Page 1

User’s Guide

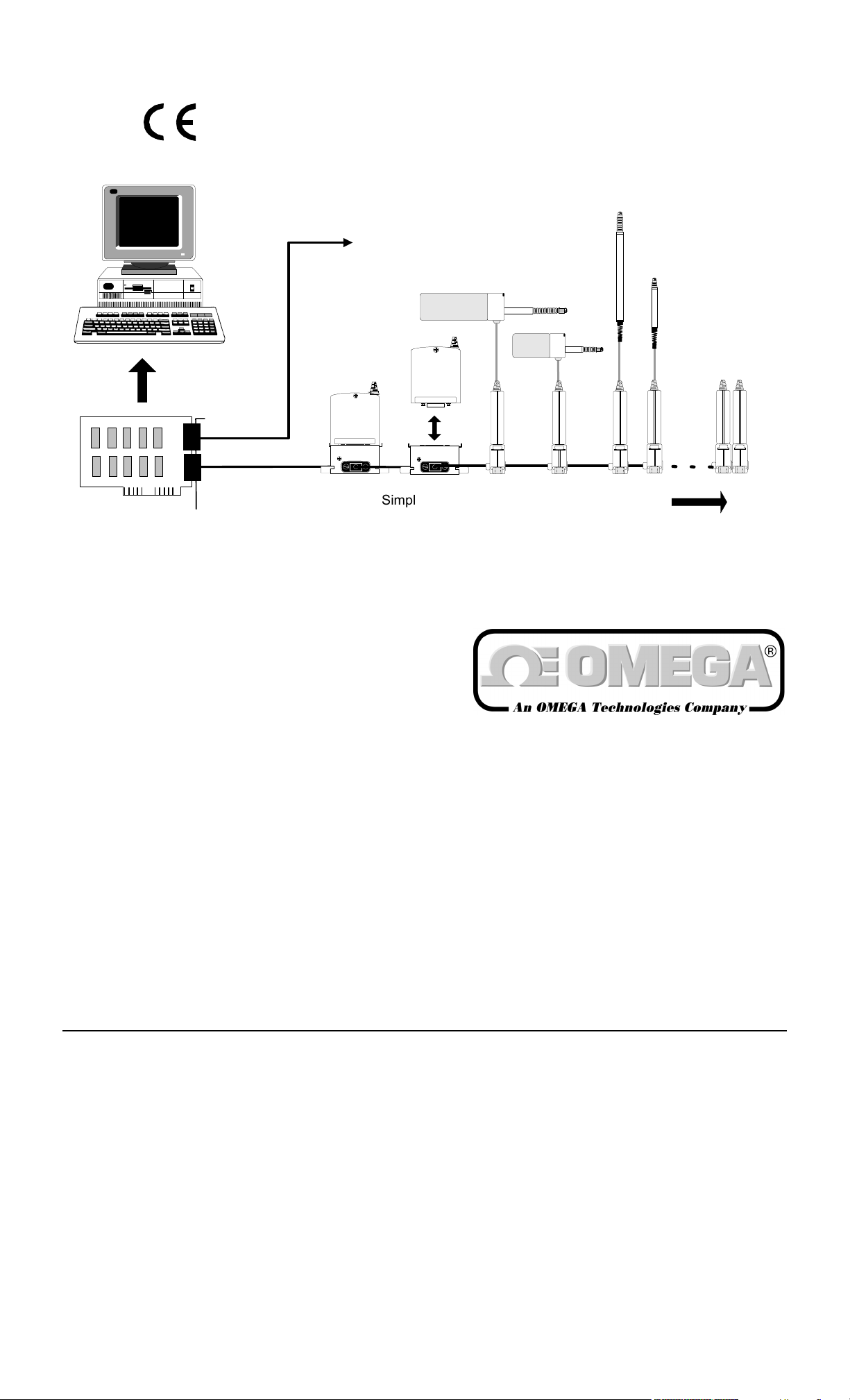

Orbit Network Card

(Up to 4 cards per PC)

Channel 1

Channel 2

Up to 31

Modules

6

9

51

Simple installation

using T-CON

Mixed probe

capability

Up to 31 Modules

per Channel

network.wmf

http://www.omega.com

e-mail: info@omega.com

LDN101

Network Card and Driver

LDN101 M-3338 02/99

Page 1 of 54

Page 2

OMEGAnet® On-Line Service

http://www.omega.com

Internet e-mail

info@omega.com

Servicing North America:

USA: One Omega Drive, Box 4047

ISO 9001 Certified

Stamford, CT 06907-0047

Tel: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1

Tel: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Customer Service: 1-800-622-2378 / 1-800-622-BEST

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico and

Latin America: Tel: (95) 800-826-6342 FAX: (95) 203-359-7807

En Espan˜ol: (95) 203-359-7803 e-mail: espanol@omega.com

SM

SM

SM

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

Tel: (31) 20 6418405 FAX: (31) 20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: nl@omega.com

Czech Republic: ul. Rude armady 1868, 733 01 Karvina-Hranice

Tel: 420 (69) 6311899 FAX: 420 (69) 6311114

Toll Free: 0800-1-66342 e-mail: czech@omega.com

France: 9, rue Denis Papin, 78190 Trappes

Tel: (33) 130-621-400 FAX: (33) 130-699-120

Toll Free in France: 0800-4-06342

e-mail: france@omega.com

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: 49 (07056) 3017 FAX: 49 (07056) 8540

Toll Free in Germany: 0130 11 21 66

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified

Northbank, Irlam, Manchester

M44 5EX, England

Tel: 44 (161) 777-6611 FAX: 44 (161) 777-6622

Toll Free in the United Kingdom: 0800-488-488

e-mail:

info@omega.co.uk

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that apply. OMEGA is constantly pursuing certification of

its products to the European New Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts

no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING

LDN101 M-3338 02/99

: These products are not designed for use in, and should not be used for, patient-connected applications

Page 2 of 54

.

Page 3

TRADEMARKS

IBM and PC-DOS are registered trademarks of International Business Machines.

MS-DOS, Quick Basic, Quick C, Quick Pascal and are registered trademarks of Microsoft Corporation.

Turbo Pascal is a registered trademark of Borland International.

LDN101 M-3338 02/99

Page 3 of 54

Page 4

CONTENTS

Section Page

1 Introduction

1.1 Safety Summary 6

1.2 This Manual 6

1.3 PC System Requirements 6

1.4 Carton Contents 6

1.5 Glossary 6

2 Installing The Orbit Network Card

2.1 Introduction 7

2.2 Precautions 7

2.3 Card Preparation 7

2.4 Installation 9

2.5 Software Installation 11

2.6 Orbit Network Card Specification 12

3 Setting-Up The Orbit Network Measurement System

3.1 Introduction 13

3.2 Connecting The Orbit Network 13

3.3 System Power Requirements 13

4 The Orbit Network Card Driver

4.1 Making Backup Copies 15

4.2 Driver Types 15

4.3 Memory Driver Installation and PC Configuration 16

4.4 Linkable Network Card Driver 16

4.5 Driver Error Codes 17

5 Using the Utility Programs

5.1 ORBSET.EXE 18

5.2 ORBINST.EXE 20

6 Orbit Network Commands

6.1 Introduction 23

6.2 Orbit Command Summary 24

6.3 Orbit Command Application Table 26

6.4 Orbit Command Detail Descriptions 27

6.5 Probe Error Codes 41

7 Example Application Programs

8 Installation of PIE and T-CON

Warranty/Disclaimer

18

23

42

48

53

LDN101 M-3338 02/99

Page 4 of 54

Page 5

This page intentionally left blank.

LDN101 M-3338 02/99

Page 5 of 54

Page 6

1.0 Introduction

1.1 Safety Summary

Terms in this manual :-

WARNING

CAUTION

statements identify conditions or practices that could result in personal injury or loss of life.

statements identify conditions or practices that could result in damage to the equipment or other property.

Symbols in this manual :-

This symbol indicates where applicable cautionary or other information is to be found.

!

WARNINGS:

Do not operate in an explosive atmosphere

To avoid explosion, do not operate this equipment in an explosive atmosphere.

NOTES:

This equipment contains no user serviceable parts

This equipment must be returned to an Omega Dealer for all service and repair.

Low Voltage

This equipment operates at below the SELV and is therefore outside the scope of the Low Voltage Directive.

1.2 This Manual

This manual covers the Orbit Network installation and provides information and guidance on using the Orbit software

driver, installation of software together with detailed descriptions of Module commands. The information is principally

for users of IBM PC systems who wish to develop applications programs for use with the Orbit Network Measurement

System.

1.3 PC System Requirements

The Orbit Network and accompanying software have been designed for use on IBM PC/XT/AT and fully compatible

systems with:

(a) A minimum of 640K user memory;

(b) DOS version 3.0 or higher;

(c) One free slot (half card);

(d) Sufficient +5V power available from the PC to operate the Orbit Network(s) and Orbit module(s).

1.4 Carton Contents

The Orbit Network Card is supplied in a carton with the following accompanying items:

(a) Cable 6.5 feet (2 metre) long 9 Pin D-Type plug to socket;

(b) 9-Pin D-Type Terminator plug;

(c) A 3

(d) This operating manual.

1

/

” disk carrying the Driver and installation software;

2

1.5 Glossary

Orbit Module Generic description for any module that can attach to the Orbit

Network. This may have built in intelligence or be a simple interface.

Probe Interface Electronics

(PIE)

An Orbit Module that contains Electronic circuit to interface between

a particular type of Probe or Transducer and the Orbit network i.e.

Digital Probe PIE and Linear Encoder PIE.

Interface Module (IM) An Orbit Module used to interface in a non-probe application such as

power supplies (PSIM) and RS232 (RS232IM)

LDN101 M-3338 02/99

Page 6 of 54

Page 7

2.0 INSTALLING THE ORBIT NETWORK CARD

2.1 Introduction

This chapter describes the preparation and installation of the Orbit Network card in an IBM PC/XT/AT or fully

compatible system.

2.2 Precautions

Before handling the Orbit Network card read the following warning information.

Static Electricity

2.2.1

The Orbit Network card contains components that can be damaged by static electricity. To reduce

the risk of damage to the card keep it in its conductive plastic packaging until it is required. When

!

fitting the card handle it by its free edges and do not touch the card edge

connector

High Voltages

2.2.2

Before opening the cabinet of the computer, switch the power off and disconnect the supply lead

from the mains power supply. Do not operate the unit with the cover removed.

!

This equipment contains no user serviceable parts

2.2.3

This equipment contains no user serviceable parts except for the card number and base

selection switch. This equipment must be returned to a Omega Dealer for all service and repair.

!

2.3 Card Preparation

2.3.1 Card Number and Base address Switch

Before fitting the Orbit Network card in the host computer, the card number and base address have to be set. These

are set by means of the 8 way DIL (dual in line) switch on the card, see below.

