Page 1

HX80 SERIES

OPERATORS MANUAL

January 2012

Rev. E

MADE IN

Page 2

Page 3

HX80 SERIES

QUICK STARTUP GUIDE – Page 1

STARTUP

WHEN USING PROBE ONLY:

1. Mount the Probe in position to measure the desired gas.

2. Connect Probe wiring by cutting off connector or using a mating

connector, as shown below:

ITEM RIBBON CABLE WIRE #

Power Supply – Pos. 7

Power Supply – Neg. 1 (blue tracer)

Output 1 – Pos. 2

Output 2 – Pos. 6

Output 3 – Pos. 8

Output Common 4

Serial Output – TX 5

Serial Output – RX 3

Notes: Connect only the Outputs desired. See drawing in the HTPB Manual for

further connection details.

Do not apply DC Power until all wiring is completed.

1

Page 4

HX80 SERIES

QUICK STARTUP GUIDE – Page 2

WHEN USING PROBE WITH ELECTRONICS UNIT:

1. Mount the Probe and Electronics Unit.

2. Connect cable from Probe to Electronics Unit

(if applicable).

3. Connect Power Supply to Electronics Unit.

4. Connect Analog Outputs of Electronics Unit.

5. Connect Digital Output of Electronics Unit.

6. Connect Alarm Relays of Electronics Unit.

7. Connect RS-232 Serial Port of Electronics Unit.

ITEM CONN. TERM.

Power Supply (+) J8 2

Power Supply (-) J8 1

Analog Out 1 (+) J9 1

Analog Out 1 (-) J9 2

Analog Out 2 (+) J9 3

Analog Out 2 (-) J9 4

Analog Out 3 (+) J9 5

Analog Out 3 (-) J9 6

Alarm Relay 1 J2 1

Alarm Relay 1 J2 2

Alarm Relay 2 J2 3

Alarm Relay 2 J2 4

RS-232 TX J6 2

RS-232 RX J6 3

RS-232 RTN J6 5

Notes:

Connect only the Outputs desired. See the HX80 Manual for details.

Do not apply DC Power until all wiring is completed.

2

Page 5

TABLE OF CONTENTS Page

1.0 Quick Startup 1

List of Illustrations 4

List of Tables 4

2.0 Introduction 5

2.1 General Description 5

2.2 Specifications Summary 6

2.3 Model Descriptions 7

2.4 Available Options 8

3.0 Installation 10

3.1 Mounting the Probe 10

3.2 Mounting the Electronics Unit 11

3.3 Electrical Wiring 11

3.3.1 Probe Only 11

3.3.2 Probe with Electronics 13

4.0 Basic Block Diagram 16

4.1 Probe Assembly 16

4.2 Electronics Module 17

4.3 Complete System 17

5.0 Operation 19

5.1 Initial Bench Testing 19

5.2 Normal Operation 19

5.3 Factory Default Conditions 19

5.4 RS-232 Serial Port 21

5.4.1 Serial Port Setup 21

5.4.2 Changing the Digital Display 21

5.4.3 Changing the Output Ranges 22

5.4.4 Programming the Alarm Relays 23

5.4.5 Calibrating the Analog Outputs 24

6.0 Maintenance 25

6.1 Sensor Circuit Board 25

6.1.1 Replacing the Sensor Board 25

6.1.2 Removing Components 25

6.1.3 Sensor Reassembly 26

7.0 Specifications 27

3

Page 6

LIST OF ILLUSTRATIONS Page

2-1 Some HX80 Configurations 5

3-1 System with Sample Cell 10

3-2 Installing the Mounting Lugs 11

3-3 Probe Wiring, Ribbon Cable 12

3-3a Probe Wiring 13

3-4 Electronics Unit Wiring 15

4-1 Probe Block Diagram 16

4-2 System Block Diagram 18

6-1 Removing Retaining Ring 25

6-2 Sensor Exploded View 26

LIST OF TABLES Page

2-1 Standard Configurations 7

2-2 Measurement Ranges 8

3-1 Probe Wiring, Ribbon Cable 12

3-1a Probe Wiring 13

3-2 Electronics Wiring 14

3-3 Serial Port Wiring 14

5-1 Standard Output Scaling 20

4

Page 7

2.0 INTRODUCTION

2.1 GENERAL DESCRIPTION

The HX80 Series is a family of humidity probes and electronic modules that offer a

variety of measurement parameters with high accuracy. In addition to Percent Relative

Humidity (%RH), probes are available to also measure Temperature and Pressure.

Electrical analog and digital outputs are provided for not only these measured

parameters, but may be provided for microprocessor- computed parameters as well.

These include parts-per-million by volume (ppmv), parts-per-million by weight (ppmw),

grains of water per pound of dry gas (gr/lb), and others.

The HX80 system is designed for ease of installation and operation. Field-replaceable

sensor modules have standardized outputs for interchangeability without recalibration.

The power requirement is a common unregulated DC power supply. User-available

electrical outputs include linear analog voltage (or optional current), a digital bidirectional serial port, and alarm relays. Mounting options include Wall Mount, Remote

Mount, and Duct Mount configurations. Additional options include high temperature and

high pressure probes. A remote or local Display Unit (Type DIS) is available, with a

two-line LCD display, alarm relays, and three 4 to 20 mA electrical outputs.

