Omega Products IOP-241 Installation Manual

(1*,1((5,1* ,1&

Users Manual

IOP-241 Users Manual 1

IOP-241

24 Channel Digital Input/Output

Type II PCMCIA Card

INTERFACE CARDS FOR PERSONAL COMPUTERS

OMEGA ENGINEERING, INC. Tel: (203) 359-1660

One Omega Drive Fax: (203) 359-7700

P.O. Box 4047 Toll free: 1-800-826-6342

Stamford, CT 06907-4047 E-mail: das@omega.com

http://www.dasieee.com

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC., warrants this unit to be free of defects in materials and workmanship fo r a period of 13

IOP-241 Users Manual 2

months from the date of purchase. OMEGA warranty adds an additional one (1) month grace period to the normal one (1)

year product warranty

coverage on each product. If the unit should malfunction, it must be returned to the factory for evaluation. OMEGA’s

Customer Service Department will issue an Authorized Return (AR) number im mediately upon phone or written request.

Upon examination by OMEGA, if the unit is found to be defective it will be repaired or replaced at no charge. OMEGA’s

warranty does not apply to defects resulting from any action of the purchaser, including but not limited to mishandling,

improper interfacing, operation o utside design limits, impr oper repair or unauthorized modif ication. This WARRANTY is

VOID if the unit shows evidence of having been tampered with or shows evidence of being damaged as a result of excessive

corrosion; or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating

conditions outside of OMEGA’s control. Com ponents which wear are not warranted, including but not limited to contact

points, fuses and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However, OMEGA neither assumes

responsibility for any omissions or errors nor assumes liability for any damages that result from the use of its products

in accordance with information provided from OMEGA, either verbal or written. OMEGA warrants only that the parts

manufactured by it will be as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR

REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE, AND

ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PU RPOSE ARE HEREBY D ISCLAIMED . LIMITA TION O F LIABILITY: The remedi es of purc haser set

forth herein are exclusive and the total liability of OMEGA with respect to this order, whether based on contract,

warranty, negligence, indemnification, strict liability or otherwise, shall not exceed the purchase price of the component

upon which liability is based. In no event shall OMEGA be liable for consequential, incidental or special damages.

CONDITION S: Equipment so ld by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic Comp onent”

under 10 CFR 21 (NRC), used in or with any nuclear installation or activity, medical application or used on humans.

Should any Product(s) be used in or with any nuclear installation or activity, medical application, used on humans or

misused in any way, OMEGA assum es no respo nsibility as set forth in o ur basic WA RRAN TY/DISCLAI MER language, and

additionally, purchaser will indemnify OMEGA and hold OMEGA harmless from any liability or damage whatsoever

arising out of the use of the Product(s) in such a manner.

to cover shipping and handling time. This ensures that OMEGA’s customers receive maximum

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE RETURNING

ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN (AR) NUMBER FROM

OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID PROCESSING DELAYS). THE ASSIGNED

NUMBER SHOULD THEN BE MARKED ON THE OUTSIDE OF THE RETURN PACKAGE AND ON ANY

CORRESPONDEN CE. THE PURCHASER IS RESPONSIBLE FOR SHIPPING C HARGES, FREIGHT, IN SURANCE AND

PROPER PACKAGING TO PREVENT BREAKAGE IN TRANSIT.

FOR WARRANTY

(1) P.O. Number under which the product was purchased,

(2) Model and serial number of the product under warranty, and

(3) Repair instructions and/or specific problems relative to the product.

FOR NON-WARRANTY

BEFORE contacting OMEGA:

(1) P.O. Number to cover the cost of the repair,

(2) Model and serial number of the product, and

(3) Repair instructions relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvem ent is possible. This af fords our

customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC. © Copyright 1999 OMEGA ENGIN EERING, IN C. A ll

rights reserved. This document may not be copied, photocopied, reproduced, translated or reduced to any electronic

medium or machine readable form, in whole or in part, without prior written consent of OMEGA ENGINEERING, INC.

RETURNS, please have the following information available BEFORE contacting OMEGA:

REPAIRS, consult OMEGA fo r current repair charges. Have the fo llowing information available

Declaration of Conformity

IOP-241 Users Manual 3

Manufacturer's Name: Omega Engineering, Inc.

