Page 1

LD610 Series

B.I.C.M.

Displacement Transducers

With In-Line Signal

Conditioners

omega.com

e-mail: info@omega.com

For latest product manuals:

omegamanual.info

User’s Guide

Shop online at

Page 2

Servicing North America:

USA:

One Omega Drive, Box 4047

ISO 9001 Certified

Stamford CT 06907-0047

Tel: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada:

976 Bergar

Laval (Quebec) H7L 5A1, Canada

Tel: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

USA and Canada:

Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

®

Customer Service: 1-800-622-2378 / 1-800-622-BEST

®

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

®

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico:

En Espan˜ ol: (001) 203-359-7803 e-mail: espanol@omega.com

FAX: (001) 203-359-7807 info@omega.com.mx

Servicing Europe:

Benelux:

Postbus 8034, 1180 LA Amstelveen, The Netherlands

Tel: +31 (0)20 3472121 FAX: +31 (0)20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: sales@omegaeng.nl

Czech Republic:

Frystatska 184, 733 01 Karvina´, Czech Republic

Tel: +420 (0)59 6311899 FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342 e-mail: info@omegashop.cz

France:

11, rue Jacques Cartier, 78280 Guyancourt, France

Tel: +33 (0)1 61 37 2900 FAX: +33 (0)1 30 57 5427

Toll Free in France: 0800 466 342

e-mail: sales@omega.fr

Germany/Austria:

Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: +49 (0)7056 9398-0 FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

United Kingdom:

One Omega Drive, River Bend Technology Centre

ISO 9002 Certified

Northbank, Irlam, Manchester

M44 5BD United Kingdom

Tel: +44 (0)161 777 6611 FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

OMEGAnet®Online Service Internet e-mail

www.omega.com info@omega.com

It is the policy of OMEGA to comply with all worldwide saf ety and EMC/EMI regulations that

apply. OMEGA is constantly pursuing certification of its p roducts to the European New Approach

Directives. OMEGA will add the CE mark to every appropriat e device upon certification.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts

no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These produc ts are not designed for u se in, and should not be used for, human applicati ons.

Page 3

LD610

M-3342 08/09

Index

Section Title Page

Index . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.0 Introduct ion . . . . . . . . . . . . . . . . . 2

2.0 Technical Specification . . . . . . . . . . . . . . . 3

3.0 Operational and Set-Up G uide - BI CM Kit . . . 6

3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . 6

3.2 Screen Connection . . . . . . . . . . . . . . . . . 8

3.3 Gain Adjustment . . . . . . . . . . . . . . . . . . . 10

3.4 Offset . . . . . . . . . . . . . . . . . . . . . . . . 10

3.5 Set Up Using Fixed Value Resistors . . . . . 11

3.6 Gain Set Up Procedure . . . . . . . . . 13

3.7 Offset Set Up Procedure . . . . . . . . . 14

4.0 The Case . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.0 The "Why Doesn 't it Work Guide" . . . . . . 17

6.0 Application Notes . . . . . . . . . . . . . . . . . . . . 18

6.1 Transducer Installation . . . . . . . . . . . . . . . . 18

6.2 Example 1 . . . . . . . . . . . . . . . . . . . . . 22

6.3 Example 2 . . . . . . . . . . . . . . . . . . . . . 23

1

Page 4

M-3342 08/09

LD610

1.0: Introduction & Glossary

The Boxed Inline Conditioning Module (BICM) is an electronics module that may be used with a wide range of LVDT transducers. Layout and size are

designed to allow the BICM to be easily fitted inline with the transducer cable and installed with the minimum of effort (or changed if ready connected to a

transducer)

The BICM output may be set for a full scale range up to ±10 VDC, offset facilities are provided. The BICM is either powered from a bipolar ±15 VDC supply

or a unipolar ±24 VDC supply depending on product type.

BICM - Boxed Inline Conditioning Unit

Gain - The output voltage per mm of transducer stroke

Offset - The output voltage when the transducer core is at null

P.C.B. - Printed Circuit Board

NPV - Nearest Preferred Value. A resistor selected from a standard range of value

(E24, E48, etc.) that is closest to the required value

BICM kits are supplied for user connection to an LVDT transducer.

