Page 1

OMEGA ENGINEERING

ISE-8882 ION SELECTIVE ELECTRODE FOR SURFACTANT

INSTRUCTION MANUAL

GENERAL INSTRUCTIONS

Introduction

The Omega ISE-8882 Surfactant Electrode indicates the potentiometric endpoint when titrating

anionic or

cationic

surfactants in solution. Titration procedures for manual titrations are discussed

in this manual, though adaptation to automatic titration techniques is quite simple. The electrode

0.05M

comes packaged with one 50 ml bottle of

O.OlM

one 50 ml bottle of

sodium lauryl sulfate (sodium dodecyl sulfate) titrant, and one 50 ml

Hyamine 1622 (benzethonium chloride) titrant,

bottle of sample additive, diluted Triton X- 100.

Required Equipment

1.

2.

3.

A

pH/mV meter, either line operated or portable.

A hand controlled delivery system, such as a 10 ml

ISE-8882 Surfactant Electrode (glass)

Required Solutions

1.

2.

Distilled or de-ionized water to prepare all solutions and standards.

Titrant for the titration of anionic surfactants is Hyamine 1622,

To prepare this titrant from your own laboratory stock, add 22.405 grams of

Hyamine 1622 and 5 ml of 1 M

de-ionized water. Swirl the flask to dissolve the solid and fill to the mark with

distilled water. Cap the flask and invert several times to mix the solution.

3.

Titrant for the titration of

(SLS) To prepare this titrant from your own laboratory stock, add 2.883 grams

sodium lauryl sulfate (SLS) to a one liter volumetric flask about half full of distilled

water. Swirl the flask to dissolve the solid and fill to the mark with distilled water.

Cap the flask and invert several times to mix the solution.

pipet

or burette.

0.05M

NaOH to a 1 liter volumetric flask about half full of

O.OlM

cationic

surfactants is

Sodium Lauryl Sulfate

3.

Sample Additive, diluted Triton X- 100, to keep electrodes clean when added to all

Page 2

samples. To prepare, add 10 ml of reagent-grade Triton X-100 to a one liter volumetric

flask about half full of distilled water. Cap the flask and invert several times to mix the

solution.

4.

Electrode Filling Solution, 4M KC1 (with

Ag’), for filling the reference chamber of

the electrode.

5.

6.

(O.OlM

(O.lM HCl) and polyacrylates

NaOH).

Electrode Rinse Solutions consisting of about 50 ml 0.

for acidic rinse (anionic or

cationic

surfactant analysis) and 50 ml 0.

cationic

HCl diluted to 1000 ml

1M

1M

surfactantspH of both anionic and pH Adjuster Solutions for adjusting the

NaOH

diluted to 1000 ml for alkaline rinse (polyacrylate analysis).

GENERAL PREPARATION

Electrode Preparation

Remove the rubber cap(s) covering the electrode tip(s) and the rubber insert covering the filling

hole of the reference electrode. Fill the combination electrode or the reference electrode with the

filling solution shipped with the electrode to a level just below the fill hole. No preparation is

required with a sealed reference electrode. Gently shake the electrode downward in the same

manner as a clinical thermometer to remove any air bubbles which might be trapped behind the

surfactant membrane.

O.OlM

Prepare

O.OOOlM

SLS by diluting 1 ml of the

first usage, or after long-term storage, soak the tip of the surfactant electrode in

SLS to 100 ml with distilled water. Prior to

O.OOOlM

SLS for

10 minutes before using the electrode each day. Use fresh solution daily. The electrode is now

ready for use.

Connect the electrode(s) to the proper terminal(s) as recommended by the meter manufacturer.

If the stock solution becomes cloudy or contaminated in any way, discard it.

Titrant Preparation

Based on the recommendations found in

Required Solutions,

select an appropriate titrant.

Determine the concentration of titrant needed for the analysis from Table 1.

