Page 1

OPTICAL LIQUID-LEVEL SENSOR

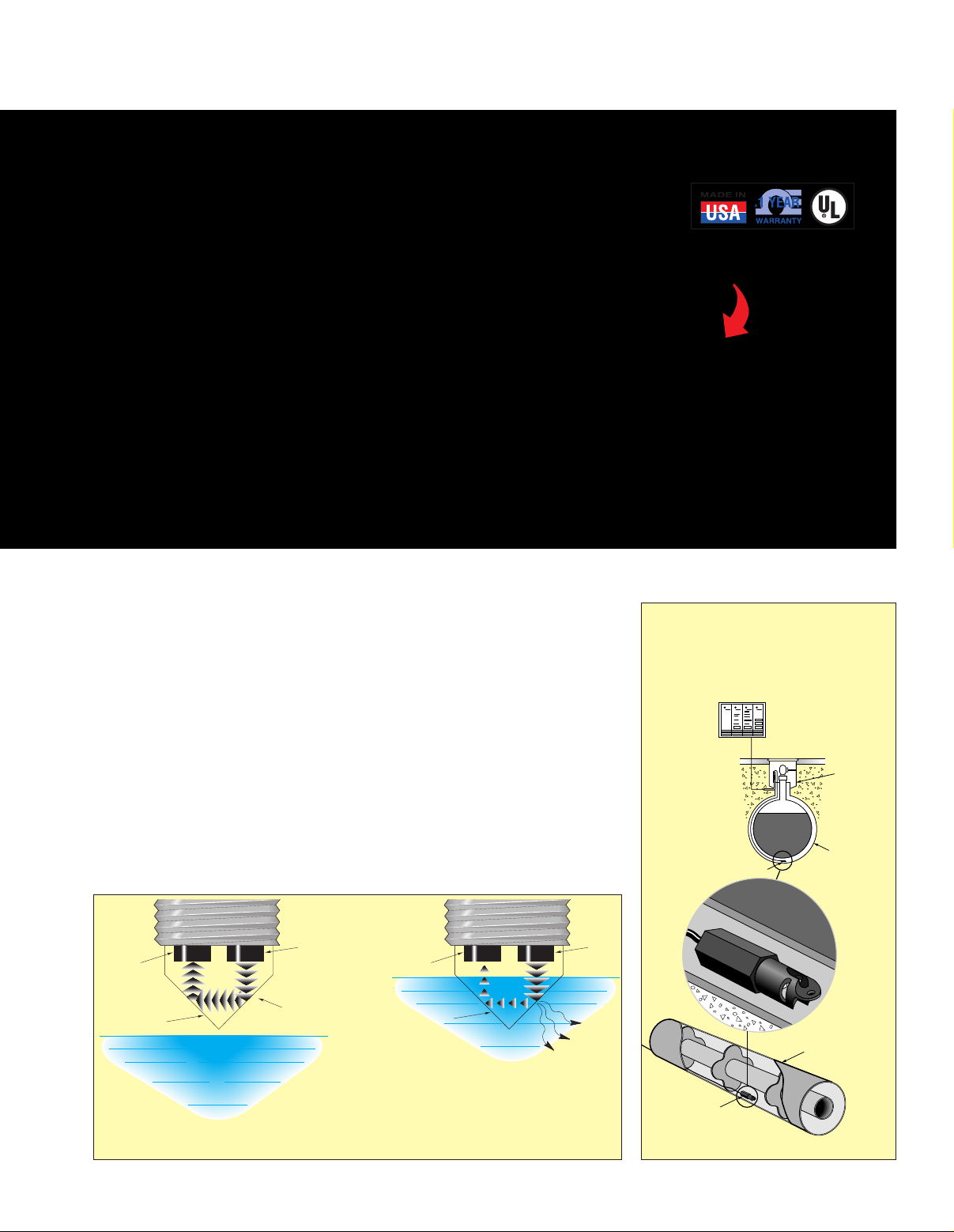

Double-Wall Pipe

LV 17 0

LV 17 0

Fiberglass,

Double-Wall

Ta nk

Containment

Sump

Your Controls

Light

Lost in

Liquid

Liquid immersing

the sensing prism.

Receiver

Prism

LED

Light

from

LED

Liquid below the

sensing prism.

Prism

Receiver

LED

Integral Pull

LV171, $144, shown

larger than actual size.

⻬ Compact—Fits Interstitial

Spaces

⻬ Unaffected by Vapors,

Even at High

Concentrations

⻬ Easily Removed,

Cleaned, and Reinstalled

⻬ No Moving Parts

The LV170 optical liquid sensor

accurately detects the presence of

liquid in fiberglass double-wall

tanks, containment sumps, and

double-wall pipes. Built-in electronic

switching ensures dependability

throughout its long service life. This

reusable sensor easily fits small,

interstitial spaces and senses liquid

hydrocarbons or water. The unit is

unaffected by hydrocarbon vapors,

Note: The LV170 sensor is a non-voltage-producing device and does not contain energy

storing components. However, because primary use is in hazardous locations, an appropriate

intrinsically safe interface device is required for its use.

thereby greatly reducing the risk of

false alarms. The LV170 sensor is

easy to remove, clean, and reinstall

after an alarm condition is triggered,

or for maintenance.