2

1.0: Introduction

Page 5

M-3342 08/09

LD610

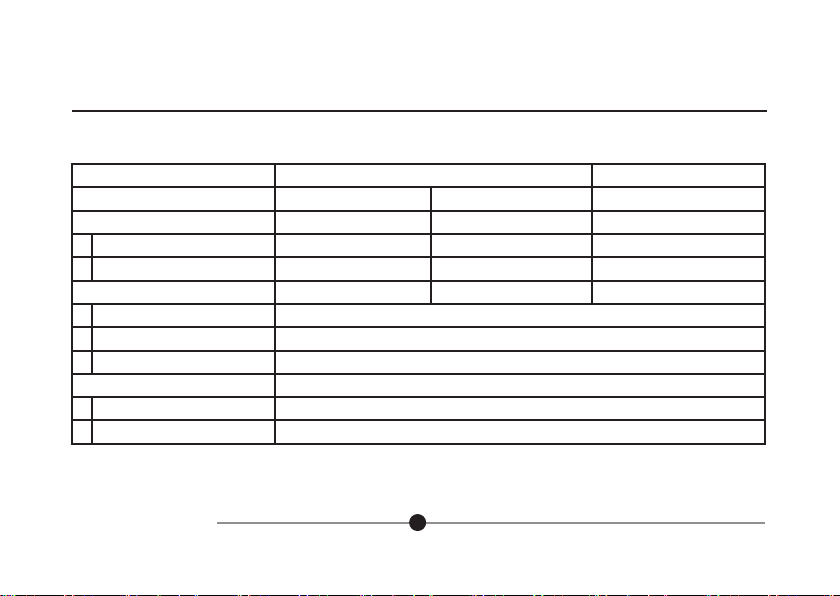

Standard BICM IP67 BICM

Bipolar Supply Unipolar Supply Bipolar Supply

Power Requirement

Voltage ±15 V ±1.5 V 24 V ±2.4 V ±15 V ±1.5 V

Current

±15 mA nominal

30 mA nominal ±15 mA nominal

Transducer Excitation

Primary Voltage 2 Vrms nominal

Primary Frequency

1

5 kHz typical

Primary Current 10 mA nominal

Signal Input

Input Voltage Range Up to 2.5 Vrms

Input Load Resistance 100 kW

3

2.0: Technical Specication

Page 6

M-3342 08/09

4

LD610

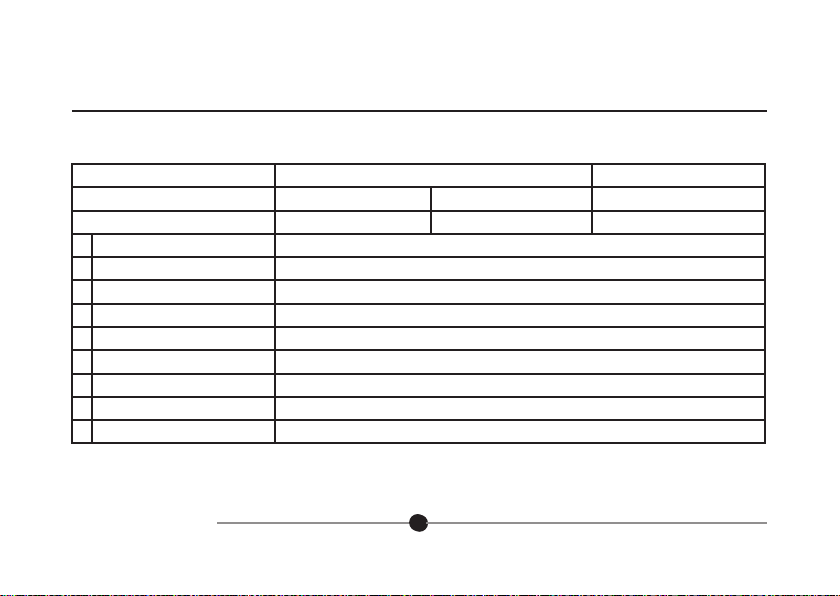

Standard BICM IP67 BICM

Bipolar Supply Unipolar Supply Bipolar Supply

Signal Output

Voltage Output Up to ±10 V

Current Output 11 mA

Output Ripple <14 mVrms

Output Offset 100%

Temp Co. Gain <0.03% FRO / oC

Temp. Co. Offset <0.025% FRO / oC

Warm up Time 15 minutes recommended

Linearity 2 (electronics only) <0.1% FRO

Bandwidth (-3 dB)

3

250 Hz typical

1

Other frequencies are available on request.

2

The electronics has a specification of <0.1%, the overall linearity is dominated by the transducer.

3

Other bandwidths available on request.

