Page 1

®

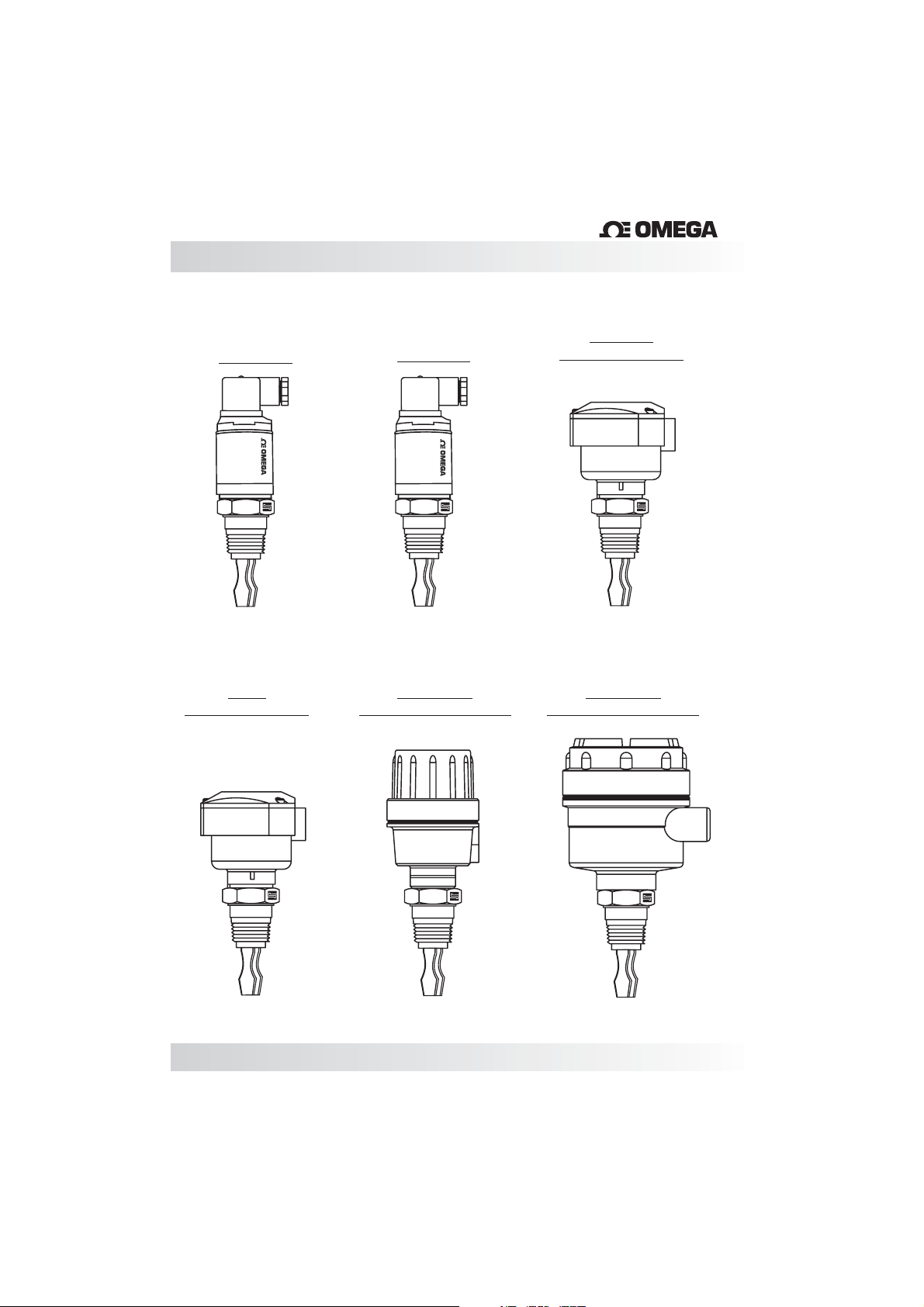

LTU-2000 Series and

Tuning Fork Sensors

Page 2

®

Page 3

®

Contents

Introduction .................................................4

Models.....................................................5

Models and Dimensions .......................................6

Wiring Diagram ..............................................7

LTUP and LTUR Status Guide...................................9

LTum Status Guide ..........................................10

Installation .................................................11

Handling ..................................................12

Technical Specifications ......................................13

Trouble Shooting ........................................... 17

03

Page 4

Introduction

LTU-2000 Series:

Point Level Switch

Omega's LTU-2000 Series use a piezo-electric crystal that enables the switch to vibrate

at a fixed pre-defined resonant frequency. When the tuning fork is submerged in the

medium the frequency at which the switch is vibrating, changes. This change is detected

by the electronics and is converted into a switch output (either relay or PNP/NPN

unit’s

depending on the model).

