Page 1

omega.com

e-mail: info@omega.com

For latest product manuals:

omegamanual.info

HPWS SERIES

Long Range Wireless System

®

MADE IN

Shop online at

User’s Guide

Page 2

Servicing North America:

U.S.A.: Omega Engineering, Inc., One Omega Drive, P.O. Box 4047

ISO 9001 Certified Stamford, CT 06907-0047 USA

Toll Free: 1-800-826-6342 TEL: (203) 359-1660

FAX: (203) 359-7700 e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec), H7L 5A1 Canada

Toll-Free: 1-800-826-6342 TEL: (514) 856-6928

FAX: (514) 856-6886 e-mail: info@omega.ca

For immediate technical or application assistance:

U.S.A. and Canada: Sales Service: 1-800-826-6342/1-800-TC-OMEGA

®

Customer Service: 1-800-622-2378/1-800-622-BEST

®

Engineering Service: 1-800-872-9436/1-800-USA-WHEN

®

Mexico/ En Español: 001 (203) 359-7803 FAX: 001 (203) 359-7807

Latin America: info@omega.com.mx e-mail: espanol@omega.com

Servicing Europe:

Benelux: Managed by the United Kingdom Office

Toll-Free: 0800 099 3344 TEL: +31 20 347 21 21

FAX: +31 20 643 46 43 e-mail: sales@omegaeng.nl

Czech Republic: Frystatska 184

733 01 Karviná, Czech Republic

Toll-Free: 0800-1-66342 TEL: +420-59-6311899

FAX: +420-59-6311114 e-mail: info@omegashop.cz

France: Managed by the United Kingdom Office

Toll-Free: 0800 466 342 TEL: +33 (0) 161 37 29 00

FAX: +33 (0) 130 57 54 27 e-mail: sales@omega.fr

Germany/Austria: Daimlerstrasse 26

D-75392 Deckenpfronn, Germany

Toll-Free: 0800 6397678 TEL: +49 (0) 7056 9398-0

FAX: +49 (0) 7056 9398-29 e-mail: info@omega.de

United Kingdom: OMEGA Engineering Ltd.

ISO 9001 Certified One Omega Drive, River Bend Technology Centre, Northbank

Irlam, Manchester M44 5BD United Kingdom

Toll-Free: 0800-488-488 TEL: +44 (0) 161 777-6611

FAX: +44 (0) 161 777-6622 e-mail: sales@omega.co.uk

OMEGAnet®Online Service Internet e-mail

omega.com info@omega.com

It is the policy of OMEGA Engineering, Inc. to comply with all worldwide safety and EMC/EMI

regulations that apply. OMEGA is constantly pursuing certification of its products to the European New

Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA accepts no liability for any

errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, human applications.

Page 3

i

Table of Contents

Section Page

Section 1 Introduction ................................................................................... 1-1

1.1 Precautions .......................................................................................... 1-1

1.2 Product Labeling ................................................................................ 1-2

1.3 FCC........................................................................................................ 1-3

1.4 CE Marking .......................................................................................... 1-3

1.5 General Description and System Components ............................... 1-3

Section 2 Hardware ....................................................................................... 2-1

2.1 Package Inspection.............................................................................. 2-1

2.2 Included Items .................................................................................... 2-1

2.3 Accessories ........................................................................................... 2-1

Section 3 Transmitter Operation ................................................................. 3-1

3.1 Figures .................................................................................................. 3-1

3.2 Open Enclosure.................................................................................... 3-1

3.3 Initial Wiring........................................................................................ 3-2

3.3.1 Pass Wires Into Enclosure ......................................................... 3-2

3.3.2 Connect Signal Wires To Barrier Strip..................................... 3-2

3.3.3 Connect AC Power..................................................................... 3-3

3.3.4 Connect Battery .......................................................................... 3-4

3.4 Connect External Antenna ................................................................ 3-5

Section 4 Receiver Operation ....................................................................... 4-1

4.1 Switch Operation................................................................................. 4-1

4.2 Initial Setup .......................................................................................... 4-1

4.2 1 Open Transmitter Enclosure ..................................................... 4-1

4.2.2 Pass Wires Into Enclosure ......................................................... 4-1

4.2.3 Connect Signal Wires To Barrier Strip..................................... 4-2

4.2.4 Connect AC Power..................................................................... 4-3

4.4 Connect External Antenna .................................................................4-5

Section 5 System Operation.......................................................................... 5-1

5.1 Introduction.......................................................................................... 5-1

5.2 RF Communication Basics ................................................................. 5-1

5.3 Basic System Overview ...................................................................... 5-1

5.4 Transmitter/Receiver Operation....................................................... 5-1

5.4.1 Button Operation....................................................................... 5-1

5.5 Environment/Operating Conditions ............................................... 5-2

5.5.1 Environment................................................................................ 5-2

5.5.2 Operating Conditions ................................................................ 5-2

5.6 Determining and Maximizing Range ............................................... 5-3

5.7 Mounting the HPWS Unit.................................................................. 5-3

5.8 Installing the Antenna ........................................................................ 5-4

HPWS SERIES

Long Range Wireless System

Page 4

ii

Table of Contents continued

Section Page

Section 6 Advanced Features ....................................................................... 6-1

6.1 Address Codes .................................................................................... 6-1

6.2 Multiple Transmitters ........................................................................ 6-2

6.3 Normally Open vs. Normally Closed Outputs............................... 6-3

6.4 Status Alerts ......................................................................................... 6-5

6.4.1 Location of the Status Alert Dipswitches on Transmitter..... 6-5

6.4.1 Location of the Status Alert Dipswitches on Receiver.......... 6-6

6.5 Low Battery Alert (Receiver Only).................................................... 6-7

6.6 Auto Restore (Transmitter Only)....................................................... 6-7

6.7 Replacing the Battery.......................................................................... 6-8

Section 7 Specifications General ................................................................. 7-1

Section 8 Approvals, Regulatory Compliance ......................................... 8-1