4

2.0: Technical Specication

Page 7

M-3342 08/09

5

LD610

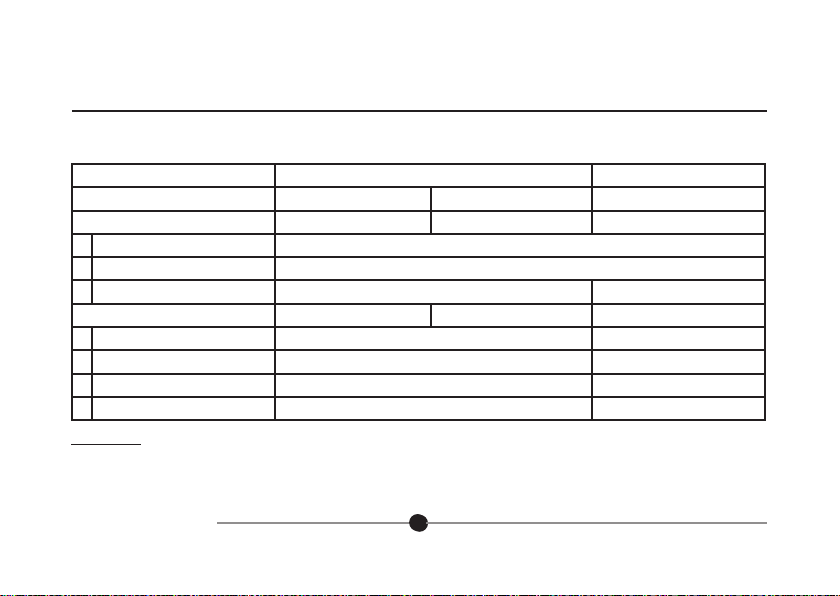

Standard BICM IP67 BICM

Bipolar Supply Unipolar Supply Bipolar Supply

Environmental

Operation Temperature Range 0 - 70 oC

Storage Temperature Range -20 to +85 oC

IP Rating IP40 IP67

Mechanical and Connections

Connections Solder pad or factory fit Factory fit only

Enclosure Size 98.5 x 30.5 x 13.0 mm 73.0 x 20.6 mm

Weight 30 g 75 g

Material ABS 400 Series Stainless Steel

Cable Lengths

All specification limits assume a nominal 3 m cable length between transducer and BICM. The BICM can be mounted up to 10 m from the transducer, but

this may result in reduced performance. Not all transducers can cope with long cable lengths. Cable from the BICM to the processing unit or display should

be limited to 100 m.

5

2.0: Technical Specication

Page 8

M-3342 08/09

LD610

3.1: Introduction

The BICM kit is supplied with a selection of potentiometers and an output cable allowing users to connect LVDT sensors and set up to their own

requirements. Connections are made to the BICM PCB as shown in Fig. 3.1A or Fig. 3.1B below depending on the PCB version.

The BICM output is adjustable for GAIN and OFFSET. See the specification for range of adjustments possible.

Gain is sometimes called span or range. This control will affect the output voltage at the full transducer stroke. Adjusting the control clockwise will increase

the output.

Offset is sometimes called DC shift or zero shift. This control may be used to zero the output if mechanically nulling the transducer is not convenient or

can provide as much as 100% offset to enable the output to be unipolar ie. 0V to 10 V for full transducer stroke. Adjusting the control clockwise will make

output more negative.

Adjustment is by means of trimmer potentiometers (also called variable resistor or pots). The BICM will accept fixed value resistors in place of

potentiometers.

The BICM is designed to accept the following types of potentiometer or resistor:-

Potentiometer - Standard 3/8in square top adjust type potentiometer, see Fig. 3.1 (ie. Bourns 3299 type). The BICM kit comes complete with four

potentiometers.

Resistors - 1/4W MRF4 style.

6

3.0: Operational and Set-Up Guide - BICM Kit

Page 9

M-3342 08/09

LD610

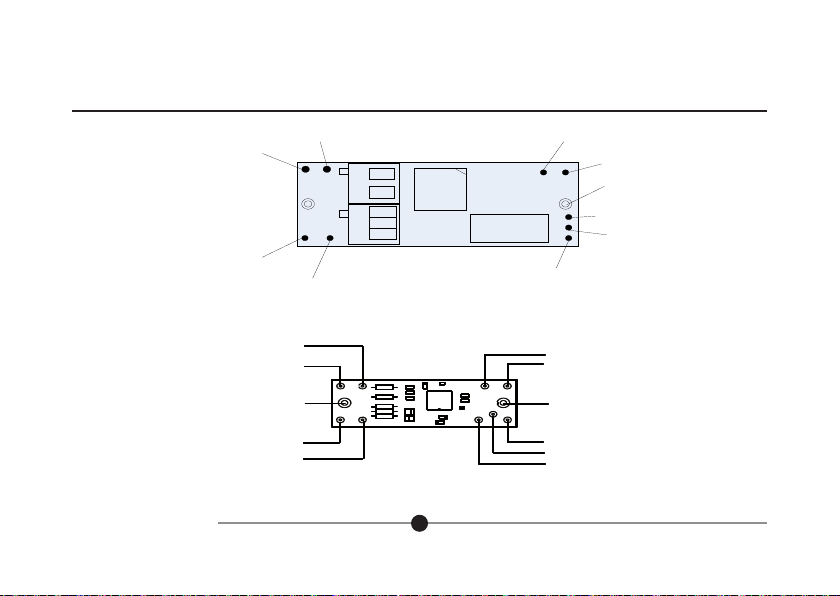

Fig. 3.1A Connections to PCB - 105186 (Bipolar or Unipolar)

Fig. 3.1B Connections to PCB - 103766 (Bipolar only)