Figure 3-1 Some of the Available HX80 Configurations

a. Stand-alone Probe

b. Remote Mount with Display

Option

5

Page 8

2.2 SPECIFICATIONS SUMMARY

(See Specifications for additional information)

2.2.1 STAND-ALONE PROBE

Analog Outputs: 0 – 10 Vdc (X3)

Digital Output: RS-232C

Power Supply: 18 to 30 Vdc, unregulated, 50 mA max.

RH Accuracy: +/- 1% nominal

Temp. Accuracy: +/- 0.5°C

Mounting: Cable Length: 6 feet

Fitting: ¾ inch stainless steel

NPT thermocouple fitting

Dimensions: Length: 8 inches

Diameter: ¾ inch

Materials: Housing: Stainless Steel

Filter: Sintered Stainless Steel (removable)

2.2.2 PROBE WITH ELECTRONICS UNIT

Analog Outputs: 4 to 20 mA (X3)

Digital Output: RS-232C, bi-directional

Alarm Relays: Form A (SPST, NO) X2

Power Supply: 18 to 30 Vdc unregulated, 50 mA max.

RH Accuracy: +/- 1% nominal

Temp. Accuracy: +/- 0.5°C

Electronics Housing Protection:

IP66 (NEMA 4X) Dust tight and moisture resistant

6

Page 9

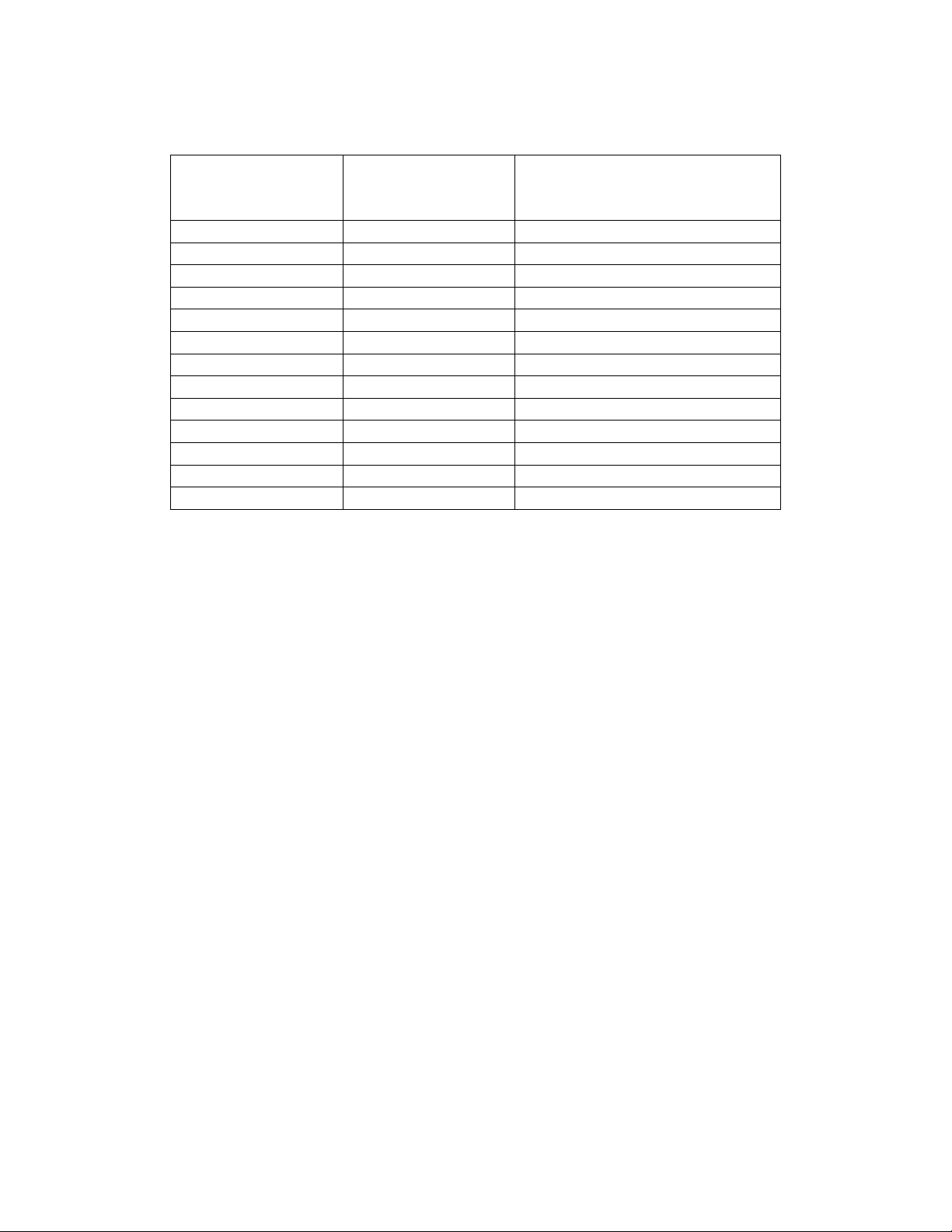

Table 2-1 HX80 Series, Standard Available Configurations

MODEL NO.

