Page 1

• Product must be maintained and installed in strict accordance with the National Electrical Codes, Omega Operator's manual,

and any applicable electrical code in the country in which the product is installed. Failure to observe this

warning could result in serious injuries or damages.

Important Points!

Continuous Level Transmitters

LVR20 Analog Output (Proportional Voltage)

LVR30 Signal Conditioned Output (4-20mA, 0-5 VDC, 0-12 VDC)

• For hazardous area applications involving such things as (but not limited to) ignitable mixtures, combustible dust and flammable

materials, use an appropriate intrinsically safe interface device.

• The pressure and temperature limitations shown on the individual catalog pages and drawings for the specified level sensors

must not be exceeded. These pressures and temperatures take into consideration possible system surge pressures/

temperatures and their frequencies.

• Selection of materials for compatibility with the media is critical to the life and operation of Omega level sensors. Take care

in the proper selection of materials of construction, particularly wetted materials.

• Electrical entries and mounting points in an enclosed tank may require liquid/vapor sealing.

• Physical damage sustained by the product may render it unserviceable.

Servicing USA and Canada: Call OMEGA Toll Free

OMEGA Engineering. Inc.

One Omega Drive, Box 4047

Stamford, CT 06907-0047 U.S.A.

Headquarters: (203) 359-1660

Sales: 1-800-826-6342 / 1-800- TC-OMEGA

Customer Service: 1-800-622-2378/ 1-800-622-BEST

Engineering: 1-800-872-9436 / 1-800-USA-WHEN

FAX: (203) 359-7700 TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Servicing Europe: United Kingdom Sales and Distribution Center

OMEGA Technologies Ltd.

P.o. Box 1, Broughton Astley, Leicestershire LE9 6XR, England

Telephone: (0455) 285520 FAX: (0455) 283912

M2021/0602

Operator's Manual

Designed for continuous liquid level sensing, Omega's transmitters are considered "components".

Operating Principle

The LVR20/30 series utilize reed switch/magnet technology.

Meter

(Optional)

Junction

Box

A magnet-equipped float rises or lowers with corresponding

liquid level. The magnetic field generated from the float

actuates a series of reed switches mounted within a sealed

hollow tube. The series of reed switches is combined with

Sealed

Hollow

Tube

resistors to form a voltage divider.

When a regulated DC voltact is applied to an LVR20, the

resulting voltage output is directly proportional to liquid level.

Float

An LVR30 is anLVR20 with a signal conditioned output, for

use in applications that require unregulated input voltage or

current output.

Installation / Mounting

Units operate normally in any attitude, from vertical to a 30° inclination, up or down.

WARRANTY

OMEGA warrants this unit to be free of defects in materials and workmanship and to give satisfactory service for a period of 13 months from date of purchase. OMEGA Warranty adds an additional

one (1) month grace period to the normal one (1) year product warranty to cover handling and shipping time. This ensures that our customers receive maximum coverage on each product. If the unit

should malfunction, it must be returned to the factory for evaluation. Our Customer Service Department will issue an Authorized Return (AR) number immediately upon phone or written request.

Upon examination by OMEGA, if the unit is found to be defective it will be repaired or replaced at no charge. However, this WARRANTY is VOID if the unit shows evidence of having been tampered

with or shows evidence of being damaged as a result of excessive corrosion; or current, heat, moisture or vibration; improper specification; misapplication; misuse or other

operating conditions outside of OMEGA’s control. Components which wear or which are damaged by misuse are not warranted. These include contact points, fuses, and triacs.

We are glad to offer suggestions on the use of our various products. Nevertheless OMEGA only warrants that the parts manufactured by it will be as specified and free of defects.

OMEGA MAKES NO OTHER WARRANTIES OR REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESSED OR IMPLIED. EXCEPT THAT OF TITLE AND ALL IMPLIED

WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED.

LIMITATION OF LIABILITY: The remedies of buyer set forth her ein are exclusive and the total liability of OMEGA with respect to this order, whether based on contract. warranty ,

negligence, indemnification, strict liability or otherwise, shall not exceed the purchase price of the component upon which liability is based. In no event shall OMEGA be liable for

consequential, incidental or special damages.

Every precaution for accuracy has been taken in the preparation of this manual, however, OMEGA ENGINEERING, INC. neither assumes responsibility for any omissions or errors that may appear

nor

assumes liability for any damages that result from the use of the products in accordance with the information con taine d in the manual.

RETURN REQUESTS /INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA ENGINEERING Customer Service Department. Call toll free in the USA and Canada: 1-800-622-2378, FAX: 203-359-7811;

International:203-359-1660,FAX: 203-359-7807.

BEFORE RETURNING ANY PRODUCT(S) TO OMEGA, YOU MUST OBTAIN AN AUTHORIZED RETURN (AR) NUMBER FROM OUR CUST OMER SERVICE DEPARTMENT (IN ORDER TO AVOID

PROCESSING DELAYS).

