Page 1

Where Do I Find Everything

I Need for

Process Measurement and Control?

OMEGA...Of Course!

TEMPERATURE

AssembI,es

&

Panels

&

Ice

Contmllerr

I’ymmetm

Prelrure

&

TransducersW

&

Id

RTD

&Thermistor

Refelc”ccs

I’“,“,

I’mcas &

Gauges&Strain

Gauges

Accrssories

Mo”itors

Conn~tors,

Therm”m”pIe,

Gr

Wire:

B

Calibrators

li3

Recorders,

Infrared

w

PRESSURE, STRAIN AND FORCE

Transducers

Id

Ca

Load Cells

Displacement

l”sb”me”tatlOn

FLOW/LEVEL

pH/CONDUCNVlTY

EIe&x&s,

pft B

Be”chtop/Laburatory

Contmllers,

[d

W

DATA

S

B

B

HEATERS

ra Heating Cable

ENVIRONMENTAL

MONfTORlNG AND CONTROL

0

w

Calibrators,

pl-I

Industrial

ACQUlSlTfON

Acq”lslti””

Data

w

Communications-8ased

Plug-i”

Cards for Apple, W

Datalogging

Systems

Printers

I&orders,

6r

Control Instrumentation

Metering

Refractometers

&TubingPumps

w

Accessor&

&

Testers

Meters

W

Simuiators

&

Conductivity

Engineenng

6r

Acquisition Systems

Plotters

&

&

Pumps

Fxyqmw”t

s&ware

Compahb,e+

& IBM

Ultrasonic Level Transmitter

OMEGAnet” On-Line Service

www.omega.com

9001

Certified

Is0

USA:

One Omega Drive, Box 4047

Stamford CT

Tel:

FAX:

e-mad:

USA and Canada:

Sales Service: l-800-826-6342

Customer Service: l-800-622-2378

Engineering

TELEX: 996404 EASYLINK: 62968934

CABLE: OMEGA

06907-0047

359-1660

(203)

359-7700

(2”3)

mfoQomega.com

For immediate technical or application assistance:

Service: l-800-872-9436

Servicing North America:

ldC&TC-OMEGA’

/

l-800-622-BEST@

/

/

Servicing Europe:

H/U-201

l-80%USA-WHEN@

Mtp:/hww.omega.com

inio@omega.com

e-mail:

Series

Internet e-mail

info@omega.com

Canada:

976

Berear

H7L

&bec)

LavaI

Tel:

Iv.x:

e-mad:

856-692X(514)

“56-6886

(514)

info@omega.ca

Mexico:

Espaiiol:

En

FAX:

espanol@omega.com

e-mall:

l”f&omega.com.mx

203-359-7807(001)

(001)

5A1,

Canada

203-359-7803

running

to is policy

OMEGA%

This affords our

OMEGA is a registered trademark

0

Copyright

copied.

without the prior written

~ustomm

the latest in technology

2M3

OMEGA ENGINEERING. INC. All

reproduced,tra”slated.

m”~ent

engineering.

01

OMEGA ENGINEERING, INC.

of OMEGA ENGINEERING. INC.

and

orreducedtuanyelectronic mediu m

resewed. This rights

an changes. whenever model changes. not make

document

may not be copied. photo-

possible.

is

imprO”Fment

inwhaleori”

pan.