Page 3

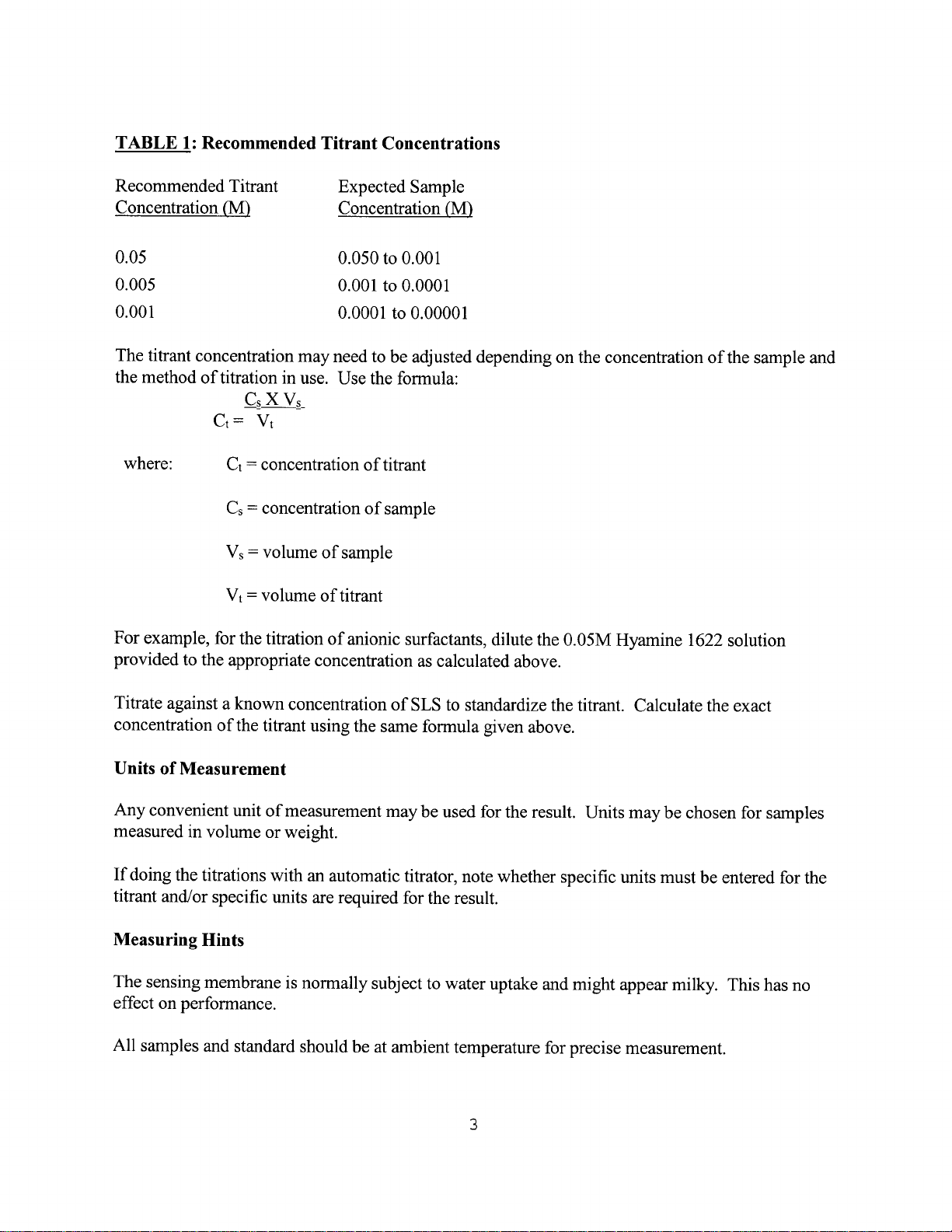

TABLE 1: Recommended Titrant Concentrations

Recommended Titrant

Concentration

(M)

Expected Sample

Concentration

(M)

0.05 0.050 to 0.001

0.005 0.001 to 0.0001

0.001

0.0001 to 0.00001

The titrant concentration may need to be adjusted depending on the concentration of the sample and

the method of titration in use. Use the formula:

~&_.Ys_

Vt

Ct

=

Ct

where:

= concentration of titrant

C,

= concentration of sample

V, = volume of sample

Vt

= volume of titrant

For example, for the titration of anionic surfactants, dilute the

0.05M Hyamine 1622 solution

provided to the appropriate concentration as calculated above.

Titrate against a known concentration of SLS to standardize the titrant. Calculate the exact

concentration of the titrant using the same formula given above.

Units of Measurement

Any convenient unit of measurement may be used for the result. Units may be chosen for samples

measured in volume or weight.

