Page 1

omega.com

e-mail: info@omega.com

For latest product manuals:

omegamanual.info

LVU30 Series Ultrasonic Sensors

Installation and Operation Guide

Shop online at

User’s Guide

Page 2

Servicing North America:

U.S.A.: One Omega Drive, P.O. Box 4047

ISO 9001 Certified Stamford, CT 06907-0047

TEL: (203) 359-1660

FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1, Canada

TEL: (514) 856-6928

FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

U.S.A. and Canada: Sales Service: 1-800-826-6342/1-800-TC-OMEGA

®

Customer Service: 1-800-622-2378/1-800-622-BEST

®

Engineering Service: 1-800-872-9436/1-800-USA-WHEN

®

Mexico: En Espan˜ ol: (001) 203-359-7803

e-mail: espanol@omega.com

FAX: (001) 203-359-7807

info@omega.com.mx

Servicing Europe:

Czech Republic: Frystatska 184, 733 01 Karviná, Czech Republic

TEL: +420 (0)59 6311899

FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342

e-mail: info@omegashop.cz

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

TEL: +49 (0)7056 9398-0

FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified Northbank, Irlam, Manchester

M44 5BD United Kingdom

TEL: +44 (0)161 777 6611

FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

OMEGAnet®Online Service Internet e-mail

omega.com info@omega.com

It is the policy of OMEGA Engineering, Inc. to comply with all worldwide safety and EMC/EMI

regulations that apply. OMEGA is constantly pursuing certification of its products to the European New

Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA accepts no liability for any

errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, human applications.

Page 3

TABLE OF CONTENTS

Section Page

1 Introduction ........................................................................................................ 1

2 Quick Guide on Getting Started ..................................................................... 2

Mounting the Sensor ........................................................................................................................ 2

Operating an Sensor Without a Computer .................................................................................. 2

Operating an Sensor Connected to a Computer ........................................................................ 3

Operating Up to 32 Sensors Simultaneously Using a Multi-Drop Configuration ................. 5

3 Product Description ......................................................................................... 6

DC Power Requirements .................................................................................................................. 6

Voltage Output (V-out) of a Sensor ............................................................................................... 6

RS485 Port ............................................................................................................................................ 8

4 Installing LVU30 Series Software ................................................................... 10

5 Status and Setup Screen .................................................................................. 11

Establishing Communication between a PC and the Sensor ..................................................... 11

Editing the Sensor Parameters ......................................................................................................... 12

Sensor Selection Box of the Status and Setup Screen ................................................................. 13

Status Box of the Status and Setup Screen .................................................................................... 14

Mode Selection for Output Voltage Box of the Status and Setup Screen ............................... 15

Sampling Settings Box of the Status and Setup Screen ............................................................... 17

Miscellaneous Box of the Status and Setup Screen ..................................................................... 18

Messages Box of the Status and Setup Screen .............................................................................. 19

Self Heating Correction ..................................................................................................................... 19

Calibration of the Voltage Output .................................................................................................. 20

Displaying the Ultrasonic Signal ...................................................................................................... 21

Overview of Main Drop Down Menus of the Status and Setup Screen Settings ................... 23

6 Factory Default Programmed Settings ........................................................... 27

7 Troubleshooting ................................................................................................ 28

8 Terminology ........................................................................................................ 28

9 Wire Color Code ................................................................................................ 30

i

Page 4

1 Introduction

In operation, an LVU30 Series Sensor generates a high frequency ultrasonic pulse, measures the time

it takes for the reflected echo to return from a target, and then calculates the target distance using the

speed of sound. The value of the speed of sound, which is a function of temperature, is determined

by the sensor using its internal temperature probe. The distance to a target can be obtained from an

LVU30 Series Sensor in a variety of ways. For example, the sensor output can be a DC voltage, the

value of which is proportional to the target distance, or the sensor can be programmed to produce a

switched voltage output at a user-determined target distance. Information regarding the target can be

sent by an RS485 communication link to a computer and displayed using the LVU30 Series Software,

or another host device can be used.

Key Features of LVU30 Series Sensors include:

• Analog or Setpoint Switched Output

• Plug & Play Setup - No Targets Needed

• Software Set Span and Zero - No Pots or Pushbuttons

®

• Easy to use Setup Software using Windows

• Built-in Temperature/Sound Speed Compensation

98 /NT/2000 / XP operating systems

• Up to 32 Sensors on RS485 Multi-drop Loop

1

Page 5

2 Quick Guide on Getting Started

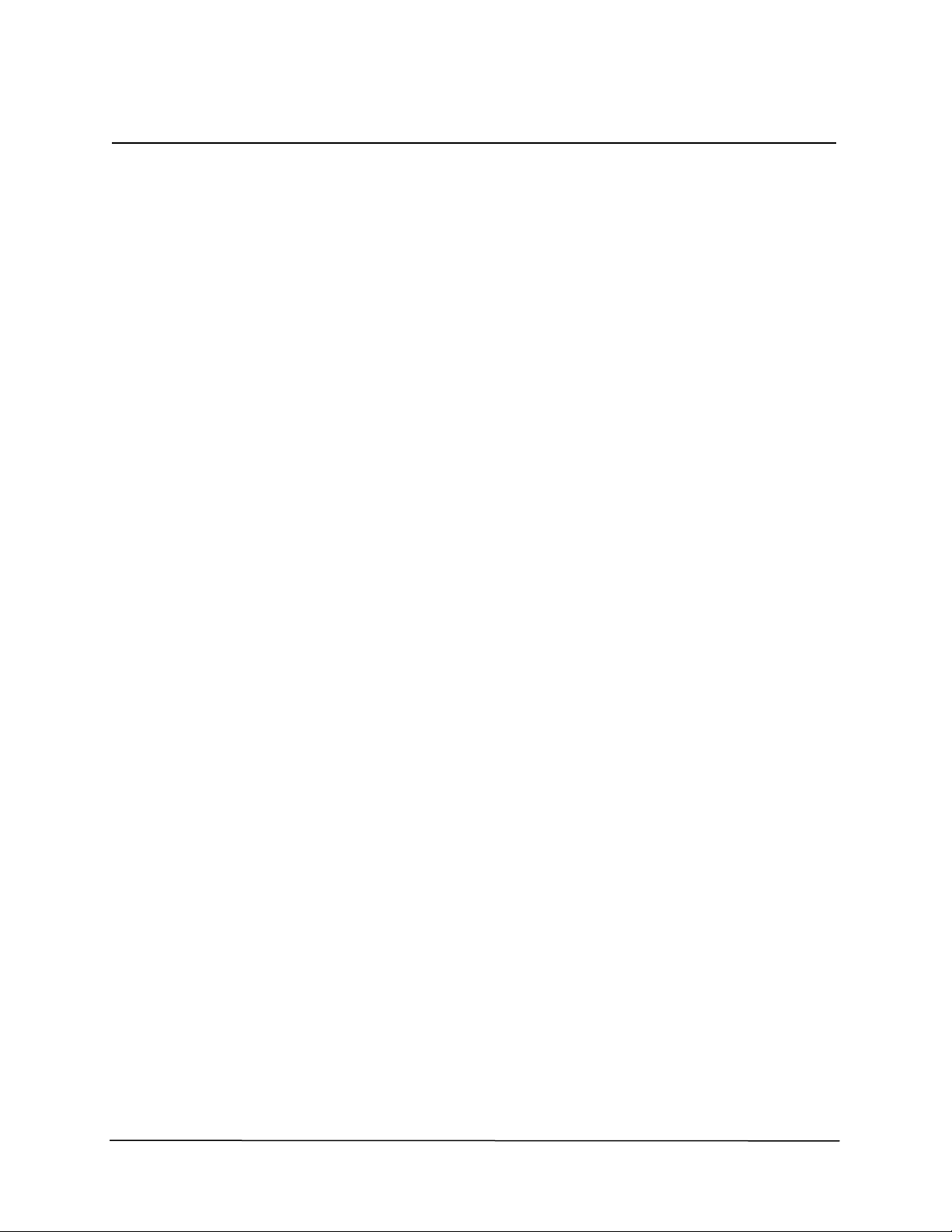

Mounting the Sensor

The LVU30 Series Family of Low Cost Sensors is designed to be easily mounted by using the 1” NPT

threaded shaft that is part of the housing of each sensor. The sensor can be screwed into a 1” NPT

tapped hole in a mounting plate, or it can be mounted onto a flat plate by inserting the threaded shaft

of the housing through a hole in the plate and securing the sensor using the locknut that is included

with each sensor. An optional Mounting Bracket can also be purchased, as shown in Figure 1.