HX85 X

HXB85 X

HXP85 X

HX86 X

HXB86 X

HXP86 X

HX86N x

HX85A x

HX85BA x

HX85PA x

HX86A x

HX86BA x

HX86PA x

SENSOR ONLY

SENSOR WITH

ELECTRONICS MODULE

2.3 HX80 SERIES MODEL DESCRIPTIONS

HX85 – A Humidity/Temperature probe providing RH, Dew Point, and Temperature

outputs.

HXB85 – A Humidity/Temperature/Barometric Pressure probe providing RH,

Temperature, and Pressure outputs.

HXP85 – A Humidity/Temperature/High Pressure probe providing RH, Temperature,

and Pressure outputs.

HX86 – A Humidity/ High Temperature probe providing RH, Temperature, and Dew

Point outputs, with remote Electronics Unit including Digital Display.

HXB86 – A Humidity/High Temperature/Barometric Pressure probe providing RH,

Temperature, and Pressure outputs, with remote Electronics Unit including Digital

Display.

HXP86 – A Humidity/High Temperature/High Pressure probe providing RH,

Temperature, and Pressure outputs, with remote Electronics Unit including Digital

Display.

HX86N – Identical to HX86, with Remote Electronics Unit, but with no Digital Display.

HX85A – A Humidity/Temperature probe providing RH, Dew Point, and Temperature

outputs with an operating temperature up to 120C.

7

Page 10

HX85BA – A Humidity/Temperature/Ba rometric Pressure probe providing RH,

Temperature, and Pressure outputs with an operating temperature up to 120C.

HX85PA – A Humidity/Temperature/High Pressure probe providing RH, Temperature,

and Pressure outputs with an operating temperature up to 120C.

HX86A – A Humidity/ High Temperature probe providing RH, Temperature, and Dew

Point outputs, with remote Electronics Unit including Digital Display with an operating

temperature up to 120C.

HX86BA – A Humidity/High Temperature/Barometric Pressure probe providing RH,

Temperature, and Pressure outputs, with remote Electronics Unit including Digital

Display with an operating temperature up to 120C.

HX86PA – A Humidity/High Temperature/High Pressure probe providing RH,

Temperature, and Pressure outputs, with remote Electronics Unit including Digital

Display with an operating temperature up to 120C

2.4 AVAILABLE OPTIONS

HX80-DIS – Remote electronics module with two-line LCD digital display, three 4 to 20

mA analog outputs, RS-232C, and two programmable alarm relays. This unit can be

added to existing Probes in the field.

HX80-NDIS – Similar to HX80-DIS but without Digital Display

HX80- SENSOR – Field-replaceable sensor module for RH/Temperature.

Interchangeability accurate to published specification.

HXP80-SENSOR – Field-replaceable sensor module for RH/Temperature/Pressure.

Interchangeability accurate to published specification.

HXB80-SENSOR – Field-replaceable sensor module for RH/Temperature/Barometric

Pressure. Interchangeability accurate to published specification.

HX80-CHAMBER – Sample chamber with inlet and outlet fittings.