If doing the titrations with an automatic titrator, note whether specific units must be entered for the

titrant and/or specific units are required for the result.

Measuring Hints

The sensing membrane is normally subject to water uptake and might appear milky.This has no

effect on performance.

All samples and standard should be at ambient temperature for precise measurement.

3

Page 4

Constant, but not violent, stirring is necessary for accurate measurement. Slow stirring is

recommended to avoid foaming.

Always rinse the electrode tip(s) with the slightly acidic (or alkaline) rinse solution described in

Required Solutions

and blot dry with a fresh tissue between titrations to prevent solution

carryover.

Check the electrode for air bubbles adhering to the membrane surface after immersion in solution.

Agitate the electrode gently to remove any air bubbles.

A slow or sluggish electrode response may indicate surface contamination of the electrode

membrane. Soak the electrode tip in distilled water for about 5 minutes to clean the membrane.

Rinse the membrane and soak in

O.OOOlM

SLS for about 5 minutes to restore performance.

The electrode should be reconditioned daily before storage as described in

Cleaning,

Reconditioning, and Storage.

Sample Requirements

To help keep the electrode clean and working properly, add sample additive, diluted Triton X- 100,

to all samples. For every 50 ml of sample, use 1 ml of sample additive.

Samples should be diluted to approximately

10m5

to

lOA

M to help preserve electrode life, help

avoid foaming during the titration, and help improve long term results.

pH

Adjust the

of the sample depending on the method being used.

Anionic surfactants, as well as sulfated and sulfonated surfactants, may be titrated with Hyamine

1622. Adjustment to

Polyacrylates should be adjusted to

Cationic

acidification to

surfactants should be titrated with an anionic reagent, such as sodium lauryl sulfate,

O.OlM

HCl.

pH 3 with

pH

1 O-l 1 with 0.

O.OlM

1M

NaOH before analysis.

HCl.