Page 2

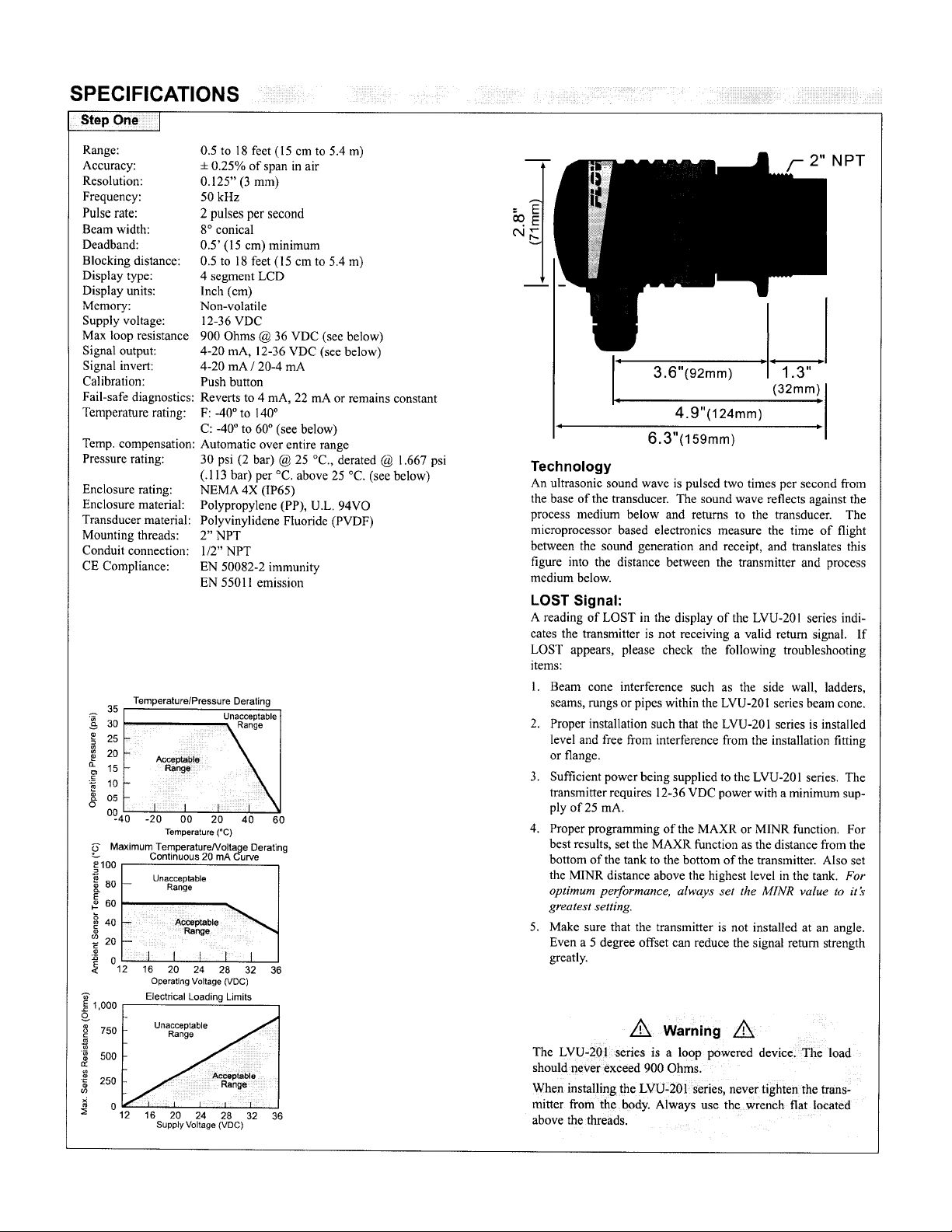

SPECIFICATIONS

Step One

Range:

Accuracy:

Resolution:

Frequency:

Pulse rate:

Beam width:

Deadband:

Blocking distance:

Display type:

Display units:

Memory:

Supply voltage:

Max loop resistance

Signal output:

Signal invert:

Calibration:

Fail-safe diagnostics:

Temperature rating:

Temp. compensation:

Pressure rating:

Enclosure rating:

Enclosure material:

Transducer material:

Mounting threads:

Conduit connection:

CE Compliance:

Temperature/Pressure Derating

-20 00 20 40 60

Temperature (“C)

z

Maximum

TemperatureNoltage

Continuous 20

16 20 24

Operating Voltage (VDC)

Electrical Loading Limits

0.5tol8feet(l5cmto5.4m)

* 0.25% of span in air

0.125” (3 mm)

kfIz

50

2

pulses per second

8” conical

0.5’ (15 cm) minimum

0.5 to 18 feet (15 cm to 5.4 m)

4 segment LCD

Inch (cm)

Non-volatile

12-36 VDC

@

900 Ohms

4-20

4-20

36 VDC (see below)

mA,

12-36 VDC (see below)

mA

/

20-4

mA

Push button

Reverts to 4

mA,

mA

or remains constant

22

F: -40” to 140”

C: -40” to 60” (see below)

Automatic over entire range

@

30 psi (2 bar)

(.

113 bar) per

25 “C., derated

“C.

above 25

NEMA 4X (IP65)

Polypropylene (PP), U.L. 94V0

Polyvinylidene Fluoride (PVDF)

2” NPT

l/2” NPT

EN 50082-2 immunity

EN 55011 emission

Derating

mA Curve

28 32 36

@

“C.

(see below)

1.667 psi

3.6”(Wmm)

n

.