Manufacturer’s Address: One Omega Drive

Stamford, CT 06907-0047

Application of Council Directive: 89/336/EEC

Standards to which

Conformity is Declared: * EN50081-2

(EN55022)

* EN50082-1

(IEC 801-2, IEC 801-3, & IEC 801-4)

Type of Equipment: Information Technology Equipment

Equipment Class: Commercial, Residential and Light Industrial

Product Name: PCMCIA Card

Model Number : IOP-241

OMEGAnet On-line Service: Internet e-mail:

http://www.omega.com

Servicing North America

: One Omega Drive, Box 4047 E-mail: info@omega.com

USA

ISO 9001 Certified

Canada

: 976 Bergar E-mail: info@omega.com

Stamford, CT 06907-0047

Tel: (203) 359-1660 FAX: (203) 359-7700

Laval (Quebec) H7L 5A1

Tel: (514) 856-6928 FAX: (514) 856-6886

info@omega.com

:

For immediate technical or application assistance

USA and Canada

Mexico and Latin America

: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Customer Service: 1-800-622-2378/ 1-800-622-BEST

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

:Tel: (001) 800-826-6342 E-mail: espanol@omega.com

En Espanol: (001) 203-359-7803 FAX: (001) 203-359-7807

SM

:

SM

SM

Benelux

Czech Republic

France:

Germany/Austria

: Postbus 8034, 1180 LA Amstelveen, The Netherlands

: ul.Rude armady 1868, 733 01 Karvina-Hraniee

9, rue Denis Papin, 78190 Trappes

Servicing Europe

Tel: (31) 20 6418405

Toll Free in Benelux: 0800 0993344

E-mail: nl@omega.com

Tel: 42 (69) 6311899

Toll Free: 0800-1-66342

FAX: 42 (69) 6311114

E-mail: czech@omega.com

Tel: (33) 130-621-400

Toll Free in France: 0800-4-06342

E-mail: france@omega.com

: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: 49 (07056) 3017

Toll Free in Germany: 0130 11 21 66

E-mail: germany@omega.com

:

IOP-241 Users Manual 4

United Kingdom: One Omega Drive, River Bend Technology Drive

ISO 9002 Certified

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that apply.

OMEGA is constantly pursu ing certification of it’s products to the Eu ropean New App roach Directives.

OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct but OMEGA Engineering, Inc.

accepts no liability for any errors it contains , an d rese rves the rig ht to alte r spe cifications without no tice.

WARNING: These p roducts are not designed for us e in, and should not be u s ed for, patient connected

applications.

Northbank, Irlam, Manchester

M44 5EX, England

Tel: 44 (161) 777-6611

FAX: 44 (161) 777-6622

Toll Free in England: 0800-488-488

E-mail: info@omega.co.uk

IOP-241 Users Manual 5

Table of Contents

5.10 Programming Example

5.9 Summary of Input/Output Options

5.8 Summary of Interrupt Source Options

5.7 Interrupt Acknowledge Register (Write Only) (Base + 7)

5.6 Interrupt Status Register (Read Only) (Base + 7)

5.5 Interrupt Mode Control Register (Base + 6)

5.4 Port C Interrupt Enable Register (Base + 5)

5.3 Data Port C Control Register (Base + 2)

5.2 Data Port B Control Register (Base + 1)

5.1 Data Port A Control Register (Base + 0)

5. Register Descriptions

4. Theory of Operation

3.4 After Completing Configuration

3.3 Changing Resource Settings with Device Manager

20

3.2.1 Viewing Resource Settings with Device Manager

3.2 Resource Settings in Windows 95/98

3.1 Installing the IOP-241 Under Windows 95/98

3. Windows 95/98® Installation

2.3 After Completing Configuration

18

2.2.3 Common Problems

17

2.2.2 Command Line Options

16

2.2.1 Enabler Installation

2.2 IOP-241 Enabler for DOS

14

2.1.3 Common Problems

12

2.1.2 Command Line Options

11

2.1.1 Client Driver Installation

2.1 IOP-241 Client Driver for DOS

2. DOS / Windows 3.x Installation

1. Introduction

IOP-241 Users Manual 6

.........................................................

1.1 IOP-241 Features

..................................................

1.2 System Configuration

..............................................

9

9

9

...........................................

............................................

................................................

.........................................

................................................

............................................

................................................

..............................................

4.1 I/O Port Description

.............................................

4.2 Port C Interrupt Description

4.3 External Interrupt Description

...............................

....................................

..................................

...................................

.....................

..............................

.......................

................

..................................

......................................

....................................

10

10

15

19

20

20

20

21

22

23

23

24

24

............................................

...........................

............................

............................

........................

........................

...................

...........

.............................

...............................

..........................................