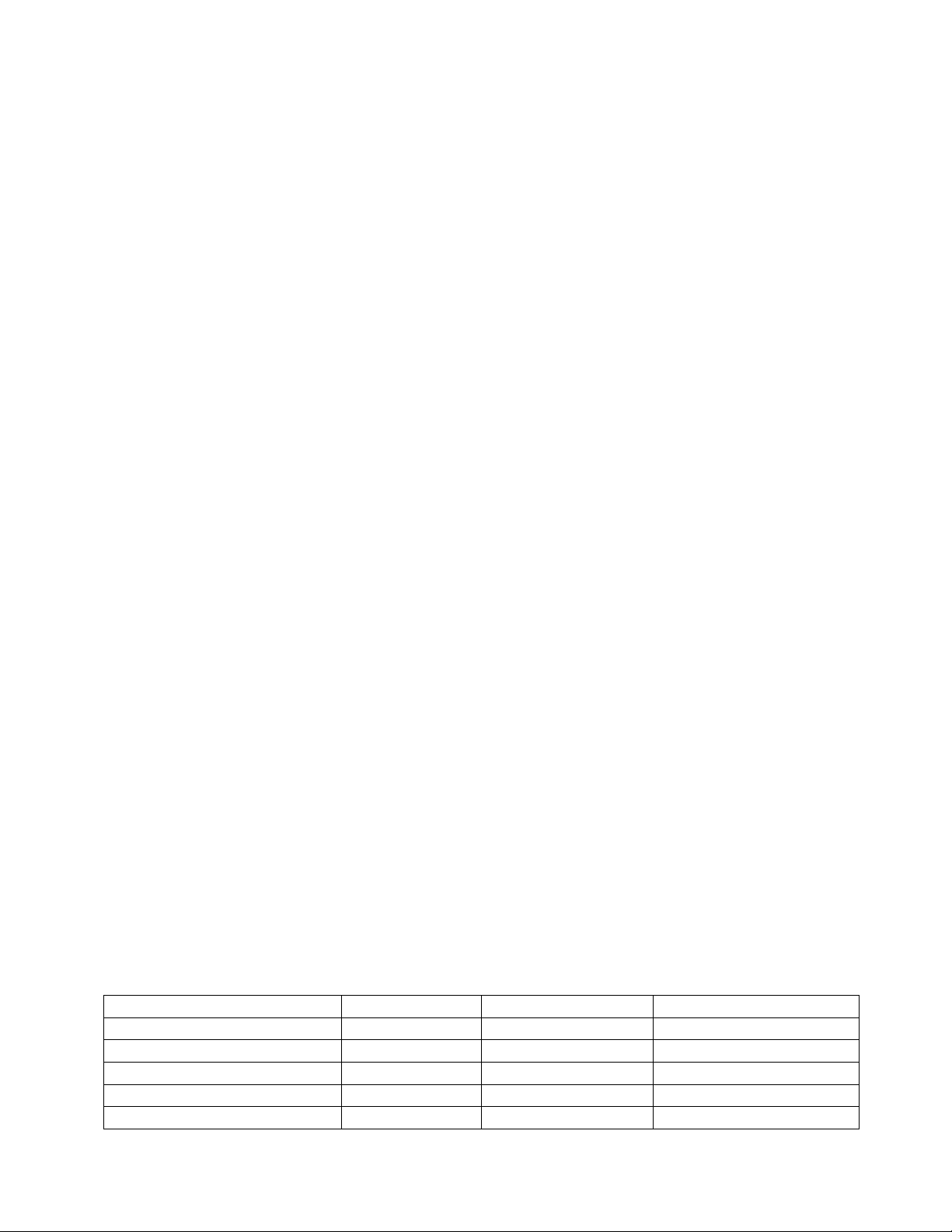

Table 2-2 HX80 Series Sensor Actual Measurement Ranges.

MODEL NO. OUTPUT 1 OUTPUT 2 OUTPUT 3

HX85

MEASUREMENT RANGE 5 to 95% -20 to +70ºC -60 to +30ºC

HXB85

PERCENT RH AIR TEMP. DEW POINT

PERCENT RH AIR TEMP. BAR. PRESSURE

8

Page 11

MEASUREMENT RANGE 5 to +95% -20 to +75ºC 10 to 1100 MB

HXP85

MEASUREMENT RANGE 5 to +95% -20 to + 75ºC 0 to 200 psia

HX86

MEASUREMENT RANGE 5 to 95% -20 to +115ºC -40 to +60ºC

HXB86

MEASUREMENT RANGE 5 TO 95% -20 to +115ºC 10 to 1100 MB

HXP86

MEASUREMENT RANGE 5 TO 95% -20 to +115ºC 0 to 200 psia

HX85A

MEASUREMENT RANGE 5 TO 95% -20 to +120ºC -60 to +40ºC

HX85BA

MEASUREMENT RANGE 5 TO 95% -20 to +120ºC 10 to 1100 MB

HX85PA

MEASUREMENT RANGE 5 TO 95% -20 to +120ºC 0 to 200 psia

HX86A

MEASUREMENT RANGE 5 TO 95% -20 to +120ºC -60 to +40ºC

HX86BA

MEASUREMENT RANGE 5 TO 95% -20 to +120ºC 10 to 1100 MB

HX86PA

MEASUREMENT RANGE 5 TO 95% -20 to +120ºC 0 to 200 psia

NOTES: 1. THE STANDARD RANGES ARE FIELD PROGRAMMABLE

VIA THE RS-232 PORT.

2. SEE TABLE 5-1 FOR STANDARD FACTORY SCALING.

PERCENT RH AIR TEMP. ABS. PRESSURE

PERCENT RH AIR TEMP. DEW POINT

PERCENT RH AIR TEMP. BAR. PRESSURE

PERCENT RH AIR TEMP. ABS. PRESSURE

PERCENT RH AIR TEMP. DEW POINT

PERCENT RH AIR TEMP. BAR. PRESSURE

PERCENT RH AIR TEMP. ABS. PRESSURE

PERCENT RH AIR TEMP. DEW POINT

PERCENT RH AIR TEMP. BAR. PRESSURE

PERCENT RH AIR TEMP. ABS. PRESSURE

9

Page 12

3.0 INSTALLATION

3.1 MOUNTING THE PROBE

The Probe includes a stainless steel mounting sleeve, commonly called a thermocouple

mount. It has a tapered male ¾-inch NPT pipe thread. The female mating fitting, usersupplied, should be mounted in a gas-tight manner to a flat surface of a duct or

chamber wall containing the gas to be measured.

To install the mount and Probe:

1. Separate the two parts of the mounting sleeve.

2. Screw the front portion of the mounting sleeve (the tapered NPT fitting) into the

pre-mounted mating fitting. Teflon™ tape may be used for a good seal. Do not

over-tighten.

3. Insert the Probe into the rear portion, and screw this part of the mount into the

previously mounted front portion, so that the Probe is gripped snugly. Do not

over-tighten. As much of the Probe as possible should protrude inside the area

to be measured, to avoid possible laminar flow errors.

If the optional sample chamber is to be used, simply screw it down to any flat surface,

and connect ¼ inch OD tubing to the inlet and outlet compression fittings.

