations you have purchased:

Par

t Number Range Supply Mount

LVU816 16.4’ (5 m) 12-28 VDC 2” NPT

LVU816G 16.4’(5 m) 12-28 VDC 2” G

LVU826 26.2’ (8 m) 12-28 VDC 2” NPT

LVU826G 26.2’(8 m) 12-28 VDC 2” G

LVU832 32.2’ (10 m) 12-28 VDC 2” NPT

LVU832G 32.2’(10 m) 12-28 VDC 2” G

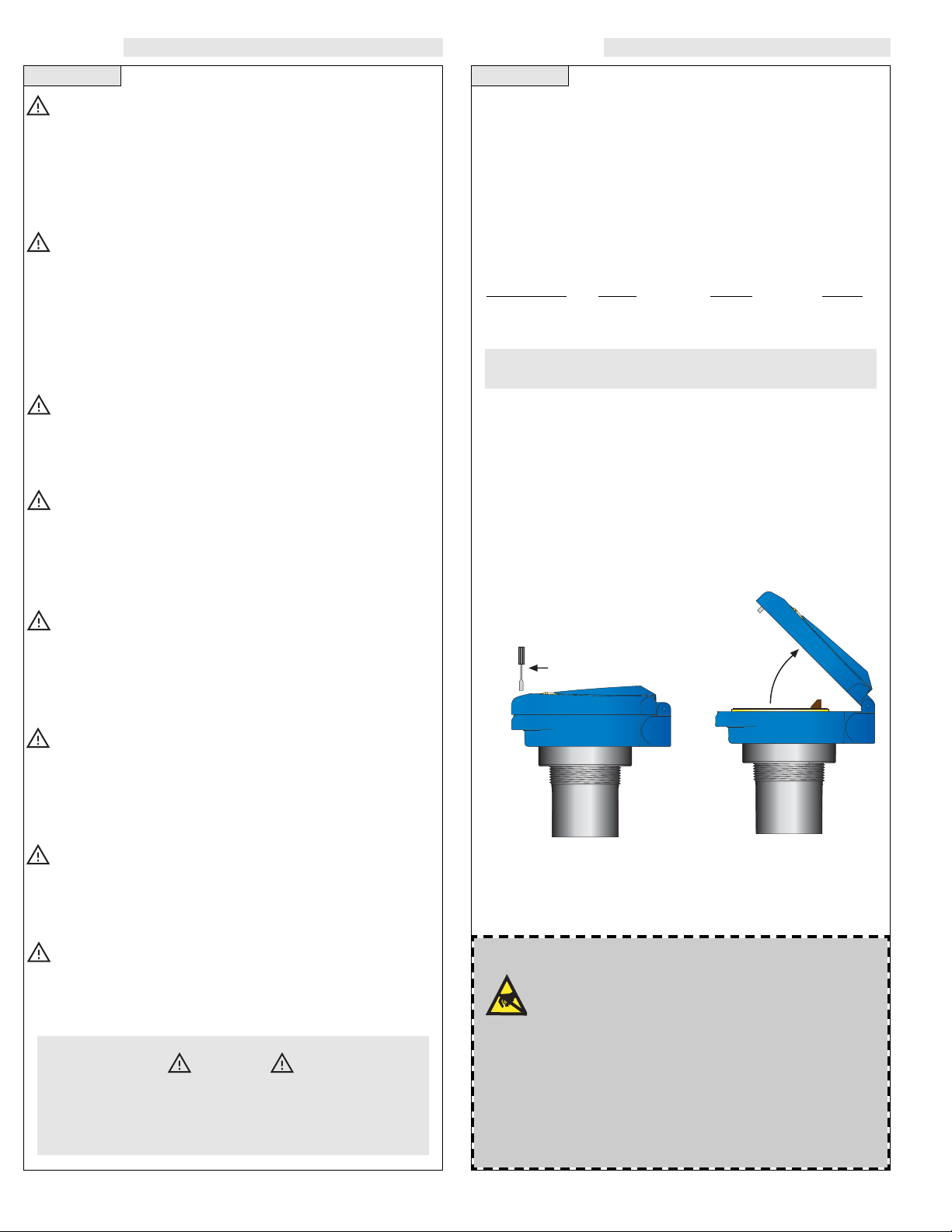

C. NEMA 4X Enclosure: The NEMA 4X (IP65) enclosure has

a flip cover with two 1/2” NPT female conduit ports and an internal

terminal strip for wiring. T o open the enclosure, you will need a small

small screwdriver. Insert the tool into the hole located at the top edge

of the enclosure and turn counter-clockwide. Rotate the hinged cover

up for 135° access to the faceplate screen and terminal strip.

About this Manual: PLEASE READ THE ENTIRE MANU-

AL PRIOR TO INSTALLING OR USING THIS PRODUCT. This

manual includes information on then LVU800 Ultrasonic Level

Transmitter from OMEGA. Please refer to the part number located

on the transmitter label to verify the exact model configuration

which you have purchased.

User’s Responsibility for Safety: OMEGA manufactures

a broad range of level sensing technologies. While each of these

sensors is designed to operate in a wide variety of applications, it is

the user’s responsibility to select a sensor model that is appropriate

for the application, install it properly, perform tests of the installed

system, and maintain all components. The failure to do so could

result in property damage or serious injury.

Proper Installation and Handling: Only properly trained

staff should install and/or repair this product. Install the transmitter

with the Viton gasket and never overtighten the transmitter within

the fitting. Always check for leaks prior to system start-up.

Wiring and Electrical: A supply voltage (loop power) of 12

-28 VDC is used to power the LVU800 series. The sensor circuit

should never exceed a maximum of 28 volts DC. Electrical wiring

of the sensor should be performed in accordance with all applicable national, state, and local codes.

Material Compatibility: The LVU800 series enclosure is

made of a flame retardant Polycarbonate (PC/ABS FR). The transducer is made of Polyvinylidene Fluoride (PVDF). Make sure that

the model which you have selected is chemically compatible with

the application media and it’s environment.

Enclosure: While the transmitter housing is liquid-resistant the