8.1 FCC (Domestic Use) .................................................................................. 8-1

8.2 Internation Usage & CE Marking............................................................ 8-1

8.3 Declaration of Conformity ...................................................................... 8-1

HPWS SERIES

Long Range Wireless System

Page 5

List of Figures

Section Figure Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page

1.2 1-1 HPWS-TX Transmitter/Receiver Label . . . . . . . . . . 1-2

1.2 1-2 HPWS Battery Backup Caution Label . . . . . . . . . . . . 1-3

1.2 1-3 Power Supply DC Terminal Label . . . . . . . . . . . . . . . 1-3

1.2 1-4 Power Supply AC Terminal Label . . . . . . . . . . . . . . .1-3

1.2 1-5 Transmitter Barrier Strip Label . . . . . . . . . . . . . . . . . . 1-3

1.2 1-6 Receiver Barrier Strip Label . . . . . . . . . . . . . . . . . . . . 1-3

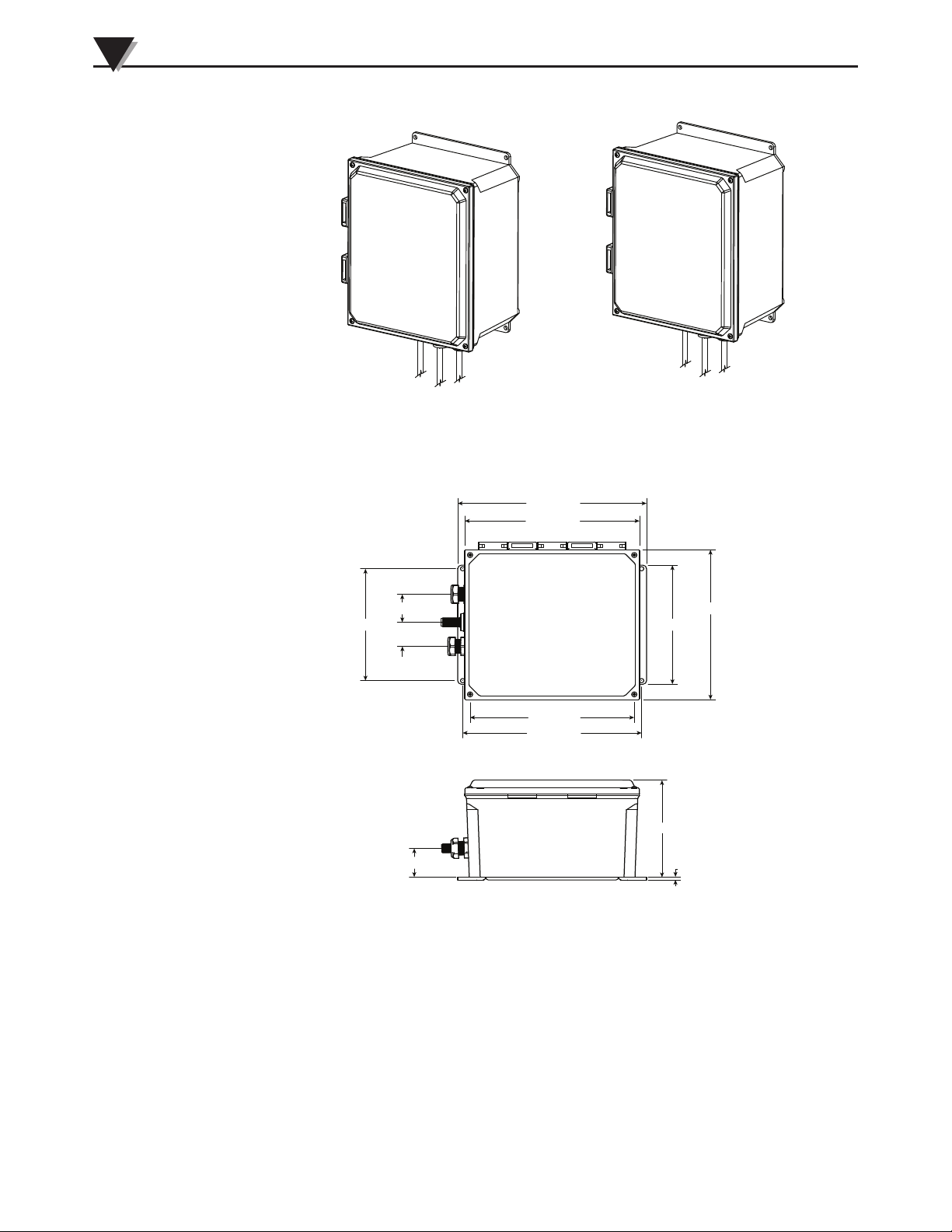

1.3 1-7 System Components . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-3 1-8 General Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

3.1 3-1 Open Enclosure (Model HPWS-TX) . . . . . . . . . . . . . . 3-1

3.1 3-2 Transmitter Wiring Diagram - (Model HPWS-TX) . . . 3-1

3.3 3-3 HPWS Enclosure Connections . . . . . . . . . . . . . . . . . . 3-2

3.3 3-4 Barrier Strip Connections (Model HPWS-TX) . . . . . 3-3

3.3 3-5 Grounding Bus Bar Connection . . . . . . . . . . . . . . . . . 3-3

3.3 3-6 HPWS Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

4.2 4-1 HPWS Enclosure Connections . . . . . . . . . . . . . . . . . . 4-1

4.2 4-2 Transmitter Wiring Diagram -

(Model HPWS-REC and HPWS-REC-BATT) . . . . . . 4-2

4.2 4-3 Grounding Bus Bar Connection

(Model HPWS-REC) . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.2 4-4 HPWS Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

5.6 5-1 Basic System Overview . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.6 5-2 Fresnel Zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

6.1 6-1 Address Codes On HPWS Receiver . . . . . . . . . . . . . 6-1

6.2 6-2 Multiple Transmitters . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

6.3 6-3 Transmitter Dip Switches . . . . . . . . . . . . . . . . . . . . . . .6-3

6.3 6-4 Signal Input Block (Model HPWS-REC) . . . . . . . . . . .6-4

6.4 6-5 Transmitter Option Switches (Model HPWS-TX) . . . 6-5

6.4 6-6 Receiver Status Alert Dipswitches . . . . . . . . . . . . . . . 6-6

6.7 6-7 Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

iii

HPWS SERIES

Long Range Wireless System

Page 6

NOTES:

iv

HPWS SERIES

Long Range Wireless System

Page 7

Section 1 - Introduction

Please read this manual completely before installing and operating your wireless

transmitter and receiver system. It is important to read and follow all notes,

cautions, warnings, and safety precautions before operating this device.

“Device” referrers to your transmitter or receiver unit.

1.1 Precautions

Equipment sold by OMEGA Engineering, Inc. is not intended

to be used, nor shall it be used: 1) As a "Basic Component"

under 10 CFR21 (NRC), used in or with any nuclear

installation or activity; or 2) In medical applications or used

on humans. Should this equipment be used in or with any

nuclear installation or activity, medical application, used on

humans, or misused in any way, purchaser will indemnify

OMEGA and hold OMEGA harmless from any liability or

damage whatsoever arising out of the use of the equipment in

such a manner.

This device is subject to FCC regulations under 47 CFR Part 95

and may only be used within the territorial limits of the United

States. Please refer to FCC regulation 47 CFR Part 95.405 for

a definitive list. Transmitters contained in this device have

limited transmitter power and limited range. A receiver cannot

respond to more than one transmitted signal at a time and

may be blocked by radio signals that occur on or near the

operating frequencies, regardless of code settings. Changes or

modifications to this device may void FCC compliance.

Infrequently used radio links should be tested regularly to

protect against undetected interference or fault.

This device should not be used in life safety or medical

appplications. The FCC allows high powered and/or

unlicensed transmissions around the frequency used by this

device. These transmissions may interfere or prevent normal

operation of the device. This device should not be used near

equipment which uses the medical device radio

communication service or wireless medical telemetry device

service or wireless medical telemetry device service, such as

but not limited to, implanted medical devices or

electrocardiogram equipment.

This product may not be used aboard an in-flight aircraft.

This device is marked with the international caution symbol. It is important to

read this manual before installing or commissioning this device as it contains

important information relating to Safety and EMC (Electromagnetic

Compatibility).

1-1

Introduction

1

WARNING:

WARNING:

Page 8

EMC Considerations

• Whenever EMC is an issue, always use shielded cables.

• Never run signal and power wires in the same conduit.

• Use signal wire connections with twisted-pair cables.

• Install Ferrite Bead(s) on signal wires close to the instrument if EMC problems

persist.

Failure to follow all instructions and warnings may result in injury!

Other Precautions

• This device is not designed for use in any medical or nuclear applications.

• Do not operate this device in flammable or explosive environments.

• Never operate with a power source other than the one recommended in this

manual or listed on product labels.

• Do not operate this device outside of the recommended use outlined in this

manual.

• Never use your HPWS transmitter as a portable device. Your unit has been

designed to be operated in a permanent installation only.

• Never install and/or operate your HPWS transmitter closer than 20 cm to

nearby persons.

1.2 Product Labeling

Figure 1-1. HPWS-TX Transmitter/Receiver Label

The main product label contains two white boxed areas that

can be used as write-on surfaces for your convenience. The

bottom box is intended to reference the address code of the

transmitter or receiver. The top box is ‘free-space’ and can be

used for designating where the unit is located or for other

user-desired purposes.

Introduction

1

1-2

®

!

HPWS SERIES

TRANSMITTER

RECEIVER

LONG RANGE WIRELESS SYSTEM

27.255 MHz

OMEGA ENGINEERING, INC.

