Page 1

Page 2

Page 3

Congratulations on your purchase of the Manometer ! This

instrument is portable, battery operated pressure measuring

device.

The Manometer is ideal for HVAC/R technicians measuring

pressure level ,Medical equipment ,Computer peripherals ,

Pneumatic Controls.

INTRODUCTION

The meter will display all LCD s egments when it is f irst turned

on for a pp r o x . 3 secon ds. Though you mi gh t have se en

DATALOGGER,Y/M/D, REL, AVG ..these are not available

for the meter.

The LCD is divided into two distinct sections : One large

(Primary) top screen and one smaller right-bottom bottom

screens (Relative Clock). The 2 display areas keep you

constantly updated with the pressure measurements.

The Meter measures Gauge pressure-a measure of pressure

in psi that is referenced to ambient pressure and Differential

pressure - a measure of the difference of two pressures .

Meter has 11 selectable units of measure.: bar ,mmHg, ozin ,

kgcm , psi, inH2O, kPa, ftH2O,inHg ,mH2O,mbar.

2

2

1

Page 4

4 Measurement ranges are available:

Pressure range

:0~ 5 psi (HHP 8205)

:0~ 15 psi ( 8215)

:0~ 30 psi ( 8230)

:0~ 100 psi ( 8210)

Please check the tubing is not leaking or damaged before using.

