Page 1

LVU-

1000

Ultrasonic Level Measurement

System

Operator’s Manual

Page 2

Unpacking instructions

L

A.

Trr...l.#h OMIYEA

Servicing USA and Canada: Call OMEGA Toll Free

One Omega Drive, Box 4047

Stamford, CT 06907-0047

Telephone: (203) 359-1660

FAX: (203) 359-7700

Engineering Service: l-800-872-9436

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

USA

Sales Service: 1-800-826-6342

Customer Service: I-800-622-2378

J

(ir,..y

Canada

ar

976 Ber

(

Lava1

Telephone: (514) 856-6928

FAX: (514) 856-6886

/

l-800.TC-OMEGA“’

I-ROO-622-BEST”

/

I-800.USA-WHEN”’

/

H7L

8

5A1

twbec)

Remove the Packing List and verify that you have received ail equipment,

including the following (quantities in parentheses):

LVU-1000 Ultrasonic Level Measurement System (1)

Operator’s Manual (1)

If you have any questions about the shipment, please call the OMEGA Customer

Service Department.

the

When you receive the shipment, inspect

container and equipment for

damage. Note any evidence of rough handling in transit. Immediately report any

damage to the shipping agent.

Servicing Europe: United Kingdom Sales and Distribution Center

25 Swannington Road, Broughton Astley, Leicestershire

Telephone: 44 (1455) 285520

The OMEGA Complete Measurement and

Control Handbooks

ti

Temperature

v

Pressure, Strain

r/

Flow and Level

pH and Conductivity

w

&

Force

LE9

6TU,

England

FAX: 44 (1455) 283912

& Encyclopedias

r/

Data Acquisition Systems

V

Electric Heaters

V

Environmental Monitoring

and Control

The carrier will not honor damage claims unless all shipping

material is saved for inspection. After examining and removing

contents, save packing material and carton in the event reship-

ment is necessary.

Call for Your FREE Handbook Request Form Today: (203)

359-RUSH

Page 3

LVU-

1000

Series

System Description

Chapter 1

Chapter 2

Chapter 3

Chapter 4

Chapter 5

Chapter 6

Chapter 7

System Description

Principles of Operation

Installation

Control Unit Installation

Sensor Installation

Wiring Diagram

Sensor Diagram

System Features and Operating Modes

General

Standard Features

Optional Features

System Calibration

General ........................................ .

Calibration Procedure

Calibration Diagram

Specifications

Linear Characterization Rrief Description

Analog Output Calibration VERIFICATION Procedure

Programming Prompt list

System Configuration Document

....................... .

-

-

Figure 2

........................................... .

....................................

.................... .

...................

..............................

...................................

Figure 1

............................

.............................

.......

....................................

.................................. .

.................... .

............................

-

Figure 3

.....................

...........

.............. .

............

.

... .

Page

..l-

.2-l

3-1

.3-l

.3-l

.3-2

.3-3

.4-l

..4- 1

.4-l

..4- 1

..5- 1

.

5-1

.

.

5-1

.

.

5-4

.

.

5-5

5-6

.5-B

. .

.6-l

.

.7- 1

1

System Description

The OMEGA Model LVU-1000 series liquid level system is a

of-the-art level measurement instrument. Based on the latest

ultrasonic technologies, the LVU-1000 series provides an efficient,

reliable and cost effective means of level control.

The LVU-1000 series consists of 2 major components: a

contacting ultrasonic sensor and a compact, remote electronic

control.

The LVU-1000 series is available in a variety of sizes and materials to

suit virtually any application. Standard mounting configurations

%”

include a

to meet user specifications. Sensor materials of construction include

CPVC, 316 SS, Kynar or Teflon.

and 2 ” NPT fittings. Flange mounting is also available

Chapter 8

ii

Dimensional Drawings

-

Dimensional Drawings

Figure 4

....................

......................

.8- 1

.8-l

Page 4

.::::

System Description

s

Principles of Operation

.:::.

..::r.

.::F

..::;.

.::F

.::..