7

3.0: Operational and Set-Up Guide - BICM Kit

Yellow

SEC2

SEC1

Green

White

Screen

Primary

Blue

Red

I/O CONNECTIONS

PRI1

PRI2

Screen

VOUT

0V

-15 V

0V

+15 V

Power

Supply

Output

Signal

SEC2

SEC1

Green

White

Screen

Primary

Blue

Red

TRANSDUCER CONNECTIONS

I/O CONNECTIONS

PRI1

PRI2

Screen

VOUT

0V

-15 V

0V

+15 V

Power

Supply

Output

Signal

Yellow

White

Green

Blue

Red

0V (Signal

white

)

Secondary 2 Green

0V Supply

Green

+15 V Bipolar

+24 V Unipolar

Red

Vout Yellow

Gain Offset

R2

+R4

R3

-R4

RV2RV1

R2

R1

Secondary 1 White

Primary Exc 2 Red

Primary Exc1 Blue

-15V Bipolar only

Blue

Screen

Page 10

M-3342 08/09

LD610

3.2: Screen Connection

The screen connection is arranged so that the transducer cable screen and I/O cable screen is connected and that some cable strain relief is

provided whilst setting up the board. Screens are not connected to 0V on the PCB. Screen and 0V may be connected on the PCB by using a wire

link or at the user connection end, for example at the PSU, but it all depends on the installation requirements.

Colours are for Omega LD610 Series transducers. Check individual transducer data sheets before connecting.

If a different polarity output is required secondary connections may be reversed. See application notes.

Centre Tap (CT), yellow wire, connection not required. Ensure no loose wires.

3.2 Screen Connection

Fit the potentiometers in the positions indicated in Fig. 3.3. The table below gives suggested values for use with some Omega LVDT's. Once fitted

the set up procedure can be followed to give the required output.

8

3.0: Operational and Set-Up Guide - BICM Kit

Page 11

M-3342 08/09

LD610

9

3.0: Operational and Set-Up Guide - BICM Kit

TRANSDUCER POTENTIOMETER VALUE (ohms)

GAIN OFFSET

LD610 2.5 100K 5K

LD610 5.0 50K 10K

LD610 10 100K 5K

LD610 15 100K 5K

LD610 25 100K 5K

LD610 50 50K 10K

LD610 100 50K 10K

Fig. 3.3 Component Installation

Top View

Side View

Fit this way round

Transducer

Connection

End

Page 12

M-3342 08/09

LD610

3.3. Gain Adjustment

Gain adjustment is best done before offset adjustment. If an OFFSET potentiometer has been fitted then set this to the mid position.

GAIN SETUP PROCEDURE

1) Adjust the potentiometer to the approximate mid position, about 12 full turns from either end.

2) Adjust the LVDT core position to give 0V output.

3) Move the core to a full scale position either inwards (+ve output) or outwards (-ve output). Adjust the potentiometer value to give the required

full scale output voltage such as + or -10 V. Adjusting the control clockwise will increase the output.

4) Return the core to the null position and check the output. Repeat steps 2 & 3 as required.

3.4. Offset

Any offset required is set by simply adjusting the OFFSET potentiometer until the required positive or negative offset is achieved. Adjusting the

control clockwise will make the output more negative.

Example:- Output required is 0V to +8 V for full transducer stroke (fully out to fully in). Set the gain for an output of 0V ±4 V then apply an offset

of +4 V.

Applying the required offset can sometimes be difficult if the gain is not correctly set. The application notes may help.

If no offset is required it is best not to fit the OFFSET potentiometer.

10

3.0: Operational and Set-Up Guide - BICM Kit

Page 13

M-3342 08/09

LD610

3.5. Set Up Using Fixed Value Resistors

Fit the components into the positions shown in Fig 3.4 once component values have been determined using the set up procedure.

The term nearest preferred value (NPV) is used throughout. This is a resistor selected from standard ranges (E24,E48 etc) that most closely

matches the value required.

Two resistors (in series) may be fitted to allow for more accurate calibration of gain and offset. If only one resistor is required a wire link is fitted

in place of the second resistor.

Gain adjustment is best done before offset adjustment. If an OFFSET potentiometer is fitted, set this to the mid position. If a resistor is fitted,

temporarily disconnect this.

If an offset is to be applied take this into account when setting the gain.

Example:- Output required is 0V to +10 V for full transducer stroke (fully out to fully in). Set the gain for an output of 0V ±5 V then apply an

offset of +5 V.

Some suggested start values for resistors are shown in the table below. If the transducer being used is not in the list then start with an arbitrary

value such as 50 Kohms.

11

3.0: Operational and Set-Up Guide - BICM Kit

Page 14

M-3342 08/09

LD610

TRANSDUCER APPROXIMATE RESISTOR VALUE (ohms)

GAIN OFFSET (+ or -5V)

LD610 1.5 85K 20K

LD610 2.5 61K 13K

LD610 5.0 40K 7K5

LD610 10 70K 15K

LD610 15 52K 11K

LD610 25 51K 11K

LD610 50 39K 7K5

LD610 100 25K 4K3

Fig 3.4 Resistor Positions

12

3.0: Operational and Set-Up Guide - BICM Kit

Page 15

M-3342 08/09

LD610

3.6. Gain Set Up Procedure

If this procedure is to be used to determine the value of potentiometer required perform up to step (6). The potentiometer value will be the NPV

greater than the resistor value determined.