pH 2.5-4.5 should be done by addition of

after

Page 5

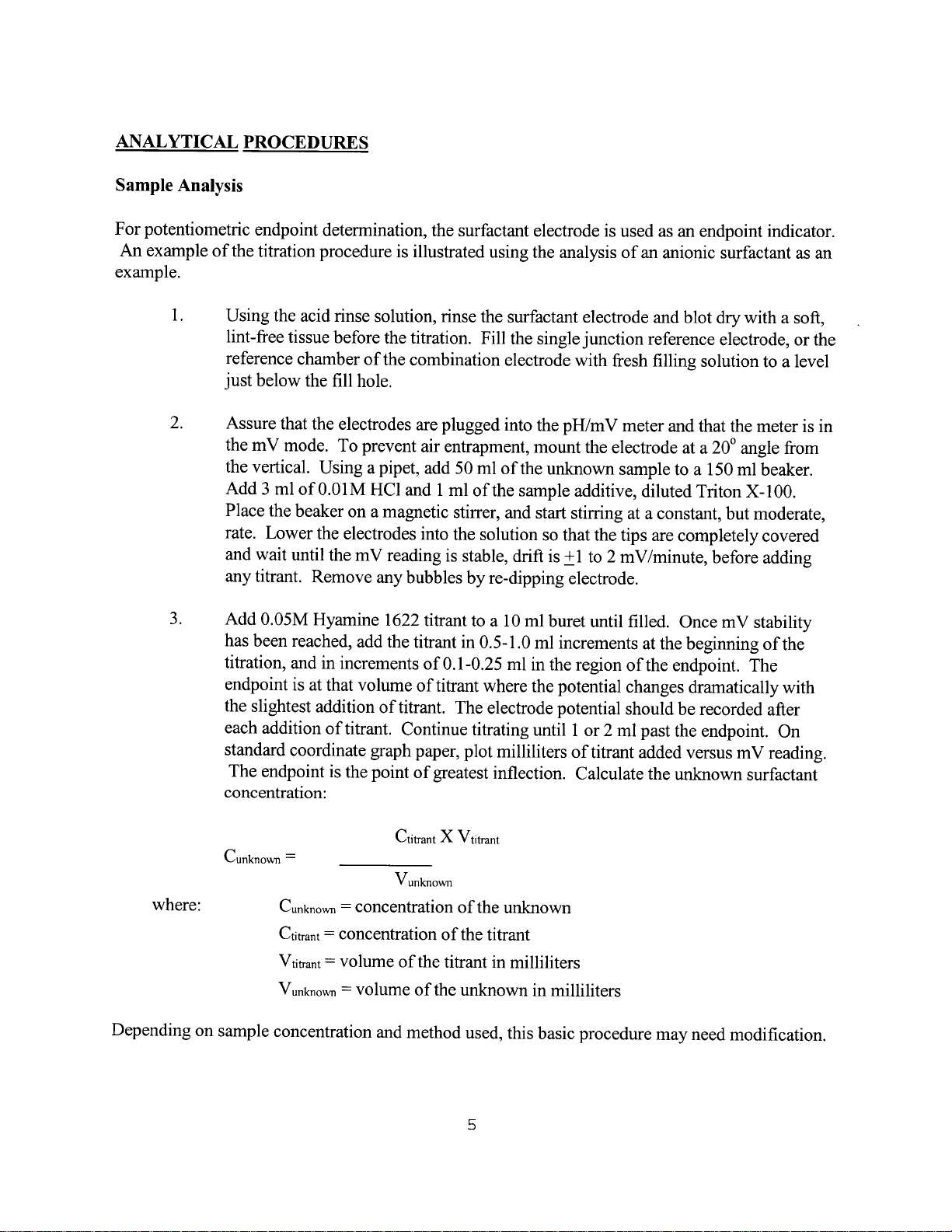

ANALYTICAL PROCEDURES

Sample Analysis

For potentiometric endpoint determination, the surfactant electrode is used as an endpoint indicator.

An example of the titration procedure is illustrated using the analysis of an anionic surfactant as an

example.

2.

3.

1.

Using the acid rinse solution, rinse the surfactant electrode and blot dry with a soft,

lint-free tissue before the titration. Fill the single junction reference electrode, or the

reference chamber of the combination electrode with fresh filling solution to a level

just below the fill hole.

Assure that the electrodes are plugged into the

mV mode. To prevent air entrapment, mount the electrode at a 20 ” angle from

the

pipet,

the vertical. Using a

O.OlM

Add 3 ml of

HCl

add 50 ml of the unknown sample to a 150 ml beaker.

and 1 ml of the sample additive, diluted Triton X-100.

pH/mV meter and that the meter is in

Place the beaker on a magnetic stirrer, and start stirring at a constant, but moderate,

rate.

Lower the electrodes into the solution so that the tips are completely covered

+l

and wait until the

to 2 drift is mV reading is stable,

mV/minute, before adding

any titrant. Remove any bubbles by re-dipping electrode.

Add

0.05M Hyamine 1622 titrant to a 10 ml buret until filled. Once

t&rant

has been reached, add the

in 0.5-l .O ml increments at the beginning of the

titration, and in increments of 0.1-0.25 ml in the region of the endpoint.

mV stability

The

endpoint is at that volume of titrant where the potential changes dramatically with

the slightest addition of titrant. The electrode potential should be recorded after

each addition of titrant. Continue titrating until 1 or 2 ml past the endpoint. On

standard coordinate graph paper, plot milliliters of titrant added versus

mV reading.

The endpoint is the point of greatest inflection. Calculate the unknown surfactant

concentration:

Vtitrant

X

unknown

Of

theunknown

where:

C

unknown

=

&horn

Ctibant

Vtibant

Vunknown

=COnCenkitiOn

=

concentration of the titrant

=

volume of the titrant in milliliters

= volume of the unknown in milliliters

Ctitmt

V

Depending on sample concentration and method used, this basic procedure may need modification

Page 6

ELECTRODE CHARACTERISTICS

Electrode Response

The time for the analysis may vary, depending on the sample, the titrant, the method, and the

equipment used. The average time for manual titration of anionic surfactants is 2-5 minutes.

Temperature

The surfactant electrode should be used in the operating range of

0-4O’C.

The membrane may be

permanently destroyed at other temperatures.

Reproducibility

The reproducibility of the surfactant electrode will depend heavily on the good laboratory practices

of the technician, but will usually be less than 1% with manual techniques and less than 0.5% with

automatic techniques.

Limit of Detection

For anionic surfactants, the lower limit of detection is

-10W5M.