HHP

HHP

HHP

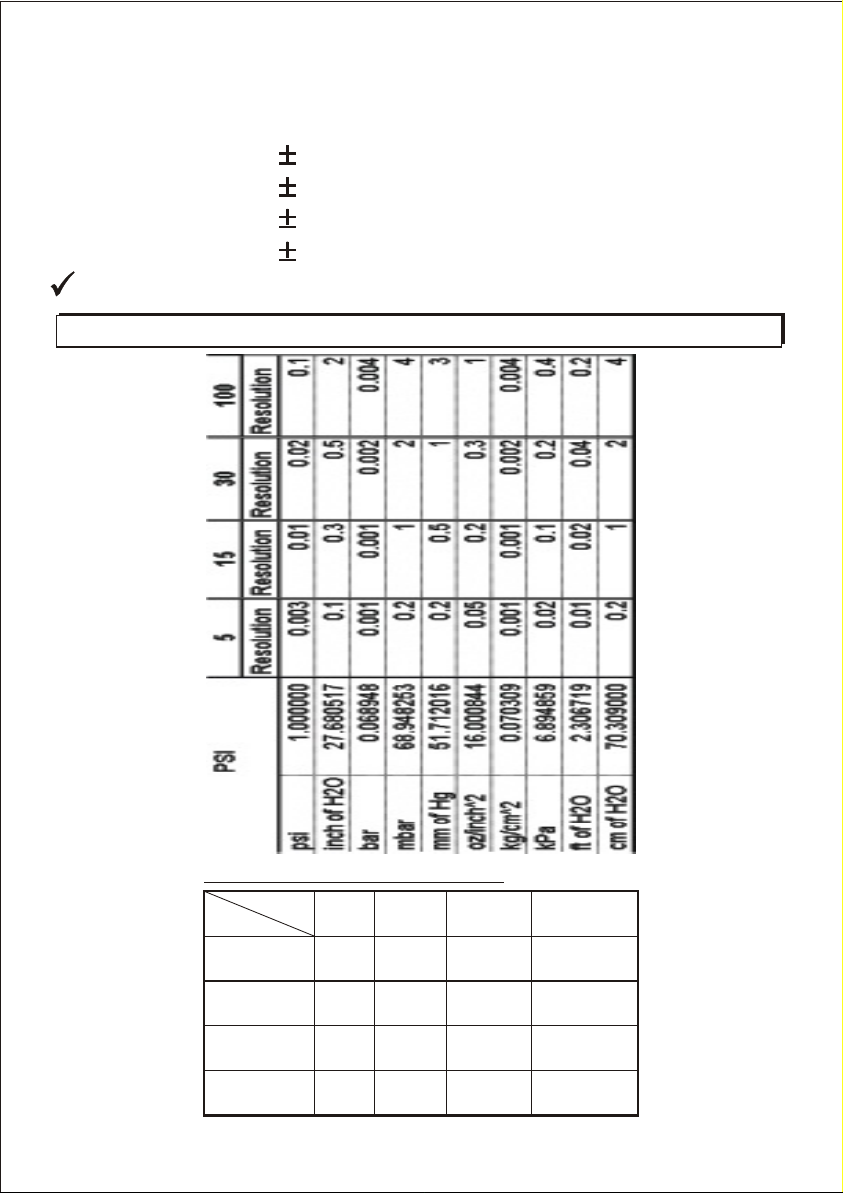

CONVERSION & RESOLUTION

Quick Conversion Sheet

unit

model

HHP8205

HHP8215

HHP8230

HHP8210

Psi

5

15

30

100

inH2O

138

415

830

2768

mbar

345 0.35

1034

2068

6895

2

kg/cm

1.05

2.10

7.03

2

Page 5

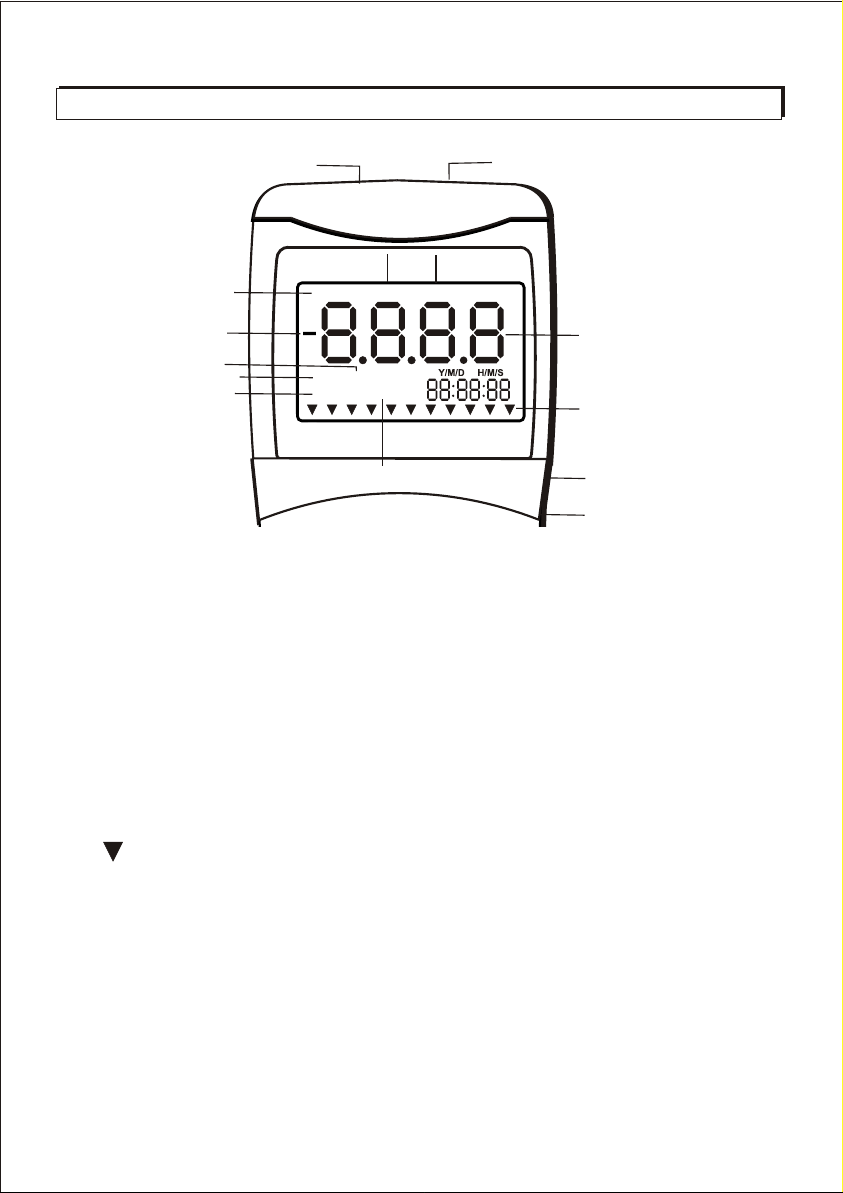

CONTROLS AND INDICATORS

12

11

DATA LOGGER

1

8

9

7

6

14

2

5

13

15

HOLD REL DIF

4

3

REC AVG

MAX MIN BAT

10

1. Primary Data Screen displays pressure value.

2. "-" . Minus pressure display.

3. MAX MIN presssure recorded.

4. REC starts recording mode and displays max./min.

pressure recorded.

5. AVG. Average records (N/A).

6. DC power in Jack.

7. RS232 output port.

8. H/M/S 88:88:88 displays data for Hour / Minute / Second.

9. . Pressure unit indication.

10. BA T . Battery low indicator.

11. DIF. Differential pressure mode.

12. "+" Positive pressure connection.

