Page 1

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

TEMPERATURE

䡺⻬

Thermocouple, RTD & Thermistor Probes,

Connectors, Panels & Assemblies

䡺⻬

Wire: Thermocouple, RTD & Thermistor

䡺⻬

Calibrators & Ice Point References

䡺⻬

Recorders, Controllers & Process Monitors

䡺⻬

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

䡺⻬

Transducers & Strain Gauges

䡺⻬

Load Cells & Pressure Gauges

䡺⻬

Displacement Transducers

䡺⻬

Instrumentation & Accessories

FLOW/LEVEL

䡺⻬

Rotameters, Gas Mass Flowmeters & Flow Computers

䡺⻬

Air Velocity Indicators

䡺⻬

Turbine/Paddlewheel Systems

䡺⻬

Totalizers & Batch Controllers

pH/CONDUCTIVITY

䡺⻬

pH Electrodes, Testers & Accessories

䡺⻬

Benchtop/Laboratory Meters

䡺⻬

Controllers, Calibrators, Simulators & Pumps

䡺⻬

Industrial pH & Conductivity Equipment

DATA ACQUISITION

䡺⻬

Data Acquisition & Engineering Software

䡺⻬

Communications-Based Acquisition Systems

䡺⻬

Plug-in Cards for Apple, IBM & Compatibles

䡺⻬

Datalogging Systems

䡺⻬

Recorders, Printers & Plotters

HEATERS

䡺⻬

Heating Cable

䡺⻬

Cartridge & Strip Heaters

䡺⻬

Immersion & Band Heaters

䡺⻬

Flexible Heaters

䡺⻬

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

䡺⻬

Metering & Control Instrumentation

䡺⻬

Refractometers

䡺⻬

Pumps & Tubing

䡺⻬

Air, Soil & Water Monitors

䡺⻬

Industrial Water & Wastewater Treatment

䡺⻬

pH, Conductivity & Dissolved Oxygen Instruments

M-3939 / 0203

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a

period of 13 months from date of purchase. OMEGA Warranty adds an additional one (1) month grace

period to the normal one (1) year product warranty to cover handling and shipping time. This ensures

that OMEGA’s customers receive maximum coverage on each product.

If the unit should malfunction, it must be returned to the factory for evaluation. OMEGA’s Customer Service

Department will issue an Authorized Return (AR) number immediately upon phone or written request. Upon

examination by OMEGA, if the unit is found to be defective it will be repaired or replaced at no charge.

OMEGA’s WARRANTY does not apply to defects resulting from any action of the purchaser, including but not

limited to mishandling, improper interfacing, operation outside of design limits, improper repair, or unautho-

rized modification. This WARRANTY is VOID if the unit shows evidence of having been tampered with or

shows evidence of being damaged as a result of excessive corrosion; or current, heat, moisture or vibration;

improper specification; misapplication; misuse or other operating conditions outside of OMEGA’s control.

Components which wear are not warranted, including but not limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However, OMEGA neither

assumes responsibility for any omissions or errors nor assumes liability for any damages that result

from the use of its products in accordance with information provided by OMEGA, either verbal or writ-

ten. OMEGA warrants only that the parts manufactured by it will be as specified and free of defects.

OMEGA MAKES NO OTHER WARRANTIES OR REPRESENTATIONS OF ANY KIND WHATS0EVER,

EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE, AND ALL IMPLIED WARRANTIES INCLUDING ANY

WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DIS-

CLAIMED. LIMITATION OF LIABILITY: The remedies of purchaser set forth herein are exclusive and the

total liability of OMEGA with respect to this order, whether based on contract, warranty, negligence,

indemnification, strict liability or otherwise, shall not exceed the purchase price of the component

upon which liability is based. In no event shall OMEGA be liable for consequential, incidental or spe-

cial damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic

Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical

applications or used on humans. Should any Product(s) be used in or with any nuclear installation or activity,

medical application, used on humans, or misused in any way, OMEGA assumes no responsibility as set forth

in our basic WARRANTY/ DISCLAIMER language, and additionally, purchaser will indemnify OMEGA and

hold OMEGA harmless from any liability or damage whatsoever arising out of the use of the Product(s) in

such a manner.

RETURN REQUESTS / INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service

Department. BEFORE RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST

OBTAIN AN AUTHORIZED RETURN (AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE

DEPARTMENT (IN ORDER TO AVOID PROCESSING DELAYS). The assigned AR number

should then be marked on the outside of the return package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging

to prevent breakage in transit.

FOR W

ARRANTY RETURNS, please have

the following information available BEFORE

contacting OMEGA:

1. P.O. number under which the product

was PURCHASED,

2. Model and serial number of the product

under warranty, and

3. Repair instructions and/or specific

problems relative to the product.