25

25

26

26

27

28

28

29

29

30

31

8. Specifications

7.2 UIO-37 Screw Terminal Block

7.1 CP-1037 Cable Assembly

7. Optional Accessories

6. External Connections

.............................................

IOP-241 Users Manual 7

32

.............................................

.........................................

....................................

......................................................

33

33

34

35

List of Figures and Tables

29

Table 5-8. Interrupt Status Register (Write Only)

28

Table 5-7. Interrupt Status Register (Read Only)

28

Table 5-6. Interrupt Mode Control Register

27

Table 5-5. Port C Interrupt Control Register

26

Table 5-4. Data Port C Control Register

26

Table 5-3. Data Port B Control Register

25

Table 5-2. Data Port A Control Register

25

Table 5-1. IOP-241 Program Registers

10

Table 1-1. Client Driver versus Enabler

34

Figure 7-2. UIO-37 Screw Terminal Block

33

Figure 7-1. CP-1037 D37 Pin Assignments

32

Figure 6-1. IOP-241 33-Pin Connector

21

Figure 3-1. Windows 95/98 Resource Settings

9

Figure 1-1. IOP-241 System Configuration

.........................................

IOP-241 Users Manual 8

............................................

...........................................

..........................................

..........................................

..........................................

.....................................

.........................................

.........................................

.........................................

......................................

.......................................

..................................

..................................

1. Introduction

The IOP-241 is a 24 channel digital input/output card for systems equipped with PCMCIA

IOP-241 Users Manual 9

Type II and/or Type III expansion sockets.

1.1 IOP-241 Features

PC Card Standard Specification 2.10 Compliant

24 TTL compatible digital I/O channels (8 channels can be used as interrupt sources)

Channels individually programmable as either input or output

Active high sensitive, active low sensitive, low-to-high transistion or high-to-low

transition interrupt modes (external interrupt available)