Figure 1

Photograph of a LVU30 Series Sensor Attached to an Optional Mounting Bracket

Operating a Sensor Without a Computer

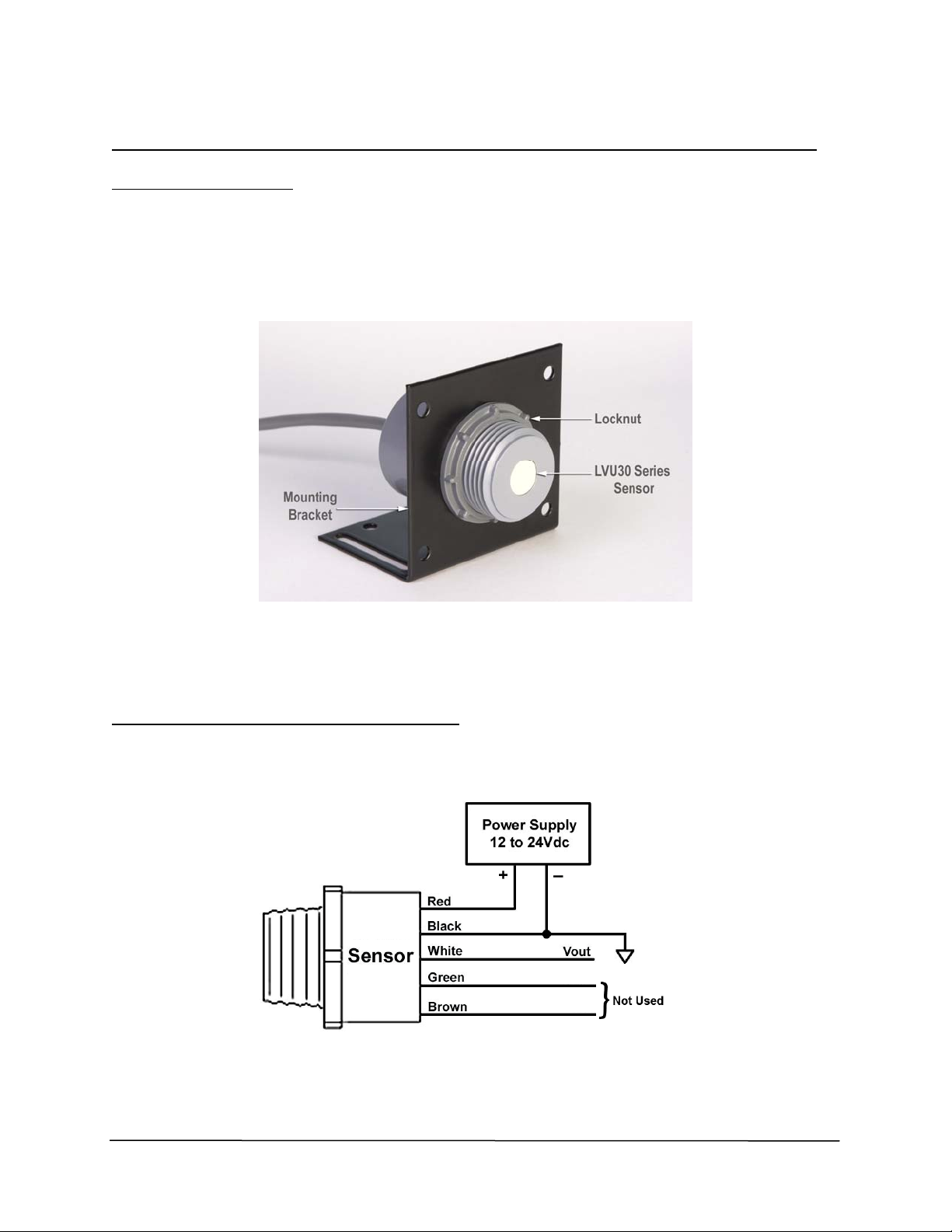

• With the 12-24 V DC Power Supply turned OFF, connect it to the red and black leads of the

Sensor, as shown in Figure 2.

Figure 2

Wiring Diagram for an LVU30 Series Sensor Used Without a Computer

2

Page 6

2 Quick Guide on Getting Started (continued)

• Turn the Power Supply ON.

• The DC voltage on the white lead of the sensor will be proportional to the distance to the

target.

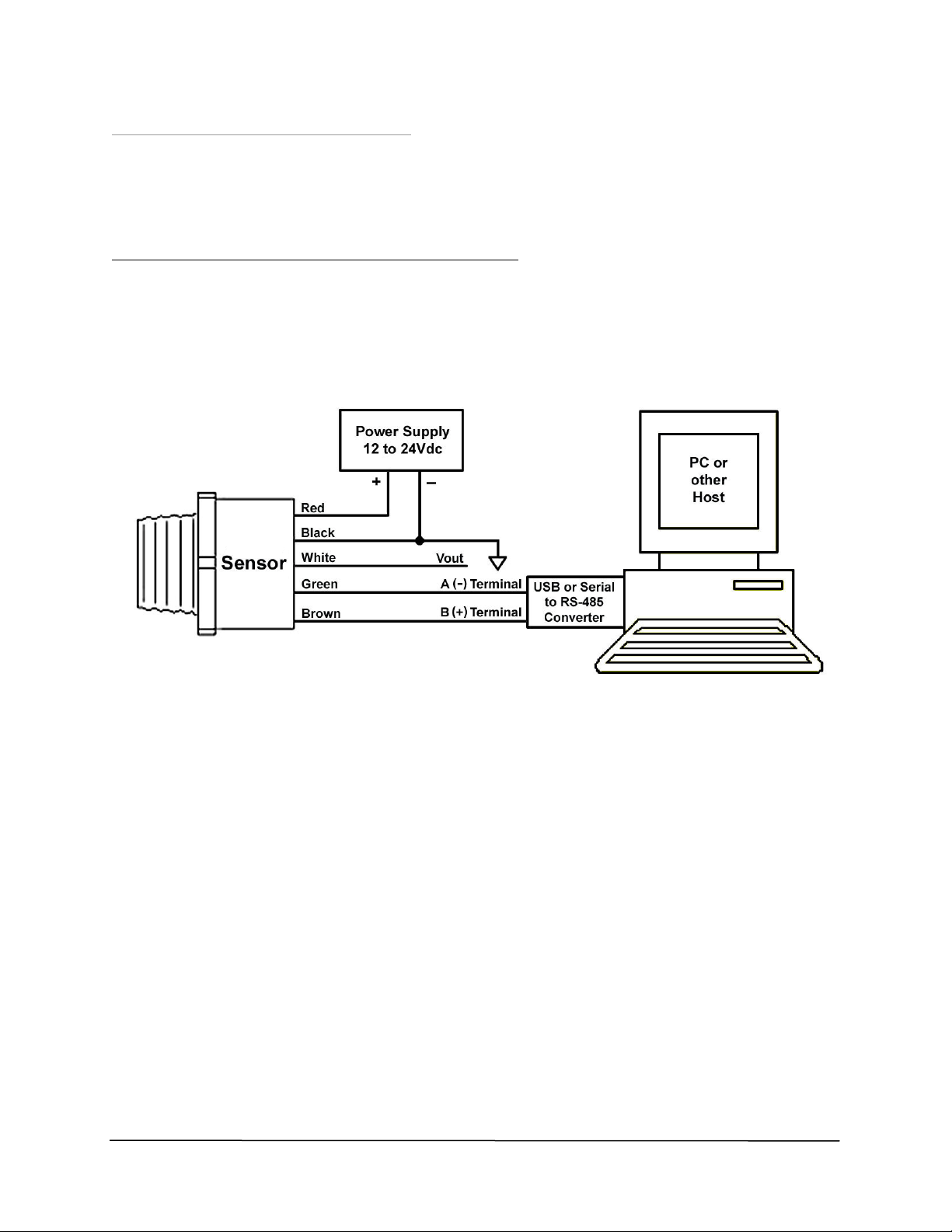

Operating an Sensor Connected to a Computer

• Download the LVU30 Series Software into the computer from the Omega website at

www.omega.com.

• With the 12-24 V DC Power Supply turned OFF, connect it to the red and black leads of the

sensor, as shown in Figure 3.

Figure 3

Wiring Diagram for an LVU30 Series Sensor Used With a Computer

• For the sensor to communicate with a computer, either an RS232/RS485 converter is

required when connecting to a serial port, or a USB/RS485 converter is required when

connecting to a USB port.

• Connect the sensor’s green lead to the converter’s A (-) terminal [the TDA (-) terminal on a

USB converter], and the brown lead to the converter’s B (+) terminal [the TDB (+) terminal

on USB converter].

NOTE: Use of termination resistors on the RS485 network is not required.

• Plug the Communication Converter into the appropriate serial or USB port on the

Computer.

• Turn the Power Supply ON.

• Execute the LVU30 Series program.