1) Temporarily connect a variable resistance (such as a decade box) to the board as in

Fig. 3.5(a). Set the resistor to an initial value as shown in the table.

Fig 3.5 Temporary Resistor Connections - Gain

2) Move the core to a full scale position either inwards (+ve output) or outwards (-ve output). Adjust the potentiometer value to give the

required full scale output voltage such as + or -10 V.

3) Move the core to the full scale position. Adjust the variable resistor value to give the required full scale output voltage such as + or - 10 V.

4) Return the core to the null position and check the output. Repeat steps 2 & 3 as required.

5) If a single resistor is to be fitted, fit a NPV fixed resistor to position R1. Fit a wire link to position R2. If two resistors are to be used for a more

accurate calibration see step (6)

13

3.0: Operational and Set-Up Guide - BICM Kit

Resistance

Box

Resistance

Box

(a)

(b)

Page 16

M-3342 08/09

LD610

6) Fit a NPV fixed resistor that is just below the value required to position R1. Reconnect the temporary variable resistor to position R2, see Fig 3.6(b).

7) Repeat steps 2 & 3, moving the core between the null position and the full scale position adjusting the variable resistor as necessary to achieve the

required output.

8) Substitute a NPV fixed resistor for the temporary variable resistor position R2.

3.7 Offset Set Up Procedure

It is assumed that the gain has been set up consistent with the overall required result.

1) Set the transducer core to the null position. If this cannot be determined mechanically then, with no OFFSET resistors connected, adjust the core

position for a 0V output.

2) Connect temporary SOT or variable resistors (leads to be kept as short as possible) as shown for the required polarity offset. Fig. 3.6(a) for a positive

offset and Fig. 3.6(b) for a negative offset.

Fig 3.6 Temporary Resistor Connections - Offset

14

3.0: Operational and Set-Up Guide - BICM Kit

Resistance

Box

(a)

(b)

POSITIVE OFFSET

NEGATIVE OFFSET

Resistance

Box

Page 17

M-3342 08/09

LD610

3) Adjust the variable resistance until the required offset is achieved.

4) If a single resistor is to be fitted, fit a NPV fixed resistor to position +R4 or -R4 . Fit a wire link to position R3. If two resistors are to be used for a more

accurate calibration see step (5).

5) Fit a resistor with NPV that is just below the required value to position +R4 or -R4.

Re-connect the temporary variable resistor to position R3.

6) Repeat steps 1 & 3, moving the core between the null position and the full scale position adjusting the variable resistor as required to achieve the

required output.

7) Substitute the temporary variable resistor for a fixed resistor of the nearest preferred value.

15

3.0: Operational and Set-Up Guide - BICM Kit

Page 18

M-3342 08/09

LD610

The BICM case comprises two identical halves which are simply clamped around the PCB and connecting cables. Four self tapping screws are used to

secure the halves together.

Please note each half has a step along the side. The case halves will only mate correctly one way round.

DO NOT OVER TIGHTEN THE SCREWS when reassembling the case.

The strain relief blades in each half of the case may be removed if not required.

If enhanced environmental protection is required it is recommended that a suitable adhesive/sealant is applied to all edges of the case before assembly.

A suitable potting agent may also prove effective.

Fig 4.1 Case Assembly

16

4.0: The Case

Strain Relief

Blades

Page 19

M-3342 08/09

LD610

This is not an exhaustive list of problems but may help cure some of more common problems.

FAULT CONDITION POSSIBLE CAUSE OF FAULT

NO OUTPUT Power supply

Is it connected correctly?

Is it turned on?

Is there at least ±13.5 VDC at the power supply pads of the bipolar or +21.6 V for unipolar BICM?

Transducer

Is it connected correctly?

Is the transducer functional (perform continuity tests)?

SUPPLY CURRENT HIGH Power supply (see NO OUTPUT)

Transducer

Core not in transducer?

Short on primary connection?

Short on secondary connection?

Is the transducer functional (perform continuity test)?

Is the primary drive to transducer correct (compare with specification)?

Output load

Is the output shorted or wrong load?

INSUFFICIENT OUTPUT Power supply

Is there at least ±13.5 VDC at the power supply pads of the bipolar or +21.6 V for unipolar BICM?

Is there a proper 0V connection?

Transducer

Is the transducer core able to move the required amount?

Setup

Is gain and offset set correctly?

Have the components been fitted properly (any dry joints)?

WRONG POLARITY OUTPUT Transducer

Secondary connection wrong way round (swap white and green wires).