FOR NON-WARRANTY REPAIRS,

consult

OMEGA for current repair charges. Have

the following information available

BEFORE contacting OMEGA:

1. P.O. number to cover the COST

of the repair,

2. Model and serial number of product, and

3. Repair instructions and/or specific

problems relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible.

This affords our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 1996 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied,

photocopied, reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or

in part, without prior written consent of OMEGA ENGINEERING, INC.

USA

MADE

IN

Servicing North America:

USA: One Omega Drive, Box 4047

ISO 9001 Certified Stamford, CT 06907-0047

Tel: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1

Tel: (514) 856-6928 FAX: (514) 856-6886

e-mail: canada@omega.com

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

SM

Customer Service: 1-800-622-2378 / 1-800-622-BEST

SM

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

SM

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico and

Latin America:

Tel: (95) 800-TC-OMEGA

SM

FAX: (95) 203-359-7807

En Espan˜ol: (203) 359-1660 ext: 2203 e-mail: espanol@omega.com

Servicing Europe:

Benelux: Postbus 8034, 1180 LAAmstelveen, The Netherlands

Tel: (31) 20 6418405 FAX: (31) 20 6434643

Toll Free in Benelux: 06 0993344

e-mail: nl@omega.com

Czech Republic: Ostravska 767, 733 01 Karvina

Tel: 42 (69) 6311899 FAX: 42 (69) 6311114

e-mail: czech@omega.com

France: 9, rue Denis Papin, 78190 Trappes

Tel: (33) 130-621-400 FAX: (33) 130-699-120

Toll Free in France: 0800-4-06342

e-mail: france@omega.com

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: 49 (07056) 3017 FAX: 49 (07056) 8540

Toll Free in Germany: 0130 11 21 66

e-mail: germany@omega.com

United Kingdom: 25 Swannington Road, P.O. Box 7, Omega Drive,

ISO 9002 Certified Broughton Astley, Leicestershire, Irlam, Manchester,

LE9 6TU, England M44 5EX, England

Tel: 44 (1455) 285520 Tel: 44 (161) 777-6611

FAX: 44 (1455) 283912 FAX: 44 (161) 777-6622

Toll Free in England: 0800-488-488

e-mail: uk@omega.com

OMEGAnet

SM

On-Line Service Internet e-mail

http://www.omega.com info@omega.com

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that apply. OMEGA is constantly

pursuing certification of its products to the European New Approach Directives. OMEGA will add the CE mark to every

appropriate device upon certification.

The information contained in this document is believed to be correct but OMEGA Engineering, Inc. accepts no liability for any errors it con-

tains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient connected applications.

http://www.omega.com

e-mail: info@omega.com

®

User’s Guide

LVR-50 Series

High-Temp Vertical Level Transmitter

OMEGA

®

TM

omega.comomega.com

Page 2

Step One

SPECIFICATIONS

Range: 5" to 72" (12.7 cm to 1.8m)

Accuracy: 0.25”over span in water

Specific gravity: 0.75 minimum

Orientation: ± 30° vertical

Supply voltage: LVR-50-PP series: 10 to 30 VDC

LVR-50 series: 10 to 40 VDC

Loop resistance: 600 Ohms @ 24 VDC

Signal output: 4-20 mA, two-wire

Signal invert: 4-20 or 20-4 mA

Calibration: None, fixed span

Process temp.: F: -40° to 300°

C: -40° to 148.9°

Electronic temp.: F: -40° to 160°

C: -40° to 71°

Pressure: 300 psi max.

20.7 bar max.

Enclosure rating: LVR-50-PP series: NEMA 4X (IP65)

LVR-50 series: NEMA 7 (IP65)

Installed height: LVR-50-PP series: 5.2" (13.2 cm)

LVR-50 series: 6.2" (15.7 cm)