LVU800 series is not designed to be operational when immersed. It

should be mounted in such a way that the enclosure and transducer do not come into contact with the application media under normal operational conditions.

Make a Fail-Safe System: Design a fail-safe system that

accommodates the possibility of transmitter and/or power failure.

OMEGA recommends the use of redundant backup systems and

alarms in addition to the primary system.

Flammable, Explosive or Hazardous Applications:

Do not use the L VU800 seriesof general purpose transmitters within classified hazardous environments.

Warning

Always use the Viton gasket when installing the LVU800 series

transmitter in its fitting, and always connect the shield wire to

the common ground.

Handling Static-Sensitive Circuits/Devices

When handling the transmitter, the technician should follow

these guidelines to reduce any possible electrostatic charge

build-up on the technicians body and the electronic part.

1. Always touch a known good ground source before handling the

part. This should be repeated while handling the part and more

frequently after sitting down from a standing position, sliding

across the seat or walking a distance.

2. Avoid touching electrical terminals of the part unless making connections.

3. DO NOT open the unit cover until it is time to calibrate.

Before closing the enclosure, make sure that the enclosure gasket is

properly seated, and that any conduit fittings, liquid tight cable connectors and/or plugs are properly installed and sealed.

Closed

Open

Page 4

Step Four

PREPARATION

A. Supply V oltage: The transmitter power supply voltage should

never exceed a maximum of 28 VDC. Omega controllers and meters

have built-in 24 VDC power supplies for use with the transmitter.

Alternative controllers and/or power supplies with a minimum output

of 12 VDC may also be used with the transmitter for calibration

and/or operation.

B. Cable Length: The cable length between the transmitter and

it’s point of termination may be extended up to a maximum of 1000

feet, using a well-insulated, shielded wire from 14 to 18 gauge.

C. Factory Span: All transmit-

ter models are factory calibrated with

4 mA at their maximum range (tank

empty) and 20 mA at their minimum

range (tank full). The 4 and 20 mA

span set points can be reverse calibrated on all models.

