Omega Products LDX-CA Installation Manual

An OMEGA Technologies Company

User’s Guide

http://www.omega.com

e-mail: info@omega.com

LDX-CA

LDX-CA card

LDX-CA M-3373 09/05

Page 1 of 16

OMEGAnet® On-Line Service

http://www.omega.com

Internet e-mail

info@omega.com

Servicing North America:

USA: One Omega Drive, Box 4047

ISO 9001 Certified

Stamford, CT 06907-0047

Tel: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1

Tel: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Customer Service: 1-800-622-2378 / 1-800-622-BEST

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

SM

SM

SM

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico and

Latin America: Tel: (95) 800-826-6342 FAX: (95) 203-359-7807

En Espan˜ol: (95) 203-359-7803 e-mail: espanol@omega.com

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

Tel: (31) 20 6418405 FAX: (31) 20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: nl@omega.com

Czech Republic: ul. Rude armady 1868, 733 01 Karvina-Hranice

Tel: 420 (69) 6311899 FAX: 420 (69) 6311114

Toll Free: 0800-1-66342 e-mail: czech@omega.com

France: 9, rue Denis Papin, 78190 Trappes

Tel: (33) 130-621-400 FAX: (33) 130-699-120

Toll Free in France: 0800-4-06342

e-mail: france@omega.com

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: 49 (07056) 3017 FAX: 49 (07056) 8540

Toll Free in Germany: 0130 11 21 66

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified

Northbank, Irlam, Manchester

M44 5EX, England

Tel: 44 (161) 777-6611 FAX: 44 (161) 777-6622

Toll Free in the United Kingdom: 0800-488-488

e-mail: info@omega.co.uk

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that apply. OMEGA is constantly pursuing certification

of its products to the European New Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts

no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient-connected applications

LDX-CA M-3373 09/05

Page 2 of 16

.