ON

OFF

Card

Number

ON

OFF

Not

Used

1 2 3 4 5 6 7 8

All Cards (1 - 4 )

Base Address

cardswit.wmf

LDN101 M-3338 02/99

Page 7 of 54

Page 8

Base Address Selection

2.3.2

The base address can be set to any even address in the range 100(Hex) to 11E(Hex) and 300(Hex) to 31E(Hex).

The only restrictions on the choice of address are those due to conflicting port usage within the PC. The following

table shows some of the I/O channel port assignments originally defined by IBM.

I/O CHANNEL PORT ASSIGNMENTS

Port values (Hex) Function

1F0 - 1F8 Fixed Disk

200 - 20F Game control

210 - 217 Expansion unit

220 - 24F Reserved

278 - 27F Reserved

2F0 - 2F7 Reserved

2F8 - 2FF Asynchronous communications (secondary)

300 - 31F Prototype card

320 - 32F Fixed disk

378 - 37F Printer

380 - 38C SDLC communications

380 - 389 Binary synchronous communications (secondary)

3A0 - 3A9 Binary synchronous communication (primary)

3B0 - 3BF IBM monochrome display/printer

3C0 - 3CF Reserved

3D0 - 3DF Color/graphics

3E0 - 3F7 Reserved

3F0 - 3F7 Diskette

3F8 - 3FF Asynchronous communications (primary)

To avoid conflicting port assignments, ensure that both the base address and the base address +1 are not assigned

to other hardware in the PC. Card base address section is shown in the table below:

SWITCH

45678 (HEX)

OFF OFF OFF OFF OFF 100

OFF OFF OFF OFF ON 102

OFF OFF OFF ON OFF 104

OFF OFF OFF ON ON 106

OFF OFF ON OFF OFF 108

OFF OFF ON OFF ON 10A

OFF OFF ON ON OFF 10C

OFF OFF ON ON ON 10E

OFF ON OFF OFF OFF 110

OFF ON OFF OFF ON 112

OFF ON OFF ON OFF 114

OFF ON OFF ON ON 116

OFF ON ON OFF OFF 118

OFF ON ON OFF ON 11A

OFFONONONOFF 11C

OFFONONONON 11E

ON OFF OFF OFF OFF 300

ON OFF OFF OFF ON 302

ON OFF OFF ON OFF 304

ON OFF OFF ON ON 306

ON OFF ON OFF OFF 308

ON OFF ON OFF ON 30A

ON OFF ON ON OFF 30C

ON OFF ON ON ON 30E

ON ON OFF OFF OFF 310

ON ON OFF OFF ON 312

ON ON OFF ON OFF 314

ON ON OFF ON ON 316

ON ON ON OFF OFF 318

ON ON ON OFF ON 31A

ON ON ON ON OFF 31C

ON ON ON ON ON 31E

CARD BASE

ADDRESS

LDN101 M-3338 02/99

Page 8 of 54

Page 9

Orbit Network Card Number Selection

2.3.3

The card number switch allows up to 4 cards to share the same base address in the PC. For correct operation each

card in the PC must have the same base address and a different card number. The method of card number selection

is shown in the table below.

SWITCH CARD NUMBER

12

OFF OFF 1

OFF ON 2

ON OFF 3

ON ON 4

Note: Orbit Network cards are shipped as base address 100(Hex) and card number 1.

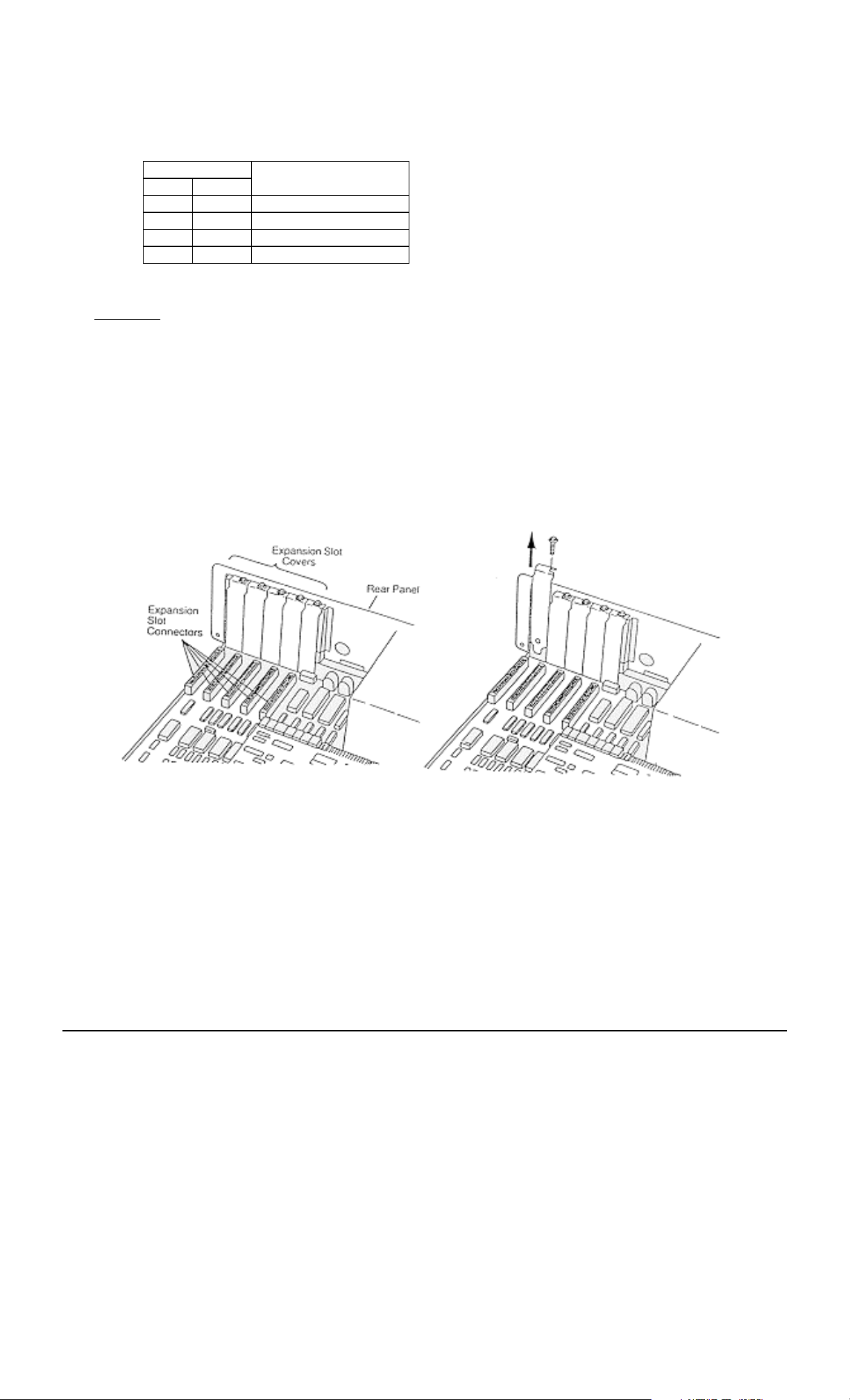

2.4 Installation

The Orbit Network card can be installed in one half slot of either the system unit or an expansion unit. The procedure

is the same in both cases.

2.4.1 Refer to the user manual of the computer being used for instructions on removing the outer casing or access

panels. Be sure to follow any special instruction that may apply to installation of cards in the computer being

used.

2.4.2 Remove the screw holding the expansion slot cover in place and slide out the expansion slot cover. Save this

screw for fitting the Orbit Network card later. Card support brackets that provide additional security for long

option cards are available from IBM sources. These may already be fitted. If required, fit these now, to the front

panel of the PC chassis, by pushing into the holes

provided.

LDN101 M-3338 02/99

Page 9 of 54

Page 10

2.4.3 Remove the Orbit Network card from its conductive packaging. Handle the card by its edges only. Set switches

to appropriate address.

2.4.4 Holding the Orbit Network card by its corners, press it firmly into the expansion slot.

2.4.5 Align the ’U’ shaped slot in the card-retaining bracket with the hole in the rear of the unit. When

fitted, the screw should be snug against the inside of the ’U’. Fit and tighten the screw.

2.4.6 Refit the cabinet cover and retaining screws according to the computer manufactures Instructions.

LDN101 M-3338 02/99

Page 10 of 54

Page 11

2.5 Software Installation

The Orbit Network card requires a driver program to interface between the application programs and the Orbit

Network card. For further details refer to the section on the Orbit Network Card Driver.

LDN101 M-3338 02/99

Page 11 of 54

Page 12

2.6 Orbit Network Card Specification

Electrical

Power Consumption 200 mA max.(no Orbit Modules connected)

RS485 serial two wire differential

Dual channel 9 Pin sub D (sockets fitted to PC card)

Network terminator 120R (between 2 and 3) of 9 Pin D-type

Parallel connected 9 Pin D connectors male and female are pin to pin connected on the network

9 Pin D designations

1 = Not used

2 = A (RS485)

3 = B (RS485)

4 = 0V

5 = 0V

Pin 1

1

6

9

5

Channel 1

6 = +5V

7 = +5V

8 = +5V

9 = 0V

Pin 1

1

6

9

5

Channel 2

orbcard.wmf

ORBIT Network

:

General The Orbit Measurement System communicates with multiple Orbit

Modules, via an RS485 multi-drop network.

Communications Method Asynchronous, half duplex, poll / response

Baud Rate 187.5 K Baud

Data Byte Structure 1 start, 8 data, 1 odd parity, 1 stop bit

Network Control Break character implemented

(low(space) signal of >90 µs)

Network 1,000 readings per second minimum

Reading Rate

Max. Number of Orbit Modules 31 addressed per channel (62 per PC card)

Max. Cards per System 4 off Orbit Network Cards giving Max. 248 Orbit Modules

PC Bus:

Communication Method A special hardware protocol allows data to be passed between the

Orbit Network Card and the device driver (ORBITDVR.SYS)

Command Set The commands available via ORBITDVR.SYS are listed in the Orbit

Network Commands section.

LDN101 M-3338 02/99

Page 12 of 54

Page 13

3.0 SETTING UP THE ORBIT MEASUREMENT SYSTEM

3.1 Introduction

This section gives some basic information on the connection of the various components of an Orbit Measurement

Network. It is assumed that an Orbit Network card has been installed in a PC and that this PC will be used to provide

power to the Orbit Network. For further details about the mechanical installation of PIE, Orbit Modules, probes and TCON refer to the section on Installation of PIE and T-CON.