Stamford, CT 06907

ADDRESS:

800-TC-OMEGA

®

NOTE:

Page 9

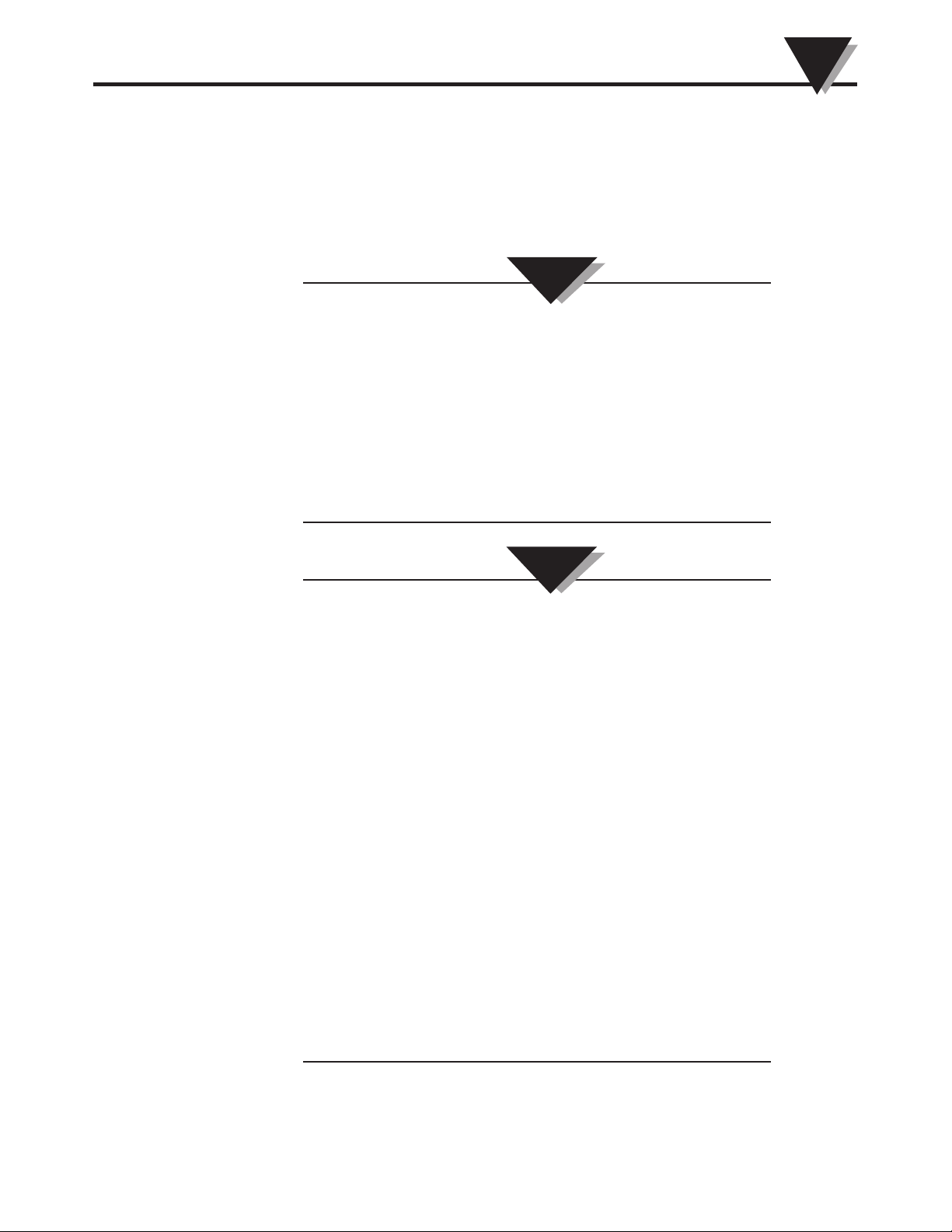

Figure 1-2. HPWS Battery Backup Caution Label

Figure 1-3. Power Supply DC Terminal Label

Figure 1-4. Power Supply AC Terminal Label

Figure 1-5. Transmitter Barrier Strip Label

Figure 1-6. Receiver Barrier Strip Label

1.3 FCC

This product complies with Part 95 of the FCC rules. Normal operation as

intended by this manual does not require a radio license.

1.4 CE Marking

It is the policy of OMEGA to comply with all worldwide safety and EMI/EMC

regulations that apply. OMEGA is constantly pursuing certification of its

products to the European New Approach Directives. OMEGA will add the CE

mark to every appropriate device upon certification.

Since the HPWS is not intended for use in Europe, CE status has not been

verified at this time.

1.5 General Description and System Components

The HPWS Series long range wireless system allows users to remotely monitor

the status of up to four discrete switches such as level, flow, or other contact

switches. The HPWS-TX transmitters are capable of sending signals to their

corresponding HPWS-REC receivers up to a distance of 8 miles.

The HPWS series wireless system is programmed to work with discrete input,

SPST switches; the HPWS-REC unit can monitor up to four switches located on

one to four HPWS-TX transmitters.

Introduction

1

1-3

CAUTION

:

UNIT IS POWERED

WHENEVER BATTERY IS CONNECTED!

TO COMPLETELY POWER DOWN,

DISCONNECT AC POWER AND

BATTERY CONNECTORS.

BAT

++

--

DC

NLG

AC

GND

CH1

GND

CH2

GND

CH3

GND

CH4

N/A

N/A

COM

CH1

COM

CH2

COM

CH3

COM

CH4

STAT

BATT

Page 10

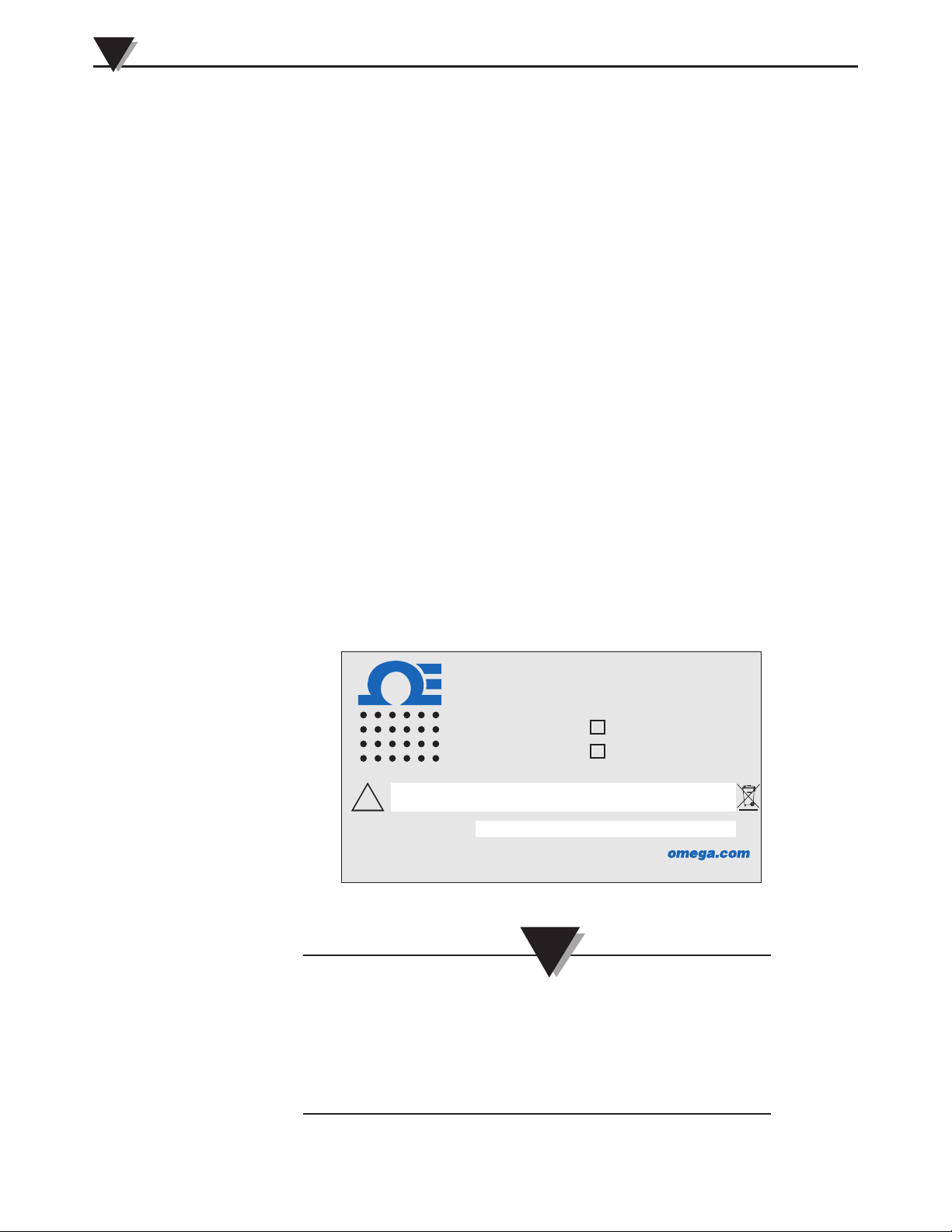

Figure 1-7. System Components

Figure 1-8. General Dimensions

Introduction

1

1-4

HPWS-REC/ HPWS-REC-BATT RECEIVER

HPWS-TX TRANSMITTER

298 (11.74)

272 (10.71)

51 (2.00)

44 (1.72)

325 (12.80)

DIMENSIONS mm (in)

343 (13.50)

203 (8.00)

216 (8.51)

272 (10.71)

5 (0.20)

176 (6.94)

53 (2.07)

Page 11

2-1

Hardware

2

Section 2 - Hardware

It is important that you read this manual completely and follow all safety

precautions before operating this instrument

2.1 Package Inspection

Remove the packing list and verify that you have received all your equipment.

