Page 1

I

R

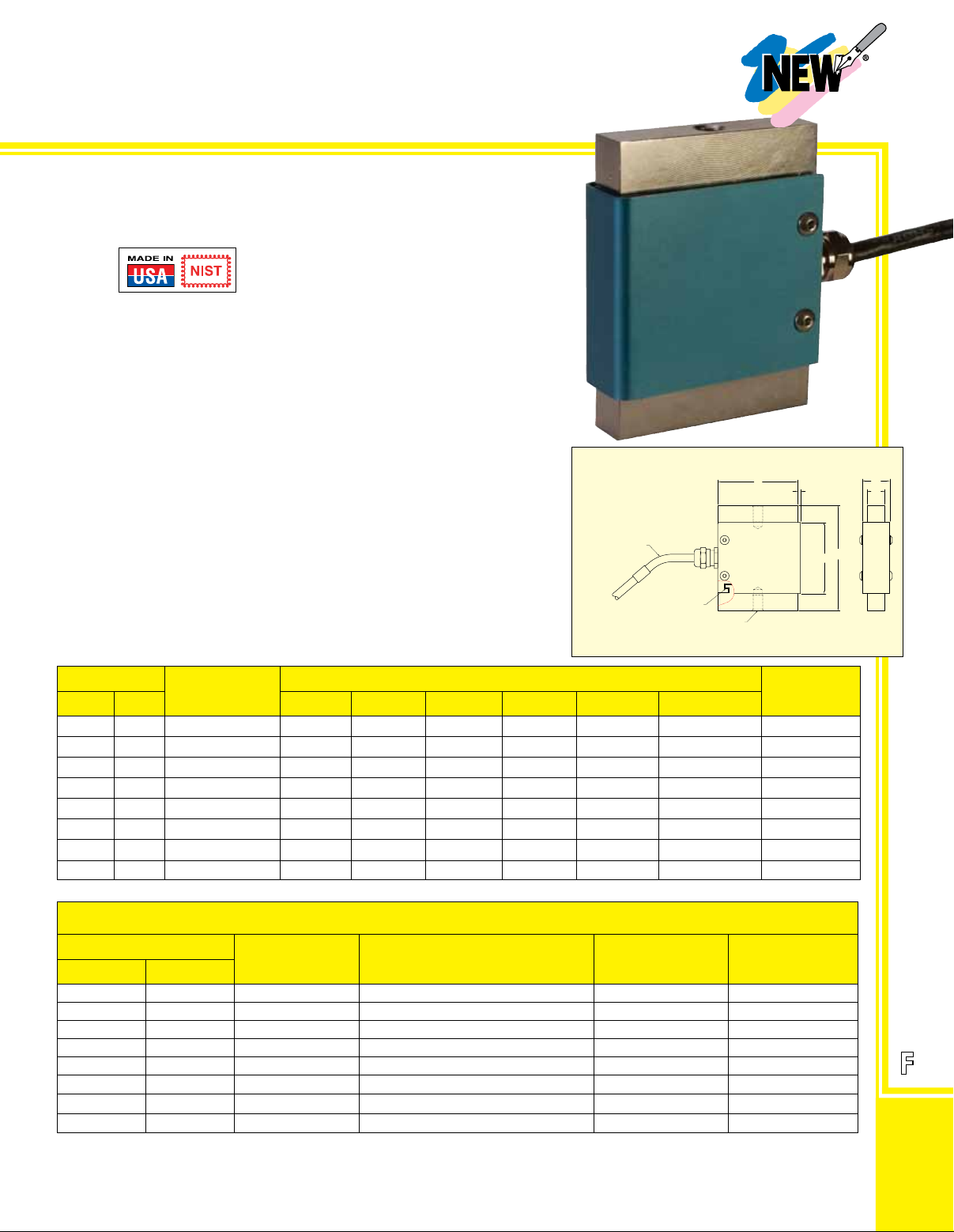

LOW RANGE S-BEAM LOAD CELLS

WITH 500% OVERLOAD PROTECTION

25 to 750 lb Capacities

11 to 340 kg Capacities

LCCE Series

Standard

U Protected to 500% Full

Scale Overload

U High Accuracy

U

5-Point Calibration Included

U 0.25% Interchangeability

for Multiple Load Cell

Applications

U Rugged Stainless Steel

Construction on All Ranges

The LCCE S-Beam load cells are

designed with mechanical overload

protection to 500% of FS in both

tension and compression. This

unique design gives you an extra

level of protection and functionality

that is typically an extra cost option

on most load cells. When overloaded,

the load cell is protected by a unique

locking design. When the overload

is removed, the load cell unlocks

and returns to normal funtion. The

stainless steel sensing element

makes this load cell one of the most

durable models available.