D.Maximum Applied Range:

The Individual or cumulative effects

of agitation, vapor or foam can

reduce the overall quality of signal

return and shorten the maximum

applied range of the transmitter. To determine the maximum applied

range of the transmitter in your application, refer to the below derating chart.

0

Maximum Applied Range Derating Chart

LVU800

Agitation = 1-3 @ 50 kHz

Vapor = 3-5 @ 50 kHz

Foam = 4-6 @ 50 kHz

Step Five

MENU ITEMS

A. WARMUP: This is the initial power up mode. When this mes-

sage is displayed, the transmitter is going through its power up routine, and validating the target value. After a short period of time, this

message will disappear and be replaced by a numeric value.

B. FULL: Level has reached the programmed FULL set point.

C. EMPTY: Level has reached the programmed EMPTY set point

D. UNITS: Selectable in Inches Centimeters or Percent. The facto-

ry default is Inches.

E. INCHES: Inch units of measurement.

F. CM: Centimeters units of measurement.

G. PERCNT: 0-100% units of measurement. Percent is the calcu-

lated value based on the 4mA and 20mA set points.

H. DISPLAY: Allows the user to select if the display will read in

units of air or units of liquid. Factory default is units of air.

H.TANK: Menu through which the 4-20 mA span is adjusted.

I. HEIGHT: The point in inches

or centimeters from the transducer

face where the output will be 4 mA

(generally the bottom of the tank).

Factory default is the same as the

unit’s maximum range. Example:

LVU816 = 197” maximum range

which is also the same 4 mA set

point under factory default.

J. Fill H (Fill Height): The

point in inches or centimeters from

the bottom of the tank to the high

level where the output will be 20

mA(generally the straight wall distance from the bottom of the tank).

NOTE: The transmitter dead band

is automatically subtracted from

the FILL H. Example: LVU816 =

8” dead band. Therefore the maximum FILL H is 197” [maximum

range] - 8” [dead band] = 189”.

K. REV mA (Reverse mA): Allows the user to select 20 mA at

the bottom and 4 mAat the top of the tank (20-4 mA). Factory default

is 4 mA (MaxR) at the bottom and 20 mA (MinR) at the top.

L. SAFE: The FAIL-SAFE current output of the transmitter if the

acoustic signal is LOST. Selectable at 4 mA, 20 mA, 21 mA, 22 mA

or HOLD. (HOLD is the last 4-20 mA value prior to LOST).

M.TG CAL:Allows the user to use an unknown distance for setting

of the 4 mA and 20 mA span.

HEIGHT

(MaxR)

FILL H

(MinR)

EMPTY

FULL

LVU800 Series

Reverse Mode

4 mA

20 mA

0%

50%

100%

01234567891

50Khz

Page 5

Step Six

MENU ITEMS

Step Seven

PROGRAMMING

A. Introduction: The transmitter has two modes, RUN and PRO-

GRAM. In the RUN mode, the transmitter is operational and the display will indicate the liquid height in inches, centimeters or percent.

In the PROGRAM mode, the display will indicate the selected mode

of calibration. The transmitter arrives from the factory with its settings at 4 mA = maximum range and 20 mA = minimum range

(defined by the dead band or minimum measurement distance). The

transmitter is programmed with it’s built-in display and three button

keyboard. Under normal application circumstances, users typical-

ly program the HEIGHT distance value, FILL H distance value

and FAIL-SAFE mode.

+

UP DOWN

SELECT

FAST

--

+

UP DOWN

SELECT

FAST

--

Hold for

5 Seconds

Top Menu

B. Entering the Program Mode: Press and hold the

SELECT/FAST button for approximately 5 seconds until the display

changes from a numeric value to PROG, indicating that you have

entered the PROG mode.

Note: When PROG mode is active, the sensor will hold the last

current value. The value will not change until the transmitter is

returned to RUN Mode.

After entering the PROG mode, the display will scroll through the top

menu, alternately flashing UNITS, TANK, SAFE, TG CAL, VALUES, HELP and RUN.

