Page 1

Page 2

Page 3

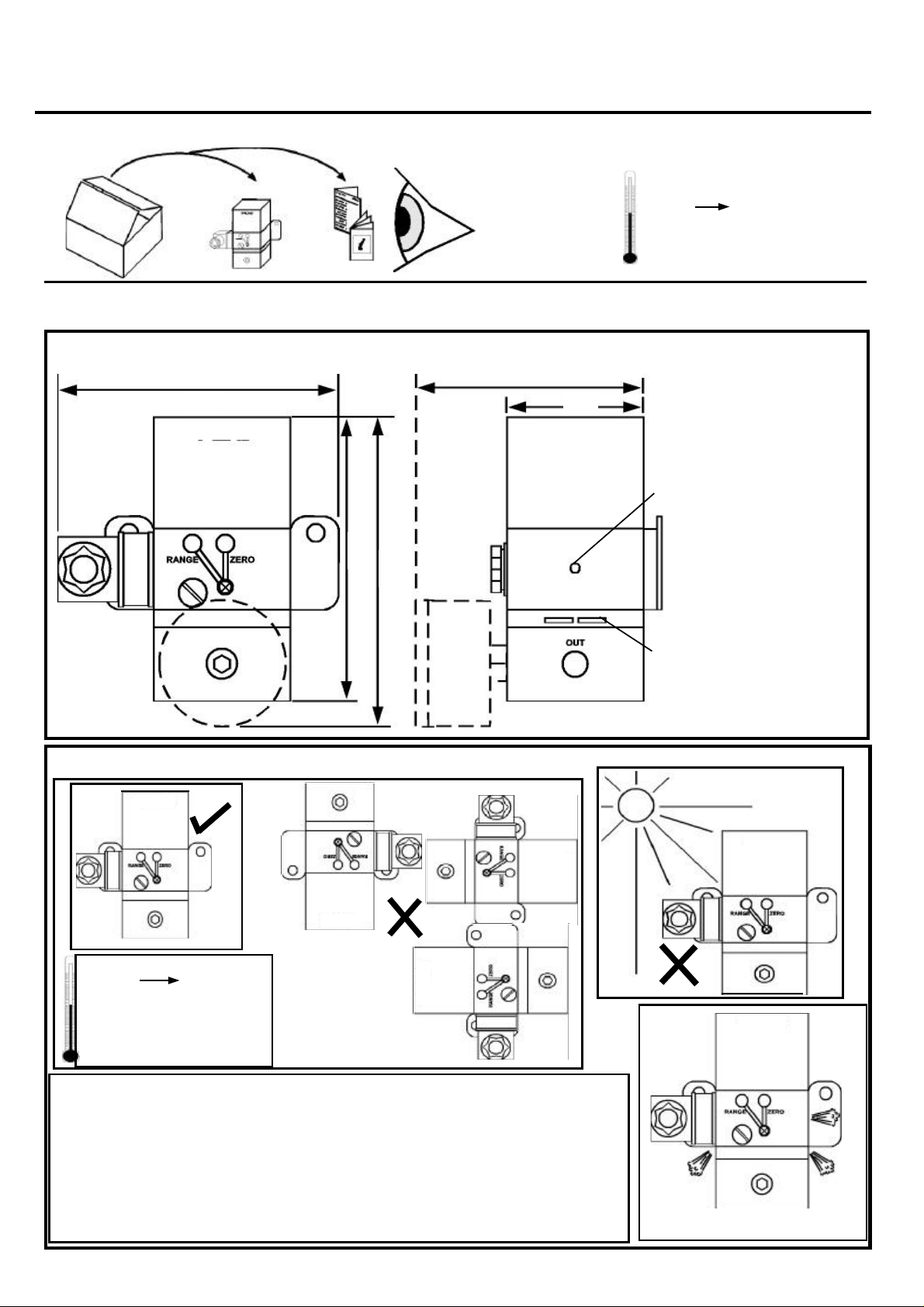

IMPORTANT

STORING

-40ºC +80ºC

INSTALLATION

1. Dimensions in mm

114

Note: Pictures shown as block diagrams: not to scale or diagrammatically

102

54

Bleed vent

102

121

Exhaust vents

2. Requirements

-40ºC +80ºC

Protection IP65 in

operating conditions

Recalibration Required

To conform with the Health and Safety at Work Act 1974 our product should be

installed, used and maintained in accordance with:

1 Normal Safety Procedures

2 The installation and operating instructions provide for each instrument.

3 BS 6379 for general applications or ANSI/ASA-57.3 1975

4 BS 5345 for hazardous area applications

Do not block side vents

Page 4

INSTALLATION (continued)