13 . "-" Negative pressure connection.

14. HOLD. Freezes pressure reading.

3

Page 6

15. RE L. Establish a relative zero for the primary screen

information.(N/A)

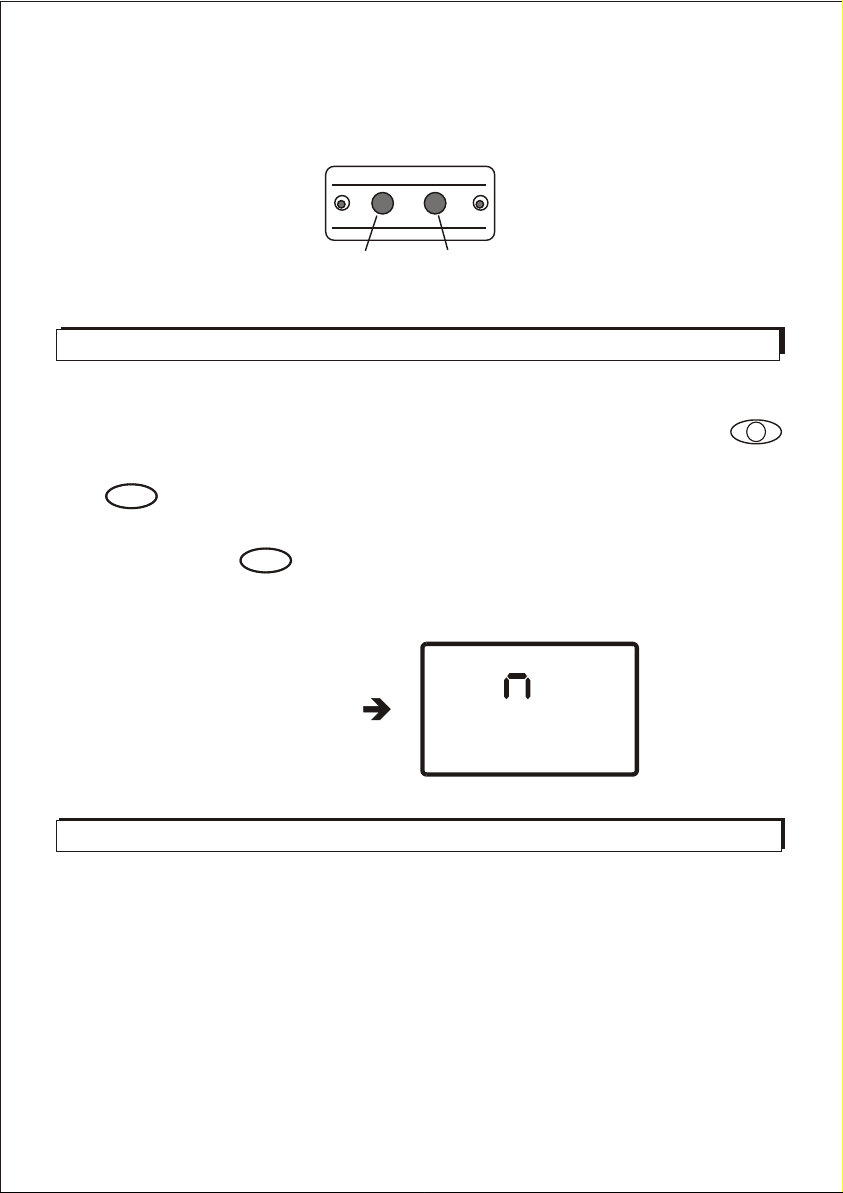

"-" Negative

pressure

"+" Positive

pressure

AUTO POWER OFF (SLEEP FUNCTION)

This instrument will shut off automatically in approx. 20 minutes

for every power on. For recording or operating over longer

I

periods of time, you can disable the sleep mode by pressing

HOLD

and simultaneously before power on.

An "n" will appear in the middle of the screen at which time you

can release the button. (See Fig. A) The disable sleep

HOLD

mode will be invalid after power off.

Fig. A

MODE OPTIONS

Delete and replace with programmable user selectable startup mode.The display will default to the mode last used.

4

Page 7

HOLDHOLD

DIFDIF

RECREC

UNITUNIT

l l

++

==

==

==

DISABLE SLEEP MODE

ZERO SETTING

SELECT UNIT / SKIP CAL.

HOLD

HOLD

Hold 2 sec.

The following table lists the modes of

operation that can be invoked by

pressing the button indicated.

I

Turns instrument on (Default set-ting) and off.