The red LED in the housing stays blinking when the is in contact with the

product. The same light stays on continuously when there is no contact with the product,

giving a positive indication at all times that the LTU-2000is working.

All models are made with 316 Stainless Steel and are available with ECTFE or epoxy

coatings and hygienic fittings for sanitary applications. Standard versions can operate at

temperatures up to 80ºC (176ºF) and higher temperature versions can operate at

temperatures up to 120ºC (248ºF). All models (except the mini-versions) have

adjustable time delay adjustment of 1, 5, 10 or 20 seconds and also have a Wet/Dry

selection for both High and Low level application requirements.

LTU-2000

Features

Unaffected by variations in density, conductivity, dielectric constant or viscosity

Unaffected by foam, tank agitation or vibration

Available in Threaded, Sanitary and Flanged connections

Available with customized length options to best suit your application

All 316SS body and wetted parts, coating when necessary

Adjustable response time (from 1 to 20 seconds)

Relay and Transistor outputs available

ECTFE

04

Page 5

Models

LTUM1-DC

LTUM2-AC

®

LTUP-DC

HOUSINGNYLON

LTUM1-DC

®

LTUR

NYLON HOUSING

LTUM2-AC

®

LTUR-2012

ALUMINUM HOUSING

LTUR-2012

ALUMINUM HOUSING

05

Page 6

Models and Dimensions

Mounting Options for LTU-2000

76mm

89mm

Nylon

Aluminum Aluminum

89mm

80mm

126mm

LTUM

48mm

28mm

56mm

ø38mm

Extended Necks for High Temperature

MT

50mm

Extended necks for medium (up to 100ºC) and high temperature (up to 120ºC)temperature

HT

100mm

Insertion Length

Standard

80mm

TC Standard

LTU

64mm

TC Standard

LTUM

80mm

130mm

130mm

Extended Length

L

118mm

Process Connections

Threaded Connections

3/4”

1”

1½”

2”

NPT

1,75

BSP

Tri-Clamp Connection

1½”

2”

2½”

3”

TC Connection

Rubber Seal

Process Connection

Flange Connections

1”

FF

1½”

2”

RF

2½”

ANSI 150#

ANSI 300#

06

Page 7

Wiring Diagram

®

LTUP - Housing

Time Delay

Central LED

1

- Power Supply (+)

2- (-)

Power Supply

Power Supply

3 - PNP/NPN Output

or +24v/0v (I Máx 500mA)

4-

Ground

LTUP - with M12 Connector

1

- Power Supply (+)

2- (-)

Power Supply

3 - PNP/NPN Output

or +24v/0v (I Máx 500mA)

4-

Ground

LTUR - Universal Power Supply

Nylon Housing

Central LED

Power Supply

- Power Supply (+)

1

Power Supply

2- (-)

3 - Ground

(

)

(

)

4 - NO Contact

5 - Common

6-

NC Contact

LTUR - with M12 Connector

1

- Power Supply (+)

2- (-)

Power Supply

3 - NO Contact

(

)

(

)

4 - Common

5-

NC Contact

Time Delay Guide

ON

1

5

ON

10

ON

20

ON

Time Delay Guide

Wet/Dry

3

OUT

2

_

1

+

20…60Vdc

( IL ) 500 mA Máx

5

10

20

1

ON

ON

ON

ON

ON

1

1

1

1

2

2

2

2

WET

DRY

WET

DRY

Mode

®

2

1

4

Time Delay Guide

Time Delay

Relay Contact

5A - 220Vac

3

1

2

N

L

85... 264Vac (50/60Hz)

20...60Vdc

5

10 20

1

ON

ON

ON

ON

ON

1

1

1

1

2

2

2

2

2

1

4

5

6

WET

DRY

NC

NO C

®

Power Supply

AC: 20... 264Vac (50/60Hz)

(I) < 10mA

DC: 20...60Vdc

(I) < 6mA

The different key positions indicate

the time delay in seconds.