N. FULL: Target calibration technique that allows the user to enter

the present distance from the transducer face to the liquid or a reflective target as the 20 mA (FULL) set point

O. EMPTY: Target calibration technique that allows the user to

enter the present distance from the transducer face to the liquid or a

reflective target as the 4 mA (EMPTY) set point.

P. WAIT: Indicates that you have selected either FULL or EMPTY

and the transmitter is calculating the distance value.

Q.VALUES: Allow the user to view the present calibration settings

that are programmed in the transmitter.

R. SETUP: Displays the present calibration settings such as UNITS,

MinR, MaxR, and SAFE.

S. MINR: The lesser distance from the transducer to the full tank

height of liquid.

T. MAXR: The greater distance from the transducer to the empty tank

height of liquid.

U. RESET: Allows the user to reset the transmitter to its original

factory default settings.

V. DIAG (Diagnostics):Allows the user to view the present val-

ues of LEVEL, TEMP, ECHO, POWER, MOUNT and VER.

W. LEVEL: Displays the current Inch, Centimeter or Percent mea-

sured value.

X.TEMP: Displays the temperature in the vessel at the transducer.

Y. ECHO: Displays the present acoustic signal strength.

Z. POWER: Displays the present acoustic power level

AA. MOUNT: Displays either QUIET (no fitting noise) or NOISY

(potential fitting noise), If NOISY with transmitter performance

issues, please contact Omega to discuss your installation.

BB.VER (VERSION): Displays the transmitter software version.

CC. DONE: Indicates that the new value has been saved in memo-

ry (after depressing the SELECT/FAST key).

DD. ERROR: Indicates that the new value has NOT been saved in

memory (after depressing the SELECT/FAST or EXIT key).

EE. RUN: When displayed, if the user depresses the

SELECT/FAST key, the transmitter will exit the programming mode

and return to the RUN mode for normal operation.

FF. UP / DOWN:Increases or decreases the SET20 and SET 4 dis-

play values in the programming mode. NOTE: Simultaneously holding down the SELECT/FASTbutton while pressing the UP or DOWN

button will increase the speed of the display.

Page 6

Step NineStep Eight

PROGRAMMING

C. Programming UNITS: To change UNITS from INCHES to

CM or PERCENT.

1. Press the SELECT/FAST button and hold it for 5 seconds until

PROG appears.

2. When UNITS appears, press the SELECT/FAST button. The display

will rotate between INCHES, CM, PERCENT and DISPLAY.

3. Press the SELECT/FAST button when the UNITS you want

(INCHES, CM or PERCENT) appear. The display will then display SAVED.

You have successfully changed the UNITS function.

Note: Percent units can only be selected after the transmitters Height (4 mA) and Fill H (20 mA) set points have

been programmed. Therefore initial programming should

always be done in INCH or CM UNITS.

D. Display Mode: The transmitter is factory set such that the

display reads the distance from the bottom of the transmitter to

the liquid surface. This is also referred to as the Air distance (Air

Mode). As the level of liquid increases, the display will decrease

and vice versa. Conversely, the transmitter may be set to read the

actual height of liquid in the tank (Liquid Mode). Below, a tank

height of 100” will display 40.0, which represents 40.0” of air in

the AIR Mode. In the Liquid Mode, the display will change to

60.0, which represents 60.0” of liquid.

AIR MODE LIQUID MODE

PROGRAMMING

SELECT

FAST

SELECT

FAST

HEIGHT

(MaxR)

FILL H

(MinR)

E. Change Display Mode: To change the display to indicate

the height of liquid, follow the instructions below:

1. Press the SELECT/FAST button and hold it for 5 seconds until

PROG appears.

2. When UNITS appears, press the SELECT/FAST button. The display will rotate between INCHES, CM, PERCENT and DISPLAY.

3. When DISPLAY appears, press the SELECT/FAST button. The

display will rotate between AIR or LIQUID.

4. When LIQUID appears, press the SELECT/FAST button.

You have successfully programmed the LIQUID mode.