1.2 System Configuration

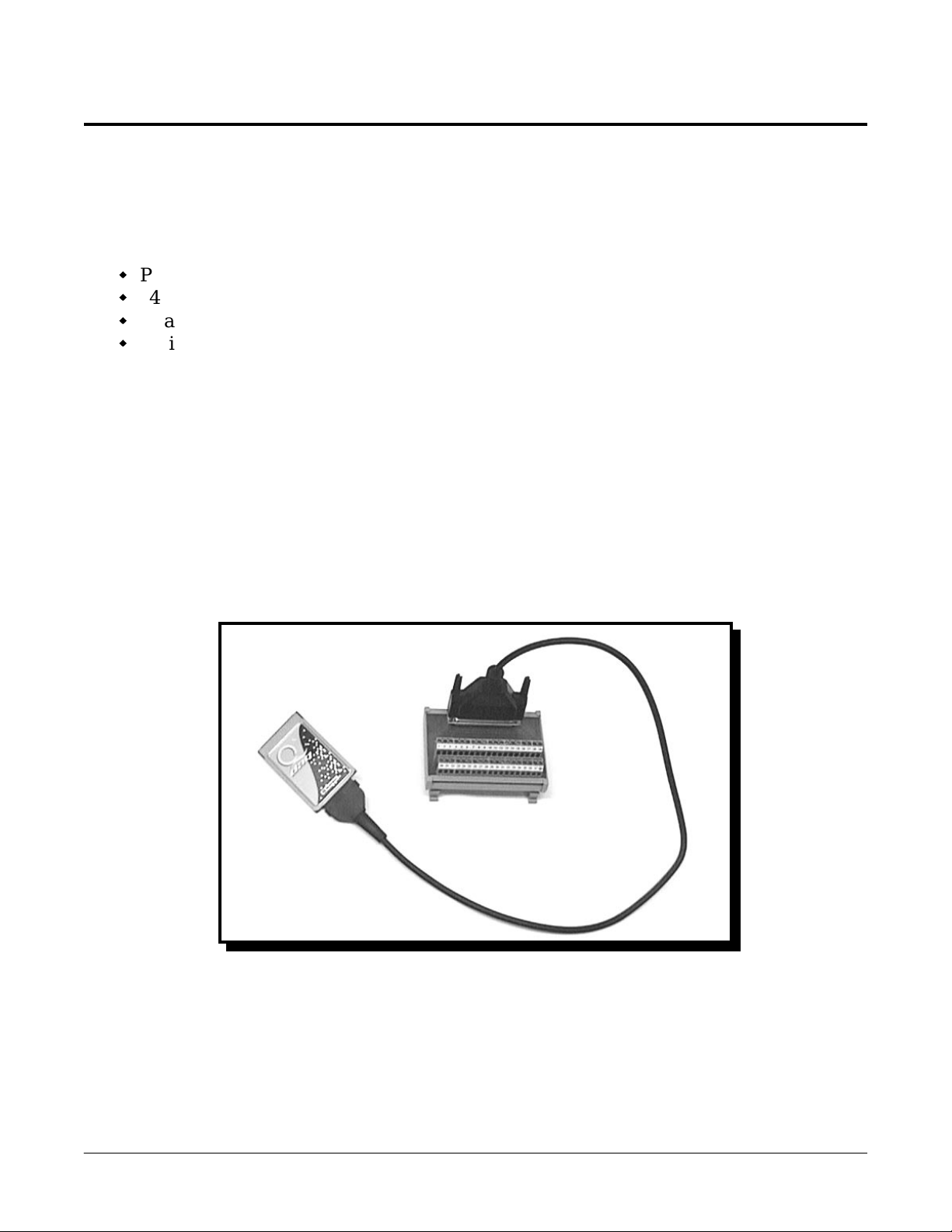

The figure below illustrates a complete IOP-241 system. For users that do not wish to interface

to the IOP-241 0.8mm I/O connector, an optional adapter cable (CP-1037) is available to

convert this connector into an industry standard D-37 connector. For applications requiring

discrete wiring hook-ups, an optional scr ew te r mi na l b l ock ( U IO- 3 7) is availa b l e to conver t the

D-37 connector into 37 single screw terminal b locks. These optional accessories are described

in detail in Chapter 7.