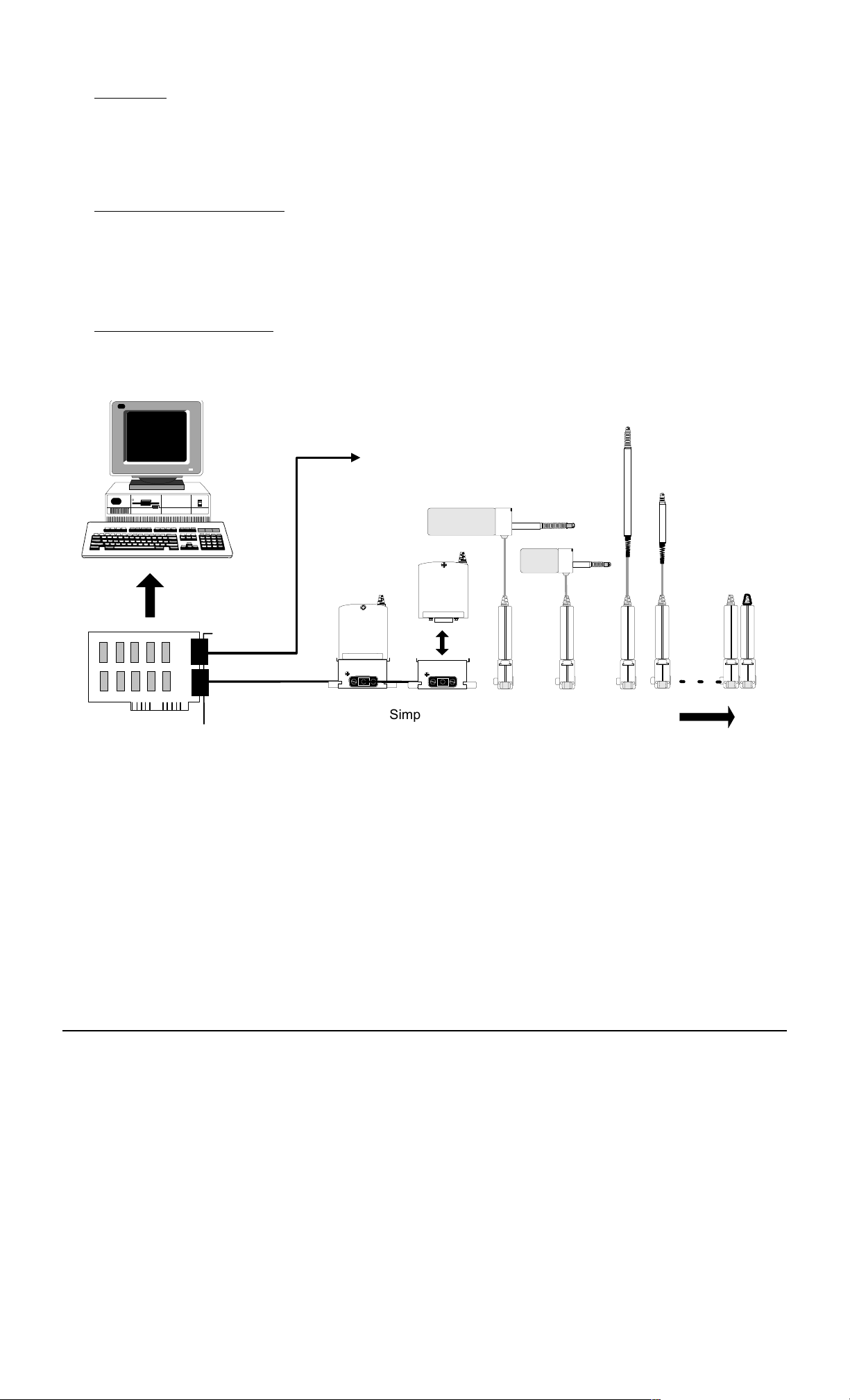

3.2 Connecting The Orbit Network

The Orbit network must be fully connected before switching on the PC or other power supply. Using the 9 pin ’D’

type cable provided, connect between the appropriate channel on the Orbit Network card and the Orbit Module(s), an

example Orbit Network is shown below.

3.3 System Power Requirements

Because the Orbit Network obtains its power from the PC the following factors should be taken into account to

ensure correct operation. If this is not possible consult your Omega Dealer for advice.

Up to 31

Modules

Mixed probe

capability

Channel 1

6

9

51

Channel 2

Up to 31 Modules

per Channel

network.wmf

Orbit Network Card

(Up to 4 cards per PC)

PC’s +5V Power Supply Capacity

3.3.1

Simple installation

using T-CON

All PC’s have a nominal +5.0 Volt regulated DC supply which is available to the Orbit Network. This supply must

have sufficient capacity to power the number of Orbit Modules required for the system. Although most PC’s will have

enough power supply capacity, it is worth checking the total system power requirement before switching the PC on.

Note that a Orbit Network with 62 Orbit Modules connected will require about 4 Amps (typically 60 mA per Orbit

Module plus 200 mA for the Orbit Network card). For power requirements of individual Orbit components refer to

sections relating to those modules.

LDN101 M-3338 02/99

Page 13 of 54

Page 14

Orbit Network Voltage Drop

3.3.2

All Orbit Modules are designed to work from a supply voltage of 4.75 to 5.25 V d.c. and care must be taken to

ensure that all modules especially those furthest from the power supply have the right working voltage applied.

When being used with a PC power supply it is unlikely that the upper voltage limit will be exceeded, but the possibility

of Orbit Module voltages dropping below the lower voltage limit can exist. Factors that will contribute to a drop in

voltage are connecting cable length and resistance.

If any doubt exists, a digital voltmeter should be used to check the voltage at the last Orbit Module in the Orbit

Network. This can be done by removing the terminator plug and measuring the voltage between pins 6 and 9 on the

socket, as shown below.

If the voltage is below 4.75 V dc the configuration must be re-arranged to reduce the voltage drop.

Orbit Network Card

Installed in PC

up to 31 Orbit

Modules per

channel

1 = No connection

2 = RS485 (A)

3 = RS485 (B)

4 = 0V

5 = 0V

6 = +5V

7 = +5V

8 = +5V

9 = 0V

5

9

1

6

V

Must be within 4.75 V

dc and 5.25 V dc

LDN101 M-3338 02/99

Page 14 of 54

Page 15

4.0.THE ORBIT NETWORK CARD DRIVER

4.1 Making Backup Copies

Before using the software provided make a backup copy of the Software Support disk supplied. The copy should be

stored in a safe place and used only to restore the original if it gets damaged. All the files on the disk are listed in the

file CONTENTS.LST.