F .Programming Off Tank: If you know the dimensions of your

tank, you may input the 4 mA and 20 mAset points manually without

performing target calibration (requiring you to raise and lower the liquid level). To do so, review the following:

HEIGHT: The point in inches or centimeters from the transducer

face where the output will be 4 mA (generally the bottom of the

tank). Factory default is the same as the unit’s maximum range.

Example LVU816 = 197” maximum range which is also the same

4 mA set point under factory default.

FILL H:The point in inches or centimeters from the bottom of the

tank to the high level where the output will be 20 mA(generally the

straight wall distance from the bottom of the tank). NOTE: The

transmitter dead band is automatically subtracted from the FILL H.

Example: LVU816 = 8” dead band. Therefore the maximum FILL

H is 197” [maximum range] - 8” [dead band] = 189”.

40.0" of Air

100.0"

Height

60.0" of Liquid

100.0"

Height

SELECT

FAST

SELECT

FAST

SELECT

FAST

Page 7

Step Ten Step Eleven

PROGRAMMING

I. Programming REV mA (Optional): In factory default, the

transmitter operates with 4 mA at the maximum range (MaxR), and

20 mA at the dead band (MinR). Using the menu item REV mA, you

can change the unit to reverse this to 20 mA at the furthest distance

(MaxR) and 4 mA at the closest distance (MinR).

NOTE: You must set HEIGHT and FULL R prior to reversing

the 4 and 20 mA. Regardless of which mode you are in (Norm

or Rev), changes to the HEIGHT or FULL R are always with

respect to the original settings programmed.

NOTE: Any changes to the HEIGHT will effect the FULL R

value. The FULL R will stay at the same physical level in the

tank. An increase to the HEIGHT value will result in an equal

increase to the FULL R value. A decrease to the HEIGHT value

will result in an equal decrease to the FULL R value.

4 mA

20 mA

SELECT

FAST

SELECT

FAST

SELECT

FAST

20 mA

4 mA

Normal mA Mode

MaxR (4 mA) set at empty tank

and MinR (20 mA) set at full tank.

Reverse mA Mode

MaxR (20 mA) set at empty tank

and MinR (4 mA) set at full tank.

PROGRAMMING

G. Programming HEIGHT: To change HEIGHT 4 mA value.

1. Press the SELECT/FAST button and hold it for 5 seconds until

PROG appears.

2. When TANK appears, press the SELECT/FAST button. The display will rotate between HEIGHT, FILLH and REV mA.

3. When HEIGHT appears, press the SELECT/FAST button. The

display will show a decimal reading in the selected UNITS.

4. Press the UP/DOWN buttons to increase or decrease this value to the

distance from the transducer face to the bottom of the tank. NOTE:

Simultaneously holding down the SELECT/F ASTbutton while pressing the UP or DOWN button will increase the speed of the display.

5. When you have reached the desired value, press SELECT/FAST

to SAVE.

You have successfully programmed the HEIGHT or 4 mA value.

H. Programming FILL H: To change FILL H 20 mA value.

1. Press the SELECT/FAST button and hold it for 5 seconds until

PROG appears.

2. When TANK appears, press the SELECT/FAST button. The display will rotate between HEIGHT, FILLH and REV mA.

3. When FULL H appears, press the SELECT/F ASTbutton. The display will show a decimal reading in the selected UNITS.

4. Press the UP/DOWN buttons to increase or decrease this value to

the distance from the bottom of the vessel to the full point (typically the straight wall height).

5. When you have reached the desired value, press SELECT/FAST

to SAVE it.

You have successfully programmed the FILL H or 20mA value.

NOTE: You can increase the speed at which the display changes

by pressing the SELECT/FAST button while simultaneously holding down the UP or DOWN button.

SELECT

FAST

SELECT

FAST

SELECT

FAST

UP

DOWN

SELECT

FAST

SELECT

FAST

SELECT

FAST

UP

DOWN

Page 8

Step ThirteenStep Twelve

L. Programming TG CAL EMPTY Tank: With the tank

EMPTY or the liquid in a low level state, apply power to the transmitter. Begin programming after WARMUP.