Set up

Voltmeter/indicator connected wrong way round.

17

5.0: The "Why Doesn't it Work Guide"

Page 20

M-3342 08/09

LD610

6.1. Transducer

The LD610 Series range of Transducer coil assemblies are designed for protection against dust and water to IP66, making them suitable for use in harsh

environments. Designed to be rugged and yet still cost effective, these devices offer the Customer all the attributes associated with LVDT’s. A variety of

combinations and accessories are available as options.

6.1.1. Introduction

The LD610 Series range of transducers operate on the LVDT principal, where movement of a core inside the transducer body is detected by a differential

change in output on two secondary coils, the primary coil(s) being energised by an appropriate AC signal. With the core in a central position, the coupling

from the primary to each secondary is equal and opposite and therefore cancel out, thus the resultant output voltage is zero. As the core is displaced

further into one secondary, its voltage increases proportionally and the other secondary voltage decreases, hence the output changes in magnitude and

phase in proportion to movement in either direction from null.

The red and white connections are in phase for inward movement (ie. towards the cable end).

The output signal depends on both core movement and energisation voltage and is expressed as a sensitivity in mV output / V energising / mm travel.

6.1.2. Installation

LVDT transducers generally are a reliable and proven technology that is well established in all areas of manufacturing and control industries. The majority

of the associated problems experienced with their application and use are totally avoidable, particularly if sufficient thought is given during the initial design

stages of equipment, to the positioning and clamping methods employed for these feedback elements.

LVDT’s being of inductive nature are susceptible to some degree to the influence of magnetic fields and therefore should be positioned well away from

electric motors, relays and permanent magnets, where this is not possible then magnetic shielding should be considered as an alternative.

Clamping of the coil assembly should be carefully considered, some example methods are shown overleaf. Ideally the body of the transducers should be

clamped centrally in a pinch or yoke type clamp, manufactured from a low conductivity, non-magnetic material, if this is not possible then the introduction

of a non-metallic bush between body and clamp is a preferred alternative.

18

6.0: Application Notes

Page 21

M-3342 08/09

LD610

6.1.2. Installation (continued)

Irrespective of clamping method care must be taken not to overtighten retaining screws as distortion of the body may prove damaging to the integrity of the

transducer and adversely affect the geometry of the installation.

If the LVDT is to be mounted on equipment subject to high ”g” then dependent on the direction of these forces, it may be advantageous to consider end to

end clamping in preference to over body clamping.

The magnetic core supplied with each transducer has been manufactured and heat treated to achieve the optimum magnetic performance, any subsequent

handling of the core which results in stress being imparted will render the calibration void, this includes overtightening of the core during installation onto its

carrier. Hand tightening and retention by means of a suitable thread locking anaerobic retainer is the recommended procedure.

6.1.3. Cores

The standard core supplied with each transducer incorporates an M4 x 0.7 x 12 mm deep female thread at both ends for mounting onto a carrier. An

alternative 6-40 UNF female thread is available as a standard option upon request.

6.1.4. Carriers

A standard length carrier is available for each model of transducer, manufactured from 316 stainless steel and incorporating an M4 x 0.7 x 10 mm long

male thread for attachment to the standard core and an M4 x 0.7 x 20 mm male thread for attachment to the fixture.

6.1.5. Guided Carrier

MOUNTING Normal mounting methods apply (see section 6.1.2. on Installation). Careful consideration should be given to alignment, the carrier must be

able to move freely within the transducer core. Side force should be kept to a minimal level.

MAINTENANCE: Check for free movement of the carrier when in the vertical plane. Lubrication is provided via an oilite bush which is impregnated with

molybdenum disulphide and in normal usage is maintenance free.

19

6.0: Application Notes

Page 22

M-3342 08/09

LD610

6.1.6. Ball Tip

This option is for use with the Guided Carrier and is attached via an adapter fitted to the threaded end of the core carrier. Side forces which may exert

undue pressure and flex the carrier must be avoided.

6.1.7. Rod End Bearings

MOUNTING: With the exception of the B100 the Transducer may be mounted in an axis; it is recommended that the rear rod end bearing (near cable exit)

is mounted on the static component. The B100 because of the increase in weight may exhibit bowing of the carrier and therefore mounting in the horizontal

plane should either be avoided or additional support given to the body. This option is used with the guided core.

MAINTENANCE: Rod end bearings are supplied pre-lubricated with mineral oil; for higher temperature applications the use of a molybdenum disulphide

impregnated oil is recommended and your representative should be consulted about the maximum temperature.

Periodic inspection of locking screws and nuts etc. is advisable depending upon the Customers application. Rod end bearings should be able to move

freely and have minimal side play.

6.1.8. Cable

Omega cable is specially manufactured to optimise performance with respect to temperature, chemical resistance, flex life, abrasion resistance and

electrical performance. However, no single cable design can fulfil every known requirement and by taking a few simple precautions cable failure can be

avoided. In flexture conditions then a minimum bend radius of 150 mm should be maintained. Avoid contact with sharp edges and rough surfaces and

inspect at periodic intervals.