Figure 3-1, System with Sample Cell, ready for mounting

10

Page 13

3.2 MOUNTING THE REMOTE ELECTRONICS MODULE

MOUNTING CONSIDERATIONS

1. If the Digital Display has been provided, is it easily visible?

2. Is the location convenient for routing electrical wiring?

3. Is the module within 6 feet (1.8 meters) of the Sensor location?

Use a small hammer to tap in the pins that hold the four corner mounting lugs in place.

See Figure 3-2 below. Mount the box to a flat surface with screws or bolts through the 4

mounting holes.

Figure 3-2 a,b,c,d

Installing Mounting Lugs

3.3 ELECTRICAL WIRING

3.3.1 PROBE ONLY

See Wiring Table 3-1 and Figure 3-3 below.

1. Connect Power Supply wiring as shown.

2. Connect the Analog Output wiring as shown. Three 0 to 10Vdc outputs are

available. Connect Outputs 1, 2, and 3 as required.

3. Connect the RS-232 Serial Output if desired. Only 2 wires are required if

the output is needed for transmitting information only. A third wire is

added for bi-directional communications with the serial port.

11

Page 14

4. Table 3-1 Hx80 Series Probe (with Ribbon Cable)

Wiring Table

ITEM RIBBON CABLE WIRE #

Power Supply – Pos. 7

Power Supply – Neg. 1 (blue tracer)

Output 1 – Pos. 2

Output 2 – Pos. 6

Output 3 – Pos. 8

Output Common 4

Serial Output – TX 5

Serial Output – RX 3

1 (WITH BLUE TRACER)

PWR SUPPLY – NEG.

2 OUTPUT 1 – POS.

3 SERIAL OUT -- RX

4 OUTPUT COMMON

5 SERIAL OUT -- TX

6 OUTPUT 2 – POS.

7 PWR SUPPLY – POS.

8 OUTPUT 3 – POS.

9 NOT USED

10 NOT USED

Figure 3-3 HX80 Series Probe (with Ribbon Cable)

Wiring Diagram

12

Page 15

Table 3-1a HX80 Series Probe (with Discrete Wires)

Wiring Table

ITEM COLOR CODE

Power Supply – Pos. Yellow

Power Supply – Neg. Green

Output 1 – Pos. Brown

Output 2 – Pos. Red

Output 3 – Pos. Orange

Output Common Black

Serial Output – TX Blue

Serial Output – RX White

Serial Common Green

Figure 3-3a HX80 Series Probe (with Discrete Wires) Wiring Diagram

3.3.2 PROBE WITH ELECTRONICS MODULE

See Tables 3-2, 3-3, and Figure 3-4 below.

Notes:

1. Cable bushings are shipped separately. Carefully tap out the desired

knockouts, and mount the bushings.

2. We recommend that you route the Probe Cable through a bushing on the

left. Route all other wiring through the bushing on the right.

13

Page 16

1. Run the cable from the Probe to the connector labeled Probe Input.

2. Wire the Power Supply as shown in Table 3-2.

3. Wire the three 4 to 20 mA Analog Outputs and Alarm Relays as shown in Table

3-2 if desired.

4. Connect to the RS-232C Serial Port at J6 if desired.

Table 3-2 Electronics Unit Wiring Table

ITEM CONN. TERM.

Power Supply (+) J8 2

Power Supply (-) J8 1

Analog Out 1 (+) J9 1

Analog Out 1 (-) J9 2

Analog Out 2 (+) J9 3

Analog Out 2 (-) J9 4

Analog Out 3 (+) J9 5

Analog Out 3 (-) J9 6

Alarm Relay 1 J2 1

Alarm Relay 1 J2 2

Alarm Relay 2 J2 3

Alarm Relay 2 J2 4

Table 3-3 J6 Wiring Table

DB-9 SERIAL CONNECTOR ITEM

Pin 2 TX

Pin 3 RX

Pin 5 RTN

14

Page 17

A

A

OUTPUT 1

RTN 1

OUTPUT 2

RTN 2

Figure 3-4 Electronics Unit Wiring

PROBE CONN.

RS232

OUTPUT 3

RTN 3

24 VDC

NEG -

POS +

LARM 2

LARM 1

15

Page 18

4.0 BASIC BLOCK DIAGRAM THEORY OF OPERATION

4.1 PROBE ASSEMBLY

See Figure 4-1, the Probe Assy. Basic Block Diagram.

The Probe Assembly is a stand-alone, completely self-contained measuring system. All

units include the RH and Temperature Sensors, and some optional probes include a

Pressure Sensor as well. The field-replaceable Sensor Circuit Board has standardized

output levels for all three measured parameters. Therefore, boards may be quickly

replaced while in operation without the need for recalibration, maintaining full system

accuracy. The Microprocessor performs the system control, parameter calculation, and

serial digital communications. Digital-to-Analog (D-A) conversion provides three 0 to 10

Vdc linear Analog Outputs corresponding to the measured and/or calculated

parameters.

The serial digital RS-232 interface is bi-directional, allowing the user to not only receive

and record measured information, but to remotely control output scaling, alarm relay

setpoints, and other functions as well.

SENSOR BOARD PLUG-IN ASSY.

RH

SENSOR

TEMP.