1. Press the SELECT/FAST button and hold it for 5 seconds until

PROG appears.

2. When TG CAL appears, press the SELECT/FAST button. The

display will rotate between FULL and EMPTY.

3. When EMPTY appears, press the SELECT/FAST button. WAIT

will be displayed followed by SAVED.

You have successfully programmed the EMPTY or 4 mA value.

M. Programming TG CAL FULL Tank:With the tank FULL,

or the liquid in a high level state, apply power to the transmitter.

Begin programming after WARMUP.

1. Press the SELECT/FAST button and hold it for 5 seconds until

PROG appears.

2. When TGCAL appears, press the SELECT/F ASTbutton. The display will rotate between FULL and EMPTY.

3. When FULL appears, press the SELECT/F ASTbutton, W AITwill

be displayed followed by SAVED.

You have successfully programmed the FULL or 20 mA value.

PROGRAMMING

SELECT

FAST

SELECT

FAST

SELECT

FAST

SELECT

FAST

SELECT

FAST

SELECT

FAST

Note: The display will now indicate LEVEL height in the RUN

mode.

J. Programming SAFE Mode: To change SAFE mode.

1. Press the SELECT/FAST button and hold it for 5 seconds until

PROG appears.

2. When SAFE appears, press the SELECT/FAST button.

3. The display will now rotate through 22mA, 21mA, 20mA, 4mA

and HOLD. When you reach the desired setting, press the

SELECT/FAST button to SAVE it..

You have successfully programmed the SAFE mode.

K. Programming Target Calibration (Optional): The

transmitter’s 4 mA and 20 mA set points can be target calibrated ON

the tank by raising and lowering the liquid level, or OFF the tank

using the distance to a flat reflective target such as a wall. Generally,

target calibration is done ON the tank. To do so, follow the EMPTY

and FULL tank programming steps on the next page.

NOTE: A transmitter installed on a tank operating in the factory default RUN mode will display the distance from the bottom

of the sensor to the liquid surface. The value will decrease as the

tank is filled or increase as the tank is emptied. Make sure that

you do not overflow the tank or completely empty the tank while

moving the liquid level to the desired high or low set point distance for target calibration.

TG CAL:Allows the user to use an unknown distance for setting

of the 4 mA and 20 mA span.

FULL: Target calibration technique that allows the user to enter

the present distance from the

transducer face to the liquid or a

reflective target as the 20 mA

(FULL) set point

EMPTY: Target calibration

technique that allows the user to

enter the present distance from

the transducer face to the liquid

or a reflective target as the 4 mA

(EMPTY) set point.