07

1

2

1

2

1

2

1

2

(1;5;10;20sec. )

Page 8

LTUR-2012 Universal Power Supply

Aluminum Housing

Power Supply

(

1

- Power Supply (+)

2- (-)

Power Supply

3 - Ground

4 - NO Contact

5 - Common

6-

NC Contact

LTUR-2012 with

M12 connector

1

- Power Supply (+)

2- (-)

Power Supply

3 - NO Contact

4 - Common

5-

NC Contact

)

(

)

3

2

1

_

+

20...60Vdc

(

)

(

)

20...264Vac

V-TORK-G

LTUM with DIN Connector 43650

To avoid burning the unit, make sure that the load has been

!

installed in series with the LTUM before powering it up.

ON

12

Wiring Diagram

LED Central

®

WET

DRY

1

6

5

4

20

5

10

Time Delay

Relay contact

5A - 250Vac

Time Delay Guide

LTUM1

LTUM2

+V

NC

OUT

3

2

NO

L1

3

2

DC 20...60 VdcDC 20...60 Vdc

0V

3

1

OUT

3

1

3

1

L1

N

1

3

2

4

AC 85...264VacAC 85...264Vac

2

4

NO

+V

NC

0V

1

2

LTUM

®

N

1

2

08

Page 9

LTUP and LTUR Status Guide

For LTUP / DC

®

Switch Position

Level

Out

WET

Probe Covered

Maximum

fail-safe

Probe Uncovered

DRY

Probe Covered

Minimum

fail-safe

Probe Uncovered

For LTUR (Universal Power Supply)

Level

NO - NC

4

5

Central LED

WET

(Blink)

DRY

(On)

WET

(Blink)

DRY

(On)

Central LED

09

Probe Covered

Probe Uncovered

WET

(Blink)

5

6

5

4

DRY

(On)

5

6

Page 10

LTUM Status Guide

LTUM1 / DC ( Operating Mode NC )

LTUM1 / DC ( Operating Mode NO )

LTUM2 / AC ( Operating Mode NC )

DIN43650 Connector

4

1

2

3

N-C

DIN43650 Connector

4

1

2

3

N-O

DIN43650 Connector

4

1

2

3

Ground

R

Ground

R

Ground

2A

R

20…60Vdc

+V OUT 0V

3

+

-

20…60Vdc

OUT +V 0V

3

+

-

85…264Vac

L1 N

3

L1

1

2

1

2

1

2

LTUM2 / AC ( Operating Mode NO )

N-C

DIN43650 Connector

Ground

4

1

2

3

N-O

N

85...264Vac

L1 N

3

1

2

L1

2A

R

N

10

Page 11

Installation

®

Confirm that the wire connections are correct

and that the available power supply is

compatible with the LTU unit.

Verify that the operating pressure and

temperature of the process corresponds to the

operating parameters of the unit.LTU

The can be installed at any angle of the pipe

LTU

or vessel to detect the presence of liquids.

Verify that the forks are inserted

into the medium

until the proper point within the vessel and that

they stay clear from the inside walls (Fig. 1 and2).

Ensure that the conduit is facing downward and

makes a U-turn on the bottom of the cable to avoid

moisture from entering the housing enclosure

(Fig.3).

For proper installation of the use the mark as

LTU

a reference for correctly positioning the forks. It is

recommended that the correct orientation be used

to avoid build up between the forks (Fig. 4).

Side View

(Fig.4)

(Fig.1)

(Fig.2)

Switching

hysteresis

1mm

Switching

point=1/2” (13mm)

11

Top View

(Fig.3)

Switching

hysteresis

1mm

Switching

point=1/2” (12mm)

Page 12

Seal the thread with Teflon tape before

installation (Fig. 1).

Handling

Fig. 1

Do not thread the unit into the vessel, or turn it,

by the housing (Fig. 2).

Use the correct tools during the installation of

the (Fig. 3).LTU

The should not be dropped or suffer any

LTU

impact or fall that could damage the electronics,

coating or the forks of the probe (Fig. 4 and5).

Periodic visual inspection of the is required to

check for corrosion or deposit build-up. If deposits

are found, clean the sensor to ensure optimum

performance.

When cleaning the Forks use a soft brush to

ensure that the coating or polishing is not

damaged or scratched.

Do not alter or bend the shape of the forks( Fig. 6).