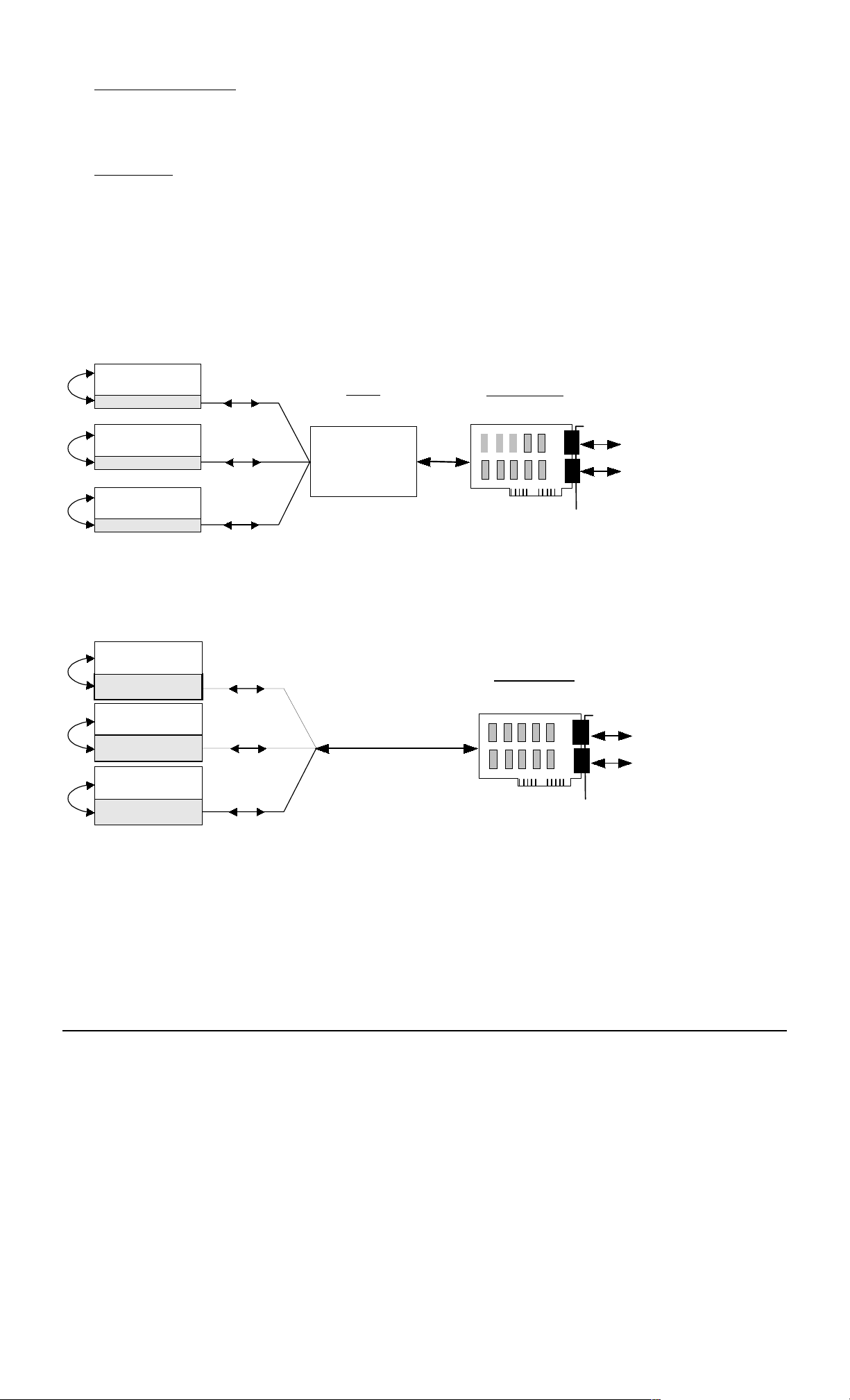

4.2 Driver Types

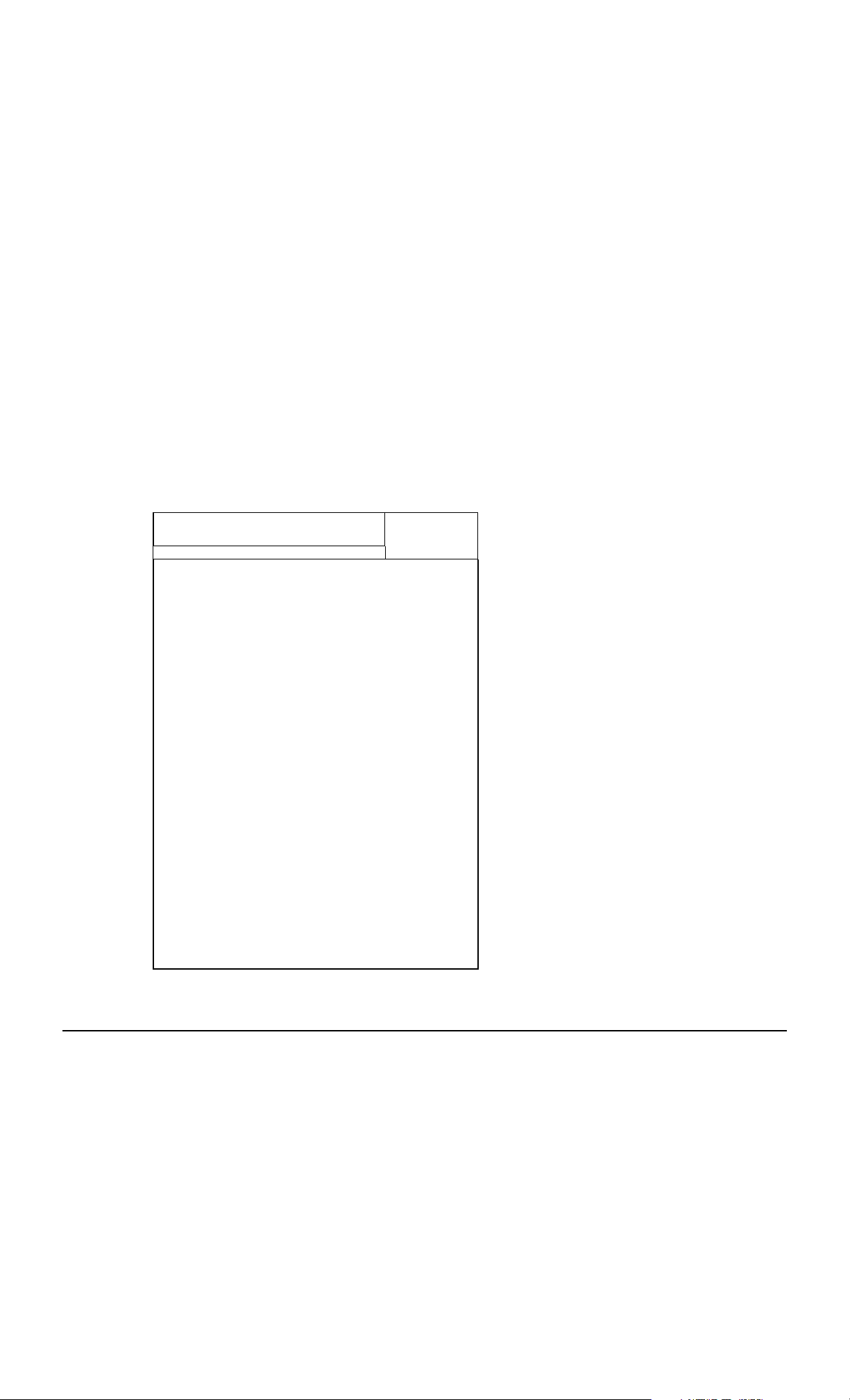

There are two ways an application program can be interfaced with the Network Card; via a resident driver which is

loaded into the PC’s memory or via an object module which is linked with each application program. See diagrams

below.

The first method, in which the link to the driver is through the small section of code called ODVRIFxx.OBJ, is more

efficient if several programs will need access to the Network Card. See Software Support disk.

The second method has the advantage of being ‘stand alone’ and does not involve a change to the PC’s config.sys

file. The link to the Network Card is through the larger ONCIFxx.OBJ. which is linked with each application during

code compilation. See Software Support disk.

Application 1

ODVRIF code

Application 2

ODVRIF code

Application 3

ODVRIF code

Application 1

ONCIF code

Application 2

ONCIF code

Driver

loaded via config.sys

Network Card

ORBITDVR

Resident in

PC memory

Card Interface Using Memory Resident Driver

Network Card

Orbit

Network

Orbit

Network

Application 3

ONCIF code

dvr_drg.wmf

Card Interface Using Linkable Driver

LDN101 M-3338 02/99

Page 15 of 54

Page 16

4.3 Memory Driver Installation and PC Configuration

The Driver is an installable device Driver which occupies approximately 1.5K bytes of the PC’s memory.

To load the Driver the ORBITDVR.SYS file should be copied from the disk supplied to the boot disk of the PC. The

CONFIG.SYS file on the PC should then be edited to include the line:

DEVICE = <path> ORBITDVR.SYS /QB /QP /CA XXX

Where: <path> is the path to the ORBITDVR.SYS file.

/QB is the Quick Basic language interface.

/QC is the C / Quick C language interface.

/QP is the Quick / Turbo Pascal language interface.

/CA XXX is the required card base address for the Orbit Network(s).

( see note below for details )

Example : DEVICE=C:\ORBIT\ORBITDVR.SYS /QB /CA 100

This is for the driver installed in the C drive, in a directory ORBIT, language interface for Quick Basic and card at

base address 100h

Since each language interface uses an additional 3K of memory it is advisable to include only the language

interface(s) required. Note that at least one language interface (/QB /QC or /QP) must be selected. If the /CA switch

is omitted the card base address will be assumed to be set to 100h. See Installing The Orbit Network Card chapter

for a list of valid base addresses.

After the CONFIG.SYS file has been modified the PC should be re-booted via the <ctrl> <alt> <del> keys or a power

down. The PC will then restart with the Orbit Network Driver loaded into memory. The PC should then display a

screen similar to:-

ORBITDVR Orbit Network Card Driver Vx.xx

loading ORBITDVR at CS=ddddh

loading /QB at IP=bbbbh

loading /QC at IP=cccch

loading /QP at IP=pppph

card(s) Base Address : 0100h

Driver Ends At Offset : 3025h

To conserve conventional memory the Driver can be loaded into high memory by means of a suitable memory

manager as in example below.

device=C:\DOS\HIMEM.SYS

device=C:\DOS\EMM386.EXE NOEMS

devicehigh=C:\ORBITDVR.SYS /QB /QC /QP /CA100

See your DOS manual for details on memory manager usage.

4.4 Linkable Network Card Driver

With this technique the applications program is linked with an object module that contains the Network Card Interface

code appropriate to the language being used. These interface modules ONCIFB.OBJ, ONCIFC.OBJ etc. are linked to

the application via the LINK command line, Quick Libraries or .MAK files etc. to give access to the Orbit Network.

LDN101 M-3338 02/99

Page 16 of 54

Page 17

4.5 Driver Error Codes

The Driver can detect two forms of error: General and Parameter. In both cases the error code is passed to the

applications program via the ‘errorword’ , for correct operation errorword must be ‘visible’ to all sections of the

applications program that call the driver. An example can be seen in the Example Application Programs chapter.

Error codes can be produced by Orbit Modules and passed to the application program via the Orbit Network. Refer to

the Orbit Network Commands section for details.

General Errors

: upper byte 00h

Error Errorword Description

No Driver: 0001h A call to ODVRIFx has been made when the Driver is not loaded in

the PC’s memory or incorrect driver version.

Card Timeout: 0002h PC interface error. Contact Omega.

I/F Write TO: 0003h PC interface error. Contact Omega.

I/F Read TO: 0004h PC interface error. Contact Omega.

Bad Reply: 0006h Orbit Module reply byte 1 was not a valid ack byte or ’!’.

No Language 007Fh Language interface not loaded (check ORBITDVR.SYS).

Parity error: 00FEh The Orbit Network Card received a character with a parity error.

Timeout: 00FFh The duration between the last transmitted command byte from the

Orbit Network and the last received reply byte is greater than 65 µs.

Applications Program Parameter Errors

: upper byte 10h

Variables shown () are as used in Quick Basic example programs.

Error Errorword Description

bad_base 1001h Base address (BASEADDR%) out of range.

bad_card 1002h Card number (CARD%) not between 1 and 4.

bad_chnl 1004h Channel number (CHNL%) not between 1 and 2.

bad_oaddr 1008h Orbit Module address (OADDR%) not between 1 and 31.

bad_lgth_1 1010h First string in parameter list is wrong length

bad_lgth_2 1020h Second string in parameter list is wrong length

bad_lgth_3 1040h Third string in parameter list is wrong length

addr_alloc 1080h Address (OADDR%) already allocated (call to OrbitSetaddr).

Example :

OrbitIdentify

command parameters are :- card, channel, address, identity, devtype, version, stroke

where identity, devtype, version are strings (the rest are numbers)

bad_lgth_1 (errorword 1010h) would be returned if “identity” was the wrong length.

bad_lgth_2 (errorword 1020h) would be returned if “devtype” was the wrong length.

bad_lgth_3 (errorword 1040h) would be returned if “version” was the wrong length.

Note that more than one parameter error may be reported. The lower byte shows all error codes or’ed together, e.g.

1006h is bad_card and bad_chnl.

Depending on the type of error, the code may be for a single error type or for a combination (or’ed). Allocation of

error codes means that or’ed codes cannot be interpreted as individual codes.

LDN101 M-3338 02/99

Page 17 of 54

Page 18

5.0 USING THE UTILITY PROGRAMS

Two utility programs are provided: ORBSET.EXE and ORBINST.EXE, these programs offer an easy way to set-up

(or initialize) and interrogate networks of Orbit modules and can be used to verify the correct operation of the Orbit

Measurement System.

ORBSET.EXE is a simple text based DOS program that enables each module on a network to be identified and

assigned an address ID. Readings from modules can then be displayed. This program can save an ASCII file

(ORBITxy.DAT) that can be used by other programs to initialize a network of Orbit modules.

ORBINST.EXE is a program that uses ORBITxy.DAT (either created by ORBSET.EXE or entered directly as a text

file) to initialize an ORBIT network.

5.1 ORBSET.EXE

This program can initialize an Orbit module by reading the module identity and assigning it an address ID. The

program can then display readings from up to 31 modules. It is also able to create and modify ORBITxy.DAT files

(refer to ORBINST.EXE section for further details on ORBITxy.DAT files). To run the ORBSET.EXE program type:

ORBSET <return>

Input Orbit Network Card Base Address in hex (Q to quit) ? 100

Input card Number (1 to 4 or < Q > to quit ) ? 1

Input channel number (1 or 2) ? 1

Press < M > for millimetres < I > for inches or < Q > to quit ? M

Underscored values are defaults and will be selected if

If a ORBITxy.DAT file exists for the card and channel selected the following will appear:

Data file for Card x channel y exists - load(L) or Create new file (N)

<Esc> to quit

New file (N)

Load (L)

the screen. Any errors in the ORBITxy.DAT file will be displayed prior to the load being terminated.

The following screen examples demonstrate show this.

will load the address ID and Comment data from the ORBITxy.DAT file into the program and display it on

, you will then see the following screen:

<return>

,the default, will display a blank table ready for module ID’s and comments to be entered.

is pressed without entering a new value.

