Omega Products LV752 Installation Manual

USE OMEGA FRONT COVER

USE OMEGA INSIDE FRONT COVER

CONTENTS

SECTION

1.0 General Description------------------------------------------------------------- 1

PAGE

2.0 Specifications -------------------------------------------------------------------- 2

3.0 Installation and Calibration----------------------------------------------------- 4

4.0 Operation -----------------------------------------------------------------------12

5.0 Maintenance and Troubleshooting --------------------------------------------14

FIGURES

Figure 2.1 Overall Dimensions----------------------------------------------------- 3

Figure 3.1 Suggested Mounting Arrangements------------------------------------ 5

Figure 3.2 Doubtful Mounting Arrangements------------------------------------- 5

Figure 3.3 Typical Field Wiring Diagram for 120 Volts A. C. ----------------- 6

Figure 3.4 Typical Field Wiring Diagram for 24 Volts D. C.------------------- 7

Figure 3.5 Typical Field Wiring Diagram for 12 Volts D. C.------------------- 8

Figure 3.6 Location of Adjustments and Controls -------------------------------10

Figure 3.7 Typical Wiring Pictorial and Device Status Chart ------------------13

LV750 11/30/01

1.0 GENERAL DESCRIPTION

1.1 The OMEGA® LV750 Series Level Switch is used to detect the presence of a

material at a given level in a tank, bin or other container. It can be used with

a wide range of both liquid and solid materials which may be electrically

conductive or non-conductive. In some cases, the LV750 can be used to detect

the level of an interface between a lighter and a heavier substance such as that

found in an oil and water separator.

1.2 The standard version of the LV750 is housed in a general-purpose enclosure

with an integral 12 inch long probe. The standard probe is a solid 3/8 inch

diameter stainless steel rod. A time delay circuit is included as standard on

the LV750. It operates on rising level and may be set to times of 0, 5, 10, and

15 seconds. The standard version of the LV750 is powered from 120 VAC

but a DC powered version is also offered.

1.3 There are four models available:

LV751 General purpose, 3/8" diameter 316SS rod, acetal bushing, 1/2"

NPT 316SS nipple

LV752 General purpose, 3/8" diameter 316SS rod, Teflon® bushing,

1/2" NPT 316SS nipple

LV753 Teflon® coated probe, 1/2" NPT 316SS nipple

LV754 Teflon® coated probe, 3/4" NPT Teflon® nipple

The standard probe length is 12 inches, however, lengths of up to 72 inches

are available.

1.4 In most applications, the installation and calibration of the LV750 are easily

accomplished by a competent electrician. Mounting the unit requires three

basic steps. First, provide an opening in the tank or other container. Second,

fit this opening with a pipe coupling or other threaded entry. Third, install

the LV750 securely into the coupling or other fitting. The wiring of the unit

may consist of as few as three wires, depending upon the application. No test

equipment is required for calibration since the necessary calibration indicators

are built into the unit. Seasonal recalibration of the unit is unnecessary due to

its exceptional stability.

1.5 Because of the patented detection technique used in the LV750, it can tolerate

reasonable amounts of sticky material buildup on the probe. In addition, the

rugged construction techniques used in building the probes allow them to

support the weight of such a buildup. For conductive liquids and materials

with a high dielectric constant (greater than 30) that additionally have a

tendancy to "bridge" between the probe and container wall, a Teflon® coated

probe should be used. For chemical compatibility considerations, also request

the 3/4" Teflon® nipple.

2.0 SPECIFICATIONS

2.1 ENVIRONMENTAL

Operating temperatures:

Electronics ..........................................-40°C to +85°C (-40°F to +185°F)

Probes.................................................12 inches min length (standard) to

Uncoated, acetal bushing..................-40°C to +85°C (-40°F to +185°F),

Uncoated, Teflon® bushing............. -40°C to +230°C (-40°F to +450°F)

Teflon® coated (except................... -40°C to +230°C (-40°F to +450°F)

Teflon® nipple) 1500 psig @ 25°C (77°F),

72 inches(special)

1500 psig @ 25°C (77°F),

0 psig @ 85°C (185°F)