SELECT

FAST

SELECT

FAST

EMPTY

FULL

PROGRAMMING

Page 9

Step FifteenStep Fourteen

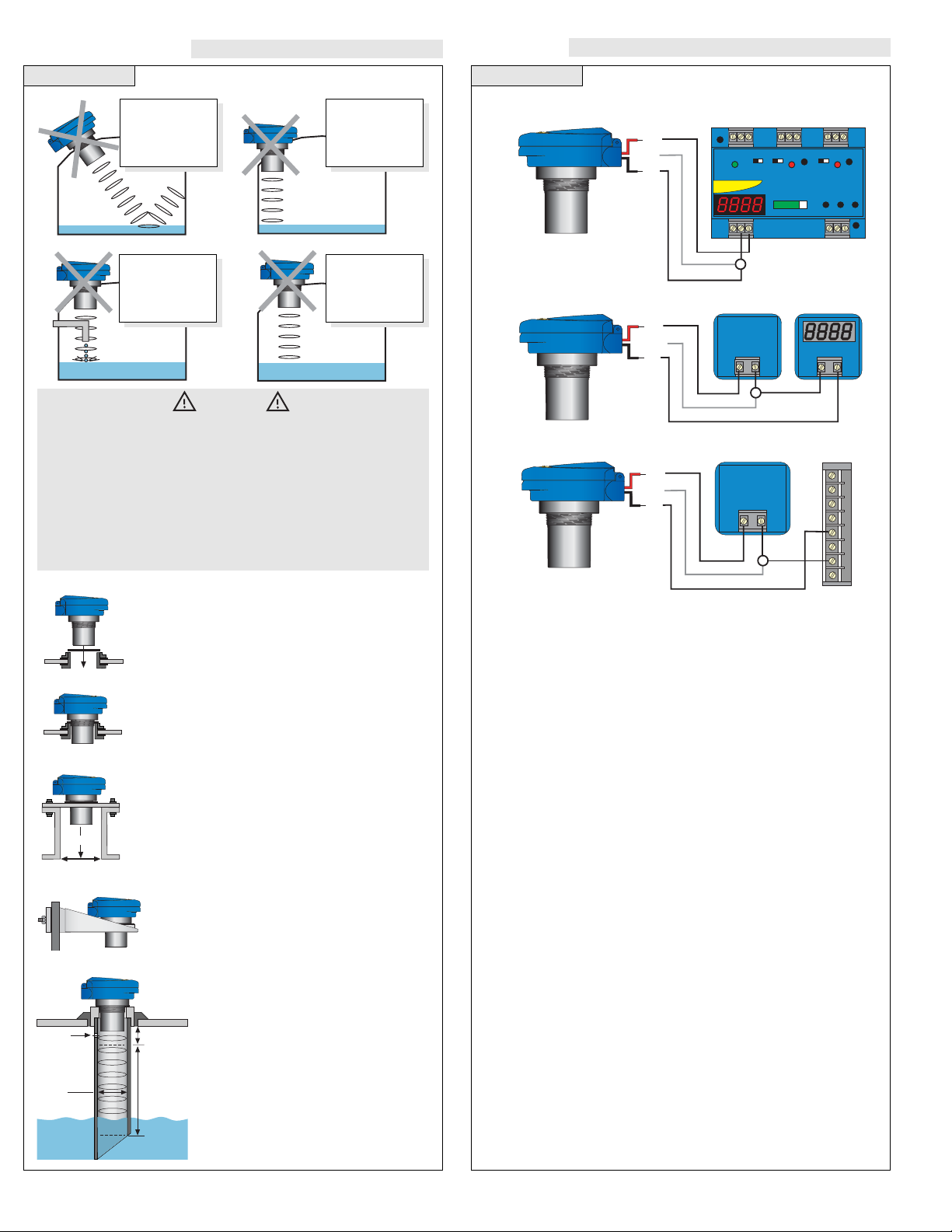

C.Wiring to a Typical Programmable Logic Controller

- ++ -

DC Power

Supply

12-28 VDC

(+)

(-)

SHIELD

+ -

DC Power

Supply

12-28 VDC

TYpical PLC

6

5

4

3

2

1

0

A

(+)

(-)

Shield

WIRING

A.Wiring to a Omega LVCN-51 Controller

B.Wiring to a Typical Two-Wire Loop Powered Indicator

LATCH

ON OFF

PWR

RELAY 1

INVERT

DELAY

RELAY 2

INVERT

DELAY

4 20 OP

EASY CAL

UP DOWN SET

INPUT

0% 100%

OFF SET

SPAN

RLY1

RLY2A

RLY2B

(+)

(-)

SHIELD

JWA mode

A. Fitting Selection: Check the transmitter

part number to determine the required 2” fitting

thread type. The transmitter is commonly installed

in tank adapters, flanges, brackets or stand pipes.

1. Adapter: Select a tank adapter fitting with

minimal height so as to ensure that the

installed transducer will not be substantially

elevated into the fitting. Avoid tank adapter

styles with threads and/or pipe stops forward

of the installed transducer.

2. Flange: Tall flanges with narrow risers

impede the acoustic signal. Select a fitting

with the right riser height versus inner diameter geometry. The transmitter may be elevated up to 12” (30 cm) in a 6” (15 cm) riser, 8”

(20 cm) in a 4” (10 cm) riser and 3” (7.6 cm)

in a 2” (5 cm) riser.