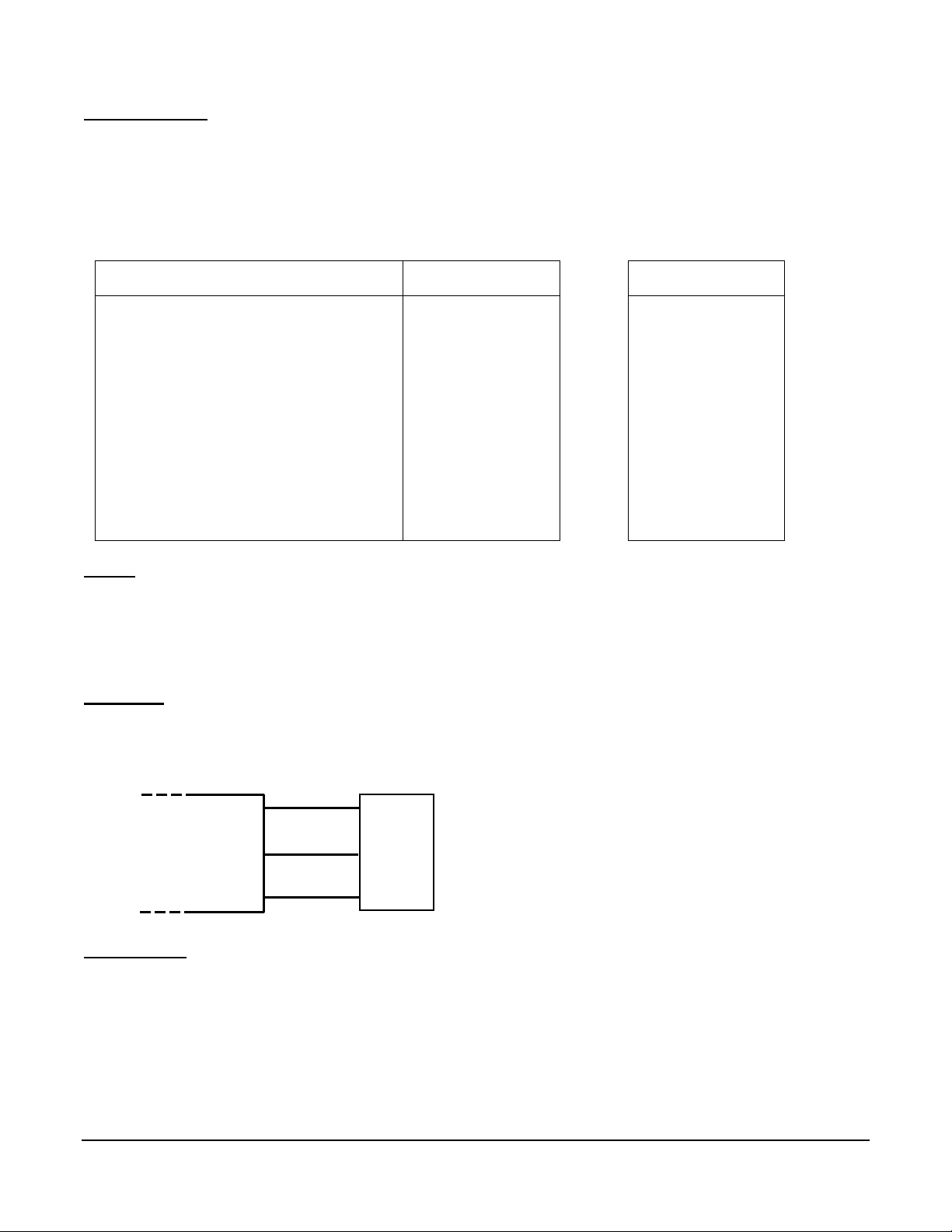

Introduction

The function of the card is to energize a transducer (LVDT, Half-Bridge or Full-Bridge) with a stable a.c.

waveform and to convert the output of the transducer to a d.c. voltage proportional to displacement, strain,

load etc. Several versions are available with either single or dual channel conditioning. An (AB)/2 facility

may be provided as an option.

The card should be powered from a stable twin rail d.c. supply of 15V.