LDN101 M-3338 02/99

Page 18 of 54

Page 19

Create new file (N)

will display the screen:

FILE: ORBIT11.DAT Card: 1 Channel: 1

Addr ID Comments Addr ID Comments

01: 17:

02: 18:

03: 19:

04: 20:

05: 21:

06: 22:

07: 23:

08: 24:

09: 25:

10: 26:

11: 27:

12: 28:

13: 29:

14: 30:

15: 31:

16:

Address: 1 UNASSIGNED

-----Alternate Menu----

L

OAD DISPLAY RESET NETWORK

<TAB>

ADD COMMENT CLEAR ADDRESS

<SPACE>

NEXT MENU

The cursor keys can now be used to select the Orbit Module address between 1 and 31. When the desired address

has been selected the Menu keys can be used to perform the following actions:

<N>

Activates the notify mode. Any unaddressed Orbit Module will send back its ID when it is

displaced by approximately 1% of its stroke. The user can use this mode when

manual entry of ID is not practical, use the following sequence:

(1) Press N to select notify mode

(2) Press the Probe tip, the PIE will send back its ID (4) Press the return key to

accept the PIE ID - Address allocation. The address will then be

automatically incremented and the procedure can then be repeated for the

next unaddressed PIE.

<M>

<RETURN>

<S>

Moves an addressed Orbit Module to another address. The destination address is

selected by pressing the

<RETURN>

key. Press

<ESC>

or

<M>

to abort.

Allows the user to enter an ID at the selected address.

Saves the updated configuration to a data file ”ORBITxy.DAT” - where x and y are the

card and channel numbers respectively.

<SPACE>

Toggles between the two menu displays. Note that all menu keys are active even

when not displayed.

<L>

Re-loads the whole program. Use this to look at a different Orbit Network.

<D>

Displays the readings for the addressed Orbit Modules. It also shows the ID, its

software version and the transducer stroke.

See Screen display below:

<R>

<TAB>

LDN101 M-3338 02/99

Resets the whole Orbit Network. All IDs and comments are deleted.

Allows a comment to be added to any address.

Page 19 of 54

Page 20

<C>

Allows the user to de-allocate an ID at the selected address. The Orbit Module can then be

allocated to any free address.

<SPACE>

toggles between the two menu displays. Note that all menu keys are active even

when not displayed.

<Q>

Quit the program, the option of saving the data as a ORBITxy.DAT file is given before

terminating.

Load (L)

Selecting

D

(Display)

loads an existing ORBITxy.DAT file and will display the identities of each module. Selecting

will display the screen below:

FILE: ORBITxy.DAT Card: x Channel: y

READING IDENTITY VER MODULE READING IDENTITY VER MODULE

01: 0.9896 MODULEyz01 Vxx DP5 17:

02: 18:

03: UNDER MODULEyz02 Vxx DP2 19:

04: 0.3421 MODULEyz03 Vxx LE12 20:

05: 21:

06: 22:

07: 23:

08: 24:

09: 25:

10: 26:

11: 27:

12: 28:

13: 29:

14: 30:

15: 31:

16:

Displaying <Esc>To Exit

Q

UIT NOTIFY ID MOVE

<RET>

ENTER ID SAVE

<F1>

HELP

↑↓→←

<SPACE>

NEXT MENU

5.2.ORBINST.EXE

This program can be used in conjunction with ORBITxy.DAT files to initialize networks of Orbit Modules. The DAT

files are an easy way to recall a network configuration.

ORBITxy.DAT files

5.2.1

The ORBITxy.DAT file is an ASCII file which holds the set-up information for each of the 8 possible networks (4

cards, 2 channels). Each Orbit Network has its own DAT file which holds the Address - Identity map and any

comments for the Orbit Modules on the Orbit Network. The ORBITxy.DAT file name is always ORBITxy.DAT where x

is the card number and y is the channel, hence the file for card 3 channel 2 would be called Orbit32.dat.

LDN101 M-3338 02/99

Page 20 of 54

Page 21

The structure of the file is as shown below.

;This is an example of a ORBITxy.DAT file

;It holds the set-up data for a complete network of Orbit Modules

;

;Header comment lines must start with a ”;” there can be as many comment lines

;as required as long as they are not placed between Address - Identity lines

;

;Address - Identity line structure:- aa-iiiiiiiiii cccccccccccccccccccc

;a=address, i=identity [10 characters] c = comment [up to 20 characters maximum]

;

01-IDENTITY01 comment for address1

020304050607080910111213-IDENTITY02 comment for addr 13

1415161718192021222324-IDENTITY03 comment for addr 24

25262728293031-

Running ORBINST.EXE

5.2.2

To run the ORBINST.EXE program type:

ORBINST /CA100 <return>

The program will then search the current directory for ORBITxy.DAT files. Before the appropriate Orbit

Network is initialized the ORBITxy.DAT file is checked for syntax errors. Note that syntax errors can only occur

if the ORBITxy.DAT file has been created or edited outside of the ORBSET environment. If any Orbit Module

identities referred to in the ORBITxy.DAT file cannot be found during the initialization of the Orbit Network, the

error will be reported to the screen.

Note: /CA100 is the default network card base address and will be used if no extension is used. For more

information on base addresses refer to the section on Installing The Orbit Network Card.

LDN101 M-3338 02/99

Page 21 of 54

Page 22

With an error free ORBITxy.DAT file and the relevant Orbit Modules connected to the Orbit Network the screen

should look as below:

ORBINST Version 3.3 22/09/97

Base address set to be: 100H

FILE: ORBIT11.DAT CARD: 1 CHANNEL: 1

Finished: 0 Errors - 1 address set

FILE: ORBIT12.DAT CARD: 1 CHANNEL: 2

FILE NOT FOUND

FILE: ORBIT21.DAT CARD: 2 CHANNEL: 1

FILE NOT FOUND

FILE: ORBIT22.DAT CARD: 2 CHANNEL: 2

FILE NOT FOUND

FILE: ORBIT31.DAT CARD: 3 CHANNEL: 1

FILE NOT FOUND

FILE: ORBIT32.DAT CARD: 3 CHANNEL: 2

FILE NOT FOUND

FILE: ORBIT41.DAT CARD: 4 CHANNEL: 1

FILE NOT FOUND

FILE: ORBIT42.DAT CARD: 4 CHANNEL: 2

FILE NOT FOUND

The Report.dat file is a log file which records errors in any of the ORBITxy.DAT files found in the current directory,

this hard copy can help when correcting files with several errors.

LDN101 M-3338 02/99

Page 22 of 54

Page 23

6.0 ORBIT NETWORK COMMANDS

6.1 Introduction

The Orbit Network Measurement System uses a differential 2-wire RS485 interface to connect between the various

types of Orbit Network PIE and Interface Module. Each Orbit Module is capable of operating at 9600 Baud or 187.5K

Baud, speed setting is by means of the

bits, 1 parity bit and 1 stop bit, odd parity.

Orbit modules are programmed with a unique 10 digit identity during manufacture. The 10 digit identity is not very

efficient for high speed communications so each module is given a temporary address during the initialization. All

subsequent commands make use of this temporary address. When power is removed from an Orbit network the

temporary addresses are lost and must be re-initialized when power is re-applied.

Because the data to and from each Orbit Module travels along a 2-wire link some form of protocol is required to stop

all the Orbit Modules from ”talking” at once. The protocol used has two basic command types: Addressed and

Broadcast.

”ADDRESSED” Commands - Only the Module being addressed will respond to an addressed command. The

Orbit Module responds with an acknowledgement followed by some information, all other Orbit Modules on the Orbit

Network will ignore the command and continue operating in their present mode.

”BROADCAST” Commands - All Modules on the Orbit Network will react to a broadcast command depending on

their previous set-up. No acknowledgement from Modules is expected after a broadcast command. Further

information from a Module can be obtained by using addressed commands.

OrbitRst

command. The character format used consists of 1 start bit, 8 data

In conjunction with the two command types the Orbit Network uses a BREAK character to get the attention of all the

Modules on the Orbit Network. The BREAK character is a low (space) signal which has a duration of >90 µs (187.5K

Baud) or >1.2 ms (9600 Baud).

Note that although the Orbit Module can operate at 9600 or 187.5 K Baud, Orbit Modules set to different speeds

cannot be used on the same network. To set the Orbit Module Baud rate a

network after power up and before any other command.

Orbit Modules may not respond to all commands as different types of module have different operating requirements.

The Command Application Table lists the appropriate commands for each module. Refer to the command detail

sections as there may be additional information on commands, error codes or special requirements for a particular

module type.

OrbitRst

command must be sent to the

LDN101 M-3338 02/99

Page 23 of 54

Page 24

6.2 Command Summary

This summary gives a brief description of each command. Orbit Modules may not respond to all commands as

different types of module have different operating requirements. Refer to the Orbit Command Detail section and

Command Application Table for full details of each command.

[OrbitSetaddr]

Module Type:

Type :

Parameters:

Set Orbit Module address.

Digital Probe, Linear Encoder

addressed

card, channel, address, identity, option

Each Orbit Module is given a unique 10 byte identity (ID) during manufacturing. When used on a network it is

more efficient to use a shorter temporary ADDRESS stored in the Orbit Module memory; this is a number

between 1 and 31. This command is used to set the temporary address.

[OrbitNotify]

Module Type:

Type :

Parameters:

This is a method for obtaining the Orbit Module ID During initial network setup, re-configuring or when using unknown

Orbit Modules. In this mode any unaddressed Orbit Module will return its ID if the measurement parameter is altered

from its initial state after

Send ID if displacement > ±1%.

Digital Probe, Linear Encoder

broadcast

card, channel, identity

OrbitRst

OrbitClr

or

commands.

[OrbitIdentify]

Module Type:

Type :

Parameters :

Returns the Orbit Module ID, type (LE12, DP2 etc.), software version and (calibrated) stroke. Additional information

may be returned by using the

[OrbitGetinfo] Command.

Module Type:

Type :

Parameters :

Will return information about the type of module and / or probe. Additional information may be returned by using the

OrbitIdentify

[OrbitGetstatus]

Module Type:

Type :

Parameters :

Returns 1 ERROR code byte and 2 STATUS bytes. The ERROR code indicates whether the Orbit Module has a

problem, or why it has not responded to a particular command. For information on ERROR codes refer to Error

Codes section. The STATUS bytes gives information on the present mode or set-up of the Orbit Module.

[OrbitRead1]

Module Type:

Type :

Parameters :

Returns a reading from the Orbit Module. Readings are updated at fixed intervals.

Identify addressed Orbit Module.

Digital Probe, Linear Encoder

addressed

card, channel, address, identity, devtype, version, stroke

OrbitGetinfo

Returns information on the Module / Probe

Linear Encoder, Digital Probe*

addressed

card, channel, address, module type, hardware type, resolution,

module info.

command. (*not currently implemented)

Returns error and status information from Orbit Module.

Digital Probe, Linear Encoder

addressed

card, channel, address, error code, status

Returns a 16 bit signed (integer) reading.

Digital Probe

addressed

card, channel, address, reading

command.

[OrbitRead2]

Module Type:

Type :

Parameters :

Returns a reading from the Orbit Module. Readings are updated at fixed intervals.

[OrbitClr]

Module Type:

Type :

Returns a 32 bit signed (long integer) reading

Linear Encoder

addressed

card, channel, address, reading

Clear addressed Orbit Module.

Digital Probe, Linear Encoder

addressed

Parameters : card, channel, address

Performs a software reset on a particular Orbit Module. The Orbit Module will then need to be re-addressed. Allow at

least 0.5 second for completion of the command.