The assigned AR number should then be marked on the outside of the return package and on any correspondence. Please have the following information available BEFORE contacting OMEGA:

1. P.O. number under which the product was PURCHASED,

2. Model and serial number of the product, and

3. Repair instructions and/or specific problems you are having with the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. That way our customers get the latest in technology and engineering. OMEGA is a registered trademark of OMEGA

ENGINEERING, INC.

© Copyright 1992 OMEGA ENGINEERING, INC. All rights reserved Including illustrations. Nothing in this manual may be reproduced in any manner, either wholly or in part for any purpose whatsoever without written

permission from OMEGA ENGINEERING, INC. Printed in U.S.A.

P/N 160999

Rev. A

Thread Treatment

Sealing: When threading metal threads into a metal coupling , pipe sealant or Teflon tape is

recommended. Due to potential compatibility problems, when sealing plastic threaded units, a

compatible pipe sealant is recommended.

Tightening: When threading a metal sensor into a metal coupling, the installer should use a

suitable wrench and tighten the threads 1-1/2 turns past hand-tight.

Specifications

Wetted Parts

Liquid Temperature

Ambient Operating Temperature

LVR20

LVR30

LVR30 Output Temperature Coefficient

Storage Temperature

LVR20

LVR30

Maximum Operating Pressure

Stem, Mounting and Float: 316 SS /Float Stop: 18-8 SS

-40° to 230°F (-40° to 110°C)

-40° to 230°F (-40° to 110°C)

5° to 160°F (-15° to 71.1°C)

+ 0.0062% FS/F°

-40° to 230°F (-40° to 110°C)

-40° to 212°F (-40° to 100°C)

300 PSIG

Page 2

Operating Voltage:

LVR20: 5 to 30 Vdc;

LVR30: 12 to 40 Vdc

LVR30 Loop Impedance:

(Volts in - 12) x 53.8 = ohms with 24 Vdc

power, max loop impedance is 640 Ω

Connections:

LVR20: 3-wire;