If you have any questions about the shipment, please call our Customer Service

Department at 1-800-622-2378 or 203-359-1660. We can also be reached on the

Internet at omega.com, and by e-mail at cservice@omega.com. When you receive

the shipment, inspect the container and equipment for any signs of damage.

Note any evidence of rough handling in transit. Immediately report any damage

to the shipping agent.

The carrier will not honor any damage claims unless all

shipping material is saved for inspection. After examining

and removing contents, save packing material and carton in

the event reshipment is necessary.

2.2 Included Items

2.2.1 The following items are supplied in the box:

With the HPWS-TX Transmitter

• 1 Transmitter

• 3 foot Antenna with mounting kit and 18’ of RG-58 Cable (may ship separately)

• User’s Manual

• 2 AC Cable Holders

With the HPWS-REC or HPWS-REC-BATT Receiver

• 1 Receiver Device (with battery backup for HPWS-REC-BATT)

• 3 foot Antenna with mounting kit and 18' of RG-58 cable (may ship separately

• 2 AC Cable Holders

• User’s Manual

2.3. Accessories

The HPWS is offered with the following accessories/replacement parts:

• OM-AMPOLEMNT10: Pole mount kit for enclosure includes:

• 14 gauge galvannealed steel

• 48" stainless steel pole clamp

• #10-32 stainless steel screws

• Washers

• Lock nuts

Note: The pole mount kit mounts only the enclosure.

• HPWS-BATT: Replacement backup battery (12V, 5 Amp-hour)

• HPWS-ANT: Replacement antenna

NOTE:

Page 12

Section 3 - Transmitter Operation

3.1 Figures

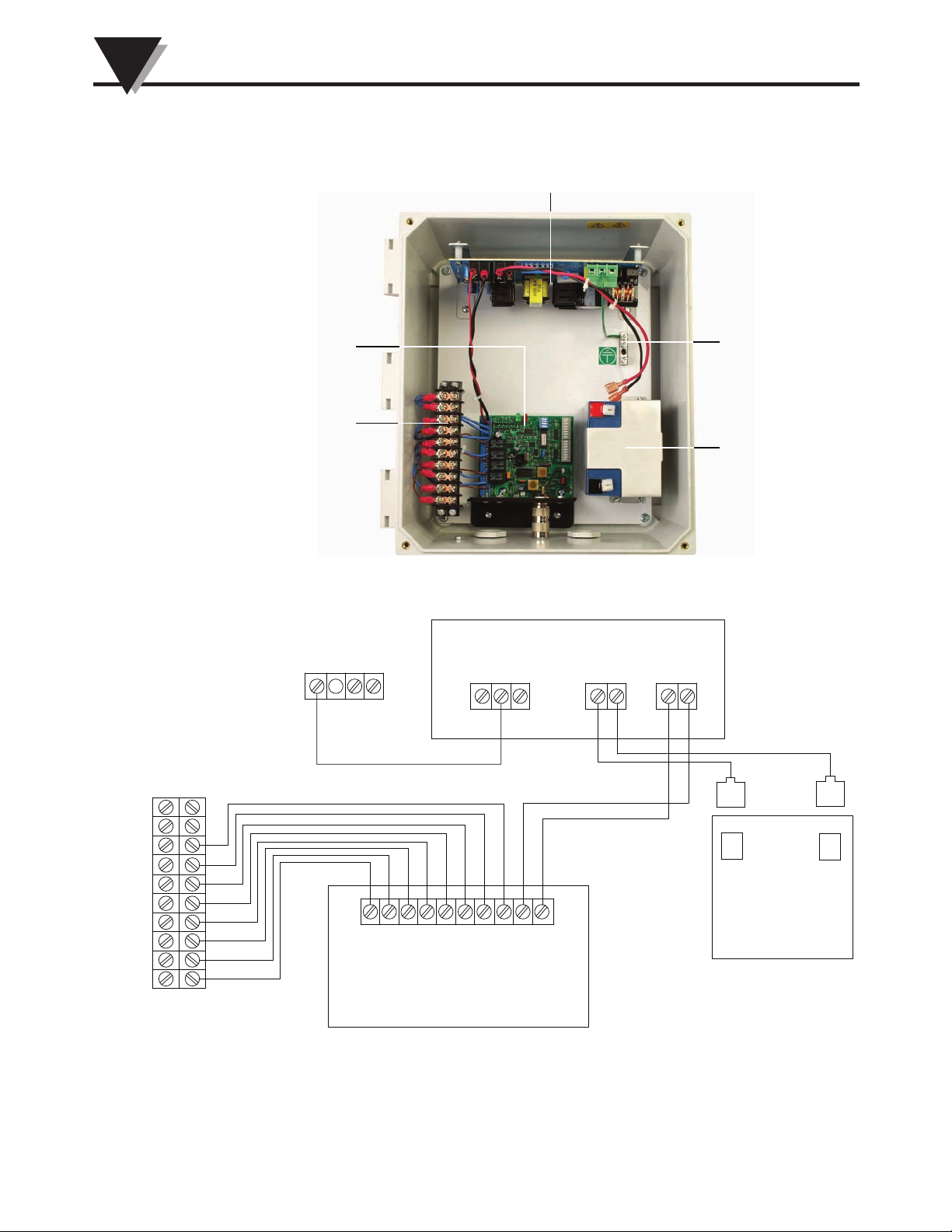

Figure 3-1. Open Enclosure (Model HPWS-TX)

Figure 3-2. Transmitter Wiring Diagram - (Model HPWS-TX)

3.2 Open Enclosure

Open transmitter enclosure by unscrewing the four (4) screws on the lid.

3-1

Transmitter Operation

3

AC/DC POWER SUPPLY

TRANSMITTER

CIRCUIT BOARD

BARRIER STRIP

GROUND BUS BAR

BACKUP BATTERY

-

+

GND

+12V DC

CH 1

CH 4

CH 2

CH 3

-

+

DC

-

+

BAT

AC

L

G

N

TRANSMITTER CIRCUIT BOARD

AC/DC POWER SUPPLY

12V BACKUP

BATTERY

BARRIER STRIP

GND

CH 1

CH 4

CH 2

CH 3

GND

GND

GND

GND

GND

GND

GND

NOT IN USE

NOT IN USE

GROUND BUS BAR

Page 13

Transmitter Operation

3

3-2

3.3 Initial Wiring

3.3.1 Pass Wires into Enclosure

Pass the signal and AC power wires into the enclosure via the cable glands.

Figure 3-3, below shows the recommended use of the included cable glands.

Signal Wires | Antenna | AC Power Cable

Figure 3-3. HPWS Enclosure Connections

The cable glands provide a watertight seal that will protect the enclosure in case

of normal rain, ice, or snow when the cables are installed correctly. In order for

the enclosure to be weatherproof, it is necessary to tighten the cap of the strain

relief of the cable gland to ensure a proper seal. If space remains in the cable

strain relief after the cap is tightened, reinsert wires using a cable fitting to

eliminate any path for moisture.