LDN101 M-3338 02/99

Page 24 of 54

Page 25

[OrbitRst]

Module Type:

Type :

Parameters :

Reset all Orbit Modules.

Digital Probe, Linear Encoder

broadcast

card, channel

Has the same affect as OrbitClr but will reset ALL the Orbit Modules on a network at the same time. To set the Orbit

Modules to the required Baud rate this command MUST be sent after the network is powered up and before any

other command. Allow at least 0.5 second for completion of the command.

[OrbitAcquire]

Module Type:

Type :

Parameters :

Set Orbit Module to acquire mode.

Digital Probe

addressed

card, channel, address, readings, delay

Set the Orbit Module to record 1 to 25 readings with a specific time delay (0.1s to 819.1s) between readings.

OrbitTrigger command is required to start taking of readings. The stored readings are read using the OrbitReadia

command. Orbit Module reading synchronization is also possible using this command.

[OrbitTrigger]

Module Type:

Type :

Parameters :

Trigger all Orbit Modules set to OrbitAcquire mode.

Digital Probe

broadcast

card, channel

Trigger all Orbit Modules that have previously been set by an OrbitAcquire command. The first reading will be taken

immediately.

[OrbitReadia]

Module Type:

Type :

Parameters :

Return integer array.

Digital Probe

addressed

card, channel, address, reading

Allows information stored during OrbitAcquire to be read. Stored Readings can be read at any time during the

OrbitAcquire period. Readings are stored until read or cleared.

[OrbitDifference]

Module Type:

Type :

Parameters :

Set Orbit Module to difference mode.

Digital Probe, Linear Encoder

addressed

card, channel, address

Readings are taken continuously once started via OrbitStartdiff. The maximum, minimum, sum and number of

readings are stored. Up to 16.7 million readings can be taken.

[OrbitStartdiff]

Module Type:

Type :

Parameters :

Start recording difference readings.

Digital Probe, Linear Encoder

broadcast

card, channel

Orbit Modules that have previously been set to OrbitDifference mode will start taking readings. All Orbit Modules will

start at the same time. Use for synchronization.

[OrbitStopdiff]

Module Type:

Type :

Parameters :

Stops all Orbit Modules that have previously been set to OrbitDifference mode and started using the

Stop recording difference readings.

Digital Probe, Linear Encoder

broadcast

card, channel

OrbitStartdiff

command.

[OrbitReaddiff1]

Module Type:

Type :

Parameters :

Return result of OrbitDifference command. 16 bit signed (integer) readings.

Digital Probe

addressed

card, channel, address, minimum, maximum, sum, number

Returns results from a Orbit Module that has been set in OrbitDifference mode and received a OrbitStopdiff or will

return the latest result from a Orbit Module still taking readings in OrbitDifference mode.

LDN101 M-3338 02/99

Page 25 of 54

Page 26

[OrbitReaddiff2]

Module Type:

Type :

Parameters :

Returns results from a Orbit Module that has been set in OrbitDifference mode and received a OrbitStopdiff or will

return the latest result from a Orbit Module still taking readings in OrbitDifference mode.

Return result of OrbitDifference command. 32 bit signed (long integer) readings.

Linear Encoder

addressed

card, channel, address, minimum, maximum

[OrbitPreset]

Module Type:

Type :

Parameters :

Preset is used where Orbit modules may be preset with a value (i.e. Linear Encoder).

[OrbitRefmark]

Module Type:

Type :

Parameters :

Probe (i.e. Linear Encoder) is set waiting until the reference marker is found. Can be interrogated using

OrbitGetstatus or set back to normal mode using and OrbitRead2.

[OrbitDirection]

Module Type:

Type :

Parameters :

This command will toggle the readings form an Orbit module to change direction. In the case of a Linear Encoder the

count from the probe would change from counting in the positive direction to the negative direction.

6.3 Command Application Table

OrbitSetaddr

OrbitNotify

OrbitIdentify

OrbitGetinfo

OrbitGetstatus

OrbitRead1

OrbitRead2

OrbitClr

OrbitRst

OrbitAcquire

OrbitTrigger

OrbitReadia

OrbitDifference

OrbitStartdiff

OrbitStopdiff

OrbitReaddiff1

OrbitReaddiff2

OrbitPreset

OrbitRefmark

OrbitDirection

Presets a reading into the Orbit Module. 32 bit signed (long integer) value.

Linear Encoder

addressed

card, channel, address, preset

Activates reference marker mode

Linear Encoder

addressed

card, channel, address

Changes direction of reading count

Linear Encoder

addressed

card, channel, address

Probe / Module Type

COMMAND Digital Probe Linear Encoder

99

99

9

9

*

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

NOTE: If a module receives a command it does not use or recognize (see table above) the module will not respond

and a network timeout will occur.

Refer to the command detail sections as there may be additional information on commands, error codes or special

requirements for a particular module type.

*not currently implemented

LDN101 M-3338 02/99

Page 26 of 54

Page 27

6.4 Orbit Command Detail Descriptions

This section gives details of all of the Orbit Module commands. Included in the description is network information on

the sequence of bytes sent to and received from the Orbit Module.

Characters marked ” ” mean that the ASCII representation of the character is transmitted/received.

Data shown as [00110111] is the binary representation of the byte.

Quick Basic is used for command examples, the following notations are used :

num! is a single precision number

num# is a double precision number

num% is a 16 bit signed integer

numLong& is a 32 bit signed long integer

text$ is a string

Not all Orbit modules respond to all Orbit commands. If a call is made using a command the module does not support

the module will not respond and the network will timeout.

The probe position or module reading is returned by

OrbitReadia

commands must be interpreted in different ways depending on the module type. For probes with a

OrbitRead1, OrbitRead2, OrbitReaddiff1, OrbitReaddiff2

and

calibrated stroke (such as Digital Probe) the position is given by Eq. 1 For probes that have incremental outputs

(such as Linear Encoder) the position is given by Eq. 2.

Eq. 1 position = N x stroke Eq. 2 position = N x resolution

16384

Where N is the returned value (rd% etc.). The probe stroke can be obtained by using the

and probe resolution can be given by the

[OrbitSetaddr] Command.

6.4.1

Module Type:

Type :

Parameters:

Digital Probe, Linear Encoder

addressed

card, channel, address, identity, option

Set Orbit Module address.

OrbitGetinfo

command.

OrbitIdentify

command

Each Orbit Module is given a unique 10 byte identity (ID) during manufacturing. When used on a network it is more

efficient to use a shorter temporary ADDRESS stored in the Orbit Module memory; this is a number between 1 and

31. This command is used to set the temporary address.

Quick Basic example: CALL

OrbitSetaddr

(card%, chnl%, oaddr%, id$, opt%)

[oaddr% → 000AAAAA, id$ → ID, reso% → resolution]

Network: To Module. <BREAK>,

”S”

,[000AAAAA],10 byte ID, 1 byte option.

From Module. “S”,[000aaaaa]

where aaaaa is the previous address allocated to this ID.

Notes: “S” and 10 byte ID are in ASCII;

[000AAAAA] and 1 byte option are in binary.

This command will set the Orbit Module with the identity ID to respond to the address 000AAAAA. The option byte is

at present not implemented and should be set to 0.

The ID used by

OrbitNotify

Note: A gap of at least 50 µS

OrbitSetaddr

command.

could be obtained from a previously stored data file, keyboard entry or from the

must

be allowed between each byte of the 10 byte ID string.

When using the Orbit Network card this gap is automatically inserted between bytes.

LDN101 M-3338 02/99

Page 27 of 54

Page 28

6.4.2 [

OrbitNotify] Command.

Send ID if displaced from an initial position

Module Type:

Type :

Parameters:

Digital Probe, Linear Encoder

broadcast

card, channel, identity

This is a method for obtaining the Orbit Module ID During initial network setup, re-configuring or when using unknown

Orbit Modules. In this mode any unaddressed Orbit Module will return its ID if the measurement parameter is altered

from its initial state after

OrbitRst

Quick Basic example: CALL

OrbitClr

or

OrbitNotify

commands.

(card%, chnl%, ID$)

[ID → ID$ when Displacement > ±1%]

Network: To Module. <BREAK>,

”N”

[00000000]

From Module. ”N”, 10 byte ID when disp > 1%

Notes. “N” and 10 byte ID are in ASCII.

[00000000] is in binary.

This command is not an alternative to

OrbitSetaddr

, it is only a method for obtaining a module ID.

OrbitSetaddr

must still be used to set the temporary network address.

This command will cause the Module to send its ID only when the displacement > ±1% of the calibrated stroke for

Digital Probe or 0.5 mm for Linear Encoder, otherwise the Orbit Module does not respond, causing a network timeout

error.

The Probe position or module value on power up or after a

OrbitRst

position for this command. Orbit Modules that have had their addresses set using the

not respond to

OrbitNotify

.

OrbitClr

or

command is used as the reference

OrbitSetaddr

command will

[OrbitIdentify] Command

6.4.3

Module Type:

Type :

Parameters :

Linear Encoder, Digital Probe

addressed

card, channel, address, identity, devtype, version, stroke

. Identify addressed Orbit Module.

Returns the Orbit Module ID, type (LE12, DP2 etc.), software version and (calibrated) stroke. Additional information

may be returned by using the

Quick Basic example: CALL

OrbitGetinfo

OrbitIdentify

command.

(card%, chnl%, oaddr%, id$, devtype$, ver$, stroke%)

[oaddr% → 000AAAAA, ID → id$, type → devtype$, version → ver$,

stroke → stroke %]

Network: To Module. <BREAK>

”I”

,[000AAAAA]

From Module. “I”,10 byte ID, 12 byte devtype, 5 byte version, 2 byte stroke).

Notes. “I” , 10 byte ID, 12 byte type, 5 byte version are in ASCII.

[000AAAAA] and 2 byte stroke are in binary.

For multi byte parameters byte order is 0(LS),1,2,3 etc..

LDN101 M-3338 02/99

Page 28 of 54

Page 29

[OrbitGetinfo] Command.

6.4.4

Returns information on the Module / Probe

Module Type:

Type :

Parameters :

Linear Encoder, Digital Probe*

addressed

card, channel, address, module type, hardware type, resolution, module info.

*not currently implemented

Will return information about the type of module and / or probe. Additional information may be returned by using the

OrbitIdentify

Quick Basic example: CALL

command.

OrbitGetinfo

(card%, chnl%, oaddr%, moduletype$, hwtype%,

reso%, moduleinfo$)

[oaddr% → 000AAAAA]

Network: To Module. <BREAK>, "B",[000AAAAA]

From Module "B", 4 byte moduletype, 2 byte hwtype, 2 byte reso, 32 byte moduleinfo

Notes. “B” , 4 byte moduletype and 32 byte moduleinfo are in ASCII.

[000AAAAA], 2 byte hwtype and 2 byte reso are in binary.