:$

7

‘:

Principles of Operation

In

operation, the electronics generates an electronic signal which is

converted by the sensor (mounted on

ultrasonic pulses. These pulses are transmitted through the air

towards the liquid surface. As the pulses reach the liquid surface,

they are reflected back to the sensor. These received echoes are

converted back to an electronic signal, which is then sent to the

microprocessor. The microprocessor uses the return signals to

calculate the time it takes for the pulses to travel to the liquid surface

and back. This “Time of Flight ” is directly proportional to the

distance of the liquid surface from the sensor. The microprocessor

then compares these calculated values with user programmed

system parameters to provide the required control outputs.

1-2

Page 5

P ri nc ip les of Operation

..&

$7

&

,:p

,:.>

4r

,$

Con tr o l

Senso r

Un it I ns ta ll a ti on

1.

2.

3.

4.

Ins ta ll a ti on

The sensor is mounted on the top of the vessel with the sensor facing

downward. A clear path, free of any obstructions, must be provided

between the sensor and the liquid surface. Due to the narrow sensor

beam pattern, vertical-axis positioning of the sensor is important.

The sensor must be installed so as to maintain perpendicularity to

the liquid surface.

1.

2.

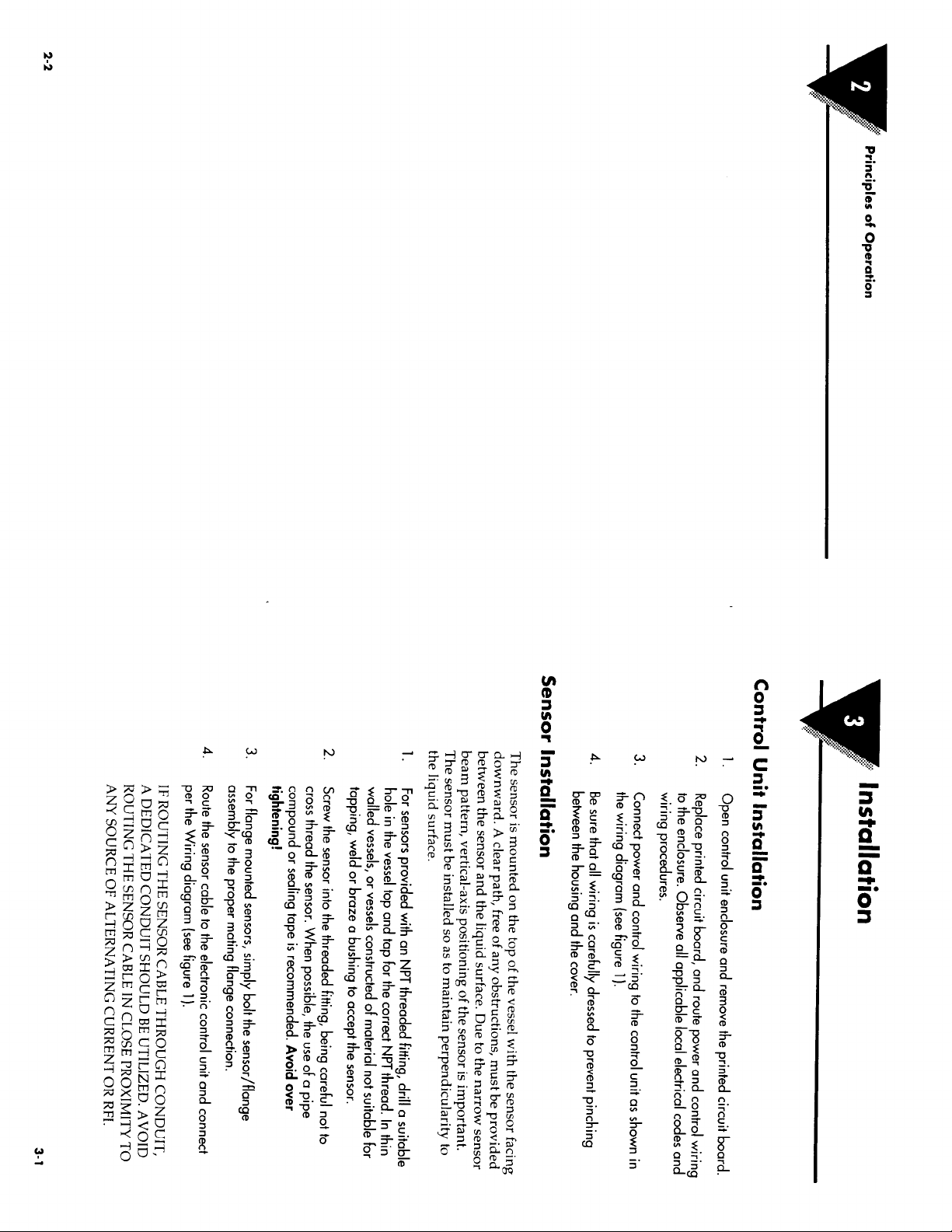

Open control unit enclosure and remove the printed circuit board.

Replace printed circuit board, and route power and control wiring

to the enclosure. Observe all applicable local electrical codes and

wiring procedures.

Connect power and control wiring to the control unit as shown in

the wiring diagram (see figure 1).

Be sure that all wiring is carefully dressed to prevent pinching

between the housing and the cover.

For sensors provided with an NPT threaded fitting, drill a suitable

hole in the vessel top and tap for the correct NPT thread. In thin

walled vessels, or vessels constructed of material not suitable for

tapping, weld or braze a bushing to accept the

Screw the sensor into the threaded fitting, being careful not to

cross thread the sensor. When possible, the use of a pipe

compound or sealing tape is recommended.