The HPWS has been tested to NEMA 4X (IP66) standards, but

has not been tested for use in extreme rain, sleet, snow, wind,

or other abnormal weather conditions.)

3.3.2 Connect Signal Wires To Barrier Strip

Connect Signal wires from up to four (4) switches to the barrier strip as shown in

wiring diagram below.

If less than four switches are being used, do not connect any wires to that

channel on the terminal block.

NOTE:

Page 14

Figure 3-4. Barrrier Strip Connections (Model HPWS-TX)

3.3.3 Connect AC Power

Only connect the HPWS unit to an AC power source of

115VAC, 60Hz, 0.95Amp, or 230VAC, 50Hz, 0.6Amp. The

power supply is not designed to work with other power modes.

Ensure the power switch on the power supply is selected to OFF before

proceeding and that power is completely disconnected from the unit.

Connect the AC Ground wire to the grounding bus bar located on the steel sub

panel. Ensure the ground wire is securely locked to the grounding bar using the

included screw.

Figure 3-5. Grounding Bus Bar Connection

Then, connect the AC Line wire to the terminal labeled L, and Neutral to N.

Transmitter Operation

3

3-3

CAUTION:

GND

+12V DC

LOW BATT

STATUS

N/O

COM

N/C

-

+

DC

-

+

BAT

AC

L

G

N

N/O

COM

N/C

N/O

COM

N/C

N/O

COM

N/C

CH

1

CH

2

CH

3

CH

4

-

+

RECEIVER CIRCUIT BOARD

POWER SUPPLY

BARRIER STRIP

COM

CH 1

COM

CH 4

CH 2

COM

CH 3

COM

STATUS

BATT

12V BATTERY BACKUP

(HPWS-REC-BATT ONLY)

GROUND BUS BAR

Page 15

Transmitter Operation

3

3-4

Figure 3-6. HPWS Power Supply

3.3.4 Connect Battery

Sealed Lead Acid (SLA) batteries may get hot, explode or

ignite and cause serious injury if exposed to abusive

conditions. Be sure to follow the safety warnings listed below:

Your HPWS operates with one 12V, 5Amp-Hour SLA Battery (Omega

Replacement Part Number HPWS-BATT). Never operate your HPWS

transmitter or receiver with a different battery than what is specified in this

manual or on the HPWS Series data sheet. Do not discharge the battery using

any device except your HPWS unit. When the battery is used in devices other

than the specified device, it may damage the battery or reduce its life expectancy.

If the device causes an abnormal current to flow, it may cause the battery to

become hot, explode or ignite and cause serious injury. Refer to the Omega

technical data sheet or this manual for the temperature ranges over which the

battery can be operated. Use of the battery outside this temperature range may

damage the HPWS or reduce the performance and life of the battery.

WARNING:

Page 16

• Do not store batteries with other hazardous or combustible materials.

• Do not install the battery backwards so the polarity is reversed.

• Do not connect the positive terminal and negative terminal of the battery to

each other with any metal object (such as wire).

• Do not carry or store the battery together with metal objects.

• Do not pierce the battery with nails, strike the battery with a hammer, step on

the battery, or otherwise subject it to strong impacts or shocks.

• Do not solder directly onto the battery.

• Do not expose battery to water or salt water, or allow the battery to get wet.

• Do not disassemble or modify the battery.

• When the battery is discharged, insulate the terminals with adhesive tape or

similar materials before disposal.

• Immediately discontinue use of the battery if, while using or storing the

battery, the battery emits an unusual smell, feels hot, changes color or

shape, leaks or appears abnormal in any other way. Contact Omega if any

of these problems are observed.

• Do not place the battery in microwave ovens or high-pressure containers.

• Always dispose of discharged batteries in accordance with all local, state and

national laws.

Once the battery is connected, it will immediately begin to

power the unit, even if the power supply is set to off. The

ON/OFF switch only controls AC power. As a result, only

connect the battery when the unit is ready for use.

Do NOT connect the battery until just before the unit is ready for use—the unit

will receive power as soon as the battery is connected. Once battery is connected,

place power switch in the ON position to run the unit using AC power. When

device receives AC power, the power supply will charge the battery.

To connect the battery:

Attach the connectors from the battery lead wire to the terminals of the battery.

The battery may come with plastic protective covers attached to the terminals –

remove if necessary.

The connector with a red wire connects to the positive (+) terminal, which is

shaded red.

The connector with a black wire connects to the negative (-) terminal, which is

also shaded black.

3.4 Connect External Antenna

Connect the antenna (included) to the UHF connector on the outside of the

antenna.

Transmitter Operation

3

3-5

NOTE:

Page 17

4-1

Receiver Operation

4

Section 4 - Receiver Operation

The HPWS-REC receivers come in two different versions:

• HPWS-REC: 4-Channel 27.255MHz Switch Receiver without battery backup

• HPWS-REC-BATT: 4-Channel 27.255MHz Switch Receiver with battery

backup

In this manual, HPWS-REC will refer to both versions, unless

otherwise noted.

4.1 Switch Operation

The HPWS-REC receiver will trigger a relay output, when appropriate, of up to

1A at 32Vdc per channel when the switch on a respective channel is activated by

the transmitter.

4.2 Initial Setup

4.2.1 Open Transmitter Enclosure

Open Transmitter Enclosure by unscrewing the four (4) screws on the lid.

4.2.2 Pass Wires Into Enclosure

Pass the signal and AC power wires into the enclosure via the cable glands. This

watertight seal will protect the enclosure in case of normal rain, ice, or snow

when the cables are installed correctly. Tighten the cap of the strain relief on the

cable gland to ensure a tight seal. If space remains in the cable strain relief after

the cap is tightened, reinsert wires using a cable fitting to eliminate any path for

moisture.

Signal Wires | Antenna | AC Power Cable

Figure 4-1. HPWS Enclosure Connections

(Note, the unit has not been tested for use in extreme rain, sleet, snow, wind, or

other abnormal weather conditions.)

NOTE:

Page 18

4.2.3 Connect Signal Wires To Barrier Strip

Connect signal wires for up to 4 outputs to the barrier strip as shown in wiring

diagram below. If less than four switches are being used, do not connect any

wires to that channel. The receiver assumes all switches are normally open

(N/O) switches.

Figure 4-2. Receiver Wiring Diagram - (Model HPWS-REC and HPWS-REC-BATT))

If using a normally closed switch, move the lead wire from the N/O terminal to

N/C terminal on the appropriate channel of the receiver circuit board. It is also

necessary to program the transmitter to N/C for the input signal wires (see

Section 6.3 for more details on normally closed switches).

In addition, the HPWS receiver offers a low battery and signal status alarm. The

low battery will switch up to 50mA @ 20Volts DC (with ground) when the

backup battery drops below 10.5 Volts. The signal status alarm will trigger when

the receiver has not received a transmission from a transmitter channel in the last

4 hours.

4-2

Receiver Operation

4

GND

+12V DC

LOW BATT

STATUS

N/O

COM

N/C

-

+

DC

-

+

BAT

AC

L

G

N

N/O

COM

N/C

N/O

COM

N/C

N/O

COM

N/C

CH

1

CH

2

CH

3

CH

4

-

+

RECEIVER CIRCUIT BOARD

POWER SUPPLY

BARRIER STRIP

COM

CH 1

COM

CH 4

CH 2

COM

CH 3

COM

STATUS

BATT

12V BATTERY BACKUP

(HPWS-REC-BATT ONLY)

GROUND BUS BAR

Page 19

Receiver Operation

4

4-3

4.2.4 Connect AC Power

Failure to properly connect electrical wiring can lead to

shock, fire, explosion, personal injury, or death. Do not

connect AC power or battery unless properly trained. Always

use standard protection and safety procedures when

connecting electrical components.

Only connect the HPWS unit to an AC power source of

115VAC, 60Hz, 0.95Amp, or 230VAC, 50Hz, 0.6Amp. The

power supply is not designed to work with other power

modes.

Ensure the power switch on the power supply is selected to OFF before

proceeding and that power is completely disconnected from the unit.