3

Page 7

2 Quick Guide on Getting Started (continued)

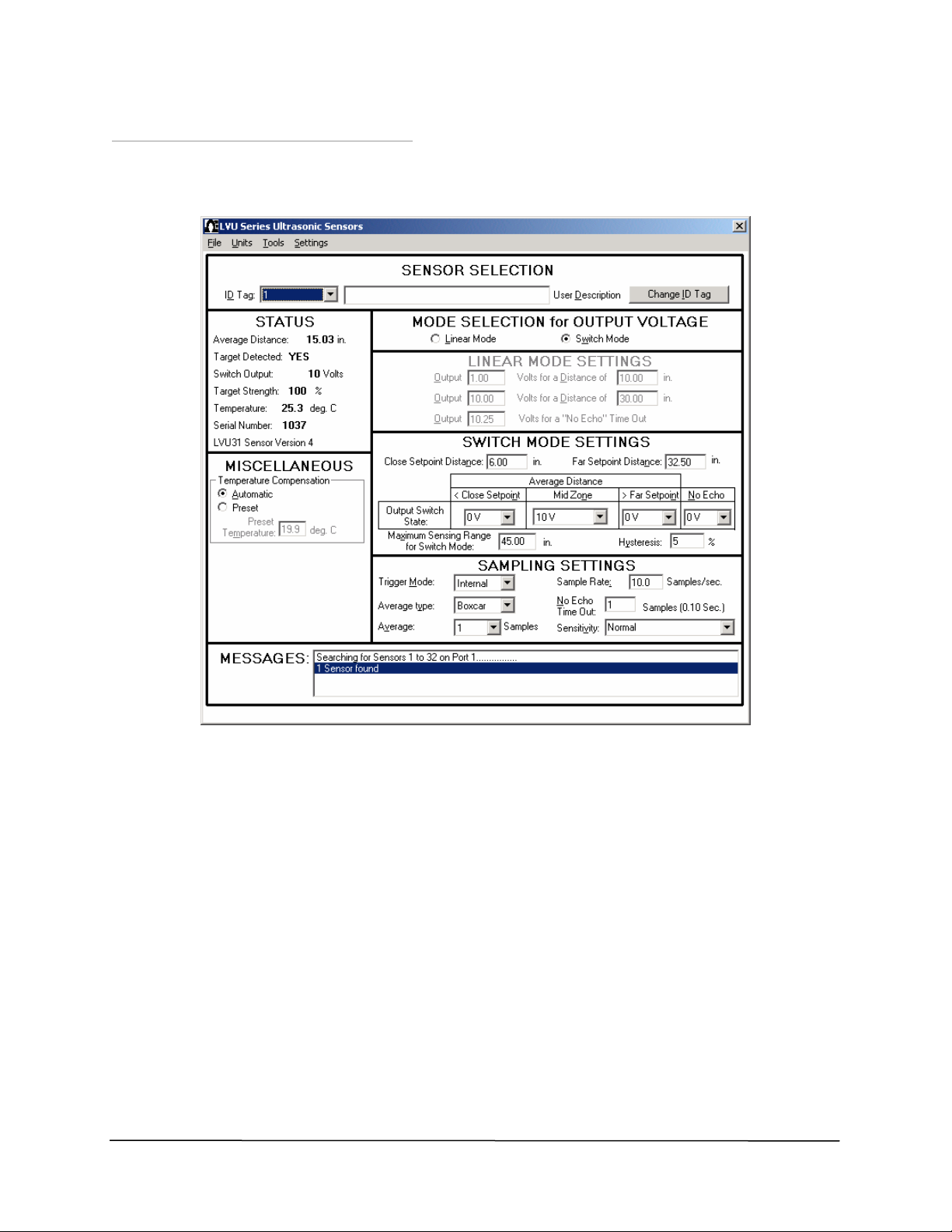

• The Status and Setup Screen will appear, as shown in Figure 4, and an indication that the

sensor was “found” will appear in the ‘Messages’ box at the bottom of the screen.

Figure 4

Example of the Status and Setup Screen for an Sensor

NOTE: If the sensor is not “found”, you may have to select another communications port. Use

the drop-down menu ‘Settings’ then ‘Communications Port’ to select another port. Use

the ‘Tools’ drop-down menu and then ‘Search for Sensors’ to establish communications

on the new port.

• Point the LVU30 Series sensor towards a target, such as a wall, to obtain a distance

measurement.

• To change any of the settings, move the mouse pointer and click on the field to be

modified. After all changes have been made, click on the ‘Program’ button. There is no

limit to the number of times the sensor can be reprogrammed. The Sensor’s settings are

non-volatile and the programmed values will be retained even if power is lost.

• The sensor can be adjusted for optimum performance in each application by adjusting its

settings. (See Section 5 for detailed information regarding utilization of these adjustment

features.)

4

Page 8

2 Quick Guide on Getting Started (continued)

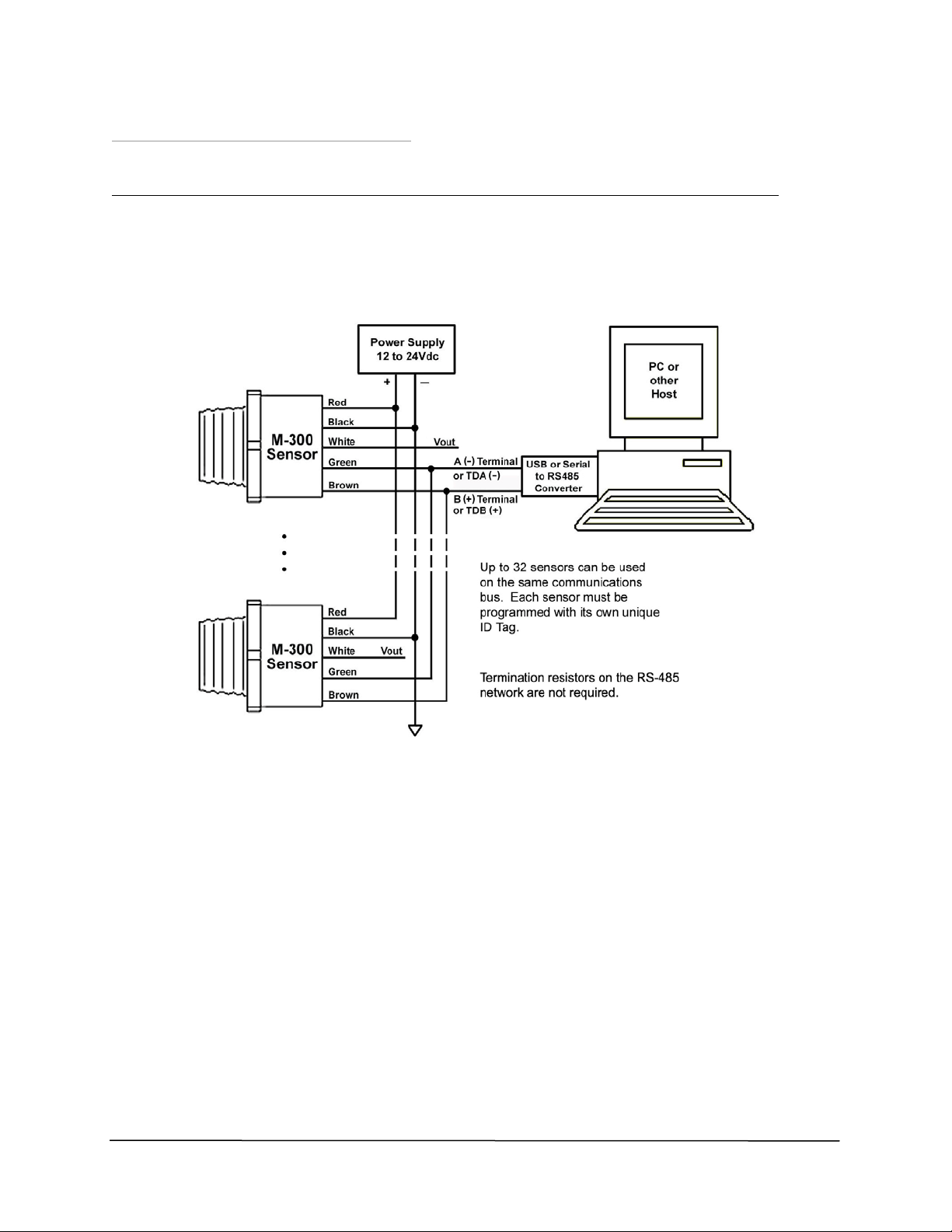

Operating Up to 32 Sensors Simultaneously Using a Multi-Drop Configuration

• Download the LVU30 Series Software into the Computer from the Omega Engineering

website at www.omega.com.

• With the 12-24 V DC Power Supply turned OFF, connect it to the red and black leads of the

sensor, as shown in Figure 5.

‘

Figure 5

Wiring Diagram for LVU30 Series Sensors Using a Multi-Drop Configuration

• Connect the first sensor to the Computer using the steps shown in the subsection entitled

“Operating a Sensor Connected to a Computer”, and insert a unique ID Tag from 1 to 32

into the sensor.

• Disconnect the sensor and then sequentially connect to the computer, by themselves one at

a time, each of the remaining multiple sensors that are going to be placed on the

communications bus, and insert a unique ID Tag from 1 to 32 into each of them. Once this

has been done, all the sensors can be wired in parallel to the RS485 communications bus, as

illustrated in Figure 5.

• Restart the LVU30 Series program. Any sensor can now be selected from the drop down list

next to the ID Tag and its status viewed.

• Any sensor can be reprogrammed, including changing its ID Tag, by selecting it and making

the desired changes.

5

Page 9

3 Product Description

This section contains a general overview of the LVU30 Series of Ultrasonic Sensors. For detailed

information on any specific model of sensors, refer to the datasheet located on the Omega

Engineering, Inc. website (www.omega.com) for the particular model.

DC Power Requirements

LVU30 Series Sensors are powered from 12 to 24 V DC sources, either batteries or power supplies,

that are capable of supplying currents of approximately 30 ma. The red and black wires of the sensor

must be connected to the DC power, as shown in Figures 2, 3, and 5 in Section 2.

Voltage Output (V-out) of a Sensor

The white lead of an LVU30 Series Sensor produces a DC analog Output Voltage, V-out, as shown in

Figure 2, 3, and 5 in Section 2. The value of V-out provides information regarding the Target Distance,

which is the distance from the sensor to a target. Sensors have two modes of operation. In the

Proportional Voltage Output Mode, V-out is an analog DC voltage that is directly proportional to the

Target Distance. In the Switched Setpoint Output Mode, V-out switches between two different

voltage levels based on the Target Distance falling within specific distance zones that are programmed

into the sensor as Setpoints. More detailed information regarding the use of these two operational

modes is contained in Section 5.