tightening!

2-2

For flange mounted sensors, simply bolt the sensor/flange

3 .

assembly to the proper mating flange connection.

Route the sensor cable to the electronic control unit and connect

4.

per the Wiring diagram (see figure 1).

IF ROUTING THE SENSOR CABLE THROUGH CONDUIT,

A DEDICATED CONDUIT SHOULD BE UTILIZED. AVOID

ROUTING THE SENSOR CABLE IN CLOSE PROXIMITY TO

ANY SOURCE OF ALTERNATING CURRENT OR RFI.

Page 6

9

..$f

Installation

Q

q

kogrammlng

Leme”,

I -

Vogramming

Switches

Dlsplay

-a-

- -

Enter

Temperature

rTransmttler/RCV

r

-

-

-

Compcnsahon

-

Sensifhr~AdJwlmetW

I

Compensallon

Temp.

-

El

Ad/uslmsnl

Anabg

‘OPTIONAL

Lad

Echo Relay

mmm lsssl m

LllZGnd

-- d -I\-

Power

OVIC 1

NOCNC NOCNC NOCNC NOCN C

Alan-n

wwnl

lnpul

1

\

Relay

Oulpuls

Alum

lOAmp

_

3A&m 2

SPDT

-1

analog

4Alam,

/

Serrscf

noI

Do

adpst

Oubul

Do not attempt to remove a threaded sensor from the vessel

with the cable attached to the control unit, otherwise cable

may be damaged.

W-0)

r

I

L

3-2

Figure

1 Wiring Diagram

Figure 2 Sensor Diagram

Page 7

System Features and

General

The LVU-1000 series is an extremely versatile instrument. It ’s many

standard programmable features and available options can be

utilized to perform a wide variety of control functions. In many

cases, a single LVU-1000 can accomplish control functions which

would otherwise only be possible through the use of multiple

instruments or expensive computer based systems.

Standard

1.

2.

3.

4.

5.

6.

7.

Operating

Modes

Features

Automatic temperature compensation compensates for sound

velocity errors (due to temperature variations) over the entire

sensor temperature range.

Simple 2 button programming.

Four programmable Alarm point relays.

User selectable Height or Distance operating mode.

fully

isolated analog output with programmable output offset.

Three “Lost Echo” condition modes (user selectable).

Internal 4-digit display provides programming prompts, system

heartbeat, and “Lost Echo” feedback.

Enhanced noise rejection algorithm ignores spurious signals and

8.

other noise sources such as 60 cycle and RFI.

