Page 1

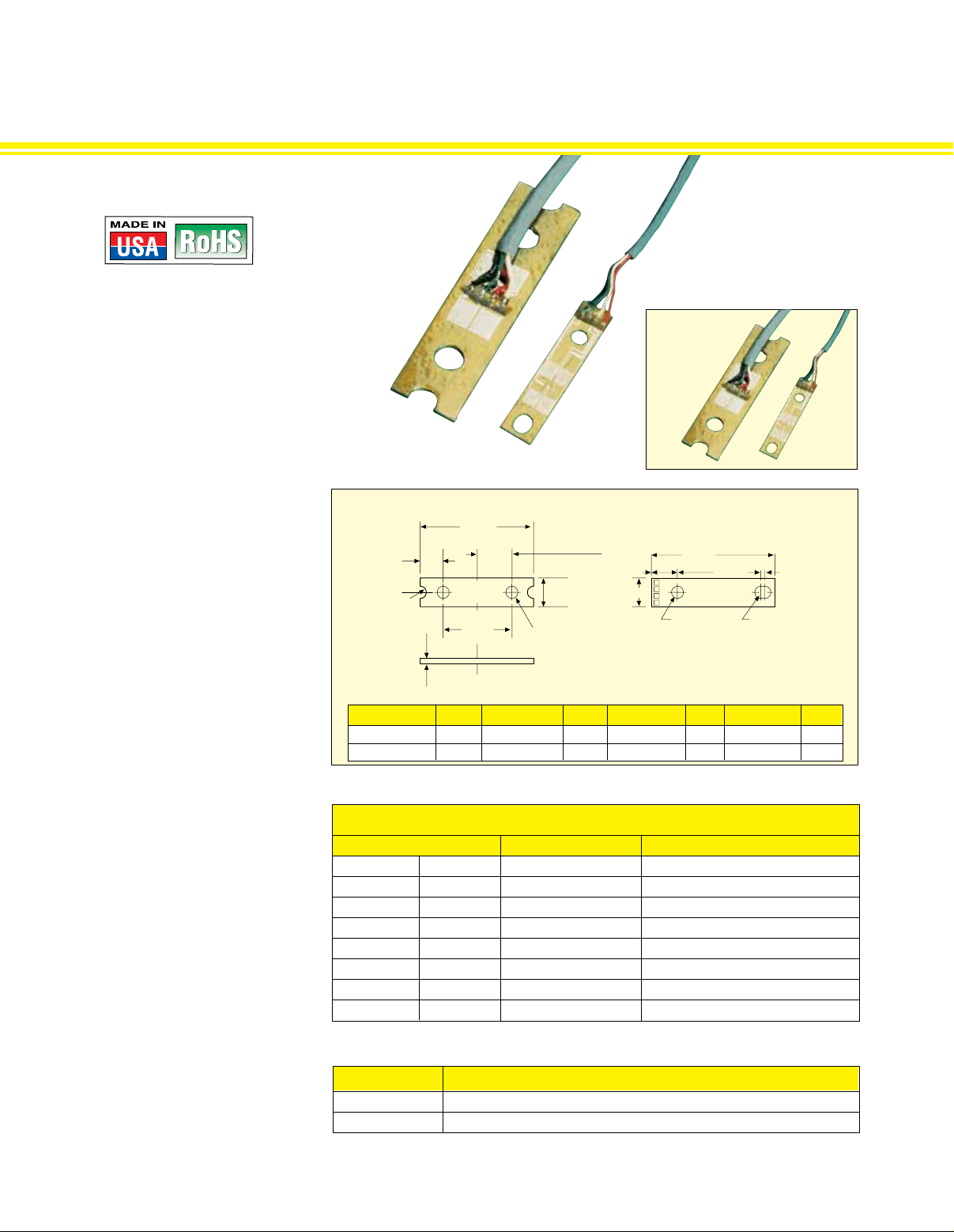

LCL-113G/816G

(GRAM MODELS)

LCL-005/040

(POUNDS MODELS)

DIMENSIONS

FULL-BRIDGE THIN-BEAM LOAD CELLS

FOR LOADS 0-113 g to 0-18 kgf

LCL Series

U Measures Force

or Displacement

U Thermally Matched,

Fully Active,

Full-Bridge

Gage for Optimal

Temperature Tracking

When frequent small-load

measurements are required,

OMEGA® LCL Series thin-beam

load cells are the answer. The LCL

Series is designed to measure

many different parameters found

in medical instrumentation, home

appliances, process control,

robotics, automotive, and other

high-volume applications.

A specially developed integrated

strain gage includes all balancing,

compensating, and conductive

elements and is laminated to the

beam to provide excellent stability

and reliability.