4.9”(124mm)

6.3”(159mm)

I 1.3 ”

(32mm)

cl

cl

Technology

An ultrasonic sound wave is pulsed two times per second from

the base of the transducer. The sound wave reflects against the

process medium below and returns to the transducer. The

microprocessor based electronics measure the time of flight

between the sound generation and receipt, and translates this

figure into the distance between the transmitter and process

medium below.

LOST Signal:

A reading of LOST in the display of the

LVU-201

series indi-

cates the transmitter is not receiving a valid return signal. If

LOST appears, please check the following troubleshooting

items:

1.

Beam cone interference such as the side wall, ladders,

seams, rungs or pipes within the LVU-201 series beam cone.

2.

Proper installation such that the LVU-201 series is installed

from

level and free

interference from the installation fitting

or flange.

Sufficient power being supplied to the LVU-201 series. The

3.

transmitter requires 12-36 VDC power with a minimum sup-

ply of 25

4.

Proper programming of the MAXR or MINR function. For

mA.

best results, set the MAXR function as the distance from the

bottom of the tank to the bottom of the transmitter. Also set

the MTNR distance above the highest level in the tank.

MNR

u1wuy.r

optimum performance,

greatest setting.

5.

Make sure that the transmitter is not installed at an angle.

set the

value to

Even a 5 degree offset can reduce the signal return strength

greatly.

I

For

it:k

16 20 24

Supply Voltage

26 32 36

(WC)

A Warning

A

The LVU-201 series is a loop powered device. The load

should never exceed 900 Ohms.

When installing the LVU-201 series, never tighten the trans-

mitter from the body. Always use the wrench flat located

above the threads.

Page 3

SAFETY PRECAUTIONS

1

Step Two

DEFINITIONS

)

Step

Three

h

About this Manual:

PLEASE READ THE ENTIRE MANUAL PRIOR TO

INSTALLING OR USING THIS PRODUCT. This manual

includes information on all versions of the continuous ultrasonic

level transmitter from Omega; model LVU-201. Please refer to the

part number located on the sensor label to verify the exact model

which you have purchased.

User’s Responsibility for Safety:

h

Omega manufactures a wide range of liquid level sensors and tech-

nologies. While each of these technologies are designed to operate

in a wide variety of applications, it is the user ’s responsibility to

select a technology that is appropriate for the application, install it

properly, perform tests of the installed system, and maintain all

components. The failure to do so could result in property damage

or

serious injury.

h

Proper Installation and Handling:

Because this is an electrically operated device, only

trained staff should install and/or repair this product. Use a proper

sealant with all installations. Never overtighten the transmitter

within the fitting. Always check for leaks prior to system start-up.

A

Wiring and Electrical:

A supply voltage of 12-36 VDC is used to power the LVU-201

series transmitter. The sensor systems should never exceed a max-

imum of 36 VDC for the LVU-20 I series.

sensor should bc

national, state, and local codes.

$

Temperature and Pressure:

The

LVU-201 series is designed for use in application temperatures

from -40

to 30 psi

Material Compatibility:

d

The continuous ultrasonic level transmitter, LVU-201 series, is

made of two materials. The enclosure is of Polypropylene (PP) and

the transducer is made of Polyvinylidene Fluoride (PVDF). Make

sure that the model which you have selected is chemically compat-

ible with the application liquids.

liquid-resistant when installed properly, it is not designed to be

immersed.

mally come into contact with fluid.

1

Flammable, Explosive and Hazardous Applications:

DO NOT USE THE LVU-201 SERIES TRANSMITTER IN

CLASSIFIED HAZARDOUS LOCATIONS.

ti

Make a Fail-Safe System:

Design a fail-safe system that accommodates the possibility of

transmitter or power failure. In critical applications, Omega rec-

ommends the use of redundant backup systems and alarms in addi-

tion to the primary system.

“C

@

performed

(-40 “F) to 60

25 “C, derated

It

should be mounted in such a way that it does not nor-

in accordance with all applicable

“C

(140 “F), and for use at pressures up

@

1.667 psi per

While

Electrical wiring of the

“C

above 25 “C.

the transmitter housing is

properly-

mA

EC4:

The 4

201 series. The EC4 is the distance

from the bottom of the LVU-201 to

mA

the 4

measured in either inches or cen-

timeters on the display. The EC4 set-

ting is typically greater than the

EC20 setting and is equal to the dis-

tance from the bottom of the trans-

ducer to the bottom of the tank.