Good laboratory practice and

selection of titrant may allow lower levels of detection for some sample types.

pH Effects

The surfactant electrode has an operating

pH

range of 2-12. Use at other

pH values can adversely

affect the membrane.

pH

For anionic, sulfated and sulfonated surfactants, the analysis should take place at a

between 2.5

and 4.5.

For other samples, the

pH

range may need to be adjusted. Polyacrylates require adjustment to

pH

10, for example.

Interferences

Interferences may be caused by any organic anion or cation which chemically resembles the species

of interest.

Page 7

Cleaning, Reconditioning, and Storage

Acidic (or alkaline) rinse solution should be used to rinse the electrode between measurements.

To recondition an electrode when the response had become noisy, sluggish, or

10m4M

in slightly acidic (or alkaline) distilled water for one hour, followed by

SLS solution for 10

&producible,

soak

minutes.

The ISE-8882 Surfactant Ion Selective Electrode may be stored in

O.OOOlM

SLS for short periods

of time. For storage over 3 weeks, rinse and dry the membrane element and cover the tip with any

protective cap shipped with the electrode(s). The reference portion of the combination electrode (or

the reference chamber of the reference electrode) should be drained of filling solution, if refillable,

and the rubber sleeve placed over the filling hole.

Electrode Life

The surfactant electrode will last six months in normal laboratory use.

Continuous titrations on an

automatic sample changer might shorten operational lifetime to several months. In time, the

response time will increase and the titration endpoint breaks will not be as sharp. At this point,

titration is impossible and electrode replacement is required.

ELECTRODE THEORY

Electrode Operation

The surfactant electrode is an endpoint indicator for the potentiometric determination of anionic

surfactants in solution.

Cationic

surfactants may also be determined with this electrode.

The reaction that occurs when a sulfated or sulfonated anionic surfactant is titrated with Hyamine

1622 is as follows:

R

-

&N+Cl-

RS03NR4

6 S03Na+ +

+

NaCl

where: R = surfactant carbon chain

R4Nf

= Hyamine ion

Page 8

TROUBLESHOOTING GUIDE

The goal of troubleshooting is the isolation of the problem through checking each of the system

components in turn: the instrumentation, the electrodes, the reagents, the sample, and the technique.

Instrumentation

For manual titration, assure that the

mV meter is operating correctly and that the glassware is clean.

Most meters are provided with an instrument check-out procedure in the instruction manual and a

shorting strap for ease of troubleshooting.

Consult the manual for complete instructions and verify

the instrument operates as indicated.

when rinsed with distilled or de-ionized water, the water does

Clean glassware will drain clean..

.

not bead on the inside walls of the glassware.

If using automatic titration instrumentation, check the instrument instruction manuals/operators ’

handbook for the correct check-out procedure or call the instrument manufacturer for the check-out

procedure.

Electrodes

1.

2.

3 .

Using distilled or de-ionized water, rinse the electrodes thoroughly.

Titrate a known standard to check the electrode ’s operation.

If the electrode fails to respond as expected, see the section

Measuring Hints.

Repeat Step 2.

4.

5.

6.

If the electrode still fails to respond as expected, substitute another surfactant

electrode that is known to be in good working order for the questionable electrode.

If the problem persists, try the same routine with a working reference electrode.

If the problem persists the reagent may be of poor quality, interferences in the

sample may be present or the technique may be faulty. See

Technique

sections below.

Reagents, Sample, and

If another electrode is not available for test purposes, or if the electrode in use is

suspect, review the instruction manual and be sure to:

-

Clean and rinse the electrode(s) thoroughly.

-

Prepare the electrode(s) properly.

-

Use the proper filling solution, titrant, and sample additives.

pH

-

Adjust the

of the solution according to the method being used for the analysis.

Page 9

-

M easure correctly and accurately.

-

Rev ie w

TROUBLESHOOTING HINTS.

Reagents

W henever proble m s arise w it h the m easuring procedure that has been used successfully in the past,

be sure to check the reagent solutions.

prepare the m again.

E rrors m ay result fro m conta m ination of the titrant, incorrect dilution, poor

If in doubt about the credibility of any of the reagents,

quality distilled/ de-ionized w ater or additive, or a si m ple m athe m atical m iscalculation.

Sample

Look for possible interferences,

co m p lexing agents, or substances wh ich could affect the response

or physically da m age the sensing electrode or the reference electrode if the electrodes wo rk

perfectly in the standard, but not in the sa m p le.