REC

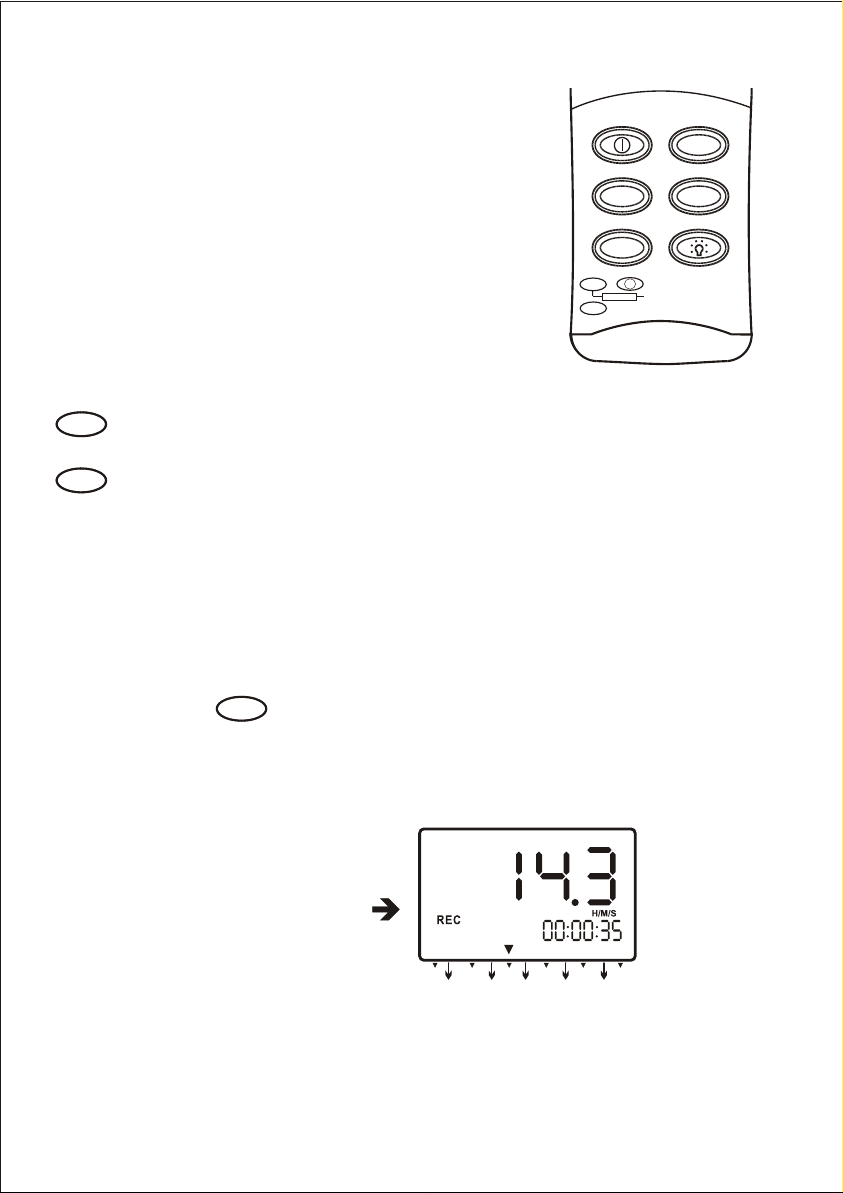

Press momentarily and relative clock starts in the lower

right screen.

REC is displayed in the middle left of (Fig. B) other button

functions are locked out except Power , Unit and

Backlight. Press momentarily again and the unit cycles

through MAX (Fig. C) and MIN (Fig.D) and back to current

pressure ; the recordmode is displayed on the LCD. Press

and hold for 3 seconds to turn off the record function

REC

and return to normal mode.

Fig. B

2

bar ozin psi kPa inHg mbar

mmHg kgcm inH2O ftH2O cmH2O

2

5

Page 8

Fig. C

2

bar ozin psi kPa inHg mbar

mmHg kgcm inH2O ftH2O cmH2O

2

Fig. D

2

bar ozin psi kPa inHg mbar

mmHg kgcm inH2O ftH2O cmH2O

HOLD

Press momentarily to freeze the pressure reading . (Fig.E)

2

Fig. E

2

bar ozin psi kPa inHg mbar

mmHg kgcm inH2O ftH2O cmH2O

DIFDIF

Press momentarily ,DIF appears on top of the LCD and the

2

display indicates the relative zero (Relative zero causes the

value of the display to show as "0.0")-only the amount of

pressure change will be indicated. Press momentarily again

and the unit returns to the normal mode of pressure

differential (see Fig.F).