EC20: The 20

LVU-201 series. The EC20 is the

distance from the bottom of the

LVU-201 to the 20

This setting is measured in either

inches or centimeters on the display. The EC20 setting is typically the

distance from the bottom of the transducer to the highest level in the

tank.

SAFlISAFZISAF3:

SAF_

the

When

becomes LOST. When

mA

remain constant if the signal becomes LOST.

FAST/SLOW:

is the typical setting for the LVU-201 series to operate. [SLOW] is

designed to help dampen out effects caused by severe turbulence. In

the [FAST] mode, the LVU-201 series will

es per second and update every second. In the [SLOW] mode, the

LVU-20

onds. When used with [SAF

is 30 seconds for [FAST] mode and 2.5 minutes for [SLOW] mode.

ALIN:

show the return signal strength in

mechanical alignment of the LVU-201 series and/or signal attenua-

tion. Typical readings range between 2 and 60

alignment, first energize the unit and receive a valid return signal.

Then select the

display is maximized.

ON/OFF:

turned [OFF] when alignment is completed.

This mode will not automatically default back

to [LEVL].

MAXR:

maximum range. The MAXR sets

mum tank height and will filter out

all

(value):

maximum distance is 216.0 inches.

The MAXR value is typically set

equal to the EC4 setting.

MINR:

[MINR] or the minimum range. The

MINR value is the

to the transducer face where no sig-

nal will be generated. The MINR sets the minimum distance between

the liquid and the transducer.

(value):

The

settings to determine a fail-safe mode for the current signal.

[SAFl] is set, the current will increase to 22

if the signal becomes LOST. When

1

series will average signal returns over the preceding 10 sec-

Indicates that the unit is in the Alignment mode. Display will

Actual

Used as an indication for

returns greater than this value.

Actual MAXR setting. The

Used as an indication for

Actual MINR setting. The minimum distance is 6.0 inches,

MINR

value is typically set equal to the EC20 setting.

Fail-Safe setting for the LVU-201 series. Use

[SAF2]

is set, the current will decrease to 4

Setting for echo averaging on the LVU-201. [FAST]

l/2/3], the time for the current to default

dB’s.

ALIN mode and adjust the LVU-201 series until the

setting

for

ALM mode. The

[

deadband

closest

setting for the

set point. This setting is

mA

setting for the

mA

mA

if the signal

the

[SAF3]

average

Used

is set,

ALIN

current will

2 signal respons-

as an indicator for

dB’s.

For optimum

mode must be

set point.

LVU-

Page 4

PROGRAMMING

Step Four

EC4:

I.

Hold [MENU] key until EC4 appears in display.

2. Release [MENU] key and wait until a value appears. This value is

the

current measured level value.

3. If this is

4. From here, use the

5. Press the [SET] key to enter this value as the new EC4 set point.

EC20:

I.

Hold [MENU] key until EC20 appears in display.

2. Release [MENU] key and wait until a value appears. This value is

3. If this is acceptable, press [SET] to lock the value as the new EC20

4. From here, use the

5. Press the [SET] key to enter this value as the new EC20 set point.

SAFlISAFZISAF3:

I.

Hold [MENU] key until

2. Release [MENU] key and hold [SET] key to toggle between SAF 1,

3. When desired setting is reached, release [SET] key. The last dis-

acceptable, press [SET] to lock

set point. If not, press either the

setting for the EC4 will appear.

]

keys to raise or lower the value to the

]

or [t

[s

desired value.

the current measured level value.

set point. If not, press either the

setting for the EC4 will appear.

desired value.

play.

SAF2 and SAF3.

played setting will bc locked into memory. To change, start again

at step 1.

]

keys to raise or lower the value to the

]

or [t

[e

SAFl, SAF2 or SAF3 appears in the dis-

the

value as the new

]

keys once and the old

]

or [t

[S

]

keys once and the old

]

or [t

[S

EC4

WIRING

Step Five

LVU-201

the

in order to operate.

1. Wiring

2.

Wiring to a Two-Wire Loop Indicator:

3.

Wiring to a PLC:

1

requires 12-36 VDC power with at least 25

to a Omega Continuous Controller:

mA

supply

FAST/SLOW:

1.

Hold [MENU]

2. Relcasc [MENU] key and hold [SET] key to toggle between FAST

and SLOW.

3. When desired setting is reached, release [SET] key. The last dis-

played setting will be locked into memory. To change, start again

at step 1.