Connect the AC Ground wire to the grounding bus bar located on the steel sub

panel. Ensure the ground wire is securely locked to the grounding bar using the

included screw.

Figure 4-3. Grounding Bus Bar Connection (Model HPWS-REC)

Connect AC Line and Neutral wires to the green terminal block on the power

supply as shown. Connect the AC Line wire to the terminal labeled L, and

Neutral to N.

CAUTIION:

WARNING:

Page 20

Figure 4-4. HPWS Power Supply

Ensure all screws are tightened securely around wire.

.

Sealed Lead Acid (SLA) batteries may get hot, explode or

ignite and cause serious injury if exposed to abusive

conditions. Be sure to follow the safety warnings listed below:

Your HPWS operates with one 12V, 5Amp-Hour SLA Battery. Omega

Replacement Part Number HPWS-BATT. Never operate your HPWS transmitter

or receiver with a different battery than what is specified in this manual or on

the HPWS Series data sheet. Do not discharge the battery using any device

except your HPWS unit. When the battery is used in devices other than the

specified device, it may damage the battery or reduce its life expectancy. If the

device causes an abnormal current to flow, it may cause the battery to become

hot, explode, or ignite and cause serious injury. Refer to the Omega technical

data sheet or this manual for the temperature ranges over which the battery can

be operated. Use of the battery outside this temperature range may damage the

HPWS or reduce the performance and life of the battery.

Receiver Operation

4

4-4

WARNING:

Page 21

Receiver Operation

4

4-5

• Do not place the battery in fire or heat the battery.

• Do not store batteries with other hazardous or combustible materials.

• Do not install the battery backwards so the polarity is reversed.

• Do not connect the positive terminal and negative terminal of the battery to

each other with any metal object (such as wire).

• Do not carry or store the battery together with metal objects.

• Do not pierce the battery with nails, strike the battery with a hammer, step on

the battery, or otherwise subject it to strong impacts or shocks.

• Do not solder directly onto the battery.

• Do not expose battery to water or salt water, or allow the battery to get wet.

• Do not disassemble or modify the battery.

• When the battery is discharged, insulate the terminals with adhesive tape or

similar materials before disposal.

• Immediately discontinue use of the battery if, while using or storing the

battery, the battery emits an unusual smell, feels hot, changes color or

shape, leaks or appears abnormal in any other way. Contact Omega if any

of these problems are observed.

• Do not place the battery in microwave ovens or high-pressure containers.

• Always dispose of discharged batteries in accordance with all local, state and

national laws

Once the battery is connected, it will immediately begin to

power the unit, even if the power supply is set to off. The

ON/OFF switch only controls AC power. As a result, only

connect the battery when the unit is ready for use.

Do NOT connect the battery until just before the unit is ready for use—the unit

will receive power as soon as the battery is connected. Once battery is connected,

place power switch in the ON position to run using AC power. When device

receives AC power, the power supply will charge the battery.

4.4. Connect External Antenna

Connect the antenna (included) to the UHF connector on the outside of the

enclosure.

NOTE:

Page 22

5-1

System Operation

5

Section 5 - System Operation

5.1 Introduction

Compared to wired switch systems, wireless switches provide much simpler

installation. It is not necessary to lay wire or signal cables over long distances.

However, based on the physical principle of propagation of radio waves, certain

basic conditions should be observed. The following recommendations are provided

to ensure proper installation and correct operation of your wireless system.

5.2 RF Communication Basics

The HPWS-TX model sends wireless transmissions to a receiver unit. The receiver

unit processes the signal and creates an appropriate output. Radio signals are

electromagnetic waves; hence, the signal becomes weaker the farther it travels.

While radio waves can penetrate some solid materials like a wall, they are

dampened more than when a direct, line-of-sight path between the transmitting

and receiving antenna exists.

5.3 Basic System Overview

The HPWS wireless system is comprised of two main components: a transmitter

and a receiver. Up to four (4) switches can be observed by one receiver.

The receiver can accept signals from up to four (4) different transmitters,

provided each unit is transmitting/receiving on a common address code and a

net total of four (4) switches or less are being observed.

Figure 5-1. Basic System Overview

This system onerview would require the OM-AMPOLEMNT10

accessory. See page 2-1 for more information.

HPWS-TX

TRANSMITTER

(SINGLE SWITCH)

HPWS-TX

TRANSMITTER

(SINGLE SWITCH)

HPWS-TX

TRANSMITTER

(SINGLE SWITCH)

HPWS-TX

TRANSMITTER

(SINGLE SWITCH)

HPWS-REC/ HPWS-REC-BAT

T

RECEIVER

8 MILES

6 MILES

4 MILES

2 MILES

NOTE:

Page 23

5-2

System Operation

5

5.4. Transmitter/Receiver Operation

5.4.1 Button Operation

There are no external buttons on the transmitter or receiver enclosures.

Each unit has an on/off switch, located inside the enclosure on the power supply

circuit board. The on/off switch controls AC power only. Once the battery is

connected, the unit will be activated and powered by DC power.

To completely turn off the unit's electrical power, you must

disconnect the battery lead wires from the battery terminals

5.5. Environment/Operating Conditions

5.5.1 Environment

Omega’s wireless end devices and receiver units have been designed to be fixedmounted and operated in an appropriate, clean environment. Care should be

taken to prevent the internal components of the HPWS wireless system from

being exposed to moisture, toxic chemicals, and extreme cold or hot

temperatures that are outside the specifications listed in this manual.

Operating your HPWS transmitter or receiver outside the

specified conditions listed in Section 7 of this manual may

cause your unit to malfunction and stop working correctly.

5.5.2 Operating Conditions

The following is a list of basic good practices you should apply when operating

your HPWS wireless system:

• Never operate your wireless device outside the recommended environmental

limits specified in this manual.

• Never operate your wireless device in flammable or explosive environments.

• Never use your wireless device in medical, nuclear or other dangerous

applications were failure can cause damage or harm.

• Never operate your transmitter with any other battery or power source than

what is specified in this manual or on the battery compartment label.

• No co-location with other radio transmitters is allowed. By definition, colocation is when another radio device or its antenna is located within 20 cm

of your transmitter and can transmit simultaneously with your HPWS unit.

• Never install transmitters within 20 cm or less from each other.

• Never use your transmitter as a portable device. Your unit has been designed

to be operated in a permanent installation.

• Never install and/or operate your transmitter closer than 20 cm to nearby

persons.

NOTE:

IMPORTANT:

Page 24

• Never operate your transmitter with any other antenna than what is supplied

or listed here in this manual for approved use.

5.6 Determining and Maximizing Range

The available maximum range specified for the HPWS series system in this

manual is only achievable under optimum installation conditions. Mounting

height, obstructions in your Fresnel Zone, and ambient conditions can degrade

signal strength, resulting in shorter range. The following recommendations will

help to improve the range of the HPWS wireless system.

Be aware of the Fresnel Zone

The Fresnel Zone is a football shaped area that represents the path of best signal

strength between the transmitter and the receiver.

Figure 5-2. Fresnel Zone

This configuration would require the OM-AMPOLEMNT10

accessory. See page 2-1 for more information.

Position the receiver in a central location

When multiple transmitters are in operation, position the HPWS receiver in a

central space with equal distance to each transmitter, if possible.

Test your system before permanent mounting,

Before permanently mounting a HPWS transmitter or receiver, try moving the

devices or antenna to multiple locations and mounting angles to determine

which installation achieves best signal strength.

Mount antenna high from ground and away from walls

Avoid installing system components near the ground or floor (this will cause the

bottom portion of the Fresnel Zone to be obstructed) or near buildings’ external

walls. Walls can create interference and degrade signal strength.

Maintain a line of sight between antennas

Maintaining a line of sight between a transmitter and receiver unit will greatly

improve signal strength when compared to a system with obstructions in the

path between transmitter(s) and a receiver.

System Operation

5

5-3

RECEIVER

ANTENNA

TRANSMITTER

ANTENNA

FRESNEL ZONE

NOTE:

Page 25

System Operation

5

5-4

5.7 Mounting the HPWS Unit

The HPWS series of products have flanges at the top and bottom of the enclosure

for mounting the HPWS. Use four (4) screws to secure the flanges to a wall or

other solid object.