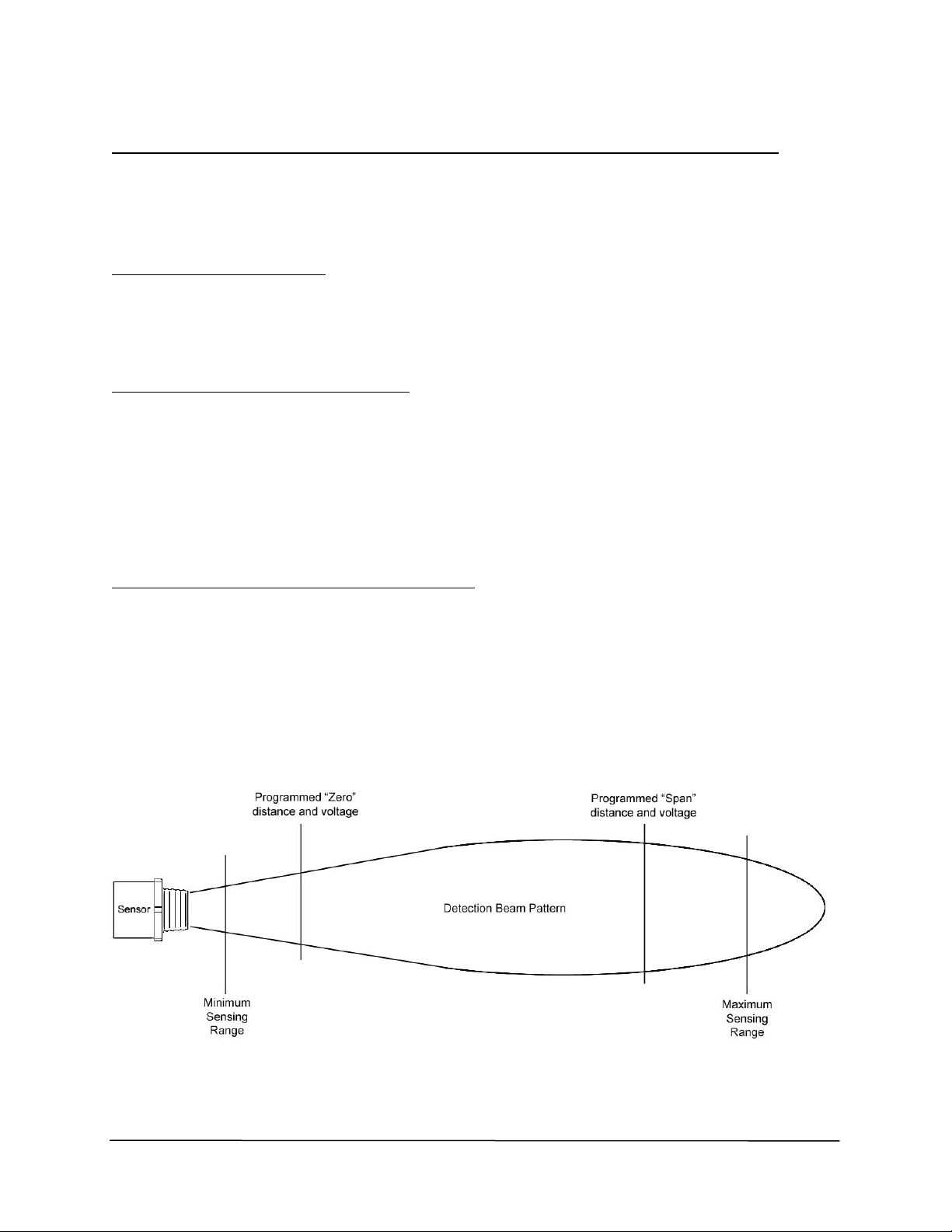

Proportional Voltage Output Mode (‘Linear Mode’)

Figure 6 is a schematic illustration of the Proportional Voltage Output Mode (‘Linear Mode’) of V-out

for an LVU30 Series Sensor. A Zero distance and a Span distance that are anywhere within the

Minimum Sensing Range and Maximum Sensing Range of the sensor can be programmed into the

sensor. The values of V-out will then be proportional to the Target Distance in the zone between the

distances set for Zero and Span. If a target is any closer than the Zero distance, V-out will be the

voltage value that was programmed into the sensor for the Zero distance. If the target is further away

than the Span distance, V-out will be the voltage value that was programmed into the Sensor for the

Span distance. If no target is detected, than V-out will be a third voltage, which is programmed as the

Loss of Echo Voltage.

Figure 6

Schematic Illustration of the Proportional Voltage Output Mode of V-out for an LVU30 Series Sensor

6

Page 10

3 Product Description (continued)

In the ‘Linear Mode’, the user can set the values for the following programming options using the

Status and Setup Screen shown in Figure 4 in Section 2 on Page 4.

1) Set any Output Voltage value from 0 V DC to 10.25 V DC for the Zero Distance

2) Set any Output Voltage value from 0 V DC to 10.25 V DC for the Span Distance

3) Set any Output Voltage value from 0 V DC to 10.25 V DC for the No Echo Time Out to indicate that

the target is “lost”, which occurs after the preset number of samples that were programmed into

the ‘No Echo Time Out’ in the ‘Sampling Settings’.

With this flexibility, positive or negative slopes can be programmed, along with any start and end

voltage value. Targets within the detection zone, established by the Zero and Span distances, will

produce an output voltage that is proportional to the Target Distance between the Zero Output

Voltage and the Span Output Voltage. Targets detected beyond the endpoints of the selected

distance zone will produce output voltages equal to the nearer endpoint. Targets detected closer

than the minimum specified Sensing Range will produce a V-out equal to the Outpoint Voltage

programmed for the Zero distance. Targets detected at distances greater than the programmed Span

distance will produce a V-out equal to the Outpout Voltage programmed for the Span distance. If no

target is detected, V-out will be the Output Voltage programmed for ‘No Echo Time Out’.

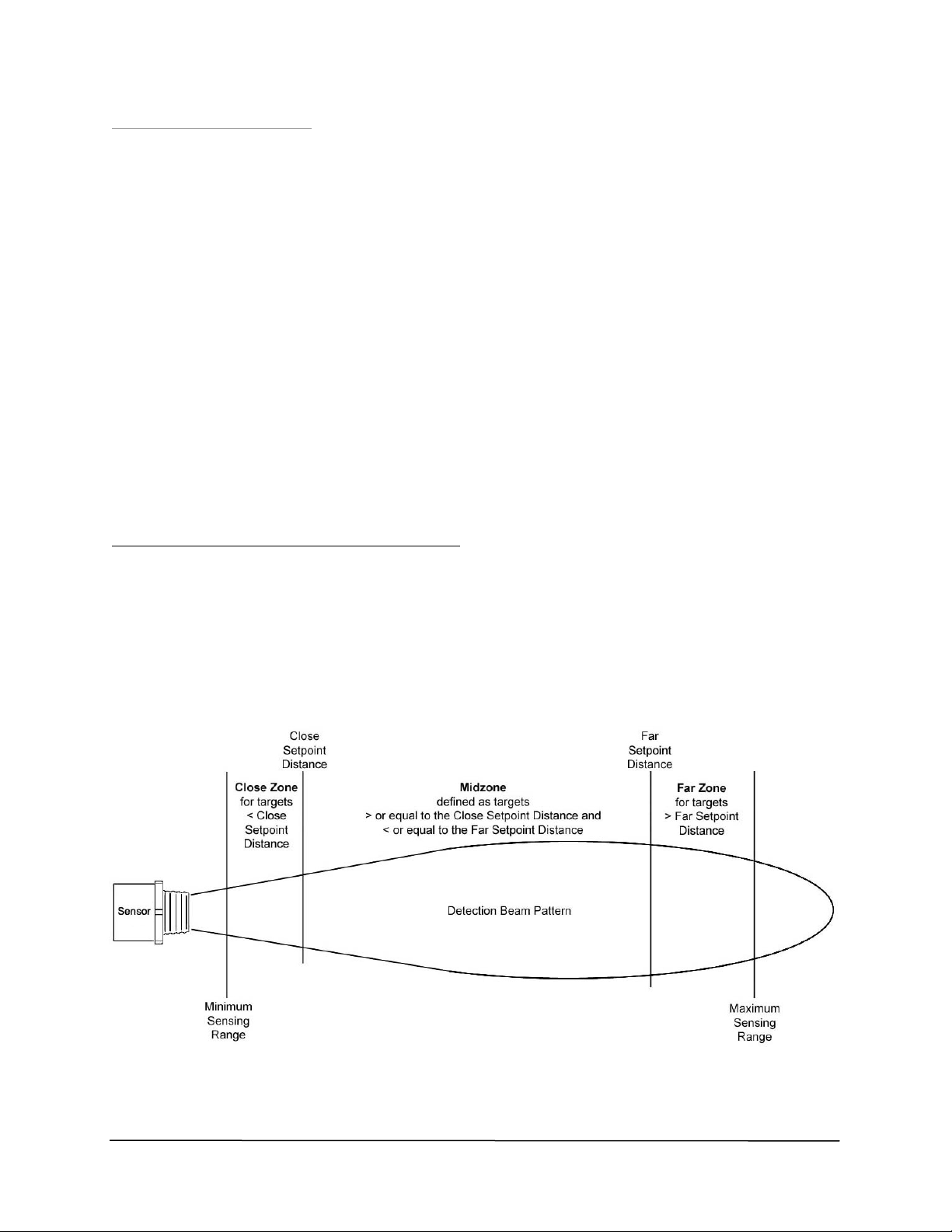

Switched Setpoint Output Mode (‘Switch Mode’)

Figure 7 is a schematic illustration of the Switched Setpoint Output Mode (‘Switch Mode’) of V-out for

an LVU30 Series Sensor. In this Switch Mode, a Close Setpoint Distance and a Far Setpoint Distance,

that are anywhere within the Minimum and Maximum Sensing Range, can be programmed into the

sensor. These two setpoint distances will then establish three distance zones, which are the CIose

Zone for Target Distances less than the Close Setpoint Distance, the Mid Zone for target distances

between the Close Setpoint Distance and the Far Setpoint Distance, and the Far Zone for Target

Distances greater than the Far Setpoint Distance. Different value of V-out can be selected to be

produced for when the target is located in each of the three zones.