LVR30: 2-wire

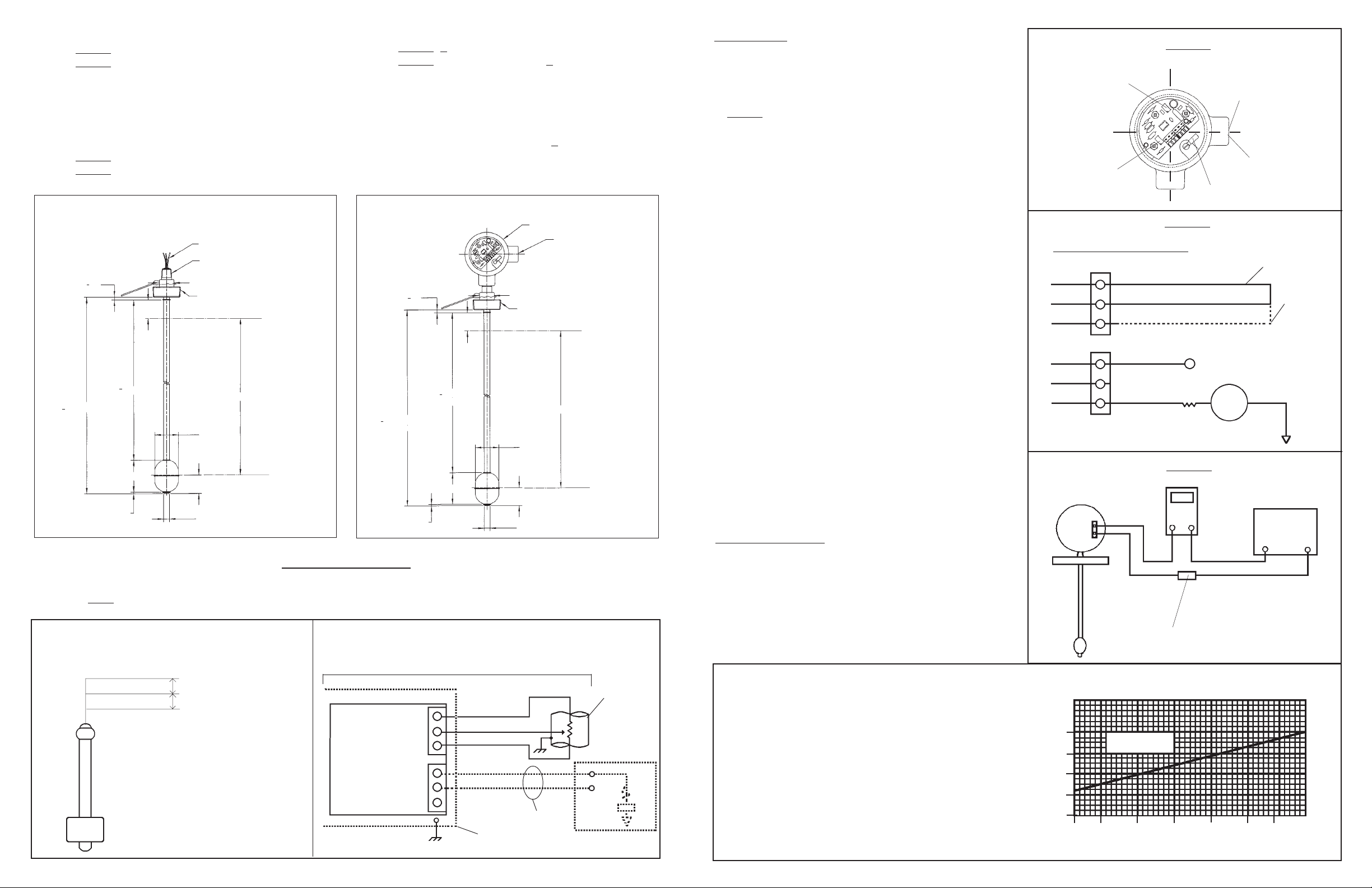

Dimensions of LVR20 Transmitter Dimensions of LVR30 Transmitter

#22 AWG TEFLON WIRES

24" - 26" EXTENDED

1/2" NPT

"B"

1/4"

+1/16"

+1/16"

"A"

TRAVEL

STEM LENGTH

1/8" REF

+1/4"

FLOAT

2 3/4"

1 9/16"

REF

1 1/4" NPT

2" NPT

HIGHEST LEVEL INDICATED

INCHES OF INDICATION

2" DIA

1 9/16" REF

1/2" DIA REF

Note: For hazardous area applications, use an appropriate intrinsically safe interface device.

LVR20 Wiring Diagram

Analog Output (Proportional Voltage)

LOWEST LEVEL INDICATED

Wiring Diagrams

Accuracy (at fixed temperature and voltage):

LVR20: + 1/2"

LVR30: 1.0% of full scale or + 1/2",

whichever is greater

Minimum Fluid Specific Gravity: 0.75 S.G.

Dimensions:

A: Float travel = indicating length + 3/8"

B: Overall Length = indicating length + 3 7/16"

J/BOX (COVER REMOVED)

1/2" NPT

"B"

+1/16"

+1/16"

1/4"

"A"

STEM LENGTH

1/8" REF

+1/4"

FLOAT

TRAVEL

2 3/4"

1 9/16"

REF

1 1/4" NPT

2" NPT

HIGHEST LEVEL INDICATED

INCHES OF INDICATION

2" DIA

1 9/16" REF

1/2" DIA REF

LOWEST LEVEL INDICATED

LVR30 Wiring Diagram

(4-20mA Output)

Calibration

The signal conditioner on yourLVR30 has been Factoryset. You do not need to calibrate.

Steps:

Calibration should be performed with the probe

A.

disconnected from the signal conditioner. Turn

off power to loop. Disconnect the red, black and

white wires from terminals 1, 2, and 3.

Adjust both the null and span potentiometers at

B.

approximately mid-range. (Figure 1)

Wire as shown per Figure 2, connecting a jumper

C.

wire in place of the black and white probe wires.

Connect an ammeter in series to monitor loop

current. Apply power to loop. Adjust null pot for

4mA.

Remove power from loop. Reposition the jumper

D.

wire in place of red and white probe wires.

Reapply power and with the span pot, set the

output current to 20mA.

Repeat Steps C and D for final adjustment.

E.

If power is maintained during jumper connections,

F.

current level may increase to 36mA. This is

normal. Current will return to regular readings

when connections are made.

Troubleshooting

Verify proper wiring, power supply, and loop resistance. If

transmitter is not functioning properly, isolate the transmitter

from the system and wire per Figure 3. Meter should read

4mA with float at bottom and 20mA with float on top of

transmitter. If unit is still not operating properly, please

consult Factory for further troubleshooting details.

Figure 1

Span

Potentiometer

Null

Potentiometer

Figure 2

Using 300 Ohm Resistor

Red

White

Black

Brown

Wht/Blk

Orange

1

3

2

5

6

4

R

Loop

Figure 3

4.12

AMMETER

+24V

Return

COM

Choose loop resistance (RL)

to match application

Customer Wiring

(See Wiring Diagram)

1/2" Trade Size

Ground Terminal

+V (Typically 24V)

Ammeter

_

+

mA

(both Ports)

Place Jumper

Here for 20 mA

Output

Place Jumper

Here for 4 mA

Output

Power Supply

(24 VDC)

+

_

Red

Black

White

Input: 10 - 30 VDC

Output: Proportional

Voltage

4-20 mA Tank Level Transmitter

1

3

2

4

5

6

Red

Wht

Blk

Junction

Box

Process

Control

Loop

Transmitter

+VA

Voltage

Source

or

Simulator

R

L

Excitation Required for Transmitters

Using 4-20 mA Signal Conditioners

The minimum excitation required for operation of

transmitters with 4-20 mA, DC signal converters

(See Chart) can be determined for a given total loop

resistance from the graph shown. (Total loop resistance = the sum of the DC termination resistance plus

loop resistance.) For optimum operation, which is a

function of source voltage (+VA) and total loop resistance, the source voltage value used should be above

the minimum load line for the related loop resistance.

Minimum Excitation Required For Loop Resistance

40

30

20

10

DC Source Voltage

0

0 200 400 600 800 1000 1200

RL (Ohms) Termination Plus DC Loop Resistance

Area

of Operation

Loading...

Loading...