SPECIFICATIONS

Excitation: 5 Vdc, 12V max

Rated Output: 2 mV/V ±20%

(to minimize ±20% tolerance, end user

must calibrate with a known weight)

Zero Balance: 0.3 mV/V

Combined Error: 0.25% FS

Operating Temperature: -54 to 93°C

(-65 to 200°F)

Compensated Temperature:

-7 to 49°C (20 to 120°F)

Temperature Effects: Zero balance

0.02% FS/°F; output 0.02%/°F

Resistance (Input and Output):

1200 ±300 Ω

Insulation Resistance: 1000 @ 50 Vdc

Seal: Urethane coated

Safe Overload: 150% FS

Full Scale Deflection: 0.25 to 1.27 mm

(0.010 to 0.050")

Lead Wire: 9" shielded PVC

4-conductor 30 AWG

Material:

>816 gf (2 lb): 301 SS

≤816 gf (2 lb): Beryllium copper

Shown

actual size.

LCL-010

LCL-454G

High Ranges 2 to 18 kgf

31.75

(1.25)

6.35

(0.25)

1.575

R.

(0.062)

TYP

mm

(in)

MODEL NO. t MODEL NO. t MODEL NO. t MODEL NO. t

LCL-113G 0.15 LCL-454G 0.28 LCL-005 0.56 LCL-020 1.12

LCL-227G 0.23 LCL-816G 0.38 LCL-010 0.79 LCL-040 1.6

19.05

(0.750)

C

t

L

Dimensions:

mm (in)

9.525 REF

(0.375)

7.925

(0.312)

3.175

DIA.

(0.125)

TYP

.

6.4 (0.25)

.

WIRING CODE

Low Ranges 113 to 816 g

30.5

66

(0.26)

RED = +EXC.

GREEN = +SIGNAL

(1.20)

3.1 DIA.

(0.12)

20.3

(0.80)

(2 PLCS)

BLACK = -EXC.

WHITE = -SIGNAL

To Order Visit omega.com/lcl for Pricing and Details

CAPACITY MODEL NO. COMPATIBLE METERS

113 gf 0.25 lb LCL-113G DP2000S5, DP25B-S, DPiS

227 gf 0.5 lb LCL-227G DP2000S5, DP25B-S, DPiS

454 gf 1 lb LCL-454G DP2000S5, DP25B-S, DPiS

816 gf 2 lb LCL-816G DP2000S5, DP25B-S, DPiS

2.27 kgf 5 lb LCL-005 DP2000S5, DP25B-S, DPiS

4.54 kgf 10 lb LCL-010 DP2000S5, DP25B-S, DPiS

9.07 kgf 20 lb LCL-020 DP2000S5, DP25B-S, DPiS

18.14 kgf 40 lb LCL-040 DP2000S5, DP25B-S, DPiS

MOUNTING HARDWARE

MODEL NO. MOUNTING BRACKETS

LCL-CL1 For LCL-113G through LCL-816G

LCM-CL1 For LCL-005 through LCL-040

Ordering Examples: LCL-113G, beam and LCL-CL1, mounting bracket.

LCL-020, beam lead cell and LCM-CL1, mounting bracket.

1.5 RAD

(0.06)

1.0

(0.04)