For multi byte parameters byte order is 0(LS),1,2,3 etc..

moduletype - 4 byte string - Returns a constant that identifies the module / probe type regardless of options or

version. Examples :- “DP ” for Digital Probe

“LE “ for Linear Encoder

hwtype - 2 byte integer - Code indicating hardware option or special configuration, i.e. buffering etc. for most

modules this will be set to 1 meaning “standard”. Refer to appropriate module or probe documentation

for detailed information.

reso - 2 byte integer - Number representing resolution of module. Currently set to 0 for DP and 5 for LE, the

moduletype$ will dictate how to interpret reso%

moduleinfo - 32 byte string - Information specific to a particular module / probe type. This may be unassigned (set to

all spaces) or be sub-divided into fields as defined by moduletype. For field descriptions refer to

appropriate module or probe documentation.

LDN101 M-3338 02/99

Page 29 of 54

Page 30

[OrbitGetstatus] Command.

6.4.5

Returns status and error code from Orbit Module.

Module Type:

Type :

Parameters :

Digital Probe, Linear Encoder

addressed

card, channel, address, error code, status

This command will return 1 ERROR code byte and 2 STATUS bytes. The ERROR code indicates whether the Orbit

Module has a problem, or why it has not responded to a particular command. For information on ERROR codes refer

to Error Codes section. The STATUS bytes gives information on the present mode or set-up of the Orbit Module.

Quick Basic example: CALL

OrbitGetstatus

(card%, chnl%, oaddr%, errcode%, status%)

[oaddr% → 000AAAAA, error code → errcode%, status → status%]

Network: To Module. <BREAK>

”G”

,[000AAAAA]

From Module. “G”,1 byte error code 2 byte status

Notes. “G” is in ASCII

[000AAAAA], 1 byte error code and 2 byte status are in binary.

For multi byte parameters byte order is 0(LS),1,2,3 etc..

Digital Probe

Byte 1

2 Byte Status format:

(sent after byte 0)

Byte 0

(sent first)

D7 D6 D5 D4 D3 D2 D1 D0 D7 D6 D5 D4 D3 D2 D1 D0

TR ST NU NU NR C C C NU RT RT RT RT RT RT RT

Default values

00001000 00000000

Flag meaning when set:

TR Orbit Module triggered (after

1 = triggered via

OrbitTrigger

ST Orbit Module stopped (after

1 = stopped via

OrbitAcquire stop

OrbitAcquire

OrbitStartdiff

or

OrbitAcquire

OrbitStopdiff

or

OrbitDifference

and

.

OrbitDifference

and

.

NR New Value. 1 = new rdg available. If the module is read (using

this flag is set to 0 and is only set to 1 when the next new reading is available. Because the

network reading rate can be much greater than the Orbit Module reading rate this bit can be

checked to ensure that the same reading is not read twice.

RT No. of readings taken (

OrbitAcquire

mode).

NU Not used. (currently set to 0)

CCC 000 - Normal mode

001 - OrbitDifference mode

010 - OrbitAcquire mode

011 - Sync mode

100 - 111 reserved

commands).

commands).

OrbitRead1

for example)

OrbitRst

If

OrbitClr

or

is used all status bytes will be set to their default values. This command also clears the Orbit

Module ‘hard’ error flag if set, see Error Codes section for details.

LDN101 M-3338 02/99

Page 30 of 54

Page 31

Linear Encoder

2 Byte Status format:

This command is the same as for Digital Probe except the 16 bit status word returned has a different meaning.

Byte 1

(sent after byte 0)

Byte 0

(sent first)

D7 D6 D5 D4 D3 D2 D1 D0 D7 D6 D5 D4 D3 D2 D1 D0

TR ST NU NU NR NU NU NU NU NU RS RR RF D NU NU

Default values

00001000 00000100

Flag meaning when set:

TR Orbit Module triggered (after

ST Orbit Module stopped (after

OrbitDifference

OrbitDifference

command). 1 = triggered via

command). 1 = stopped via

NR New Reading. 1 = new rdg available. If the module is read (using

OrbitRead2

OrbitStartdiff

OrbitStopdiff

.

.

for example) this flag is set to 0

and is only set to 1 when the next new reading is available. Because the network reading rate can be much

greater than the Orbit Module reading rate this bit can be checked to ensure that the same reading is not read

twice.

D Indicates direction of count. 1 = positive or 0 = negative direction (via

RS 1 = looking for reference marker (applies to

RF 1 = reference marker is found (applies to

RR 1 = reference point has been read (applies to

OrbitRefmark

OrbitRefmark

OrbitRefmark

mode)

mode)

mode)

OrbitDirection

command).

NU Not used. (currently set to 0)

OrbitRst, OrbitClr

If

occurred

OrbitGetstatus

OrbitPreset

or

is used both status bytes will be set to default values. If an overspeed has

will return both the relevant error code and the status of the module just before the

overspeed occurred. All status flags will then be set to default values and the module reading will be reset to zero.

The next

OrbitGetstatus

will return the new status of the module, if no errors have occurred or modes entered the

error code and status bytes will be at their default values. The Module will retain its network address.

LDN101 M-3338 02/99

Page 31 of 54

Page 32

[OrbitRead1] Command.

6.4.6

Returns a 16 bit signed (integer) reading.

Module Type:

Type :

Parameters :

Digital Probe

addressed

card, channel, address, reading

Returns a reading from the Orbit Module. Readings are updated at fixed intervals.

Quick Basic example: CALL

OrbitRead1

(card%, chnl%, oaddr%, rd%)

[oaddr% → 000AAAAA, 2 byte reading → rd%]

Network: To Module. <BREAK>,

”1”

,[000AAAAA]

From Module. “1”,2 byte reading

Notes: “1” is in ASCII.

[000AAAAA] and 2 byte reading are in binary.

For multi byte parameters byte order is 0(LS),1,2,3 etc..

The Digital Probe has a calibrated stroke (i.e. 1, 2, 5 or 10 mm) and a 14 bit resolution over that calibrated stroke.

Each ‘bit’ represents a distance which different for each stroke (other probe types may have a fixed resolution per bit

but no fixed stroke).

The probe position or module reading (0 to 16384) is returned by

OrbitRead1, OrbitReaddiff1

OrbitReadia

and

commands, but must be multiplied by a constant depending on module type to give a scaled result.

Eq. 1 position = N x stroke

16384

Where N is the returned value (rd% etc.). The probe stroke can be obtained by using the

OrbitIdentify

command.

Stroke / 16384 is the resolution for a particular probe. Refer to the PIE specification.

Example : 2 mm probe returned reading rd% = 18FCh (6396 dec.)

position = 6396 x 2 = 0.7808 mm

16384

If there is a fault or condition where a reading is not possible an error code sequence is returned instead of the

reading. Refer to the Error Codes section for details.

When a Digital Probe is working within its calibrated range rd% will return a reading in the range 0 to 16384. The

probe has enough mechanical travel to move outside of the calibrated range, if this happens the error code sequence

for Under Range or Over Range is returned instead of a reading. As soon as the probe is moved back within the

calibrated range rd% will return a value.

Digital Probe has an internal reading update time of 4 ms. This means that a new reading is available every 4 ms.

LDN101 M-3338 02/99

Page 32 of 54

Page 33

[OrbitRead2] Command

6.4.7

. Returns a 32 bit signed (long integer) reading.

Returns a reading from the Orbit Module. Readings are updated at fixed intervals, refer to module specifications.

Module Type:

Type :

Parameters :

QuickBASIC Example: CALL

Linear Encoder

addressed

card, channel, address, reading

OrbitRead2

(card%, chnl%, oaddr%, rdLong&)

[oaddr%→ 000AAAAA, 4 byte reading→ rdLong&]

Network: To Module: <BREAK>,”L”,[000AAAAA]

From Module “L”, 4 byte reading.

Notes: “L” is in ASCII.

[000AAAAA] and 4 byte reading are in binary.

For multi byte parameters byte order is 0(LS),1,2,3 etc..

If there is a fault or condition where a reading is not possible, such as overspeed, an error code sequence is

returned instead of the reading. Refer to the Error Codes section for details.

The Linear Encoder has a fixed resolution regardless of stroke, each ‘bit’ represents a fixed distance (other probe or

module types may have a fixed stroke but no fixed resolution per bit).

The Incremental position or reading is returned by

OrbitRead2

OrbitReaddiff2

and

commands, but must be

multiplied by the resolution depending on probe type to give a reading in mm.

Incremental position = N x resolution

Where N is the returned reading (

rdLong&

etc.). The probe stroke can be obtained by using the

command and probe resolution can be given by the

OrbitGetinfo

command.

OrbitIdentify

Linear Encoder has an internal reading update time of 1 ms. This means that a new reading is available every 1 ms.

This command will return the reference mark position if

or clear

OrbitRefmark

if the probe reference mark has not been passed. Refer to

OrbitRefmark

is set and the probe reference mark is passed,

OrbitRefmark

command for

details.

LDN101 M-3338 02/99

Page 33 of 54

Page 34

[OrbitClr] Command.

6.4.8

Clear addressed Orbit Module.

Module Type:

Type :

Parameters :

Digital Probe, Linear Encoder

addressed

card, channel, address

This command will perform a software reset on a particular Orbit Module. The Orbit Module will then need to be readdressed. Allow approximately 0.5 second for completion of the command.

Quick Basic example: CALL

OrbitClr

(card%, chnl%, oaddr%)

[oaddr% → 000AAAAA]

Network: To Module. <BREAK>,”C”,[000AAAAA]

From Module. ”C”,[000AAAAA]

Notes: “C” is in ASCII.

[000AAAAA] is in binary.

This command will clear previously set values from the addressed Orbit Module as follows :-

Clear address (cancels

Orbit Module will now respond to the

OrbitAcquire

Clear

OrbitDifference

Clear

OrbitSetaddr

)

OrbitNotify

command.

command status (single sample no delay)

command status (don’t record difference)

Reset Orbit Module software

Note: Leave at least 0.5 second delay after an

OrbitClr

command before sending any other command.

[OrbitRst] Command.

6.4.9

Module Type:

Type :

Parameters :

Digital Probe, Linear Encoder

broadcast

card, channel

This command has the same affect as

Reset all Orbit Modules.

OrbitClr

but will reset ALL the Orbit Modules on a network at the same time.

To set the Orbit Modules to the required Baud rate this command MUST be sent after the network is powered up and

before any other command. Allow approximately 0.5 second for completion of the command.

Quick Basic example: CALL

OrbitRst

(card%, chnl%)

Network: To Module. <BREAK>,”R”,[00000000]

From Module. No response

Notes: “R” is in ASCII.

[00000000] is in binary.

This command will reset all Orbit Modules as follows :-

Clear address (cancels

Orbit Module will now respond to the

OrbitAcquire

Clear

OrbitDifference

Clear

OrbitSetaddr

)

OrbitNotify

command.

command status (single sample no delay).

command status (don’t record difference)

Reset Orbit Module software and perform self test.

Note: Leave at least 0.5 second delay after a

LDN101 M-3338 02/99

OrbitRst

Page 34 of 54

command before sending any other command.

Page 35

6.4.10

[OrbitAcquire] Command.