1500 psig @ 25°C (77°F),

0 psig @ 230°C (450°F)

0 psig @ 230°C (450°F)

Teflon® coated, 3/4".......................-40°C to +85°C (-40°F to +185°F),

Teflon® nipple 150 psig @ 25°C (77°F),

Minimum dielectric constants

Liquid material sensing .......................2.0 for standard uncoated probe

Solid material sensing..........................8.0 for standard uncoated probe

2.2 ELECTRICAL

Input Power......................95 to 130 VAC, 50 to 60 Hz, 2 watts (standard)

Relay DPDT (2 form C) dry contacts

Relay Contact Rating.................5 Amps Resistive @ 120 VAC or 28 VDC

Time delay ...............................................0, 5, 10, 15 seconds, selectable

0 psig @ 85°C (185°F)

see Dielectric Chart, pages16 & 17

or 9 to 35 VDC @ 100 mA max(optional)

LV750 2 11/30/01

2.3 MECHANICAL

Process Connection ........................1/2" NPT (standard); 3/4" NPT (optional)

Wetted parts .................. 316SS rod, 316SS nipple, acetal (Teflon® optional)

Enclosure .......................................................Cast aluminum, (PVC optional)

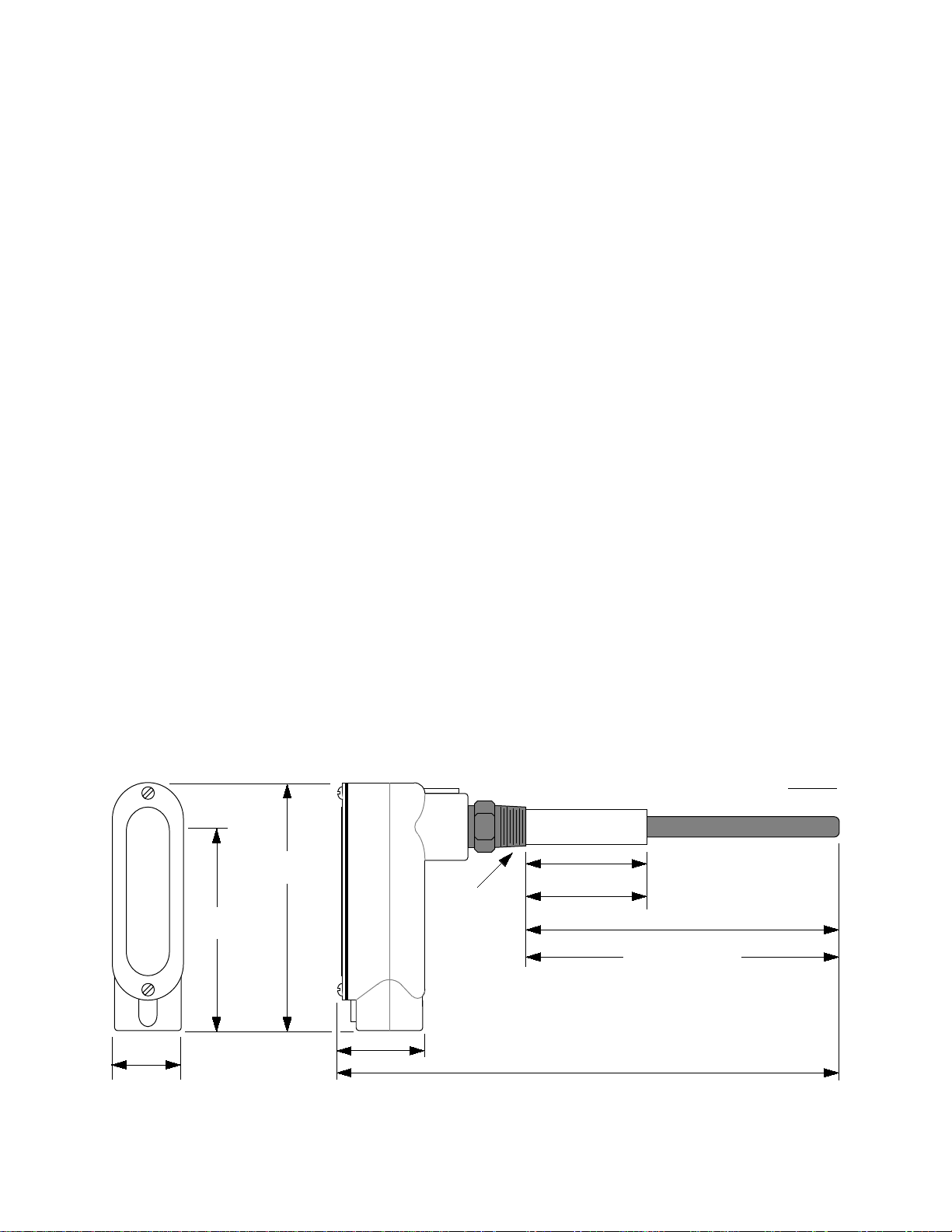

Overall Size ............................ 16.5 X 6.1 X 1.8 inches(419 X 155 X 46 mm)

Weight .......................................................................................... 2 lb (4.4 kg)

1.75

(45)

LV750

6.10

(155)

5.00*

(127)

*MINIMUM TURNING

RADIUS REQUIRED

FOR INSTALLATION

INSULATOR

LENGTH

1/2" NPT

DIMENSIONS SHOWN ARE FOR STANDARD UNIT.

PROBE LENGTHS TO 72 INCHES (1830 MM) ARE

2.10

(53)

4.00

(102)

AVAILABLE ON SPECIAL ORDER.

16.50

(419)

Figure 2.1: Overall Dimensions

3

DIMENSIONS:

12.00

(305)

PROBE LENGTH

INCHES

MM

11/16/01

3.0 INSTALLATION AND CALIBRATION

3.1 After unpacking the unit, inspect it for any evidence of shipping damage. Any

claims for damage due to shipping must be filed with the carrier who handled

the package(s).