F-67

Page 2

F

I

R

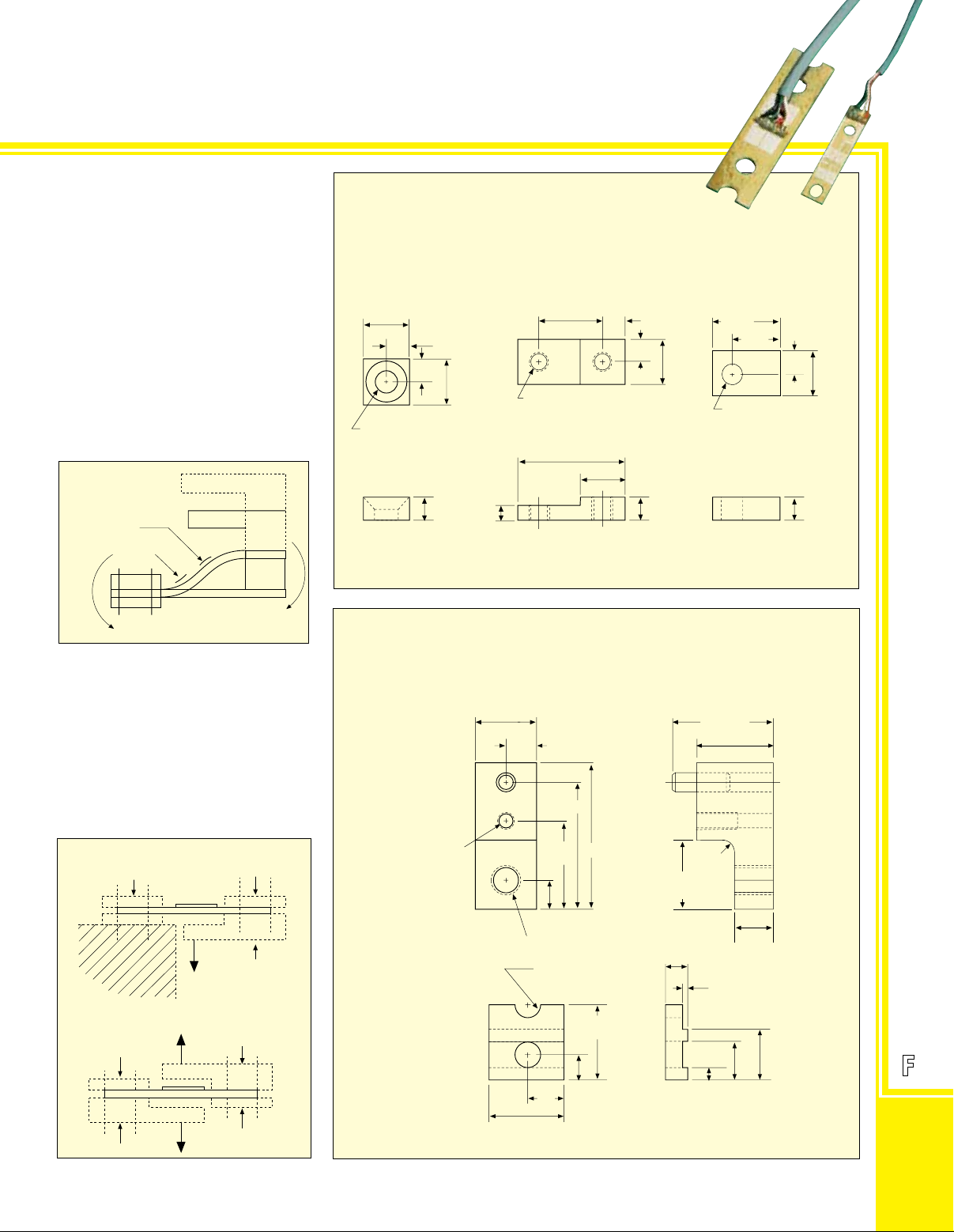

INSTALLATION CONSIDERATIONS

T

Mounting Kit LCL-CL1 for thin beam sensors LCL-1136 to LCL-816G.

ype 1 mounting only. Kit includes: Mounting blocks A,B, and C.

FOR THIN-BEAM LOAD CELLS

Careful design considerations

must be taken into account when

mounting OMEGA’s LCL Series

thin-beam load cells. The sensor’s

performance depends on the

mechanical interface. All thin-beam

load cells require mounting clamps

to create a “double bend” during

loading, as shown in Figure A.

This illustration is exaggerated to

show the clamp’s effectiveness

in producing opposing moments

that create the double bend. An

electrical output is generated as

the double bend causes tension

and compression on the sensor

strain gage.

TENSION

COMPRESSION

Mounting kit LCL-CL1 for thin-beam sensors LCL-113G through LCL-816G,

Type 1 mounting only. Kit includes mounting blocks A, B, and C.

6.4 (0.250)

0.120 (3) DIA. THRU.

82ϒOSK

0.238 (6) DIA. X 0.070 DR

BLOCK

(0.125)

(0.125)

A

3.2

(0.125)

3.2

3.2

6.4

(0.250)

(0.080)

LCL-CL1 Mounting Kit

Dimensions: mm (in)

9

(0.350)

#4-40 OUNC 2B THRU.

2 PLACES

15 (0.60)

6.4

(0.25)

2

BLOCK

B

3.2

(0.125)

3.2

(0.125)

(0.25)

3.2

(0.125)

6.4

9.3

(0.37)

6.7

(0.263)

0.120 DIA.

(3.1)

BLOCK

C

3.2

(0.125)

THRU.

3.2

(0.125)

6.4

(0.25)

Figure A

Two typical mounting arrangements

are shown below. For high-accuracy

applications, reinforcement plates

Mounting kit LCM-CL1 for thin-beam sensors LCL-005 through LCL-040.

Kit includes 4 mounting blocks, 2 each of blocks A and B.

Type 2 mounting only.

should be slightly harder than the

beam material, and the interfacing

corners should be sharp. Because

of low loads and sensor construction

associated with the LCL113G

through LCL-816G, in-line loading

(Type 2) is not recommended.

A

B

TCype 1

A

B

Type 2

B

A

LCM-CL1 Mounting Kit

9.5

(0.375)

4.7

(0.187)

21

(0.812)

2.3 (0.09)

THRU

#4-40 UNC

6.4 (1/4)

DEEP

BLOCK B

#10-32 UNF THRU

BLOCK A BLOCK A

(0.562)

4.8

(0.188)

1.7

(0.065)R

4.7

(0.187)

9.5 (0.375)

14.3

(0.937)

9.5

(0.375)

3.2

(0.125)

24

BLOCK B

16 (0.625)

12 (0.480)

1.6

(0.062)R

11

(0.437)

2.9

(0.115)

0.79

(0.031)

1.6

(0.062)

4.8

(0.188)

Dimensions: mm (in)

6.4

(0.250)

6.4

(0.250)

LOAD CELLS

F-68

Loading...

Loading...