The LV170 electro-optical sensor

contains an infrared LED and a light

receiver. Continuous light from the

LED is directed into a prism that

forms the tip of the sensor.

If no liquid is present, light from the

LED is reflected within the prism to

the receiver. When rising liquid

immerses the prism, the light is

refracted out into the liquid, leaving

little or no light to reach the receiver.

Sensing this change, the receiver

actuates electronic switching within

the unit to operate an external alarm

or control circuit.

Fiberglass Double-Wall Tank,

and Piping Sump Applications

LV170 Series

$

144

Containment Sump,

Double-Wall Pipe,

K-75

Page 2

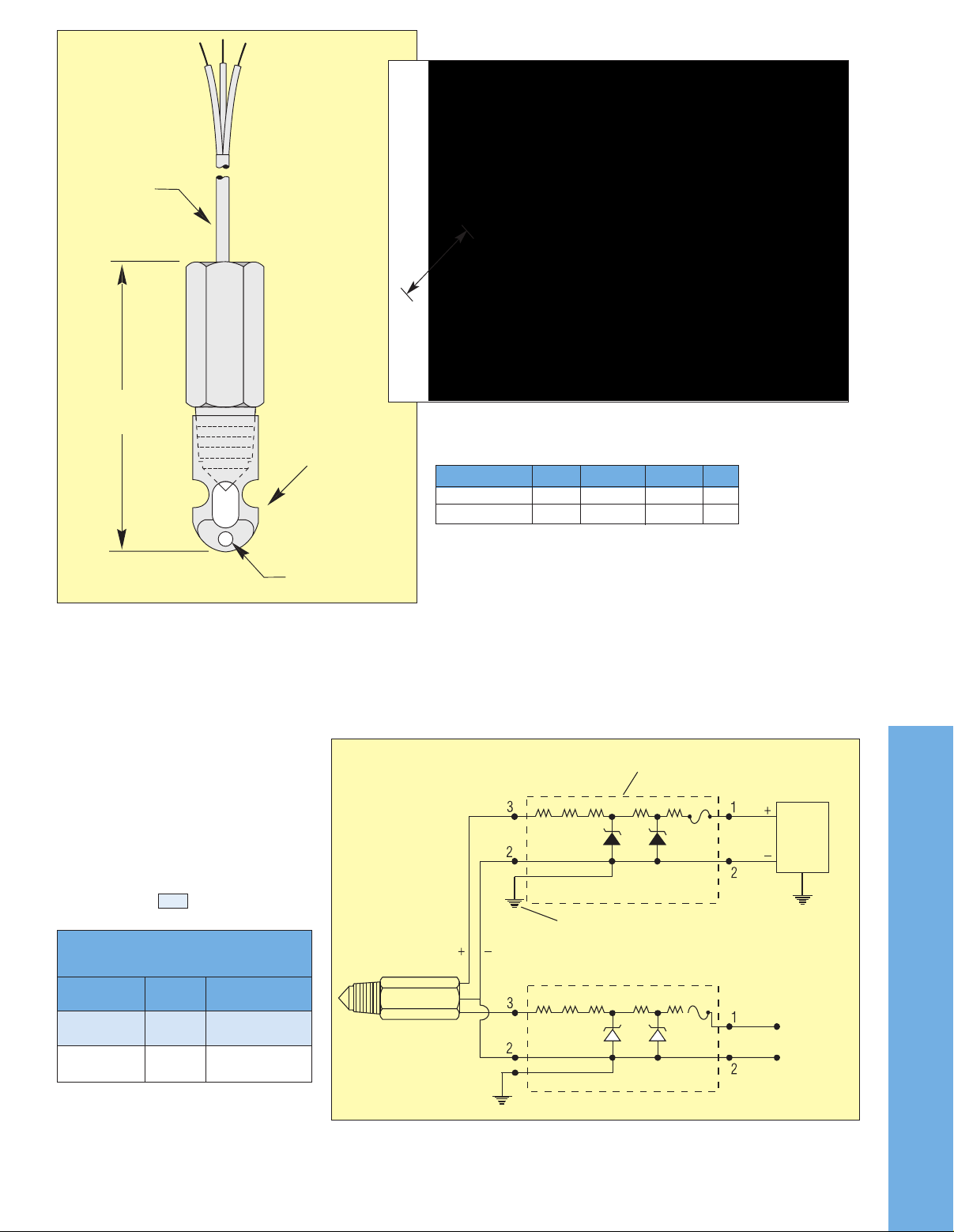

Zener Barrier*

DC

Power

Supply

GND

Earth Ground

Black

Red

Switch

Output

SPECIFICATIONS

2-5/8" REF.