Excessive cable runs may alter the output characteristics, if in doubt consult your representative.

20

6.0: Application Notes

Page 23

M-3342 08/09

LD610

Fig 6.1 Examples of Clamping Methods

21

6.0: Application Notes

IF POSSIBLE CENTRALISE L.V.D.T.

NON-METALLIC SPLIT (TUFNOL)

BUSH FOR USE WITH METALLIC CLAM P

Page 24

M-3342 08/09

LD610

6.2. Example 1

LD610 15 TRANSDUCER ±15 mm stroke (30 mm total stroke) BICM output E10 V output, no offset

1) Fit the 100 k potentiometer to the GAIN position on the BICM board.

2) No offset is required so the 50 k potentiometer is NOT fitted to the GAIN position on the BICM board.

3) Connect the transducer to the BICM according to Fig. 3.1.

4) Connect the output BICM to the display instrument, in this case a voltmeter on the DC range as shown in Fig. 6.1.

Fig 6.2

5) Move the transducer core to the approximate null position, half way along the transducer bore.

6) Turn the power supply on. A small output will probably be indicated on the voltmeter (unless the core has been placed exactly at null).

6) Adjust the core position until the voltmeter reads 0V.

22

6.0: Application Notes

Page 25

M-3342 08/09

LD610

6.2. Example 1 (continued)

7) Move the core 15 mm inwards from the null position. The voltmeter should indicate a Positive increase in output.

8) Adjust the GAIN potentiometer clockwise until +10 V is indicated on the voltmeter.

9) Move the core back to the null position then repeat steps (6) to (8) until satisfied with the calibration. Move the core 15 mm outwards and check that

-10 V is indicated on the voltmeter.

6.3. Example 2

LD610 2.5 TRANSDUCER ±2.5 mm stroke (5 mm total stroke) BICM output 0 TO 5 V OUTPUT OVER 5 mm (ie ±2.5 V output plus 2.5 V offset)

1) Fit the 100 k potentiometer to the GAIN position on the BICM board. The OFFSET potentiometer will be fitted later.

2) Connect the transducer to the BICM according to Fig. 3.1

3) Connect the output BICM to the display instrument, in this case a voltmeter on the DC range as shown in the diagram of the last example.

4) Move the transducer core to the approximate null position, half way along the transducer bore.

5) Turn the power supply on. A small output will probably be indicated on the voltmeter (unless the core and OFFSET potentiometer are exactly at null). If

the offset pot has already been fitted, see USEFUL HINTS (4). Adjust the core position until the voltmeter reads 0V.

8) Move the core 2.5 mm inwards from the null position. The voltmeter should show a positive increase in output.

9) Adjust the GAIN potentiometer clockwise until +2.5 V is indicated on the voltmeter.

9) Move the core back to the null position then repeat (6) to (8) until satisfied with the calibration. Move the core 2.5 mm outwards and check that -2.5 V is

indicated on the voltmeter.

The transducer has now been calibrated for ±2.5 V for 5 mm of movement.

10) Fit the 5 k potentiometer to the GAIN position on the BICM board and set the potentiometer to the approximate mid position.

23

6.0: Application Notes

Page 26

M-3342 08/09

LD610

6.3. Example 2 (continued)

11) For a 0 to 5 V output simply adjust the OFFSET potentiometer until the -2.5 V reading on the voltmeter shows 0V. If the core is moved to the mechanical

null position +2.5 V should be indicated and +5 V at the fully out position.

6.4. Some Useful Hints

1) If no offset facility is required it is best not to fit any OFFSET components. This makes calibration much easier.

2) If an opposite polarity output is required, ie a -ve output for an inward core movement the secondary connections to the BICM may be reversed (white

and green wires for a Omega LD610 Series transducer).

3) If the BICM is to be placed in a position where it may be subject to high levels of vibration then using resistors for calibration is advised as

potentiometers may shift.

4) If an offset potentiometer is fitted an accurate electrical null can easily be found. Put a temporary shorting link across the transducer secondary by

connecting the SEC1 and SEC2 pads on the BICM board. Adjust the OFFSET potentiometer to give an accurate 0V on the voltmeter. Now remove the

temporary short.

Best performance will be achieved if resistors are used to set gain and offset. Potentiometers whilst being of high quality have a poorer temperature

coefficient than resistors. Output noise and stability are also improved by using resistors.

24

6.0: Application Notes

Page 27

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and

workmanship for a period of 13 months from date of purchase. OMEGA’s Warranty adds an

additional one (1) month grace period to the normal one (1) year product warrantyto cover

handling and shipping time. This ensures that OMEGA’s customers receive maximum

coverage on each product.