3.2 Select a mounting location for the LV750 unit and its attached sensing probe.

See Figure 3.1 for recommended mounting practices. Figure 3.2 shows some

mounting methods which have proven to be troublesome. Be sure that there is

sufficient clearance around the mounting position to allow for the turning

radius as the unit is screwed into place. Also, in the case of rigid probes,

allow sufficient room to be able to insert the probe into the opening in the

vessel. Cut a hole in the vessel that is at least large enough to allow the

insulator portion of the probe to extend into the inside of the vessel and mount

a threaded coupling to the vessel. The thread size of the coupling should be

1/2" NPT for standard probes. A 3/4" NPT fitting is required for some of the

optional probes.

CAUTION: WHEN MAKING THE OPENING IN THE VESSEL, OBSERVE

ALL SAFETY REQUIREMENTS OF THE AREA IN WHICH THE WORK IS

BEING DONE. BE ESPECIALLY CAREFUL OF PRESSURIZED VESSELS.

CAUTION: SHOULD IT BE NECESSARY TO REMOVE THE PROBE

ASSEMBLY FROM THE HOUSING FOLLOW THE DISASSEMBLY

INSTRUCTIONS IN PARAGRAPHS 3.13 AND 3.14.

3.3 Screw the LV750 unit into the coupling and install conduit suitable to the

environment in which the unit is to be used. See Figure 3.1 for a suggested

conduit arrangement.

3.4 Wire the LV750 unit in accordance with the typical wiring diagrams of

Figure 3.3, 3.4, or 3.5 or as may be required by the particular application in

which the unit is to be used. Because of the extremely wide range of control

and/or alarm applications in which the unit may be used, it is not possible to

show all conceivable wiring diagrams. Consult OMEGA Engineering if

assistance is desired.

CAUTION: BE SURE THAT ALL WIRING CONFORMS TO THE REQUIREMENTS

OF THE NATIONAL ELECTRICAL CODE AND ANY ENFORCING AUTHORITIES OR

AGENCIES HAVING JURISDICTION OVER THE INSTALLATION.

LV750 4 11/30/01

Loading...

Loading...