Encl. material: LVR-50-PP series: PP, UL94VO

LVR-50 series: Aluminum

Guide/float mat.: 316 ss

Process mount: 2" NPT

Conduit entrance: Single, 1/2" NPT

Classification: LVR-50-PP series: General purpose

LVR-50 series: Explosion proof

Approvals: FM, CSA: Class I, Division I, Groups B,

(LVR-50 series only) C & D; Class II, Groups E, F and G

CE compliance: EN 50082-2 immunity

EN 55011 emission

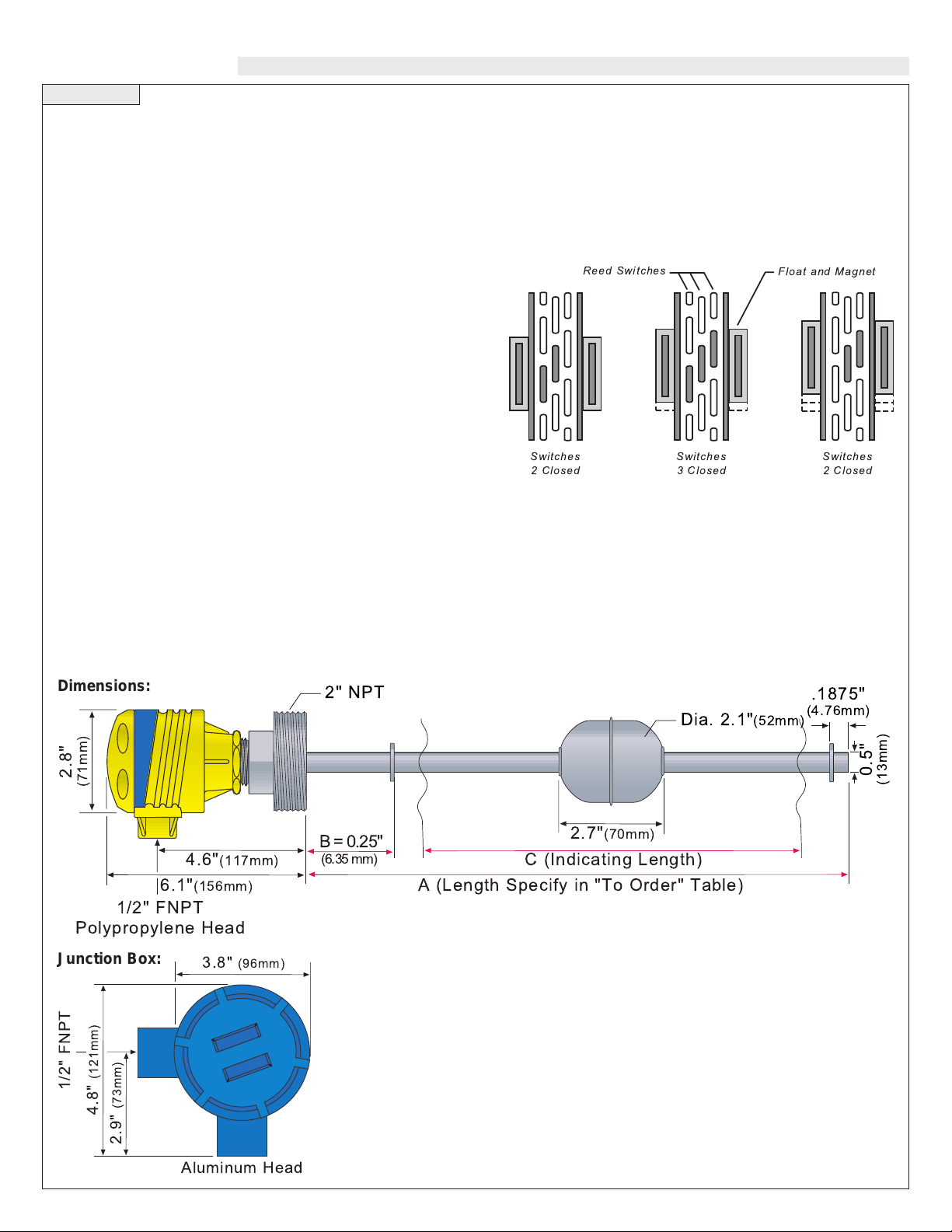

Technology

A single float is attached to a stainless steel rod, which is installed

through the top of the tank. Internal to the rod is a series of reed

switches designed to open and close as the float changes with the liquid level. The internal magnets within the float will open or close the

reed switches in a “2-3-2 at-a-time” sequence, which enables the

transmitter to provide accurate level indication. With every movement of the float, either one additional switch closes or opens.

Dimensions:

Junction Box:

Switches

2 Closed

Reed Switches

Switches

3 Closed

Float and Magnet

Switches

2 Closed

2.8"

(71mm)

4.6"(117mm)

6.1"(156mm)

1/2" FNPT

Polypropylene Head

1/2" FNPT

4.8" (121mm)

3.8" (96mm)

2" NPT

B = 0.25"

(6.35 mm)

Dia. 2.1"(52mm)

2.7"(70mm)

C (Indicating Length)

A (Length Specify in "To Order" Table)

.1875"

(4.76mm)

0.5"

(13mm)

2.9" (73mm)

Aluminum Head

Page 3

Step Two Step Three

SAFETY PRECAUTIONS INSTALLATION

About this Manual:

PLEASE READ THE ENTIRE MANUAL PRIOR TO

INSTALLING OR USING THIS PRODUCT. This manual

includes information on the L VR-50 series Level T ransmitter , models LVR-50-PP series & LVR-50 series. Please refer to the part

number located on the sensor label to verify the exact model which

you have purchased.

User's Responsibility for Safety:

OMEGA manufactures a wide range of liquid level switches and

technologies. While each of these switches is designed to operate

in a wide variety of applications, it is the user's responsibility to

select a switch model that is appropriate for the application, install

it properly, perform tests of the installed system, and maintain all

components. The failure to do so could result in property damage

or serious injury.