IOP-241

UIO-37

Hirose-32

Figure 1-1. IOP-241 System Configuration

D37

CP-IO37

2. DOS / Windows 3.x Installation

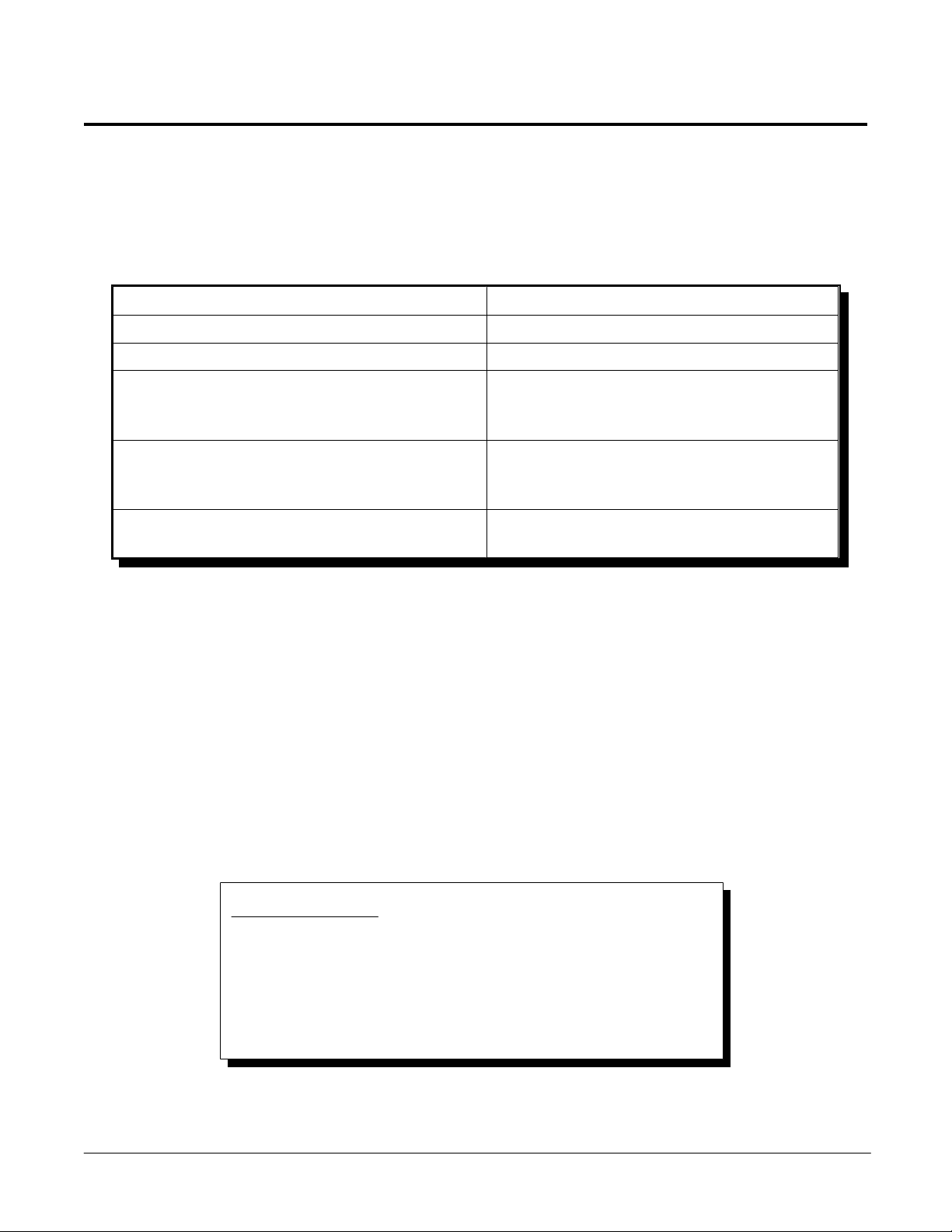

Two configuration software programs are provided with the IOP-241: a Client Driver and a

Does not require PCMCIA Card and Socket

Requires PCMCIA Card and Socket Services

Does not support automatic configuration

Allows automatic configuration of IOP-241

Interfaces directly to Intel 82365SL and

Interfaces to PCMCIA Card and Socket

File type: DOS executable

File type: DOS device driver

File name: IOP241EN.EXE

File name: IOP241CL.SYS

IMPORTANT:

IOP-241 Users Manual 10

card Enab ler. Both of these programs ar e executed from D OS (before enter ing Windows) and

allow operation of the IOP-241 in both the DOS and Windows 3.x environments. For optimal

operation, the Client Driver is the preferred method of installation and configuration. The

table below highlights the differences between these programs.

EnablerClient Driver (recommended)

Services software (PCMCIA host adapter

independent)

adapters upon insertion (Hot Swapping)

software

other PCIC compatible PCMCIA host

adapters

of IOP-241 adapters upon insertion

(Hot Swapping)

Services software

Table 1-1. Client Driver versus Enabler

If you are unsure whether Card and Socket Services software is currently installed on your

system, install the IOP-241 Client Driver as discussed in following section. When loaded, the

Client Driver will display an error message if Card and Socket Services software is not

detected.

2.1 IOP-241 Client Driver for DOS

In order to use the IOP-241 Client Driver, the system must be configured with Card and

Socket Services software. (Card and Socket Services software is not provided with the

IOP-241).

Some versions of Card and Socket Services dated before

1993 do not support general purpose I/O cards. If after

careful installation of the Client Dri ver, the IOP-241 does

not configure or operate properly, an updated version of

Card and Socket Services software may be required.

2.1.1 Client Driver Installation

IOP-241 Users Manual 11

The following procedure is used to install the IOP-241 Client Driver:

1. Copy the file IOP241CL.SYS from the customer software CD-ROM directory

PCMCIA\DOS\CLIENTS onto the root directory of the system hard drive.

2. Using an ASCII text editor, open the system CONFIG.SYS file located in the root

directory of the boot drive.

3. Locate the line(s) in the CONFIG.SYS file where the Card and Socket Services

software is installed.

4. AFTER the line(s) installing the Card and Socket Services software, add the

following to the CONFIG.SYS file: DEVICE = drive:\path\IOP241CL.SYS(options),

where options are the IOP-241 Client Driver command l ine options discussed on the

following pages. (Path is only required if the user places the Client Driver

executable file in a directory other than the root directory).

5. Save the CONFIG.SYS file and exit the text editor.

6. Insert the IOP-241 into one of the system PCMCIA slots.

NOTE: Since the IOP-241 Client Driver supports "Hot Swapping", it is not

necessary to have the IOP-241 installed when booting the system. However, by

inserting the card before booting, the Client Driver will report the card

configuration during the boot process thereby verifying changes made to the

CONFIG.SYS file.

7. Reboot the system and note the message displayed when the IOP-241 Client Driver

is loaded. If the Client Driver reports an "invalid command line option", correct the

entry in the CONFIG.SYS file and reboot the system again. If the Client Driver

reports "Card and Socket Services not found", then Card and Socket Services

software must be installe d on the system or the IOP-241 Enabl er program must be

used to configure the card. If the Client Driver reports the desired card

configuration, the installation process is complete and the IOP-241 may be removed

and/or inserted from the system as desired. On each insertion into the PCMCIA

socket, the IOP-241 will be automatically reconfigured according to the command

line options.

Loading...

Loading...