Figure 7

Schematic Illustration of the Switched Setpoint Output Mode of V-out for an LVU30 Series Sensor

7

Page 11

3 Product Description (continued)

In the ‘Switch Mode’, the user can set the value of the following programming options using the

Status and Setup Screen shown in Figure 4 in Section 2 on Page 4.

1) Set a value for the Close Setpoint Distance.

2) Set a value for the Far Setpoint Distance.

3) Set a value of 0 V DC or 10.25 V DC for V-out when the Target Distance is in the Close Zone

(<Close Setpoint Distance).

4) Set a value of 0 V DC or 10.25 V DC for V-out when the Target Distance is in the Mid Zone (>Close

Setpoint Distance and <Far Setpoint Distance).

5) Set a value of 0 V DC or 10.25 V DC for V-out when the Target Distance is in the Far Zone (>Far

Setpoint Distance).

6) Set a value of 0 V DC or 10.25 V DC for when No Echo has been detected after a preset timeout.

7) The Mid Zone also has a ‘No Change’ programmable option where the value of V-out will not

charge when a target enters this zone from another zone.

8) Hysteresis around the setpoints can be programmed from 0% to 75%.

9) V-out for targets detected closer than the minimum specified Sensing Range of the specific model

of LVU30 Series Sensor used will be the same as the value for V-out set for the Close Zone.

RS485 Port

Monitoring and programming the sensor occurs through the RS485 serial communications port. The

advantages of an RS485 based system include the ability to have long cable lengths while wiring up to

32 sensors on just one pair of wires (multi-drop). This method allows for access to all sensors from

any convenient location. When communicating with a PC, a communications converter will be

required (either a USB or RS232 to RS485).

Wire the sensor to the RS485 Communication Converter as shown in Figure 3 in Section 2. The

converter’s terminal for the green wire of the sensor will be marked as TDA, A (-), or some

combination for the A terminal wiring. The converter’s terminal for the brown wire of the sensor will

be marked as TDB, B (+), or some combination for the B terminal wiring. If the converter has any of

the switches shown below, set to the following positions:

• TD 422 or TD 485, set to TD 485 position

• ECHO ON or ECHO OFF, set to ECHO OFF position

• 4 Wire or 2 Wire, set to 2 Wire position

The sensor is now ready to communicate using the LVU30 Series Software Program.

8

Page 12

3 Product Description (continued)

Multi-drop Operation

When planning to connect more than one sensor on the same communications bus, each must be

programmed with its own unique ‘ID Tag’ from 1 to 32. To do this, only one sensor at a time must be

placed and each is then programmed with its own unique ‘ID Tag’. The available ‘ID Tag’ numbers are

1 to 32. Repeat this procedure for all the sensors on the communications port.

The software will now allow the monitoring and editing of any sensor on-line. To monitor any sensor,

simply go to the ‘ID Tag’ field in the ‘Sensor Selection’ box and select a sensor by using the ‘ID Tag’

drop down menu and highlighting the numbering of the sensor that is to be monitored. (See Figure

14 in Section 5 on Page 13 for more details.)

Note 1: The RS485 Converter must have automatic send data control for proper operation. The LVU30

Series Sensors are configured for half-duplex operation (2-wire), which allows only one device

to communicate at a time. In normal operation a host device (typically a PC) requests data or

sends a command to a particular sensor resulting in a response. Signal ground should be

connected between the sensor and the RS485 Converter to keep the common mode voltage

between the devices within safe limits. Not wiring the RS485 Converter ground may sacrifice

reliability and noise immunity. Termination of the network is not recommended on port

powered converters, and is not necessary for the sensors due to the use of slew rate limited

components.

Note 2: LVU30 Series Sensors continuously monitor themselves for system integrity. If a fault occurs,

the sensor and its outputs will be placed into the No Echo state. The fault can be identified via

the serial communications port. Some faults are self-correcting, but some may require user

intervention to “Reset” the software of the sensor.

9

Page 13

4 Installing LVU30 Series Software

The minimum requirements to run the LVU30 Series Software program is a PC operating under

Windows

Engineering, Inc. website (www.omega.com).

Start by running ‘setup.exe’, and the screen shown in Figure 8 will be displayed.

Click on ‘OK’ and the screen shown in Figure 9 will be displayed. Continue with the installation by

clicking the button and proceed with the rest of the installation.

Once the software has been installed, connect the sensor to the computer, as shown in Figure 3 of

Section 2, and then execute the program.

®

98/NT/2000/XP operating system. This software can be downloaded it from the Omega

Figure 8

First Screen That Is Displayed After Running ‘Setup.exe’ During Installation of the LVU30 Series

Software

Figure 9

Screen That Is Displayed After the ‘OK’ Button in Figure 8 is Clicked

10

Page 14

5 Status and Setup Screen

Establishing Communication between a PC and the Sensor

Once the LVU30 Series Software has been installed and a sensor has been found, communication

between the computer and the sensor will begin. The Status and Setup Screen shown in Figure 4 in

Section 2 will be displayed. This is the main operating screen of the LVU30 Series System, and it

provides status information, ID Tag and all the operating parameters of the sensor. If no sensor is

found, then the screen shown in Figure 10 will be displayed, and the ‘Messages’ box at the bottom will

indicate

’0 Sensor found’. It may be necessary to select another communications port, especially if a USB port

converter is being used that typically is assigned a port address other than Comm1.

Figure 10

LVU30 Series Software Status and Setup Screen When No Sensor is Found

To select another communications port, use the ‘Settings’ drop

down list and select ‘Communications Port…’ and the screen in

Figure 11 will be displayed. To select another comm. port, enter

another number in the ‘Port Number’ box and click ‘OK’. If a

port is not available, an error message will be indicated. Once a

port number has been successfully entered, the ’Messages’ box

in the Status and Set up Screen will indicate that the sensor has

been found. Click on the ‘Establish Communications’ button to

Figure 11

LVU30 Series Software Select

Communication Port Screen

connect to the sensor. If unsuccessful, continue to try other

port numbers until the port address assigned to the USB

Converter is found.

11

Page 15

5 Status and Setup Screen (continued)

Editing the Sensor Parameters

The Status and Setup Screen provides status information and all the operating parameters for the

sensor. Editing is performed using standard Windows

®

text editing or by drop down menus. When a

field is changed, the ‘Editing’ box, shown in Figure 12, will replace the ‘Status’ box in the Status and

Setup Screen.

Figure 12

‘Editing’ Box

Make the desired changes to the various sensor parameters and then click the ‘Program Sensor’

button. It is possible to recall previously saved settings by using the drop down menu item ‘File’ then

‘Recall Settings…’. If it is preferred to defer to the sensors default settings, use the drop down menu

item ‘Settings’ followed by ‘Display Default Settings’. Then click ‘Program Sensor’ to apply the

defaults to the sensor.

If a value of a parameter is entered that is invalid for the operation of the sensor, the LVU30 Series

Software will highlight the invalid value in red and will display a red error message in the ‘Messages’

box, as illustrated in Figure 13.

Figure 13

LVU30 Series Software Status and Setup Screen When an Invalid Parameter Has Been Entered

12

Page 16

5 Status and Setup Screen (continued)

Sensor Selection Box of the Status and Setup Screen

‘ID TAG’’

The ID Tag is a programmable sensor address that allows multiple sensors to be connected to the

same pair of wires of a communications bus. Figure 14 shows the ‘Sensor Selection’ box of the Status

and Setup Screen. The sensor being monitored is identified by the number displayed in the ‘ID Tag’.

There are two methods of programming multiple sensors placed on the same network. The first

method is to program each sensor by itself on the bus with its own unique ‘ID Tag’. Once this has

been completed, place all the sensors on the bus in parallel. To change the ‘ID Tag’ of a sensor, click

the ‘Change ID Tag’ button and the ‘Change ID Tag’ box shown in Figure 15 will appear. Select a new

‘ID Tag’ from the drop down menu and then click the ‘OK’ button.

Figure 14

Sensor Selection Box of the Status and Setup Screen

Figure 15

Change ID Tag Box

The second method of placing multiple sensors on the same network is to place only the 1

the network and assign 2 or greater for its ‘ID Tag’. Disconnect power and connect another sensor on

the network. Reconnect power to the sensors and restart the LVU30 Series Software Program or reestablish communications. The new sensor will have 1 for its ‘ID Tag 1’. Using the ‘Change ID Tag’

button, select the next available ‘ID Tag’ from the drop down list. Repeat this procedure until all the

sensors are placed on the network. This method should only be used with new sensors that have

been assigned 1 for their ‘ID Tag ‘ at the factory.

User Description

st

sensor on

Each sensor can be identified with up to 32 ACSII characters of descriptive information, such as

“Process Tank #3”, that can be entered into the ‘User Description’ box. Once editing of the User

Description box has begun, then the ‘Editing’ box shown in Figure 12 will replace the “Status” box. To

save the information, click the ‘Program Sensor’ button in the ‘Editing’ box.

13

Page 17

5 Status and Setup Screen (continued)

Status Box of the Status and Setup Screen

The ‘Status’ box displays the various parameters for the particular sensor whose ‘ID Tag’ is displayed

in the ‘Sensor Selection’ box of the Status and Setup Screen. This field is updated approximately

every ¼ of a second. An example of this box is shown in Figure 16.

Figure 16

Example of the Status Box of the Status and Setup Screen

‘Average Distance’: Measured average Target Distance to target. Number of samples in the average

and the average type is programmable by using the ‘Sampling Settings’ box.