(66.7 mm)

Cable

1/8" DIA. Hole

Through

Removable

PVC

Pull Ring

Wetted Materials:

Polysulfone, PVC, epoxy

Operating Temperature:

-17.8 to 80°C (0 to 176°F)

Current Consumption:

Approximately 18 mA

Output: TTL/CMOS compatible;

may sink up to 40 mA

Cable: 3-conductor PVC jacketed

[7.6 m (25') extended]

Approvals: UL for Class I,

Group D Hazardous Locations

Weight: 340 g (0.75 lb)

Max Pressure: 150 psig

Integral pull

"

4

1

⁄

Electrical Parameters

Entity Parameters for 10 to 28 Vdc Input

Terminal V

Red/Black 38V 150 mA 0.052 µf 0

White/Black 38V 150 mA 0.052 µf 0

V

≥ VOC(Barrier)

MAX

I

≥ ISC(Barrier)

MAX

CI+ Ccable ≤ C(Barrier)

LI+ Lcable ≤ L(Barrier)

Definitions:

VOC= Maximum Open Circuit Voltage

ISC= Maximum Short Circuit Current

CI= Internal Capacitance

LI= Internal Inductance

Typical Wiring Diagram

MAX

I

MAX

LV171, $144,

shown larger than

actual size.

I

C

I

L

K

MOST POPULAR

MODELS HIGHLIGHTED!

To Order

(Specify Model Number)

Model No. Price Conditions

LV171 $144 Wet probe =

LV172 144 Dry probe =

Comes complete with 7.6 m (25'),

3-conductor PVC jacketed cable

and operator’s manual.

Ordering Example: LV171, wet probe

sensor, $144.

Output

current sink

current sink

*Source voltage not greater than 250 Vac. Zener barriers must be installed in

accordance with barrier manufacturer’s instructions.

K-76

Page 3

One Omega Drive | Stamford, CT 06907 | 1-888-TC-OMEGA (1-888-826-6342) | info@omega.com

EPG05

www.omega.com

UNITED KINGDOM

www. omega.co.uk

Manchester, England

0800-488-488

UNITED STATES

www.omega.com

1-800-TC-OMEGA

Stamford, CT.

CANADA

www.omega.ca

Laval(Quebec)

1-800-TC-OMEGA

GERMANY

www.omega.de

Deckenpfronn, Germany

0800-8266342

Karviná, Czech Republic

FRANCE

www.omega.fr

Guyancourt, France

088-466-342

CZECH REPUBLIC

www.omegaeng.cz

596-311-899

BENELUX

www.omega.nl

Amstelveen, NL

0800-099-33-44

More than 100,000 Products Available!

Temperature

Calibrators, Connectors, General Test and Measurement

Instruments, Glass Bulb Thermometers, Handheld Instruments

for Temperature Measurement, Ice Point References,

Indicating Labels, Crayons, Cements and Lacquers, Infrared

Temperature Measurement Instruments, Recorders Relative

Humidity Measurement Instruments, RTD Probes, Elements

and Assemblies, Temperature & Process Meters, Timers and

Counters, Temperature and Process Controllers and Power

Switching Devices, Thermistor Elements, Probes and

Assemblies,Thermocouples Thermowells and Head and Well

Assemblies, Transmitters, Wire

Flow and Level

Air Velocity Indicators, Doppler Flowmeters, Level

Measurement, Magnetic Flowmeters, Mass Flowmeters,

Pitot Tubes, Pumps, Rotameters, Turbine and Paddle Wheel

Flowmeters, Ultrasonic Flowmeters, Valves, Variable Area

Flowmeters, Vortex Shedding Flowmeters

pH and Conductivity

Conductivity Instrumentation, Dissolved Oxygen

Instrumentation, Environmental Instrumentation, pH

Electrodes and Instruments, Water and Soil Analysis

Instrumentation

Data Acquisition

Auto-Dialers and Alarm Monitoring Systems,

Communication Products and Converters, Data

Acquisition and Analysis Software, Data Loggers

Plug-in Cards, Signal Conditioners, USB, RS232, RS485

and Parallel Port Data Acquisition Systems, Wireless

Transmitters and Receivers

Pressure, Strain and Force

Displacement Transducers, Dynamic Measurement

Force Sensors, Instrumentation for Pressure and Strain

Measurements, Load Cells, Pressure Gauges, Pressure

Reference Section, Pressure Switches, Pressure Transducers,

Proximity Transducers, Regulators,

Strain Gages, Torque Transducers, Valves

Heaters

Band Heaters, Cartridge Heaters, Circulation Heaters,

Comfort Heaters, Controllers, Meters and Switching

Devices, Flexible Heaters, General Test and Measurement

Instruments, Heater Hook-up Wire, Heating Cable

Systems, Immersion Heaters, Process Air and Duct,

Heaters, Radiant Heaters, Strip Heaters, Tubular Heaters

click here to go to the omega.com home page

Loading...

Loading...