Fig. F

DIF

2

bar ozin psi kPa inHg mbar

mmHg kgcm inH2O ftH2O cmH2O

2

6

Page 9

Differential Pressure : A measure of the difference between two

pressures , i.e. use differential pressure sensor to measure

gauge pressure by leaving one process connection open

to atmosphere and connecting the second sensor port to your

system.

UNIT

Press momentarily and the units will cycle through "bar" ,

"mmHg","ozin2","kgcm2" ,"psi","inH2O","kPa",

"ftH2O" ," inHg" ,"cmH2O" ,"mbar" ,which are

indicated on the bottom of the display (See Fig.G &H).

Fig. G

2

bar ozin psi kPa inHg mbar

mmHg kgcm inH2O ftH2O cmH2O

2

Fig. H

2

bar ozin psi kPa inHg mbar

mmHg kgcm inH2O ftH2O cmH2O

2

Press momentarily and the back-light illuminates for

approx. 30 seconds then turns off automatically. Or press

momentarily to decrease the figure when calibration is

being performed.

7

Page 10

MAINTENANCE

The meter is calibrated in house before shipping.

When properly maintained , the meter will maintain its

accuracy specification, to ensure your meter is performing

at its peak, send it to the factory or a qualified instrument

calibration facility for annual calibration.

Always set zero before measurement .Refer to the zero

setting procedure in page 10.

Cleaning:

Use a d am p cloth and mild soap to clean the case of the

Manometer, do not use harsh detergents or abrasives as these

may mar the finish or damage the unit's case with an adverse

chemical reaction.

CALIBRATION MODE

Calibration mode is only applicable for a standard Manometer

calibrator or any qualified meter calibration facility for annual

calibration.

1. First , manually set the display to zero ( no pressure applied

to the connector ), refer to the Manual zero procedure.

8

Page 11

2. Turn the meter off.

3. Press & simultaneously ,"CA" appears on the

RECREC

display, (See Fig.I )the meter enters to the calibration mode

,make sure the units setting on "PSI" to start positive (+)

pressure calibration

Fig. I

psi

4. The meter has defaulted as 80 psi calibration point , the

adjustable pressure range is from 78.0 to 82.0 if calibration

pressure source is not 80psi ,increase by pressing key ,

RELREL

or decrease by pressing key to set calibration point as

required.

5. Save the calibration point by pressing key , "SA" and

RECREC

small "CA"appears on the display (See Fig. J ) in 2 seconds

, the meter auto-skips to the negative pressure (-) point for

next calibration mode.