SENSOR

PRESSURE

SENSOR

NORMALIZATION - CALIBRATION

STAGE

SENSOR BOARD PLUG-IN CONNECTOR

MICROPROCESSOR

D-A D-A D-A

0 - 10 VDC

RH OUT

0 - 10 VDC

TEMP. OUT

PRESSURE OUT

0 - 10 VDC

RS-232

(TX)

SERIAL PORT

RS-232

(RX)

Figure 4-1 Basic Block Diagram, Probe Assy

16

Page 19

4.2 HX80-DIS ELECTRONICS MODULE

Although the Probe may be used as a stand-alone measuring device (HX85), it also

may be connected to the type DIS remote display unit, for additional capability. This

combination is called the HX86. A complete HX86 system consists of the Probe, the

interconnecting 6 foot (1.8 meter) cable, and the electronics module. Outputs of the unit

include a Serial Port, two Alarm Relays and three 4 to 20 mA Analog Outputs. A twoline LCD Digital Display is also included.

4.3 THE COMPLETE HX86 SYSTEM

Figure 4-2 is a basic block diagram of the complete Humidity, Temperature and

Pressure measuring system. The remote Probe is connected, via the attached cable, to

the electronics module. The system is completely controlled by the microprocessor in

this module.

The three sets of analog voltage outputs from the Probe are routed through the Analog

Scaling and Selection stage. The scaling of these output signals may be programmed

by the user to any desired range by using the RS-232 Serial Port. The bi-directional

RS-232 is brought out to a connector in the electronics module. The user can also

program the two Alarm Relay set points via this digital interface. The built-in LCD

Digital Display, which provides information on all measured parameters, is also

controlled by the microprocessor. In addition, the microprocessor is used to calculate

other parameters than those directly measured by the sensors in the Probe. These may

be shown on the Digital Display, and they are also available on both the analog and

digital (RS-232) outputs. The Alarm Relays may also be set for these calculated values.

17

Page 20

Figure 4-2 System Basic Block Diagram

RH

SENSOR

HTPB PROBE ASSY.

DIGITAL

DISPLAY

TEMP.

SENSOR

ALARM

RELAY

#1

PRESSURE

SENSOR

(OPTION)

6 FT. SENSOR CABLE

MICROPROCESSOR

ALARM

RELAY

#2

SERIAL

PORT

(TX) (RX)

ANALOG

OUTPUTS

(0 - 10V X3)

ANALOG

SCALING

AND

SELECTION

ELECTRICAL CONNECTORS

ALARM

1

ALARM

2

USER INTERFACE

18

RS-232

(TX) (RX)

ANALO G OUTPUTS

1 2 3

Page 21

5.0 OPERATION

5.1 INITIAL BENCH TESTING

New units may be tested on the bench before installation, if desired.

For units consisting of the Probe only –

1. Connect a proper Power Supply to the correct wires.

Caution: Observe polarity!

2. Using a DC Voltmeter, measure the 0 to 10 Vdc Output and confirm that it

corresponds to the room condition. (Humidity, Temperature, etc.)

For systems consisting of the Probe and the Electronics Unit –

1. Connect the Probe to the Electronics Module.

2. Connect a proper Power Supply to the correct terminals.

Caution: Observe polarity!

3. Measure the 4 to 20 mA Output as above, or read the Digital Display.

Confirm that the reading corresponds to the room condition. (Humidity,

Temperature, etc.)

5.2 NORMAL OPERATION

Note:

This section assumes that all required electrical wiring and mounting has

been completed. See the Installation section for further information if

necessary.

Use of the HX80 series of probes is extremely simple. There are no controls to operate

during normal use, as these devices are designed for long-term unattended operation.

With the Analog Outputs, Digital Outputs, and/or Alarm Relays connected to a Data

Acquisition System, Recorder, Process Controller, Computer, or Terminal, the user has

only to periodically monitor the system for normal operation.

5.3 FACTORY DEFAULT RANGES

The scaling of the default measurement ranges may be changed in the field via the

Serial Port if required. See Section 5.4 below for range-changing instructions.

The following ranges are set at the Factory. They correspond to the three separate 0 to

10 Vdc analog outputs that are provided. The scaling of these ranges may be changed

in the field via the Serial Port if required.

19

Page 22

HX85/HX85A 0 to 100% -20 to 80OC/120 OC N/A -60 to 40˚C

HXB85/HX85BA 0 to 100% -20 to 80OC/120 OC 750 to 1100 mb

HXP85/HX85PA 0 to 100% -20 to 80OC/120 OC 0 to 200 psia

HX86/HX86A 0 to 100% -20 to 120OC N/A -60 to -40˚C

HXB86/HX86BA 0 to 100% -20 to 120OC 750 to 1100 mb

HXP86/HX86PA 0 to 100% -20 to 120OC 0 to 200 psia

Notes:

Table 5-1 Standard Output Scaling

MODEL R.H. TEMP. PRESSURE DEW POINT

HX86N 0 to 100% -20 to 120 OC N/A -60 to -40˚C

1. Although the Factory default range for the HXB85, HX85BA,

HXB86 and the HX86BA is 750 to 1100 mb, it can be reprogrammed in

the field over a range of 10 to 1100 mb.

2. If you have the Type DIS Humidity Multi-I/O accessory, the Analog

Outputs are 4 to 20 mA.