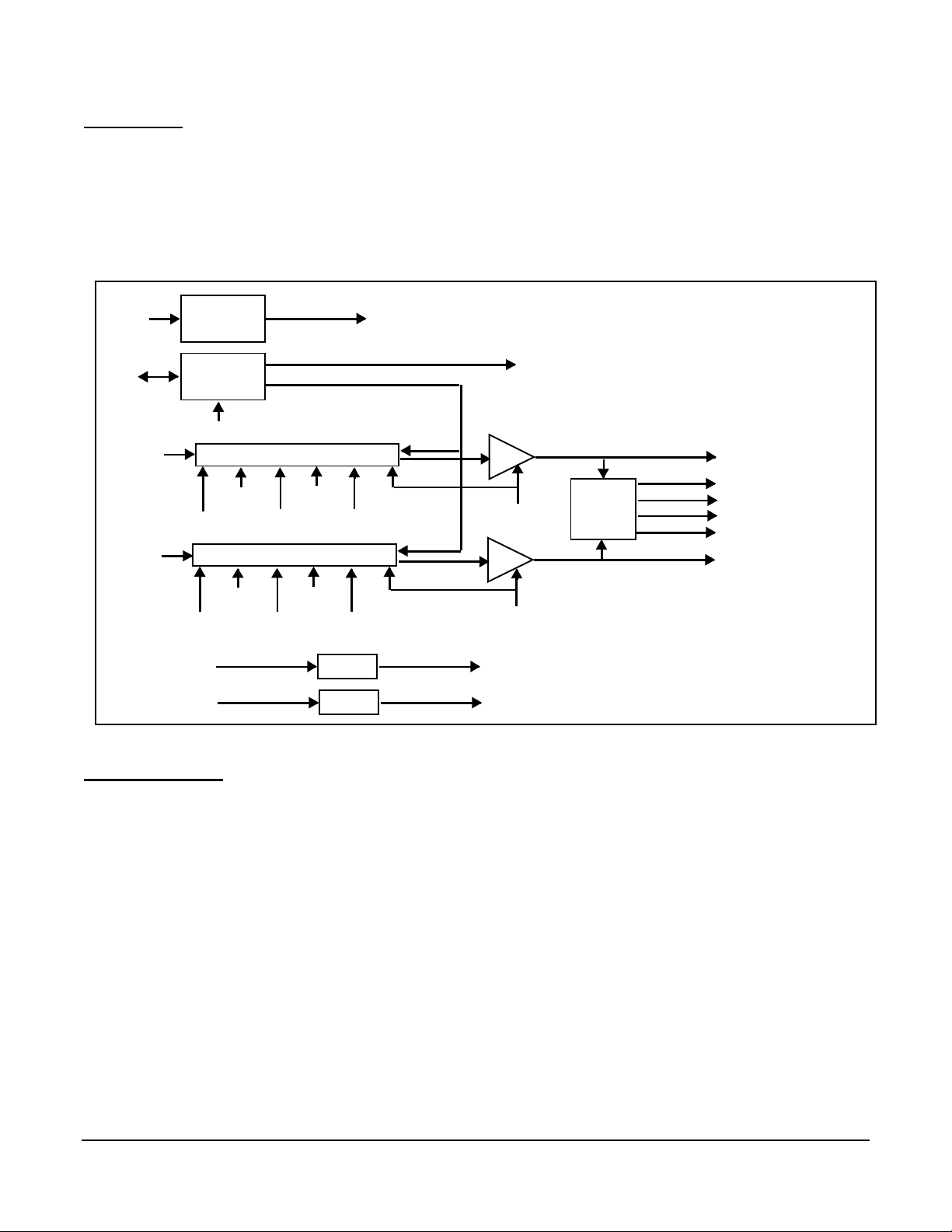

Figure 1 - Schematic

Power

Synch

Input from

transducer A

Input

impedance

select

Input from

transducer B

Input

impedance

select

Voltage input

Voltage input

Power

supply

protection

Oscillator

hybrid

Frequency

select

Demodulator hybrid

Coarse

gain

select

Demodulator hybrid

Coarse

gain

select

Coarse

zero

select

Coarse

zero

select

Reference

Fine

zero

set

Fine

gain

set

Fine

zero

set

Fine

gain

set

Current

Driver

Current

Driver

To all sections

Transducer drive

Output

filter

select

Output

filter

select

Current output

Current output

(A+B)/2

CIRCUIT

*

*

Option

Channel A

output

A+B

(A+B)/2

A-B

(A-B)/2

Channel B

output

Circuit Operation

Power supply protection is provided to protect against reversed power rails, the circuit is also tolerant of the

disconnection of one supply. A pair of zener diodes offer basic protection against voltage spikes on the

supply rails.

The oscillator hybrid drives the transducer and the signal from the transducer is fed into the demodulator

hybrid.

The d.c. output from the demodulator is fed into another filter to reduce output ripple even further and hence

to the output.

The (AB)/2 facility offers four outputs based on the two transducer outputs (A and B). These are A+B, A-B,

(A+B)/2, (A-B)/2 and they can be used for measuring diameters etc. where two transducers are involved.

The current drivers are wired up separately and so can be used with any of the d.c. outputs.

In order to exploit the transducer to the full, a number of facilities are provided. Span is adjustable in 9

coarse ranges and with a fine span control to allow the use of transducers with sensitivities in the range

0.5mV/V to 750mV/V for a full scale output of 5V d.c. Coarse and fine zero controls are provided to enable

the transducer to be zeroed anywhere in its stroke. Two operating frequencies are provided, 5kHz and

10kHz and the output filter cut off frequency can be set to 500Hz to 1kHz to allow for the best response

time/output ripple trade off. The standard card is provided with an input transformer and a pair of resistors to

be used when half-bridge transducers are in use. These two resistors are precision low drift types to reduce

drift. (The transformer option should be used in critical Half-Bridge applications.)

