Omega Products LV132 User Manual

DISCRIMINATING LIQUID SENSOR

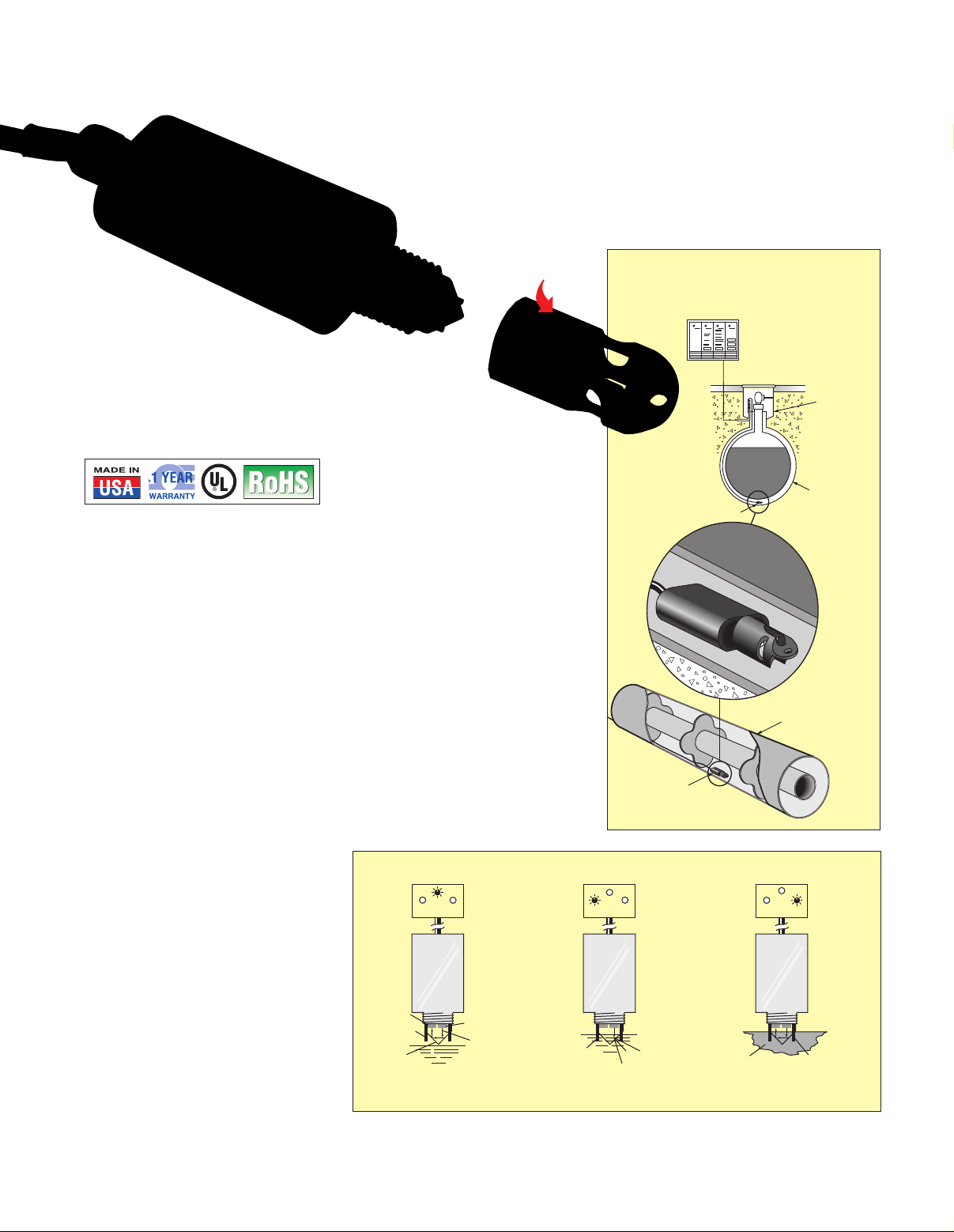

Double-Wall

Pipe

LV132

LV132

Fiberglass,

Double-Wall

Tank

Containment

Sump

Your Controls

Receiver

Conductivity

Probe

Prism

LED

Light

from

LED

Electrical

Conductance

in Water

Light

Lost In

Liquid

Hydrocarbon

Conductivity

Probe - No Electrical

Conductance In

Hydrocarbon

Water

Present

Hydrocarbon

Present

Dry

Your Controls

Water

Present

Hydrocarbon

Present

Dry

Your Controls

Water

Present

Hydrocarbon

Present

Dry

Your Controls

LV1 32

Logic

Circuit

LV1 32

Logic

Circuit

LV1 32

Logic

Circuit

for Interstitial Applications

Detachable

integral pull

ring included

LV132, $175,

shown actual size.