In addition, an accessory pole-mount kit can be used to mount the HPWS to a

pole. See secton 2.2 for more accessory information, and Section 1.5 for

Mounting Dimensions.

5.8 Installing the Antenna

The HPWS series operates on 27.255 MHz, which is part of the CB radio band.

Normal transmissions from the HPWS on the CB band do not require a license or

special approval.

The HPWS series comes with a 3-foot antenna and 18 feet (6m) of RG-58 antenna

cable. Up to 50 feet of RG-58 cable may be used to connect the HPWS antenna.

The HPWS uses UHF-Style (PL-259) connectors to connect the coaxial cable to

the antenna.

If more than 50 feet of cable is necessary to mount the antenna, up to 100

feet of RG-8 cable may be used to mount an antenna.

When mounting the antenna, it is important to comply with all FCC

regulations.

5.8.1 Antenna FCC Regulations

FCC regulations (§95.408) state the highest point of a CB antenna may not:

• “be more than 6.1 meters (20 feet) above the highest point of building or tree

the antenna is mounted upon” or

• “be more than 18.3 meters (60 feet) above the ground”

Installations near an airport are subject to stricter requirements. Check

with the local FCC office for more details if installing near an airport or

helipad.

NOTE:

NOTE:

NOTE:

Page 26

FCC regulations are subject to change at any time. While every effort

was made to ensure that the regulations cited were up to date at time of

printing (November, 2010), it is important to make sure you check any

and all FCC (or other government) regulations appropriate to your use

before using a wireless product.

System Operation

5

5-5

NOTE:

Page 27

Section 6 - Advanced Features

6.1 Address Codes

Each transmitter and receiver has a programmable address code. When ordered

as a system, the transmitter and receiver will be factory programmed to

communicate via the same address.

There are 65,536 unique address codes that can be selected.

The address codes are selected by dip switches located on a circuit board within

the transmitter unit (The address switches are circled in yellow, below). During

standard operation, it is not necessary to adjust the address switches once they

are set.

To adjust the address codes, modify the dipswitches in Switch “A” and Switch

“B” as shown in Figure 6-1 to match that of the desired receiver (or transmitter).

If the switches do not match exactly, the transmitter and receiver will not

communicate with each other.

Figure 6-1. Address Codes On HPWS Receiver

The main product label (see Figure 1-1 in section 1.2)

includes a write-on surface to easily remember the address

code.

6-1

Advanced Features

6

NOTE:

ADDRESS CODE SWITCHES

Page 28

6.2 Multiple Transmitters

To connect multiple transmitters to one receiver, each transmitter must be set to

the same address code as the receiver. See Section 6.1 for more information

regarding the address codes.

A maximum of four (4) switches can be observed by the receiver. If using

multiple transmitters, ensure each switch is transmitting on a different channel

but the same address.

Example: Transmitter A and B will communicate with a common receiver.

Transmitter A will send data regarding one (1) switch, while Transmitter B will

send data on the status of three (3) switches. Transmitter A should transmit

switch on CH1. Transmitter B should transmit its switches on CH2, CH3, and

CH4. Transmitter A and B should both have the same address code as the

receiver.

If a channel is not in use, simply leave the terminal block connections empty. No

signal will be broadcast.

If two different transmitters use the same channel to

communicate with a common receiver, incorrect signals will

be processed. This will result in unintended and potentially

dangerous operations.

Advanced Features

6

6-2

NOTE:

Page 29

6.3 Normally Open vs. Normally Closed Outputs

The receiver unit can be programmed to transmit switch data as normally open

(N/O) or normally closed (N/C) switches. The factory default is to set all

switches to normally open. However, it is possible to change this setting at any

time. To change from N/O to N/C, it is necessary to adjust both the transmitter

and receiver.

The open/closed setting must match on the transmitter and its

receiver. If the transmitter and receiver are not set to accept

the same type of switch, undesired operations will occur.

(Transmitter Only)

To modify switch output from N/O to N/C, toggle the white input selection

switch for the appropriate channel. The input switches are located on a blue

switch block above the circuit board fuse.

Figure 6-3. Transmitter Dip Switches

The switch is in the default (off) position, which represents N/O. Setting the

switch to on (up) is N/C.

Advanced Features

6

6-3

NOTE:

INPUT SELECTION SWITCHES

Page 30

(Receiver Only)

To modify switch output from N/O to N/C, move signal wire (blue wire) from

the N/O terminal to the N/C terminal on the desired channel. Do NOT modify

the COM channel.

Figure 6-4. Signal Input Block (Model HPWS-REC)

To wire N/O to N/C move the blue wire (not shown) to appropriate N/C

terminal.

Advanced Features

6

6-4

SIGNAL WIRE

TERMNAL BLOCK

Page 31

6.4 Status Alerts

The HPWS-REC receiver is able to receive transmissions regarding the signal

status of any associated transmitters. If the signal status alarm is activated, the

HPWS-REC series can be used switch up to 50mA at 20Vdc.

To activate or deactivate the status alert setting, adjust the status alert

dipswitches on both the receiver and the transmitter.

6.4.1 Location of the Status Alert Dipswitches On Transmitter

Transmitter: Switch 3 on the option switch box (below the address codes)

controls the transmitters status signal output.

Figure 6-5. Transmitter Option Switches (Model HPWS-TX)

Advanced Features

6

6-5

OPTION SWITCH

Page 32

6.4.2 Location of the Statue Alert Dipswitches on Receiver

Receiver: The dipswitches are located in the blue dipswitch box below the

address codes. The switch box is circled in yellow in the following figure.

Figure 6-6. Receiver Status Alert Dipswitches

On the receiver, status switches 1-4 control the status alerts for CH 1-4,

respectively. If the dipswitch is set to on, the receiver will require status updates

from the transmitter on that channel. Setting the dipswitch to off eliminates the

status report for that channel.

Transmitters will send status updates once every hour. If, after 4 hours, the

transmitter has not sent a signal status update, the receiver will trigger the status

alarm output.

The status alert output is on the Receiver only.

The HPWS has one status alarm output that is triggered by a

loss of status condition on ANY channel set to receive status

updates. To turn off the status alarm, it is necessary to set ALL

4 status dipswitches on the receiver to off.

Advanced Features

6

6-6

NOTE:

STATUE ALERT DIPSWITCHES

Page 33

6.5 Low Battery Alert (Receiver Only)

The HPWS-REC series of receivers are able to receive transmissions regarding

the battery status of any associated transmitters. If the voltage supplied to the

transmitter drops below 10.5V, the transmitter will send a low battery message,

triggering the low battery output on the receiver. This low battery alarm will

switch up to 50mA @ 20VDC.

The low battery output is marked on the barrier strip. It is not necessary to

adjust dipswitch settings to receive low battery output.

The low battery alert switch is on the Receiver only.

The HPWS has one battery alarm output that is triggered by

a low voltage condition on ANY transmitter communicating

with a common receiver.

6.6 Auto Restore (Transmitter Only)

The HPWS-TX transmitters can be programmed to transmit a momentary switch

signal instead of the traditional lock-and-hold signal. This function is known as

auto restore.

Manual Restore (factory default): The manual restore setting (Auto restore: off)

on the transmitter will cause the receiver to output a signal as long as a switch is

closed (or opened.)

For example, if an alarm should remain on as long as a level switch is triggered,

use manual restore function. The output will cease when the switch is returned

to its normal position.

Auto Restore: Auto restore allows the receiver to limit the maximum time a

switch can be closed before resetting. The receiver will trigger the output for up

to 30 seconds, or as long as the switch is active, whichever occurs first. After 30

seconds, the output will cease, regardless if the switch on the transmitter is still

closed. The output will not activate until the switch cycles again.

Using Auto Restore will terminate the signal output after 30

seconds, even if the switch is still activated. Auto restore is

useful in specific circumstances only, and should not be used

in a situation where an alarm needs to be on as long as a

switch is triggered.