LDX-CA M-3373 09/05

Page 3 of 16

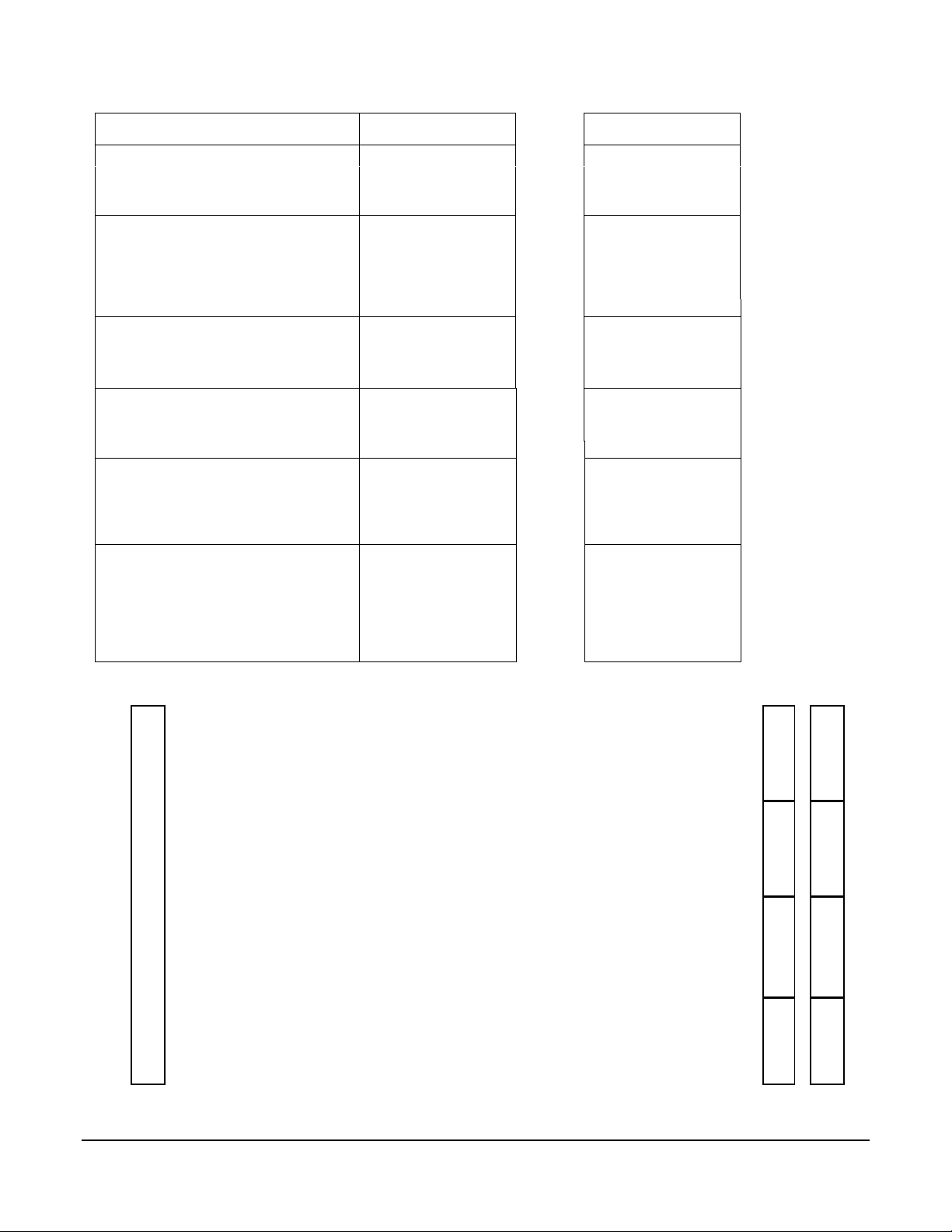

Figure 2 - Connections

FUNCTION

DIN 41612

PINS

SCREW TERMINAL

Power Supply

+15V dc 32a & c 32

0V 30a & c 30

-15V 28a & c 28

Transducer Drive

Oscillator Output (LVDT Red) 22a & c 22

Oscillator 0V Return (LVDT Blue) 20a & c 20

Oscillator/2 for use with Half-Bridges 18a & c 18

Synch (to Synchronize cards) 21a 21

Transducer Screens 24a & c 24

Channel A Demodulator

Input (LVDT White) 16a & c 16

Input return (LVDT Green) 14a & c 14

dc output 26a & c 26

Channel B Demodulator

Input (LVDT White) 19a 19

Input return (LVDT Green) 17a 17

dc output 23a 23

Current Drivers

Driver A input 25a 25

Driver A output 27a 27

Driver B input 29a 29

Driver B output 31a 31

(A B)/2 Section

A+B Output 7a 7

(A+B)/2 Output 9a 9

A-B Output 11a 11

(A-B)/2 Output 13a 13

Selected Output X 15a 15

Selected Output Y 15c

Figure 3 – Card Layout

a

32

1cca

End view on pins

DIN 41612 Connector

32

30

28

26

24

22

20

18

16

14

12

10

Top view (Component Side)

Screw Terminals

31

29

27

25

23

21

19

17

15

13

11

8

6

4

2

9

7

5

3

1

LDX-CA M-3373 09/05

Page 4 of 16

Potentiometers

If it is required to mount the span or zero potentiometers remotely, the pins are available on the edge

connector to do so. Wire lengths should be kept short to avoid pick up of electrical noise, and lengths greater

than 0.55 yards (0.5m) may cause some degradation of performance.

The potentiometer leads should be wired to the pins specified in external connections, ensuring the

clockwise and anticlockwise leads are not reversed.

Figure 4 -

FUNCTION

Potentiometers

Span and zero potentiometers are

connected to the edge connector, so

that they can be replaced by ones

off board.

Channel A & B Zero Clockwise 8a & c 8

Channel A & B Zero Counterclockwise 10a & c 10

Channel A Zero Wiper 12a & c 12

Channel B Zero Wiper 5a 5

Channel A & B Span Clockwise 2a & c 2

Channel A Span Counterclockwise 4a & c 4

Channel A Span Wiper 6a & c 6

Channel B Span Counterclockwise 1a 1

Channel B Span Wiper 3a 3

DIN 41612

PINS

SCREW TERMINAL

Synch

Pin 21a is a synchronizing pin to be used in systems using more than one card. Link pin 21a on all cards

together with short wires to synchronize the oscillators.

If this is not done it is possible to create beat notes between oscillators causing fluctuations in the dc

outputs.

Wiring Up

This section details how to connect the card to power supplies, transducer and readouts.

Figure 5 - Power Supply

+15V

0V

-15V

Power

Supply

Unit

CAH

CARD

32a&c

30a&c

28a&c

Transducers

The LDX-CA card can be used with three different types of transducers: LVDT, Full-Bridge or Half-Bridge

(either inductive or resistive). Note that on the dual channel card the two transducers are driven in parallel,

but their outputs go to separate demodulators.

LDX-CA M-3373 09/05

Page 5 of 16

Loading...

Loading...