Fig. J

psi

9

Page 12

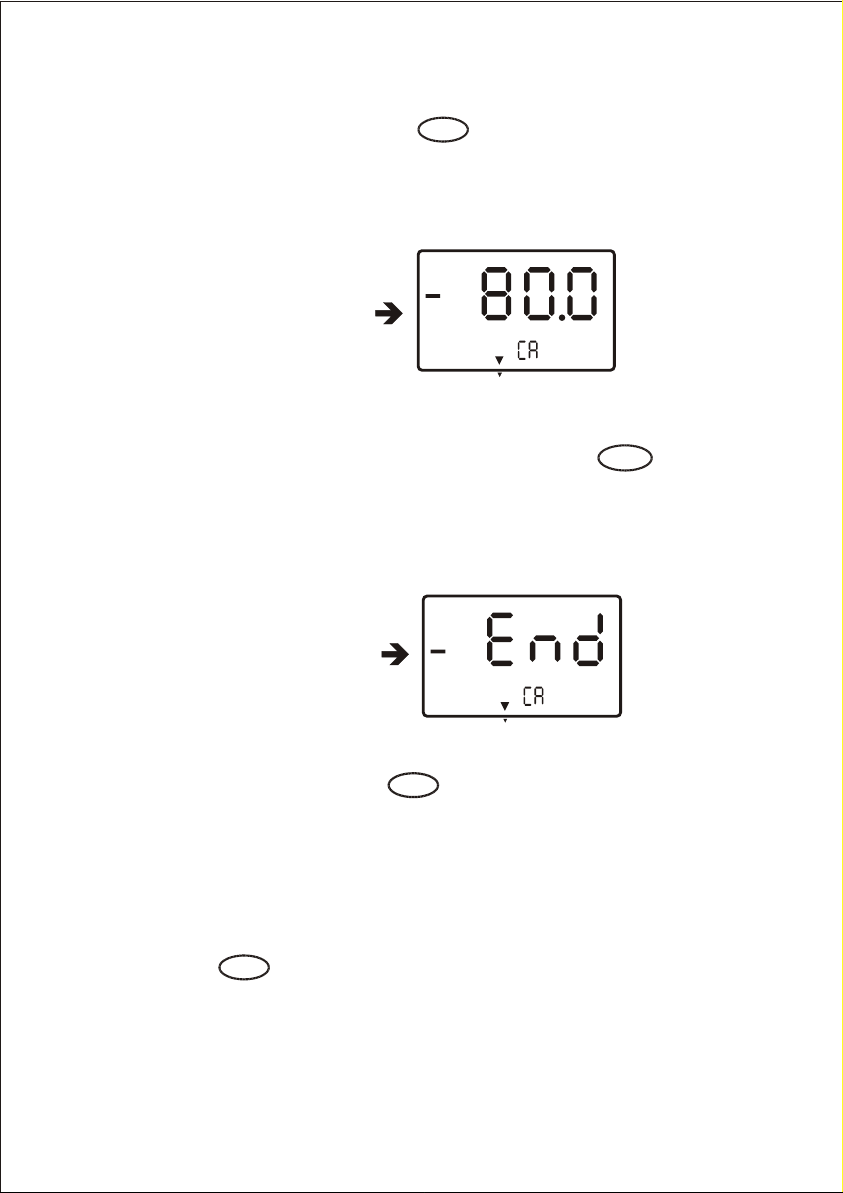

6. Follow the same procedure as step 4 for the negative pressure

calibration point by pressing key , the LCD now displays

UNITUNIT

" -80.0 " and small"CA" (See Fig.K ) , do the necessary

calibration figure refer to your pressure standard if needed.

Fig. K

psi

7. Again save the calibration point by pressing key, "SA"

RECREC

and "CA"appears in 2 seconds and then "End"and "CA"

appears in another 2 seconds, the meter turns back to

the normal mode (See Fig. L ).

Fig. L

psi

If you can't save by pressing key, i.e. no "SA" appeared ,

RECREC

please check: (a) The cabliration pressure source is between

75.0 and 85.0, or check (b) if you entered the right positive

pressure (+) or negative pressure (-).

If you want to skip positive (+) calibration when in the Calibration

mode , press to skip to negative (-) calibration point.

UNITUNIT

10

Page 13

Above calibration is an example for model HHP8210 , i.e. the

pressure range is from 0 to +100psi (Positive pressure ) or from

0 to - 100 psi (Negat iv e pressure).

Calibration point reference

Model:

psi

range

HHP8205

HHP8215

HHP8230

HHP8210

0~ 5

0~ 15

0~ 30

0~ 100

Calibration

point

4.000

12.00

24.00

Reommend

( )( )

3.900~4.100

11.70 ~12.30

23.40~24.60

80.00 78.00~82.00

MANUAL ZERO SETTING

When you set the display to zero( no pressure applied to the

connector), press button for 2 seconds , now the meter

displays "0 .0.0.0" from right to left (See Fig.M) and then disappears ,

the LCD display shows a normal mode .(See Fig.N)