T ry to deter m ine the co m position of the sa m p les prior to testing to eli m inate a proble m before it

starts. See

Sample Requirements,

Effects,

and

Interferences.

pH

Technique

Be sure that the electrodes ’ lim it of detection has not be exceeded.Be sure that the analysis m ethod

is clearly understood and is co m patible w it h the sa m ple.

Refer to the instruction m anual again. Reread

and

PROCEDURES,

ELECTRODE CHARACTERISTICS.

GENERAL PREPARATION, ANALYTICAL

If trouble still persists, call Om ega Eng ineering Custo m er Service D epart m ent.

Page 10

Symptom

Possible Causes

Next Step

Out of Range

Reading

defective

instrumentation

electrode(s) not

plugged in

properly

no reference

electrode

reference electrode

not filled

air bubble on membrane

electrode(s) not in

solution

check instrument

by using instrument

check-out procedure

unplug electrode(s)

and reseat

use reference

electrode described

Required Equipment

in

add filling

solution to the

outerchamber of the

reference electrode

remove bubble by

redipping electrode

put electrode(s) in

sufficient solution

Noisy or Unstable

Readings (readings

continuously or

randomly changing)

defective instrument

air bubble on membrane

instruments not properly

grounded

reference electrode

junction clogged

defective electrode(s)

10

check instrument

using instrument

check-out procedure

remove bubble by

redipping electrode

ground instruments

clean out junction

replace electrode(s)

Page 11

electrode exposed to

interferences

soak electrode in

0.0001 M SLS

No Endpoint

Found

Poor

Reproducibility

outer filling solution

level too low

sample too dilute or

titrant solution too

concentrated

sample too concentrated

or titrant too dilute

sample not completely

added, diluted, or poor

pipetting

fill electrode to

level just below

the fill hole

make sure that the

sample concentra-

tion is greater

10e5M;

than

dilute

titrant solution

dilute sample or

select a different

titrant concentra-

tion

when adding sample

or diluent to

beaker, avoid

splashing on the

inside walls of the

beaker; use an

pipet

automated

for

best results when

measuring volumes

“Incorrect Answer ”

sample carryover

incorrect standards

sample carryover

thoroughly between

titrations

11

rinse electrode(s),

stirrer, and

delivery tip thor-

oughly between

measurements; blot

excess rinse water

prepare fresh

standards

rinse electrode(s)

Page 12

SPECIFICATIONS

Minimum level of

pure SLS which

can be titrated:

Maximum level of

pure SLS titrable

0.05M Hyamine:

with

pH

Range:

0-5M

1

5 x

2-12

lo-*M

Temperature Range:

Resistance:

Size:

12 mm diameter

1 m cable length

Reproducibility:

Storage:

o-40°C

100 Mohms

110 mm length

+l%

-

store in 0.0001 M SLS

or store dry

12

Page 13

TABLE OF CONTENTS

General Instructions..

.l

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

.6

. . . . . . . . . . . . . . . .

.........

1

1

I

.2

2

.2

.3

.

.4

.5

.5

6

6

6

6

.6

.6

.

.7

Introduction

Required Equipment

Required Solutions

General Preparation

Electrode Preparation

Titrant Preparation.

Units of Measurement.

Measuring Hints.

Sample Requirements.

Analytical Procedures

................................... .

..........................

.............................

..........................

...........................

...................... .

...............................

...................... .

Sample Analysis.. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrode Characteristics..

Electrode Response

Temperature

................................... .

Reproducibility

Limit of Detection

pH

effects

Interferences

...................................... .

................................... .

........................... .

................................ .

............................. .

Cleaning, reconditioning, and storage

Electrode life

....................................

Electrode Theory

13

.

7

. . . . . . . . . . . . . . . . . . .

Page 14

Troubleshooting Guide..

.8

. . . . . . . . . . . . . . . . . . .

Instrumentation

Electrodes

Reagent.

Sample

........................................ .

........................................... .

Technique.

..................................

...................................... .

......................................

Troubleshooting Hints..

Specifications

Table of Contents

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

,......

. . . . . . . . . . . . . . . . . . . . . .

8

.8

.9

9

.9

.

.

10

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . 12

..13

14

Loading...

Loading...