20

Page 23

5.4 USING THE RS-232C SERIAL PORT TO PROGRAM YOUR

SETTINGS

5.4.1 SERIAL PORT SETUP

Plug a standard RS-232 cable into the DB-9 connector on the circuit board in the Type

DIS Humidity Multi I/O Electronics Unit. Plug the other end into your terminal or

computer. Use a Terminal Emulation program such as Hyperterminal. Program the

Hyperterminal settings as follows:

• Baud Rate: 19.2K

• Data Bits: 8

• Parity None

• Stop Bit 1

• Flow Control None

You should now see flowing data on your monitor,

displaying the same information as the Multi I/O front

panel Digital Display, with a rapid update rate. If you do

not, check your serial port settings and connections.

NOTE: WHEN PROGRAMMING ALPHABETIC CHARACTERS,

USE UPPER CASE ONLY.

5.4.2 CHANGING THE DIGITAL DISPLAY

You can select any measured or calculated

parameters to appear on the front panel Digital

Display. Proceed as follows:

Press the

“Escape” key

on your

keyboard. You

will see

“D)isplay C)al

Outputs” as

shown here.

Press “D”, selecting to change the Display. (We

will C)alibrate the Outputs later.) You will then be given a choice whether to keep the

present settings or to change them. For this example, we will C)hange them. Press

21

Page 24

“C”. You can then select the parameter to insert by cycling through the options using

the Space Bar. In this case, we will change VALUE 1, the Dew Point reading, from

DPoC to DPoF. Press Enter to save your change and advance to the next value. Next,

do the same for Air Temperature. When completed, press Enter again to save and

advance. For this example, we will choose not to

change the %RH value. Instead, press “X” for eX)it.

When programming is completed, press “A” to

accept the changes.

5.4.3 CHANGING THE OUTPUT RANGES

The next window to be seen will be the Output

Settings screen. Here, you can modify the 4 to 20

mA Analog Output ranges. To enter this mode,

press “C” for C)hange. You will see the Set Output

screen shown here.

To change Output 1, select “1”. You will see

this screen, which shows the present settings

for Output 1.

22

Page 25

Example: We would like to change DPoF to a range of -40 to 200 oF. Press Enter.

Enter -40. Press Enter again. Enter 200. Press Enter again. To Save the Changes,

press “Y” for Y)es. To accept the changes, press “A” for A)ccept.

5.4.4 PROGRAMMING THE ALARM RELAYS

The system will then step to the

Alarm Relay mode. The two relays

are Form A, (single-pole, singlethrow), normally open. You can

independently program the “ON”

point and the “OFF” point for each

relay. To enter the menu, press

“C” for C)hange.

We would like to change Alarm 2 to

these parameters:

Open > a reading of 10 oC

Close < a reading of 10 oC

NOTE: IN ACTUAL OPERATION YOU SHOULD PROGAM IN A SMALL OVERLAP,

SO THAT THE RELAY DOES NOT CHATTER WHEN THE MEASURED READING IS

EXACTLY AT THE SETPOINT. THIS IS CALLED “HYSTERESIS.”

Press “2” to set Alarm 2. You will note that Alarm 2 is set for Air Temperature, AToC.

Under OPEN, insert 10 and press “Enter.” Under CLOSED, insert 10 and press “Enter.”

23

Page 26

You will be asked to Save the Changes. Press “Y” for Y)es.

Then, press “A” for A)ccept.

The program will then automatically return to the normal mode, displaying data that is

continuously updated.

5.4.5 CALIBRATING THE ANALOG OUTPUTS

If you have a precise milliammeter, you can easily calibrate the three 4 to 20 mA analog

outputs. In order to utilize this convenient capability, connect the meter in series with

one of the analog outputs and the load.

Press the “Escape” key on your keyboard, which will interrupt the data stream and give

you the choice of D)isplay or C)al Outputs. Select “C”.

In order to calibrate Output 1, press “1”. You will then be able to insert the desired

current value at the ¼ FS (25% of Full Scale) point and at the 3/4FS (75% of Full Scale)

point. For 4 to 20 mA, 1/4FS is 8 mA, and 3/4FS is 16mA.

Insert these values, pressing “Enter”

after each one. You will then see a

range of what the milliammeter should

read in order to attain the desired

accuracy.

Then select “X” for eX)it. The system

will now return to the normal data

reading mode.

24

Page 27

6.0 MAINTENANCE

6.1 SENSOR CIRCUIT BOARD

Inside the barrel of the Sensor probe, mounted directly at the tip, is the plug-in sensor

circuit board. This board has been calibrated at the Factory for a standard output level.

Since all boards have been calibrated for the same normalized level, they may be

replaced in the field without the requirement for recalibration, while maintaining the full

published system accuracy specification.

6.1.1 REPLACING THE SENSOR CIRCUIT BOARD

See Figure 6-1. For the HX85 and the HX86 series only, at the tip of the Sensor probe

is a snap-ring, or retaining ring (for the HX85A and HX86A series the filter cover is a

scew on cover). It must be removed in order to gain access to the Sensor board.

There is a groove at one end

of the ring. Using a very small

screwdriver or a small knife blade

inserted into the groove in the retaining

ring, lift it out of the machined groove

in the inside of the sensor shield

barrel. The ring can then be removed,

allowing access to the interior of the

sensor assembly.