HOLDHOLD

Fig. M

Fig. N

2

bar ozin psi kPa inHg mbar

mmHg kgcm inH2O ftH2O cmH2O

2

11

Page 14

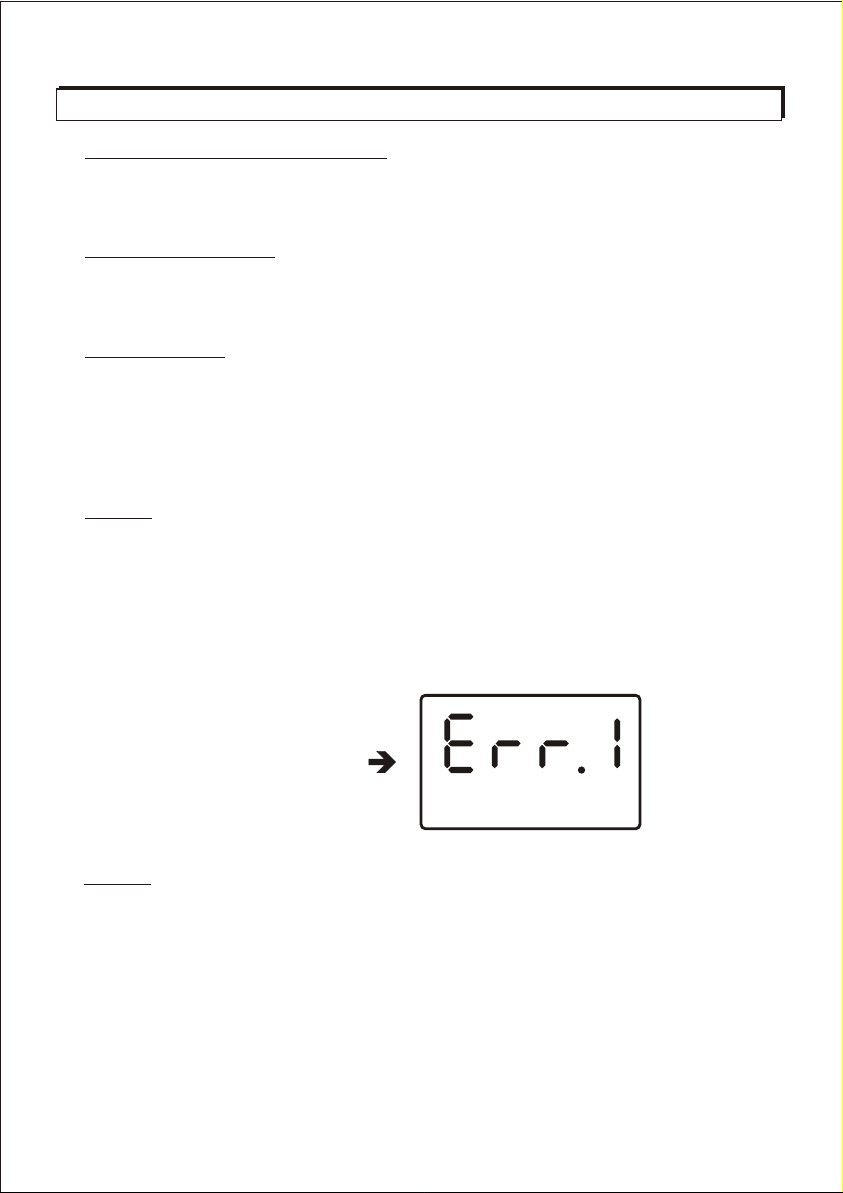

TROUBLESHOOTING

Power on but no display. Check the battery connections

?

Replace with new battery or attach optional AC adaptor.

BAT indication. Replace with a new battery when LCD

?

displays BAT at the middle bottom.

No Display. Make sure battery is not empty , if the display

?

disappear, check sleep mode is active . Refer to the Disable

sleep mode function for a long time using the measurement.

Or check the tubing is connected to the meter tightly.

Err.1. For the pressure value exceeding the maximum range ,

?

"Err.1" appears on the display ( See Fig. O ).Do not exceed

rated over pressure range of manometer. Sensor will

bedamaged.

Fig.O

Err. 2. For the measurement pressure less than minimum

?

range ,"Err. 2 " will appear (See Fig.P ).

12

Page 15

Fig. P

Err.3.For a differential pressure value larger than maximum

?

display , Err .3 appears on the display (See Fig.Q ).

Fig. Q

Err.4. When you set zero ,make sure you have disconnected

?

the tubing. If you see an Err.4 appear on the display, it means

the manometer is damaged (See Fig.R ).

P.S. Err.4 will be also appear if the tubing is connected during

zero set.

Fig.R

E1OL or E2UL. When you see the errors while operating

?

Rs232 software, it means pressure source is less or over

than the range of the instrument.

13

Page 16

REPLACING THE BATTERY

Replace your 9-volt battery when:

The BAT icon appears on the right of the screen.

The meter will not power on.

Use of the back-light causes the BAT icon to appear.

Even if the battery was recently replaced, check its voltage level

if you get no response from your instrument.To replace the

battery:

1. Remove the tubing of the instrument.

2. Lay the instrument face-down on a clean, flat surface.

3. Remove battery cover.

Remove battery from instruments that you do not plan to use for

a month or more. Do not leave battery in instrument.

OPERATING CONDITIONS

Compensated temperature range:0~50 C.

Operating temperature 0 ~50 C (32~122 F)

oo o

Storage temperature range: -20~60 C

14

o

o

Page 17

Operating Humidity Max. 80% RH

Power : One 9.0 volt battery

Exceeding Maximum pressure will

cause permanent sensor damage.