Double-wall tanks, containment sumps,

and double-wall pipes applications

LV132

$

175

⻬ Three Distinct Outputs:

Dry, Water Present,

Fuel Present

⻬ Compact—Fits

Interstitial Spaces

⻬ Unaffected by Vapors;

Even at High

Concentrations

⻬ Easy Removal

and Re-installation

for Cleaning

⻬ No Moving Parts—

Long Life

Proven electro-optic and conductive

technologies are combined to

deliver advanced capabilities in the

LV132 discriminating liquid sensor.

Internal logic discriminates between

water- and hydrocarbon-based

liquids. No moving parts and

solid-state switching encased in a

rugged housing ensure dependable,

long service.

A slim, compact form allows easy

installation into interstitial areas of

double-wall pipes and tanks using

an integral pull ring to “snake” into

place. Remove the pull ring and the

LV132 installs into any tank or

reservoir via 1⁄4 FNPT fittings for

high, low, or intermediate level

detection. The LV132 sensor is

easy to remove, clean, and

reinstall after an alarm condition

is triggered, or for maintenance.

The LV132 electro-optical/

conductivity sensor contains an

infrared LED and a light receiver.

Continuous light from the LED is

directed into a prism which forms

the tip of the sensor. Two probes

extend from the prism to measure

conductivity.