Figure 6-1 Removing the Retaining Ring

6.1.2 REMOVING THE RETAINING COMPONENTS

Figure 6-2 shows the sequence of parts that must be removed in order to gain access to

the sensor board. All are easily removed once the retaining ring is out. Store them

carefully for re-installation later in the proper sequence.

The final item to be removed in the sequence is the plug-in sensor circuit board, which

can be seen through the slot in the sensor shield. There is a small hole near the tip of

the board to aid in removal. Inserting a small screwdriver in this hole and pulling

upward gently, unplug the board from the socket built into the probe.

Note: The small humidity sensor can be seen mounted near the tip of the board.

This is fragile. Take care not to break it during board removal or installation.

25

Page 28

6.1.3 SENSOR REASSEMBLY

Carefully plug the new sensor circuit board into the socket, noting that it is installed at

the correct angle and properly aligned. Using a small screwdriver in the hole near the

tip, press it down sufficiently so that it is fully inserted in the socket.

Install the bushing in the

direction shown in Figure 6-2.

Then install the spring, O-ring,

and the sintered filter. Finally,

while pressing on the end of the

sintered filter to compress the

spring, snap the retaining ring

back into the slot on the inside

of the sensor shield. Be sure

that it is inserted completely, so

that it will securely retain the

sensor components in place.

F

i

g

u

r

e

6-2 Sensor Exploded View

For the HX85 and HX86 series only, not for the

HX85A or HX86A series

26

Page 29

Sensor exploded view for the

HX85A or HX86A series

7.0 SPECIFICATIONS

Note: See Table 2-2 for actual measurement ranges.

HX85 and the HX85A (Sensor Only)

Measured Parameters – RH/Temp.

RH Accuracy – +/- 1% RH

Temp. Accuracy – +/- 0.5oC

Output Information – RH, Temp., DP

Electrical Outputs – 0 to 10 Vdc (X3)

RS-232C

HXB85 and the HX85BA (Sensor Only)

Measured Parameters – RH/Temp./Barometric Pressure

RH Accuracy – +/- 1% RH

Temp. Accuracy – +/- 0.5

Pressure Accuracy – +/- 5 mb

Output Information – RH, Temp., Pressure

Electrical Outputs – 0 to 10 Vdc (X3)

RS-232C

HXP85 and the HX85PA(Sensor Only)

Measured Parameters – RH/Temp./Pressure

RH Accuracy – +/- 1% RH

Temp. Accuracy – +/- 0.5

Pressure Accuracy – +/- 0.75 psi

Output Information – RH, Temp., Pressure

Electrical Outputs – 0 to 10 Vdc (X3)

RS-232C

o

C

o

C

27

Page 30

HX86 and the HX86A (Sensor with Electronics Module)

Measured Parameters – RH/Temp.

RH Accuracy – +/- 1% RH

Temp. Accuracy – +/- 0.5oC

Output Information – RH, Temp., DP

Electrical Outputs – 4 to 20 mA (X3)

RS-232C

Alarm Relays (X2)

Digital Display – LCD, 2-line

HXB86 and the HX86BA (Sensor with Electronics Module)

Measured Parameters – RH/Temp./Barometric Pressure

RH Accuracy – +/- 1% RH

Temp. Accuracy – +/- 0.5oC

Pressure Accuracy – +/- 5 mb

Output Information – RH, Temp., Pressure

Electrical Outputs – 4 to 20 mA (X3)

RS-232C

Alarm Relays (X2)

Digital Display – LCD, 2-line

HXP86 and the HX86PA (Sensor with Electronics Module)

Measured Parameters – RH/Temp./ Pressure

RH Accuracy – +/- 1% RH

Temp. Accuracy – +/- 0.5oC

Pressure Accuracy – +/- 0.75 psi

Output Information – RH, Temp., Pressure

Electrical Outputs – 4 to 20 mA (X3)

RS-232C

Alarm Relays (X2)

Digital Display – LCD, 2-line

Electrical Outputs

Systems with Probe only –

0 to 10 Vdc (X 3) @ 10 mA max.

RS-232C (bi-directional)

Systems with Probe and Electronics Unit—

4 to 20 mA (X3) into 500 Ω max.

Alarm Relay (X2) Form A (SPST, NO) rated at 3A/250 Vac

RS-232C (bi-directional)

Serial Output (All Units)

RS-232C to DTE device. 19.2 kilobaud, 8 bits data, 1 stop bit, no parity

28

Page 31

Power Requirements

18 to 30 Vdc unregulated, 50 mA max.

Dimensions

Remote Sensor – Diameter: ¾ in. OD (1.9 cm)

Length: 8 inches (20.3 cm)

Cable Length – 6 feet (1.8 meters)

Consult Factory for longer lengths.

Electronics Module –

Outside Dimensions (HWD)

5.1 X 3.7 X 2.2 inches (13 X 9.4 X 5.6 cm)

Mounting Centers

4.5 2 X 3.11 inches (11.5 X 7.9 cm)

Sensor Pressure Rating

200 psia maximum

Sensor Sintered Filter

Material – Stainless Steel

Porosity – 40 microns

29

Page 32

Notes

30

Loading...

Loading...