LTU

Fig. 2

Fig. 3

Fig. 4

Fig. 5

Fig. 6

12

Page 13

Technical Specifications

LTUP

151020

ON

ON

ON

ON

ON

1

1

1

1

2

2

2

2

WET

2

1

DRY

Mode

WET

4

DRY

3

T

U

O

_

12

+

V-Tork01

18…60 V dc

(IL) 500 mA Máx

Nylon Enclosure

®

Application

Operating Voltage

Current Consumption

Output

Medium Viscosity

Accuracy

Repeatability

Time Delay

Switching Point

Load Current

Enclosure Material

Electrical Connection

Process Connection

Wetted Material

Level Switch for Liquids

20...60 Vdc

+/- 3mA

PNP (3 wires)

Max.: 20.000cs

0.1%

< 0.5mm

1 to 20 seconds (adjustable)

13mm from tip

500mA

Glass Filled Nylon

½” NPT, M12 Connector or Cable Gland

3/4” to 1 ½” BSP, NPT or Sanitary

316 Stainless Steel

Operating Temperature

Max Pressure

Class Protection

13

-14 to 176º F (-10 to 80ºC)

725 PSI (50 Bar)

NEMA 4 (IP 65)

Page 14

Technical Specifications

LTUR

6

5

4

3

2

6

5

4

3

2

151020

ON

ON

ON

ON

ON

1

1

1

1

2

2

2

2

2

1

4

5

6

3

1

2

WET

N

L

DRY

NO

CNC

20-264Vac(50/60Hz)

20-60 V dc

(I)<3mA

V-TorkRF-A

+

V=20...60Vdc

20...264Vac

V-TORK-G

1

WET

N

L

_

DRY

ON

20

5

10

1

112

1

L

+

V=20...60Vdc

20...264Vac

V-TORK-G

WET

N

_

DRY

ON

20

5

10

1

2

Nylon Enclosure

Application

Operating Voltage

Current Consumption

Output

Medium Viscosity

Accuracy

Repeatability

Time Delay

Switching Point

Load Current Relay

Enclosure Material

Electrical Connection

Process Connection

Aluminum EnclosureAluminum Enclosure

Level Switch for Liquids

20...60 Vdc

20...264 Vac (50/60Hz)

DC < 6mA

AC < 10mA

Relay (SPDT)

Max.: 20.000cs

0.1%

< 0.5mm

1 to 20 seconds (adjustable)

13mm from tip

5A ( 250 Vac)

Glass Filled Nylon or Aluminum

½” NPT, M12 Connector or Cable Gland

3/4” to 1 ½” BSP, NPT or Sanitary

Wetted Material

Operating Temperature

Max Pressure

Class Protection

316 Stainless Steel

-14 to 176º F (-10 to 80ºC)

725 PSI (50 Bar)

NEMA 4 (IP 65)

14

Page 15

Technical Specifications

LTUM1

LTUM1

®

LTUM1-DC

®

Application

Operating Voltage

Current Consumption

Output

Medium Viscosity

Accuracy

Repeatability

Time Delay

Switching Point

Load Current

Enclosure Material

Electrical Connection

Process Connection

Wetted Material

Level Switch forLliquids

20...60 Vdc

+/- 3mA

PNP (3 Wires)

Max.: 20.000cs

0.1%

< 0.5mm

1 sec.

13mm from tip

500mA

316 Stainless Steel

Plug DIN 43650

3/4” to 1 ½” BSP, NPT or Sanitary

316 Stainless Steel

Operating Temperature

Max Pressure

Class Protection

15

-14 to 248º F (-10 to 120ºC)

725 PSI (50 Bar)

NEMA 4 (IP 65)

Page 16

LTUM2

Technical Specifications

LTUM2

LTUM2-AC

®

Application

Operating Voltage

Current Consumption

Output

Medium Viscosity

Accuracy

Repeatability

Time Delay

Switching Point

Load Current

Enclosure Material

Electrical Connection

Process Connection

Wetted Material

Level Switch for Liquids

85...264 Vac

+/- 3mA

Direct Load Switching (2 Wire)

Max.: 20.000cs

0.1%

< 0.5mm

1 sec.

13mm from tip

500mA

316 Stainless Steel

Plug DIN 43650

3/4” to 1 ½” BSP, NPT or Sanitary

316 Stainless Steel

Operating Temperature

Max Pressure

Class Protection

-14 to 248º F (-10 to 120ºC)

725 PSI (50 Bar)

NEMA 4 (IP 65)

16

Page 17

Trouble Shooting

®

Fault

Does not switch

Incorrect

switching

Case

The central LED is not on

The LED flashes 3 times/sec.

The LED flashes once

every 2 seconds

The LED flashes once

every 4 seconds

The Fork is encrusted with

build-up

Dry=on

Wet=on

Fast switching

Solution

Verify the Power Supply

Internal failure

Internal failure

High current load or short circuit.

Check the installation.

Clean the forks

Properly configure the key switch

Select a longer time delay

17

Page 18

Page 19

M-3991/0712

Loading...

Loading...