SPECIFICATIONS

Excitation: 10 Vdc, 15V maximum

Output: 3 mV/V ± 0.25% full scale

Calibration: 5 point NIST traceable in

tension 0%, 50%, 100%, 50%, 0%

Linearity: ± 0.03% full scale

Hysteresis: ± 0.02% full scale

Repeatability: ± 0.01% full scale

Zero Balance: ± 1% full scale

Creep in 20 minutes: ± 0.03% full scale

Operating Temperature: -18 to 65°C

(0 to 150°F)

Compensated Temperature:

-18 to 65°C (0 to 150°F)

Thermal Effects:

Zero: ± 0.0027% FS/°C

Span: ± 0.0014% rdg/°C

Safe Overload: 500% capacity

tension and compression

Ultimate Overload: 500% capacity

Bridge Resistance: 350 Ω nominal

Protection Level: IP67

Material: 17-4 PH SS element,

aluminum side cover

Electrical Connection: 6 m (20')

4-conductor 24 AWG jacketed cable

Wiring:

Red (+) Excitation

Black (-) Excitation

Green (+) Output

White (-) Output

20 FT.,

4 CONDUCTOR,

24 AWG

JACKETED CABLE

OVERLOAD

PROTECTION

Dimensions: mm (inch)

”THREAD”

LCCE-250 shown

actual size.

W

2X

1.5

(0.06)

T2

T1

H1

H2

CAPACITY

THREADS

25 11 ¼-28 UNF-2B 64 (2.5) 43 (1.7) 48 (1.9) 10 (0.4) 17 (0.65) 0.28 (0.011) 0.18 (0.4)

50 23 ¼-28 UNF-2B 64 (2.5) 43 (1.7) 48 (1.9) 10 (0.4) 17 (0.65) 0.25 (0.010) 0.18 (0.4)

100 45 ¼-28 UNF-2B 64 (2.5) 43 (1.7) 48 (1.9) 10 (0.4) 17 (0.65) 0.23 (0.009) 0.18 (0.4)

150 68 ¼-28 UNF-2B 64 (2.5) 43 (1.7) 48 (1.9) 10 (0.4) 17 (0.65) 0.23 (0.009) 0.18 (0.4)

200 91 ¼-28 UNF-2B 64 (2.5) 43 (1.7) 48 (1.9) 10 (0.4) 17 (0.65) 0.25 (0.010) 0.18 (0.4)

250 113 ³⁄₈-24 UNF-2B 76 (3.0) 46 (1.8) 48 (1.9) 13 (0.5) 18 (0.70) 0.23 (0.009) 0.27 (0.6)

500 227 ½-20 UNF-2B 76 (3.0) 46 (1.8) 48 (1.9) 18 (0.7) 24 (0.95) 0.25 (0.010) 0.36 (0.8)

750 340 ½-20 UNF-2B 76 (3.0) 46 (1.8) 48 (1.9) 18 (0.7) 24 (0.95) 0.15 (0.006) 0.41 (0.9)

* For reference only

Dimensions: mm (inch)

To Order Visit omega.com/lcce for Pricing and Details

CAPACITY

MODEL NO. COMPATIBLE METERS

25 11 LCCE-25 DP41-S, DP25B-S, DPi8-S LBC-014 REC-014M

50 23 LCCE-50 DP41-S, DP25B-S, DPi8-S LBC-014 REC-014M

100 45 LCCE-100 DP41-S, DP25B-S, DPi8-S LBC-014 REC-014M

150 68 LCCE-150 DP41-S, DP25B-S, DPi8-S LBC-014 REC-014M

200 91 LCCE-200 DP41-S, DP25B-S, DPi8-S LBC-014 REC-014M

250 113 LCCE-250 DP41-S, DP25B-S, DPi8-S LBC-038 REC-038M

500 227 LCCE-500 DP41-S, DP25B-S, DPi8-S LBC-012 REC-012M

750 340 LCCE-750 DP41-S, DP25B-S, DPi8-S LBC-012 REC-012M

Comes complete with 5-point NIST traceable calibration certificate and 59K shunt data.

Ordering Examples: LCCE-25, 25 lb range high overload S-Beam load cell.

LCCE-500, 500 lb range high overload S-Beam load cell.

F-1

LOAD BUTTON

MODEL NO.

WEIGHT*

kg (lb)lb kg H1 H2 W T1 T2 DEFL*

LOAD CELLS

ROD END

MODEL NO.lb kg

F

Loading...

Loading...