If t he unit malfunctions, it mus t be returned to the factory for evaluati on. OMEGA’s C ustomer

Service Department wil l issue an Auth orized Return (AR) number immedia tely upon phone or

written request. Upon examination by OMEGA, if the unit is found to be defective, it will be

repaired or replaced at no charge. OMEGA’s WARRANTY does not apply to defects resu lting

from any ac tion of the purchas er, including but not limited to mis handling, improper inte rfacing,

operation outside of design limits, improper repair, or unauthorized modification. This

WARRANTY is VOID i f the unit shows evidence of having been tampered with or shows evidence

of having been dam aged as a result o f excessive corrosion; or current, hea t, moisture or vibration; improper specification; misapplication; misuse or other operating conditions outside of

OMEGA’s control. Components which wear are not warranted, including but not limited to

contact points, fuses , and triacs.

OMEGA is pl eased to offer suggestions on the us e of its various pr oducts. H owever,

OMEGA neit her assumes respo nsibility for any omis sions or errors nor assum es l iability

for any d amages that result from the u se of its products in accorda nce wi th inf ormation

provided by OMEGA, either verbal or written. OMEGA warrants only that the parts

manufa ctured by it w ill be as spe cified and free of defects. OMEG A MA KES N O OT HER

WARRANTIES OR REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESS OR

IMPLIED, EXCEPT THAT OF TITLE, A ND ALL IMPLIED WARRANTI ES INCLU DING ANY

WARRANT Y OF MER CHANTABILIT Y AN D FI TNESS FOR A P ARTICULAR PURP OSE ARE

HEREBY DISCLAI MED. LIMITATION OF LIABILITY: The remedi es of purch aser s et for th

herein are exclusiv e, and the total liabili ty of OMEGA with respect to t his or der, w hether

based on contr act, warr anty, neg ligence, indemnifi cation, strict li ability o r otherwi se, shal l

not e xceed th e purcha se price of the compone nt upon which li ability is based . In no event

shall OMEGA be liable fo r consequ ential, in cidental or specia l damages .

CONDITIONS: Equipment sold by OMEGA is no t intended to be used, nor shall it be used: (1) as

a “Basic Com ponent” under 10 CF R 21 (NRC), used in or with any nuclear installation or activity;

or (2) in medical appl ications or used on humans. Should any Pro duct(s) be used in or wit h any

nuclear ins tallation or activity, medical application, used on humans, or misused in any way,

OMEGA assumes no responsibility as set forth in our basic WARRANTY /DISCLAIMER language,

and, additionally, purchaser will indemnify OMEGA an d hold OMEGA harmless from any liability

or damage whatsoever arising out of the use of the Pr oduct(s) in such a manner.

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department.

BEFORE RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN

AUTHORIZED RETURN (AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT

(IN ORDER TO AVOID PROCESSING DELAYS). The assigned AR number should then be

marked on the outside of the return package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to

prevent breakage in transit.

FOR WARRANTY

RETURNS, please have

the following information available BEFORE

contacting OMEGA:

1. Purchase Order number under which

the product was PURCHASED,

2. Model and serial number of the product

under warranty, and

3. Repair instructions and/or specific

problems relative to the product.

FOR NON-WARRANTY REPAIRS,

consult

OMEGA for current repair charges. Have the

following information available BEFORE

contacting OMEGA:

1. Purchase Order number to cover the

COST of the repair,

2. Model and serial number of the

product, and

3. Repair instructions and/or specific problems

relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible.

This affords our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2004 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied,

reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without

the prior written consent of OMEGA ENGINEERING, INC.

Page 28

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

Shop online at www.omega.com

TEMPERATURE

Thermocouple, RTD & T hermistor Probes, Connectors, Panels & Assemblies

Wire: Thermocouple, R TD & Thermistor

Calibrators & Ice Poi nt References

Recorders, Controller s & Process Monitors

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

Transducers & Strain Gages

Load Cells & Pressure Gages

Displacement Transduc ers

Instrumentation & Acc essories

FLOW/LEVEL

Rotameters, Gas Mass Flowmeters & Flow Computers

Air Velocity Indicato rs

Turbine/Paddlewheel S ystems

Totalizers & Batch Co ntrollers

pH/CONDUCTIVITY

pH Electrodes, Testers & Ac cessories

Benchtop/Laboratory M eters

Controllers, Calibrat ors, Simulators & Pumps

Industrial pH & Conductivit y Equipment

DATA ACQUISITION

Data Acquisition & En gineering Software

Communications-Based Acquisition Systems

Plug-in Cards for App le, IBM & Compatibles

Datalogging Systems

Recorders, Printers & Plotters

HEATERS

Heating Cable

Cartridge & Strip Hea ters

Immersion & Band Heat ers

Flexible Heaters

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

Metering & Control In strumentation

Refractometers

Pumps & Tubing

Air, Soil & Water Mon itors

Industrial Water & Wa stewater Treatment

pH, Conductivity & Di ssolved Oxygen Instrument

s

Loading...

Loading...