Page 1

APPROVED

INSTALLATION OF

Am OMEGA

One Omega Drive, Box 4047

Stamford, Connecticut 06907-0047

(203) 359-1660 Telex: 996404 Cable: OMEGA

FAX: (203) 359-7700

LVC551

Tlhhnoleghs

-

Cb~&my

INTRINSICALLY SAFE CONTROLS

This bulletin should be used by experienced

personnel as a guide to the installation of the

LVC551 intrinsically safe control. Selection or

installation of equipment should always be

accompanied by competent technical assistance.

We encourage you to contact OMEGA for complete

details.

IMPORTANT: BEFORE PROCEEDING

WIRE THE CONTROL, READ AND THOROUGHLY

UNDERSTAND THESE INSTRUCTIONS.

When installed according to these instructions, the

unit is intrinsically safe for Class I and II, Division

1, Groups A, B, C, D, E, F, and G

Electrical equipment connected to associated

appartus should not use or generate more than

250V RMS.

LOCATION: The control must be situated in a non-

hazardous area where an explosive atmosphere will

not exist at any time.

WIRING:

1.

Intrinsically safe wiring must be kept separate

from non-intrinsically safe wiring.

Intrinsically safe and non-intrinsically safe

2.

wiring may occupy the same enclosure or

raceway if they are at least 2 inches (50mm) apart

and separately tied down. Inside panels, field

wiring terminals for intrinsically safe circuits

must be separated by at least 2 inches (50mm)

from non-intrinsically safe terminals.

Wire the control device(s) to the LVC551 relay

3.

as shown in the specific application wiring

diagram on reverse side. A separate rigid

metallic conduit should be used to enclose the

conductors of the intrinsically safe control

circuit.

An approved seal should be used at the point

4.

where the intrinsically safe control circuit wiring

enters the hazardous area.

INDUCTANCE AND CAPACITANCE: For intrin-

sically safe wiring use 16 AWG TYPE MTW or 14

AWG TYPE THHN.

By using these types of wire in conjunction with

the following distance recommendations, you will

not exceed the

500 mh inductance for field wiring.

.45

mf maximum capacitance, and

INSTALL AND

To

Use the following chart to determine the limits of

run:

Max. Sensitivity (K OHMS)

3.3

4.7

10

22

47

100

GROUNDING: Both tabs of the LVC551 provide an

electrical connection for earth grounding. To insure

grounding, use only metal screws and lockwashers.

Do not use nylon or any other nonmetallic material

to mount the unit in the enclosure.

NOTES:

Connecteions may be made to nonenergy

1.

generating or storing hazardous location

devices, such as switch contacts, noninductive

resistance thermometer detectors

thermocouples without necessitating a specific

approval except when the device is mounted

inside a tank subjected to pressure greater than

15 psi.

To prevent electrical shock, controller must be

2.

mounted inside a tool accessible enclosure.

For guidance on the installation see ANSI/ISA

3.

RP 12-6.

Distance (Ft.)

5000

3500

1750

1000

500

250

(RTD’s)

and

SPECIFICATIONS

CONTACT DESIGN: D PST: One normally open

(N.O.) and one normally closed (N.C.)

CONTACT RATINGS: 8 Amperes resistive load at

250 Volts A.C. and 5 ampheres at 30 Volts D.C.

CONTACT LIFE: Electrical at rated load

50/60

=

10,000,000

minus

Hertz.

.5

cycles.

50/60

15%,

seconds on rising level.

cycles. Mechanical

ELECTRONICS MODULE: Solid state components

epoxy encapsulated in nylon shell.

PRIMARY AC SUPPLY LINE:

(a) Voltage: Standard 120 VAC, optional 24,240 VAC

.5

Watt.

lo%,

models, plus

(b) Frequency:

(c) Power:

SENSITIVITY: Operates from 0

maximum specific resistance.

TEMPERATURE: (Minus) -40 to (Mlus) + 120

degrees F. ambient.

TERMINALS: Size 6 pan head screws with

captivated wire clamping plate.

TIME DELAY: Standard,

= 100,000

Hz.