‘Target Detected’: Indicates that a target is detected. If the sensor is in the ‘Switch Mode’ and if the

target is beyond the programmed ‘Maximum Sensing Range’ for ‘Switch Mode’, the ‘Target Detected’

indication will be ‘NO’.

‘Linear Output’ or ‘Switch Output’: Indicates the value of V-out, which is proportional to the Target

Distance if the sensors voltage output is programmed in the ‘Linear Mode. If the sensor’s voltage

output is programmed for ‘Switch Mode’ operation, it will indicate either 0V or 10V.

‘Target Strength’: Measure of the relative strength of the received ultrasonic echo signal and can be

used to align either the target or the sensor to produce the optimum echo.

‘Temperature’: Temperature reading of the internal probe of the sensor when ‘Automatic’ is selected

in the ‘Temperature Compensation’ box. If ‘Preset’ is selected in the ‘Temperature Compensation’

box, then the preset temperature that was entered will be displayed.

‘Serial Number’: The serial number of the sensor that was assigned at the factory.

The last line in the ‘Status’ box indicates the particular model of the sensor that is being used and the

Version number of its firmware.

14

Page 18

5 Status and Setup Screen (continued)

Mode Selection for Output Voltage Box of the Status and Setup Screen

The ‘Mode Selection for Output Voltage’ box of the Status and Setup Screen allows the sensor to

operate in either the ’Linear Mode’ or the ‘Switch Mode’.

‘Linear Mode Settings’ Box of the Status and Setup Screen

When the sensor is programmed to operate in the Proportional Voltage Output Mode (‘Linear

Mode’), V-out is an analog voltage that is proportional to the Target Distance. To enable this mode of

operation, click on the ‘Linear Mode’ radio button in the ‘Mode Selection for Output Voltage’ box of

the Status and Setup Screen, as shown in Figure 17. ‘Switch Mode Settings’ parameters are disabled

when the sensor is in the Linear Output Mode.

Figure 17

Mode Selection for Output Voltage Box of the Status and Setup Screen

Programming options in the ‘Linear Mode’ allow any voltage to be entered into the ‘Output’ box from

0 to 10.25 V DC for the 1

nd

the 2

programmed distance (Span). With this flexibility, positive or negative slopes can be realized

st

programmed distance (Zero), and any voltage from 0 V DC to 10.25 V DC for

along with any start and end voltage. (See Figure 6 in Section 3 for an explanation of Zero and Span

Distance.) In the example shown in Figure 17, the ‘Output’ is programmed for 1.00 V DC for a ‘Zero

Distance’ of 10.00 inches. The Span is programmed for an ‘Output’ of 10.00 V DC at a ‘Distance of’

30.00 inches. Targets detected between the Zero and Span distances will produce a linear value of Vout between the programmed Zero and Span Voltage values. Targets detected closer than the Zero

distance will produce a value for V-out equal to the Zero distance voltage (1.00 V DC in this example).

Targets detected greater than the Span distance will produce a value for V-out equal to the Span

distance voltage (10.00 V DC in this example). If no targets are detected, V-out will be equal to the

‘ “No Echo” Time Out’ voltage (10.25 V DC in this example).

15

Page 19

5 Status and Setup Screen (continued)

‘Switch Mode Settings’ Box of the Status and Setup Screen

The Switched Setpoint Outpoint Mode (‘Switch Mode’) allows the state of V-out to switch between

0 and 10.25 V DC based on the relationship of the measured Target Distance to the ‘Close Setpoint

Distance’ and the ‘Far Setpoint Distance’ programmed into the sensor. Figure 7 in Section 3 shows

how three zones are created; the Close Zone where the Target Distance is < the ‘Close Setpoint

Distance’, the Mid Zone where the Target Distance is between the ‘Close and the Far Setpoint

Distances’, and the Far Zone where the Target Distance is greater than the ‘Far Setpoint Distance’.

To enable this mode, click on the ‘Switch Mode’ radio button in the ‘Mode Selection for Output

Voltage’ box of the Status and Setup Screen, as shown in Figure 18. Enter values for the ‘Close

Setpoint Distance’ and the ‘Far Setpoint Distance’ that are within the allowable distances specified in

the datasheet for the particular sensor being used. Use the drop down menu to set the values of Vout for when the Target Distance is within each of the three zones. These values can be 0 V DC or 10

V DC. (In the 10 V DC settings, the actual value of V-out is 10.25 V DC). A value for V-out of 0 V DC or

10 V DC can also be set for a ‘No Echo’ condition.

Figure 18

Switch Mode Setting Box

A ‘No Change’ condition can also be chosen for the voltage setting for the Mid Zone. In this state, Vout would not change as a target transitioned into the Mid Zone. For example, if the ‘<Close Setpoint’

voltage was set at 0 V and the ‘>Far Setpoint’ voltage was set at 10 V, V-out would stay at 0 V when the

target moved from the Close Zone into the Mid Zone, and would change to 10 V when it moved into

the Far Zone. If the target started moving closer, V-out would stay at 10 V as it moved from the Far

Zone into the Mid Zone, and would change to 0 V as it moved into the Close Zone.

A percentage between 0 and 75% can also be entered in the ‘Hysteresis’ section of the ‘Switch Mode

Settings’ box. This creates a guard zone around each Setpoint Distance to keep V-out from switching

back and forth between two states when the Target Distance equals the Setpoint distance. This is

explained in more detail in Section 9 on Page 29.

A Maximum Sensing Range for ‘Switch Mode’ can also be entered into the ‘Switch Mode Settings’

box. If the Target Distance is greater than the maximum range entered, the sensor will consider it to

be a ‘No Echo’ condition, and V-out will be the programmed ‘No Echo’ voltage.

16

Page 20

5 Status and Setup Screen (continued)

Sampling Settings Box of the Status and Setup Screen

The ‘Sampling Setting’ box shown, in Figure 19, allows the tailoring of the sensor’s filter parameters to

optimize operation.

Figure 19

Sampling Settings Box of the Status and Setup Screen

‘Trigger Mode’: Use the pull down menu to select the ‘Trigger Mode’. Options are ‘Internal’ (self

trigger) or ‘Manual’. If ‘Internal’ is selected, the sensor will measure the Target Distance as many

times per second as is entered for the ‘Sample Rate’. If ‘Manual’ is selected, the sensor will wait for

serial communications to send a software trigger signal before the sensor transmits an acoustic pulse.

The screen will display a ‘Manual Trigger’ button that causes the sensor to transmit an acoustic pulse

each time it is clicked.

‘Average Type’: The Target Distance displayed, and the value of V-out, are determined by averaging a

number of measured Target Distances. The pull down menu allows the selection of either ‘Rolling’ or

‘Boxcar’ for the type of averaging to be used by the sensor. If ‘Rolling’ is selected, the sensor stores

the number of sequential Target Distance measurement entered for ‘Average’, and then computes the

average. Each new sample then replaces the oldest sample in memory, and the average is

recomputed and displayed. If ‘Boxcar’ is selected, the number of measurements entered for ‘average’

are stored and the average is computed and displayed. These samples are then discarded and the

process starts over again.

‘Average’: This drop down menu selects the number of samples to be used to obtain the average

Target Distance. If ‘Rolling’ is selected for the ‘Average Type’, ‘Average’ is limited to 32 samples. For

‘Boxcar’, the maximum number of samples is 1024.

‘Sample Rate’: When ‘Internal’ is selected for the ‘Trigger Mode’, the number of times per second the

sensor will measure the Target Distance can be entered for the ‘Sample Rate’. This rate can be

between 0.1 samples/sec to the sensor’s maximum specified rate. (This is model dependent. Refer to

the datasheet located on the Omega Engineering, Inc. website at www.omega.com for the particular

sensor being used.) In general, the faster the target is moving, the higher the sample rate required.

‘No Echo Time Out’: The number entered is the number of consecutive samples for which an echo is

not detected that must occur before the sensor enters the ‘No Echo’ state. The displayed ‘Target

Distance’ and V-out will hold these last values until the ‘Time Out’ occurs.

‘Sensitivity’: This parameter, which is set by a drop down menu, allows the sensor’s target detection

ability to be adjusted. Most applications should be set to ‘Normal’. Applications with poor reflecting

targets may require a ‘High’ setting. If unwanted reflections are detected by the sensor a ‘Low’ setting

may be required.

17

Page 21

5 Status and Setup Screen (continued)

Miscellaneous Box of the Status and Setup Screen

The ‘Miscellaneous’ box, shown in Figures 20 and 21, is used to select different methods of

‘Temperature Compensation’ to be used by the sensor to calculate the speed of sound in order to

obtain an accurate Target Distance measurement. This box is also used to display error messages.

The radio buttons under ‘Temperature Compensation’ can be used to select either ‘Automatic’ or

‘Preset’. If ‘Automatic’ is selected, the sensor uses its internal temperature probe to calculate the

speed of sound. This calculation assumes that the Target Distance measurement is being conducted

in air. The factory default setting is ‘Automatic’, and it is recommended that this setting is used for

most applications. If a specific speed of sound is desired to be used for the Target Distance

measurement, ‘Preset’ can be selected, which overrides the internal temperature probe. The desired

speed of sound to be used by the sensor is set by entering the temperature that produce this sound

speed based on the following:

Where:

( ) 13,044 1

cT =+

c(T) is the Speed of Sound in Inches per Second

T is the Temperature in ºC

T

273

Certain error conditions will be displayed in the lower portion of the ‘Miscellaneous’ box as shown in

Figure 21. They include invalid operating parameters that may have been programmed outside the

acceptable range of the Setup Software, internal temperature sensor faults, low supply voltage, and

the echo detector fault.