Optional Features

1.

External (front covered mounted) 4 digit display for local

indication.

2.3.Optional “Lost Echo” alarm relay, in place of alarm

Customized response times and output damping to meet special

application requirements. Call factory for application assistance.

Page 8

System Features and Operating Modes

General

System Calibration

The LVU-1000 series is calibrated via push-button entry switches

(Enter and Increment) and an

provides the necessary programming prompts. All data entered

during the calibration procedure is stored in a nonvolatile memory

to prevent loss of data in the event of a power failure.

During the calibration procedure, you may wish to refer to the

Programming Prompt List and the Calibration Diagram found

elsewhere within this manual.

During the Calibration procedure, if no button is pressed

for more than 60 seconds, the system will automatically

return to the Operating Mode, saving only those parameter

values already entered.

onboard

4-2

Upon completion of the Calibration procedure, the Analog Output

may be verified by following the Calibration Verification Procedure

(see step 11).

Calibration Procedure

1.

Open control unit enclosures and simultaneously depress and

hold the Enter and Increment buttons. After approximately 3

seconds, the

“COdE”.

Enter button once to bypass this prompt (this prompt is for factory

use only, and is not user accessible).

onboard

The

2.

once and the

operotion, or “d” for Distance Mode of operation, depending on

the previously programmed mode. Pressing the Increment button

now will toggle the display between “H” and “d”. The Height

Mode of operation will provide an analog output proportional to

the liquid level, while the Distance Mode will provide an inverse

onboard

Release both Enter and Increment and then press the

display will issue the prompt

display will read either “H” for Height Mode of

programming display will issue the prompt

Page 9

/’

Jr

System Calibration

output (refer to the Calibration Diagram). With the desired

operating mode displayed, press Enter to select that mode.

3. The next prompt to be displayed will be “SLOS” for “select analog

offset”. The Analog offset determines if the analog output signal is

referenced to zero or some offset

a current output, or O-l 0 V dc vs. 2-l 0 V dc for voltage output).

Press Enter to display the previously entered selection (either 0 or

1). Pressing Increment now will toggle the display between 0 and

II

1.

Entering “1

“0” disables the

displayed, press the Enter button to store the selection.

4. The display

At this time the analog output is driven to its proper state

and may be verified, see step 11.

The Zero Point is the point at which the level will be closest to the

sensor (refer to the Calibration Diagram). The minimum Zero

Point is normally 12 ” from the sensor face.

In certain applications, the LVU-

provide a closer Zero Point. Consult factory.

Press Enter now, and the display will indicate the previously

programmed Zero value, with the “hundreds” digit flashing. Press

Increment to increment the flashing digit to its desired value. With

the desired value displayed for the “hundreds” place digit, press

Enter to store the value. The next digit

be flashing. Repeat the above steps for the “Tens”, “Inches” and

will invoke the

Analog Offset. With the desired selection

will

now issue the

value

(O-20 ma vs. 4-20 ma for

Analog Offset, while entering a

“SL-0”

prompt, for “select zero”.

1000

may be configured to

(

the ‘Tens” place) will now

“Tenths of inches” places to obtain the desired Zero point as

measured in inches from the sensor face.

Upon entry of the Zero Point, the display will issue the prompt

5.

“SL_?

for “select Span”.

At this time the analog output may be verified, see step 1 1.

The Span is the measurement range in inches as measured from

the Zero Point. Press Enter now and the display will indicate the

current Span value, with the hundreds place digit flashing.

Proceed as in step 4 to enter the desired Span in inches from the

Zero Point.

6. After entering the desired Span, the system will issue the prompt

“SLdF”

for “select display function”. This parameter will define the

4

operation of the operational

provided). Press Enter now, and the on board programming

display will indicate a digit of 0 or 1, depending on the

previously entered selection. The Display Function Modes are as

follows:

digit panel-mounted display (if

Mode 0: Display reads distance of target from sensor

in inches.

Mode 1: Display indicates value of linear range

programmable by the user. See the calibration

Linear Characterization Display Scaling for details on

programming this mode.