Model Max.Pressure

HHP 8205

HHP 8215

HHP 8230

HHP 8210

20 psi

30 psi

60 psi

150 psi

SPECIFICA TION

Pressure

Range

Resolution

Accuracy

Dimension

Unit Weight

Response

time

Format

0~ (5 or 15 or 30 or 100 psi)

See Page 8 data sheet

0.3% of full scale at 25 C

72 x 182 x 30 mm (meter)

Approx. 220 gram (with

battery)

0.5 seconds

Baud Rate : 2400 bit/sec

Data Bit : 8 , Stop Bit : 1

P XXXXX , P - XXXXX (unit)

o

15

Page 18

MATERIAL SUPPLIED

This package contains:

The meter

Battery (9.0 volt)

Operation manual

Hard carrying case

Connection hose

OPTIONAL ACCESSORY:

RS232 software disk or CD with D-sub connector

DC Adaptor

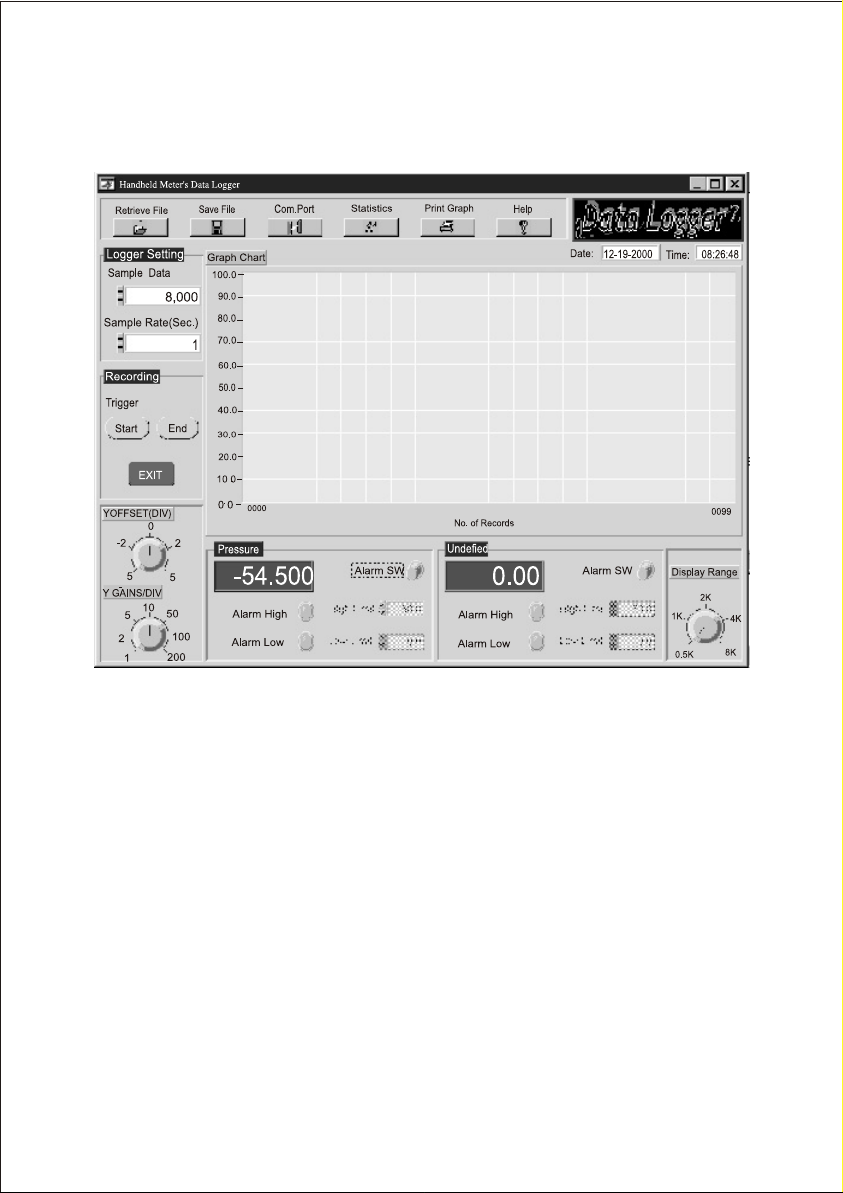

RS232 OUTPUT:

The meter can link with a personal computer to capture on-line

data ,display pressure records with real- time output, you can

retrieve files , save the data for operating data analysis, record

statistics ,multi-files display in the screen,....versatile functions

for your choice.

Connection procedures:

1. P lug the optional accessory Rs232 cable onto the DC jack

port ( at the right side of the meter)

2. Insert the D-sub 9P type connector onto computer's Com.1 or

2 port or..

3. S t art to set up RS232 software by inserting the CD-ROM or

Floppy diskette.

16

Page 19

4. When installing the RS232 software,please follow the

operation manual procedure in the software package.

17

Page 20

Page 21

Loading...

Loading...