The ‘Invalid Operating Parameter’ error is considered a fatal error since it could affect the operational

settings of the sensor. After entering new settings, the values should be validated by clicking ‘Reset

Error(s)’ . The sensor will not operate (transmit ultrasonic pulses) while in this error mode.

The ‘Low Supply Voltage Occurred’ error is non-fatal and simply indicates that the sensor went into

reset at some point due to a low power supply or glitch. The sensor will continue to transmit

ultrasonic pulses.

The ’Temperature Sensor’ and ‘Echo Detector’ error messages cannot be cleared. If these errors

occur, the sensor will attempt to fix the problem and will self-clear once they have been corrected. If

the errors do not clear after a period of time, the sensor may have a serious fault. While in these error

modes, the sensor will not transmit ultrasonic pulses and the output voltage will default to the

programmed ‘No Echo’ voltage.

Figure 20 Figure 21

Miscellaneous Box of the Miscellaneous Box

Status and Setup Screen Showing Error Message

18

Page 22

5 Status and Setup Screen (continued)

Messages Box of the Status and Setup Screen

Messages will be displayed in this box, such as “Searching for Sensors on Port 1…” as shown in

Figure 22, errors, such as user inputs that are out of parameter limits, are also displayed, as shown in

Figure 13.

Figure 22

Example of Messages in the Messages Box of the Status Setup Screen

Self Heating Correction

When in operation, the temperature of the sensor becomes slightly higher than the ambient

temperature of the air. The firmware of the sensor corrects the reading of the temperature probe to

obtain the actual temperature of the air outside of the sensor. Use the drop down menu under

‘Settings’ to enable or disable this feature by checking or not checking ‘Self Heating Correction’, as

illustrated in Figure 23. The factory default has this feature checked. It may be desirable to disable

this feature in certain applications, such as when sensors are only turned on for a short duration so

that self heating does not occur.

Figure 23

Example Showing ‘Self Heating Correction’ in the ‘Setting’

Drop Down Menu of the Status and Setup Screen

19

Page 23

5 Status and Setup Screen (continued)

Calibration of the Voltage Output

The calibration of the Voltage Output can be performed by pulling down the ‘Tools’ menu and

selecting ‘Calibrate Voltage…’, as shown in Figure 24.

Figure 24

Example Showing ‘Calibrate Voltage . . .’ in the ‘Tools’

Drop Down Menu of the Status and Setup Screen

A ‘Calibrate Voltage Warning’ Screen will be displayed, as shown in Figure 25, asking if it is desired to

proceed with the calibration.

Figure 25

The ‘Calibrate Voltage Warning’ Screen of the Status and Setup Screen

If the ‘Proceed with Calibration’ button is clicked, the ‘Calibrate Voltage’ screen will be displayed, as

shown in Figure 26. With a volt meter attached to the white lead of the sensor (V-out), adjust the

voltage by using the ‘Increase Voltage’ or ‘Decrease Voltage’ buttons. Allow several seconds each

time the button is clicked for V-out to adjust since this is a filtered output. Click ‘Exit and resume

normal sensor operation’ button when done.

Figure 26

The ‘Calibrate Voltage’ Screen of the Status and Setup Screen

20

Page 24

5 Status and Setup Screen (continued)

Displaying the Ultrasonic Signal

The LVU30 Series Sensor has a unique feature that will allow the software to display, similar to an

oscilloscope, the waveform of the received ultrasonic signal. This can be used as a valuable aid in

diagnosing difficult applications. Waveforms can be saved and recalled for future review. To access

this feature, use the ‘Tools’ drop down menu and select ‘Display Ultrasonic Signal…’ as shown in

Figure 27.

Figure 27

Example Showing ‘Display Ultrasonic Signal . . .’ in the ‘Tools’

Drop Down Menu of the Status and Setup Screen

A ‘Warning Screen’, as shown in Figure 28, will be displayed asking if it is desired to proceed. If the

sensor is actively controlling a process, then the operation of the process may be affected. Click the

‘Continue’ button to enter the Display Ultrasonic Signal mode or exit by clicking the ‘Abort’ button.

Figure 28

‘Warning’ Screen When ‘Display Ultrasonic Signals . . .’ is Selected

21

Page 25

5 Status and Setup Screen (continued)

After clicking the ‘Continue’ button on the Warning Screen, the ‘Ultrasonic Signal’ screen, shown in

Figure 29, will be displayed. Two waveform traces are shown. The “Signal” trace, in black, represents

the peak detected waveform from the received ultrasonic signal. The first peak is the sensor’s

transmit pulse, followed by a second peak at 15” that is the target. Subsequent reflections may follow

the target signal, but they are ignored by the sensor. The 2

This represents the signal detection level as determined by the “Sensitivity” setting. A reflected signal

that crosses over this ‘Threshold’ level is captured and used to calculate the Target Distance. Most

applications will have the “Sensitivity” adjustment set to “Normal”. However, if the target’s reflection

is marginal, setting the “Sensitivity” setting to “High” (which lowers the threshold level) will improve

target detection. On the other hand, if there are unwanted reflections in the application arriving

before the target echo, setting the “Sensitivity” setting to “Low” (which raises the “Threshold” level)

may be required. This valuable display tool will help to analyze and validate the sensor’s operation in

the particular application. Certain applications may require custom sensitivity adjustments.

nd

waveform, in red, is the ‘Threshold’ trace.

Figure 29

Example Showing the Display of the Received Ultrasonic Signal

Ultrasonic Signal data, Plot Comments, and other significant data can be saved to file by using the

drop down menu ‘File’ and then selecting ‘Save Data’ when in the Ultrasonic Signal mode, as shown in

Figure 30. Recalling data to be displayed is accomplished by using the drop down menu ‘File’ and

then selecting ‘Recall Data’. It is not necessary to have a sensor on line to recall previously saved data.

Figure 30

Example Showing ‘Save Data’ and ‘Recall Data’ in the ‘File’

Drop Down Menu of the Status and Setup Screen

22

Page 26

5 Status and Setup Screen (continued)

Overview of Main Drop Down Menus of the Status and Setup Screen Settings

File Menu

Figure 31 shows the selection options for the ‘File’ drop down menu.

Figure 31

The ‘File’ Drop Down Menu Selections of the Status and Setup Screen

‘Save Settings...’: Allows all the values displayed to be saved to the hard drive of the PC. This

facilitates the transfer of settings.

‘Recall Settings...’: Allows restoration of previously saved values. Only data sets that were saved for

the same specific LVU30 Series Sensor model as the selected sensor are allowed to be recalled. Click

‘Program Sensor’ to apply the settings to the selected on-line sensor.

‘Exit’: Exits the Setup Software while the sensor continues to operate normally.

Units Menu

Figure 32 shows the selection options for the ‘Units’ drop down menu.

‘Distance’: Allows the user to select the distance units to be displayed. The available selections

include inches, centimeters, feet, and meters.

Figure 32

The ‘Units’ Drop Down Menu Selections of the Status and Setup Screen

‘Temperature’: Allows the user to select the temperature units to be displayed. Select either

elsius or Fahrenheit.

C

23

Page 27

5 Status and Setup Screen (continued)

Tools Menu

Figure 33 shows the selection options for the ‘Tools’ drop down menu.

Figure 33

The ‘Tools’ Drop Down Menu Selections of the Status and Setup Screen

‘Calibrate Voltage…’: Allows the user to calibrate the V-out to 10.00 V DC.

‘Search for Sensors’: Allows the user to re-establish communications with the sensor(s) if lost or not

initially obtained.

Note: If communications were lost, the ’Status’ box area will be replaced with a ‘No Sensors On Line’

box as shown in Figure 34. Clicking on the ‘Establish Communication’ button in this box will

produce the same results as clicking on ‘Search for Sensors’.

Figure 34

‘No Sensors On Line’ Box That Replaces the ‘Status’ Box in

the Status and Setup Screen When Communication is Lost

‘Display Ultrasonic Signal’: Diagnostic tool that displays the ultrasonic waveform for information in

more difficult applications.

24

Page 28

5 Status and Setup Screen (continued)

Settings Menu

Figure 35 shows the selection options for the ‘Setting’ drop down menu.

‘Display Default Settings’: Displays the Factory Default values. Either cancel or program these values

into your sensor. You may change settings before programming the sensor.

‘Self Heating Correction’: Corrects the reading of the internal temperature probe to the outside air

temperature for use in calculating the speed of sound. A check mark indicates that the ‘Self Heating

Correction’ is enabled.

‘Communications Port…’: Allows for selection of the proper PC port for RS485 communication with

the sensor.

Figure 35

The ‘Settings’ Drop Down Menu Selections of the Status and Setup Screen

‘Search Options…’: If ‘Search Options…’ is selected, the screen shown in Figure 36 is displayed. The

software will only search for sensors with ID Tag numbers between those listed in ‘Start Search ID

Tag’ and ‘End Search ID Tag’. To change the search limits, click on the ‘Start Search ID Tag’ and ‘End

Search ID Tag’ boxes and enter ID Tag values from 1 to 32 and click ‘OK’. To search for the new ID Tag

search limits just entered, go to the ‘Tools’ drop down menu and then select ‘Search for Sensors Options’. If all the sensors on line are not found, then revert back to searching from 1 to 32.

Figure 36

Example Showing the ‘Search for Sensors - Options’ Screen

25

Page 29

5 Status and Setup Screen (continued)

‘About This Program’: If this option is selected the LVU30 Series Software version number will be

displayed, as shown in Figure 37.