Set Orbit Module to acquire mode.

Module Type:

Type :

Parameters :

Digital Probe

addressed

card, channel, address, readings, delay

This command will set the Orbit Module to record 1 to 25 readings with a specific time delay (0.1s to 819.1s) between

readings. The taking of readings will not start until a

read using the

Quick Basic example: CALL

OrbitReadia

command. Orbit Module reading synchronization is also possible using this command.

OrbitAcquire

OrbitTrigger

command is received. The stored readings are

(card%, chnl%, oaddr%, rdgs%, dly%)

[oaddr% → 000AAAAA, rdgs% → rdgs, dly% → delay]

Network: To Module. <BREAK>, ”A”,[000AAAAA],1 byte no of rdgs

(1 - 25 [0 and 255 special case]), 2 byte delay (1 - 1FFFh)

From Module. ”A”,[000AAAAA]

Notes: “A” is in ASCII.

[000AAAAA], 1 byte number of rdgs and 2 byte delay are in binary.

For multi byte parameters byte order is 0(LS),1,2,3 etc..

Once set the Orbit Module will start taking readings immediately after a

Module has been triggered it will only respond to

OrbitAcquire

and

. This command cannot be used if the Orbit Module is already in

OrbitRst, OrbitClr, OrbitIdentify, OrbitGetstatus, OrbitReadia

OrbitTrigger

OrbitDifference

command. Once the Orbit

mode.

Special Cases :-

1.

OrbitAcquire

stop i.e. to leave OrbitAcquire mode. Call the

OrbitAcquire

command again with the

number of rdgs byte set to 0.

2.

Orbit Module

synchronization. Call the

OrbitAcquire

command with the number of readings byte set to

255 (0FFh) all

Orbit Modules set in this mode will start their first measurement cycle after the

(i.e. 12 ms for Digital Probe) after the

OrbitTrigger

before taking a reading from the module. This time may be

OrbitTrigger

command. Allow time

different for other Orbit Modules, refer to module specifications.

6.4.11

Module Type:

Type :

Parameters :

[OrbitTrigger] Command

Digital Probe

broadcast

card, channel

. Trigger all Orbit Modules set to

This command will trigger all Orbit Modules that have previously been set by an

OrbitAcquire

mode.

OrbitAcquire

reading will be taken immediately, any further readings will be taken after the delay set by the

command. (See OrbitAcquire special cases)

Quick Basic example: CALL

OrbitTrigger

(card%, chnl%)

Network: To Module. <BREAK>, ”T”,[00000000]

From Module. No response

Notes: “T” is in ASCII.

[00000000] is in binary.

command. The first

OrbitAcquire

LDN101 M-3338 02/99

Page 35 of 54

Page 36

6.4.12

[ OrbitReadia] Command

. Return integer array.

Module Type:

Type :

Parameters :

This mode allows information stored during

OrbitAcquire

Digital Probe

addressed

card, channel, address, reading

OrbitAcquire

to be read. Readings can be taken at any time during the

period, though obviously all readings may not have been taken. Readings are stored until read or

cleared.

Quick Basic example: CALL

OrbitReadia

(card%, chnl%, oaddr%, rdarray%( ))

[oaddr% → 000AAAAA, 25 x 2 byte readings → rdarray%( )]

Network: To Module. <BREAK>, ”E”,[000AAAAA]

From Module. ”E”,25 x 2 byte readings

Notes: “E” is in ASCII.

[000AAAAA] and 25 x 2 byte readings are in binary.

For multi byte parameters byte order is 0(LS),1,2,3 etc..

On receiving the

reading transmitted will be the first one taken after the Orbit Module received the

readings that have not been logged yet will be transmitted as zero’s. If the

stopped the Orbit Module will be set back to single reading mode on the first

OrbitReadia

OrbitReadia

command.

command the Orbit Module will transmit the 25 reading buffer to the network. The first

OrbitTrigger

OrbitAcquire

OrbitRead1

command. Any

command has been

after a successful

Note: Reading errors are signified by the most significant bit being set, hence over and under range readings are

saved as FFFFh and 8000h, respectively.

LDN101 M-3338 02/99

Page 36 of 54

Page 37

6.4.13

[OrbitDifference] Command

Module Type:

Type :

Parameters :

. Set Orbit Module to difference mode.

Digital Probe, Linear Encoder

addressed

card, channel, address

Readings are taken continuously once started via

OrbitStartdiff

. The following is stored depending on module type :-

1. Maximum reading (2 bytes)

2. Minimum reading (2 bytes)

3. (optional) Sum of all readings (5 bytes, > 4.6 hours of readings)

4. (optional) Number of readings taken (3 bytes, 16.7 million readings)

Numbers 3 and 4 allow the calculation of the average reading. See

Quick Basic example: CALL

OrbitDifference

(card%, chnl%, oaddr%)

OrbitStopdiff, OrbitReaddiff1

(and 2).

[oaddr% → 000AAAAA]

Network: To Module. <BREAK>, ”F”,[000AAAAA]

From Module. ”F”,[000AAAAA]

Notes: “F” is in ASCII.

[000AAAAA] is in binary.

The maximum and minimum readings will start to be recorded as soon as the Orbit Module receives a

command. Once the Orbit Module has received

OrbitStartdiff

it will only respond to

OrbitIdentify, OrbitRead1, OrbitRead2, OrbitGetstatus, OrbitReaddiff1, OrbitReaddiff2

OrbitRst, OrbitClr

and

OrbitStartdiff

,

OrbitStopdiff

depending on module type. This command cannot be used if the Orbit Module is already in Acquire mode.

Orbit Modules set in this mode will start their first measurement cycle after the

(i.e. 12 ms for Digital Probe) after the

OrbitStartdiff

before taking a reading from the module. This time may be

OrbitStartdiff

command. Allow time

different for other Orbit Modules, refer to module specifications.

6.4.14

Module Type:

Type :

Parameters :

Orbit Modules that have previously been set to

start at the same time. Useful for reading synchronization. See

Quick Basic example: CALL

[OrbitStartdiff] Command

Digital Probe, Linear Encoder

broadcast

card, channel

. Start recording difference readings.

OrbitDifference

mode will start taking readings. All Orbit Modules will

OrbitStopdiff, OrbitReaddiff1

OrbitStartdiff

(card%, chnl%)

(or 2).

Network: To Module. <BREAK>, ”O”,[00000000]

From Module. No response

Notes: “O” is in ASCII.

[00000000] is in binary.

Depending on module type the contents of the buffer can be read using

OrbitReaddiff1

(or 2),

OrbitRead1

(or 2).

OrbitReaddiff commands will return a snap-shot of the buffer contents. OrbitRead commands will return a single

reading in the normal manner.

Once the Orbit Module has received

OrbitStartdiff

it will only respond to

OrbitGetstatus, OrbitRead1, OrbitRead2, OrbitReaddiff1, OrbitReaddiff2

OrbitRst, OrbitClr, OrbitIdentify

OrbitStopdiff

and

.

,

LDN101 M-3338 02/99

Page 37 of 54

Page 38

6.4.15

[OrbitStopdiff] Command

. Stop recording difference readings.

Module Type:

Type :

Parameters :

Digital Probe, Linear Encoder

broadcast

card, channel

Stops all Orbit Modules that have previously been set to

command. See

Quick Basic example: CALL

OrbitReaddiff1

(or 2).

OrbitStopdiff

(card%, chnl%)

Network: To Module. <BREAK>, ”H”,[00000000]

From Module. No response

Notes: “H” is in ASCII.

[00000000] is in binary.

The contents of the buffer can be read by the

OrbitRead1

(or 2) is used before an

OrbitReaddiff1

the OrbitReaddiff buffer will remain until cleared. See

6.4.16

Module Type:

Type :

Parameters :

[OrbitReaddiff1] Command

Digital Probe

addressed

card, channel, address, minimum, maximum, sum, number

. Returns result of OrbitDifference command. 16 bit signed (integer) readings.

OrbitReaddiff1

(or 2) a single reading is returned as normal and the contents of

OrbitReaddiff1

OrbitDifference

mode and started using the

(or 2) command depending on module type. If an

(and 2).

OrbitStartdiff

Returns results from an Orbit Module that has been set in

OrbitDifference

will return the latest result from an Orbit Module still taking readings in

mode and received an

OrbitDifference

mode.

OrbitStopdiff

or

1. Maximum reading (2 bytes)

2. Minimum reading (2 bytes)

3. Sum of all readings (5 bytes, max. 4.6 hours of readings at full stroke, more readings at less than full stroke)

4. Number of readings taken (3 bytes, up to 16.7 million readings)

Quick Basic example: CALL

OrbitReaddiff1

(card%, chnl%, oaddr%, min%, max%, sum#, num!)

[oaddr% → 000AAAAA, Min rdg → min%, Max. rdg → max%

Sum of all rdgs → sum#, Number of rdgs taken → num!]

Network: To Module. <BREAK>, ”D”,[000AAAAA]

From Module. ”D”,2 bytes - Min rdg, 2 bytes - Max. rdg, 5 bytes -

Sum of all rdgs, 3 bytes - Number of rdgs taken

Notes: “D” is in ASCII.

[000AAAAA], 2 bytes min rdg, 2 bytes max. rdg, 5 byte sum of all rdgs and

3 byte number of rdgs taken are in binary.

For multi byte parameters byte order is 0(LS),1,2,3 etc..

OrbitDifference

If the

command has been stopped via

reading mode, on the first

OrbitRead1

after a successful

OrbitStopdiff

OrbitReaddiff1

the Orbit Module will be set back to single

command.

Note: Reading errors are signified by the most significant bit being set, hence over and under range readings are

saved as -1 (FFFFh). and -32768 (8000h) respectively. If an out of range reading is detected, the sum reading is set

to zero and Max./Min. readings continue to be taken.

LDN101 M-3338 02/99

Page 38 of 54

Page 39

6.4.17

[OrbitReaddiff2] Command.

Return result of OrbitDifference command. 32 bit signed

(long integer) readings

Module Type:

Type :

Parameters :

Linear Encoder

addressed

card, channel, address, minimum, maximum

Returns minimum and maximum results from a Orbit Module that has been set in

received a

OrbitStopdiff

or will return the latest result from a Orbit Module still taking readings in

mode.

OrbitReaddiff2

is a 32 bit version analogous to

OrbitReaddiff1

which is 16 bit. Only maximum and minimum

readings are taken.

QuickBASIC Example: CALL

OrbitReaddiff2

(card%, chnl%, oaddr%, maxLong&, minLong&)

[oaddr%→ 000AAAAA, 4 byte reading→minLong&, 4 byte reading, maxLong&]

Network: To Module: <BREAK>,”X”,[000AAAAA]

From Module: “X”, 4 Byte min. reading, 4 byte max. reading.

Notes: “X” is in ASCII.

[000AAAAA], 4 byte min rdg and 4 byte max. rdg are in binary.

For multi byte parameters byte order is 0(LS),1,2,3 etc..

OrbitDifference

If the

command has been stopped via