ALIN:

1. Hold [MENU] key until

2. Continue to hold [MENU] key until OFF appears in the display.

3. Release [MENU] key and hold [SET] key to toggle from OFF to

ON.

4. Release [SET] key. the LVU-20 1 is now in

5. To exit

MAXR:

I. Hold [MENU] key until MAXR appears in

2. Continue to hold [MENU] key until a value appears in the display.

This value is the current MAXR setting.

3. If this is acceptable, press [SET] to lock the value as the MAXR

setting. If not, use the

the desired setting.

4. Press the [SET] key to enter this value as the new MAXR setting.

MINR:

I.

Hold [MENU] key until MINR appears in the display.

2. Continue to hold [MENU] key until a value appears in the display.

This value is the current

3. If this is acceptable, press [SET] to lock the value as the

ting. If not, use the

desired value.

4. Press the [SET] key to enter this value as the new MINR setting.

key until FAST or SLOW appears in the display.

ALIN

appears in the display.

ALIN

ALIN

mode, repeat steps 1-4 changing from ON to OFF.

the

raise

]

keys to

]

or [t

[s

MINR

setting.

]

keys to raise or lower the value to the

]

or [t

[s

or lower

mode.

display.

the

MINR

value to

set-

Hints:

Icvcl.

Current must change with

tion below, as level increases, the current output will increase and as

the level decreases, the current output will decrease. If the output of

the LVU-201 series is always reading 4

values for the LVU-201 series.

changes

Example: For the illustra-

in

mA

or 20

mA,

check the input

El

20

4

mA

mA-

-3

EC4

I

Page 5

INSTALLATION

Step Six

1

INSTALLATION

Step Seven

Mounting the LVU-20

1

series is critical to the successful

operation

the transmitter. Avoid the following parameters:

Avo i d

ln t e ti e r ence

fr o m s ide o f

t ank

i----l

Minimum Range

(MINR) Setting

The MINR setting is typically the dis-

tance from the bottom of the transducer to

the highest level in the tank.

installing the LVU-201 series in a flange

or any device which recesses the bottom

of the transmitter, the minimum setting

for the MINR is the distance

from

tom of the transmitter to the end of the

flange. Never set MINR to less than 6.0

set the

MINR value to

Alwyvs

inches.

greatest setting.

Maximum Application Range

The maximum range of LVU-20lseries is

I8

feet at 1 IO

dB.

less than ideal conditions, a number of factors can reduce the overall

quality of signal return and shorten the accurate range of the

determine

tcr. To

the

signal return formula against the echo attenuation graph below.

low

the maximum application range of the product, fol-

Echo Attenuation Graph

ALIGNMENT

m

tr ansduce r = 40 ”

AL I N

s i b l e

= 26dB

an ica l

a li gn m en t o f un it

d i sp l ayed

MAXIMUM RANGE

AL I N

BatD=40”

When

the bot-

Under

transmit-

va l ue

of

it?

Factory Settings:

The LVU-201 series is preset at the factory. When powering up the

transmitter the first time, the factory settings will be active. If at any

time in you need to return to these settings, remove power from the

LVU-201 series and wait IO seconds. Press the [Set] and [Menu] but-

tons simultaneously while powering up the transmitter.

EC4

EC20 8” (20.3 cm)

216” (548.4

c m )

OFF

MAXR

OFF

WA

Changing Display Units:

The LVU-201 series comes preset to measure in inches. To change the

unit to display centimeters, remove

wait IO seconds. Press

]

and [Set] simultaneously while powering

[S

power to the LVU-201

series

up the transmitter. The LVU-201 series will now read in centimeters.

To return to inches, remove power and wait 10 seconds. Press [t

[Set] simultaneously while powering up the transmitter.

Depth Radius Radius

(Feet) (Inches) (cm)

1

2

3

4

5

6

7

8

9

IO

11

12

13

14

15

16

17

18

1.2 3.1

2.1

2.9 7.3

3.7 9.5

4.6

5.4

6.2

7.1

7.9

8.8

9.6

10.4

11.3

12.1

13.0

13.8

14.6

15.5

5.2

11.6

13.7

15.9

18.0

20.1

22.3

24.4

26.5

28.7

30.8

32.9

35.1

37.2

39.3

I

I

I

f _

C -- G

I

\

\

I

R ad ius

I

I

I

I

- _ - z

1

k

w -- w -

and

]

and

00

40

80

120

DISTANCE FROM FACE OF TRANSDUCER (inches)

160 200

240

Loading...

Loading...