Figure 37

The ‘About this Program’ Screen

26

Page 30

6 Factory Default Programmed Settings

The LVU30 Series Sensors are factory programmed with the default values listed below. All of the

values can be reprogrammed if required by the application. The factory defaults are as follows:

ID Tag = 1

User Description Field = 32 ASCII spaces

Mode Selection for Voltage Output = Linear

Voltage Output Linear Mode Settings:

st

Output Setpoint: Voltage = 1.00V; Distance = *minimum specified sensing range

1

nd

Output Setpoint: Voltage = 10.00V; Distance = *maximum specified sensing range

2

No Echo Voltage = 10.25V

Voltage Output Switch Mode Settings:

Close Setpoint Distance = *minimum sensing range

Far Setpoint Distance = *maximum sensing range

Volts Out Switch State = 0 V DC for all zones

Maximum Sensing Range for Switch Mode = *maximum sensing range

Hysteresis = 5%

Sampling Settings:

Trigger Mode = Internal

Average type = boxcar

Average = 1 sample

Sample Rate = 10 Samples/sec (Hz)

No Echo Time Out = 1 Sample (0.10 Sec.)

Sensitivity = Normal

Miscellaneous:

Temperature compensation = automatic (internal probe)

Other parameters:

Self-heating correction = enabled (checked)

* Minimum and Maximum sensing ranges are different for each model in the LVU30 Series Sensor

Family. Consult the datasheet located on the Omega Engineering, Inc. website (www.omega.com)

for the specific model to obtain its minimum and maximum sensing ranges.

27

Page 31

θ

7 Troubleshooting

The Setpoint Output is erratic when the target is at the programmed setpoint:

Set the ‘Hysteresis’ to a nominal value of 5%.

Cannot find all sensors that are connected in a multi-drop network:

Verify the communications adapter is wired properly. Verify that unique ID tags were assigned

for each sensor on line. Verify that range of ‘ID Tags’ entered in the ‘Search for Sensors’ screen

is 1 to 32 (see Figure 36 on Page 25).

The Voltage Output does not respond:

Verify that power is connected to the sensor. Verify that the sensor in not

mode.

Sensor reports ‘zero’ range and ‘No Target’ when the target should be detected:

If the sensor is programmed for ‘Switch Mode’ operation the target could be beyond the Far

Zone. Under these circumstances, the sensor will report ‘Zero’ range and ‘No Target’. Adjust the

parameter ‘Maximum Sensing Range for Switch Mode’.

The sensor seems to respond slowly or erratically:

The ‘Average’ may be set to a high value and/or the ’Sample Rate’ may be set to a slow rate. There

is a balance required for adjusting these parameters. Each sensor must be adjusted to each

application based on process speed (‘Sample Rate’), the smoothness required of the outputs

(‘Average’) and occasional loss of echo filtering (‘No Echo Time Out’).

in the Manual trigger

8 Terminology

Beam: The projection, usually conical, of useable ultrasonic energy radiating from

the sensor that extends axially from the face of the transducer in the sensor.

Beam Diameter: The diameter,

insonified by a sensor with an acoustic system beam angle of

follows:

Close Setpoint A position in space within the sonar’s beam that is closer than the Far Setpoint

Distance: Distance, and between the Minimum Sensing Range and the Maximum

Sensing Range. (See Figure 7 in Section 3 on Page 7.)

Far Setpoint A position in space beyond the Close Setpoint Distance, and between the

Distance: Maximum Sensing Range and the Minimum Sensing Range. (See Figure 7 in

Section 3 on Page 7.)

Half Duplex: Operation of a communication network in which access on the line only

occurs one at a time (due to a 2 wire system). This requires full software

control on the line, typically the PC or host controls the data flow. This is the

operation of the LVU30 Series Software with the LVU30 Series Sensors.

dia (D), as a function of distance, D, of the cross-sectional area

θ

, computed as

() 2tan

dia D D

=

⎛⎞

⎜⎟

2

⎝⎠

28

Page 32

9 Terminology (continued)

Hysteresis: The distance between the operating point when a target approaches a

setpoint and the release point when the target moves away from a setpoint

towards its original position.

ID Tag: A unique sensor programmed value (address) from 1 to 32 which identifies the

sensor in a multi-drop communications loop.

Multi-drop: A communication network based on a pair of twisted wires which operates at

half-duplex. This system simplifies wiring at the expense of a rigid software

protocol. Up to 32 sensors (with their own unique ID) can be wired on the

same pair of wires.

Multiple Bounce: Ultrasonic signals that are detected after the initial reflected target may be

multiple bounce echoes. This is the result of having a good reflective target

and may require you to limit the sample rate of your system. All ultrasonic

signals must subside before the next transmit burst is to occur, otherwise

spurious output values may result.

Sample Rate: The rate at which a sensor transmits an ultrasonic pulse of energy.

T

Speed of Sound In Air:

( ) 13,044 1

cT =+

273

Where:

Temperature The technique for determining the speed of sound, which is a formation of

Compensation: temperature, used to calculate the Target Distance.

Transducer: A device capable of efficiently converting one form of energy (in this case

ultrasonic sound) back and forth into another form of energy (in this case

electricity).

c(T) is the Speed of Sound in Inches per Second

T is the Temperature in ºC

29

Page 33

9 Wire Color Code

Wire Color Code for Standard LVU30 Series Sensors:

RED: Positive Power In (12-24V DC)

BLACK: Ground

WHITE: V-out

GREEN: RS485 communications port, A (-) or TDA (-) terminal

BROWN: RS485 communications port, B (+) or TDB (+) terminal

The sensor’s cable length is 8” terminated with pigtails.

30

Page 34

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a

period of 13 months from date of purchase. OMEGA’s WARRANTY adds an additional one (1) month

grace period to the normal one (1) year product warranty to cover handling and shipping time. This

ensures that OMEGA’s customers receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Service

Department will issue an Authorized Return (AR) number immediately upon phone or written request.

Upon examination by OMEGA, if the unit is found to be defective, it will be repaired or replaced at no

charge. OMEGA’s WARRANTY does not apply to defects resulting from any action of the purchaser, including but not limited to mishandling, improper interfacing, operation outside of design limits,

improper repair, or unauthorized modification. This WARRANTY is VOID if the unit shows evidence of

having been tampered with or shows evidence of having been damaged as a result of excessive corrosion;

or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating

conditions outside of OMEGA’s control. Components in which wear is not warranted, include but are not

limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or errors nor assumes liability for any

damages that result from the use of its products in accordance with information provided by

OMEGA, either verbal or written. OMEGA warrants only that the parts manufactured by the

company will be as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR

REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF

TITLE, AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF

LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total liability of

OMEGA with respect to this order, whether based on contract, warranty, negligence,

indemnification, strict liability or otherwise, shall not exceed the purchase price of the

component upon which liability is based. In no event shall OMEGA be liable for

consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic

Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical

applications or used on humans. Should any Product(s) be used in or with any nuclear installation or

activity, medical application, used on humans, or misused in any way, OMEGA assumes no responsibility

as set forth in our basic WARRANTY/DISCLAIMER language, and, additionally, purchaser will indemnify

OMEGA and hold OMEGA harmless from any liability or damage whatsoever arising out of the use of the

Product(s) in such a manner.

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE

RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN

(AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID

PROCESSING DELAYS). The assigned AR number should then be marked on the outside of the return

package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent

breakage in transit.

FOR W

ARRANTY RETURNS, please have the

following information available BEFORE

contacting OMEGA:

1. Purchase Order number under which the product

was PURCHASED,

2. Model and serial number of the product under

warranty, and

3. Repair instructions and/or specific problems

relative to the product.

FOR NON-WARRANTY REPAIRS,

consult OMEGA

for current repair charges. Have the following

information available BEFORE contacting OMEGA:

1. Purchase Order number to cover the COST

of the repair,

2. Model and serial number of the product, and

3. Repair instructions and/or specific problems

relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords our

customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2006 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied, repro-

duced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without the prior

written consent of OMEGA ENGINEERING, INC.

Page 35

M-4582/1207

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

Shop online at omega.com

TEMPERATURE

䡺⻬

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

䡺⻬

Wire: Thermocouple, RTD & Thermistor

䡺⻬

Calibrators & Ice Point References

䡺⻬

Recorders, Controllers & Process Monitors

䡺⻬

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

䡺⻬

Transducers & Strain Gages

䡺⻬

Load Cells & Pressure Gages

䡺⻬

Displacement Transducers

䡺⻬

Instrumentation & Accessories

FLOW/LEVEL

䡺⻬

Rotameters, Gas Mass Flowmeters & Flow Computers

䡺⻬

Air Velocity Indicators

䡺⻬

Turbine/Paddlewheel Systems

䡺⻬

Totalizers & Batch Controllers

pH/CONDUCTIVITY

䡺⻬

pH Electrodes, Testers & Accessories

䡺⻬

Benchtop/Laboratory Meters

䡺⻬

Controllers, Calibrators, Simulators & Pumps

䡺⻬

Industrial pH & Conductivity Equipment

DATA ACQUISITION

䡺⻬

Data Acquisition & Engineering Software

䡺⻬

Communications-Based Acquisition Systems

䡺⻬

Plug-in Cards for Apple, IBM & Compatibles

䡺⻬

Datalogging Systems

䡺⻬

Recorders, Printers & Plotters

HEATERS

䡺⻬

Heating Cable

䡺⻬

Cartridge & Strip Heaters

䡺⻬

Immersion & Band Heaters

䡺⻬

Flexible Heaters

䡺⻬

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

䡺⻬

Metering & Control Instrumentation

䡺⻬

Refractometers

䡺⻬

Pumps & Tubing

䡺⻬

Air, Soil & Water Monitors

䡺⻬

Industrial Water & Wastewater Treatment

䡺⻬

pH, Conductivity & Dissolved Oxygen Instruments

Loading...

Loading...