Advanced Features

6

6-7

NOTE:

CAUTIION:

Page 34

6.7 Replacing the Battery

The HPWS-TX and HPWS-REC-BATT include a 12V, 5.0Amp-hour backup

battery. The battery will provide up to 24 hours of typical use in the event of AC

power loss.

The battery is designed to recharge once AC power is restored or connected.

However, over time, the capacity of the battery will decrease and the battery

may need to be replaced.

You can order spare batteries from Omega.com using part number HPWS-BATT.

Omega Customer Service (800-622-BEST) will gladly assist in ordering

replacement batteries. See Section 2.2 for more information.

To replace the battery:

1. Remove the battery lead wire connectors from the battery terminal. (Do not

remove battery wires from power supply).

2. Unscrew the battery mount bracket, and remove the battery.

3. Replace the battery and reattach the battery mount bracket.

4. When unit is ready for use, reconnect the lead wire connectors to the proper

battery terminals. The red wire connects to the positive battery terminal (red

area), and the black wire connects to the negative terminal of the battery (black

area).

Figure 6-7. Battery

The HPWS has been designed and tested to work with the

batteries provided by Omega. Omega assumes no

responsibility for substituting a battery not provided by

Omega into the HPWS. Using a non-approved battery is not

an intended use of the product and may void your warranty.

Advanced Features

6

6-8

CAUTIION:

Page 35

Section 7 - Specifications

GENERAL

Enclosure: Fiberglass Reinforced Polyester Formulation

Enclosure Dimensions

(no antenna): 342.9 x 292.1 x 190.5mm (13.5 x 11.5 x 7.5")

Weight: 5.57kg [12.28lbs]

Closing Mechanism: 4 Screws

NEMA Rating: 4X (IP66)

RF Connector: UHF

RADIO

Frequency: 27.255 MHz

Antenna Impedance: 50Ω

Address Code: 65,536 possible codes.

ELECTRICAL

Power: AC

Power Requirement: 115 VAC, 60 Hz or 230VAC 50Hz

DC Battery Backup: Standard on transmitter, optional on receiver.

BATTERY BACKUP

(HPWS-TX and HPWS-REC-BATT only)

Internal Battery Backup: 12 volts, 5.0 Amp-hour

Battery Life

(New or Charged to Full Capacity): Over 24 hours of typical use-typical use

being 10 transmissions an hour

Battery Operating Temperature: -35 to 60°C (-31 to 140°F) Discharging, -20 to

50°C (-4 to 122°F) Charging

TRANSMITTER

Inputs: 4 discrete inputs

Transmit Power: 10 Watts

Transmit Time: Pulse (500msec or less)

Transmitted Data: 4 discrete inputs and battery and signal status

Transmit Current: 2A, momentary on transmit (500msec or less)

Average Continuous Load: 15µA

RECEIVER

Outputs: 4 discrete outputs, low battery, signal status

Receiver Current: 190mA with all outputs active

Average Continuous Load: 30mA

7-1

Specifications

7

Page 36

Section 8 - Approvals, Regulatory Compliance

All FCC approvals outlined in the manual are based on

testing that was done with antennas that are supplied with

your HPWS Series products or available as accessories.

Removing and/or installing antennas other than Omegaapproved antennas will void the product compliance

demonstrated in these documents.

8.1 FCC (Domestic Use)

This device complies with Part 95 of the FCC regulations. Normal operation as

described by this manual does not require a FCC license.

8.2 International Usage & CE Marking

This product is not approved for use outside the United States of America or its

territories. As a result, CE compliance has not yet been tested or determined.

8.3 Declaration of Conformity

Contact OMEGA for status on DOC availability.

8-1

Approvals, Regulatory Compliance

8

NOTE:

Page 37

NOTES:

8-2

HPWS SERIES

Long Range Wireless System

Page 38

NOTES:

8-3

HPWS SERIES

Long Range Wireless System

Page 39

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a

period of 37 months from date of purchase. OMEGA’s WARRANTY adds an additional one (1) month

grace period to the normal three (3) year product warranty to cover handling and shipping time.

This ensures that OMEGA’s customers receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Service

Department will issue an Authorized Return (AR) number immediately upon phone or written request.

Upon examination by OMEGA, if the unit is found to be defective, it will be repaired or replaced at no

charge. OMEGA’s WARRANTY does not apply to defects resulting from any action of the purchaser,

including but not limited to mishandling, improper interfacing, operation outside of design limits,

improper repair, or unauthorized modification. This WARRANTY is VOID if the unit shows evidence of

having been tampered with or shows evidence of having been damaged as a result of excessive corrosion;

or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating

conditions outside of OMEGA’s control. Components in which wear is not warranted, include but are not

limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or errors nor assumes liability for any

damages that result from the use of its products in accordance with information provided by

OMEGA, either verbal or written. OMEGA warrants only that the parts manufactured by the

company will be as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR

REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF

TITLE, AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF

LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total liability of

OMEGA with respect to this order, whether based on contract, warranty, negligence,

indemnification, strict liability or otherwise, shall not exceed the purchase price of the

component upon which liability is based. In no event shall OMEGA be liable for

consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic

Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical

applications or used on humans. Should any Product(s) be used in or with any nuclear installation or

activity, medical application, used on humans, or misused in any way, OMEGA assumes no responsibility

as set forth in our basic WARRANTY/DISCLAIMER language, and, additionally, purchaser will indemnify

OMEGA and hold OMEGA harmless from any liability or damage whatsoever arising out of the use of the

Product(s) in such a manner.

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE

RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN

(AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID

PROCESSING DELAYS). The assigned AR number should then be marked on the outside of the return

package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent

breakage in transit.

FOR WARRANTY

RETURNS, please have the

following information available BEFORE

contacting OMEGA:

1. Purchase Order number under which the product

was PURCHASED,

2. Model and serial number of the product under

warranty, and

3. Repair instructions and/or specific problems

relative to the product.

FOR NON-WARRANTY REPAIRS,

consult OMEGA

for current repair charges. Have the following

information available BEFORE contacting OMEGA:

1. Purchase Order number to cover the COST

of the repair,

2. Model and serial number of the product, and

3. Repair instructions and/or specific problems

relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords

our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2011 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied,

reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without the

prior written consent of OMEGA ENGINEERING, INC.

Page 40

M4940/0211

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

Shop online at omega.com

SM

TEMPERATURE

䡺⻬

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

䡺⻬

Wire: Thermocouple, RTD & Thermistor

䡺⻬

Calibrators & Ice Point References

䡺⻬

Recorders, Controllers & Process Monitors

䡺⻬

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

䡺⻬

Transducers & Strain Gages

䡺⻬

Load Cells & Pressure Gages

䡺⻬

Displacement Transducers

䡺⻬

Instrumentation & Accessories

FLOW/LEVEL

䡺⻬

Rotameters, Gas Mass Flowmeters & Flow Computers

䡺⻬

Air Velocity Indicators

䡺⻬

Turbine/Paddlewheel Systems

䡺⻬

Totalizers & Batch Controllers

pH/CONDUCTIVITY

䡺⻬

pH Electrodes, Testers & Accessories

䡺⻬

Benchtop/Laboratory Meters

䡺⻬

Controllers, Calibrators, Simulators & Pumps

䡺⻬

Industrial pH & Conductivity Equipment

DATA ACQUISITION

䡺⻬

Data Acquisition & Engineering Software

䡺⻬

Communications-Based Acquisition Systems

䡺⻬

Plug-in Cards for Apple, IBM & Compatibles

䡺⻬

Data Logging Systems

䡺⻬

Recorders, Printers & Plotters

HEATERS

䡺⻬

Heating Cable

䡺⻬

Cartridge & Strip Heaters

䡺⻬

Immersion & Band Heaters

䡺⻬

Flexible Heaters

䡺⻬

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

䡺⻬

Metering & Control Instrumentation

䡺⻬

Refractometers

䡺⻬

Pumps & Tubing

䡺⻬

Air, Soil & Water Monitors

䡺⻬

Industrial Water & Wastewater Treatment

䡺⻬

pH, Conductivity & Dissolved Oxygen Instruments

Loading...

Loading...