Pressing Increment will toggle the programming

display through the above Display Function Modes. Press

Enter to store the desired Mode.

If you have selected display mode 1 at the “SLdF”

prompt, then you have chosen Custom Display Scaling and

the unit proceeds to step 6a in the following manner,

otherwise the unit proceeds to step 7.

5-2

Page 10

System Calibration

Specifications

Range:

Repeatability:

Accuracy:

Temperature

Compensation:

Input Power:

Output Signal:

Controls:

Display:

Alarm

Setpoink:

Temperahrre Range:

Sensor Pressure

Rating:

Construction:

Cable:

E&onics

Enclosures:

Mountings:

1-12 feet

1 to 30 feet

KY

Analog output-x% of

&VU-1000)

&VU-1010)

typical

Automatic over

temperature

115 V oc,

4-20

Programmable zero and span, height and

50/60

ma dc (isolated)

mode

Four digit (optional)

Four 1 OA SPDT relays. Programmable

increments of

(optional)

Sensor -22°F to

Electronics -10°F

-

250 psig

psig)

316 S.S.

20”

NEMA-4X (standard)

%“:

2”: (Range up

316 SS (Plastic models limited to 150

St&&x

up

(Range up to 12

Figure 3 Calibration Diagram

Page 11

System Calibration

linear Characterization Brief Description:

The LVU-1000 series allows the user to enter a four digit minimum

arbitrary value, a four digit maximum arbitrary value, and a decimal

position. The display output is

two

values across the previously programmed Span (Calibration

-

Procedure

step 5). The display always increases or decreases in a

manner that is directly proportional to the analog output, which is

based on the selection of Height or Distance mode.

6a.

The unit issues the “SLLO” prompt for “select

display value. Pressing Enter causes the display to advance and

show the previously programmed Low value.

then linearly scaled between these

LOw”

minimum

The unit checks that the

Hlgh value. If this error is detected the unit returns to step

6a

and the user must re-enter valid

6c.

The unit issues the

Pressing Enter causes the display to advance and show the

previously programmed Decimal Place. The display

digit from 0 to 3 indicating the desired precision or the number of

decimal digits to be displayed. Pressing Increment will step the

display through the above decimal place values. Once the desired

decimal place is displayed, press Enter to select that value.

LOw value is not greater than the

“SLdP”

prompt for “Select Decimal Place”.

Ignore the decimal point on the

and it has no meaning in this mode. Proceed as in the

Calibration Procedurestep 4 to enter the desired arbitrary

low point.

6b.

The unit next issues the “SLHI” prompt for “Select High, maximum

display value”. Pressing Enter causes the display to advance and

show the previously programmed Hlgh value.

Again, ignore the decimal point on the

Proceed as the Calibration Procedure-step 4 to enter the

desired arbitrary Hlgh point.

onboard

onboard

display-it is fixed

disploy.

Now the unit proceeds with step 7 of this Calibration Procedure.

will

The next prompt issue

7.

Press Enter to enable the flashing digits as in step 4 and enter the

desired Alarm Point

The

the sensor face, regardless of Operating Mode.

Repeat step 7 for Alarm Points 2, 3, and 4 (prompts

8.

and

After

9.

prompt “SLLE” for “Select Lost Echo Mode”. The last Echo mode

selection determines the stotus of the analog output should a loss

of valid return echo occur. Press the Enter button now and the

display will

Pressing Increment will toggle the programming display through

the Lost Echo Modes listed below. Press Enter to select the desired

Lost Echo Mode: The Lost Echo Modes are as follows:

Points are always programmed in inches from

Alarm

SLA4).

Alarm Point 4 is entered, the display will then issue the

indicate

be

in inches from the sensor face.

the current Lost Echo Mode (either 0,

5-6

Page 12

8

Programming Prompt list

.::::

#

..:..

. .. .

.::::

.:::.

$2

.:::

Jr

,g

Mode 0: Analog output goes to minimum output.

Mode 1: Analog output holds last valid reading.

Mode 2: Analog output goes to maximum output.