-

100,000 Ohm

Page 2

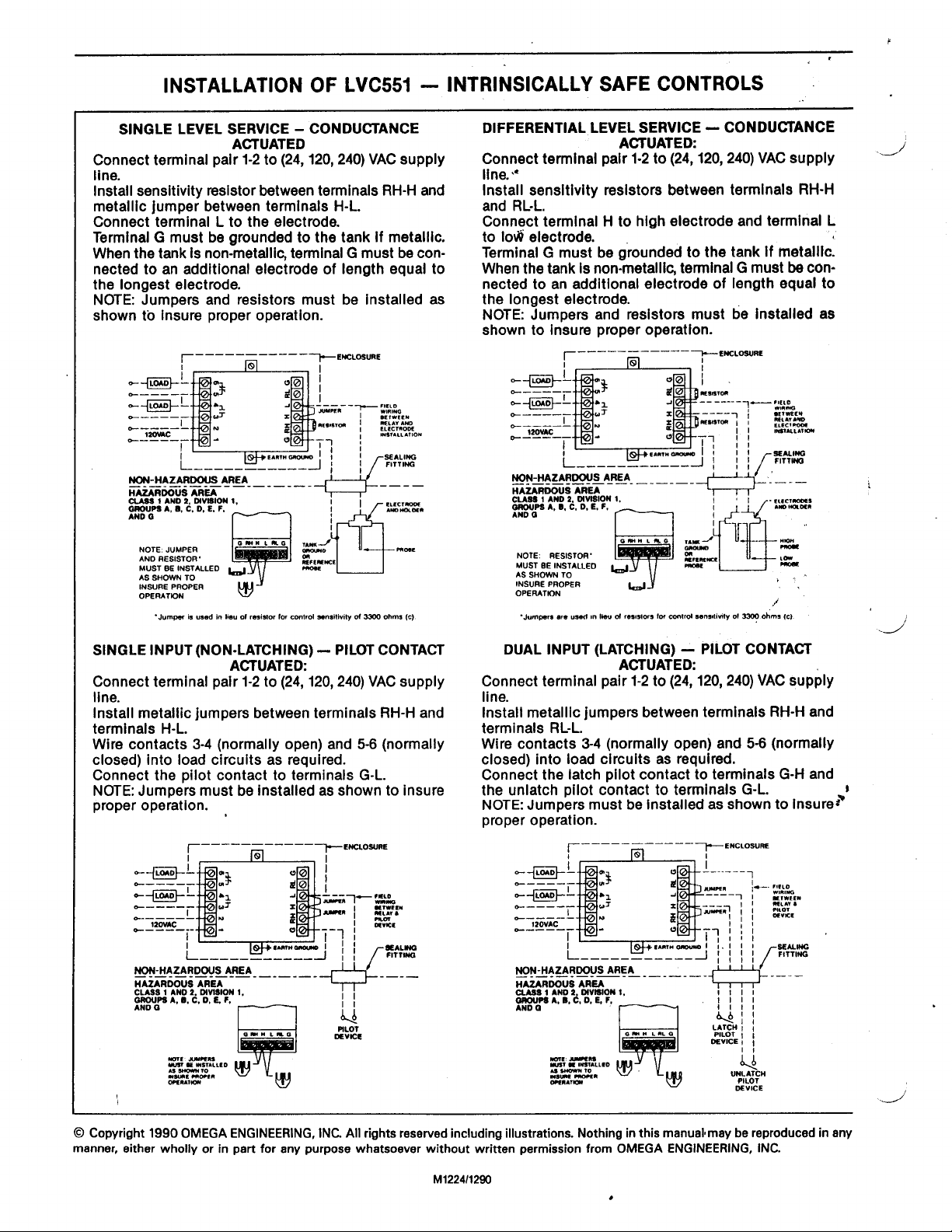

SINGLE LEVEL SERVICE

ACTUATED

;;;nect

terminal palr 1-2 to (24, 120,240) VAC supply

LVC551

-

CONDUCTANCE

INTRINSICALLY SAFE CONTROLS

-

INSTALLATION OF

DIFFERENTIAL LEVEL SERVICE

ACTUATED:

;;;;ect

terminal pair 1-2 to

(24,120,240)

.

-

CONDUCTANCE

VAC supply

.

.‘-

Install sensitivity resistor between terminals RH-H and

metallic jumper between termlnals H-L.

Connect terminal L to the electrode.

Terminal G must be grounded to the tank If

metallic.

When the tank Is non-metallic, terminal G must be con-

nected to an additional electrode of length equal to

the longest electrode.

NOTE: Jumpers and resistors must be installed as

shown to insure proper operation.

r-----

--------pENcLosURE

/xq

I

Install sensltivity resistors between terminals RH-H

RL-L.

and

Connect terminal H to high electrode and terminal L

low

electrode.

to

Terminal G must be grounded to the tank If metallic.

When the tank Is non-metallic, terminal G must be con-

nected to an additional electrode of length equal to

the longest electrode.

NOTE: Jumpers and resistors must tie Installed as

shown to Insure proper operation.

__--_--___-

NON-HAZAROOUS AREA

________---_-

HAZARDOUS AREA

CLASS

fn$uam

NOTE: RESISTOR ’

MUST

AS SHOWN TO

INSURE PROPER

OPERATION

AWD 1

BE

INSTALLED

2.

DIVISION

c. A,

F.

E. 0. 0.

_----

1.

i

q--y-__

1

PILOT

SINGLE INPUT (NON-LATCHING)

-

CONTACT

ACTUATED:

l-2

Connect terminal pair

to (24, 120,240) VAC supply

line.

Install metallic jumpers between terminals RH-H and

terminals H-L.

Wire contacts 3-4 (normally open) and 5-6 (normally

closed) into load circuits as required.

Connect the pilot contact to terminals G-L.

NOTE: Jumpers must be Installed as shown to insure

proper operation.

-+-

I

ii

DEWCC

/

_-__

NON-HAZARDOUS

-_-_-_-_-_-_-_-_-_

HAZARDOUS

WC&W

CLISB

A.

AREA

DlvlaI0M

2. A”0 1

AREA

9.

E.

F.I D.

1. C.

-

DUAL INPUT (LATCHING)

PILOT CONTACT

ACTUATED:

;;remect terminal pair 1-2 to

(24,120,240)

VAC supply

Install metallic jumpers between terminals RH-H and

terminals RL-L.

5-6

Wire contacts 3-4 (normally open) and

(normally

closed) into load circuits as required.

Connect the latch pilot contact to terminals G-H and

the unlatch pilot contact to terminals G-L.

NOTE: Jumpers must be installed as

proper operation.

NON-HAZARDOUS AREA

______-_-_-_-_-_--

HAZARDOUS AREA

CLASS

EJW

A,

DWISION 1,

1 AU0 1

E.

D. do 6.

F.I

I

I II

shown to

I II

1 !46

insure~V

9

INC.

0

Copyright 1990 OMEGA ENGINEERING,

manner, either wholly or in part for any purpose whatsoever without written permission from OMEGA ENGINEERING, INC.

All rights reserved including illustrations. Nothing in this

M1224/1290

,

manual+may

be reproduced in any

Loading...

Loading...