With no liquid present, light from

the LED is reflected within the

prism to the receiver. When rising

liquid immerses the prism, the

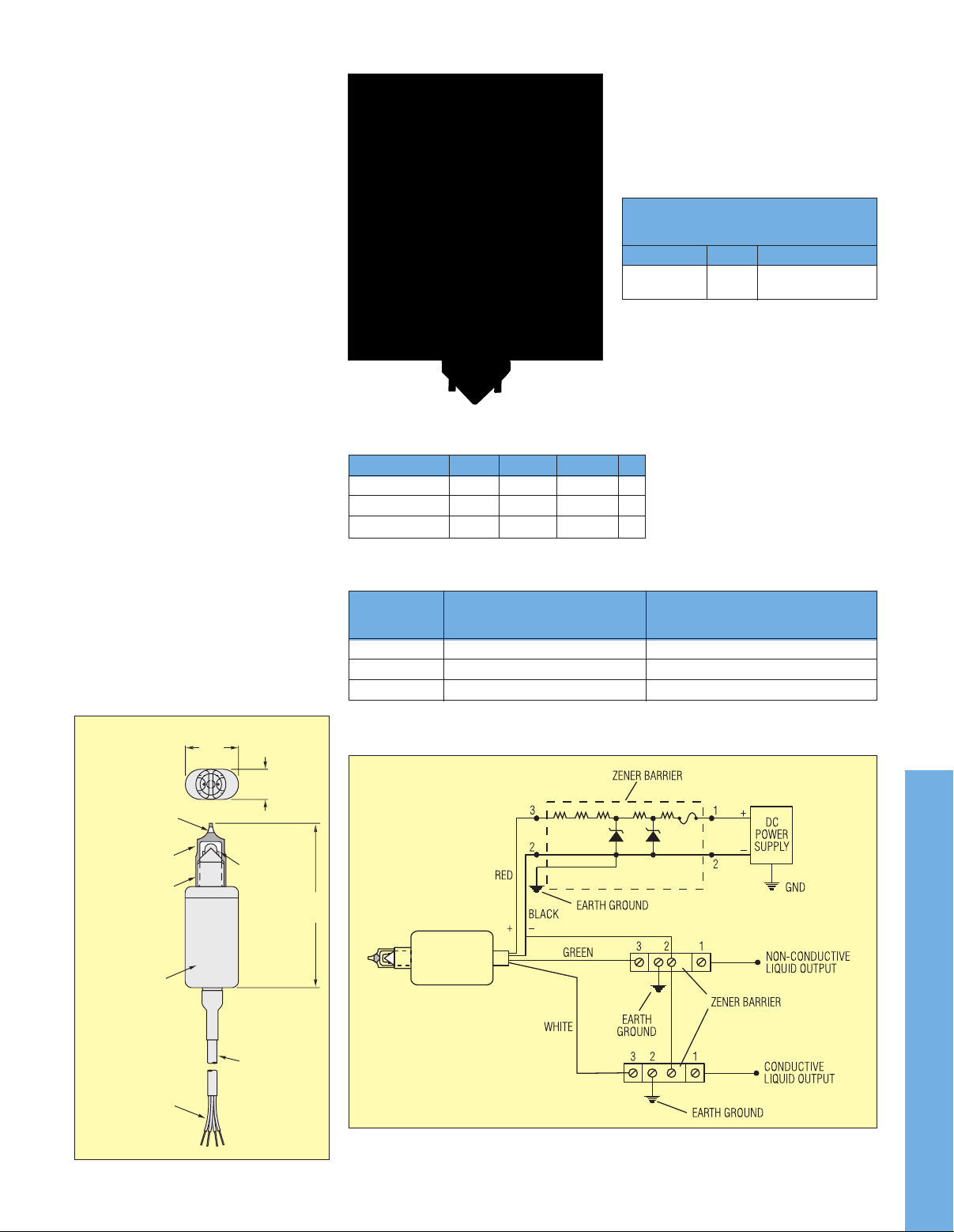

Note: The LV132 sensor is a non-voltage-producing device and does not contain energy

storing components. However, since primary use is in hazardous locations, an appropriate

intrinsically safe (I.S.) interface device is required for its use.

K-71

15.7

(.62)

27.9

(1.10)

CONDUCTIVITY

SENSORS

REMOVABLE PVC

PULL RING

ELECTRO-OPTIC

CABLE

WIRING:

RED: 10 to 28 Vdc

BLACK: GROUND

GREEN: FUEL/OIL

WHITE: CONDUCTIVE

OUTPUT

HOLE THRU

3.2

(1/8 DIA)

1/4 NPT

81.8

(3.22)

*

LV132, $175,

shown actual size.

light is refracted out into the liquid,

leaving little or no light to reach the

receiver. Simultaneously, the

conductivity probes determine if the

liquid is conductive (water-based) or

non-conductive (hydrocarbonbased). Sensing the change in light

intensity and measuring the liquid’s

conductivity level, the receiver

actuates electronic switching within

the unit. A logic circuit built into the

sensor housing evaluates the two

inputs and gives one of three output

signals: Dry, Water Present, or

Hydrocarbon Present.

SPECIFICATIONS

Wetted Materials: Polysulfone, PVC,

316 Stainless Steel, Epoxy, Nylon

Operating Temperature: -17.8 to 80°C

(0 to 176°F)

Current Consumption: 18 mA,

Approximately

Output: TTL/CMOS Compatible. May

sink up to 40 mA up to 30 Vdc

Repeatability: ± 1 mm

Cable: Four (4) Conductor PVC

Jacketed (25 ft Extended)

Approvals: UL Classified for Class I,

Group D Hazardous Locations

Weight: 340 g (0.75 lb)

Dimensions: mm (in)

AVAILABLE FOR FAST DELIVERY!

To Order

(Specify Model No.)

Model No.

LV132 $175 Discriminating

Comes complete with 7.6 m (25") four (4)

conductor PVC jacketed cable and

operator’s manual.

Ordering Example: LV132 sensor, $175.

V

Electrical Parameters

Entity Parameters for 10-28 Vdc Input

Terminal V

MAX

Red/Black 38V 150 mA 0.052 µF 0

White/Black 38V 150 mA 0.052 µF 0

Green/Black 38V 150 mA 0.052 µF 0

I

MAX

C

I

I

MAX

CI+ Ccable ≤ CA (Barrier)

LI+ Lcable ≤ LA (Barrier)

L

I

Definitions:

VOC= Maximum Open Circuit Voltage

ISC= Maximum Short Circuit Current

CI= Internal Capacitance

LI= Internal Inductance

Output Logic

Green Wire Hydrocarbon

Probe (Non-Conductive) Output White Wire Water (Conductive)

Condition (Logic State) Output (Logic State)

Air “0” “1”

Water “0” “0”

Fuel “1” “1”

Not recommended for use in any liquid that crystallizes or leaves a solid residue.

Price Description

≥ VOC(Barrier)

MAX

≥ ISC(Barrier)

light sensor

Typical Wiring Diagram

Source voltage not greater than 250 Vac. Zener barriers must be installed in accordance

*

with barrier manufacturer’s instructions. Visit omega.com/sbg54803 for additional information.

K-72

K

Loading...

Loading...