10. Upon entry of the desired Lost Echo Mode, the system will return

to the operating mode. The programming displays will display the

system “heartbeat”, a pulsing

complete.

“0”

character. Calibration is

Analog output calibration verification procedure

11. To verify the

digital current meter or voltmeter to the

(refer to Wiring Diagram, page 3-3). Access the Calibration

Mode by simultaneously pressing ond holding the Enter and

Increment buttons, until the

two buttons, then repeatedly press and release the Enter button

until the

Analog output is correct per the selected Operating Mode

(Distance or Height Mode, with or without Analog Offset. Also

refer to the Calibration Diagram). Continue to repeatedly press

and release Enter,

Verify that the Analog output is correct per the selected Operating

Mode. The system will automatically return to the normal

operating mode after 60 seconds, displaying heartbeat.

The analog output level can be adjusted through the analog

adjust multi-turn potentiometer shown in figure 1. With the

analog

adjust this potentiometer until your digital multimeter is

precisely at 20

requires no

“SL-0”

output at its maximum

adiustment.

output of the LVU- 1000 series, connect a

analog

Analog

Output terminals

“COdE” prompt appears. Release the

(Select Zero) prompt is issued. Verify that the

until

the

“SL_S” (Select Span) prompt appears.

mA

(20

or 10 V dc),

mA or

IeveI

10

V dc. The analog minimum value

Prompt

SLdH

SLOS

SL_O

SL_S

SLdF

SLLO

SLHI

SLdP

SLAl

SLA2

SLA3

SLA4

Definition

Select Distance or

Height

Mode

Select Analog

Offset

Select Zero

Select Span

Select Display

Function

Select Low or

Minimum Value

Select High or

Maximum Value

Select Decimal

Points

Select Alarm

Select Alarm 2

Select Alarm 3

Select Alarm 4

1

Description

The Height mode provides an analog output

proportional to the liquid level (4-20 ma or

dc), and the Distance mode provides an inverse

(20-4 ma or

output

Height Mode or “d” for Distance Mode.

Allows for an analog output referenced to Zero or

some Offset reference (4-20 ma vs O-20 ma for a

current output, or a 2-10 V dc vs O-10 V dc for a

voltage output). Select 0 to disable the Offset;

select 1 to invoke the Offset.

Programs the system Zero point as measured from

the sensor face in inches. The system Zero is the

point at which the level is closest to the sensor

face.

Programs the system Span as measured in inches

from the system Zero point.

Defines the operational mode of the optional 4

digit display. Mode “0” displays target distance

from sensor in inches. Mode “1” displays user

defined Linear scaled output.

Linear Characterization sub-mode that defines the

minimum value that the display should indicate.

Linear Characterization sub-mode that defines the

maximum value that the display should indicate.

Linear Characterization sub-mode that defines the

decimal digits to be displayed.

Programs Alarm Point 1 as measured in inches

from the sensor face.

Programs Alarm Point 2 as measured in inches

from the sensor face.

Programs Alarm Point 3 as measured in inches

from the sensor face.

Programs Alarm Point 4 as measured in inches

from the sensor face.

5-8

Page 13

9

.

4f

Programming Prompt List

,f

.:v

c.

System Configuration

Document

SLLE

Select Lost Echo

Mode

Programs the analog output condition in the event

of a loss of a valid return echo for more than 8

seconds.

Mode 0 Output goes to minimum.

Mode 1 Output holds last reading.

Mode 2 Output goes to maximum.

In a lost echo condition, the 4 digit display and the

onboard

display will display

“-LE-“.

SITE/LOCATION ID:

JOB:

UNIT SERIAL NUMBER:

PROGRAMMABLE PARAMETERS,

__

:

_

?

0

0

O N

??