3. Fixing

a Mounting Bracket

b Pipe Mounting Kit (option)

(i) Remove screws

2 screws

(ii) Remove bracket

(iii) screw in new bracket

(iv) clamp to pipe

(v) Tighten nuts

Ø 50mm nominal

4. Mounting Dimensions

Page 5

5. Make Pneumatic Connections

7. Expose Terminals

b

Soft sealing anaerobic

hydraulic seal

E.g. Loctite hydraulic seal

512

E.g. 6mm (1/4”) nylon

pipe

1/4" NPT OR BSP

c

6. Remove Connector

e

f

d

a

8. Insert Cable

10. Air Supply

BS 6739: 1986

Dust < 5 micron

Oil: < 1ppm mass

Pressure: 1 bar > P2

Cable ø 6 to 8

mm

View Looking at Pins of Instrument

3

-ve

2

1

+ve

Earth

Particle /Water

Removal Filter

Oil/Particle/

Water Removal

Filter

Suitable I/P Converter Up to 6 I/P Converters

Type F72G with 5 micron

Element

Type F72C F74C

9. Assemble and Fit Connector

Type F74G with 5 micron

Element

Dewpoint at least 10ºC below

minimum anticipated ambient

temperature

Regulator Type R72 Type R74

Combination

Filter/Regulator

Type B72 with 5 micron

Element (=F72+R72)

Type B74 with 5 micron

Element

Page 6

11. Calibration

When the instrument is first installed , or after a long period of downtime, a moderate zero shift is normal. This is due

to the rubber diaphragms which are stretched by the internal springs. After a few operations, the instrument will

settle into its normal operating condition. It is recommended that, under these circumstances, instruments should be

exercised by alternately applying zero and full scale signals several times. Zero calibration should then be carried

out.

a.

Air Supply

+ to Maximum Signal

c.

b.

Minimum signal

Adjust zero control (anti-clockwise) to

give minimum required output pressure

Note: Reverse Acting Operation

1 About 20 turns of the zero screw may

be required to reset the zero point.

2 3-wire instruments require to be factory

set for reverse action.

3 Reverse action is not currently

available on high pressure models

4 Do not over wind nozzle to prevent

jamming

Adjust range control (anti-clockwise on 2-wire, clockwise on 3

wire) to give maximum required output pressure

Page 7

12. Maintenance

Care must also be taken to re-align transfer passages correctly during reassembly of the instrument.

Routine maintenance consists of replacing the restrictor screw if the internal orifice becomes blocked.

Parts Breakdown

Page 8

13. Product Variations

3 Wire Versions

These are products designed for electrical control signals which differ from the normal 4-20. 060mA signals. An internal amplifier is fitted to translate the control signal into the required current

through the coil. An external 12V-24V DC signal is required to power the amplifier, which should be

capable of providing 25mA (low pressure) or 65mA. (high pressure)

It is essential that wiring be carried out correctly as incorrect wiring may destroy the amplifier

completely.

Control

3

Common

E-P Versions (Voltage Controlled converters)

These are available in the 2 and 3 wire versions. The two wire versions are recalibrated I/P converters with a suitable buffer resistor in series with the coil to adjust the sensitivity

Captured Exhaust Versions: Designed for use with certain gases. This part must be connected to

a suitable exhaust arrangement e.g. stack pipe. N.B. Check before installation.

Warning: Not for use where no escape of gas is permitted to escape to the environment due to the

constant bleed of the unit

2

3 Wire

1

+

12V –24V

Supply

Common

3

2

2 Wire

1

+

Control

14. Troubleshooting Guide

Problem Posssible Causes Suggested Action

No Output Pressure Reversed Current polarity or

faulty connections

Broken internal wiring

No air supply

Check wiring and signal

continuity with milliameter

Check instrument resistance with

ohmmeter. Repair if faulty.

Correct

Maximum output not available Insufficient supply pressure

Damaged coil or nozzle

Oil contamination

Clogged restrictor

Zero will not adjust Worm disengaged with pinion

(after excessive adjustment)

Zero calibration error on initial

turn-on

Materials of Construction:

Lid: Nylon 66; Magnet: Permanent Neodymium Iron Boron; Magnet Ironwork: Zinc plated mild steel

Flapper: Beryllium Copper; Nozzle: Brass

A small error is normal Exercise instrument several times

Adjust

Return to Factory for Repair

Replace instrument

Replace

Re-engage components

and retest

Page 9

Page 10

M-1438/09/02

Loading...

Loading...