3. Bracket: The LVM-30 bracket or equivalent

can be used for open tank top installations

against the side wall.

4. Stand Pipe: A stand pipe may be

used to dampen turbulence or separate

surface foam. Select a minimum 3” pipe

for the stand pipe. The pipe length

should run the measurement span. Cut a

45° notch at the bottom of the pipe and

drill a 1/4” pressure equalization hole

high in the dead band.

VACUUM

Do not install at

angle relative

to the liquid

Do not install

within 3” of

tank side wall

Do not install

with objects

in the beam

Do not install

in applications

with vacuum

Warning

Omega ultrasonic transmitters have been optimized for use in

non-metallic fittings. For best performance, avoid the use of

metal fittings.

Install the appropriate installation fitting. Make sure that the fitting and transmitter threads are not damaged or worn. Install the

transmitter with the included Viton mounting gasket. Hand tighten the transmitter within the fitting. Perform an installed leak test

under normal process conditions prior to system start up.

Adapter

Flange

Stand Pipe

Bracket

Gasket

Riser

INSTALLATION

Inner Diameter

Ventilation

Hole

3" Minimum

Diameter

Height

Dead Band

Highest

Liquid Level

Operational Range

Lowest

Liquid Level

Page 10

Step SeventeenStep Sixteen

C. Factory RESET:

1. Press the SELECT/FAST button and hold it for 5 seconds until

PROG appears.

2. When VALUES appears, press the SELECT/FAST button. The

display will rotate between SETUP, DIAG and RESET.

3. When RESET appears, press the SELECT/FAST button. The display will rotate between YES or NO.

4. When YES appears, press the SELECT/FAST button.

Note: FACTORY RESET resets the transmitter back to its original factory default settings: (20 mA = Minimum Range, 4mA =

Maximum Range and SAFE = 22mA).

D.Testing the Transmitter

1. Connect a multimeter in series

with the black wire to read the

current output.

2. Verify that the current increases (tank filling) and decreases

(tank emptying) appropriately

in the calibrated span.

3. If not, carefully observe and

attempt to correlate any installation, level or application

event for more specific troubleshooting.

4. Write down the information in

DIAGNOSTICS (LEVEL, TEMPECHO, POWER, MOUNT and

VER) and have it ready when you contact your Flowline representative.

SELECT

FAST

SELECT

FAST

SELECT

FAST

TROUBLESHOOTING

TROUBLESHOOTING

A.Viewing Programmed VALUES:

1. Press the SELECT/FAST button and hold it for 5 seconds until

PROG appears.

2. When VALUES appears, press the SELECT/FAST button. The

display will rotate between SETUP, DIAG and RESET.

3. When SETUP appears, press the SELECT/FAST button. You will

now begin viewing calibration settings (UNITS, Display, MinR,

MaxR and SAFE) that are programmed in the transmitter.

When complete the display will revert back to the VALUES menu.

B.Viewing DIAGNOSTICS:

1. Press the SELECT/FAST button and hold it for 5 seconds until

PROG appears.

2. When VALUES appears, press the SELECT/FAST button. The

display will rotate between SETUP, DIAG and RESET.

3. When DIAG appears, press the SELECT/FAST button. You will

now begin viewing diagnostic values (LEVEL, TEMP ECHO,

POWER, MOUNT and VER) that may be relevant to the transmitter and it’s performance in your application.

When complete the display will revert back to the VALUES menu.

SELECT

FAST

SELECT

FAST

SELECT

FAST

SELECT

FAST

SELECT

FAST

SELECT

FAST

Factory Set Points

Transmitter

LVU816

LVU826

LVU832

4 mA Setting

16.4’ (5m)

26.2’ (8m)

32.8’ (10m)

20 mA Setting

8” (10 cm)

8” (20 cm)

12” (30 cm)

Power

Supply

456

Power

Supply

mA

Red

Black

Red

Black

2

0 mA

4 mA

192021

mA

Loading...

Loading...