0

Y

0

0

HEIGHT MODE:

DISTANCE MODE:

ANALOGOFFSET:

DISPLAY MODE:

LOST ECHO MODE:

ZERO :

SPAN

ALARM1

ALARM 2

:

:

PROGRAMMED BY:

0

4-20

(

0

O-20mA

(

01

01

0

0

02

inches from sensor face

inches from zero

inches from sensor face

inches

6-2

ALARM3

ALARM4 :

LINEAR CHARACTERIZATION -DISPLAY

VALUE:

LO

HI VALUE:

DECIMAL

:

PLACE:

0

0

0

1

inches from sensor face

inches from sensor face

0

2

Page 14

8-l

Dimensional Drawings

FIBERUlllf ENCLOSURE

NW-IX

+

WARRANTY

OMEGA warrants this unit to be free of defects in materials and workmanship and to

satisfactory

adds an additional one (1) month grace period to the normal one (1) year product

warranty

receive maximum coverage on each product. If the unit should malfunction, it must be

returned to the factory for evaluation. OMEGA’s Customer Service Department will issue an

Authorized Return (AR) number immediately upon phone or written request. Upon

examination by OMEGA, if the unit is found to be defective it will be repaired or replaced at

no charge. However, this WARRANTY is VOID if the unit shows evidence of having been

tampered with or shows evidence of being damaged as a result of excessive corrosion; or

current, heat, moisture or vibration; improper specification; misapplication; misuse or other

operating conditions outside of OMEGA’s control. Components which wear or which are

damaged by misuse are not warranted. These include contact points, fuses, and

OMEGA is glad to

theless, OMEGA only

service for a period of 13 months from date of purchase. OMEGA Warrantv

to cover

handling and shipping time. This ensures that OMEGA’s customers

offer suggestions on the use of its various products. Never-

warrants that

the

parts manufactured by it will be as

specified and free of defects.

OMEGA MAKES NO OTHER WARRANTIES OR REPRESENTATIONS OF ANY KIND

WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE AND

IMPLIED WARRANTIES INCLUDING ANY WARRANTY

AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED.

LIMITATION OF LIABILITY: The remedies of purchaser set forth herein are

exclusive and the total liability of OMEGA with respect to this order, whether

based on contract, warranty, negligence, indemnification, strict liability or

otherwise, shall not exceed the purchase price of the component upon which

liability is based. In no event shall OMEGA be liable for consequential, incidental

or special damages.

Every precaution for accuracy has been taken in the preparation of this manual; however,

OMEGA ENGINEERING, INC. neither assumes responsibility for any omissions or errors

that may appear nor assumes liability for any damages that result from the use of the

products in accordance with the information contained in the manual.

SPECIAL CONDITION: Should this equipment be used in or with any nuclear installation or

activity, purchaser will indemnify OMEGA and hold OMEGA harmless from any liability or

damage whatsoever arising out of the use of the equipment in such a manner.

RETURN REQUESTS

Direct all warranty and repair requests/inquiries to the OMEGA ENGINEERING Customer

Service Department. BEFORE RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER

MUST OBTAIN AN AUTHORIZED RETURN (AR) NUMBER FROM OMEGA’S CUSTOMER

SERVICE DEPARTMENT (IN ORDER TO AVOID PROCESSING DELAYS). The assigned AR

number should then be marked on the outside of the return package and on any

correspondence.

FOR

WARRANTY

FOR

the following information available

BEFORE contacting OMEGA:

1. P.O. number under which the product

was PURCHASED,

2. Model and serial number of the product

under warranty, and

3. Repair instructions and/or specific

problems relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an

improvement is possible. This affords our customers the latest in technology and

engineering.

OMEGA

0

may not be

medium or machine-readable form, in whole or in part, without prior written consent of

OMEGA ENGINEERING, INC.

IS

a registered trademark of OMEGA ENGINEERING. INC.

Copyright 1995 OMEGA ENGINEERING, INC. All rights reserved. This documentation

RETURNS, please have

copled. photocopied, reproduced, translated, or reduced to any electronic

NON-WARRANTY

CALIBRATION,

repair/calibration charges. Have the

following information available BEFORE

contacting OMEGA:

1. P.O. number to cover the COST of the

repair/calibration,

2. Model and serial number of product, and

3. Repair instructions and/or specific

problems relative to the product.

Loading...

Loading...