Proper Installation and Handling:

Because this is an electrically operated device, only properly

trained staff should install and/or repair this product. Use a proper

sealant with all installations. Never overtighten the sensor within

the fitting, beyond a maximum of 80 inch-pounds torque. Always

check for leaks prior to system start-up. Physical damage sustained

by the product may render it unserviceable.

Material Compatibility:

The wetted portion of the LVR-50 series is available in 316

Stainless Steel. The junction box is made of either Polypropylene

(PP) for the LVR-50-PP series or Aluminum for the LVR-50 series.

Make sure that the switch is compatible with the application liquids. To determine the chemical compatibility between the sensor

and its application liquids, refer to a corrosion guide.

Temperature and Pressure:

The LVR-50-PP series is designed for use in application temperatures up to 300 °F (148.9 °C), and for use at pressures up to 300 psi

(20.7 bar). Temperature and pressure limitations must not be

exceeded.

Wiring and Electrical:

The supply voltage used for the LVR-50-PP series should never

exceed 30 VDC and for the LVR-50 series should never exceed 40

VDC. Electrical wiring of the switch should be performed in

accordance with all applicable national, state, and local codes.

Flammable, Explosive and Hazardous Applications:

The LVR-50-PP series series switch should not be used within

flammable or explosive applications. Only use the LVR-50 series

series in hazardous locations when properly connected to an

approved control device. In hazardous applications, use redundant

measurement and control points, each having a different sensing

technology. Refer to the National Electrical Code (NEC) for all

applicable installation requirements in hazardous locations.

OMEGA’s LVR-50 Series Installation:

OMEGA’s LVR-50 Series is an in tank system. The LVR-50 series

may be installed through the top wall of any tank or flange, using a

standard 2” NPT tank adapter or blind flange. If the top is not available, OMEGA’s side mount bracket, LVM-50, enables LVR-50 series

to be installed directly to the side wall or lip of the tank.

T ank Adapter:

Flange Mounting:

Side Mount Bracket:

Lip of Tank: Side Wall:

Thread Treatment:

Sealing: When threading metal threads into a metal coupling, pipe

sealant or Teflon tape is recommended. When threading a metal sensor into a metal coupling, the installer should use a suitable wrench

and tighten the threads 1-1/2 turns past hand tight.

Page 4

Step Four Step Five

WIRING MAINTENANCE

LVR-50-PP Series: General:

The LVR-50 series level transmitter has no scheduled maintenance

requirement, except to clean off any deposits or scaling from the

switch as necessary. It is the responsibility of the user to determine the

appropriate maintenance schedule, based on the specific characteristics of the application liquid.

Cleaning procedure:

1. Power: Make sure that all power to the transmitter, controller

and/or power supply is completely disconnected.

2. Switch removal: If necessary, make sure that the tank is

drained to a safe level and that the pressure is sufficient for

removal of the LVR-50 series. Carefully, remove the sensor from

the installation.

3. Cleaning the switch: Using a soft bristle brush and mild deter-

gent, carefully wash the switch. Do not use harsh abrasives, which

might damage the surface of the sensor. Do not use incompatible

solvents which may damage the sensor's 316 ss body. Take particular care to remove any scaling from the float body and make

sure that it moves freely.

4. Sensor installation: Follow the appropriate steps of installa-

tion as outlined in the Installation section of this manual.

Troubleshooting:

Verify proper wiring, power supply and loop resistance. If transmitter is not functioning properly, isolate the transmitter from the system

and wire as shown below. Multimeter should read 4 mAwith float at

the bottom and 20 mA with float at the top of the transmitter.

+

-

R

W

B

R5

R1

+

-

DC Power

Supply

18-36 VDC

-

+

123456

SPAN

NULL

+

-

DC Power

Supply

18-36 VDC

-

+

LVR-50 Series:

Warning

For hazardous area applications, use an appropriate intrinsically safe interface device.

Excitation:

The minimum excitation

required for operation of

transmitters with 4-20 mA,

DC signals can be determined

for a given total loop resistance from the graph shown.

(Total loop resistance = sum

of the DC termination resistance plus loop resistance).

For optimum operation,

which is a function of source

voltage (+VA) and total loop

resistance, the source voltage

value used should be above the minimum load line for the related loop

resistance.

+

-

Multimeter

(set for mA)

DC Power

Supply

+

24 VDC

-

COM

mA

-

Choose loop resistance (RL)

to match application

+

Minimum Excitation Required

for Loop Resistance

50

Area of

40

Operation

30

20

10

DC Source Voltage

00

000 200 400 600 800 1000 1200

RL(Ohms) Termination plus

DC Loop Resistance

Loading...

Loading...